Patents

Literature

152results about How to "Easy to assemble and locate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

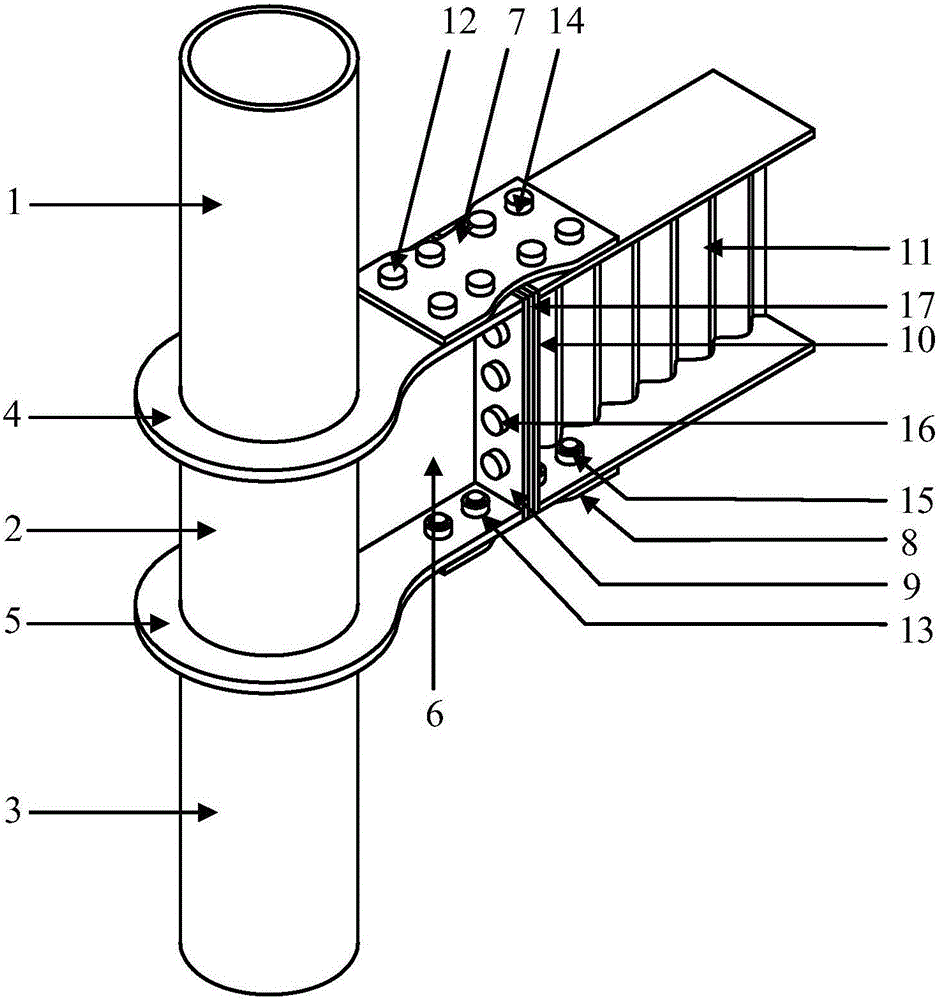

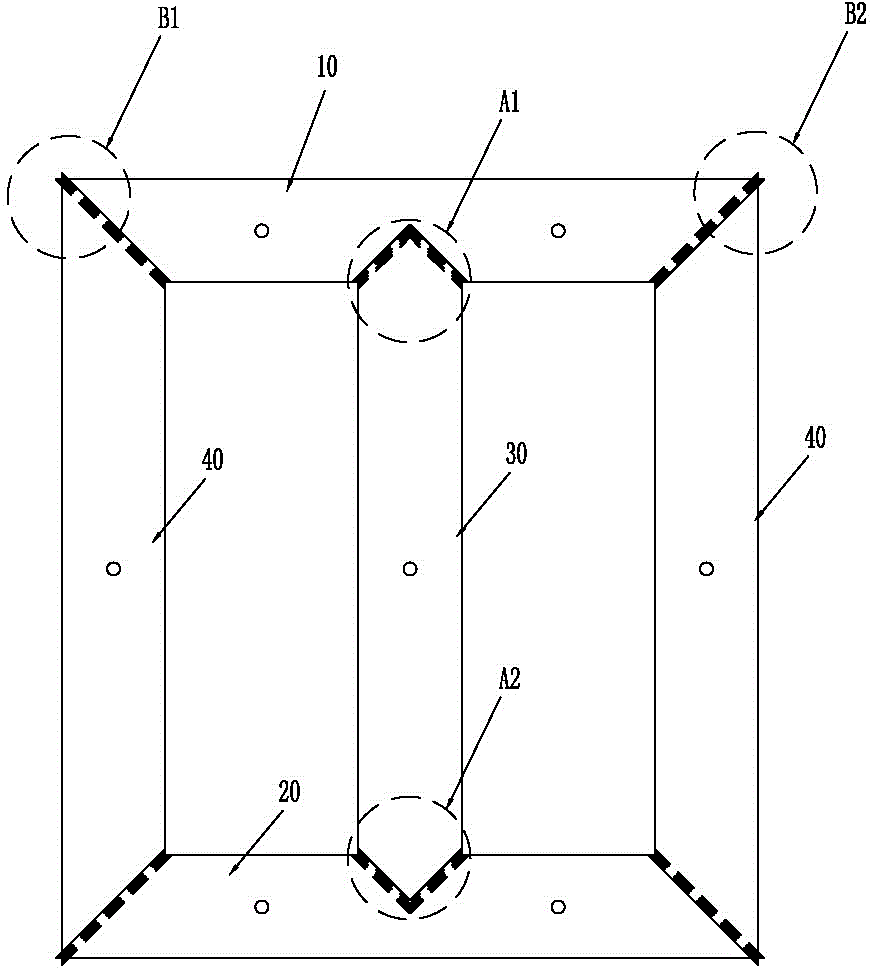

Function-restorable assembly type wave web beam-column composite joint connection device

ActiveCN105863050AReduce construction difficultyAvoid complex stress fieldsProtective buildings/sheltersShock proofingCantileverCivil/structural engineers

