Patents

Literature

76results about How to "Good brazing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

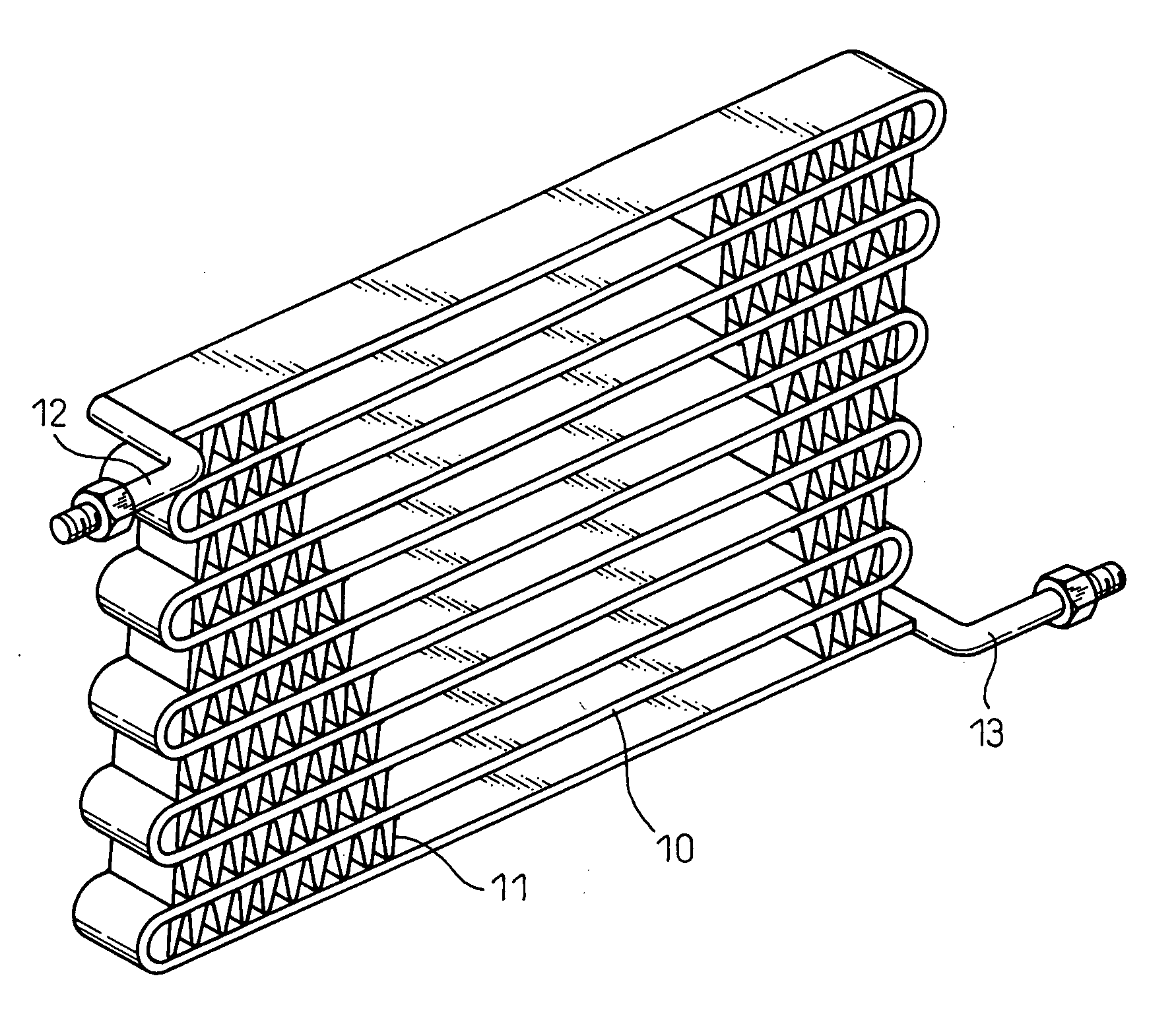

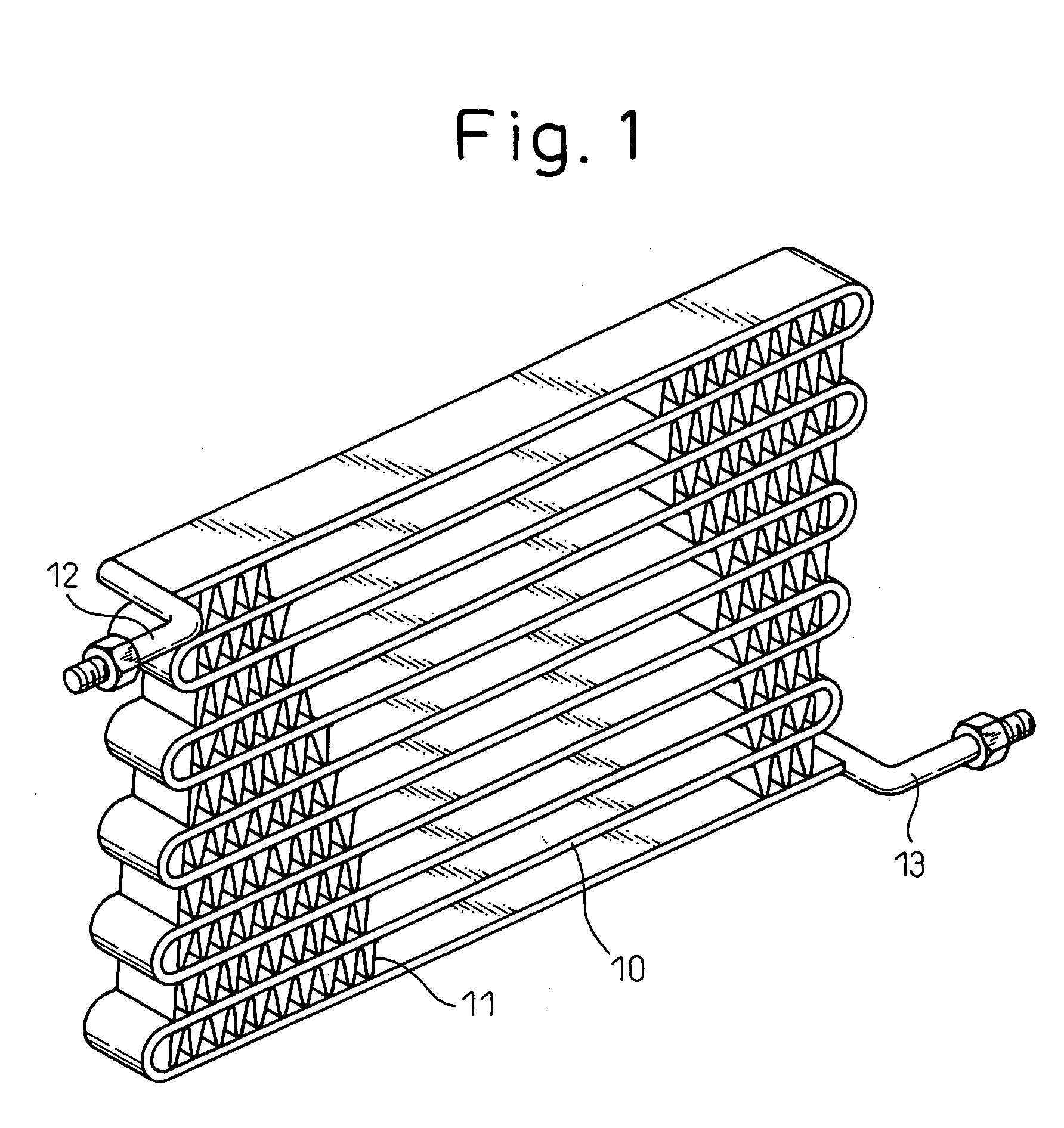

Method for manufacturing aluminum heat exchanger

A mixture of a low-temperature active-type non-corrosive flux and a low-melting point brazing material consisting of zinc, or zinc-aluminum alloy mainly composed of zinc, is applied to at least one 10 of a plurality of aluminum members 10 to 13, and the plurality of aluminum members 10 to 13 are brazed with each other by heating an assembly of the plurality of aluminum members 10 to 13 at a temperature exceeding a melting activity-initiating point of the non-corrosive flux and a melting point of the low-melting point brazing material.

Owner:DENSO CORP

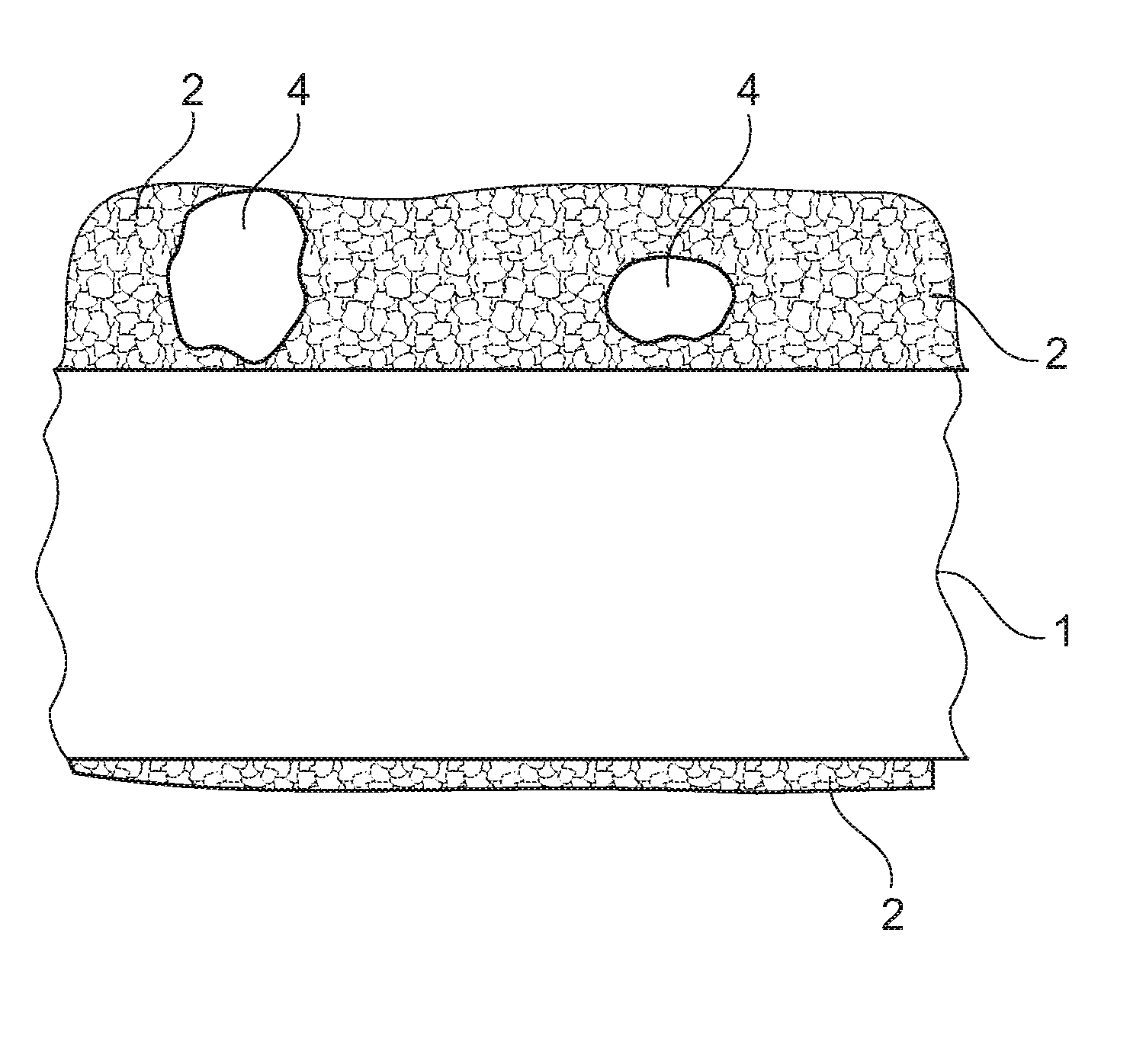

Aluminium brazing sheet material

ActiveUS20110111254A1Lower capability requirementsGood brazingElectron beam welding apparatusWelding/cutting media/materialsAlloyAluminium

A brazing sheet material for CAB brazing without applying flux. The brazing sheet material including an aluminum core alloy layer provided with a first brazing clad layer material on one or both sides of the aluminum core layer and at least one second brazing clad layer material positioned between the aluminum core alloy layer and the first braze clad layer material. The second brazing clad layer material is an Al—Si alloy brazing material having 5% to 20% Si and 0.01% to 3% Mg, and the first brazing clad layer material is an Al—Si alloy brazing material having 2% to 14% Si and less than 0.4% Mg. Also disclosed is a brazed assembly manufactured in a brazing operation.

Owner:NOVELIS KOBLENZ GMBH

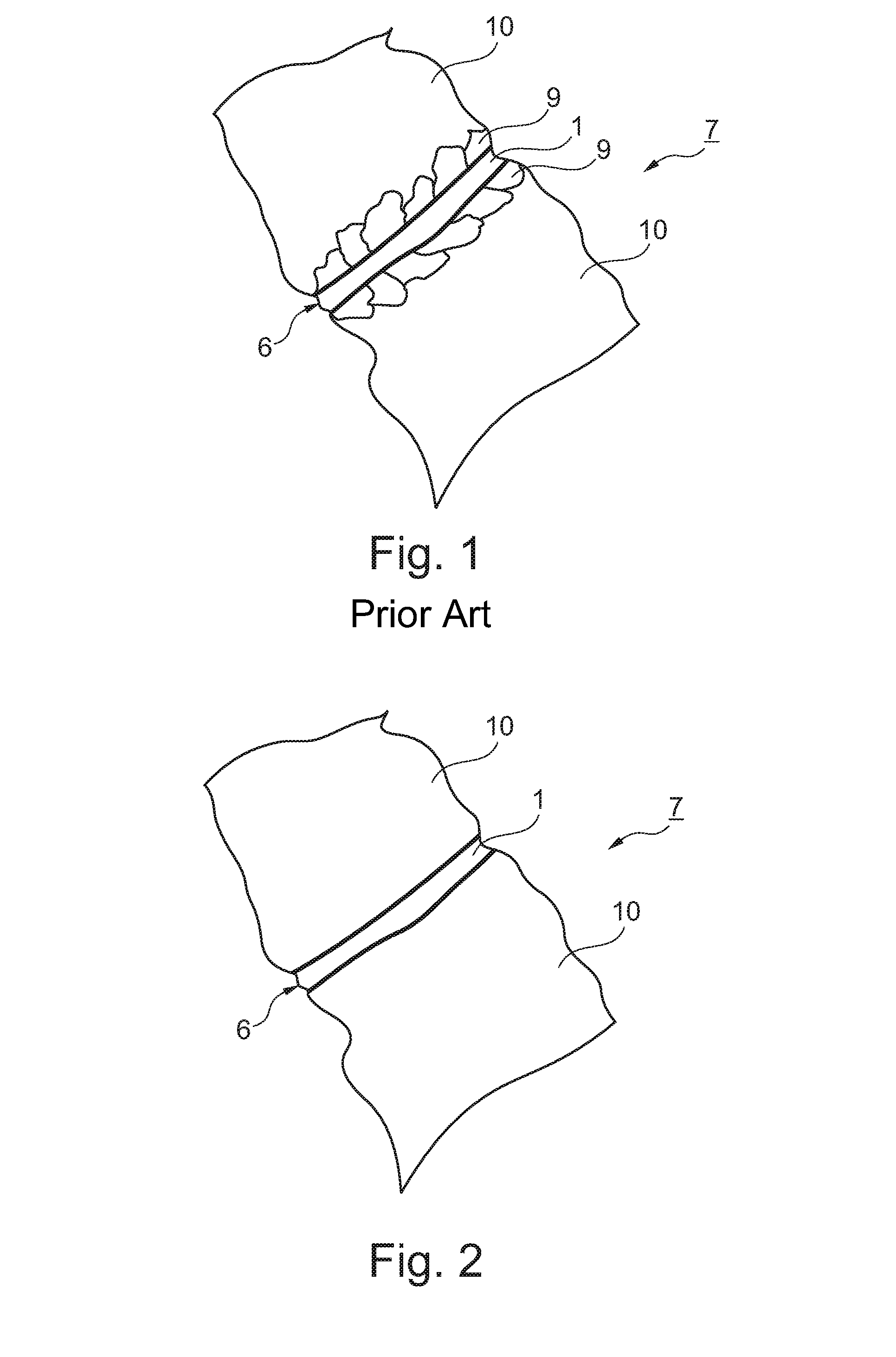

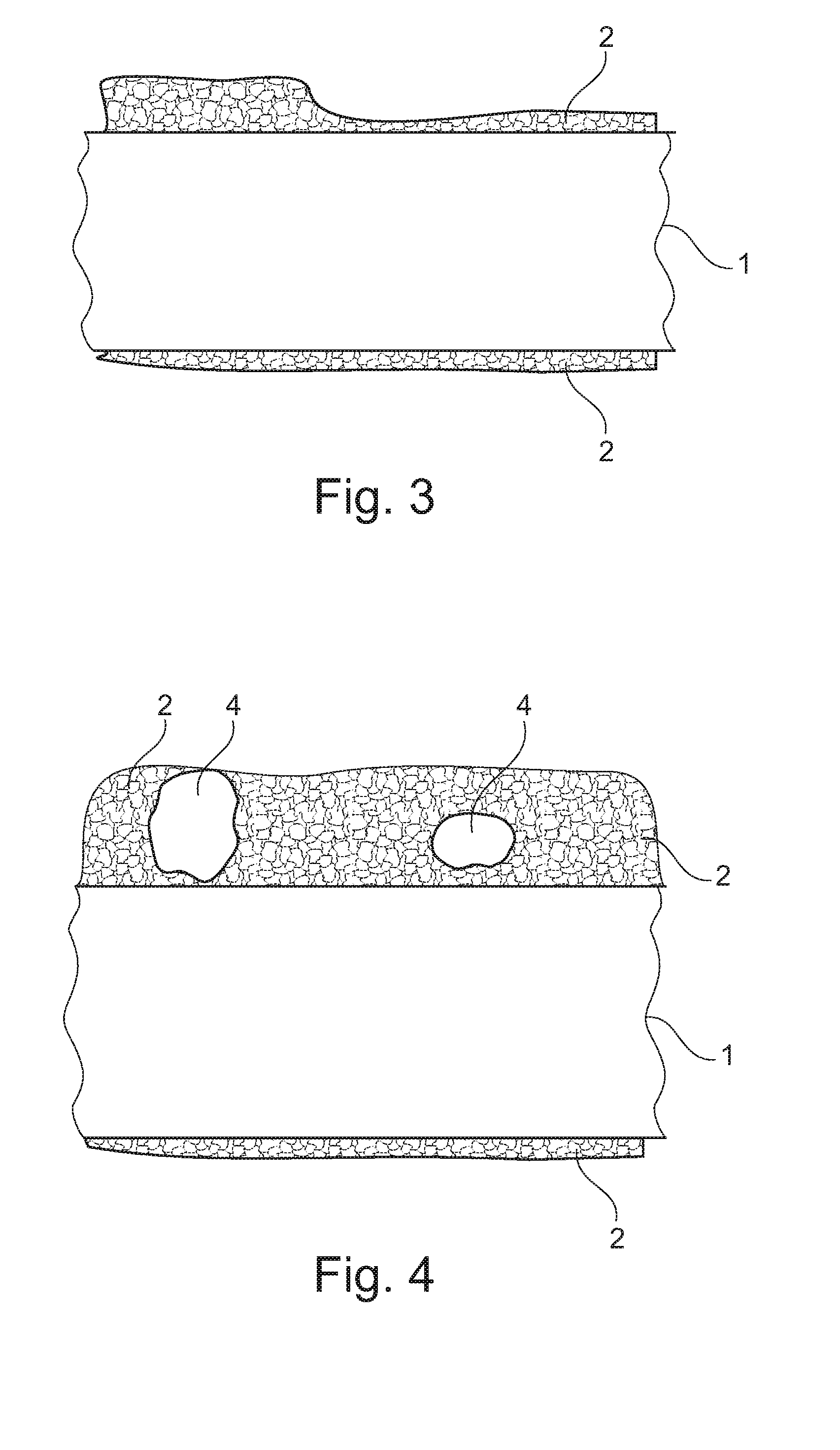

Braze foil for high-temperature brazing and methods for repairing or producing components using a braze foil

An amorphous braze foil (1) produced by a melt-spin process has an upper side and a lower side. The upper side and the lower side are thinly coated with a film of metallic Ni-based, Co-based, or Ni—Co-based braze powder (2) with a particle size in the nanometer range, wherein both the braze foil (1) and also the braze powder (2) additionally include grain boundary stabilizing elements as alloying elements. In addition, melting point depressants can be present in the braze foil or in the nano braze powder (2) in a commercially common quantity or with a considerably increased proportion. With the braze foil (1) coated in this manner, both the melting temperature of the braze material and also the probability of recrystallization are advantageously reduced when brazing in the adjacent base material (10).

Owner:ANSALDO ENERGIA IP UK LTD

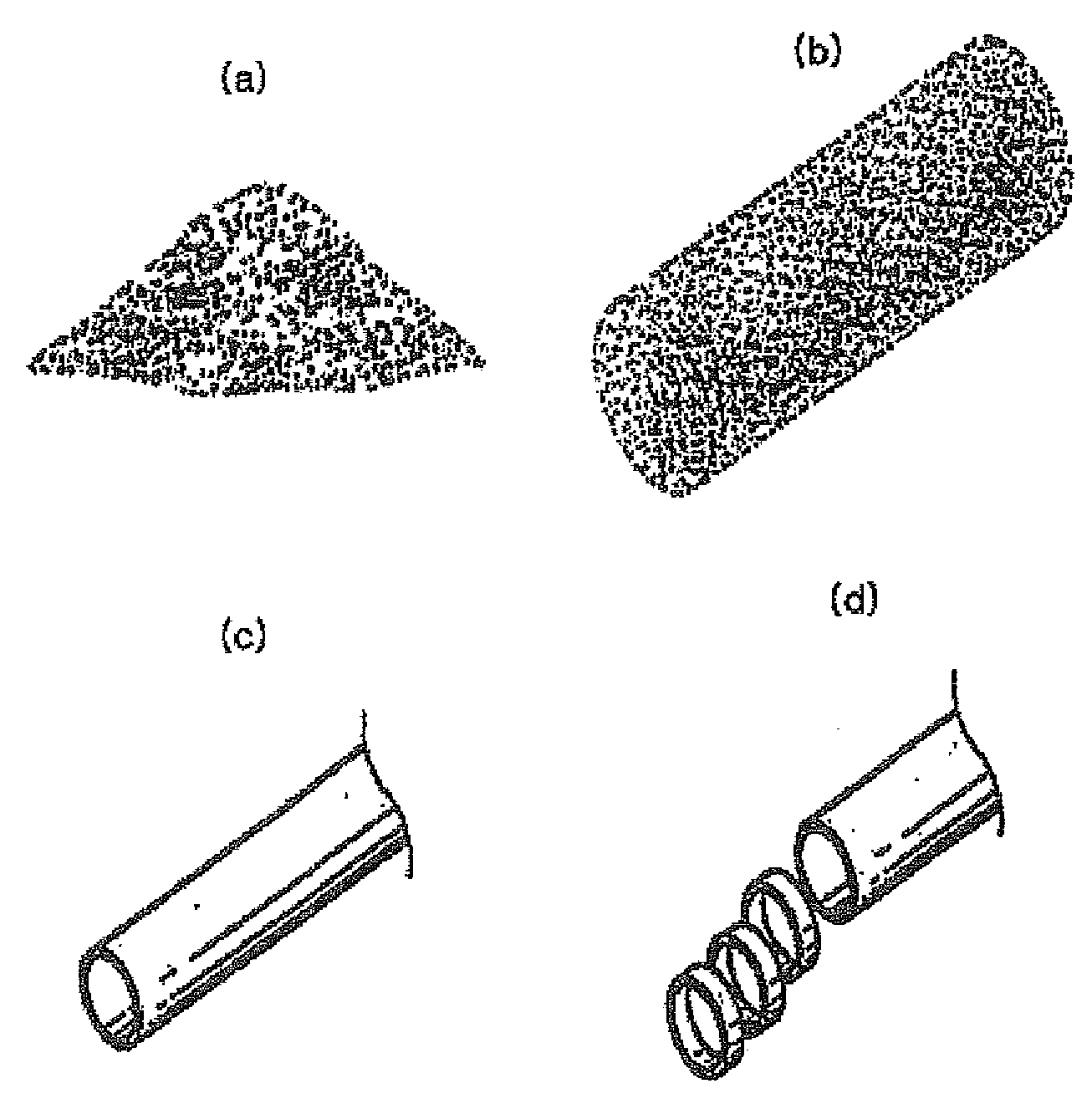

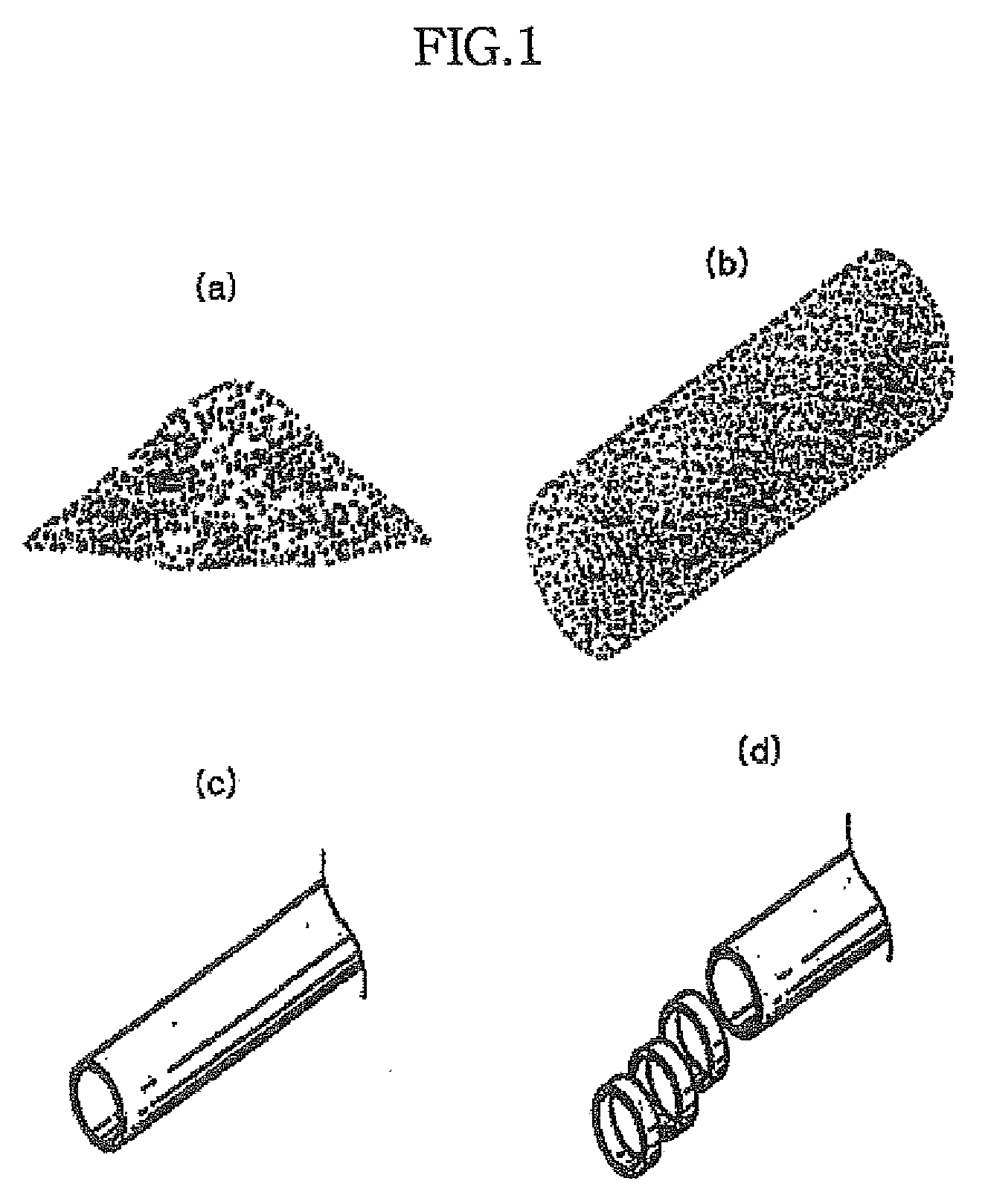

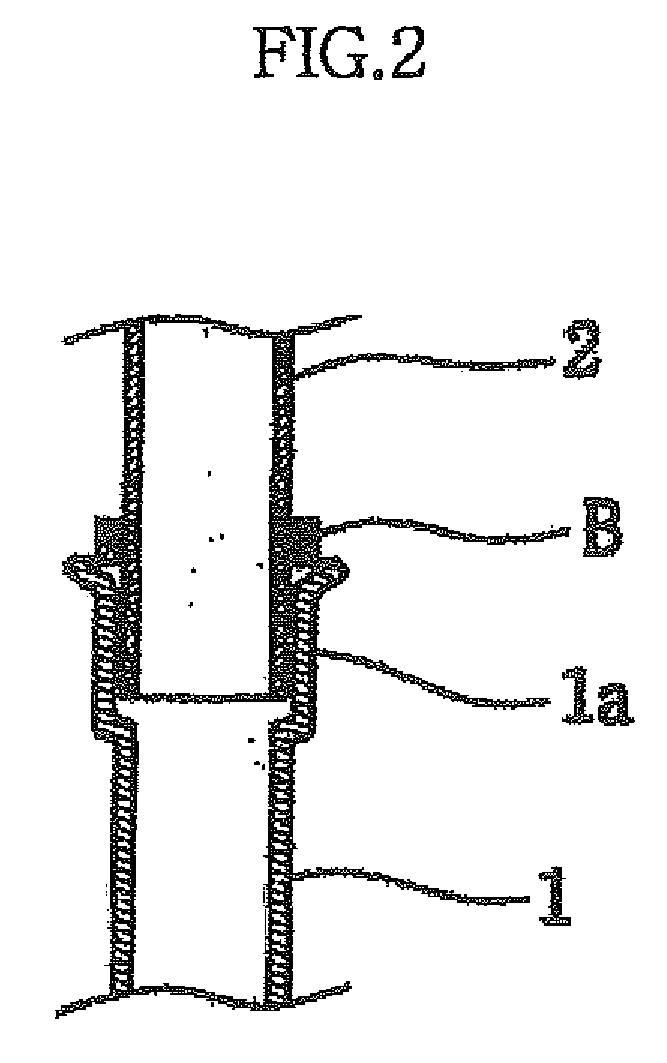

Flux-containing brazing agent brazed at low temperature

InactiveUS20080135134A1Simple processImprove brazing qualityWelding/cutting media/materialsSoldering mediaFluorideMetal

Disclosed is a flux-containing brazing material, which is used to braze the same or different kinds of metal members with each other at low temperatures. The flux-containing brazing material includes a mixed powder, comprised of Zn alloy powder, containing 10 to 40 wt % of Al or Al and Si, and remaining Zn, and 10 to 40 wt % of cesium fluoride-based flux powder on a basis of the Zn alloy powder. The mixed powder is subjected to powder forging and extruding processes to form a three-dimensional flux. The flux-containing brazing material is advantageous in that the Zn alloy and flux powders are mixed with each other and machined to form the three-dimensional flux, thereby simplifying a brazing process because a flux coating process is omitted during the brazing process. The brazing quality is improved because the flux content in the brazing material is properly controlled.

