Brazing method for high-temperature alloy assembly of aero-engine

An aero-engine and superalloy technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult positioning, difficult to guarantee the honeycomb brazing rate, large brazing deformation, etc., and achieve convenient and secure parts assembly and positioning. Brazing quality, good effect of parts brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

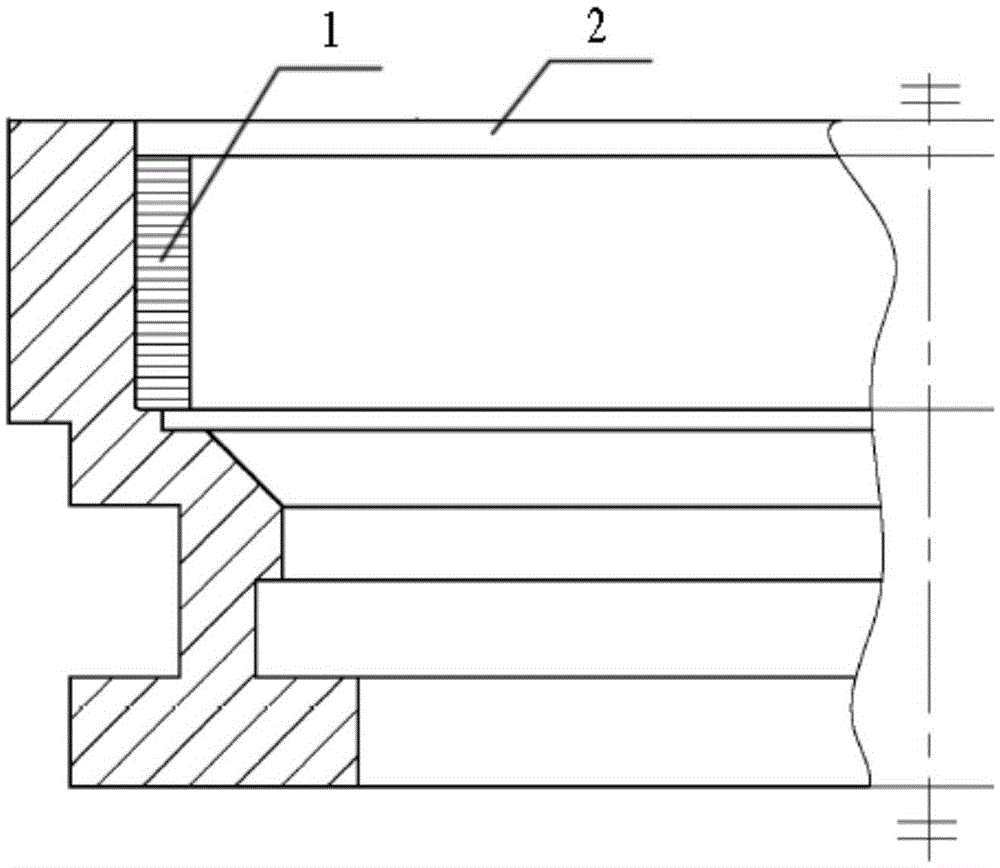

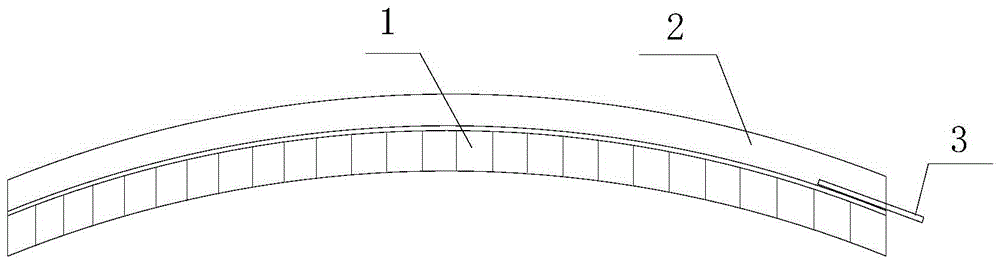

[0021] Such as figure 1 , figure 2 A method for brazing a superalloy component of an aero-engine comprises the following steps:

[0022] ①Cleaning: Ultrasonic cleaning of honeycomb ring 1 and outer ring 2, and then drying;

[0023] ② Filling brazing material: place the brazing material in the core grid of the honeycomb ring 1;

[0024] ③Assembly positioning: Spot-weld the honeycomb ring 1 on the outer ring 2 with energy storage, and check the spot welding and gap conditions;

[0025] ④Primary brazing: put the honeycomb ring 1 and outer ring 2 assembly tooling in a vacuum furnace for brazing, the brazing temperature is 1175-1185°C, keep it warm for 5-10 minutes, then cool it with argon at 1000°C, and leave the furnace when it is less than 100°C ;

[0026] ⑤Inspection: check the appearance and internal brazing quality of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com