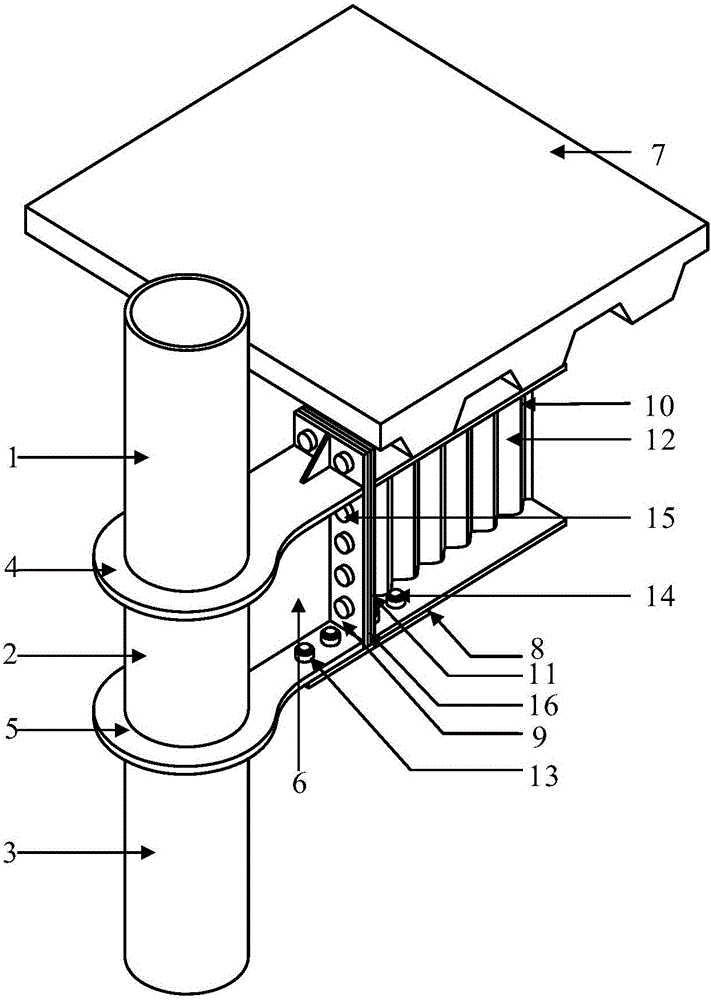

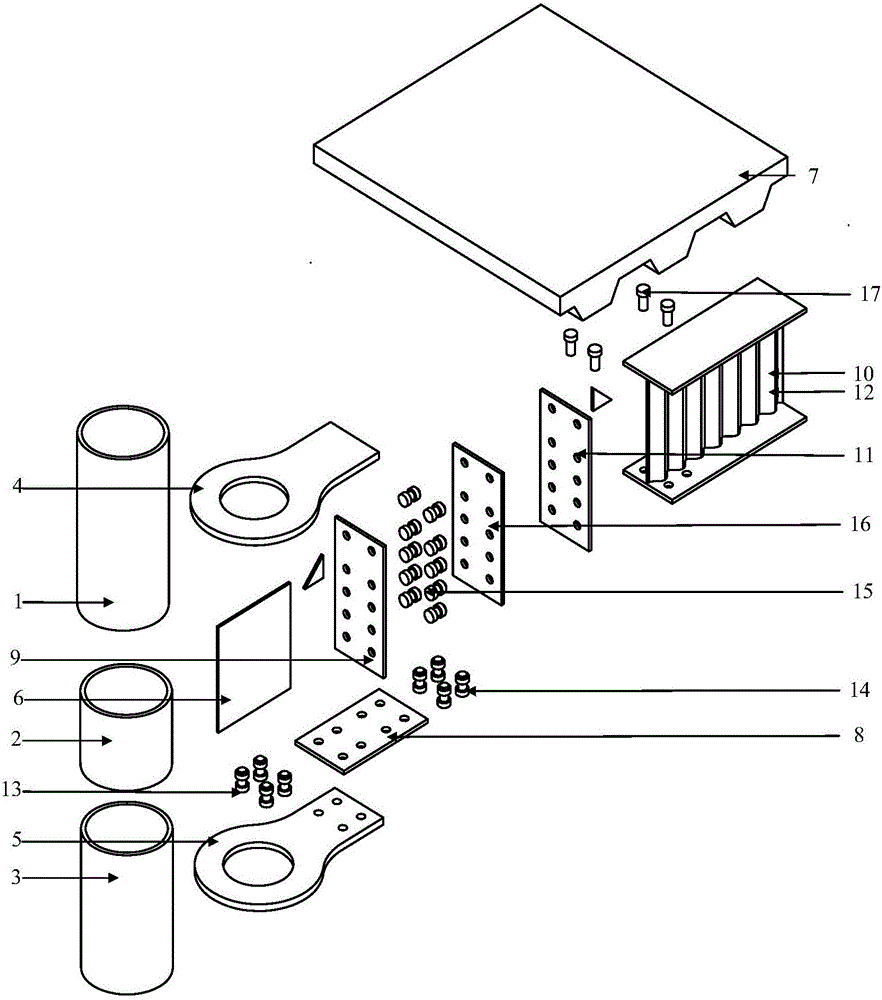

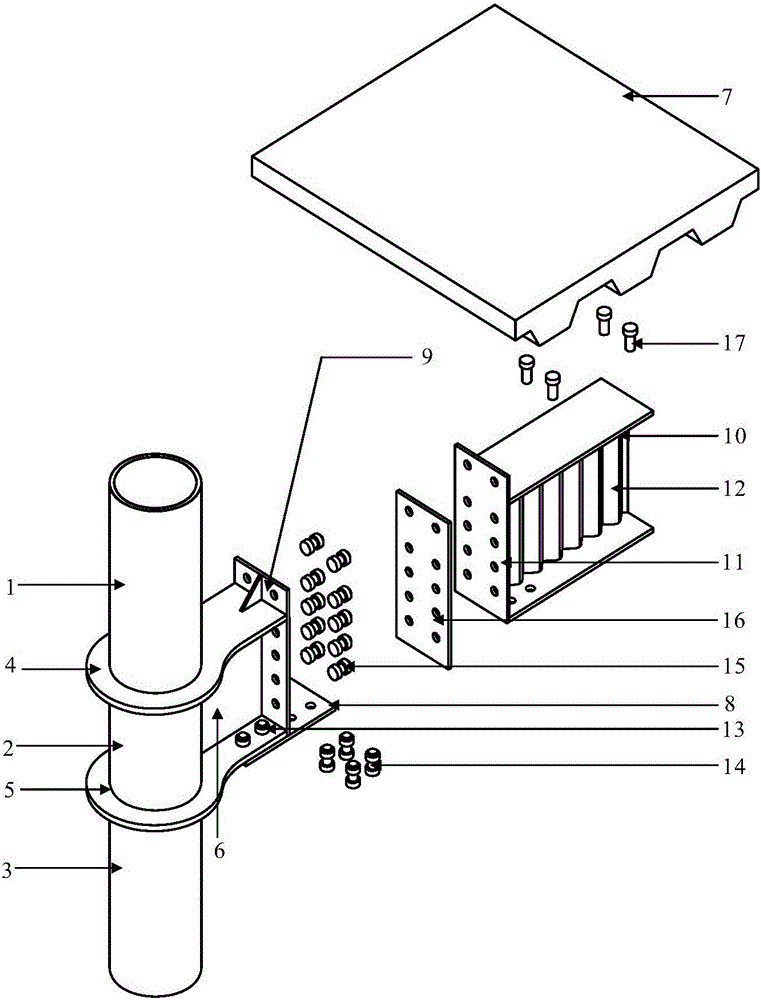

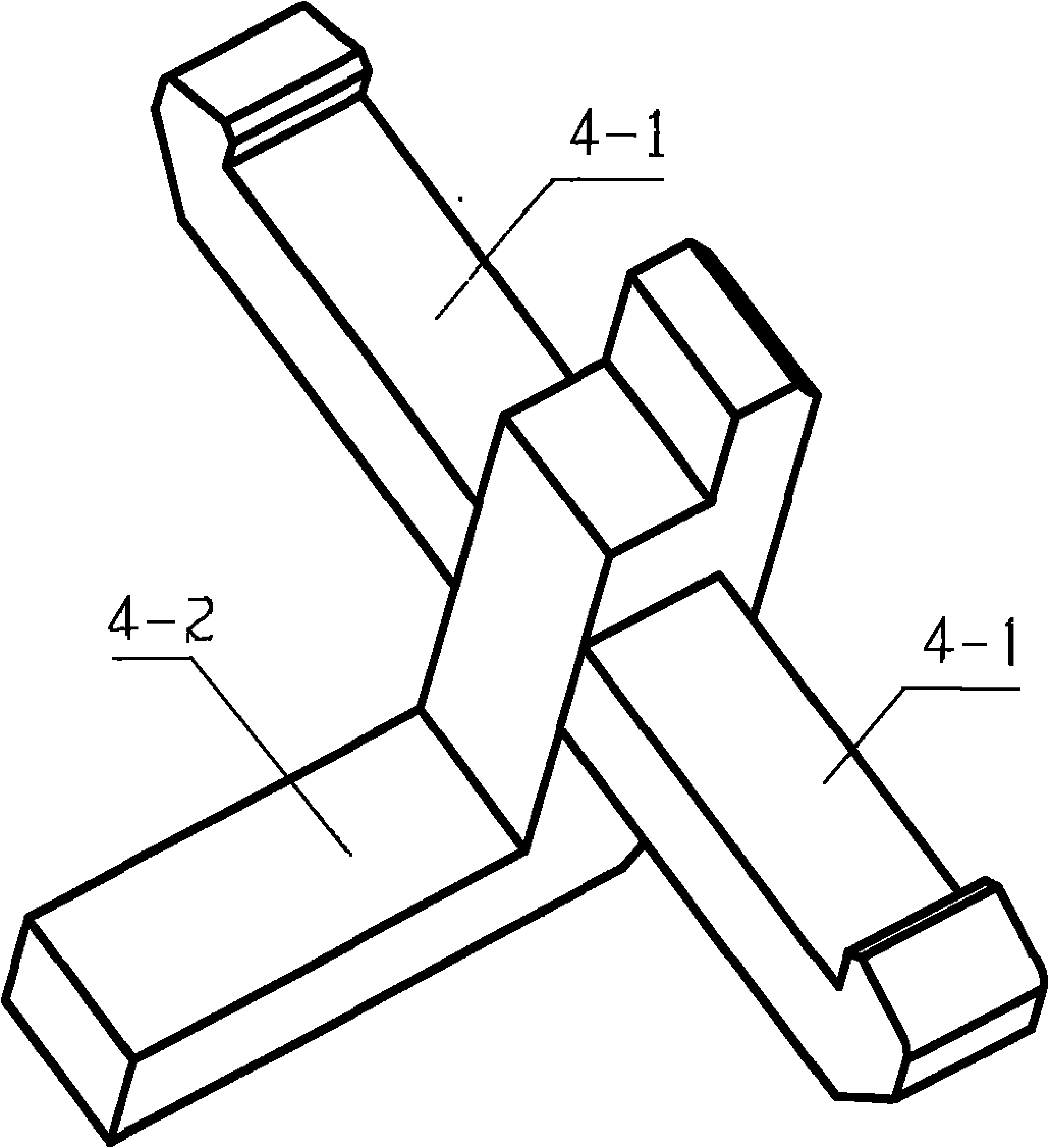

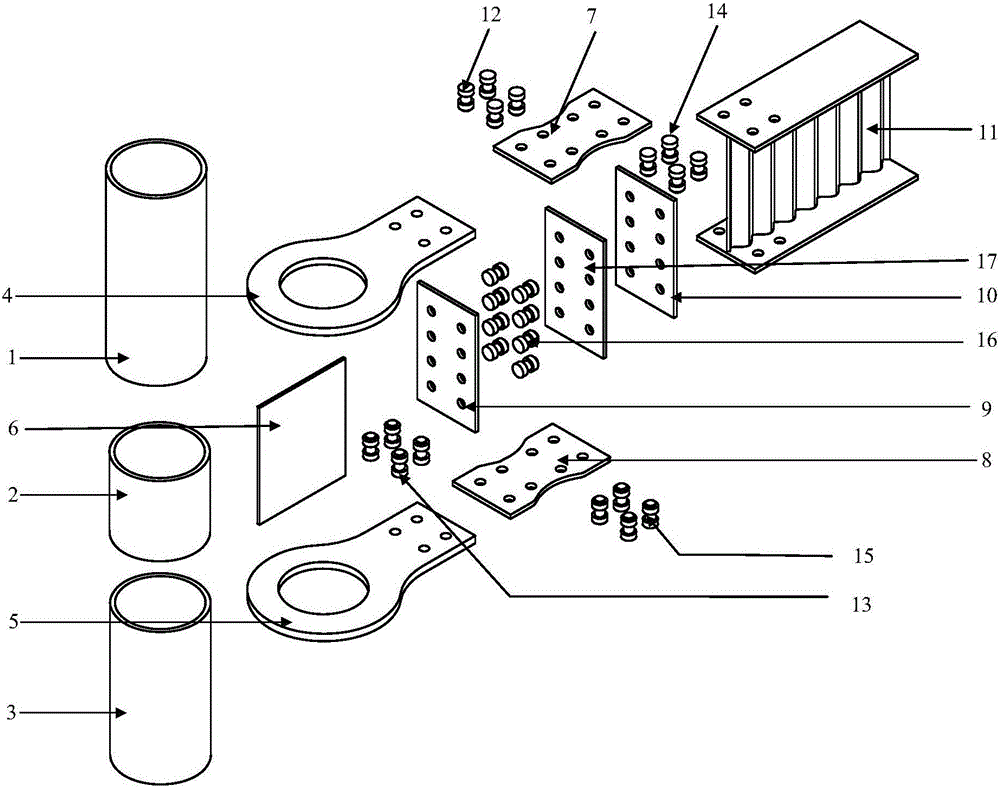

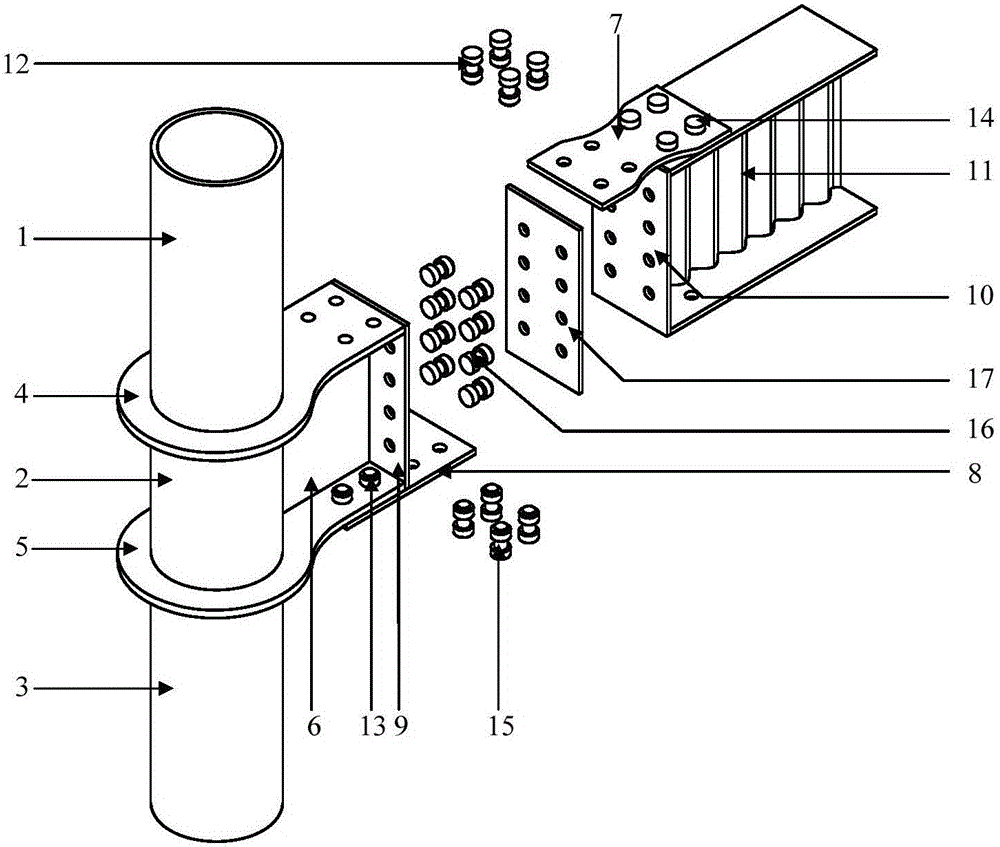

The invention relates to a function-restorable assembly type wave web beam-column composite joint connection device and belongs to the technical field of structural engineering. The function-restorable assembly type wave web beam-column composite joint connection device is composed of a round steel pipe column with a cantilever beam section, a wave web I-shaped composite beam section and a connecting device between the round steel pipe column with the cantilever beam section and the wave web I-shaped composite beam section. Welding of the joint connection device and assembly of the wave web I-shaped beam section and a composite floor are finished in a factory; weld seam and member qualities are easier to control; the round steel pipe column with the cantilever beam section and the wave web I-shaped composite beam section are assembled only through high-strength bolts and connection plates on site, so that the construction speed and quality are greatly improved; the wave web I-shaped composite beam section can be built on the lower flange connection plate of the round steel pipe column with the cantilever beam section, so that the hoisting difficulty is lowered and on-site assembly and positioning are easy; and through specific design, the structure destroyed positions can appear in the positions of energy dissipation members such as the easy-to-replace high-strength bolts and lower flange connection plate under the action of earthquake load, so that post-earthquake restoring is facilitated, and the function-restorable assembly type wave web beam-column composite joint connection device is adapted to development demands of a function-restorable assembly type steel structure.