Owner:SUNKWANG BRAZING FILLER METAL

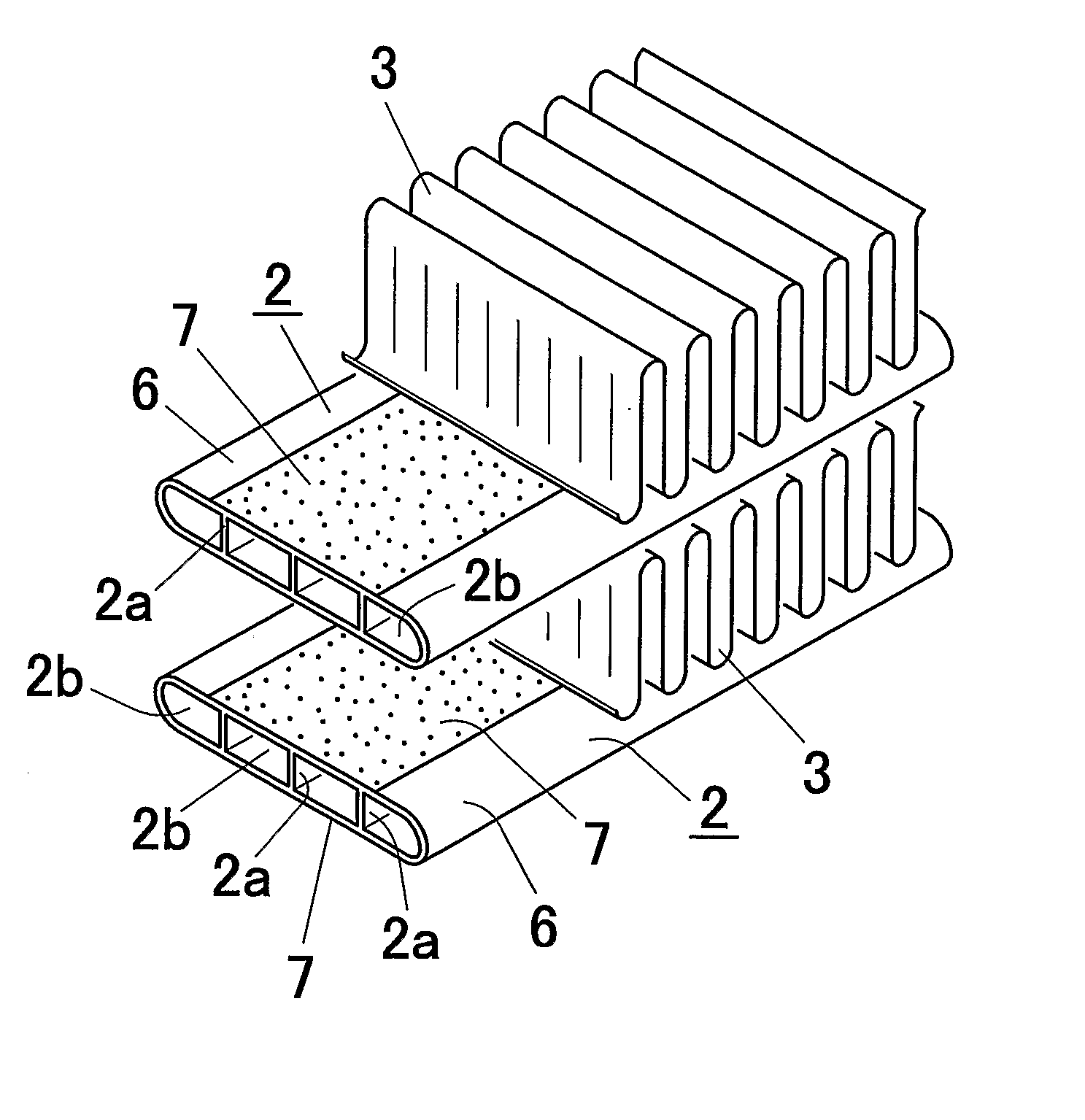

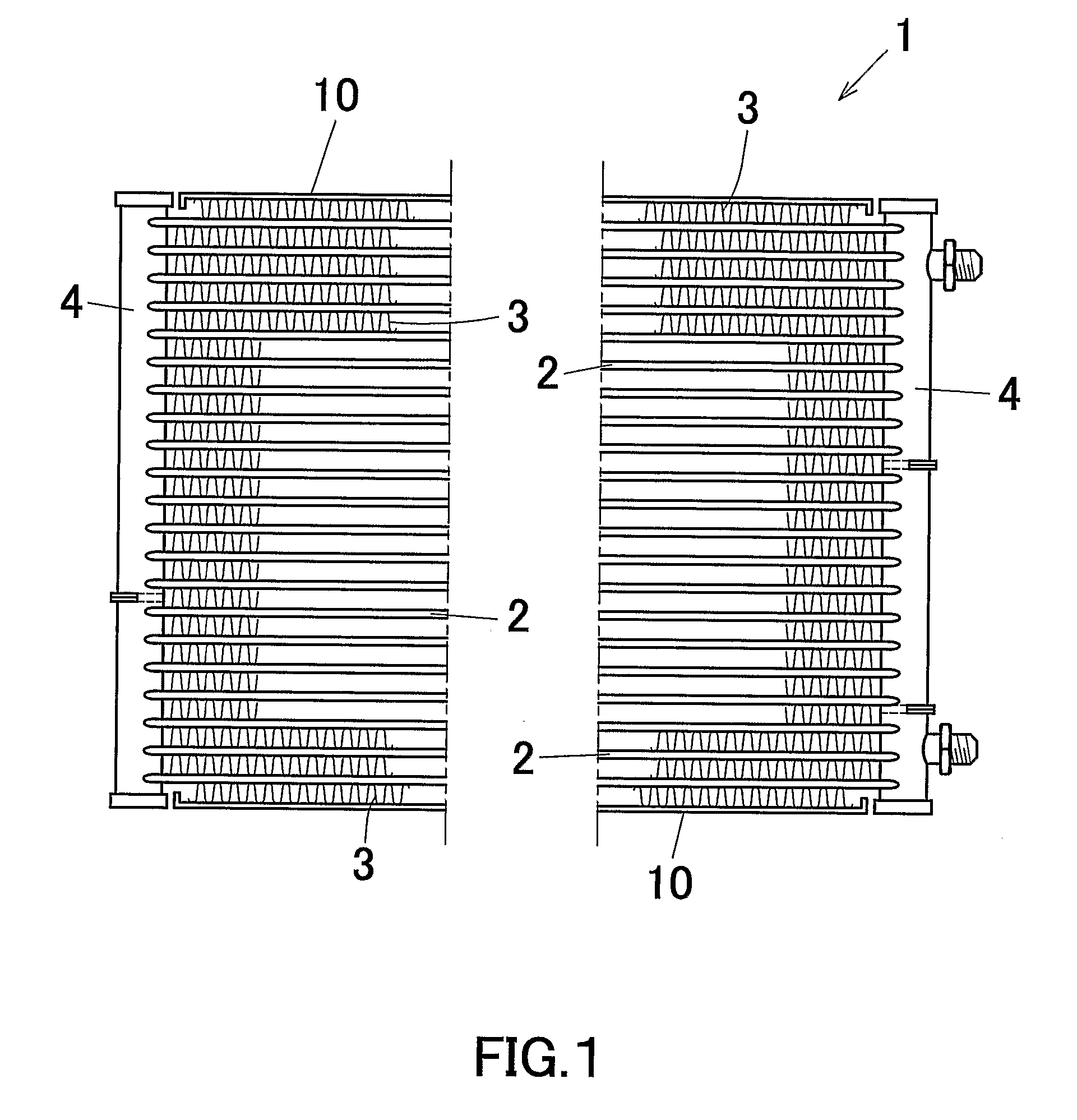

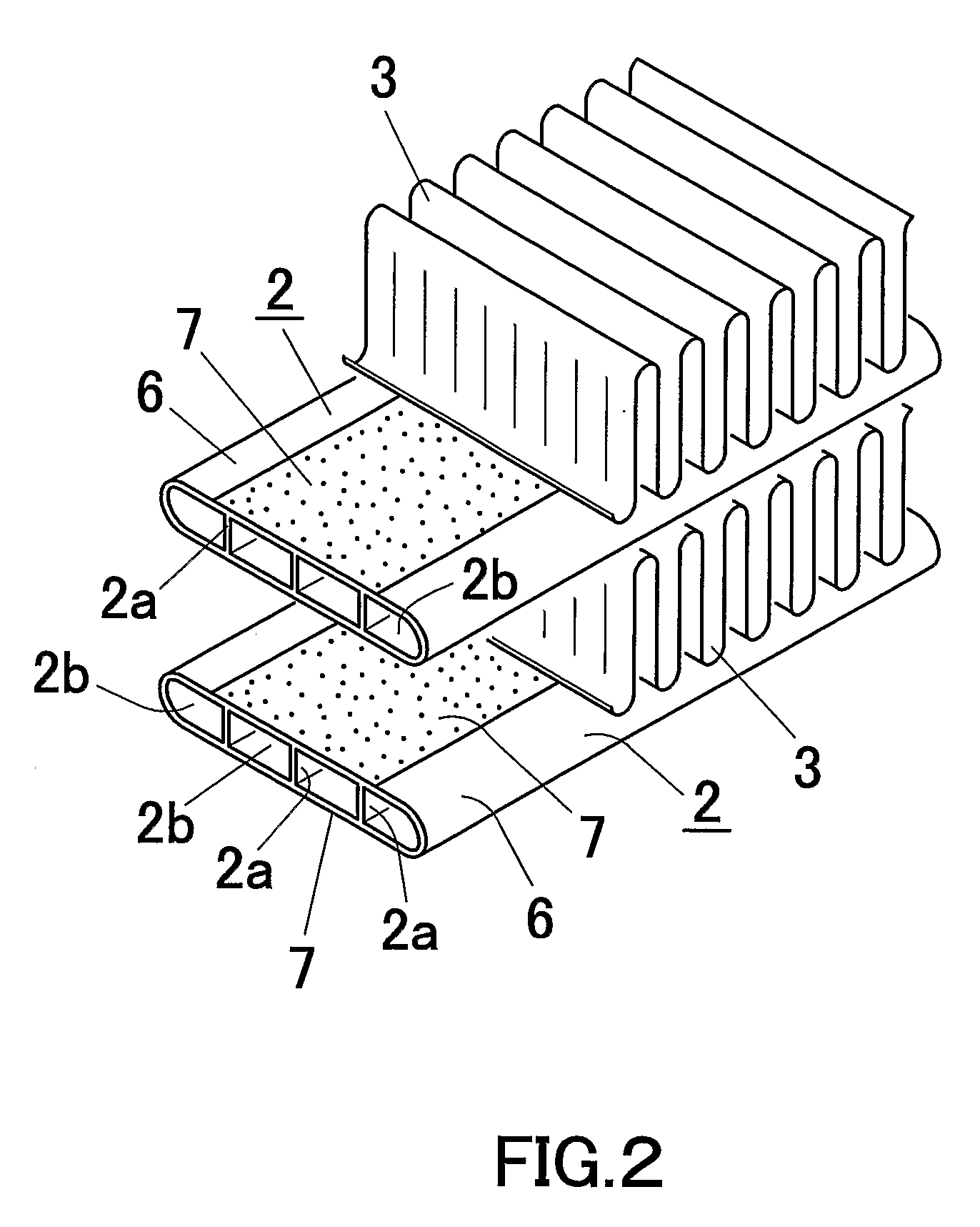

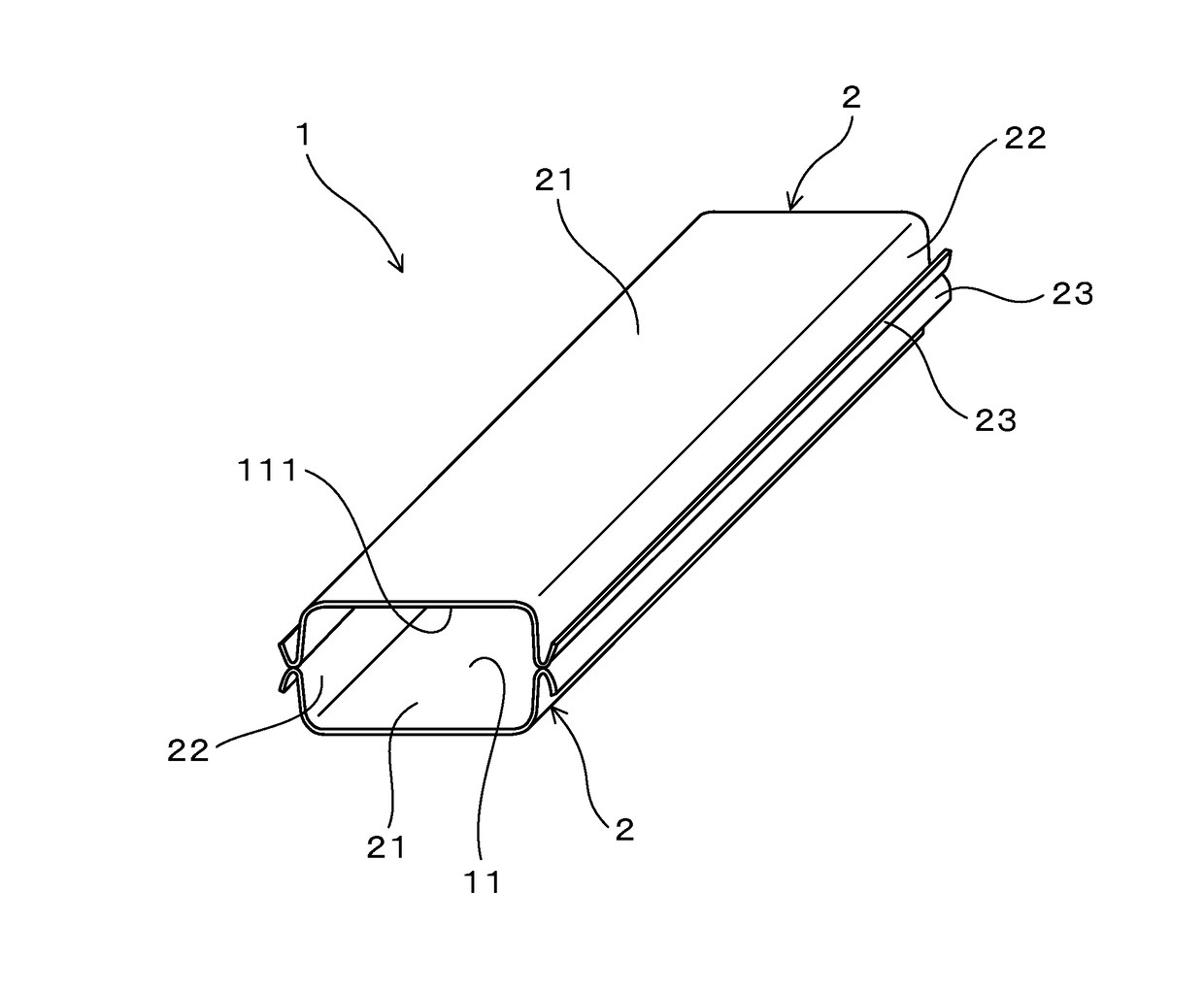

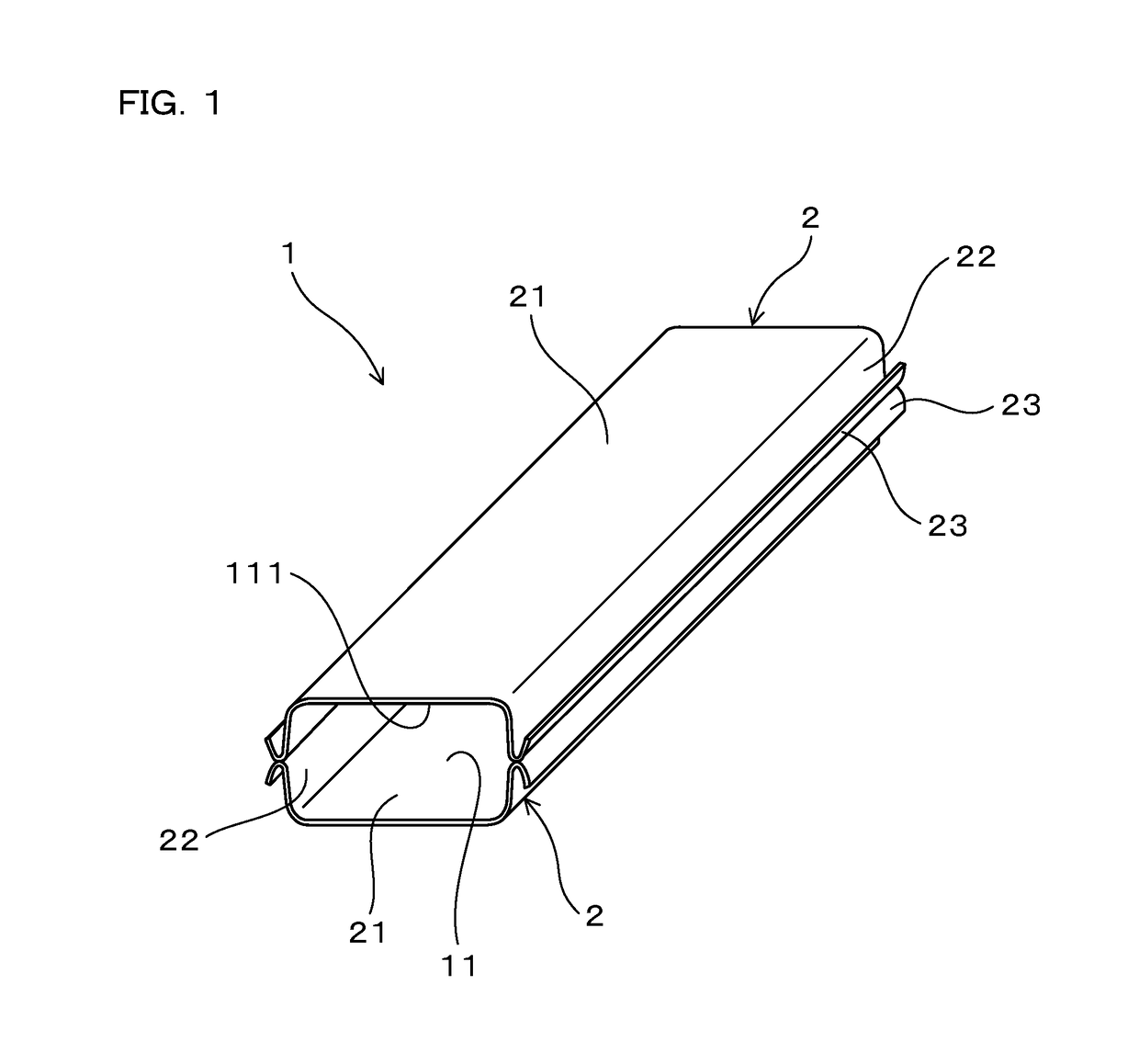

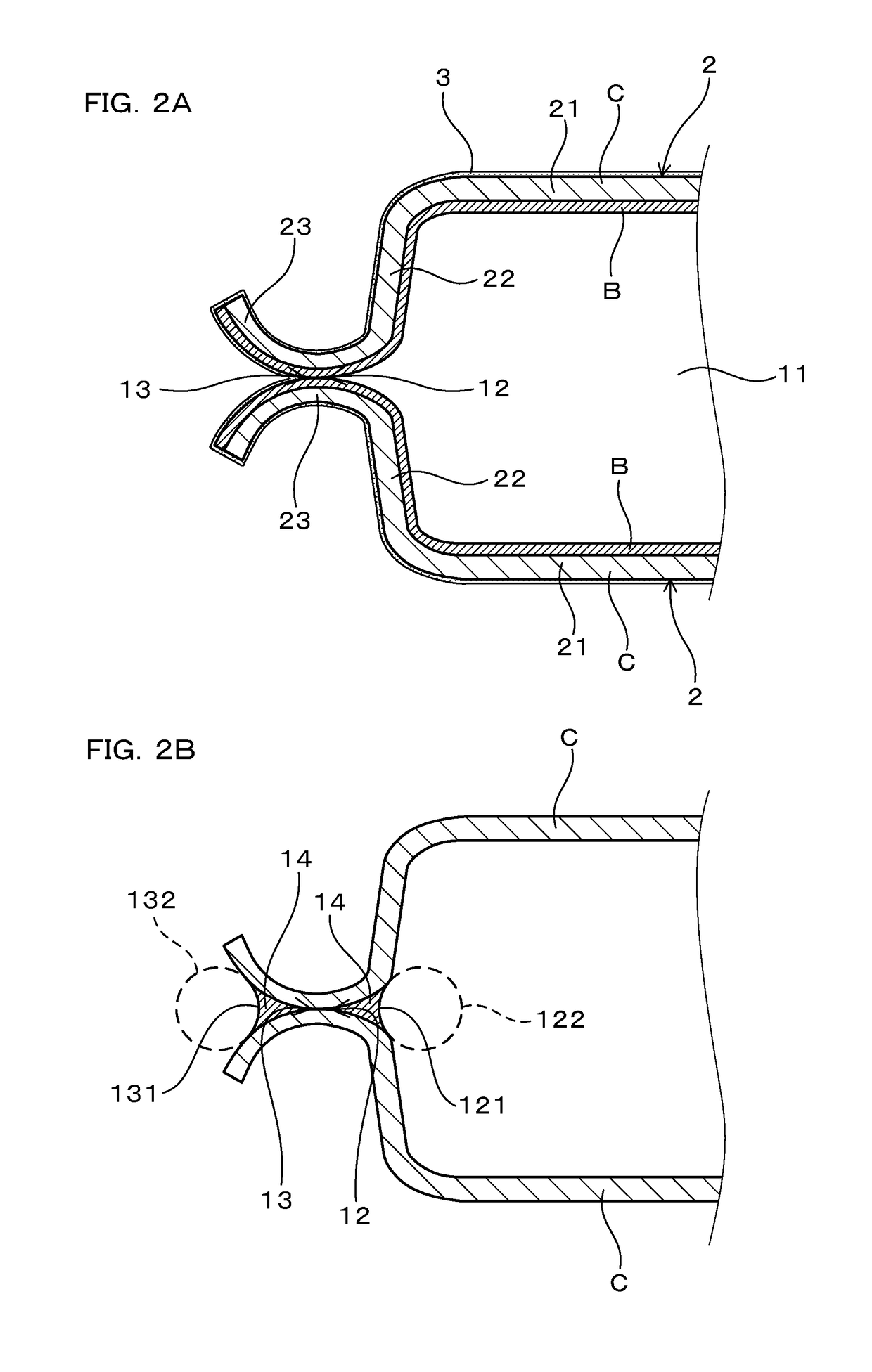

Heat Exchanger And Method For Manufacturing The Same

InactiveUS20070251091A1Improve corrosion resistanceThin and uniformSoldering apparatusStationary conduit assembliesAlloyZinc

A method for manufacturing a heat exchanger according to the present invention includes the steps of forming a thermally sprayed layer on a surface of an aluminum tube core by thermally spraying Al—Si series alloy brazing material onto the surface of the aluminum tube core to obtain a tube 2, applying flux composite containing non-corrosive flux showing zinc substitution reaction onto a surface of the tube 2, combining the tube 2 with the fin 3, and brazing the tube 2 and the fin 3 in an combined state.

Owner:SHOWA DENKO KK

Aluminium brazing sheet material

ActiveUS8455110B2Lower capability requirementsGood brazingWelding/cutting media/materialsThin material handlingAlloyAluminium

A brazing sheet material for CAB brazing without applying flux. The brazing sheet material including an aluminum core alloy layer provided with a first brazing clad layer material on one or both sides of the aluminum core layer and at least one second brazing clad layer material positioned between the aluminum core alloy layer and the first braze clad layer material. The second brazing clad layer material is an Al—Si alloy brazing material having 5% to 20% Si and 0.01% to 3% Mg, and the first brazing clad layer material is an Al—Si alloy brazing material having 2% to 14% Si and less than 0.4% Mg. Also disclosed is a brazed assembly manufactured in a brazing operation.

