Ageing strengthening copper alloy strip and preparing method thereof

A copper alloy strip, ageing strengthening technology, applied in the field of copper alloy materials and processes, can solve the problem that the performance of copper alloy strip is not very ideal, and achieve the improvement of brazing and electroplating performance, comprehensive performance, and bonding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

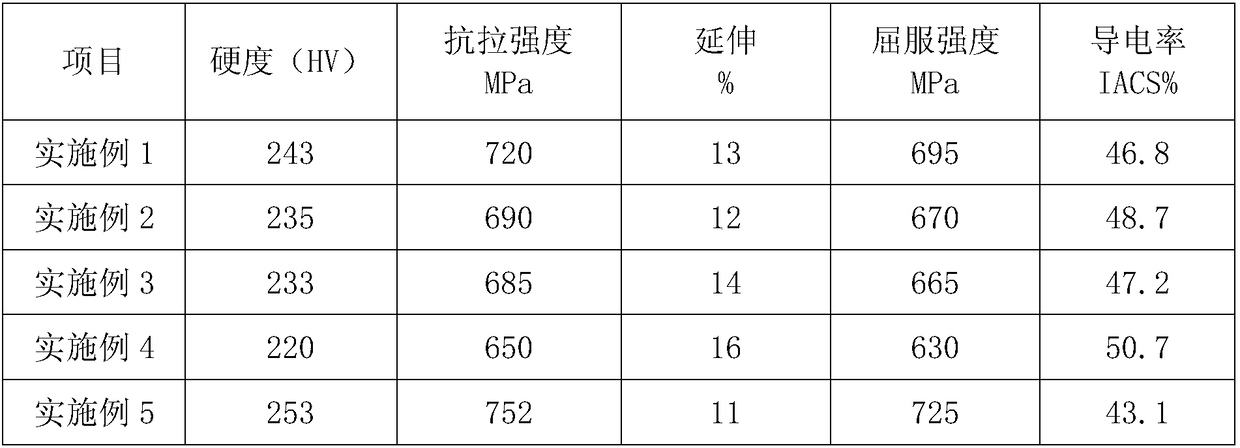

Examples

Embodiment 1

[0032] An aging-strengthened copper alloy strip and a preparation method thereof, the steps of which are:

[0033] 1) Batching and smelting: weighing according to the component distribution ratio, adding Si, Ni, Cr, Zn, Cu into the melting furnace to heat up and melt;

[0034] 2) Add Mg for deoxidation treatment, control the temperature at 1280 ° C, and start to transfer to the holding furnace after standing still for 5 minutes. Add 0.05% Mg in the holding furnace for half an hour;

[0035] 3) When the temperature of the holding furnace reaches the casting temperature of 1260°C, the horizontal continuous casting red ingot casting technology is adopted, the thickness of the slab is 16mm, the casting speed is controlled at 160-300mm / min, and the outlet temperature of the slab is controlled at 650°C-780°C. Strong cooling water (water pressure 0.5MPa, outlet water temperature 30°C) is used to carry out online quenching and solid solution cooling of the cast slab at 100mm from the...

Embodiment 2

[0048] An aging-strengthened copper alloy strip and a preparation method thereof, the steps of which are:

[0049] 1) Batching and smelting: weighing according to the component distribution ratio, adding Si, Ni, Cr, Zn, Cu into the melting furnace to heat up and melt;

[0050] 2) Add Mg for deoxidation treatment, control the temperature at 1305 ° C, and start to transfer to the holding furnace after standing still for 5 minutes. Add 0.04% Mg in the holding furnace for half an hour.

[0051] 3) When the temperature of the holding furnace reaches the casting temperature of 1275°C, the horizontal continuous casting red ingot casting technology is adopted, the thickness of the slab is 16mm, the casting speed is controlled at 160-300mm / min, and the outlet temperature of the slab is controlled at 650°C-780°C. Strong cooling water (water pressure 0.4MPa, outlet water temperature 20°C) is used to carry out online quenching and solid solution cooling of the casting slab at 100 mm from...

Embodiment 3

[0064] An aging-strengthened copper alloy strip and a preparation method thereof, the steps of which are:

[0065] 1) Batching and smelting: weighing according to the component distribution ratio, adding Si, Ni, Cr, Zn, Cu into the melting furnace to heat up and melt;

[0066] 2) Add Mg for deoxidation treatment, control the temperature at 1270°C, and start to transfer to the holding furnace after standing still for 5 minutes, cover with calcined charcoal that has been held at 600°C for 5 hours, and the covering thickness is 100mm. Add 0.04% Mg in the holding furnace for half an hour;

[0067] 3) When the temperature of the holding furnace reaches the casting temperature of 1250°C, the horizontal continuous casting red ingot casting technology is adopted, the thickness of the drawing cast billet is 16mm, the drawing casting speed is controlled at 160-300mm / min, and the outlet temperature of the billet is controlled at 650°C-780°C. Strong cooling water (water pressure 0.6MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com