Owner:BEIJING UNIV OF TECH

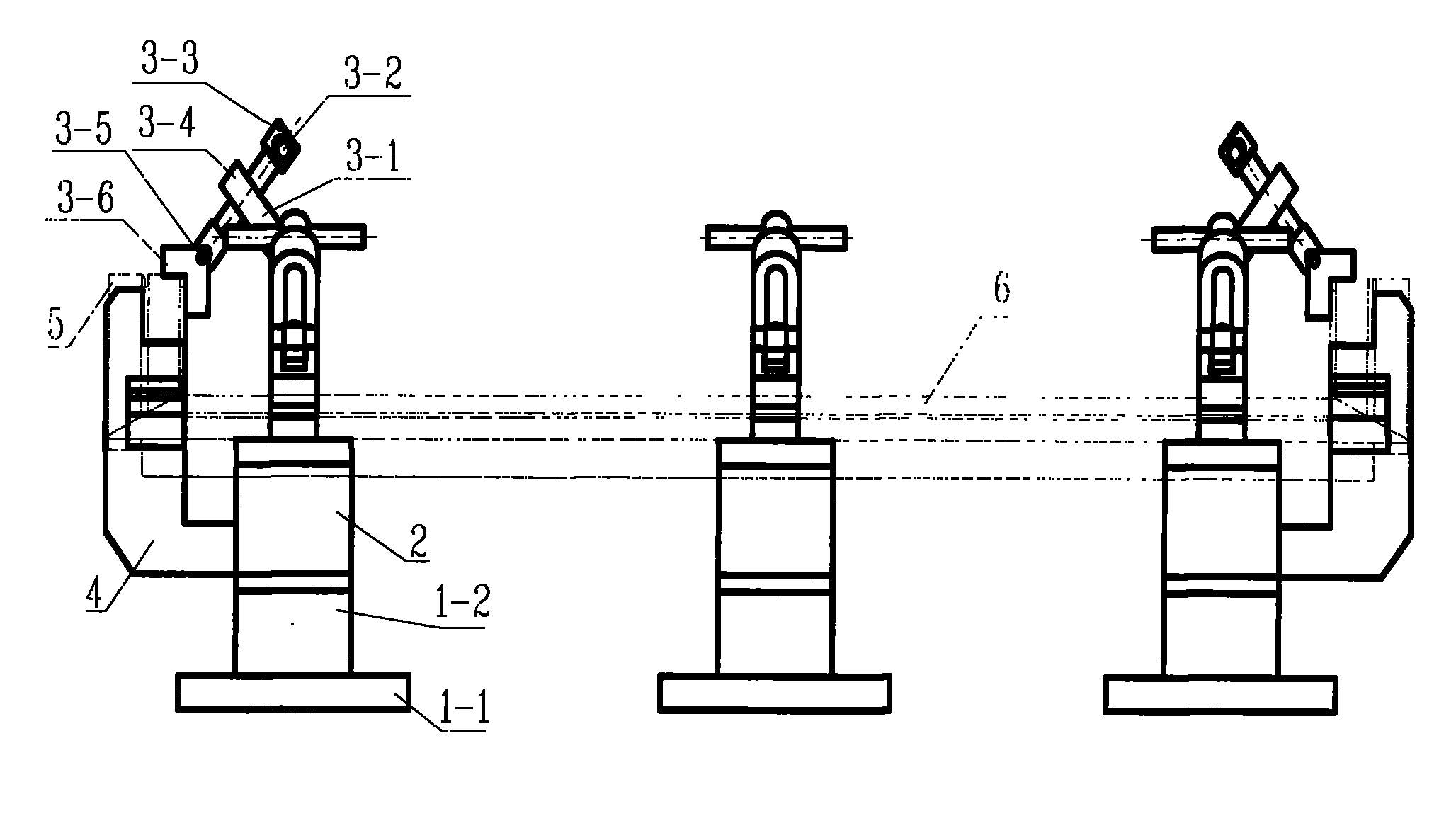

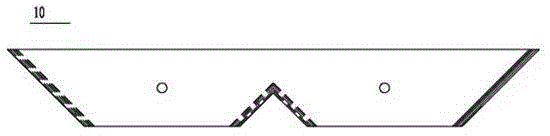

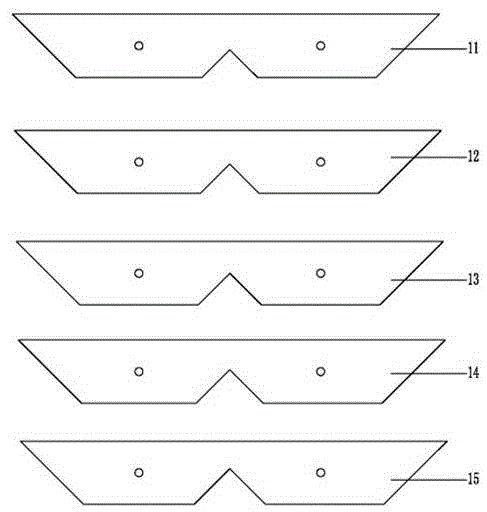

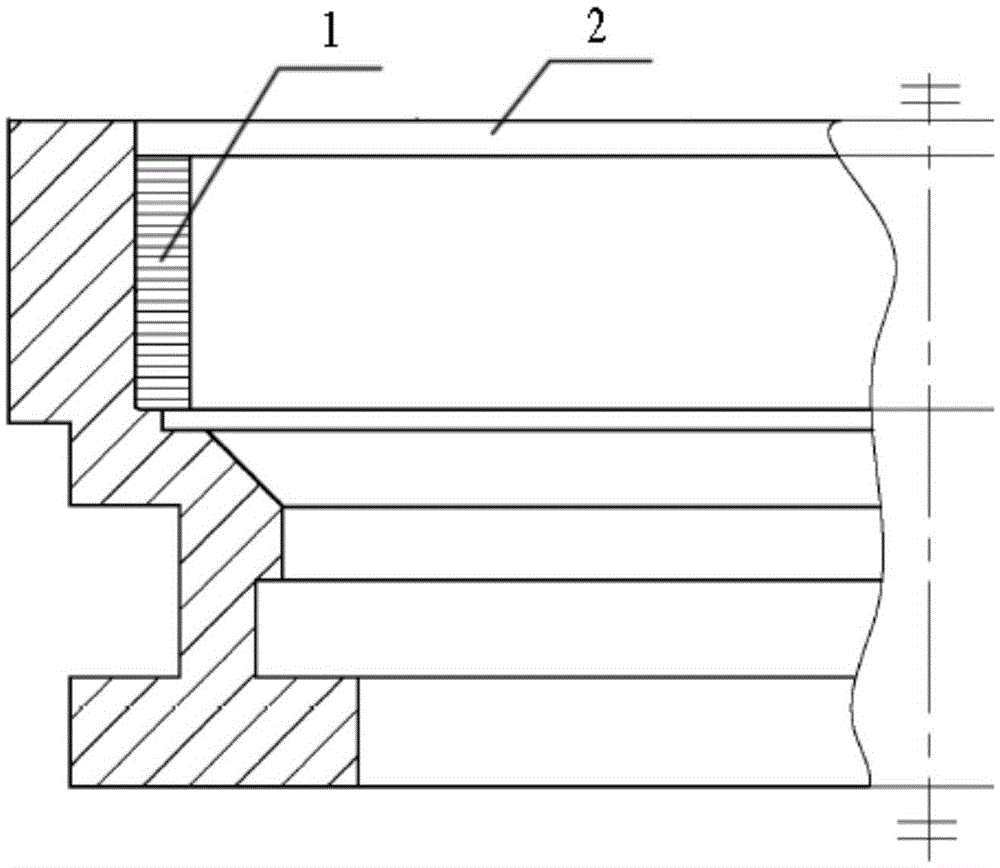

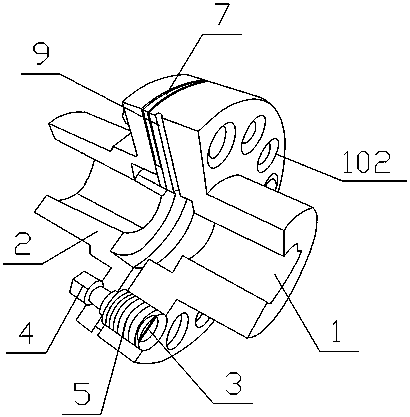

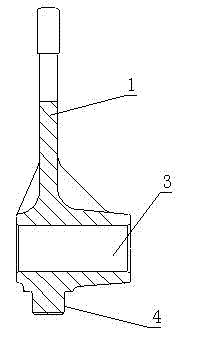

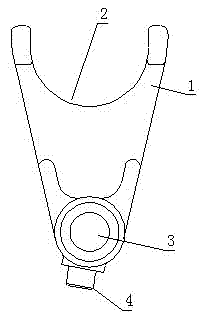

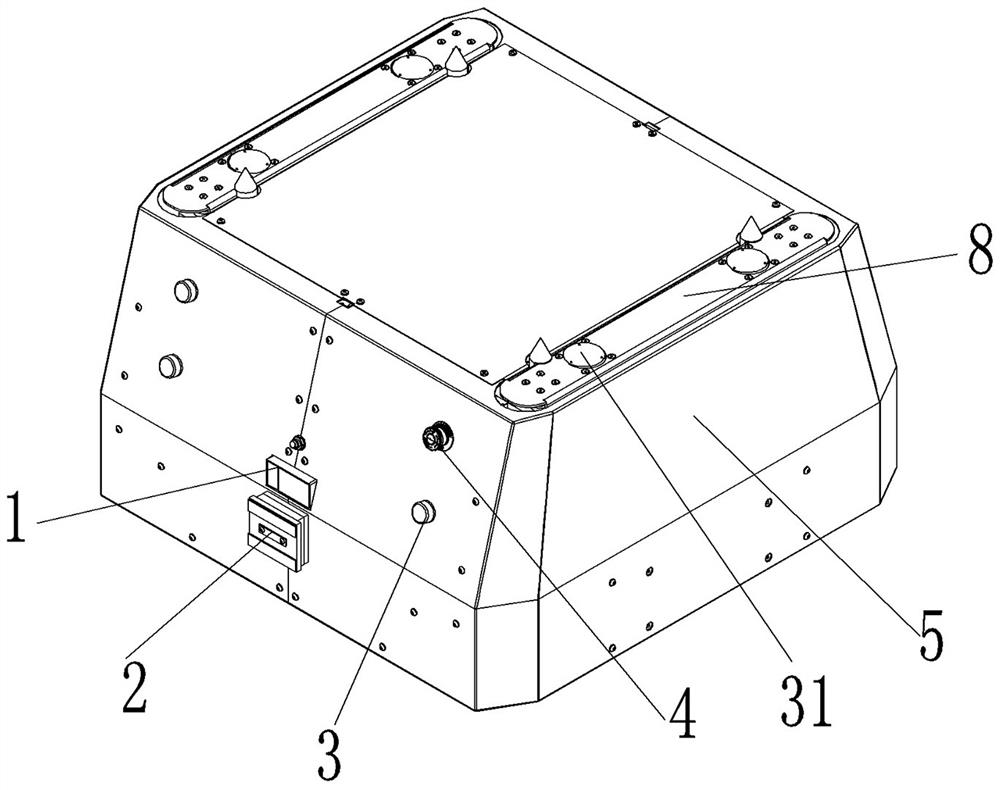

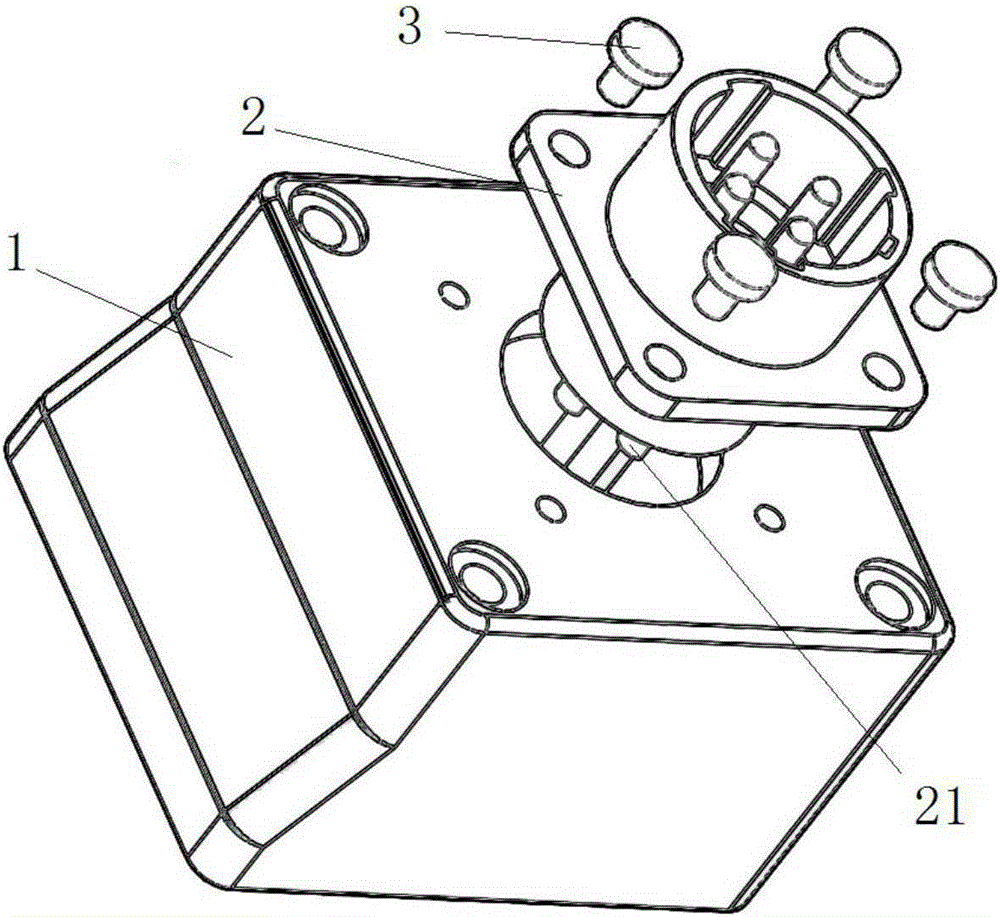

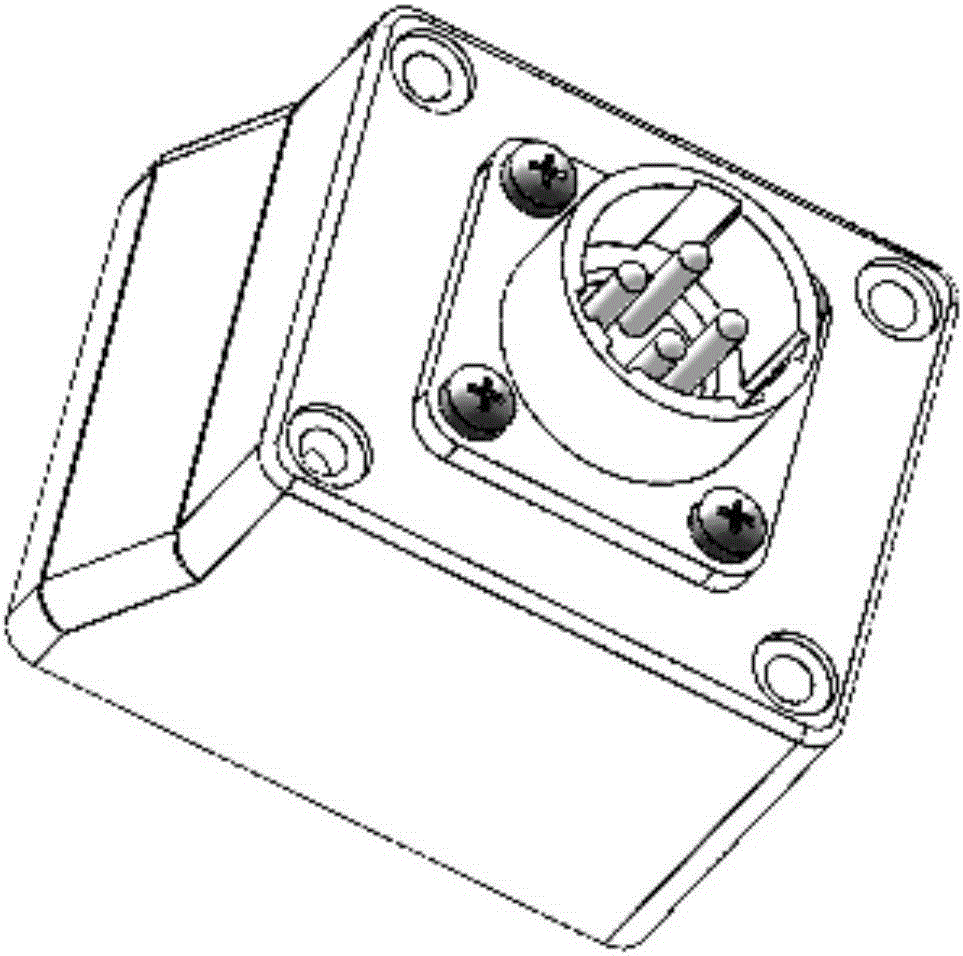

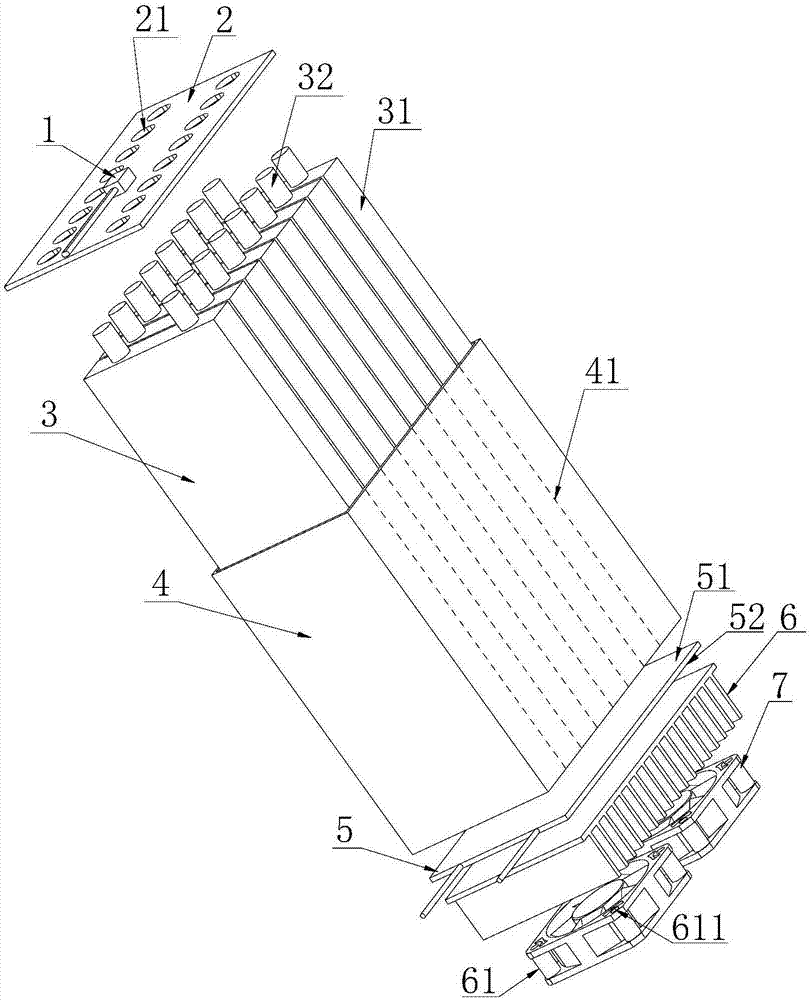

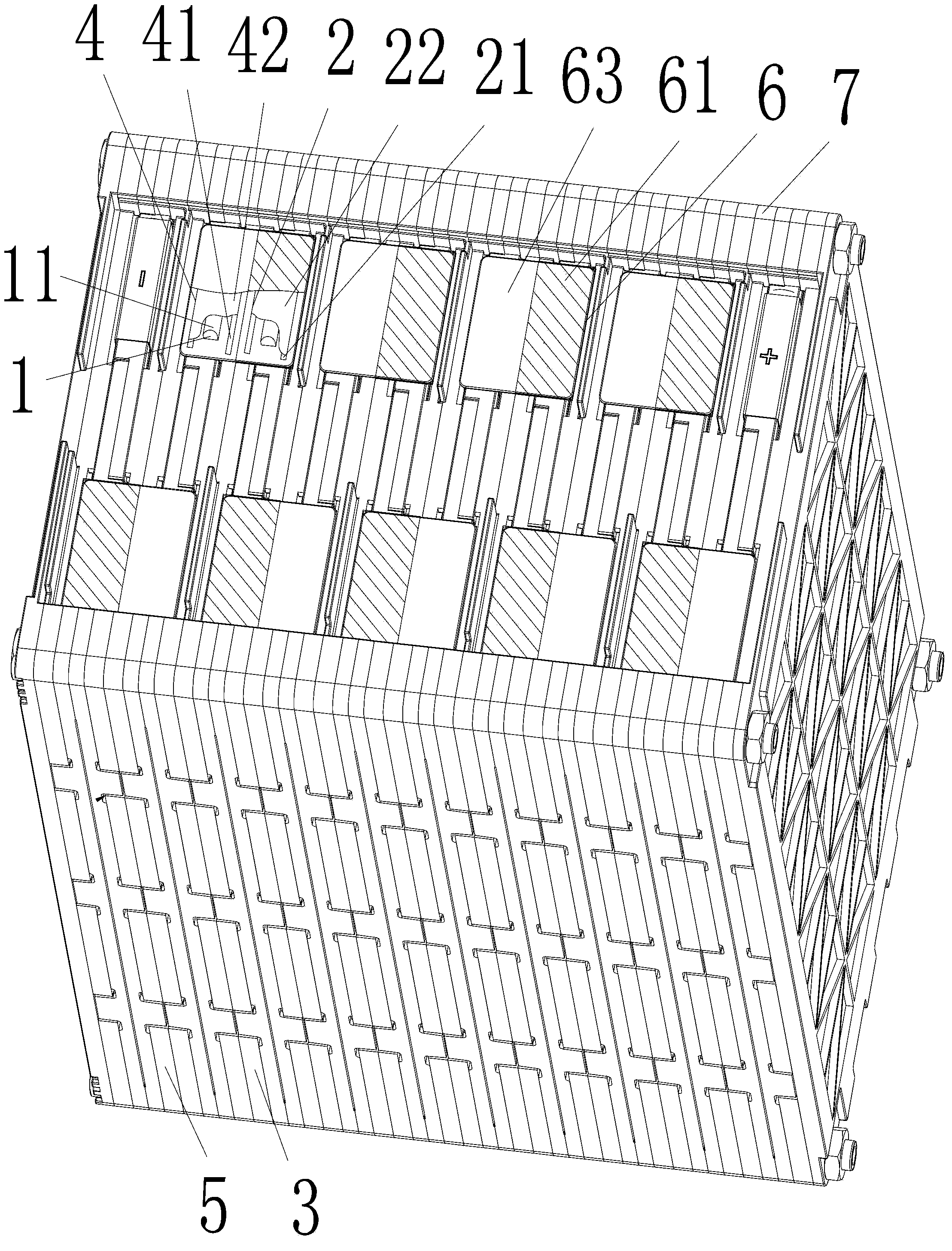

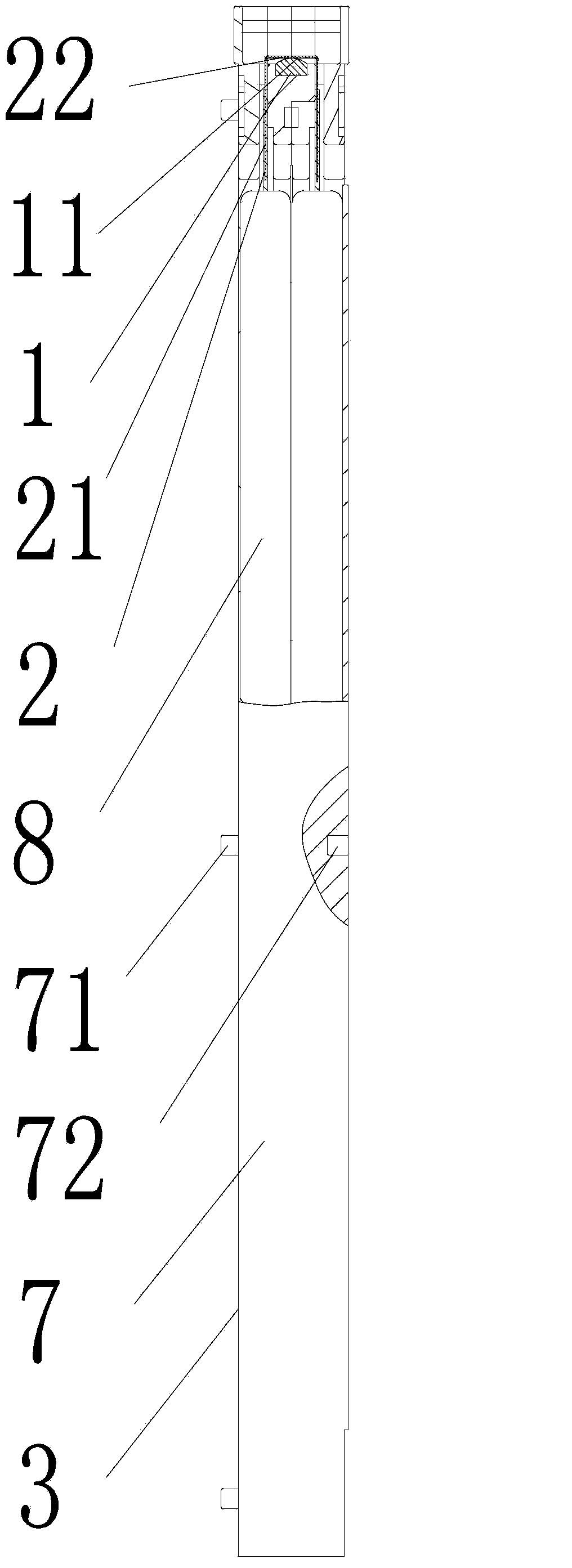

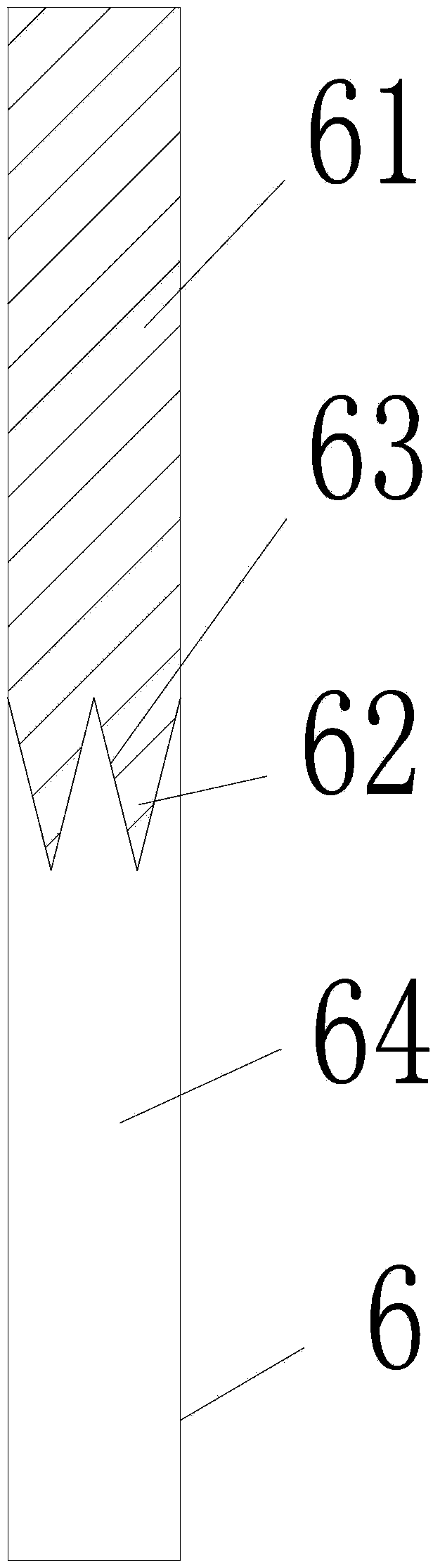

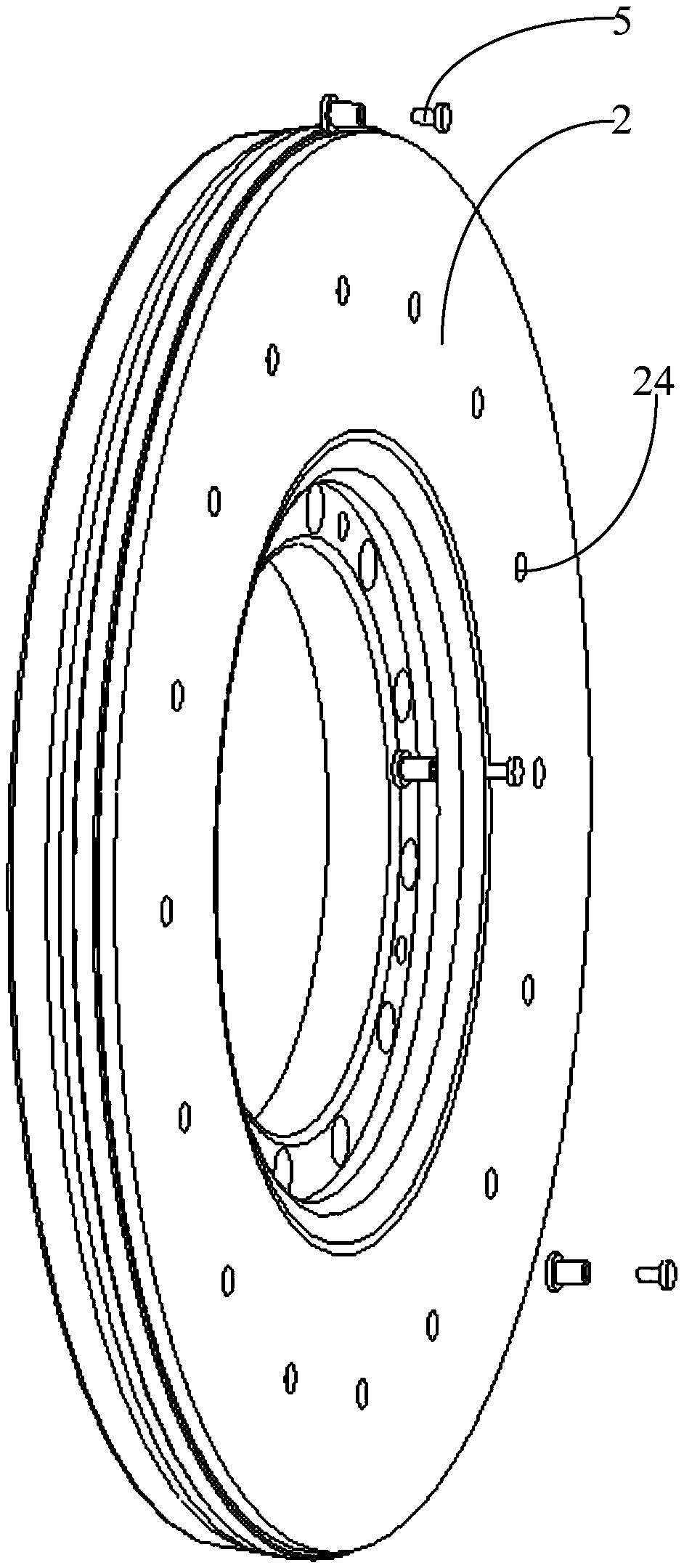

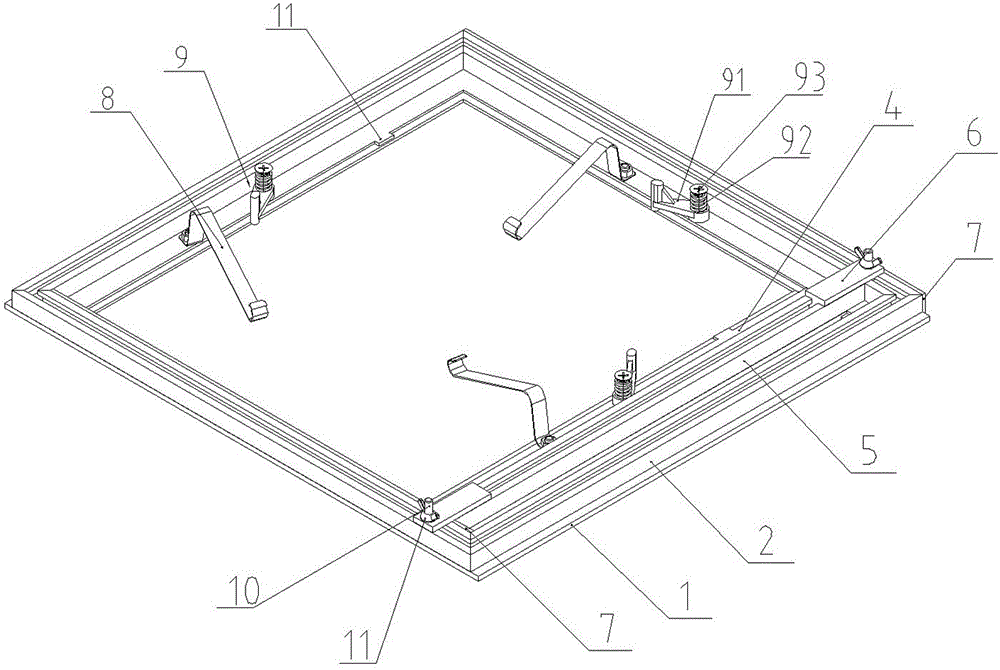

Process apparatus for fixedly welding camber profile frame and positioning method thereof