Owner:NOVELIS KOBLENZ GMBH

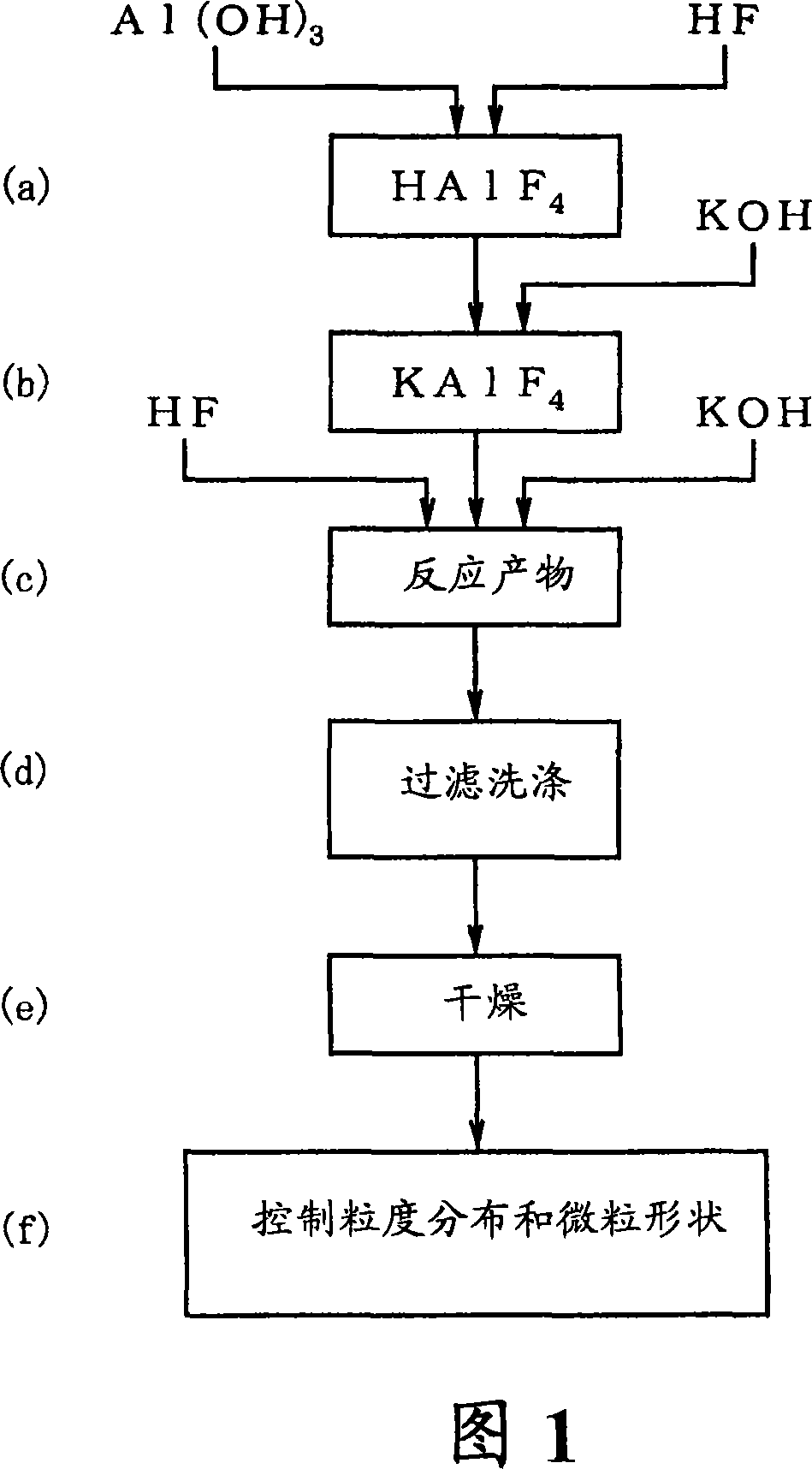

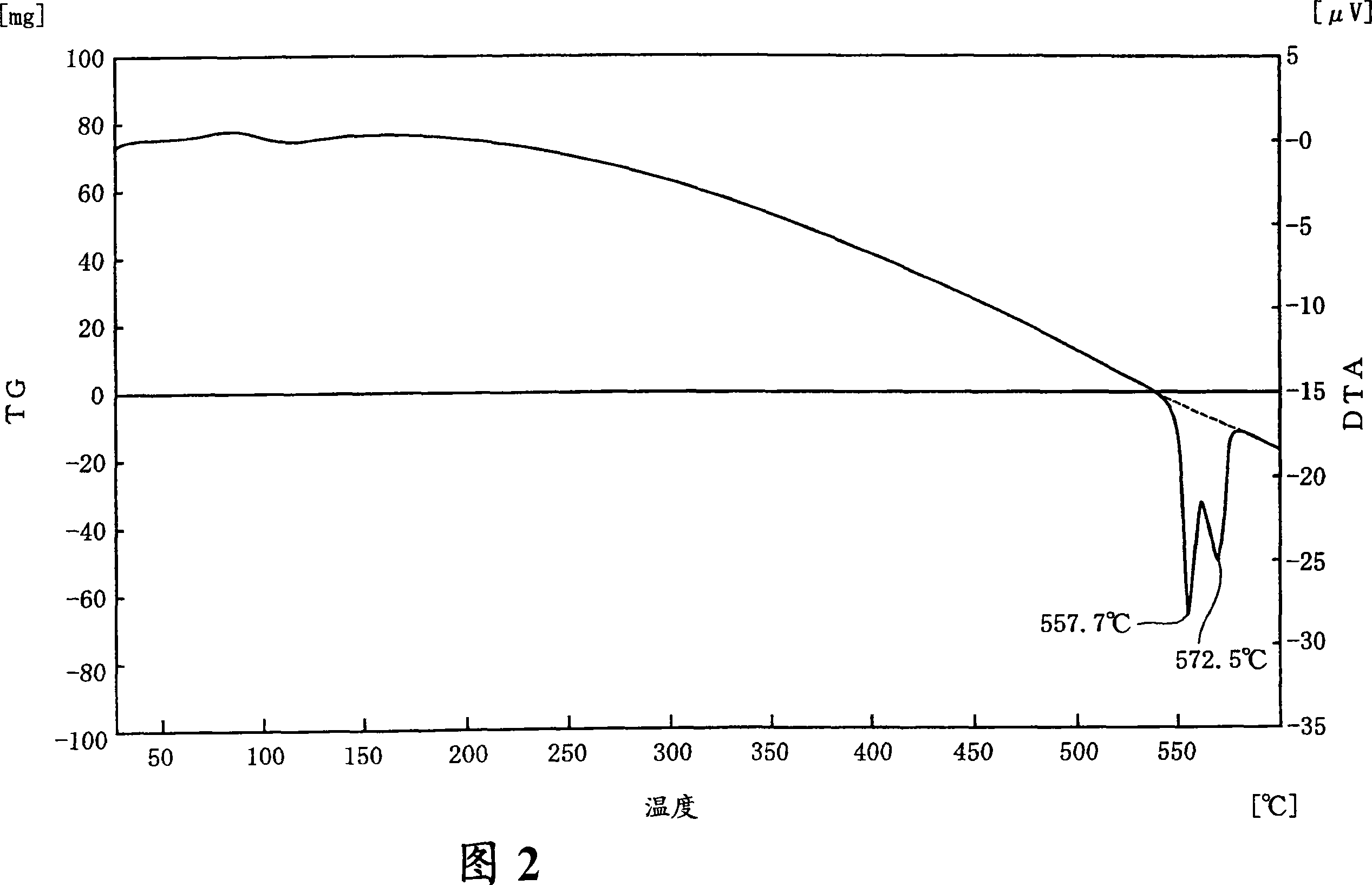

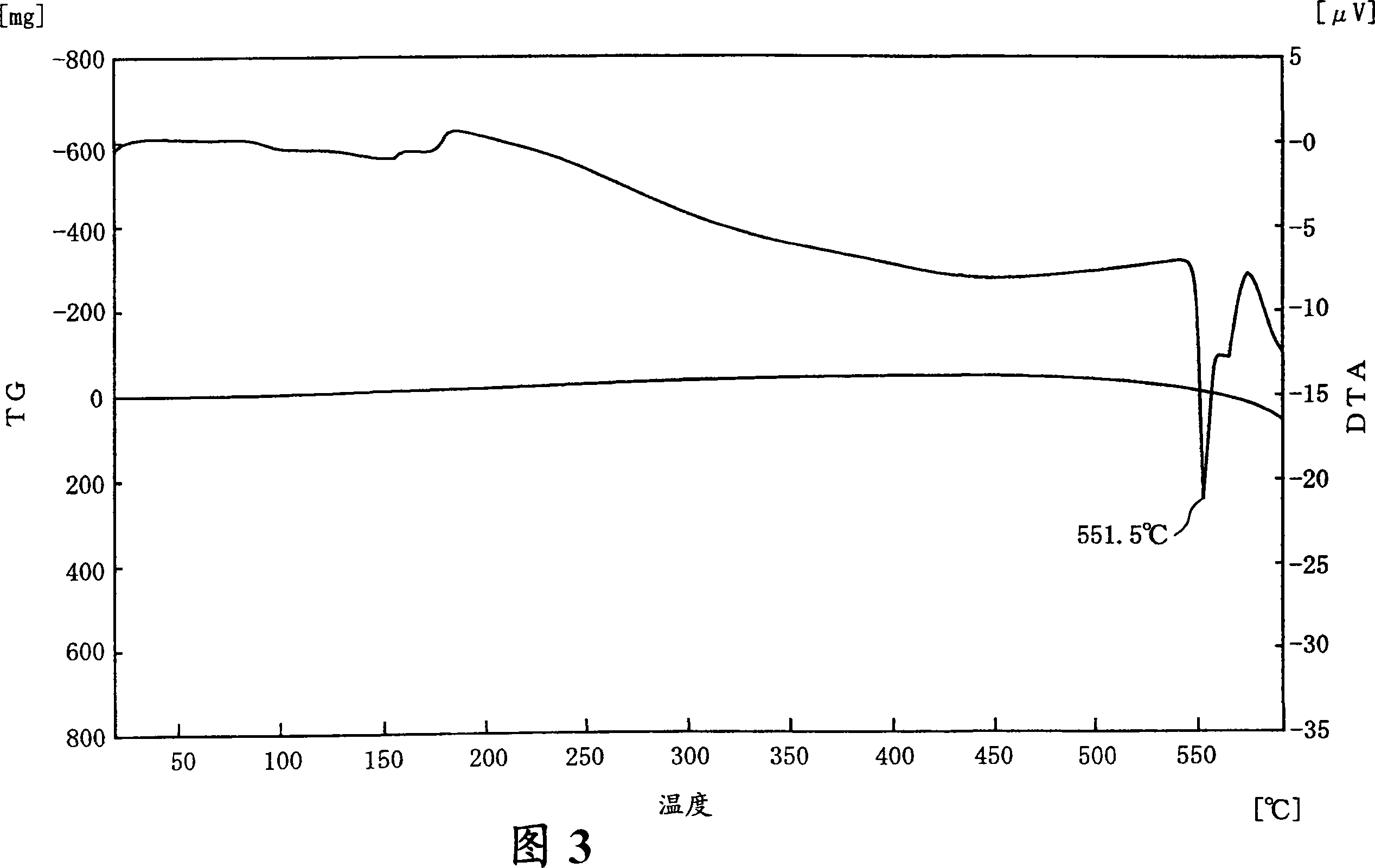

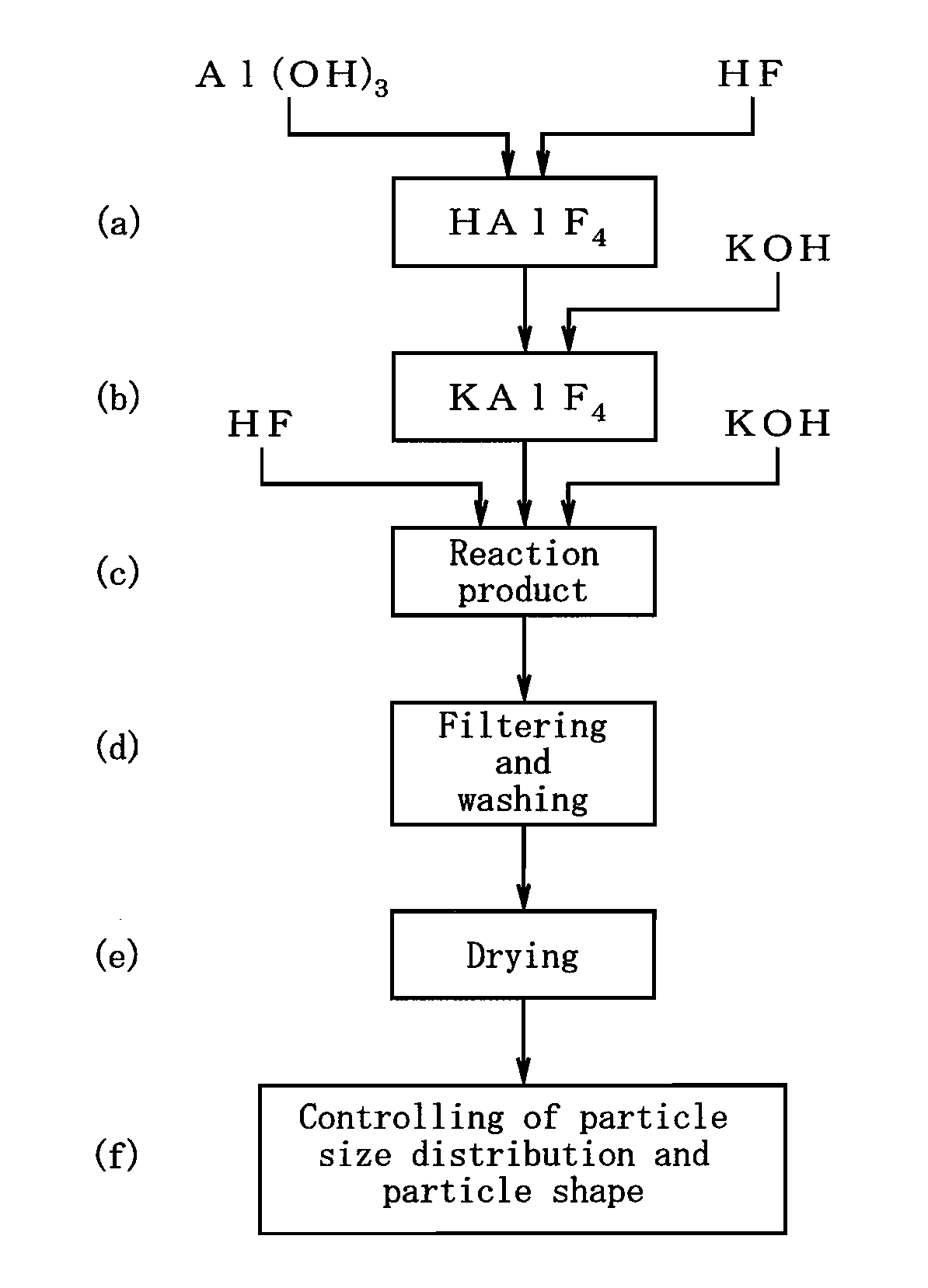

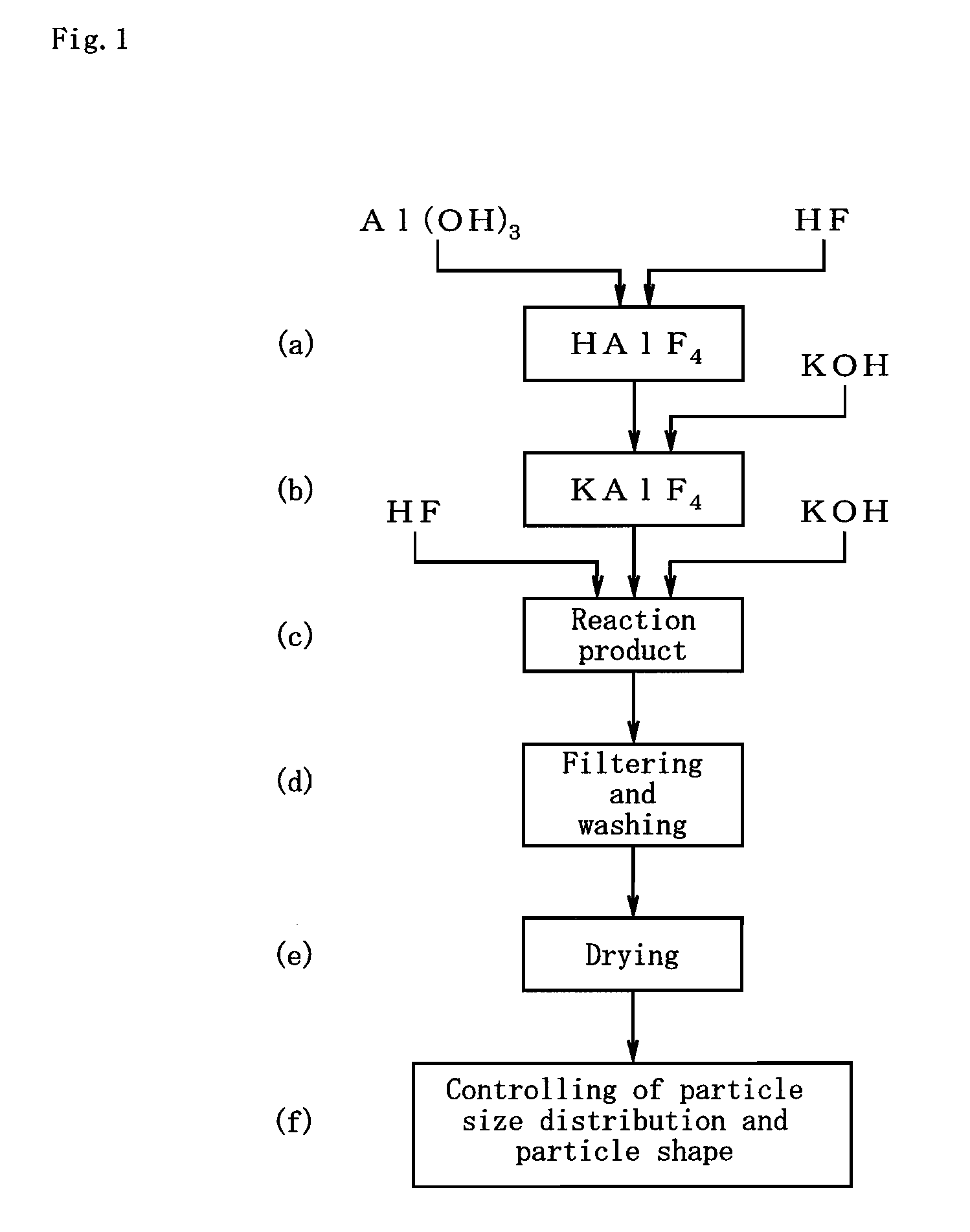

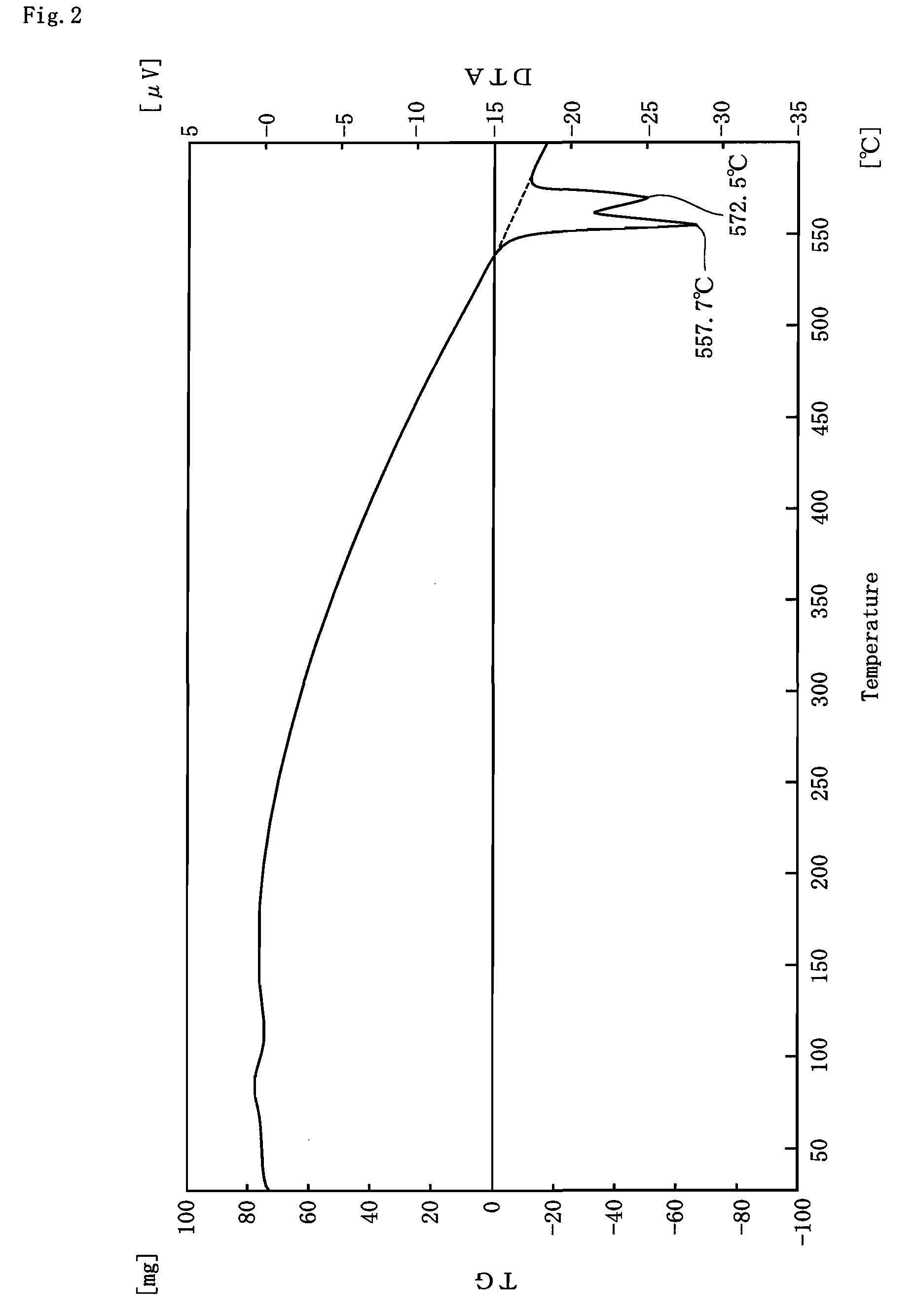

Flux powder for brazing aluminum material and process for producing the flux powder

InactiveCN101146645AImprove securityCost-effectiveWelding/cutting media/materialsSoldering mediaGeneral purposeMetallurgy

The present invention provides a flux powder, which has good expansibility when brazing Mg-containing aluminum-based materials, the flux powder is non-corrosive and has excellent safety, is inexpensive and economical, and can be widely used in General purpose. The present invention provides an improved flux powder, which contains KAlF4, K2AlF5 and K2AlF5·H2O, and is used for brazing aluminum-based materials with a Mg content of 0.1-1.0% by weight. The improved characteristic composition is that it has K / Al A composition with a molar ratio in the range of 1.00 to 1.20 and a F / Al molar ratio in the range of 3.80 to 4.10. The total content of K2AlF5 and K2AlF5·H2O is 6.0 to 40.0% by weight, and the balance is KAlF4. Part or all of the crystal structure of K2AlF5·H2O It is at least one of K-deficient, F-deficient, or K- and F-deficient crystal structures.