InactiveCN101804538ASimple structurePrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesModularityEngineering

The invention discloses a process apparatus for fixedly welding a camber profile frame, comprising at least three groups of parallel welding and positioning devices for supporting rectangular frames to be welded. The welding and positioning device comprises a base module (1) movably and fixedly connected with a universal platform, the base module (1) is respectively provided with a port positioning module (2) and a pressing module (3) for positioning the upper end face and the lower end face at two sides of the rectangular frame camber profile (5), the symmetrical central line of the base module (1) is further provided with a frame edge positioning module (4) used for flexibly positioning the two sides of the rectangular frame. By adopting the modularized assembly welding and positioning device with the combined structure, the large rectangular frame with the length of 10 meters and the camber profile are correctly positioned on the module, thereby realizing the replaceable performance of welding and positioning, the universalization of the platform, and the physical dimension seriation, the parameterization and the universalization of the welding and positioning module. The invention can be movably and fixedly connected with the universal platform, thereby greatly reducing the idleness ratio of tools and the space occupation during the idleness time.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

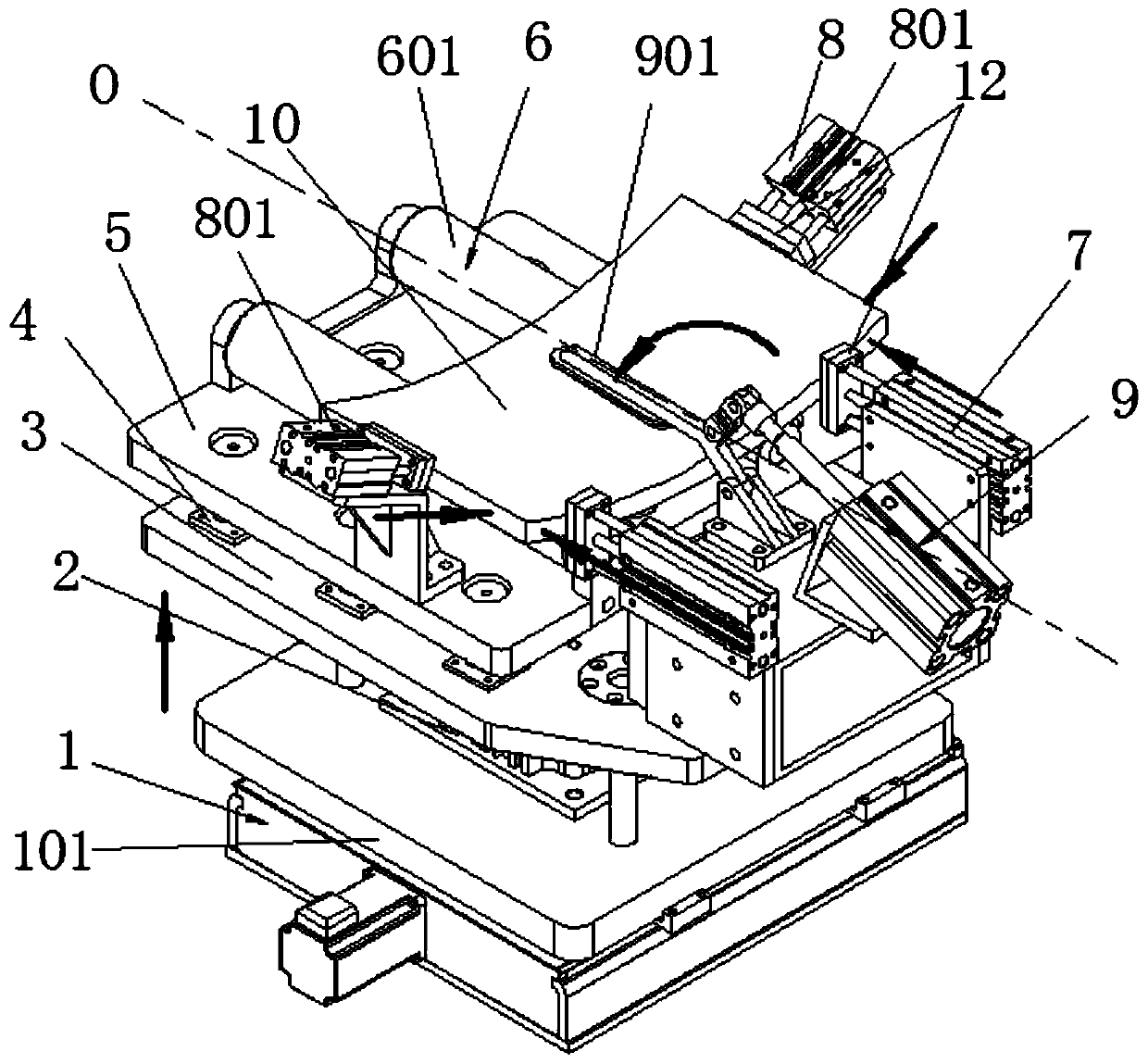

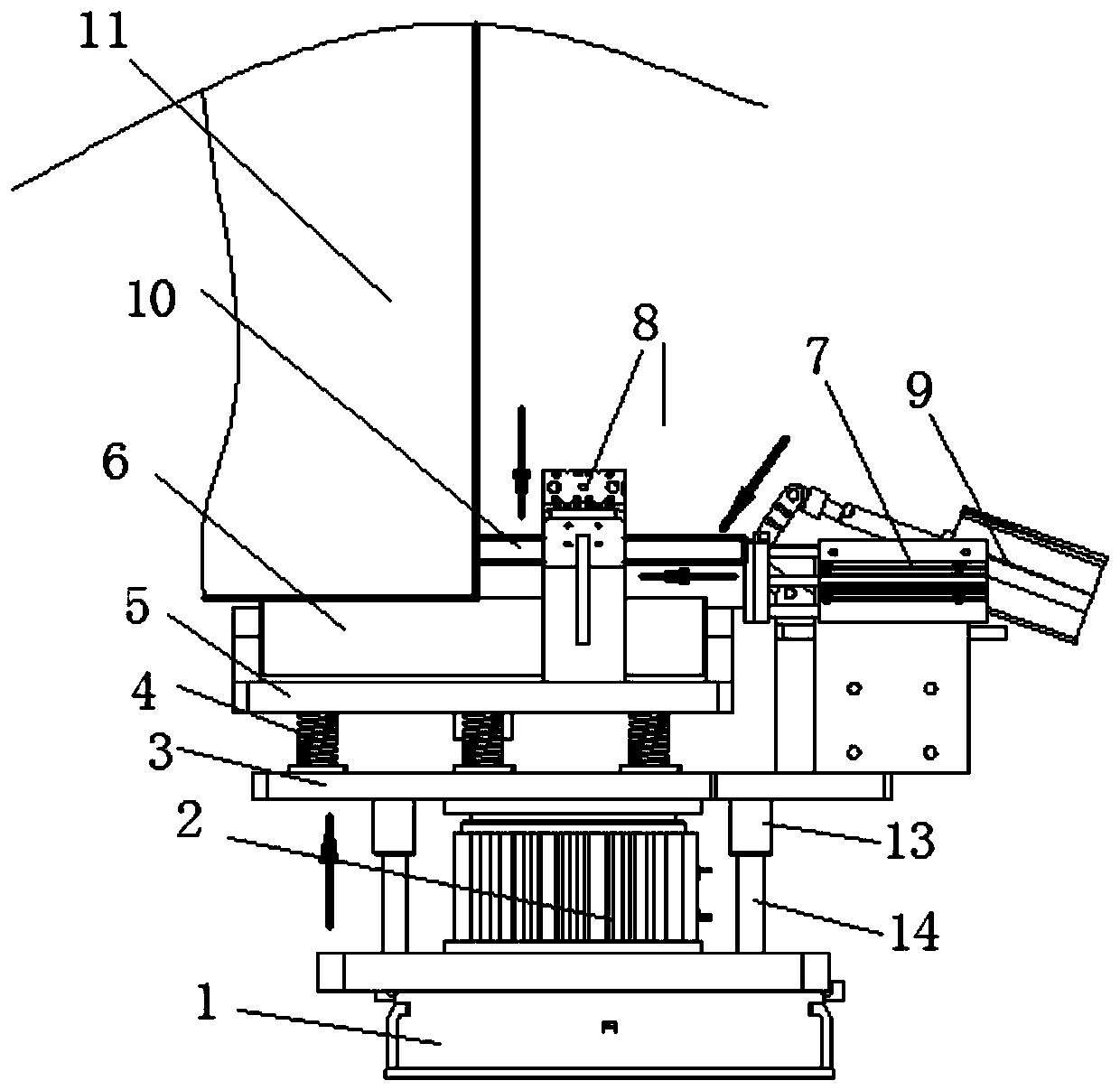

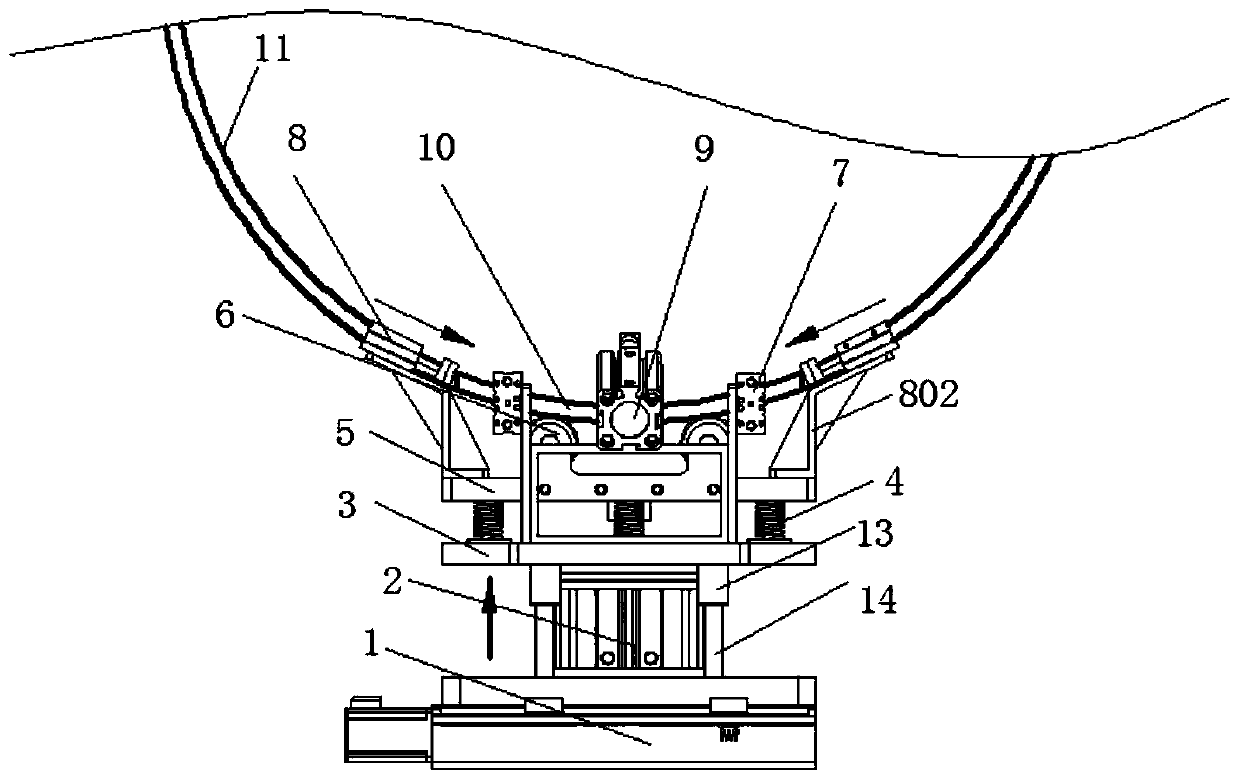

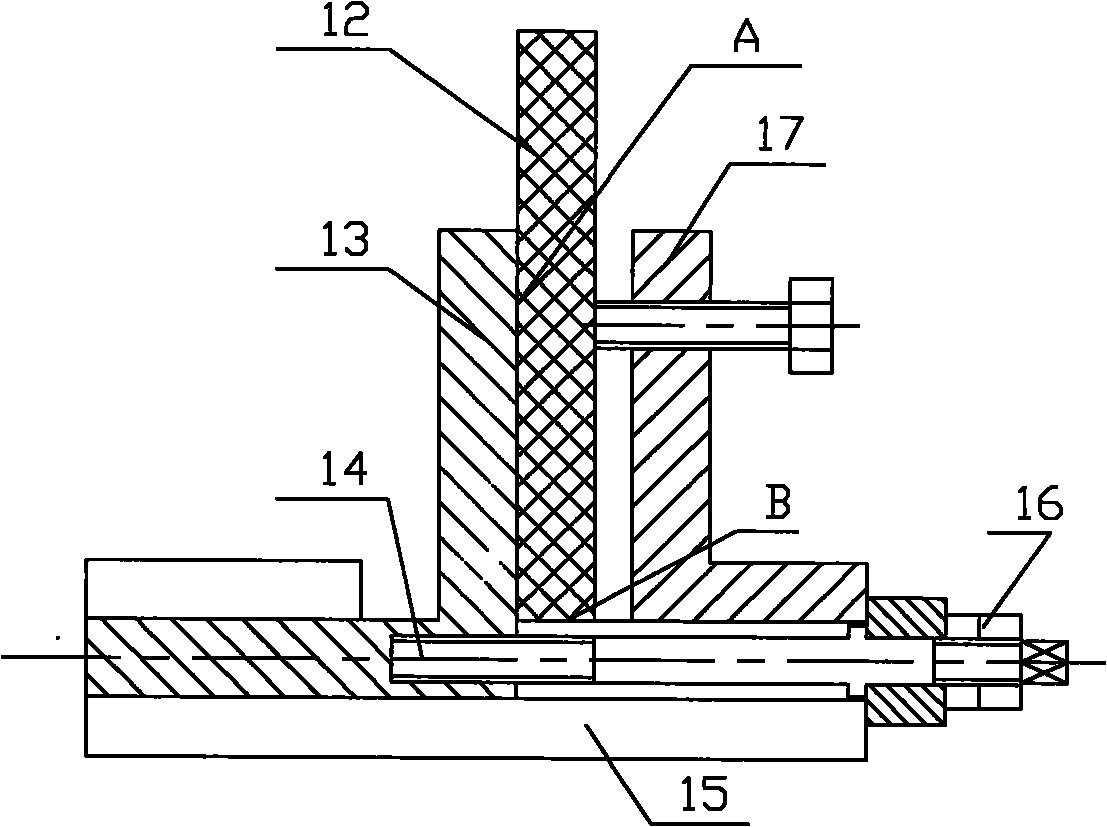

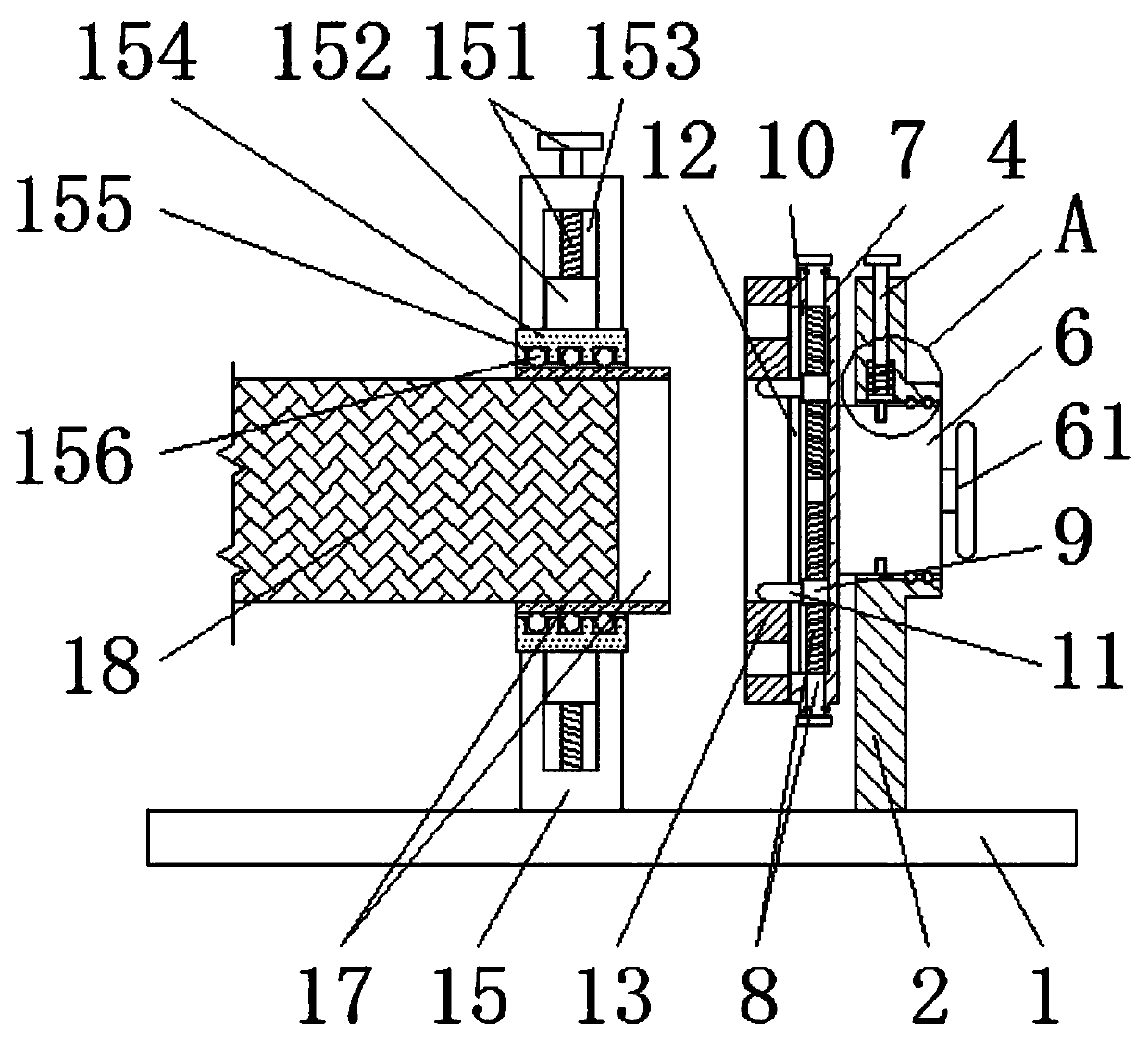

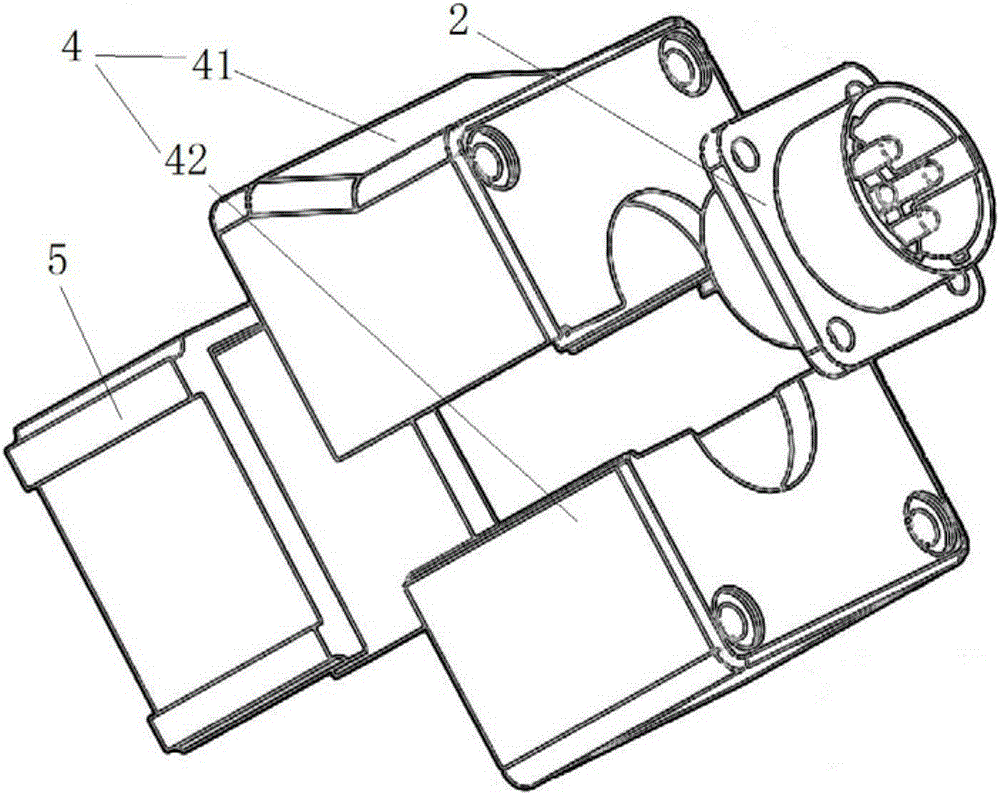

Butting positioning tool for arc striking and quenching plates and positioning butting method thereof

PendingCN111266699ARealize automatic liftingMeet the needs of unmanned productionElectrode holder supportersWelding/soldering/cutting articlesStructural engineeringMechanical engineering

The invention provides a butting positioning tool for arc striking and quenching plates and a positioning butting method thereof. The tool is provided with a translation sliding table for aligning thetool and a pipe end; the translation sliding table drives a lifting platform to lift through a vertical lifting cylinder, the lifting platform is provided with a loading platform in parallel throughflexible self-adaptive assemblies, the loading platform is provided with profiling roller assemblies for aligning the arc plates and the pipe end, the loading platform is provided with a pair of positioning and clamping mechanisms, and the lifting platform is provided with a pair of horizontal pushing mechanisms and a pressing mechanism; and automatic lifting, pushing, approaching, clamping, centering, fixing, abutting and downward pressing and aligning operations of the arc places with respect to the pipe end are realized through the mechanisms. The manpower is replaced, and the automatic plate aligning and positioning operation before welding of the arc striking and quenching plates is realized in a high efficiency, labor-saving and accurate mode.

Owner:陕西戴爱盟德电子科技有限公司

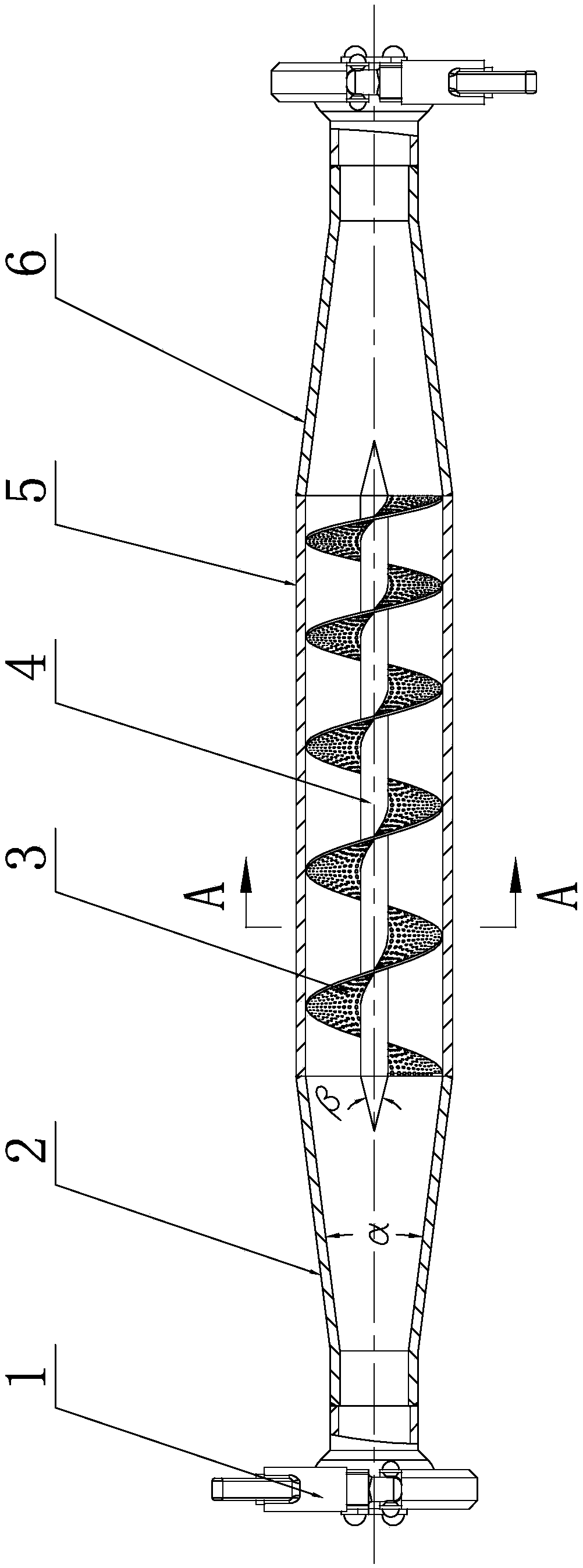

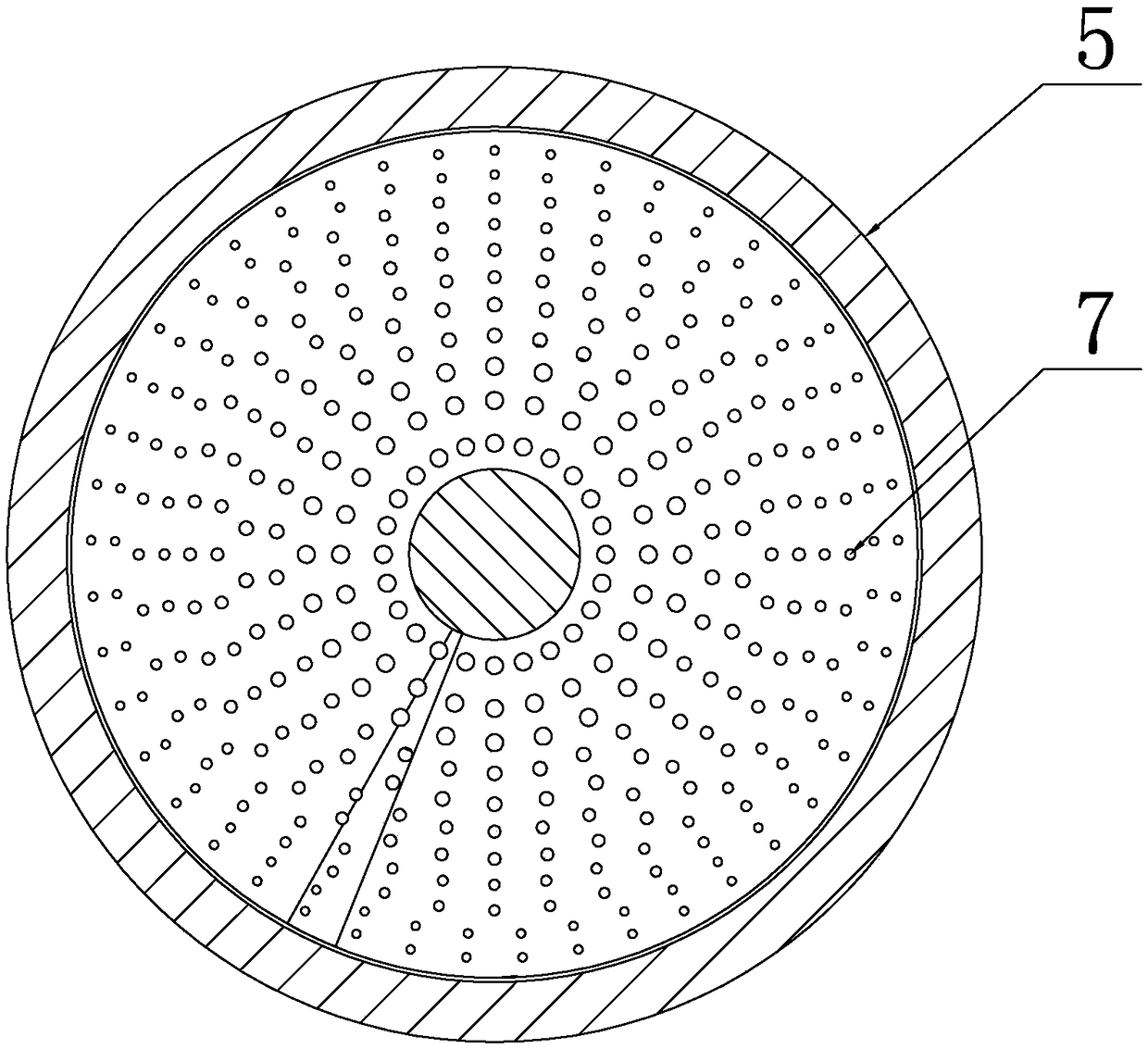

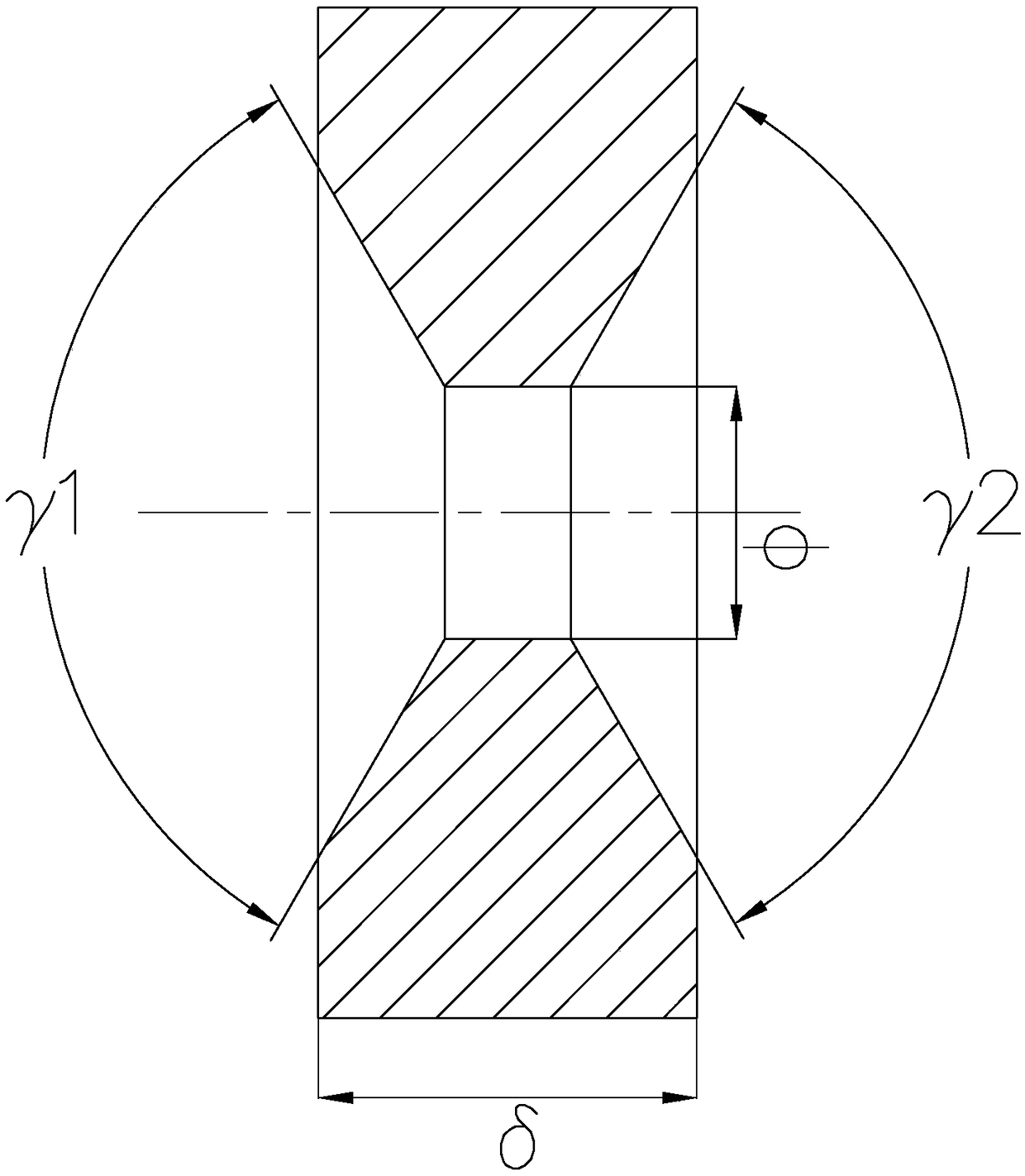

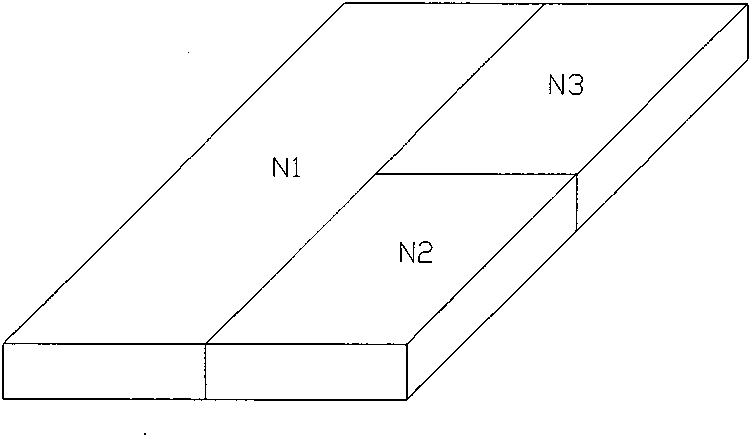

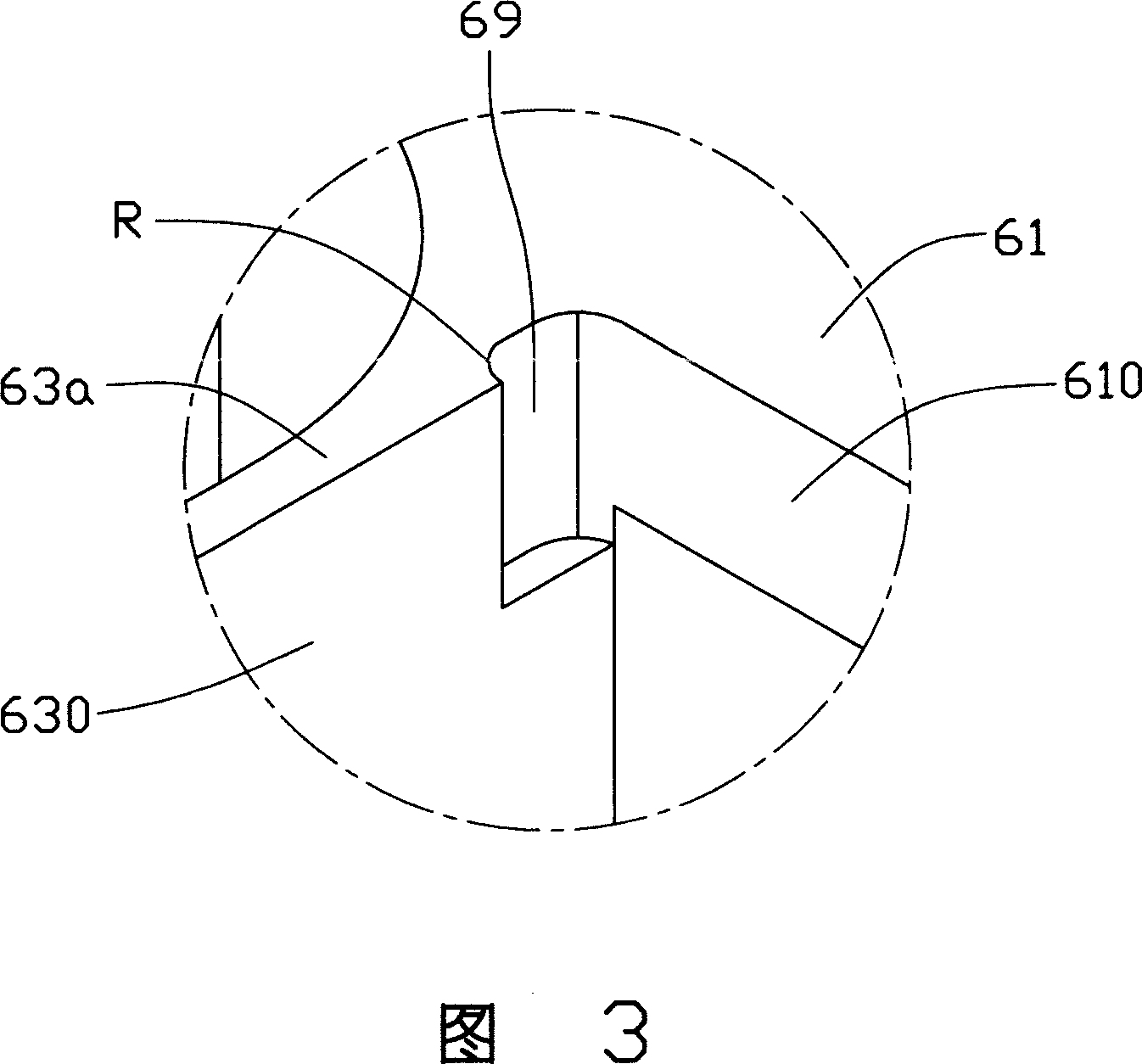

Venturi microbubble generator and application of generator in catalytic ozonation