Owner:JEMCO INC +1

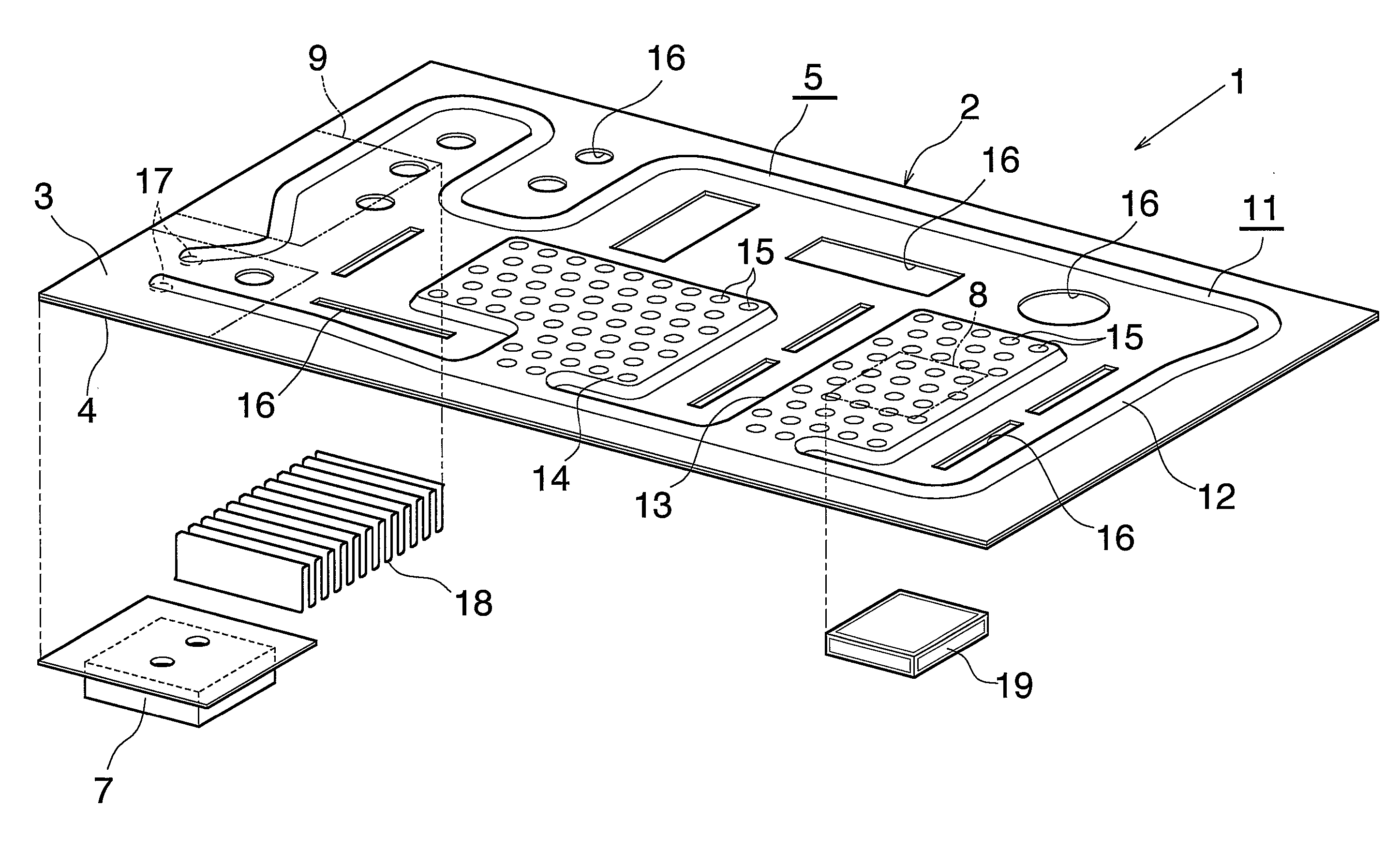

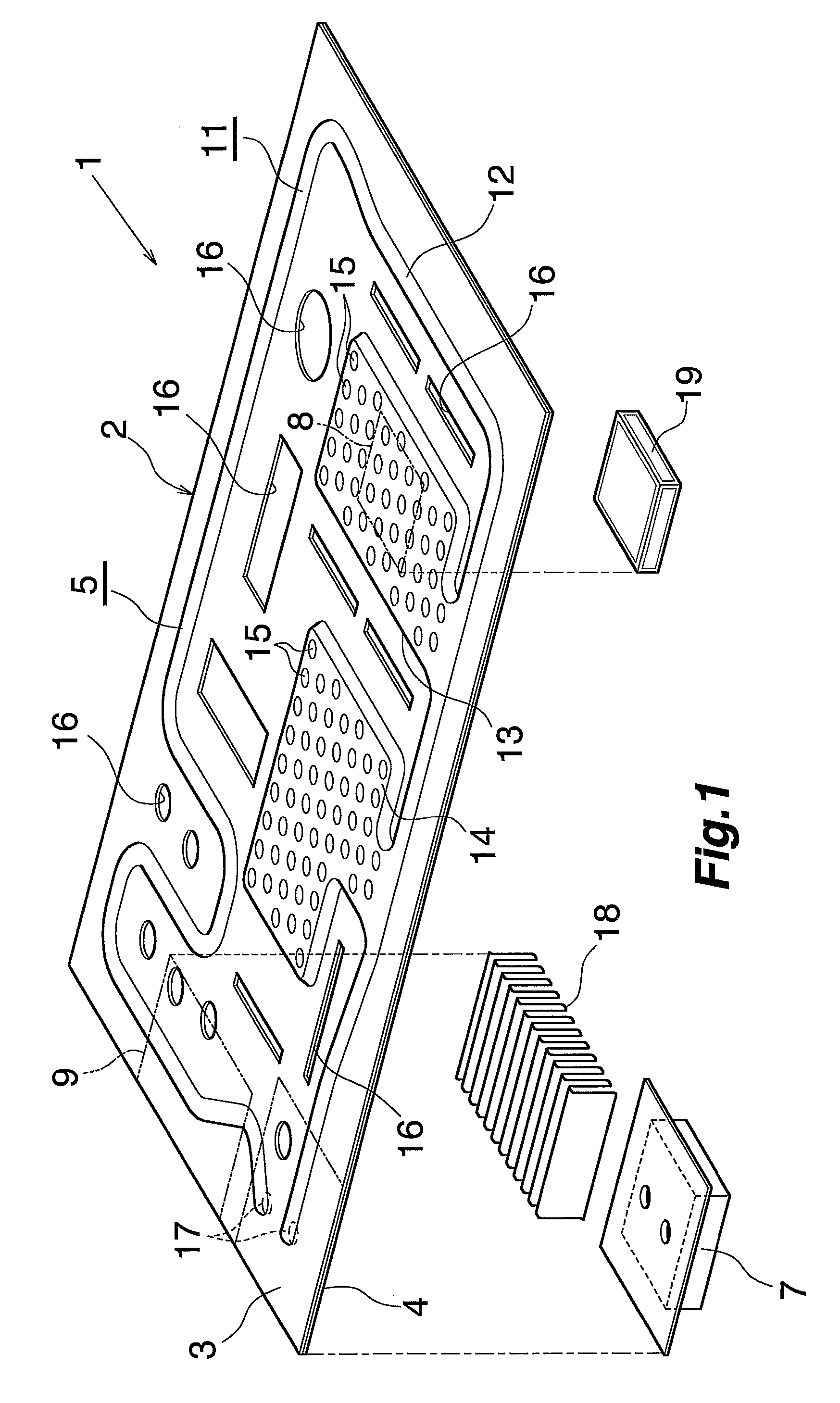

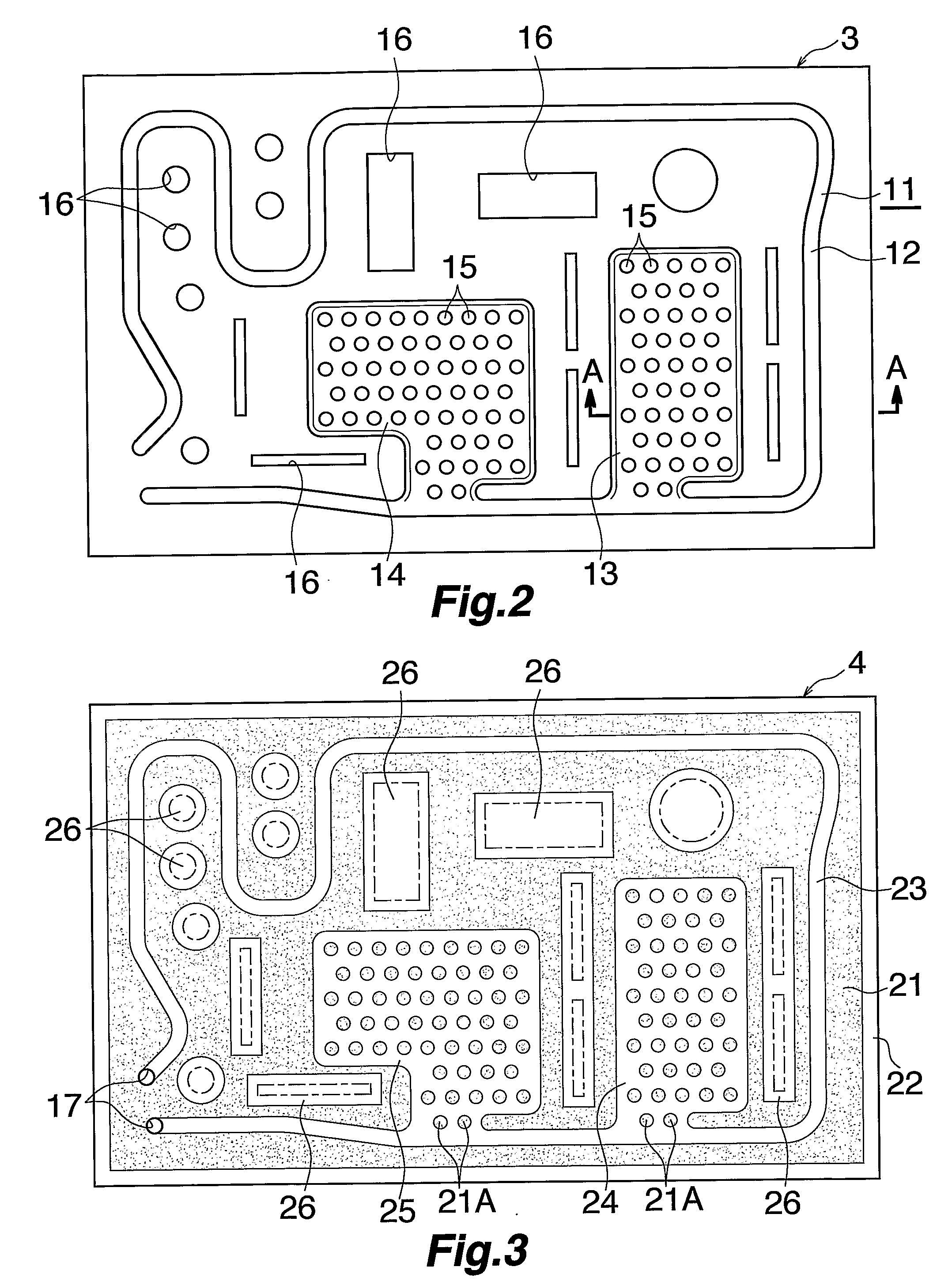

Method Of Manufacturing A Hollow Circuit Substrate

InactiveUS20080013277A1Improve external appearanceIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesMetalMaterials science

A method of manufacturing a hollow circuit substrate, of two metal sheets brazed to each other in a laminated state with a bulging hollow circuit for ed between the two metal sheets. Of the upper and lower metal sheets for forming the hollow circuit, a circuit-forming bulging portion is formed in the upper metal sheet. A flux suspension is applied by screen printing to the upper surface of the lower metal sheet so as not to overlap the circuit-forming bulging portion to form flux films. The two metal sheets are stacked on each other so as to close off the opening of the circuit-forming bulging portion and are brazed to each other. This method prevents flux from remaining in a hollow circuit of a manufactured hollow circuit substrate.

Owner:NEC CORP +1

Brazing method

ActiveUS20170320170A1Low stateGood brazingWelding/cutting media/materialsMetal working apparatusFiller metalAtmosphere

A hollow aluminum structure that will be brazed includes at least one brazing sheet having a filler metal layer clad onto a core layer. The core layer is composed of aluminum or an aluminum alloy containing less than 0.2 mass % Mg. The filler metal layer is composed of an aluminum alloy that contains Si: 4.0-13.0 mass % and Bi: 0.01-0.3 mass %, and further contains Li: 0.004-0.08 mass % and / or Be: 0.006-0.12 mass %, the filler metal layer containing less than 0.1 mass % Mg. The hollow aluminum structure is assembled such that the filler metal layer is present at locations that will form both an interior-facing brazed joint and an exterior-facing brazed joint. Then, flux is applied onto the filler metal layer at the location that will form the exterior brazed joint, and the hollow aluminum structure heated in an inert gas atmosphere to form the interior brazed joint and the exterior brazed joint.

Owner:FURUKAWA SKY ALUMINUM CORP

Brazing flux powder for aluminum-based material and production method of flux powder

InactiveUS20090050239A1Improve abilitiesImprove securityWelding/cutting media/materialsSoldering mediaCrystal structureSpreadability

It is aimed at providing a brazing flux powder, which exhibits an excellent spreadability in case of brazing of an Mg-containing aluminum-based material, which is non-corrosive and is thus excellent in safety, which is relatively inexpensive and is thus economically excellent, and which can be used in a wide and general manner. There is provided an improvement in a flux powder containing therein KAlF4, K2AlF5, and K2AlF5·H2O, usable for brazing of an aluminum-based material having an Mg content of 0.1 to 1.0 wt %, and the improving characteristic configuration resides in that the flux powder has a composition where a K / Al molar ratio is within a range of 1.00 to 1.20 and an F / Al molar ratio is within a range of 3.80 to 4.10, and the K2AlF5 and K2AlF5·H2O have a sum content of 6.0 to 40.0 wt %, balance KAlF4, and that part or the whole of the crystal structure of K2AlF5·H2O is at least one of a K-defective type, F-defective type, and K-and-F-defective type crystal structure.

Owner:MITSUBISHI MATERIALS ELECTRONICS CHEM CO LTD +1

Induction brazing method for edge scraper of shielding tunneling machine

ActiveCN105921838AExtended service lifeImprove wear resistanceHeating appliancesSoldering auxillary devicesTemperature differenceShield tunneling

The invention discloses an induction brazing method for an edge scraper of a shielding tunneling machine. An edge scraper body, silver-based brazing filler metal and a hard alloy tool bit which are well assembled are put in the lower end of a profiling coil and are tightly attached to the profiling coil, and then the welding work is completed after preheating, heating welding and post-welding thermal treatment. The adopted profiling coil is a self-made profiling coil. By means of the induction brazing method, the hard alloy at the middle part can be heated, the temperature differences of different positions of the edge scraper are reduced during welding, the same brazing filler metal can be conveniently used for brazing, and the phenomenon that because different types of brazing filler metal are used for brazing, mutual interference is caused is avoided. By means of the induction brazing method, brazing of the hard alloy tool bit and the edge scraper body can be completed at a time; and meanwhile, the weld joint brazed rate is increased, the shear strength is also improved, the service life of the edge scraper of the shield tunneling machine is prolonged, and wear resistance of the edge scraper of the shield tunneling machine is improved.

Owner:SICHUAN GUANGZHENG TECH

Antiwear Cu-base material with high electric conductivity

A copper-base alloy material contains Ti (0.4-2.9 wt.%), B (0.2-1.3 wt.%), Sn (0.1-0.9 wt.%), Ce (0.01-0.06 wt.%) and Cu (the balance). Its advantages are excellent antiwear nature, and electric and thermal conductivities, higher tension strength and elastic extreme, proper toughness, lower expandability, easy machining and welding, and sealing performance with resin.

Owner:ZHEJIANG UNIV

Tube punching and collaring system, device and method

A tube punching system for punching at least one hole into a tube, said system comprising: a punch, an external mold and a counter die. The mold and punch are positioned relative to each other such that the mold exerts a counterforce onto the tube when the hole is punched; and wherein the mold subsequently forms a collar as a result of the force applied by punch against the tube.

Owner:DAGAN MOSHE

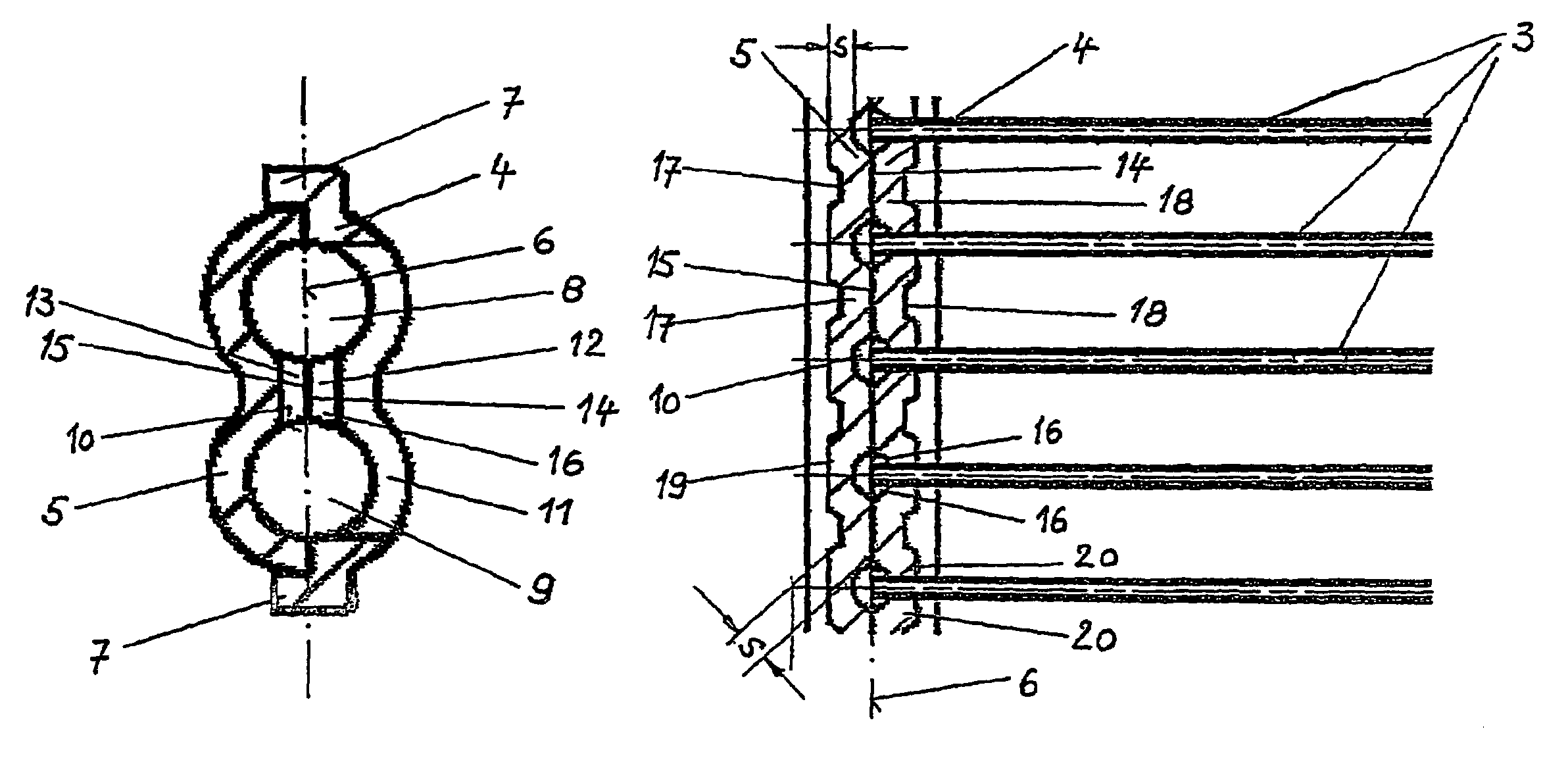

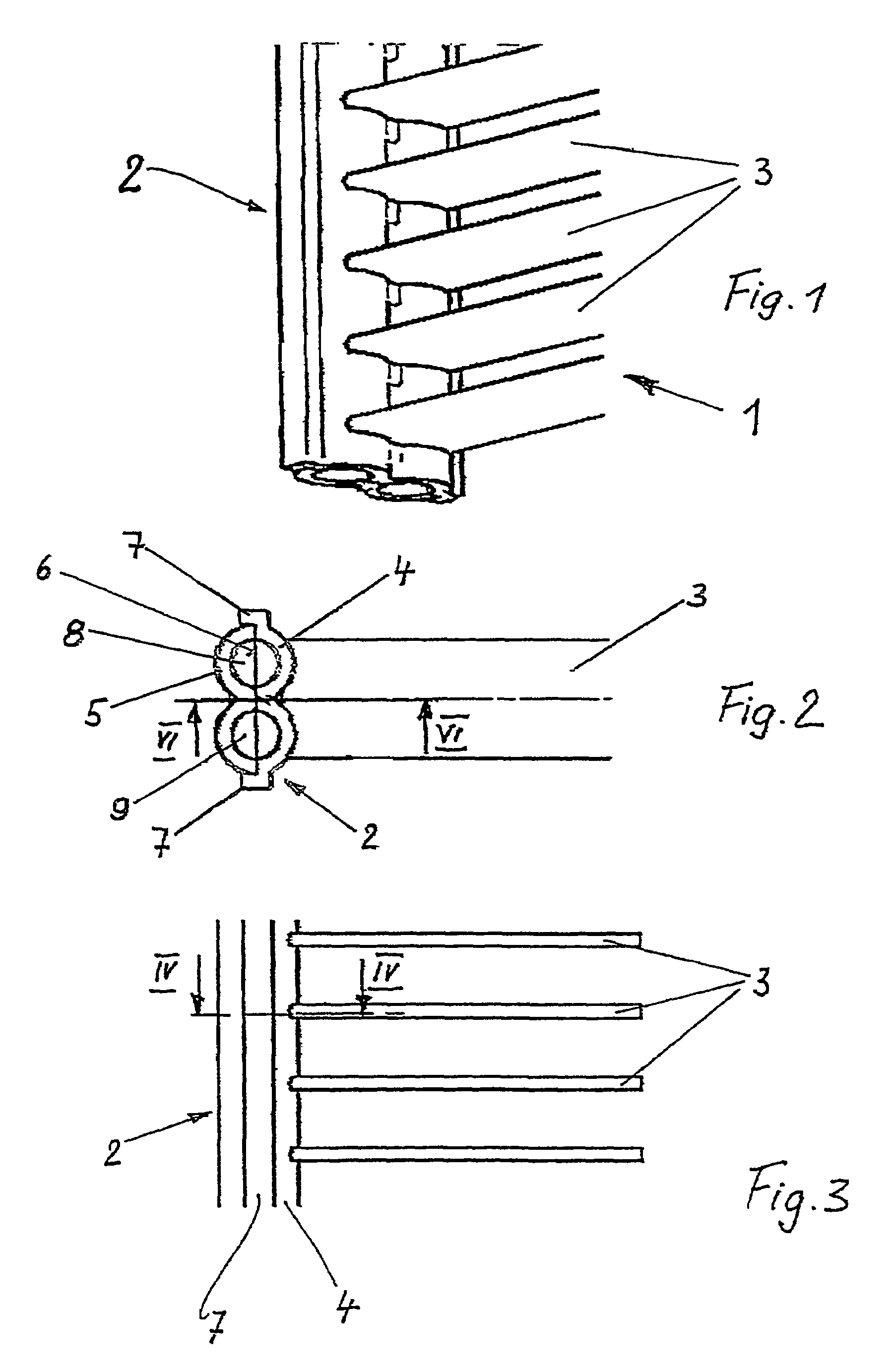

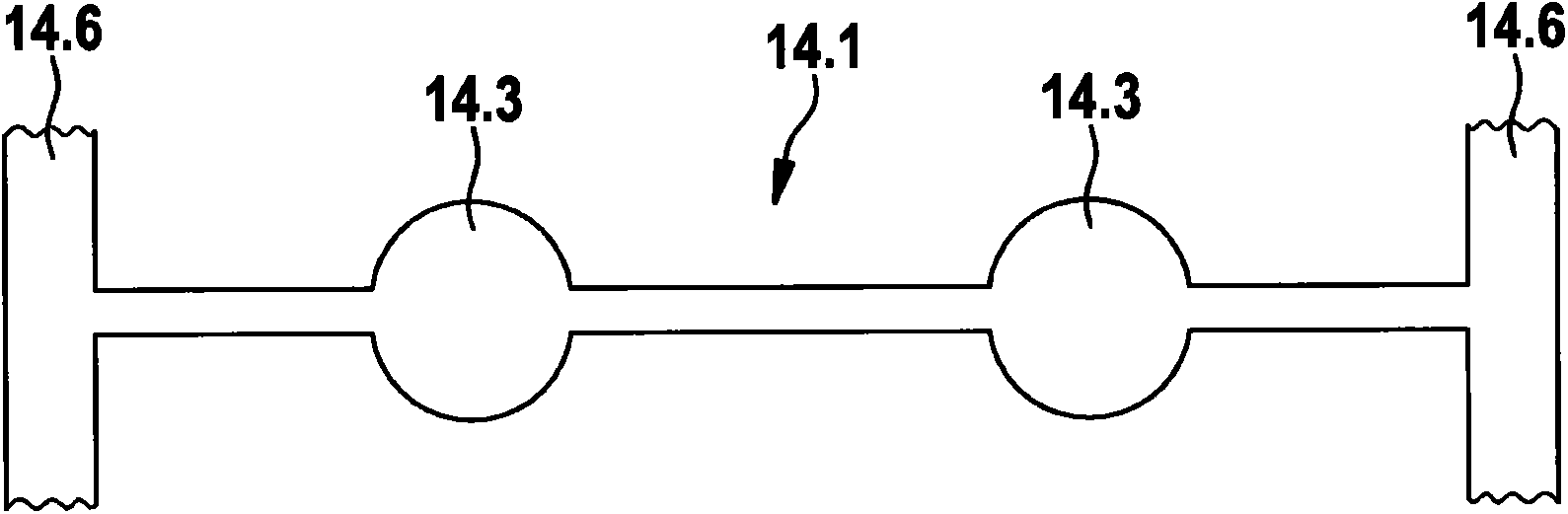

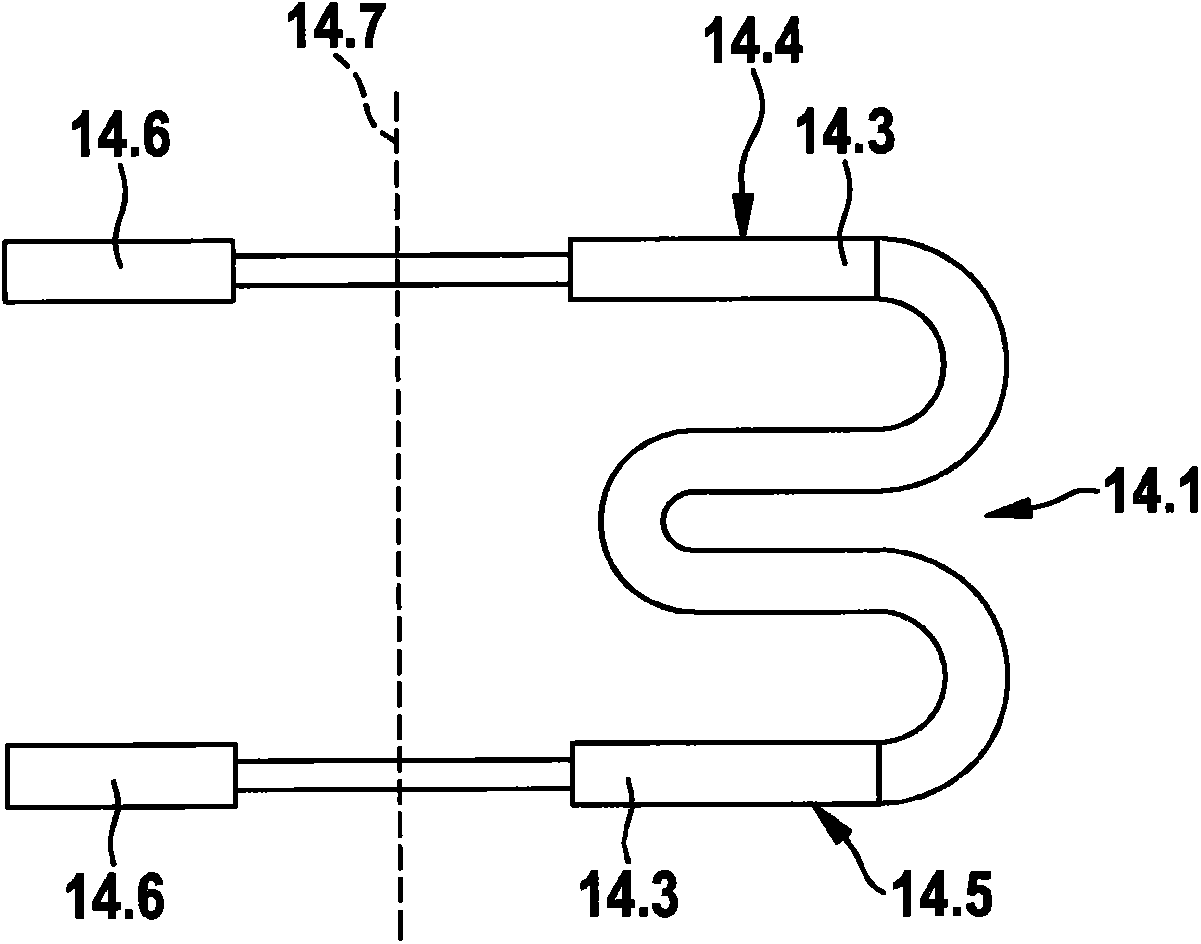

Heat exchanger

InactiveUS7578340B2Low costBetter able to withstandSteam/vapor condensersStationary conduit assembliesPlate heat exchangerEngineering

The invention relates to a heat exchanger, especially a gas cooler for CO2, embodied as a cooling agent. The heat exchanger comprises at least one two-part collector unit made of a base and a cover. Said collector unit consists of flat pipes and at least two longitudinal channels with an essentially circular cross-section. The ends of the flat pipes and the base comprise openings for receiving the ends of the pipes. The base, cover and flat pipes are soldered together.