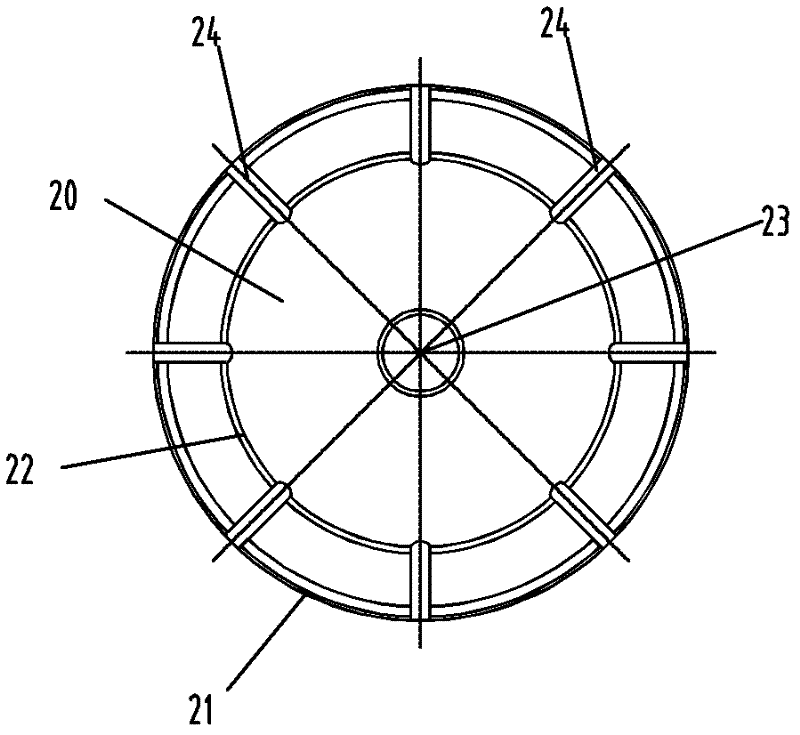

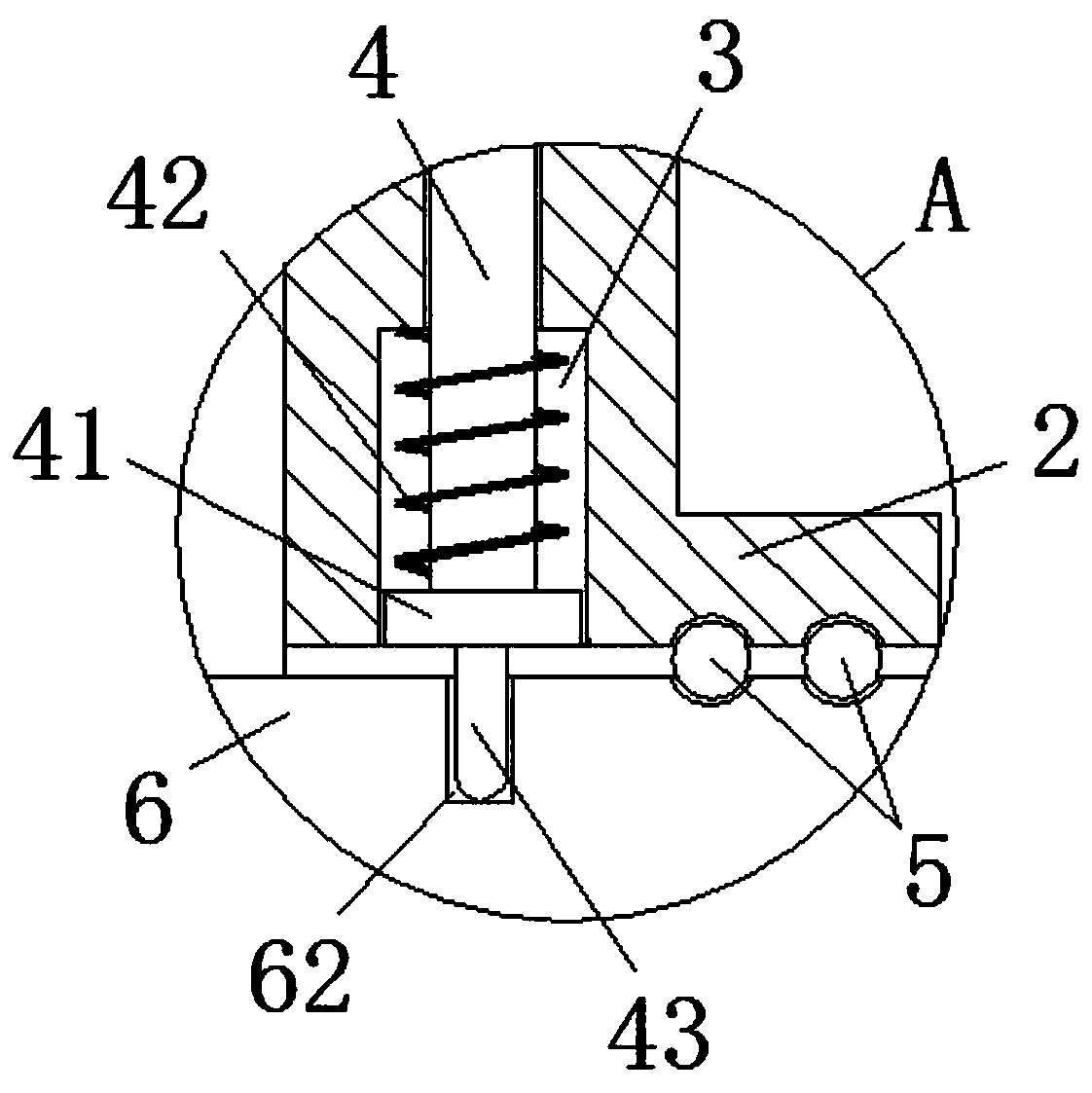

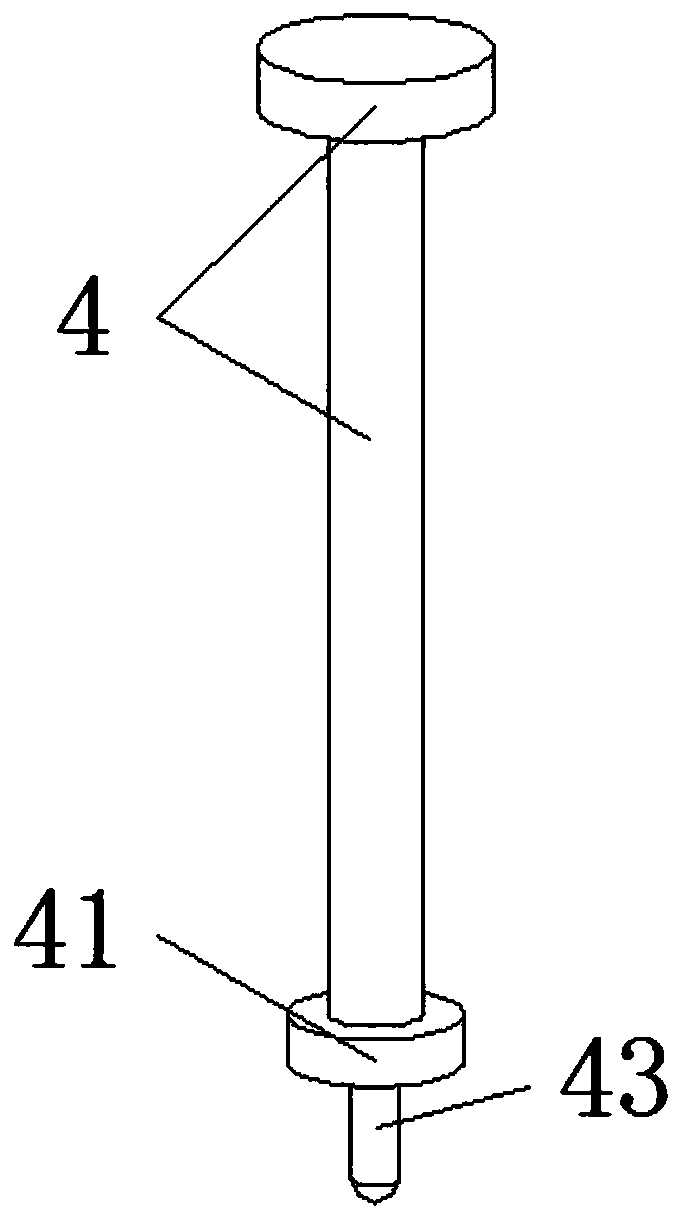

PendingCN108704504AEnhanced fine crushing effectImprove the degree of crushing and refinementWater treatment parameter controlFlow mixersThroatMicrobubbles

The invention belongs to a microbubble generation device and particularly relates to a Venturi microbubble generator and application of the generator in catalytic ozonation. The Venturi microbubble generator comprises a main pipe, wherein an inlet and an outlet are formed in two ends of the main pipe, the inlet of the main pipe is connected with an output end of a gas-liquid mixing pump through afirst Venturi tube, the outlet of the main pipe outputs through a second Venturi tube, and the first Venturi tube and the second Venturi tube comprise inlet sections, shrinking sections, throat sections and dispersion sections which are sequentially connected from outside to inside; and spiral blades homodromous with the advancing direction of materials are fixed in the main pipe, openings are formed in the spiral blades, the hole diameters of the opening decrease from inside to outside along the radial direction, and the openings in the same circumference are distributed in an equal angle interval manner. The Venturi microbubble generator can solve the technical problem of poor generation effects of microbubbles in the prior art effectively; and the Venturi microbubble generator has the advantages that the mounting is convenient, the generation and utilization effects of the microbubbles are good, and the like.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

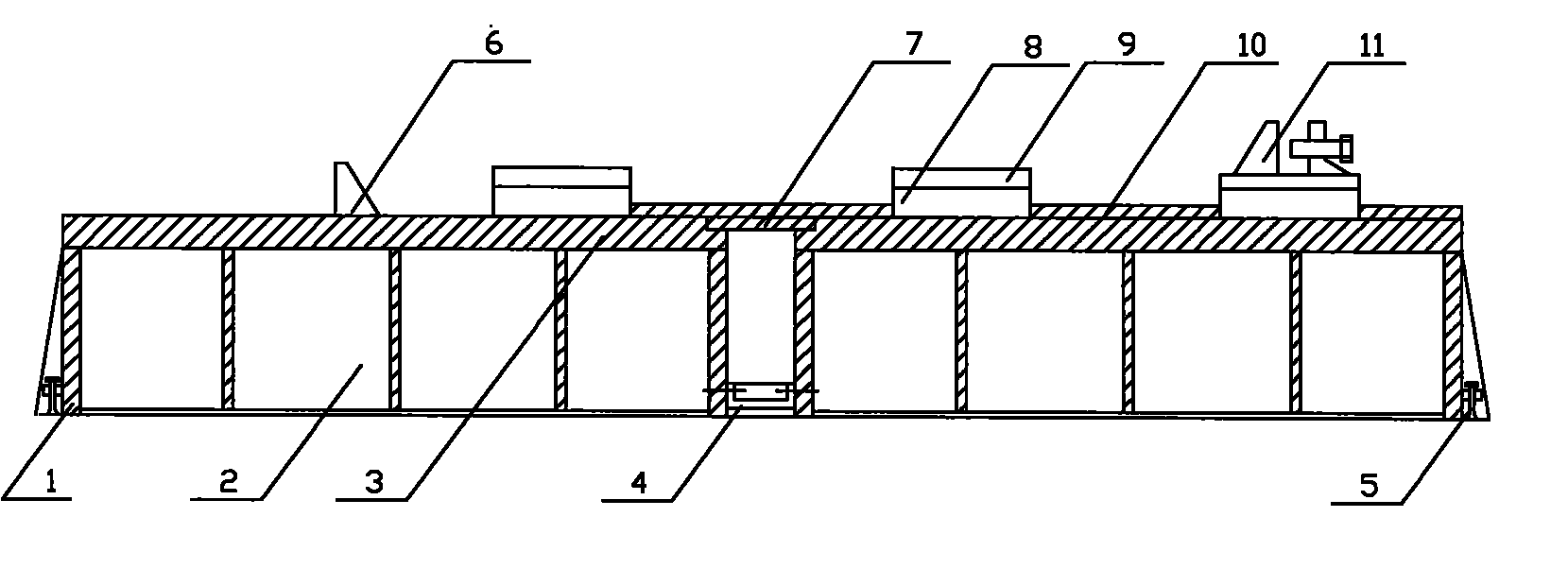

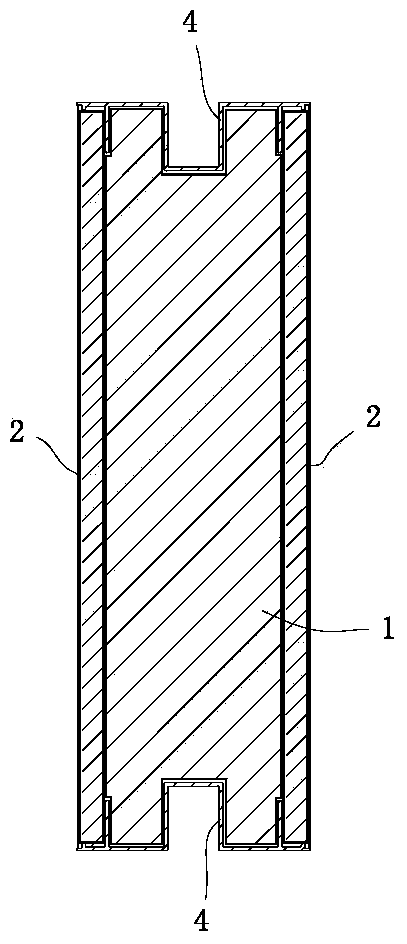

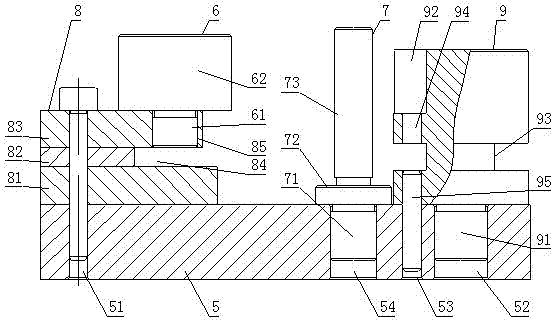

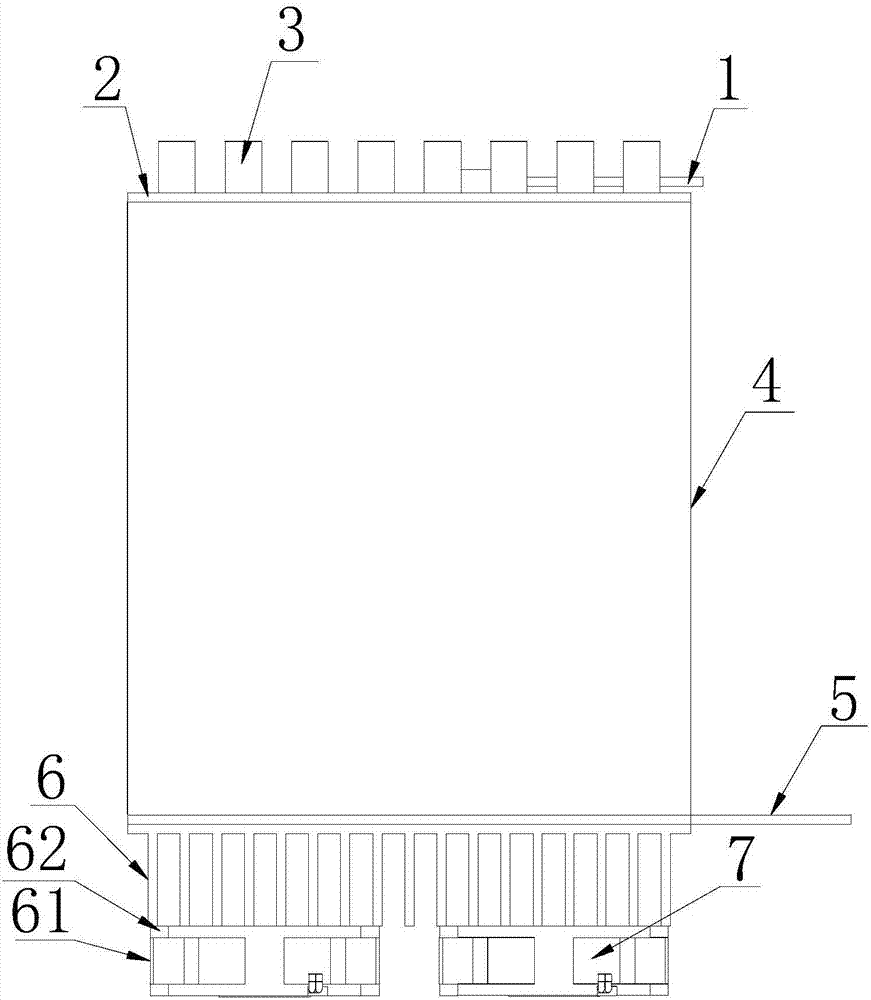

Welding and assembling platform of nuclear power station reactor cavity water gate

InactiveCN101875162AEasy to assemble and locateAvoid pollutionWelding/cutting auxillary devicesAuxillary welding devicesNuclear powerEngineering

The invention discloses a welding and assembling platform which comprises a plurality of small platforms, wherein the small platforms can be spliced, made of carbon steel, and connected through a connecting device arranged at the lower part, each small platform comprises a frame plate, a supporting rid and a panel, the frame plate is arranged around the lower part of the panel, the supporting rid is also supported below the panel, and the connecting device comprises a connecting block and a connecting bolt. Regulating support legs for regulating the small platforms to be horizontal are arranged around the frame plate of each small platform. A steel plate is arranged at the gap between the adjacent small platforms. A layer of stainless steel thin plate is arranged above the panel of each small platform. The welding and assembling platform has relatively simpler manufacturing process, can be flexibly assembled on a manufacturing site, can form a relatively precise clamp, and can prevent a stainless steel workpiece from being polluted by iron ions.

Owner:INSTALLATION & REPAIR ENG YIZHENG CHEM FIBER UNITED

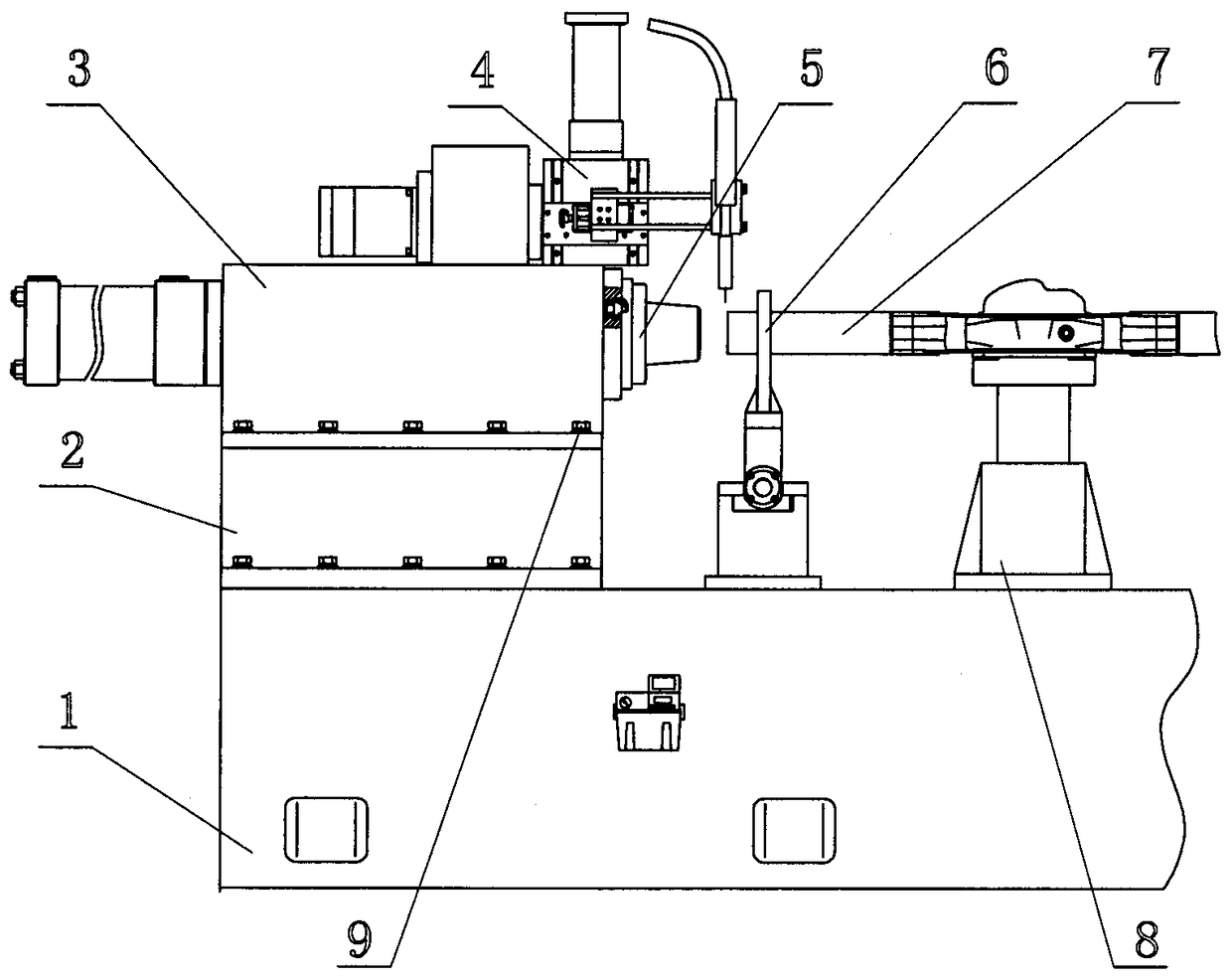

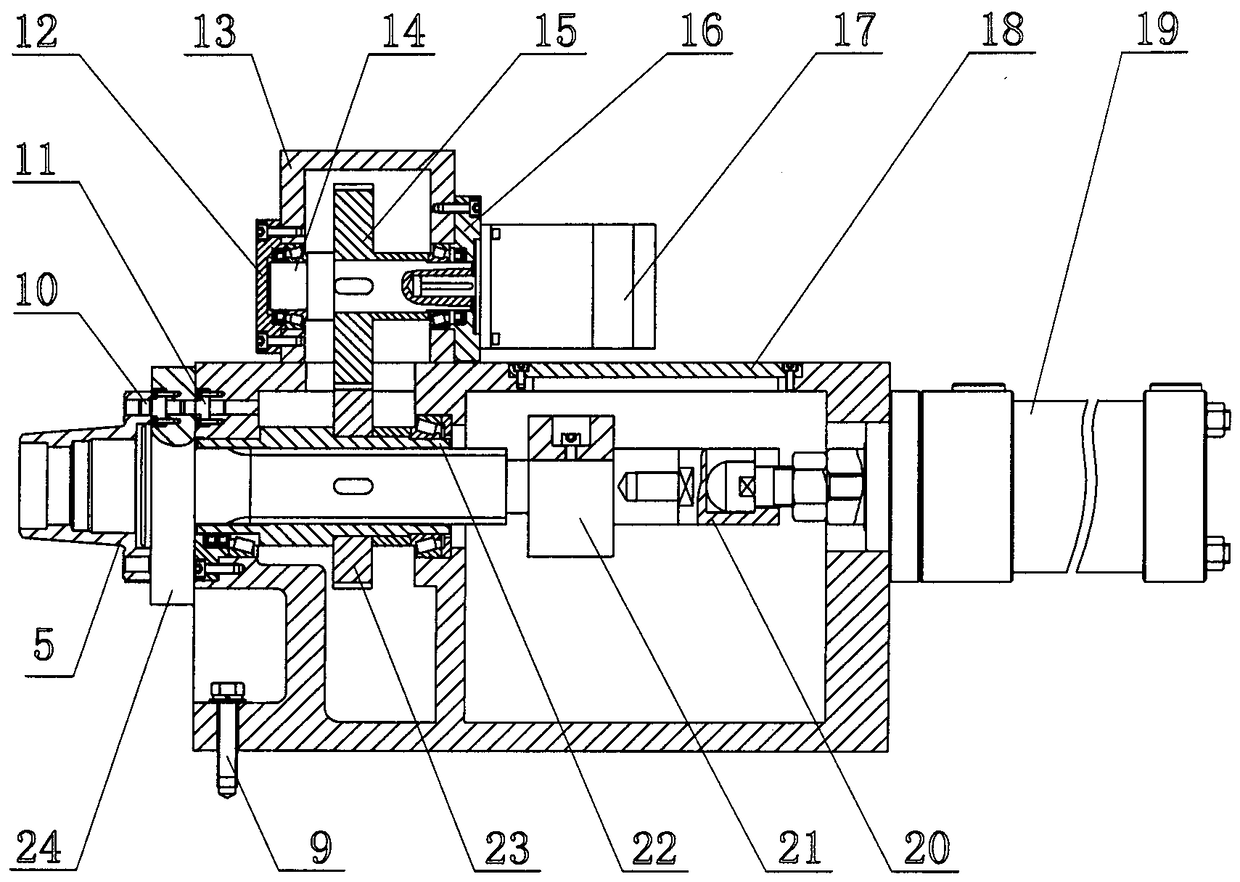

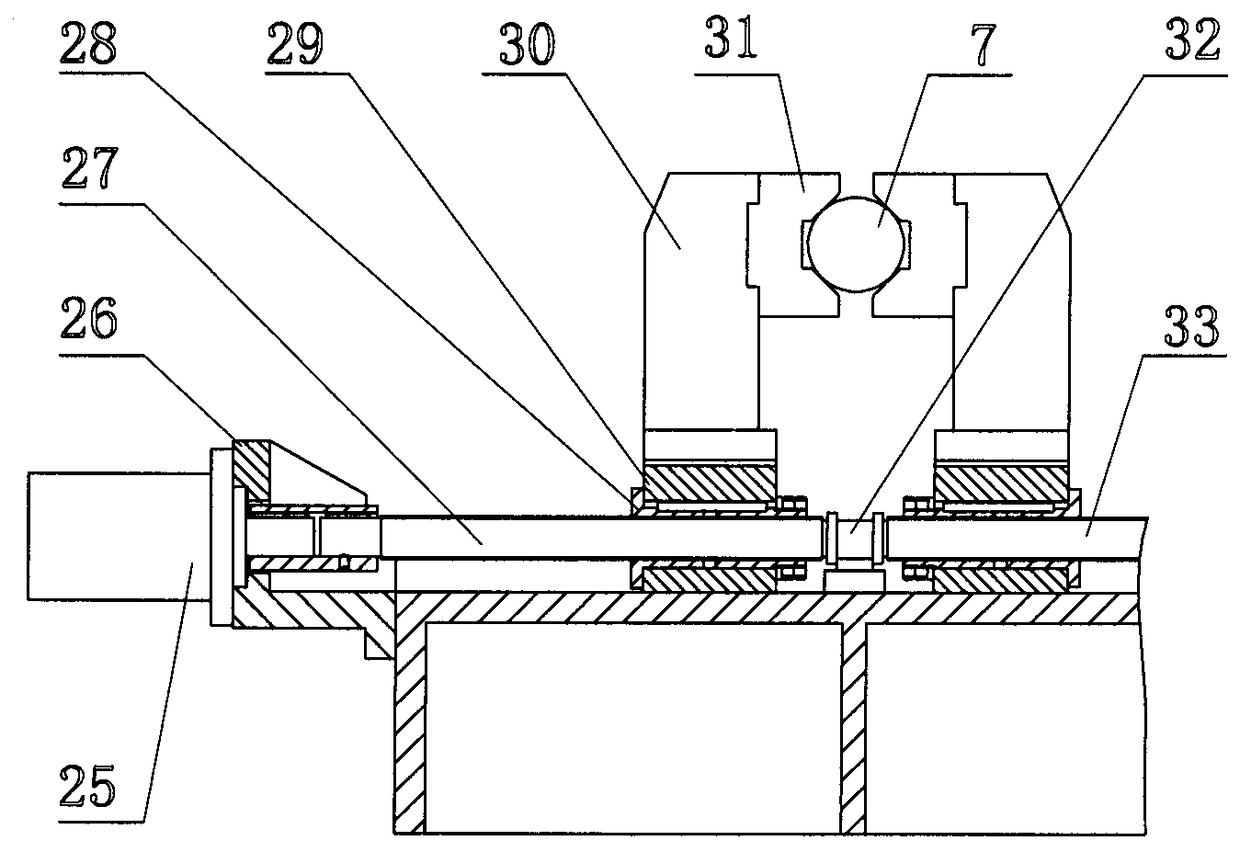

Automobile rear axle housing flange plate press-fitting welding device

PendingCN108213923AEnsure mounting surface accuracyGuaranteed accuracyWelding/cutting auxillary devicesArc welding apparatusEngineeringWelding deformation

The invention discloses an automobile rear axle housing flange plate press-fitting welding device which is used for solving the problems of being multiple in procedure, low in mounting efficiency, incapable of guaranteeing welding precision of flange plates and the like in an existing automobile rear axle housing flange plate press-fitting process. The automobile rear axle housing flange plate press-fitting welding device comprises a combined lathe bed, welding mechanisms and a clamping mechanism. According to the technical characteristics, the combined lathe bed is composed of a main body lathe bed and side lathe beds, wherein the middle of the upper surface of the main body lathe bed is provided with a lifting clamping mechanism used for limiting and smoothing a rear axle housing; rotating mechanisms with adjustable feeding strokes comprise hydraulic feeding units and rotary driving units, and the welding mechanisms are arranged on the upper surfaces of the side lathe beds; and the clamping mechanism comprises a self-centering clamping mechanism and the lifting clamping mechanism, and the lifting clamping mechanism is adjusted to enable the axes of flange plates and the axis of an axle housing pipe to be located on the same central line. According to the automobile rear axle housing flange plate press-fitting welding device, the structural design is reasonable, the technological process is simplified, assembling and positioning are accurate, welding deformation is easy to control, while precision of the mounting surfaces of the flange plates is ensured, the machining costis reasonably reduced, the quality and production efficiency of a finished product are improved, and therefore driving safety is guaranteed.