Owner:BEHR GMBH & CO KG

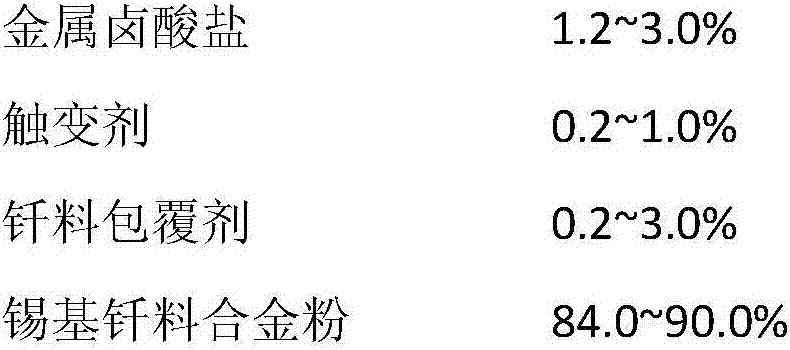

Low-residue high-storage stability low-temperature tin paste for aluminium and preparation method thereof

ActiveCN107009043AHigh activityGood storage stabilityWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention discloses low-residue high-storage stability low-temperature tin paste for aluminium and a preparation method thereof. The tin paste for the aluminium consists of paste flux and tin-based brazing material alloy powder. The tin paste is prepared from the following raw materials in percentage by mass: 8.0 to 24.0 percent of the paste flux and the balance of the tin-based brazing material alloy powder, wherein the paste flux comprises the following components in percentage by mass: 4.0 to 10.0 percent of hydroxyl amine, 0.4 to 1.0 percent of metal active salt, 2.0 to 6.0 percent of a co-solvent, 1.2 to 3.0 percent of metal halate, 0.2 to 1.0 percent of a thixotropic agent, and 0.2 to 3.0 percent of a brazing material coating agent. When the paste flux is prepared, the metal halate is dispersed into the paste flux in a low-temperature solid form through high-speed shearing. The prepared paste flux has the advantages of low residue, high storage stability and the like after soldering, and can be applied to the situation of low-temperature soft brazing of the aluminium and an aluminium alloy, and is particularly suitable for reflow soldering of electronic assembly aluminium and aluminium alloy materials.

Owner:SOUTH CHINA UNIV OF TECH

Aluminum brazing alloy for cold brazing and method for brazing low-melting aluminum material

InactiveUS6170738B1Improve wettabilityHigh melting pointWelding/cutting media/materialsSoldering mediaBraze alloyTitanium

A first aluminum brazing alloy for cold brazing, comprises 70 to 90% by weight of zinc and 0.05 to 5% by weight of titanium with the balance consisting of aluminum and impurities. A second aluminum brazing alloy for cold brazing, comprises 30 to 70% by weight of zinc, 1 to 7% by weight of silicon, and 0.05 to 5% by weight of titanium with the balance consisting of aluminum and impurities. Brazing alloys having these compositions have a low melting point and can well wet a base metal. Further, use of the above aluminum brazing alloy for cold brazing enables a low-melting aluminum material to be well brazed at 400 to 550° C.

Owner:SHOWA DENKO KK

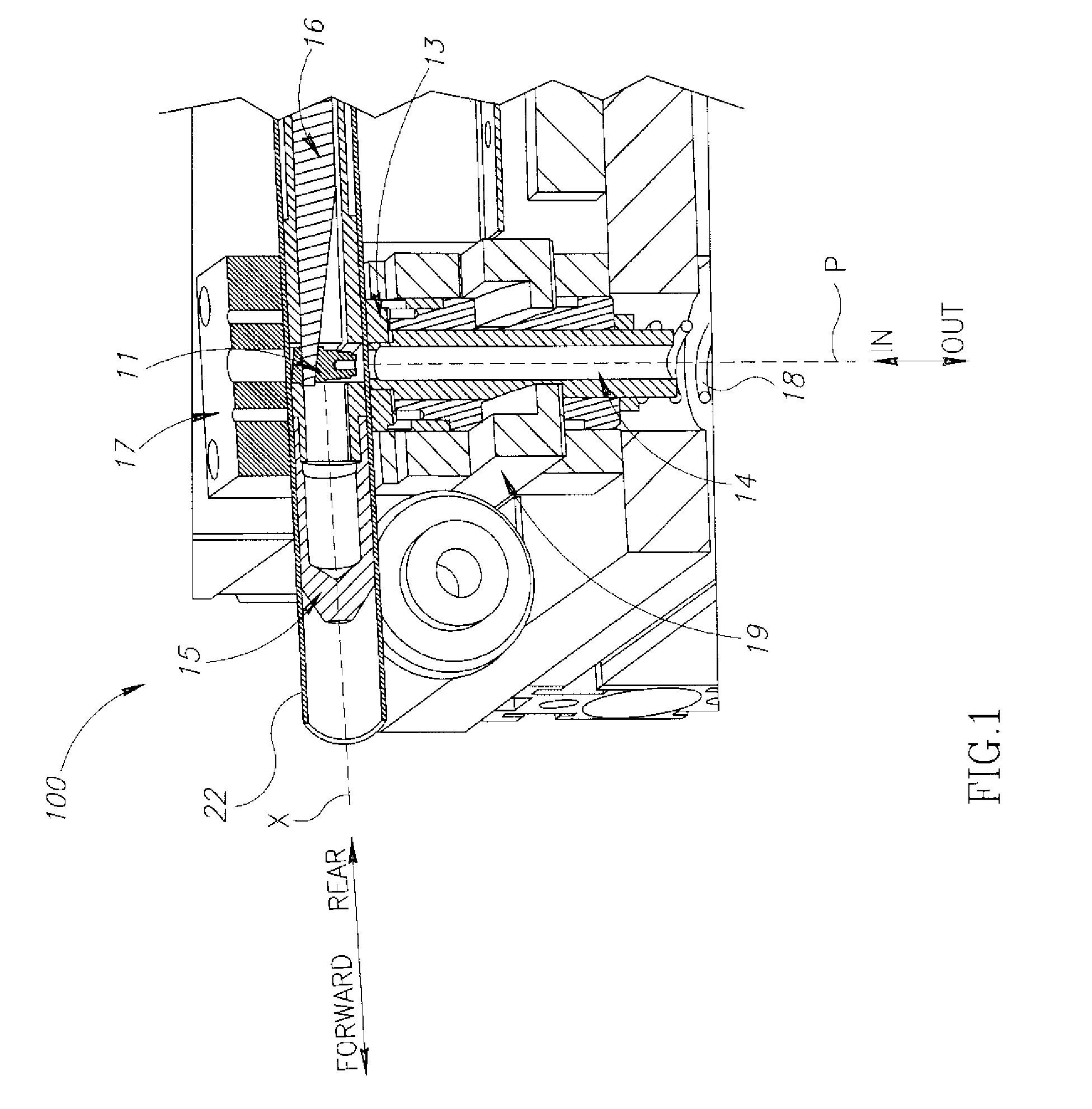

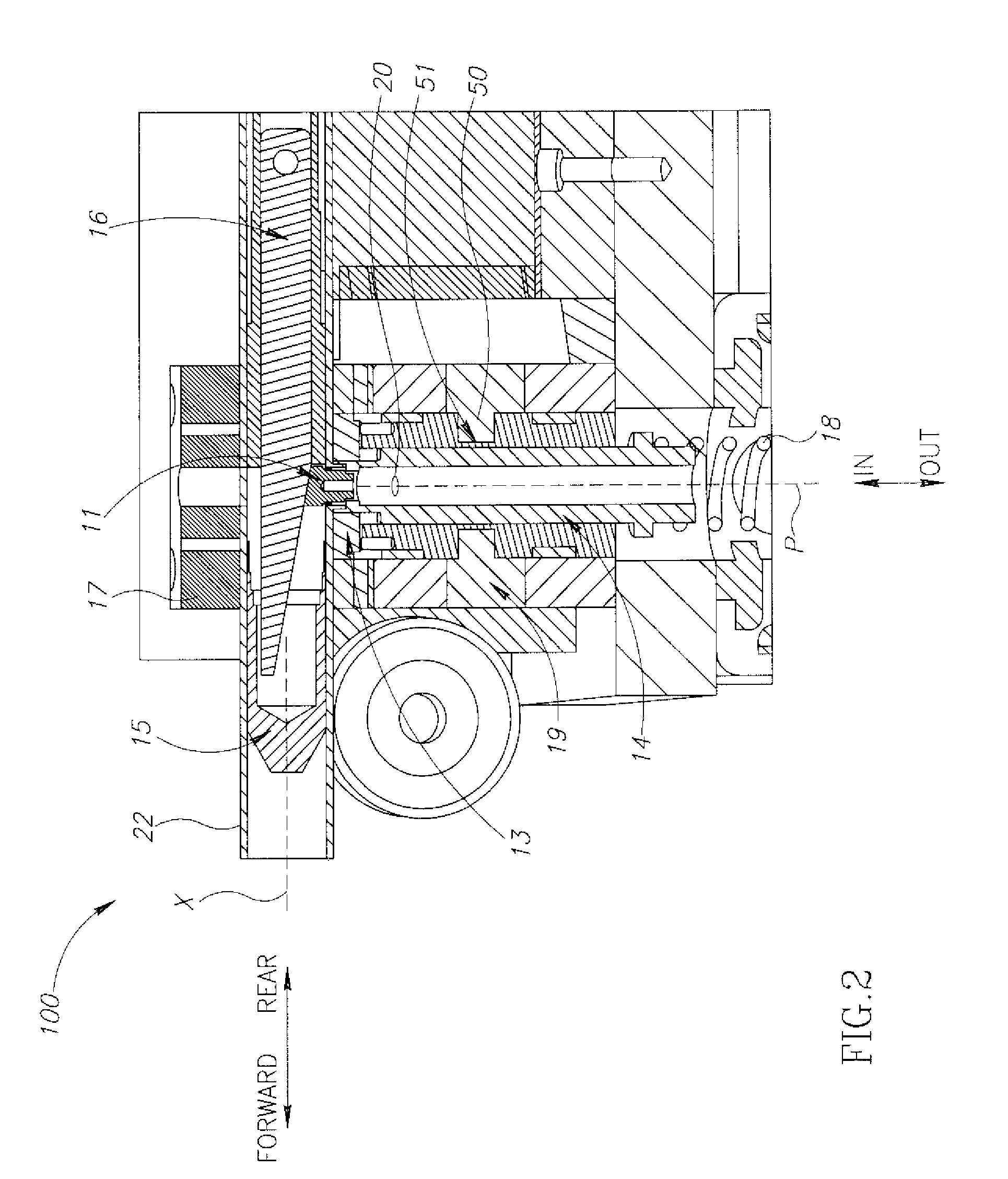

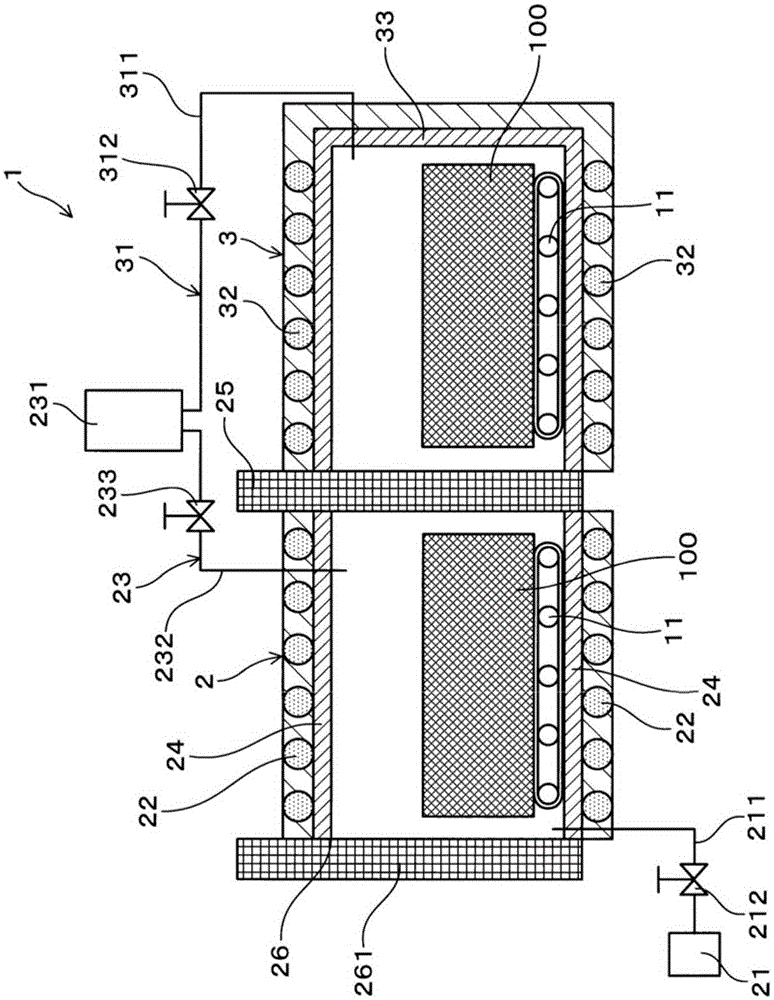

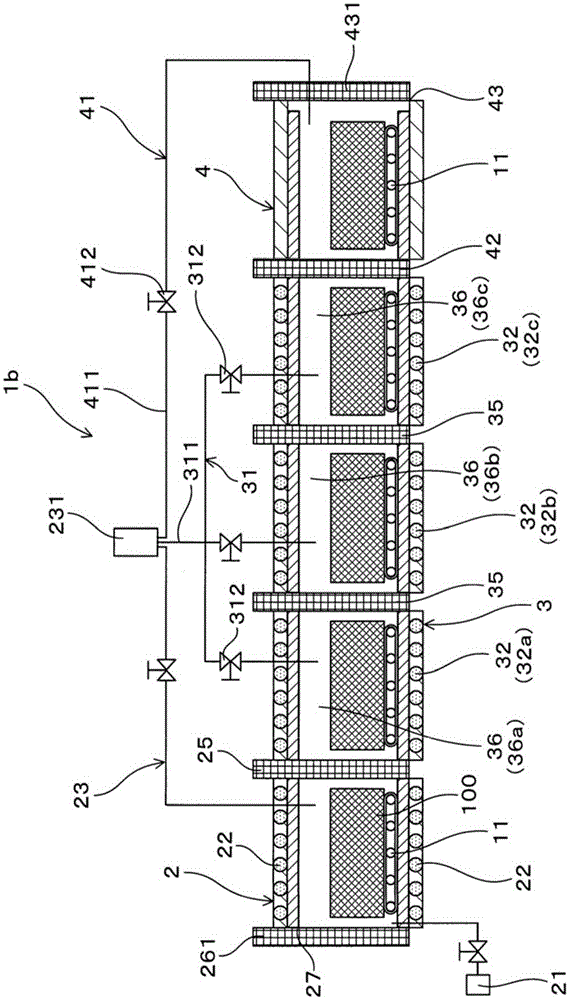

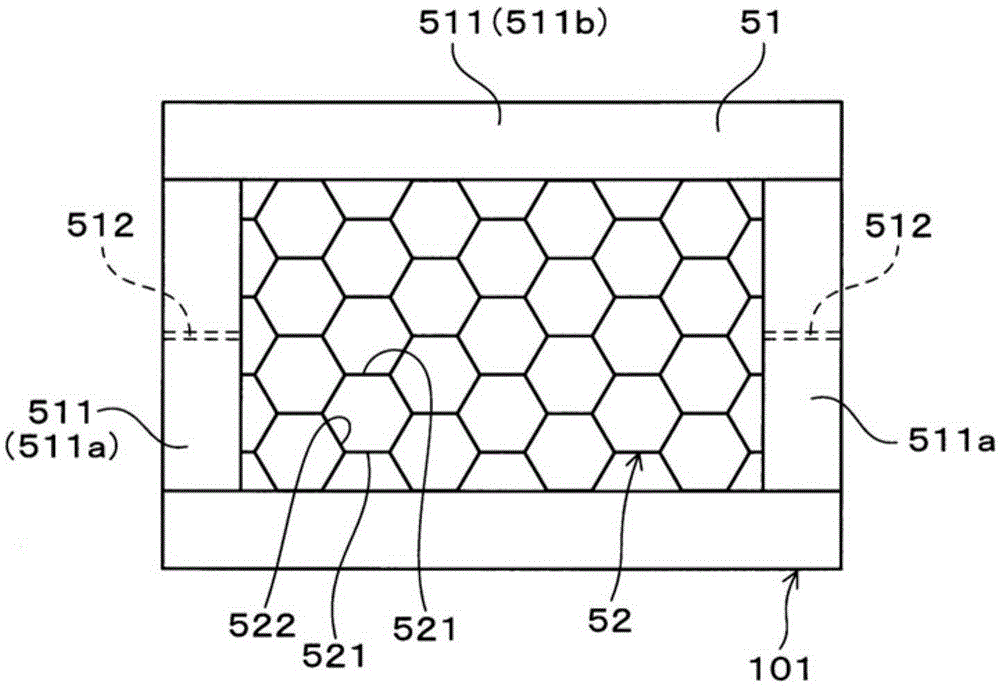

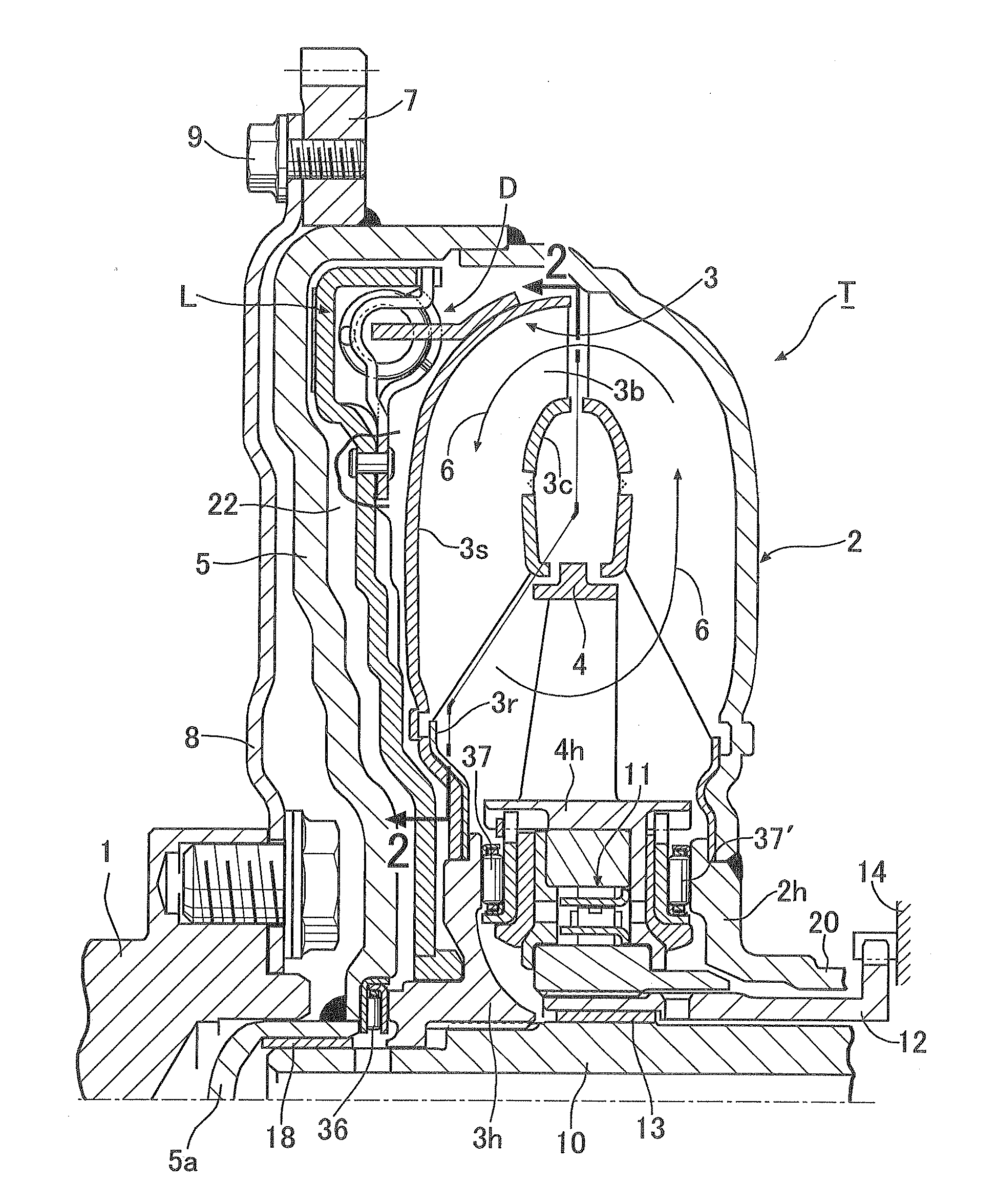

Brazing furnace and brazing method for aluminum material

InactiveCN105537717AAccelerate evaporationLess quantityHeating appliancesWelding/soldering/cutting articlesMetallurgyPressure Atmosphere

A brazing furnace (1) has a preheating chamber (2) and a brazing chamber (3). The preheating chamber (2) has the following: a vacuum pump (21) for reducing the pressure inside the chamber in a state in which the chamber houses a material to be treated (100); a preheating device (22) for preheating the material to be treated (100) under a reduced-pressure atmosphere; and a pressure-restoring gas introducing device (23) that introduces an inert gas for restoring the pressure inside the chamber after preheating. The brazing chamber (3) has a gas substitution device (31) for introducing the inert gas into the chamber and a main heating device (32) that heats the material to be treated (100) to a brazing temperature, and as a result of the foregoing, the brazing joining quality can be easily stabilized with regard to brazing in which the flux application amount is reduced or in which no flux is used.

Owner:FURUKAWA SKY ALUMINUM CORP

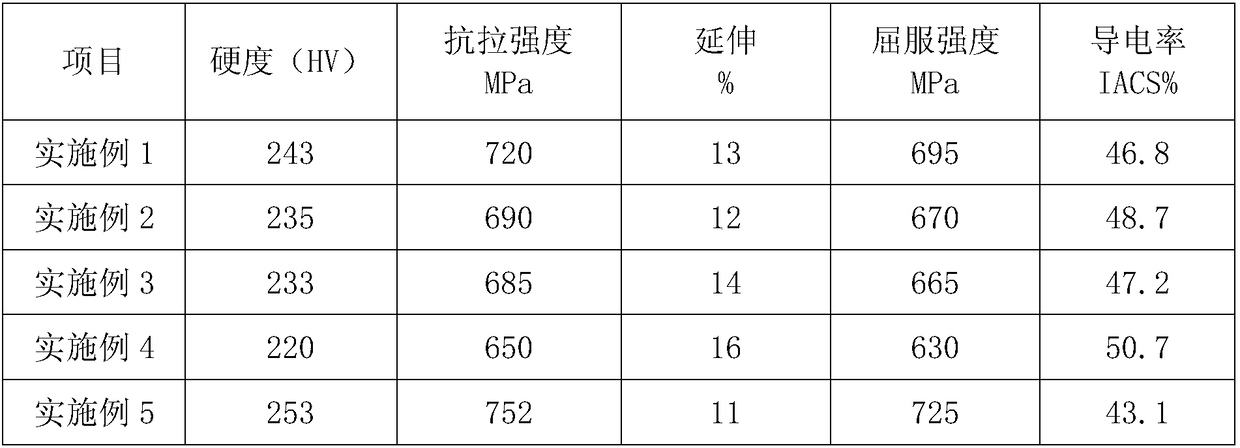

Ageing strengthening copper alloy strip and preparing method thereof

The invention relates to an ageing strengthening copper alloy strip. The copper alloy strip is composed of components including, by weight, 0.4%-1.3% of Si, 2%-4.5% of Ni, 0.06%-0.2% of Cr, 0.2%-0.8%of Zn, 0.05%-0.2% of Mg and the balance copper and inevitable trace impurities. Preparing steps include that burdening and smelting are carried out; Mg is added for deoxygenation treatment; when the temperature of a holding furnace reaches the casting temperature being 1220 DEG C-1300 DEG C, and a horizontal continuous casting red ingot casting technology is adopted; face milling, rough rolling and solution treatment are carried out; intermediate rolling is carried out after surface washing; second solid solution is carried out; finished product finish rolling is carried out after surface washing; finished product aging is carried out; surface washing and surface grinding polishing are carried out; and finished stripping, checking and packaging are carried out. The ageing strengthening copper alloy strip has the good processability and casting performance, has the advantages of high strength, high elasticity, high conductivity, excellent resistance to high temperatures and good stressrelaxation resistance and is an ideal material for a lead frame, and the preparing technology is simple.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Brazing method for high-temperature alloy assembly of aero-engine

InactiveCN105478945AGuaranteed Brazing RequirementsEasy to processSoldering apparatusTurbineFiller metal

The invention provides a brazing method for a high-temperature alloy assembly of an aero-engine. The method comprises the first step of cleaning, the second step of brazing filler metal filling, the third step of first-time brazing, the fourth step of machining, the fifth step of second-time brazing and the sixth step of machining finishing. The two-time brazing technology is adopted, the requirement for brazing of high and low-pressure turbine outer ring fan-shaped section assemblies is guaranteed, and the brazing deformation is small; and meanwhile component machining is convenient, component brazing is good, component assembling and positioning are convenient, and the brazing quality of engine components is guaranteed.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

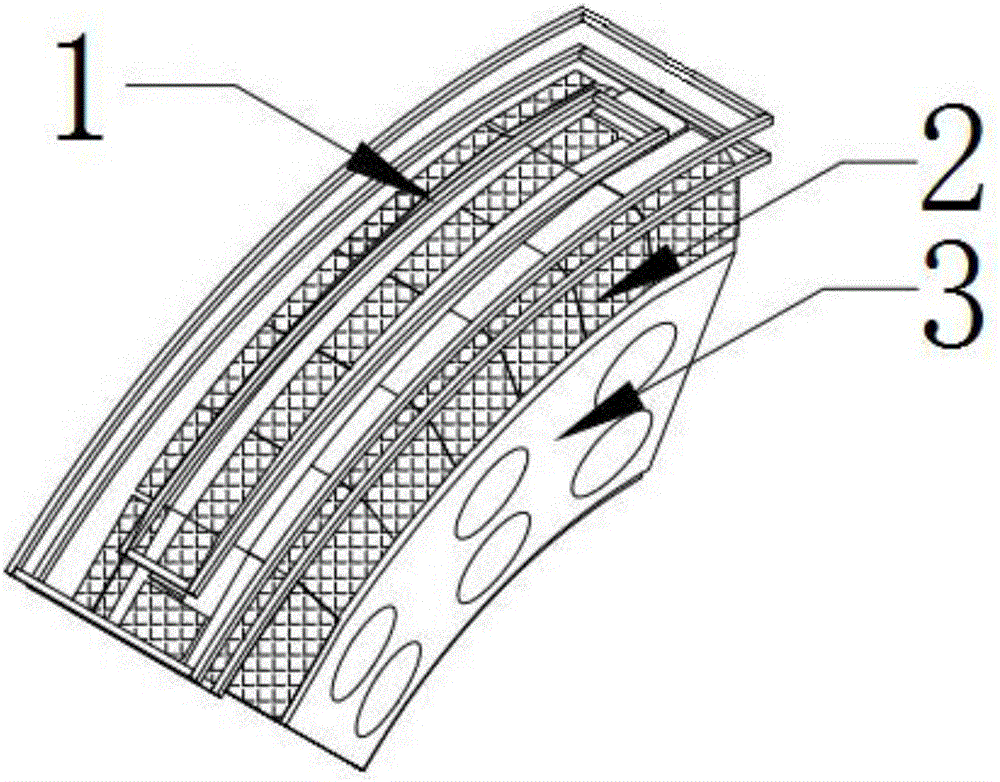

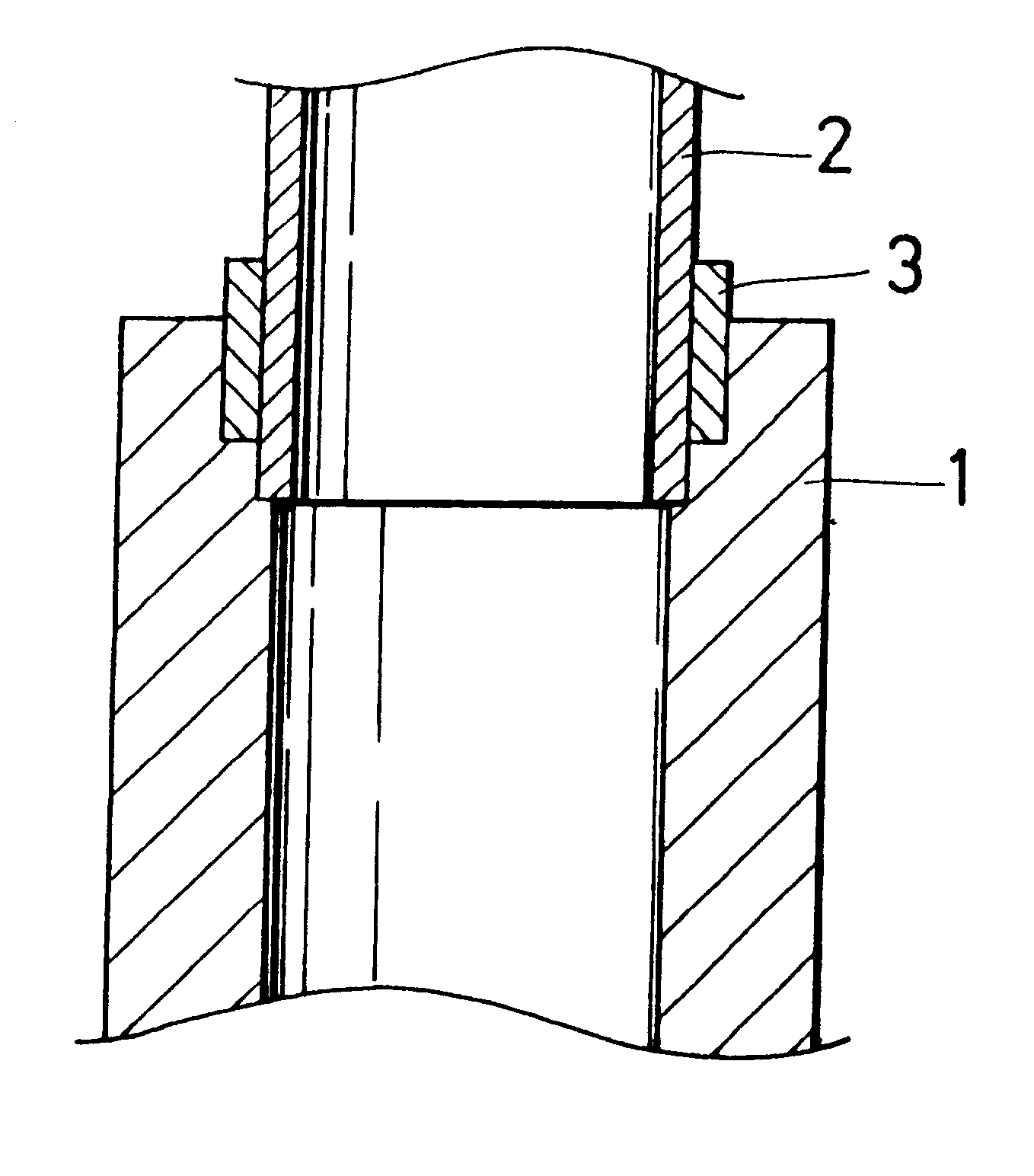

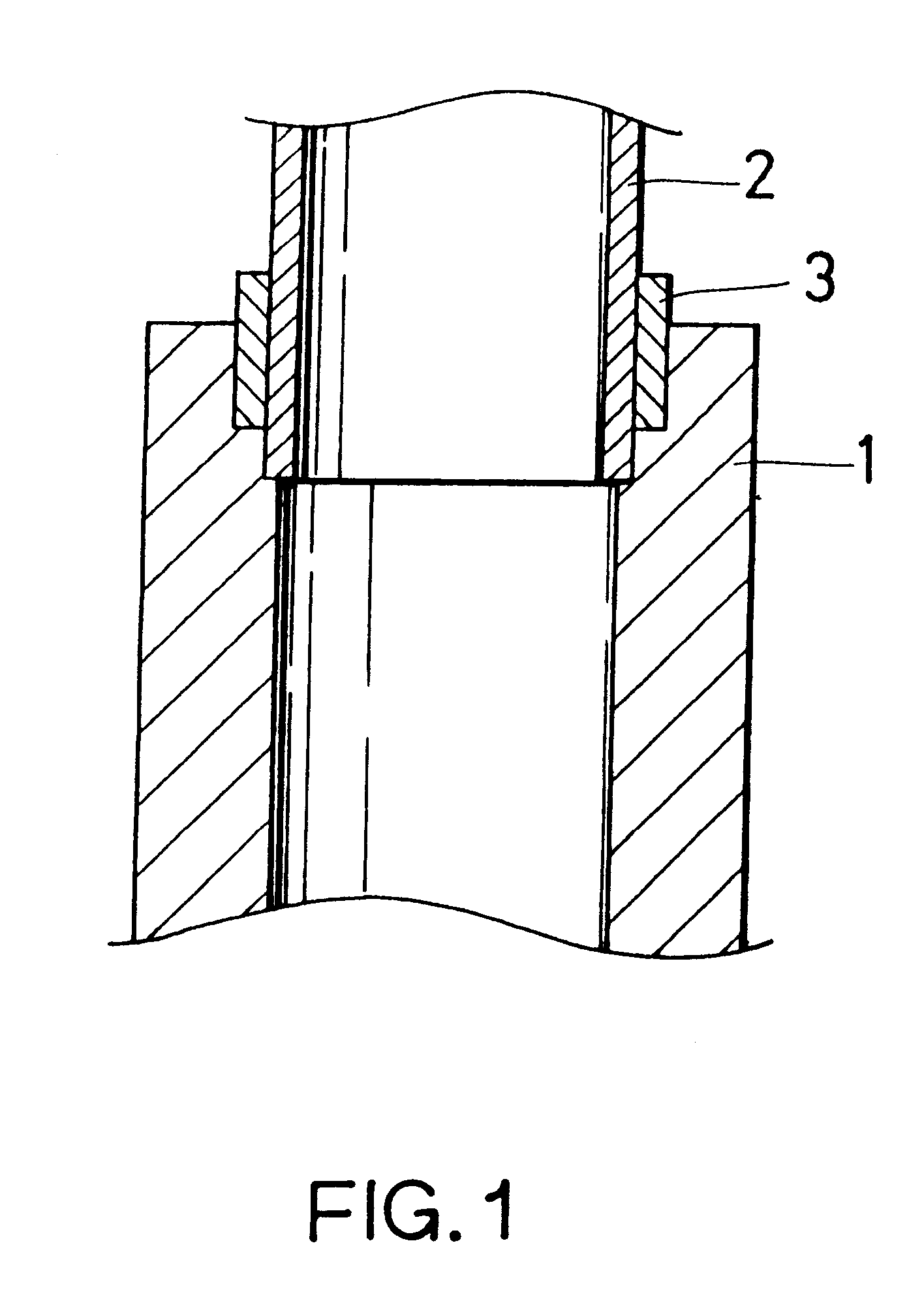

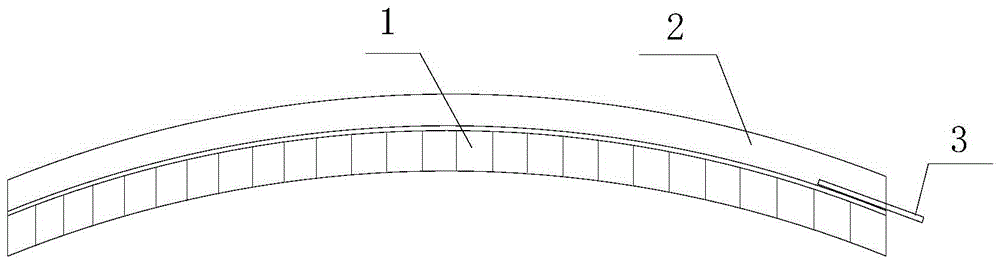

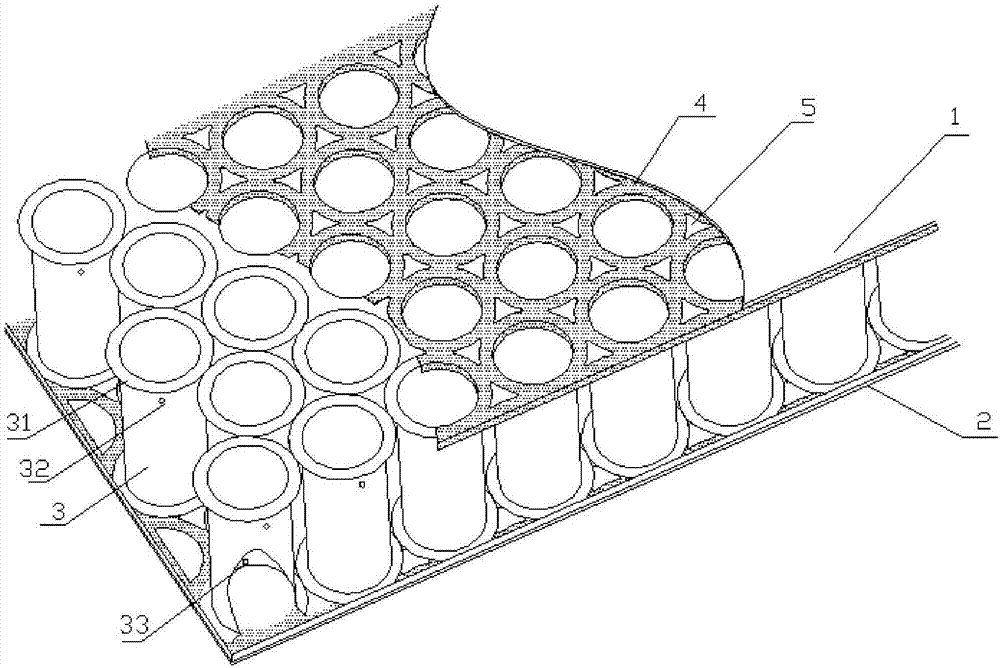

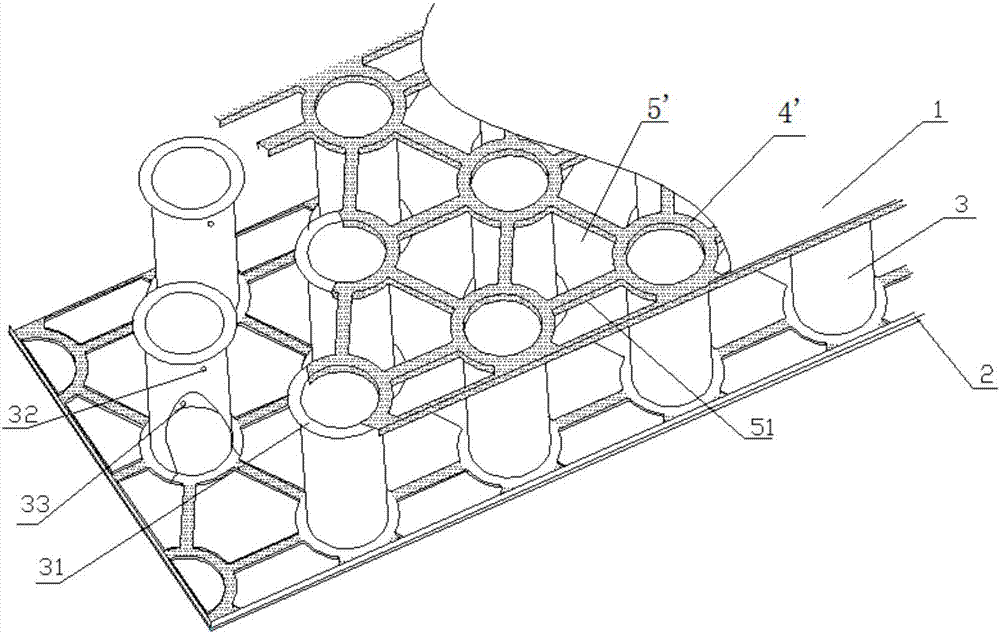

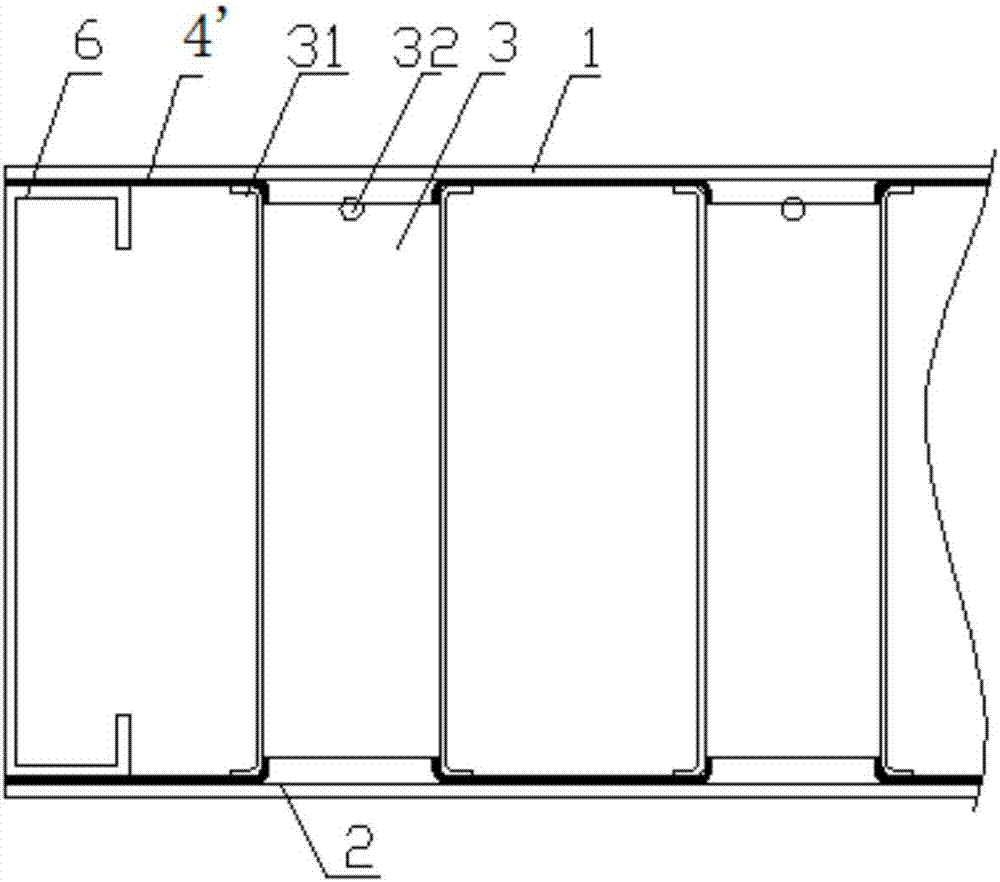

Flanged core material

InactiveCN108005302AImprove lightweightReduce stressHeat proofingThermal insulationNuclear engineering

The invention discloses a flanged core material. The flanged core material comprises an upper panel, a lower panel, a plurality of core tubes in the middle, and brazing layers between the core tubes and the upper panel and between the core tubes and the lower panel. Both upper and lower ends of the core tube are flanged. The flanges of the core tubes are brazed with the upper and lower panels. Theflanged core material has the minimum material use amount on the premise of the same strength, has the maximum strength on the premise of the same weight, improves joint interface strength between the core tubes and the brazing material thereby improving the tensile strength and impact thermal stress of the whole brazing layer, and has good thermal insulation and sound insulation effects.

Owner:张跃

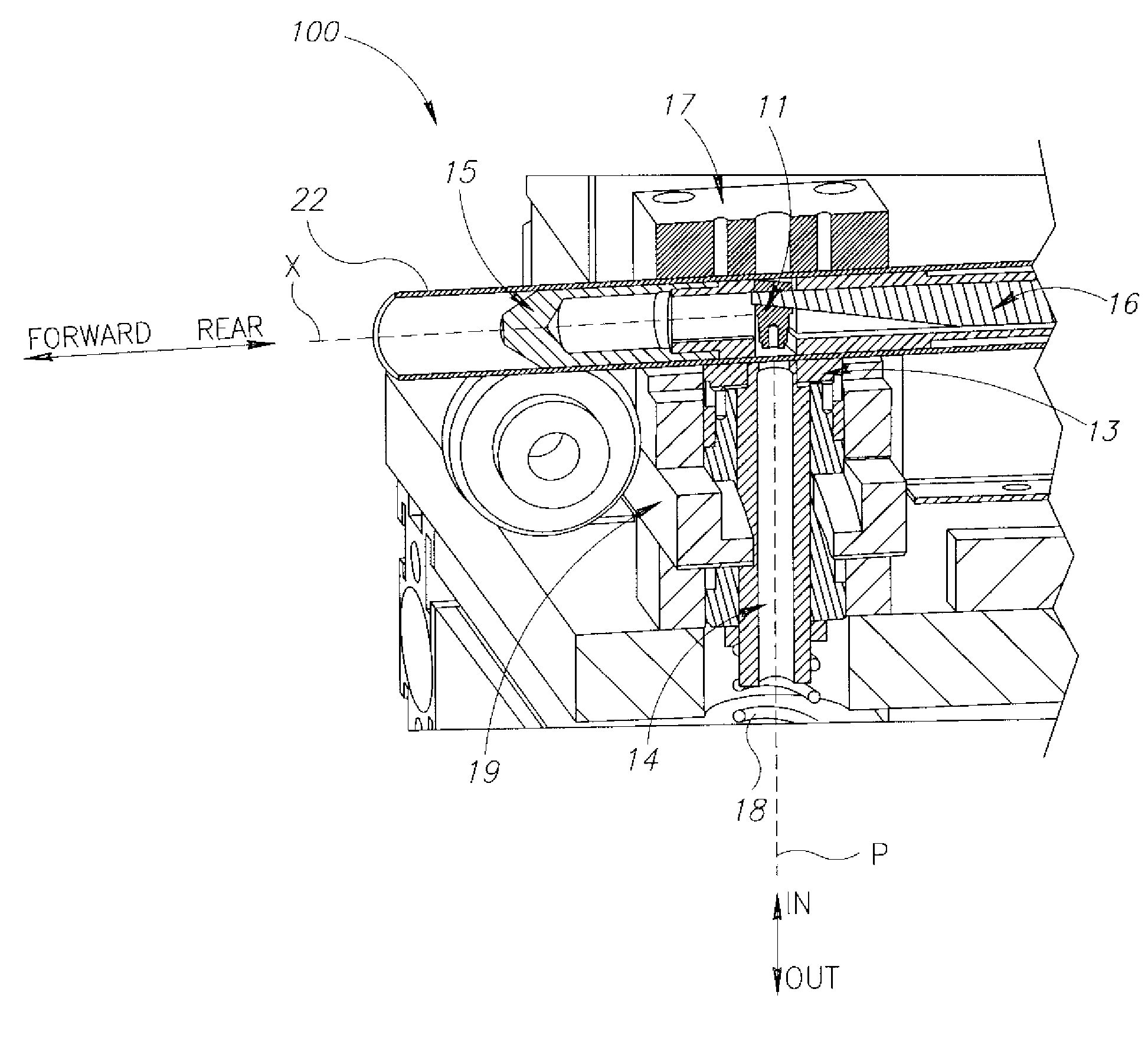

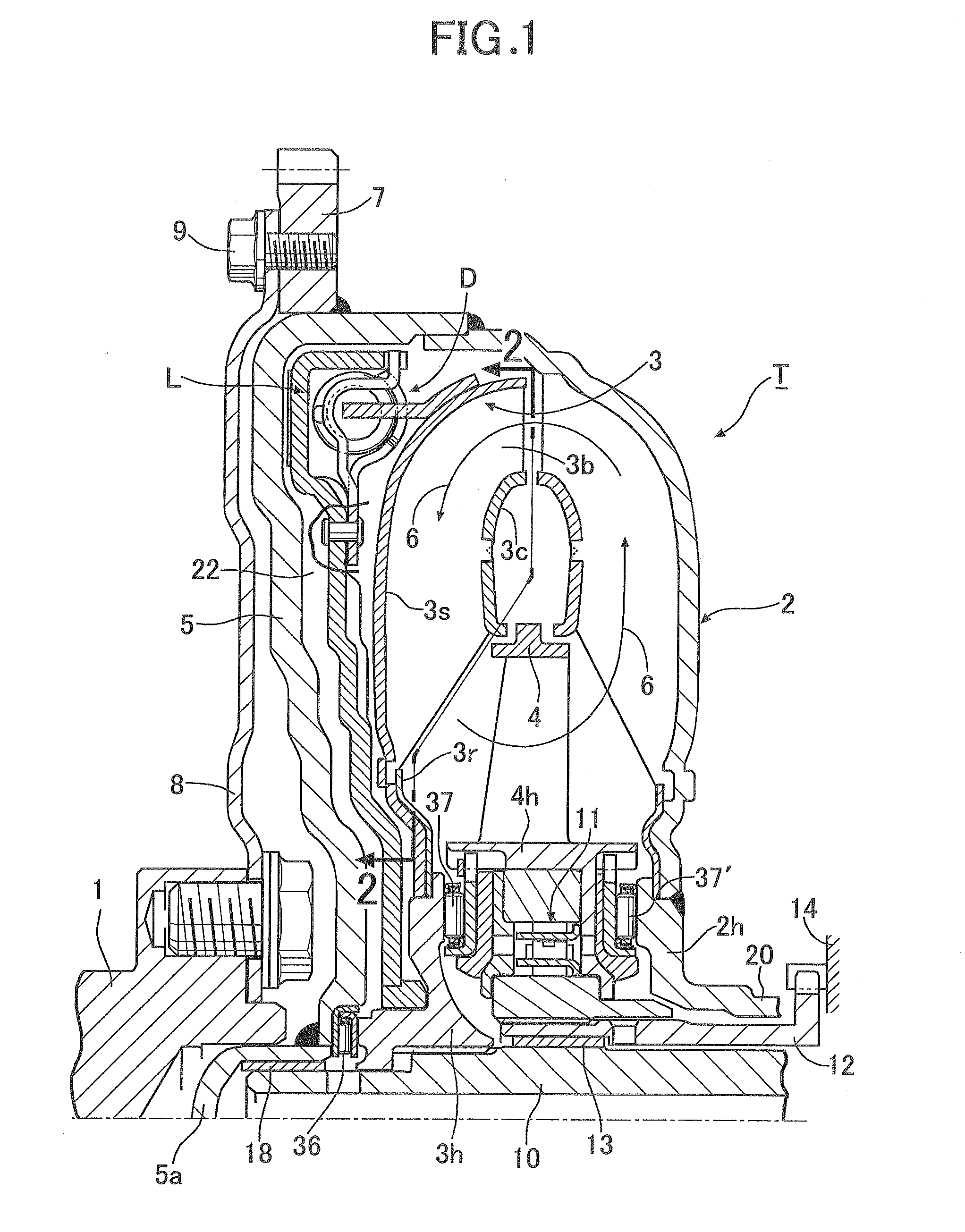

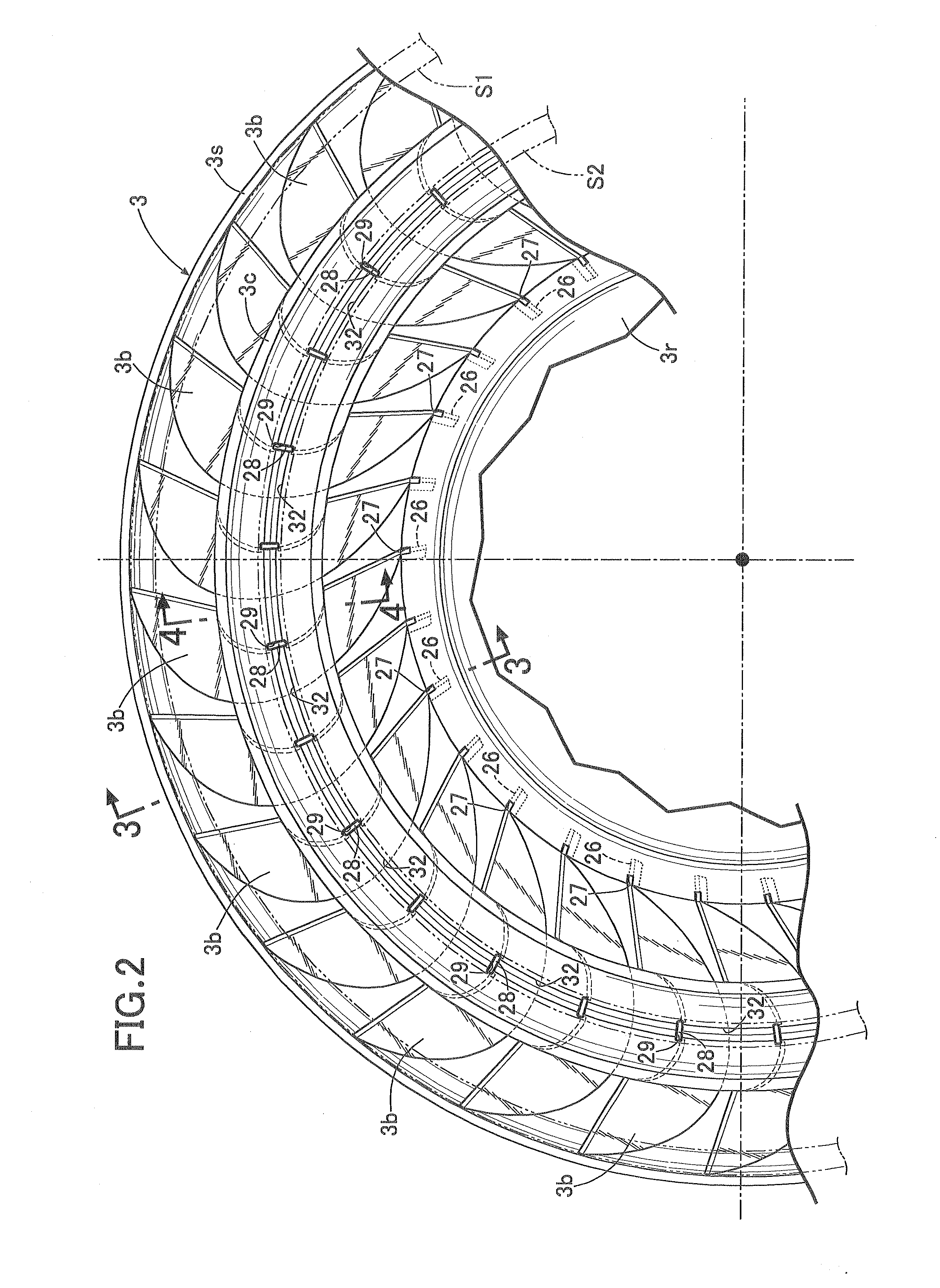

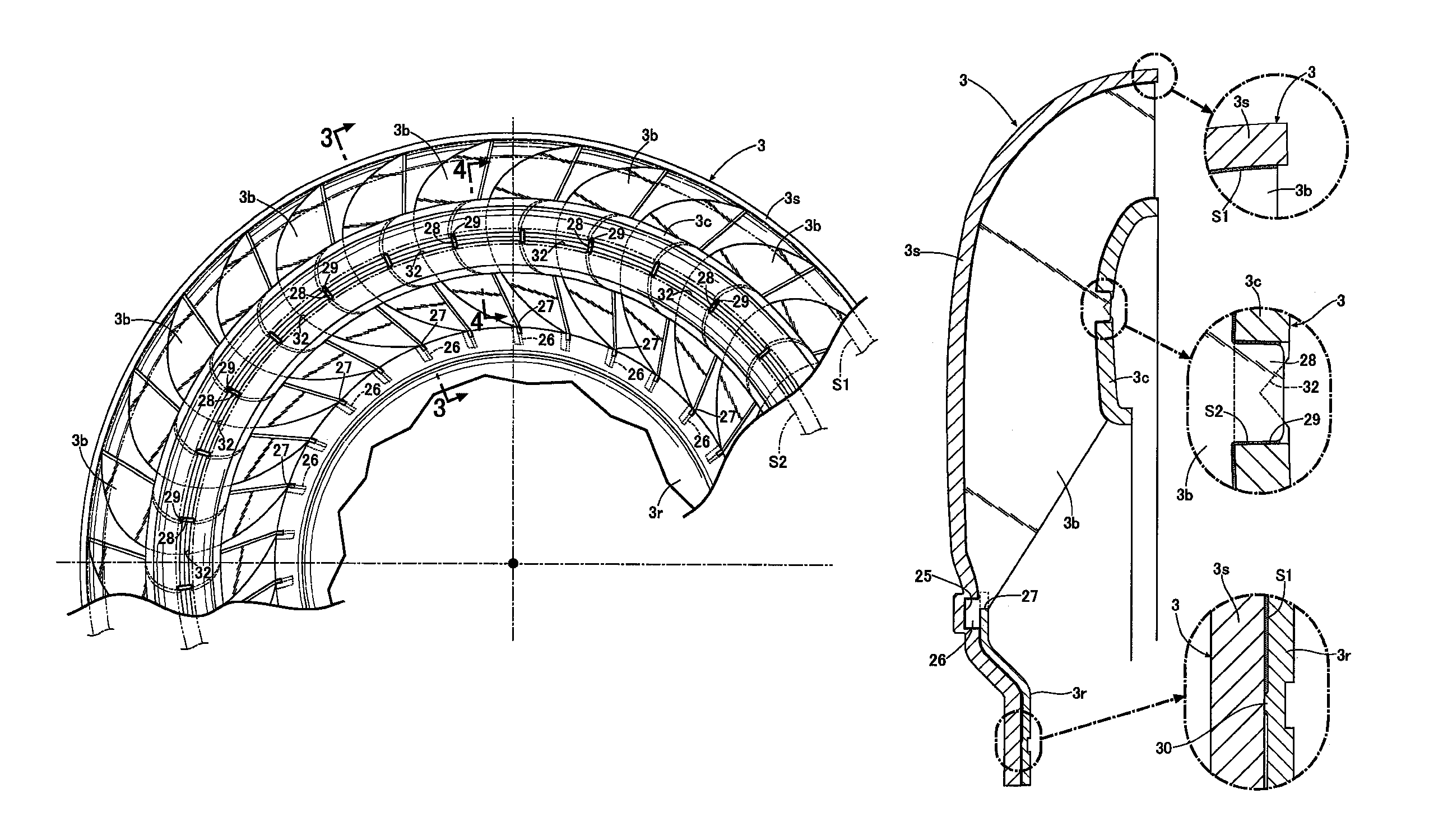

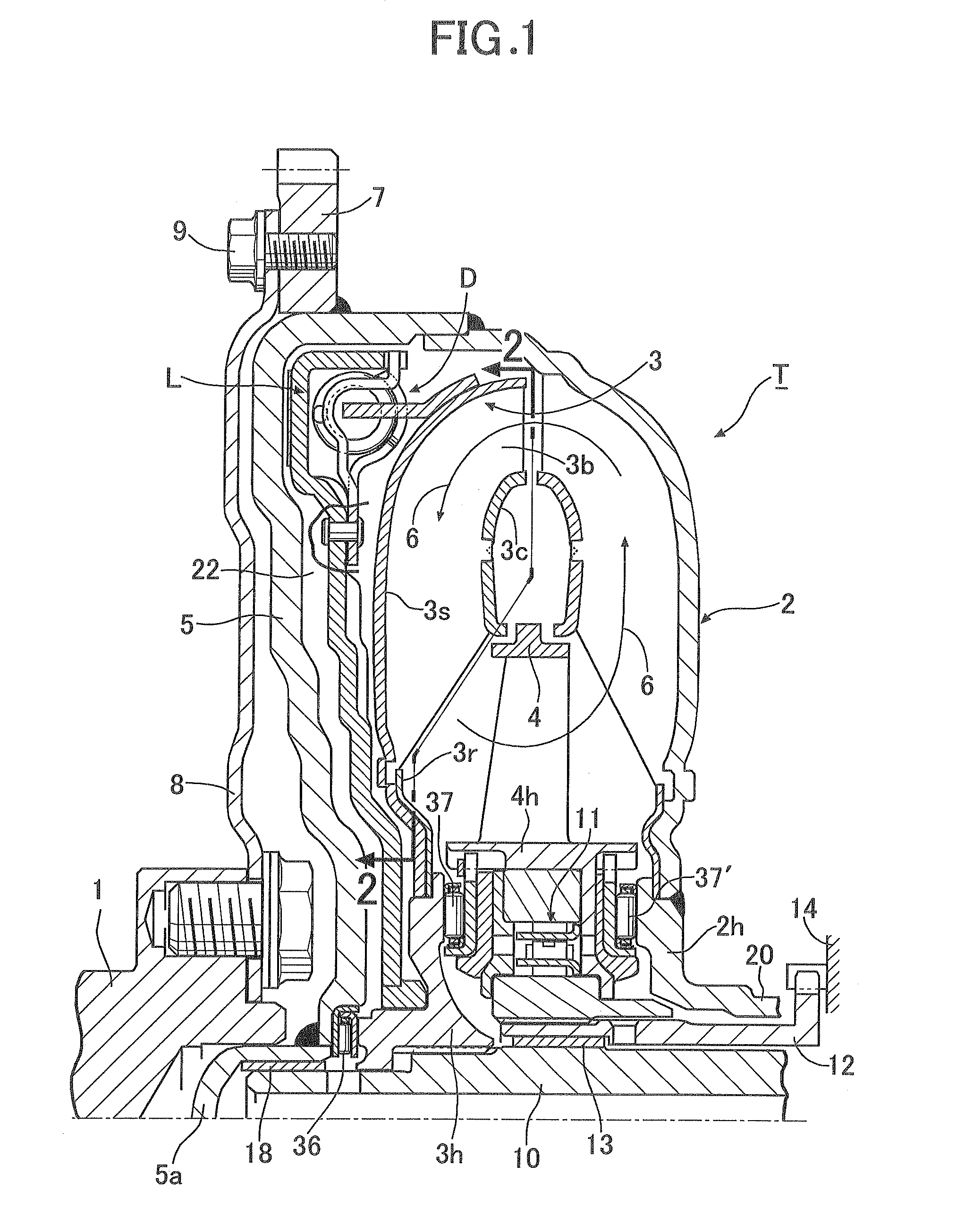

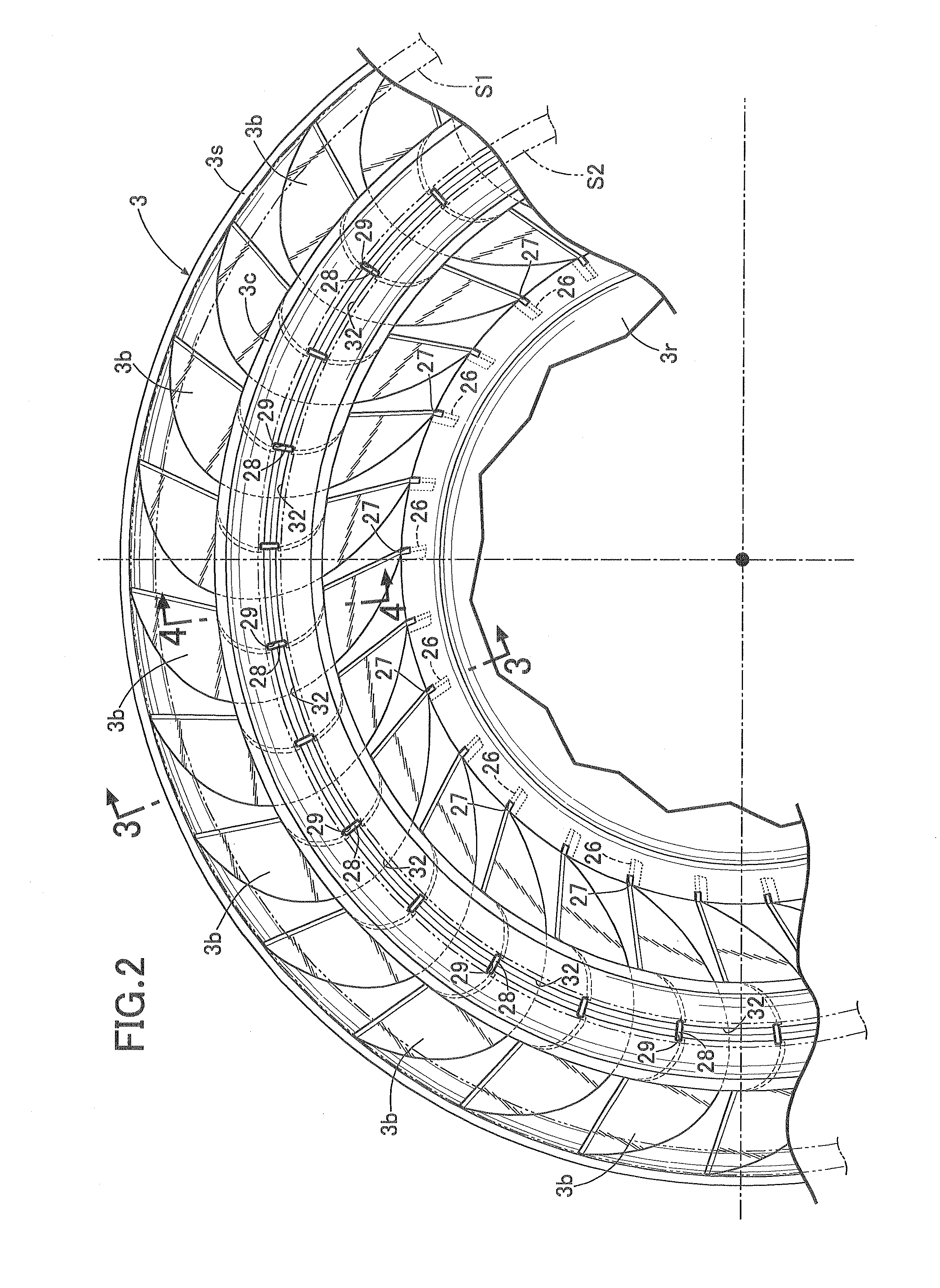

Manufacturing method of impeller for fluid transmitting device

ActiveUS20120291280A1Increase productionGood brazingMetal-working apparatusFluid gearingsImpellerBrazing

In a manufacturing method of an impeller for a fluid transmitting device, multiple guide grooves aligned in a peripheral direction to allow communication between adjacent ones of multiple positioning holes are provided in a concave inner surface of a core in advance; and in a step of melting a brazing material and causing the molten brazing material to penetrate into gaps between coupling pieces and positioning holes that are fitted to each other and further into gaps between the core and the blades, the molten brazing material is guided to the positioning holes through the multiple guide grooves. Accordingly, the step allows the molten brazing material to be efficiently guided to the gaps between the coupling pieces and positioning holes, thereby improving the yield of the brazing material and preventing an influence of a residual brazing material over the rotational balance of the impeller.

Owner:YUTAKA GIKEN CO LTD

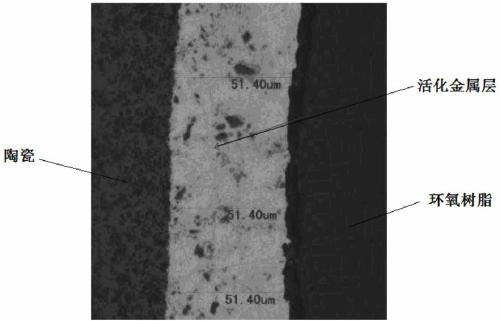

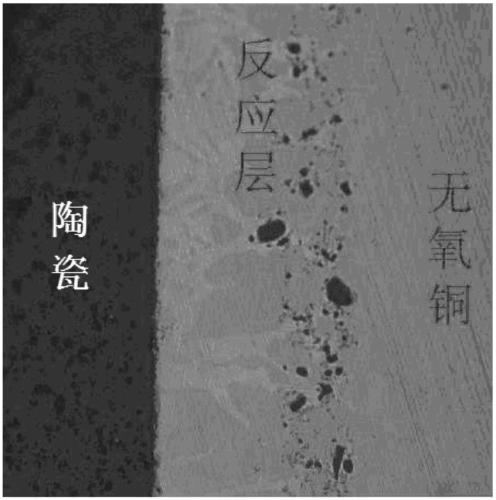

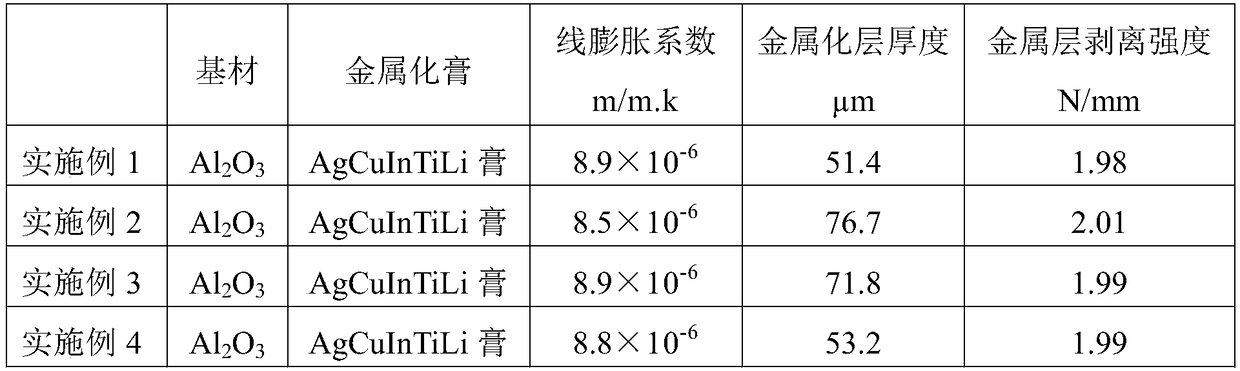

Paste used for ceramic low-temperature activity metallization, ceramic metallization method and vacuum electronic device prepared according to method

ActiveCN109384474ALower sintering temperatureSmall coefficient of linear expansionBoron nitrideWeld strength

The invention discloses a paste used for ceramic low-temperature activity metallization, a ceramic metallization method and a vacuum electronic device prepared according to the method. The paste consists of 3.0wt% to 5.0wt% of a Mo powder, 8.0wt% to 15.0wt% of a binder and the balance of an AgCuInTiLi alloy powder. The preparation method comprises the following steps: preparing the paste used forceramic low-temperature activity metallization, enabling ceramic surface to be coated with the paste, drying ceramic to remove the binder, and carrying out vacuum sintering. After ceramic activity metallization treatment, a metal transition layer with the thickness of 40 to 60 microns can be generated on the surface, the weldability is improved, and the welding rate and welding strength are improved obviously. The treatment method is applicable to the metallization of various ceramics such as aluminum oxide, zirconium oxide, beryllium oxide and boron nitride, the method is simple, the operational process is short, the cost is low, and the volume production is facilitated.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Aluminum alloy surface treatment method

InactiveCN103668200AImprove uniformityHigh hardnessLiquid/solution decomposition chemical coatingSuperimposed coating processNickel saltPotassium sodium tartrate

The invention discloses an aluminum alloy surface treatment method which comprises the following steps: 1) adding 300g / L sodium hydroxide, 150g / L zinc oxide, 20 - 25g / L potassium sodium tartrate and 30g / L potassium pyrophosphate to distilled water to prepare a zinc plating solution; 2) adding 50g / L nickel sulfate, 20-25g / L sodium hypophosphite and 80g / L sodium citrate into the distilled water to prepare a nickel salt solution; 3) wiping an aluminum alloy surface with degreasing cotton wiped with an ethyl acetate solvent to removing surface grease; 4) etching the aluminum alloy after the degreasing treatment in a nitric acid solution for 9 seconds to remove an oxidation film on the aluminum alloy surface, then washing with water and drying; 5) immerging the etched aluminum alloy in the zinc plating solution, holding for at room temperature for 2 minutes, washing, then again immerging in a 35% concentrated sulfuric acid solution for 2 minutes, then washing with water and drying; 6) immerging the galvanized aluminum alloy in the nickel salt solution with the nickel salt solution temperature controlled at 95DEG C; and 7) drying. By the aluminum alloy surface treatment method, a coating with very good uniformity can be obtained, and the coating is high in hardness, high in brittleness, smooth, easy to braze and wear-resisting.

Owner:佛山市吉诚不锈钢有限公司

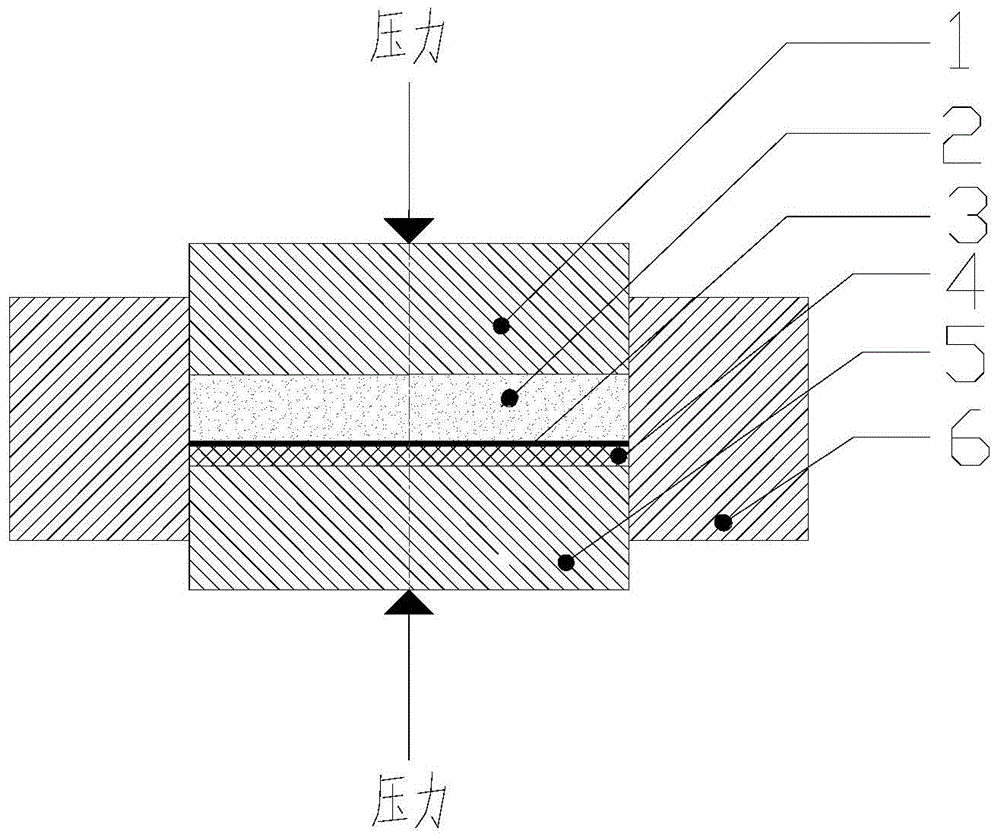

Preparation method for metalized layer of copper-indium-gallium-selenium target material

InactiveCN106180721AEffective exportImprove thermal conductivityFinal product manufactureVacuum evaporation coatingIndiumHeat conducting

The invention relates to a preparation method for a metalized layer of a copper-indium-gallium-selenium target material, and belongs to the field of nonferrous metal processing. The metalized layer is prepared while the copper-indium-gallium-selenium target material is prepared. Firstly, a graphite cushion plate is arranged on a lower pressing head of a hot-press furnace mold, then, a metal sheet is placed on the graphite cushion plate, copper-indium-gallium-selenium powder is put in, an upper pressing head is put in, the mold is placed in a hot-press furnace to be subjected to hot-press sintering, pressurization is conducted during temperature rise, heat preserving and pressure keeping are conducted, and then cooling is conducted till the room temperature is obtained; and then, the target material is taken out of the hot-press furnace, the target face is firstly processed, the metalized layer is then processed, and the processing amount is determined according to the thickness of the required metalized layer. Brazing can be easily conducted on the metalized layer, obtained through the method, of the copper-indium-gallium-selenium target material; the electric-conducting property and the heat-conducting property are good; and cost is low, the preparation method is synchronous with the target material preparation process, and the production cost is greatly reduced.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

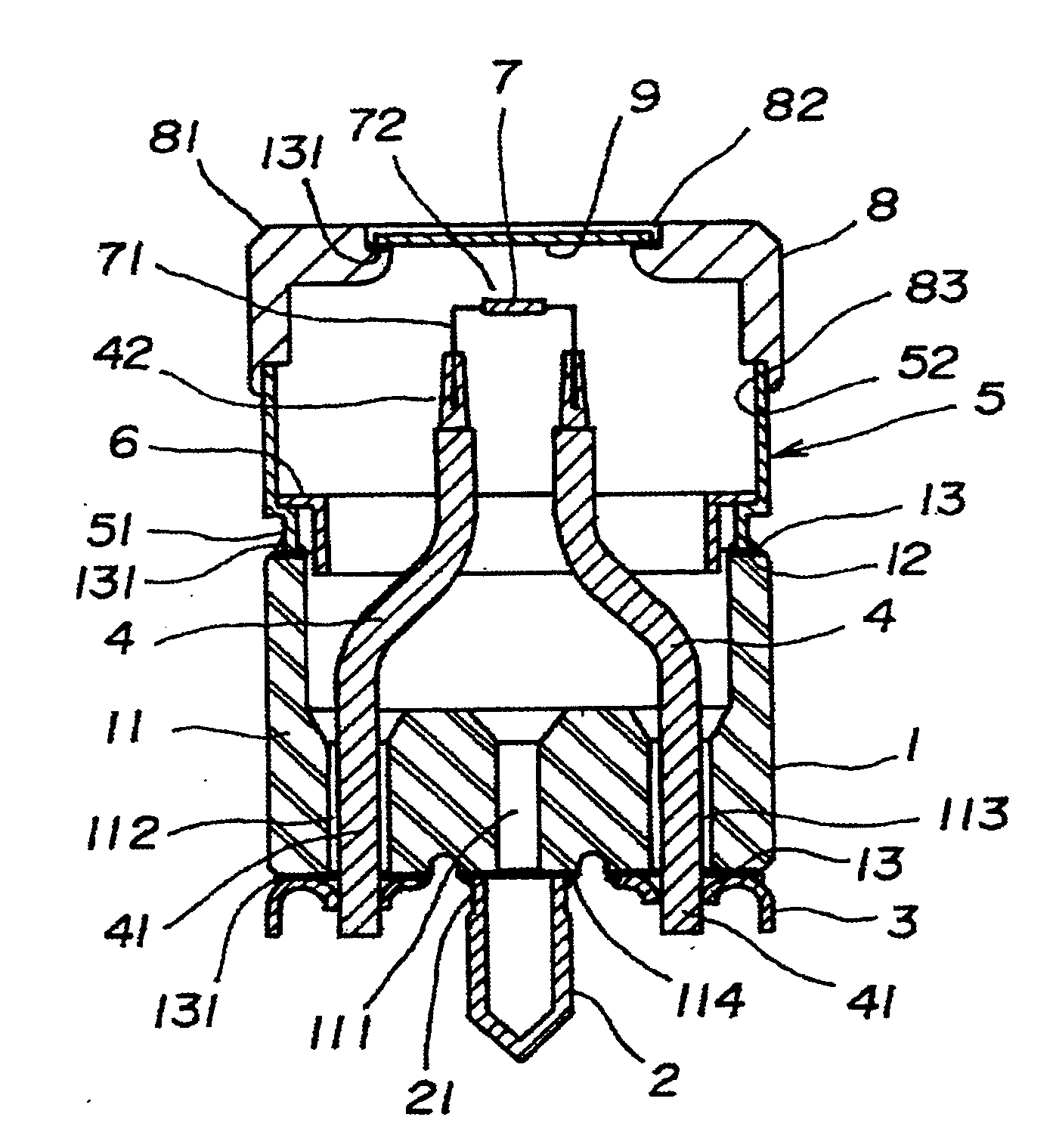

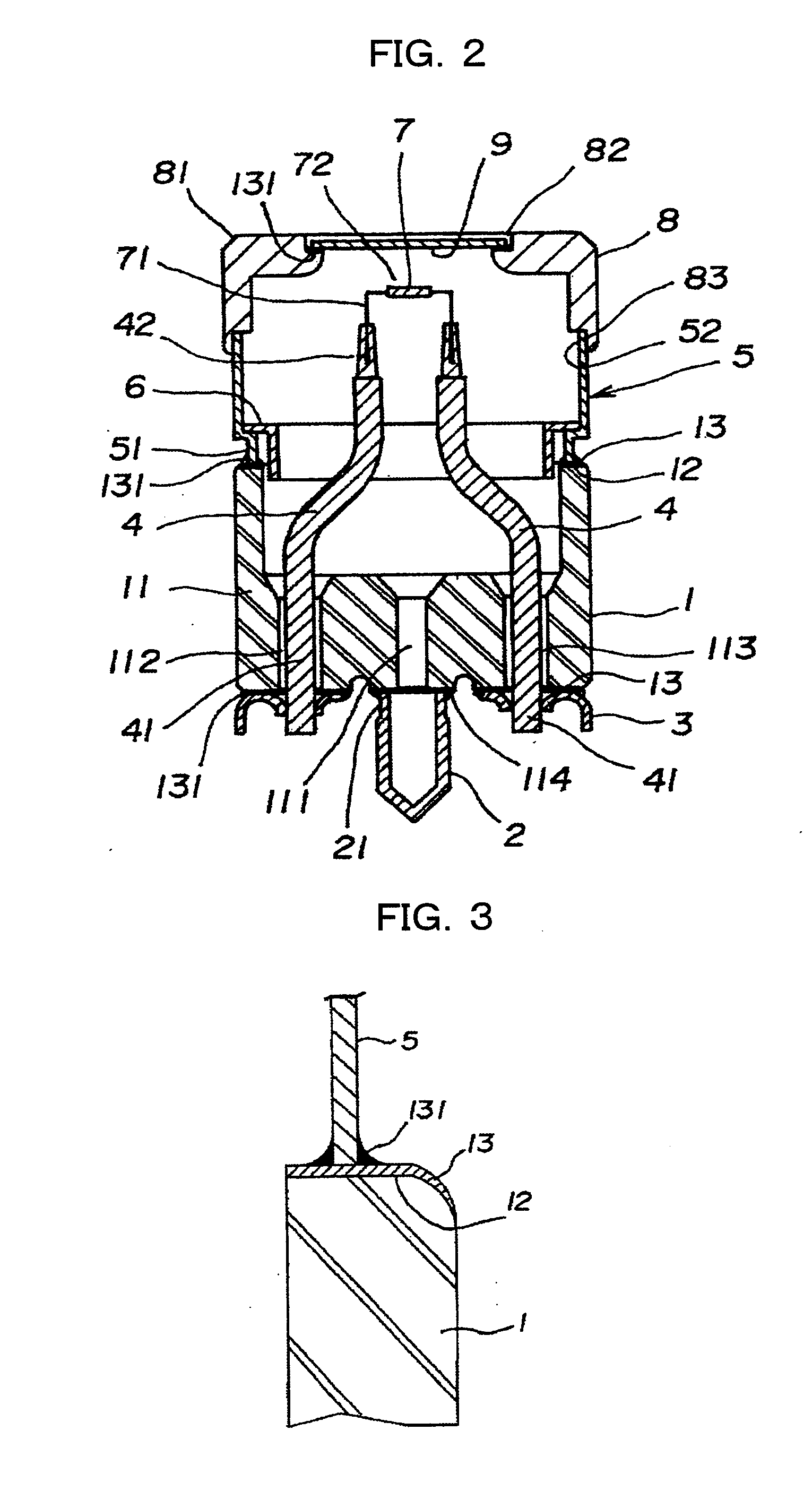

Transmission type x-ray tube and manufacturing method thereof

InactiveUS20090161831A1Long lastingQuality improvementX-ray tube electrodesX-ray tube vessels/containerEngineeringX-ray tube

A transmission type X-ray tube includes an electrode lead (4) holding a cathode filament (7) and a stem unit (1) to which a sealing member (5), an exhaust tube (2), and the like are attached by brazing, and an irradiation window frame (8) having an X-ray irradiation window (9) attached by brazing. The other end side (52) of the sealing member (5) is attached to an open end (83) of the irradiation window frame (8) by welding. Thus, it is possible to obtain a high-quality transmission type X-ray tube having a long service life at a low cost.

Owner:HITACHI LTD

Antiwear Cu-base material with high electric conductivity

Owner:ZHEJIANG UNIV

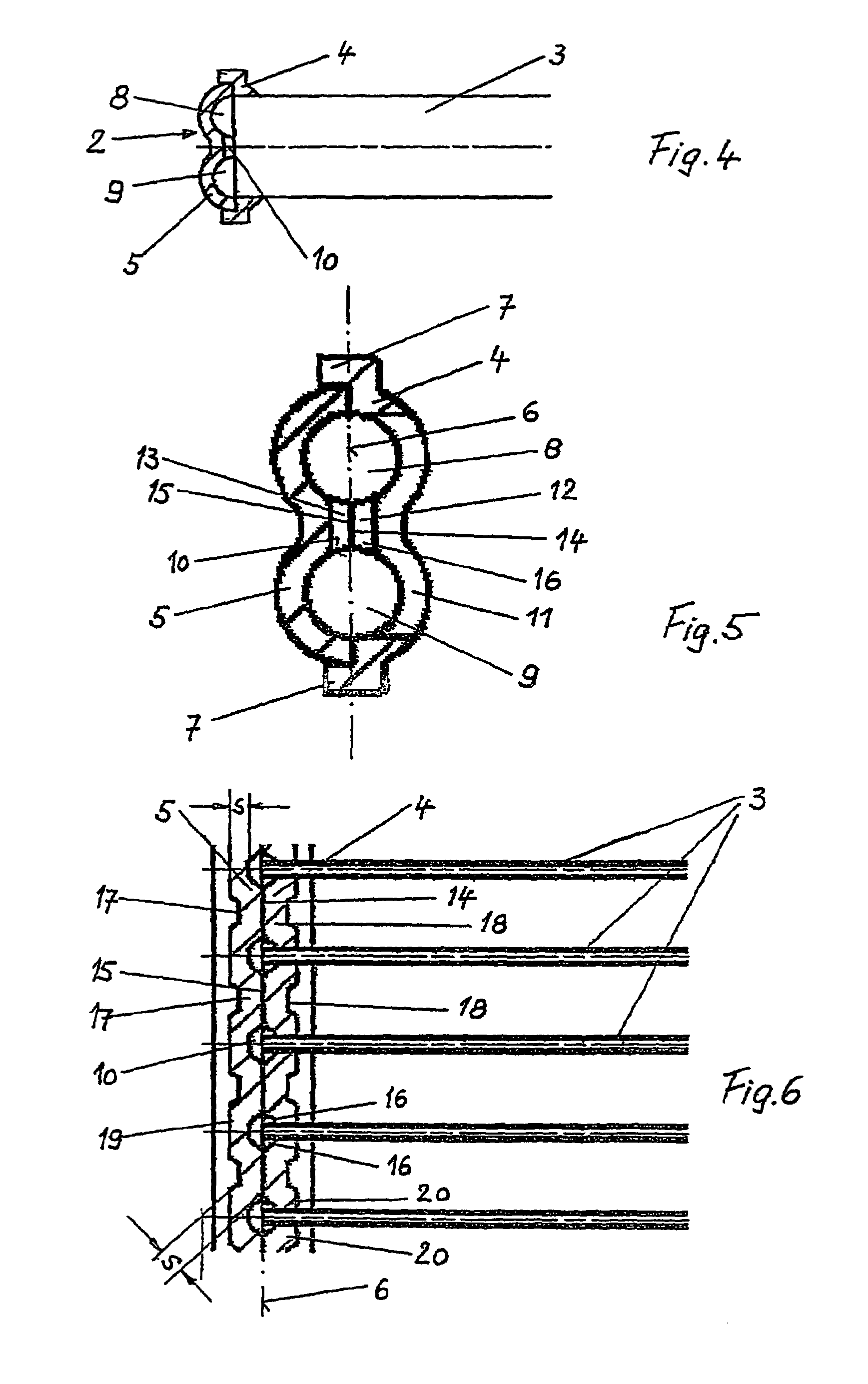

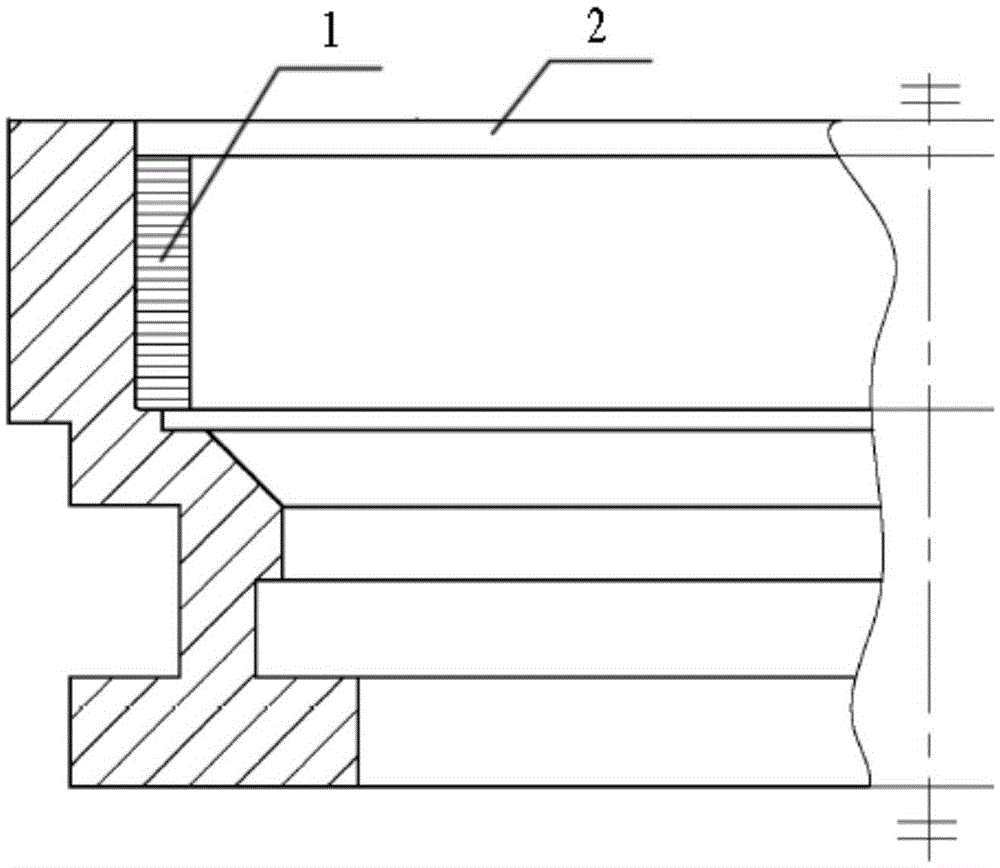

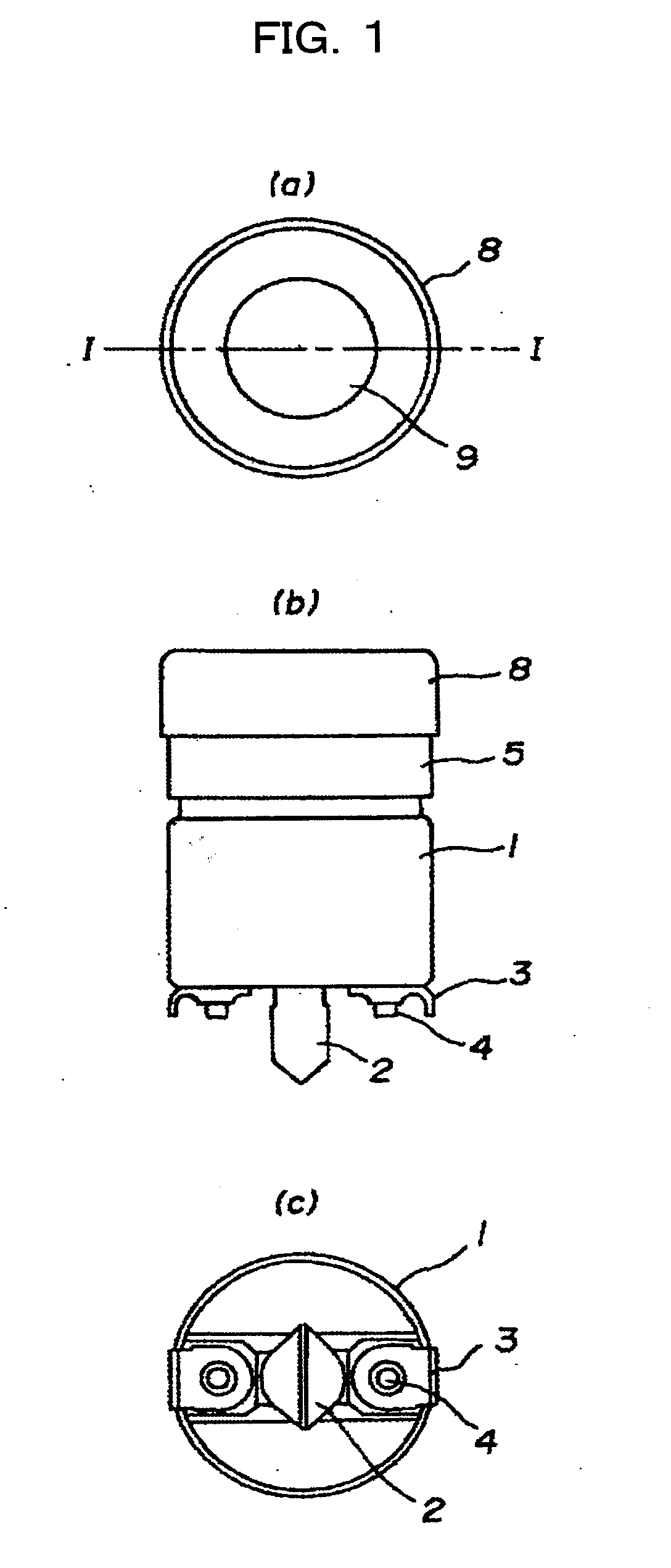

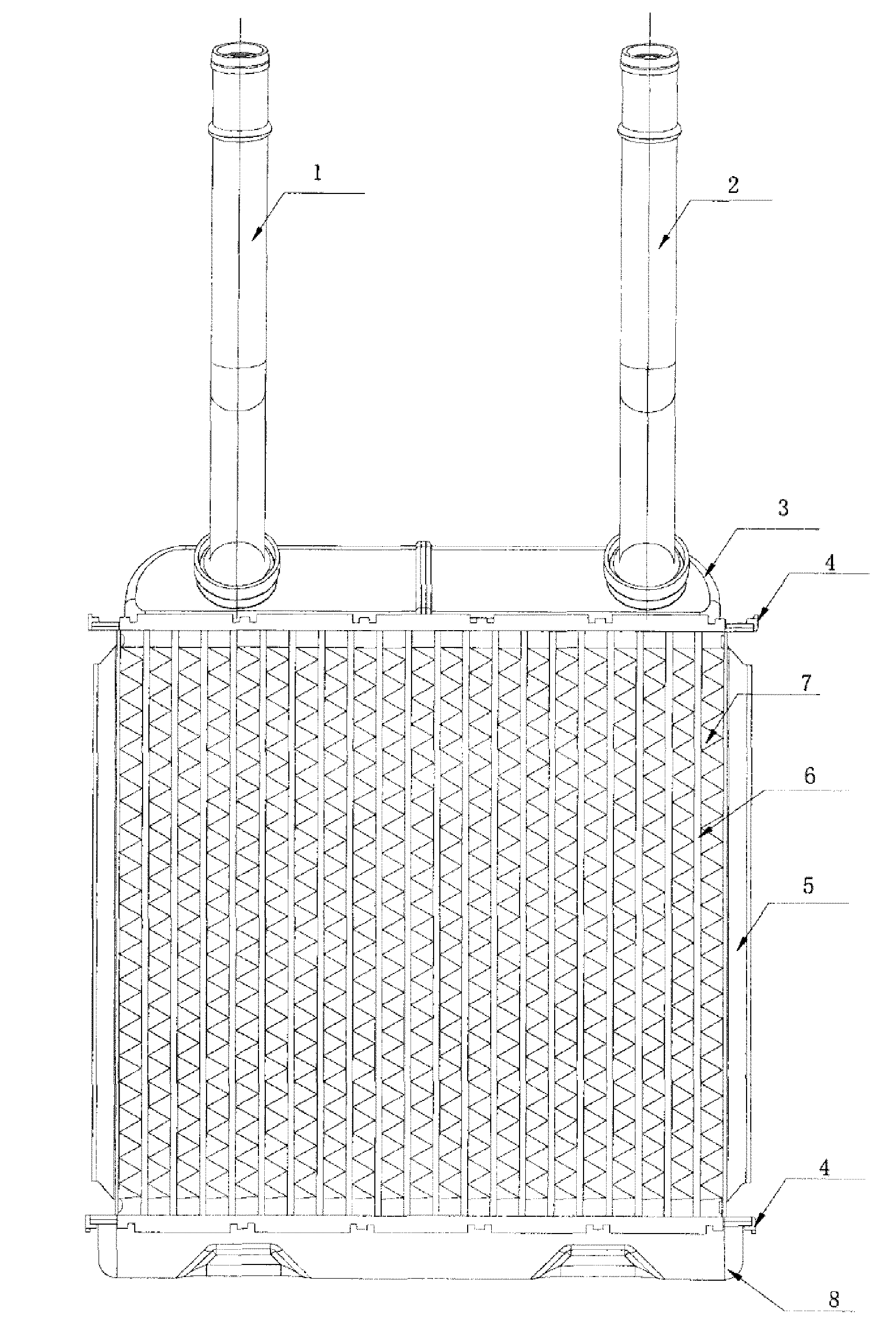

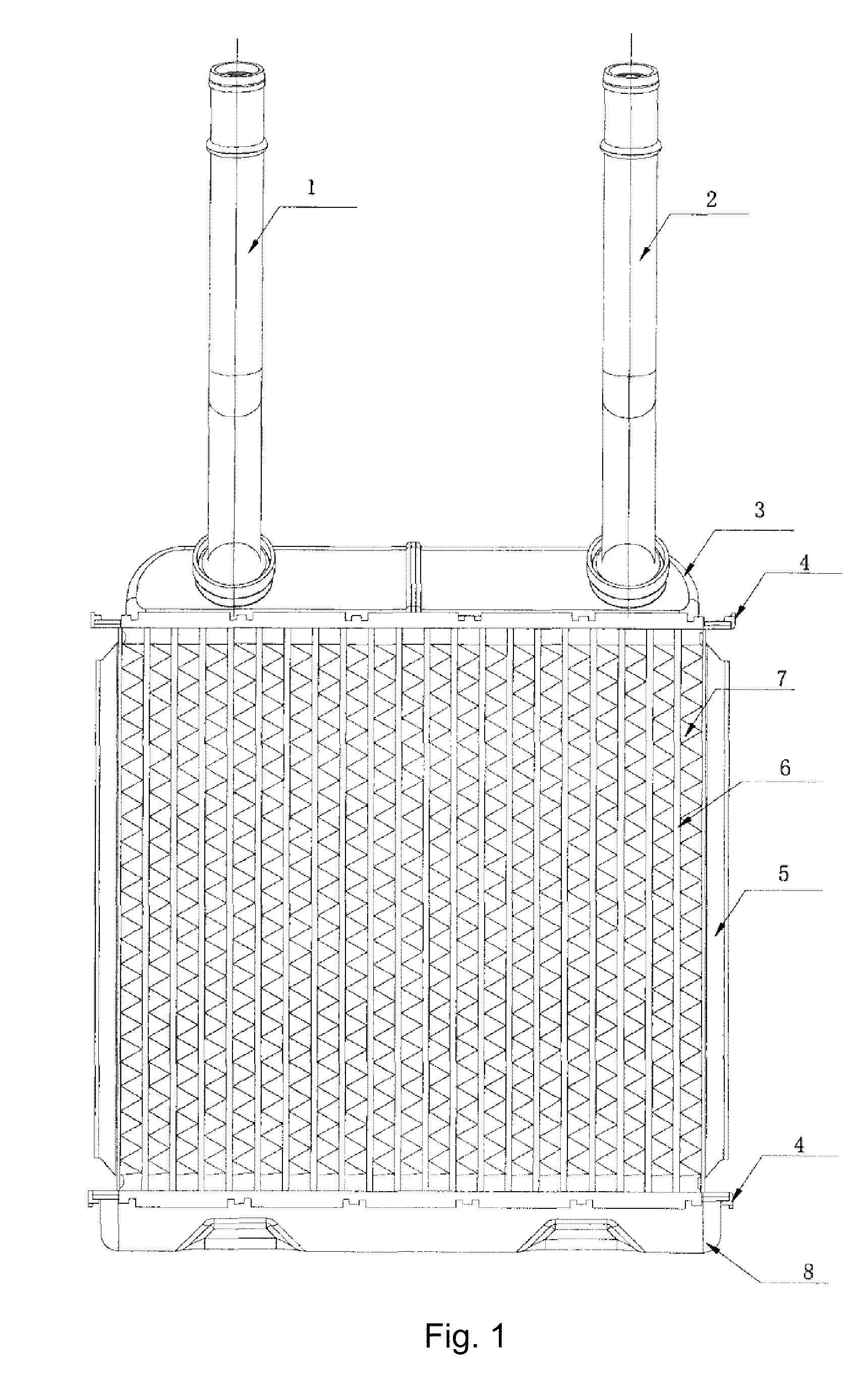

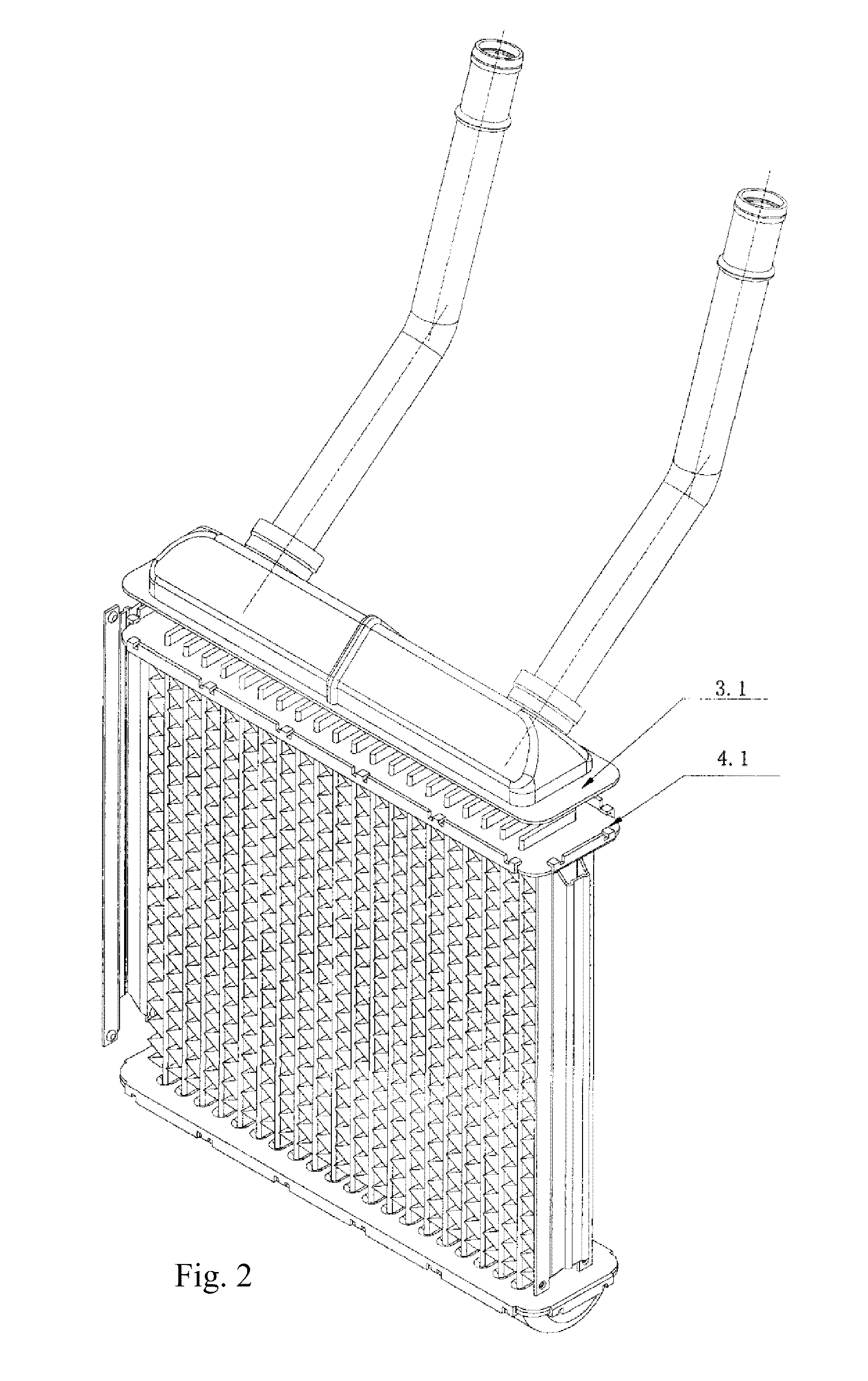

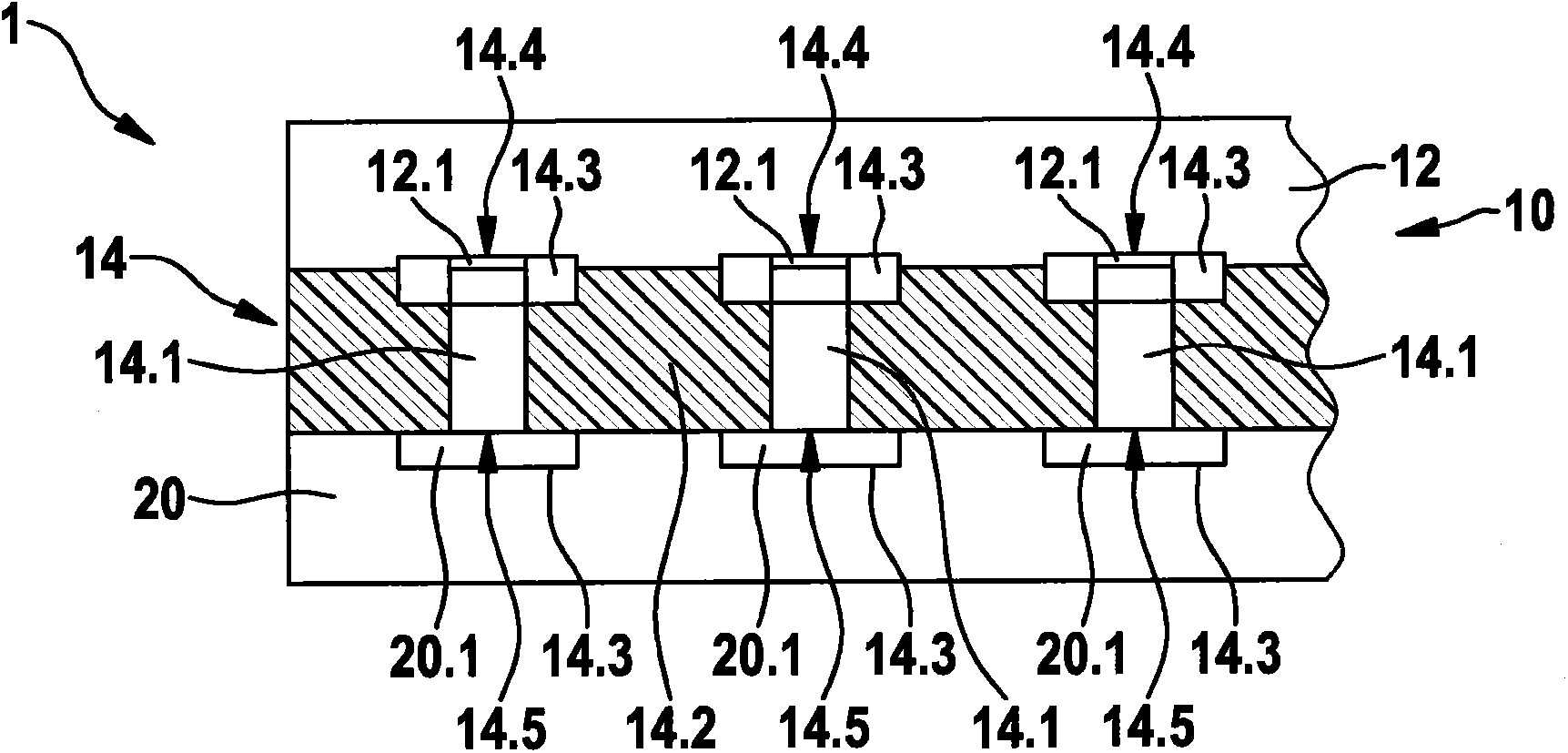

Binding Structure between Tank and Header of Automotive Heater Core

InactiveUS20090188656A1Good brazingImprove bindingHeat exchanger casingsHeat exchanger fasteningBrazingHeater core

This invention involves a binding structure between tank and header of an automotive heater core, which belongs to the field of auto parts technology. Said structure includes the upper tank (3), the bottom tank (8) and the header (4). Characteristics of said structure are that there are clinching tabs (4.1) around the headers connecting to the upper tank (3) and to the bottom tank (8). Said clinching tabs (4.1) clamp to the edges of the upper tank (3) and the bottom tank (8). The clamping of clinching tabs to the edges of the tanks structurally ensures the mechanical strength of the binding between the header to the upper tank and to the bottom tank. It ensures a good brazing and firm binding between the tanks and the header.

Owner:XU HUIXIN

Manufacturing method of impeller for fluid transmitting device

In a manufacturing method of an impeller for a fluid transmitting device, multiple guide grooves aligned in a peripheral direction to allow communication between adjacent ones of multiple positioning holes are provided in a concave inner surface of a core in advance; and in a step of melting a brazing material and causing the molten brazing material to penetrate into gaps between coupling pieces and positioning holes that are fitted to each other and further into gaps between the core and the blades, the molten brazing material is guided to the positioning holes through the multiple guide grooves. Accordingly, the step allows the molten brazing material to be efficiently guided to the gaps between the coupling pieces and positioning holes, thereby improving the yield of the brazing material and preventing an influence of a residual brazing material over the rotational balance of the impeller.

Owner:YUTAKA GIKEN CO LTD

Sensor, sensor unit, and method for producing sensor unit

ActiveCN103748434AWill not corrodeLow costAcceleration measurementSpeed/acceleration/shock instrument detailsEngineering

Owner:ROBERT BOSCH GMBH

Preparation method of Mo-Ru brazing filler metal powder

ActiveCN112170858AImprove process performanceGood brazingWelding/cutting media/materialsSoldering mediaMetallurgyRuthenium

The invention relates to a preparation method of Mo-Ru brazing filler metal powder. The method is used for preparing the Mo-Ru brazing filler metal powder by roasting and reducing pure ruthenium powder and ammonium molybdate, and the Mo-Ru brazing filler metal powder is uniform in component, small in particle size (the particle size range is 10-100 microns, and the grain size of 90% of brazing filler metal powder particles is less than or equal to 40 microns), high in apparent density, good in melting characteristic, excellent in process characteristic, high in cost performance, and suitable for industrial mass production.

Owner:CHONGQING MATERIALS RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com