Owner:LIAONING SG AUTOMOTIVE GRP CO LTD

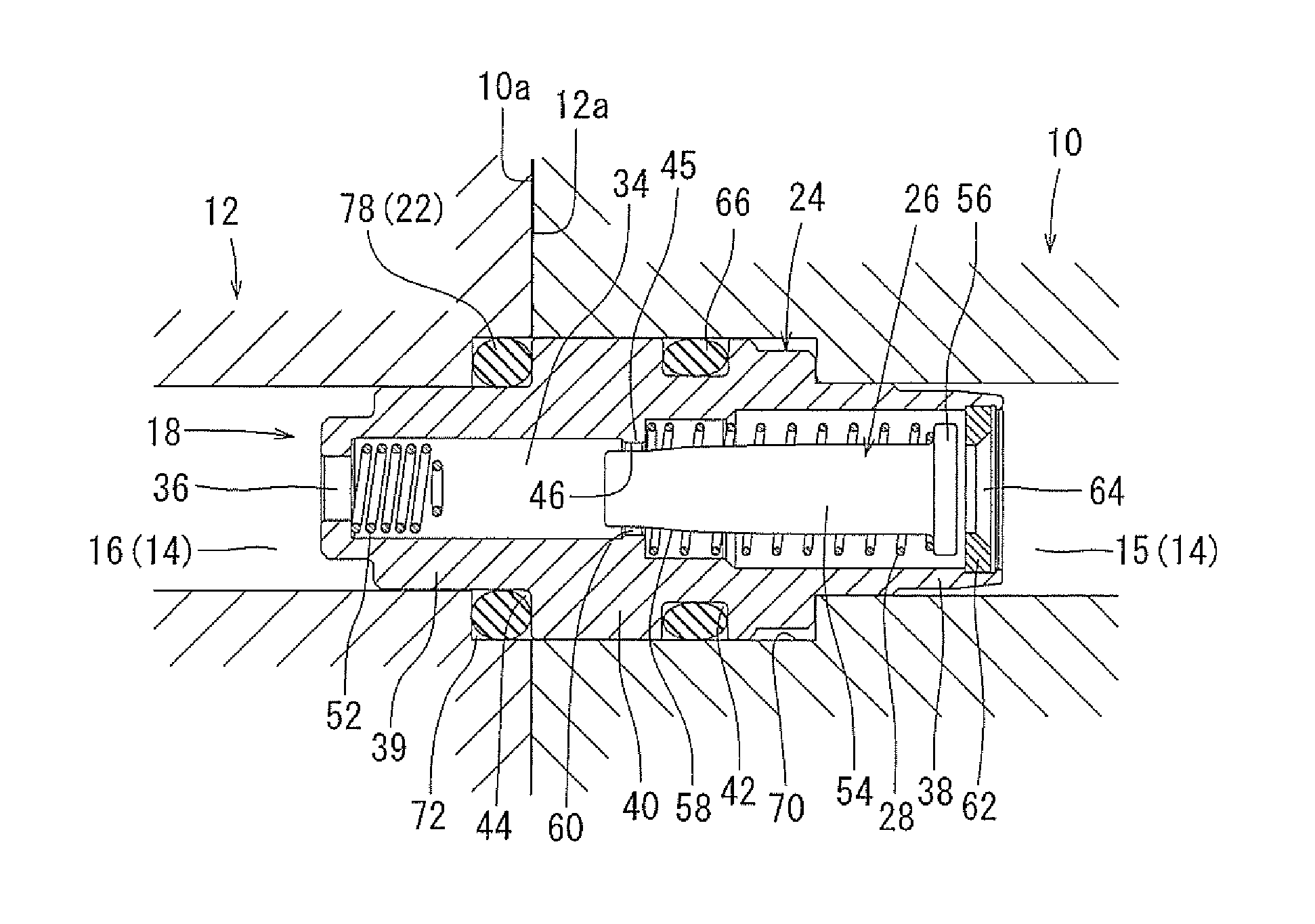

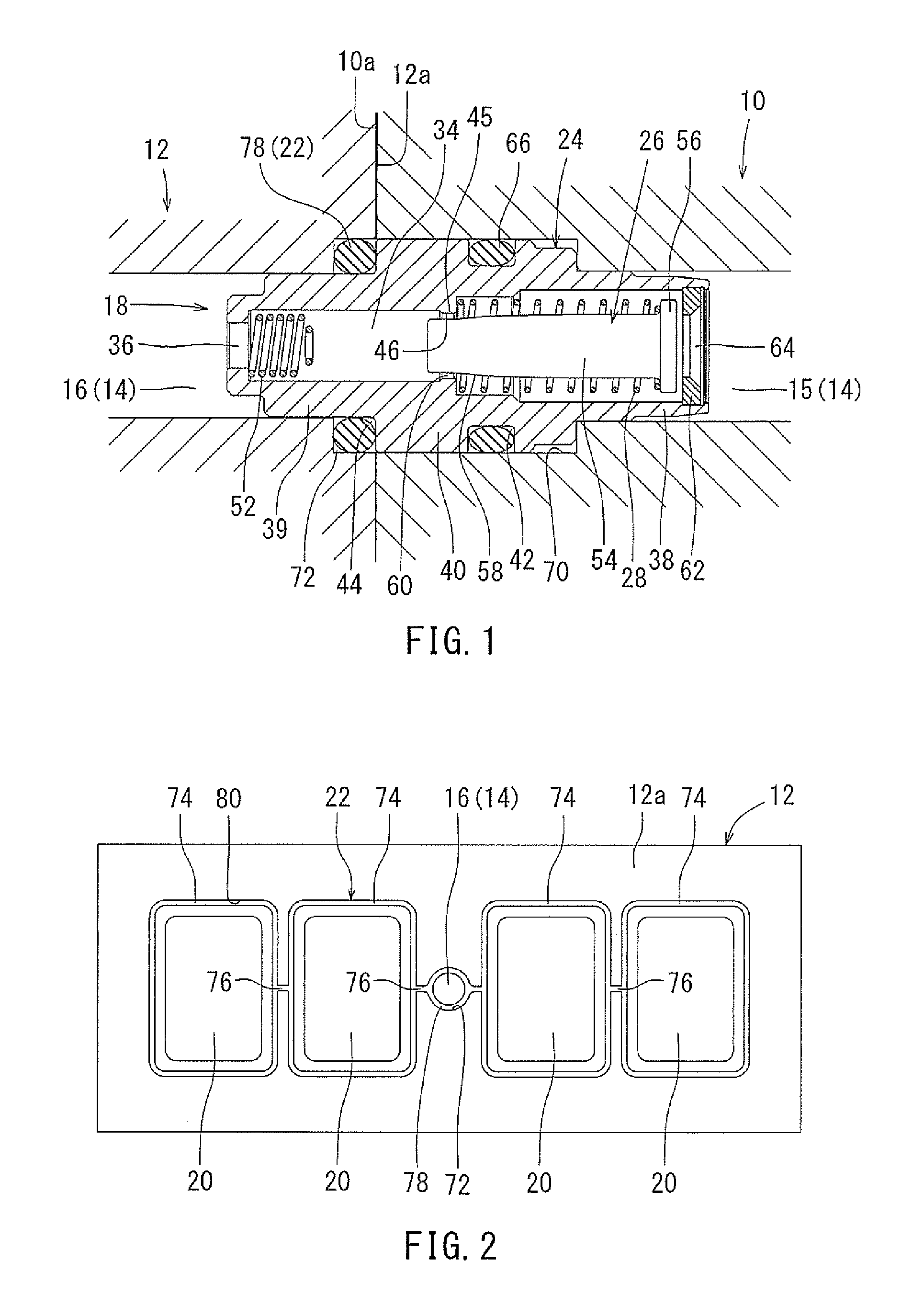

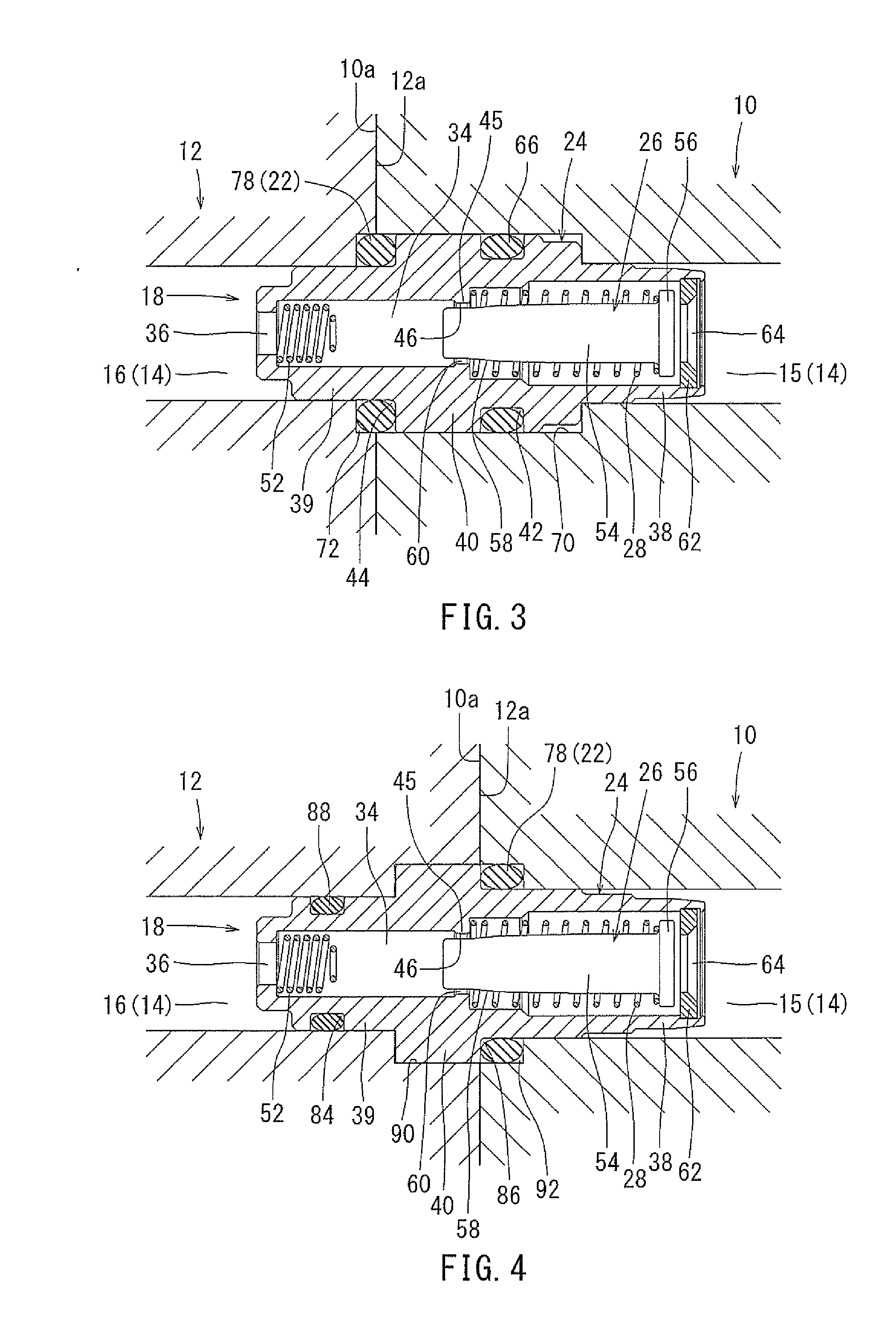

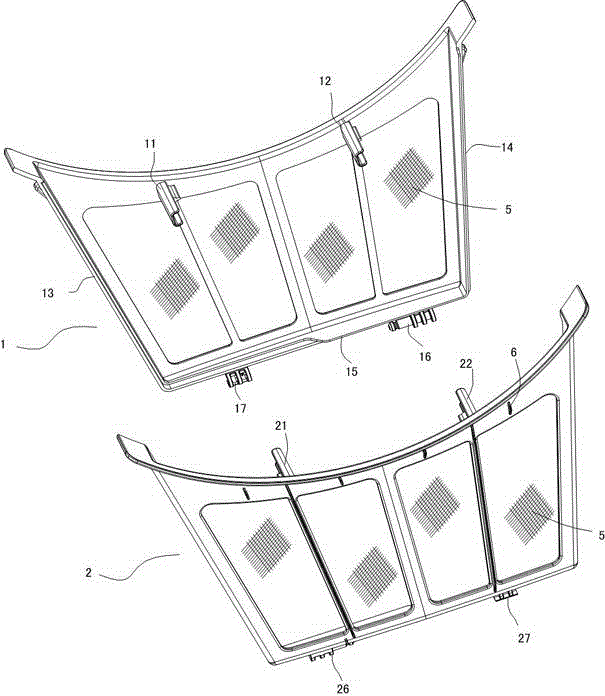

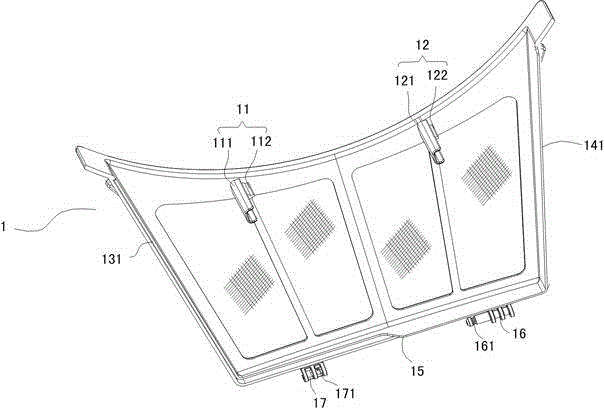

Function-restorable assembly type end plate connection joint connection device

ActiveCN105863051AEasy and fast fastening workImprove control accuracyProtective buildings/sheltersShock proofingWeld seamCantilever

The invention relates to a function-restorable assembly type end plate connection joint connection device and belongs to the field of structural engineering. The function-restorable assembly type end plate connection joint connection device is composed of a round steel pipe column with a cantilever beam section, a common beam section and a connecting device between the round steel pipe column with the cantilever beam section and the common beam section. Welded parts of the joint connection device are finished in a factory; weld seam accuracy and quality of the welded parts are easier to control; the round steel pipe column with the cantilever beam section and the common beam section are assembled only through high-strength bolts, connecting plates and Pi-shaped connecting members on site; and accordingly, the construction speed and construction quality are greatly improved. Meanwhile, the common beam section can be built on the lower connecting plate of the round steel pipe column with the cantilever beam section, so that the hoisting difficulty is lowered, and on-site assembly and positioning are easy. A joint of the joint connection device is a beam-end reinforcement and cover plate connecting weakening combined joint; through reasonable design, double energy dissipation of bolt friction slippage and connecting plate and bolt plastic deformation can be achieved, and fast restoring after an earthquake can be also achieved; and the joint ductility is good, and the energy-dissipating capacity and bearing capacity are high.

Owner:BEIJING UNIV OF TECH

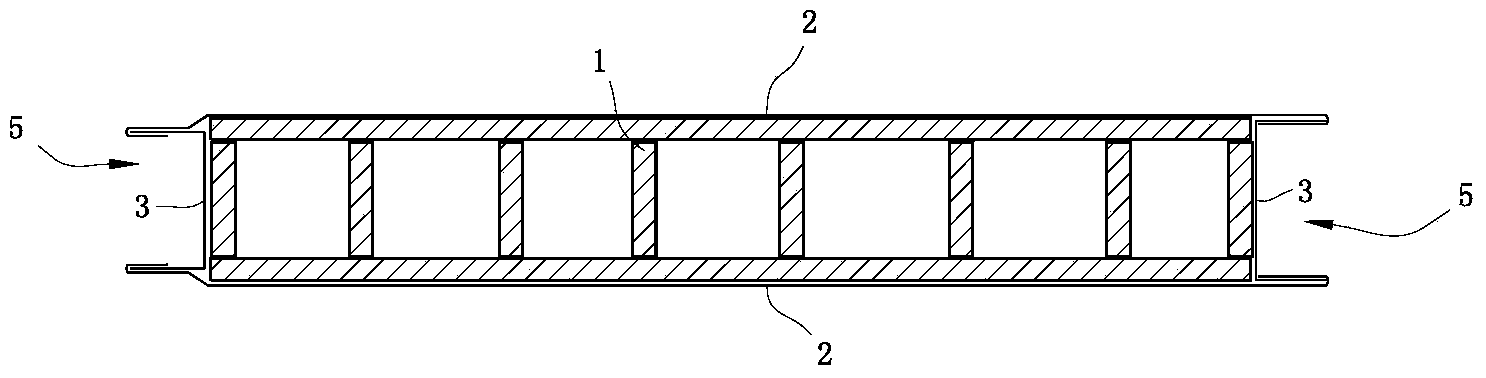

Strong-strength machine-made handmade sandwich board

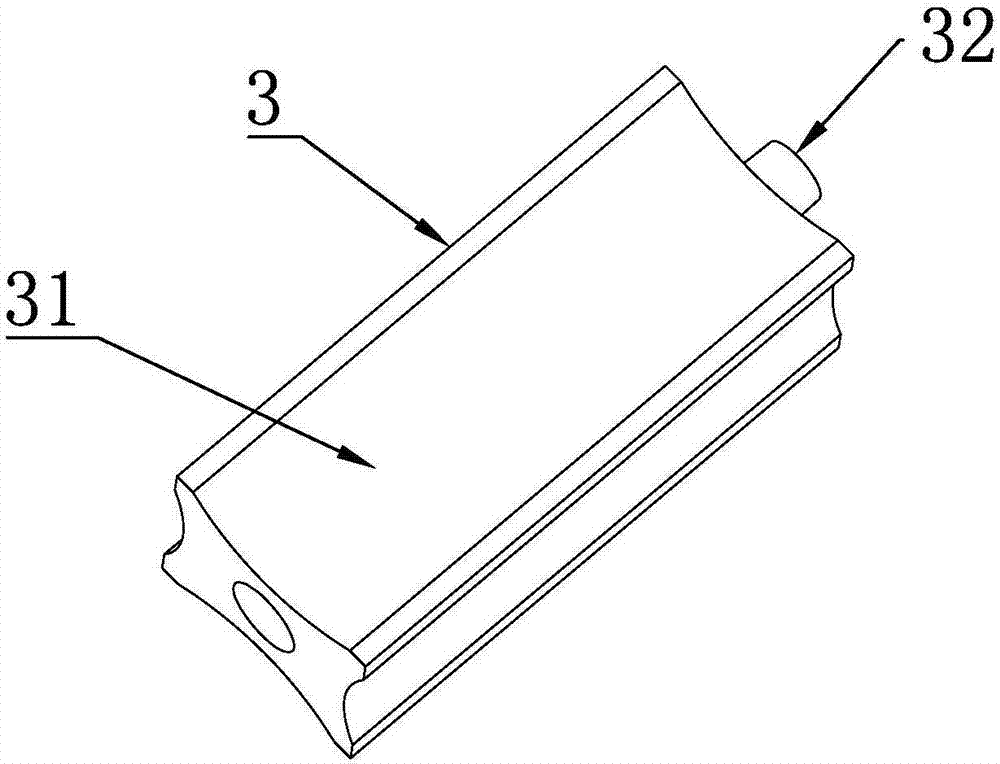

InactiveCN104234354AHigh strengthGet rid of dependenceCovering/liningsSandwich boardTongue and groove

The invention discloses a strong-strength machine-made handmade sandwich board, which comprises a sandwich core material and panels covering the surfaces of the two sides of the sandwich core material, wherein side plates with U-shaped sections are arranged at the left and right side ends of the sandwich core material respectively; the longitudinal edge ends of the two panels extend and are folded to be connected with the side plates in a rolling way to form male and female tongues and grooves at the left and right ends of the sandwich core material; reinforced connecting bands are also arranged at the upper and lower side ends of the sandwich core material; groove structures or tenon structures are formed on the middle parts of the reinforced connecting bands, are connected with the sandwich core material in an embedding way, and are closely connected with the panels to strengthen the transverse strength of the board. According to the color steel sandwich board, transversely adjacent color steel sandwich boards are spliced and matched by virtue of the male and female tongues and grooves at the left and right ends of the sandwich core materials; the reinforced connecting bands are also arranged at the upper and lower ends of the sandwich core material, the strength of the board is strengthened by the reinforced connecting bands, and meanwhile, the groove structures or the tenon structures of the reinforced connecting bands can be used for connecting longitudinally adjacent color steel sandwich boards in a matched way to ensure convenient and rapid assembly positioning.

Owner:GUANGZHOU COBORN AIR CLEANING TECH CO LTD

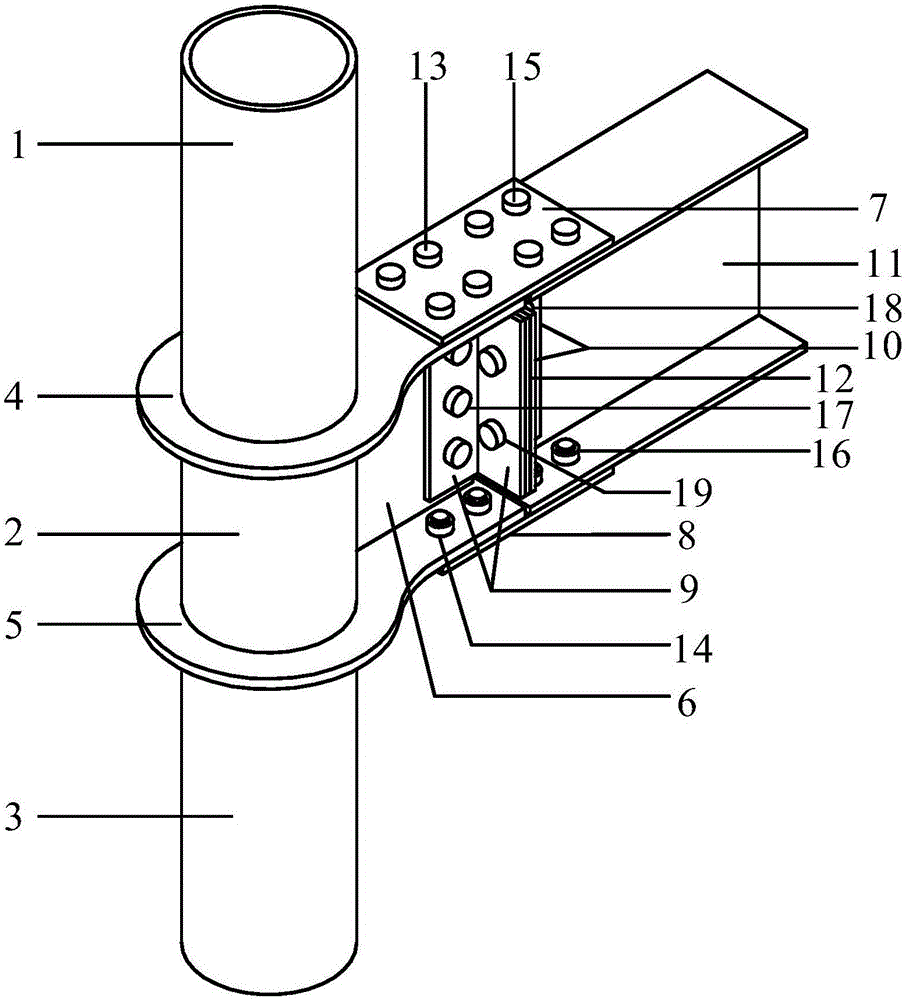

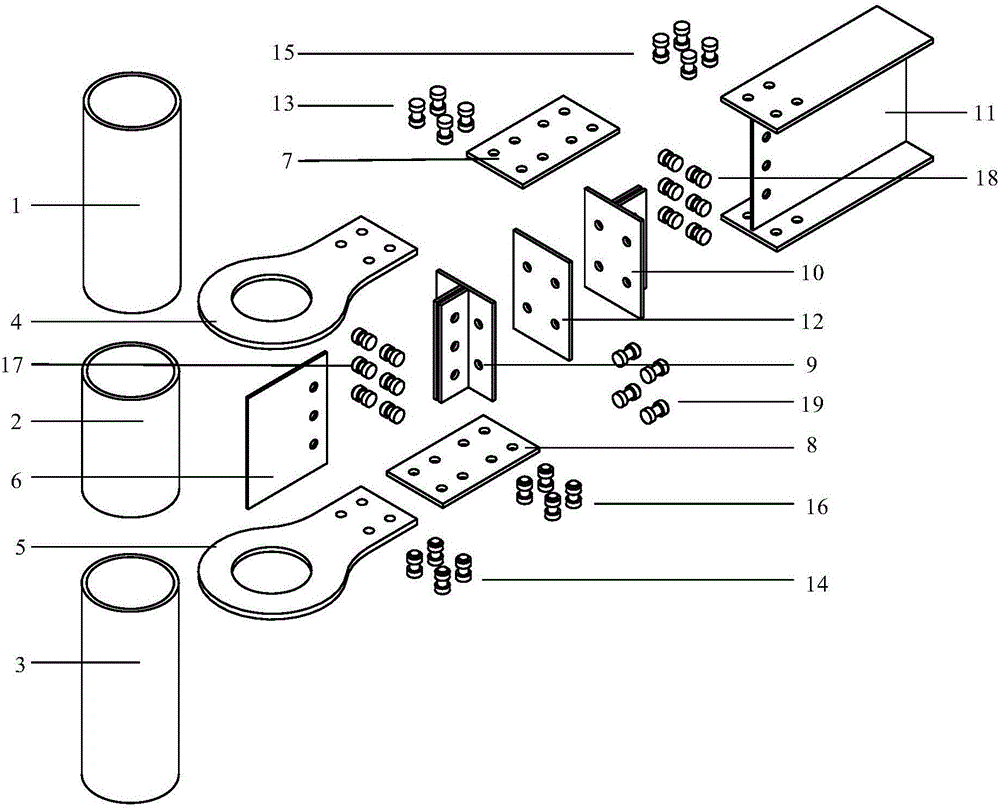

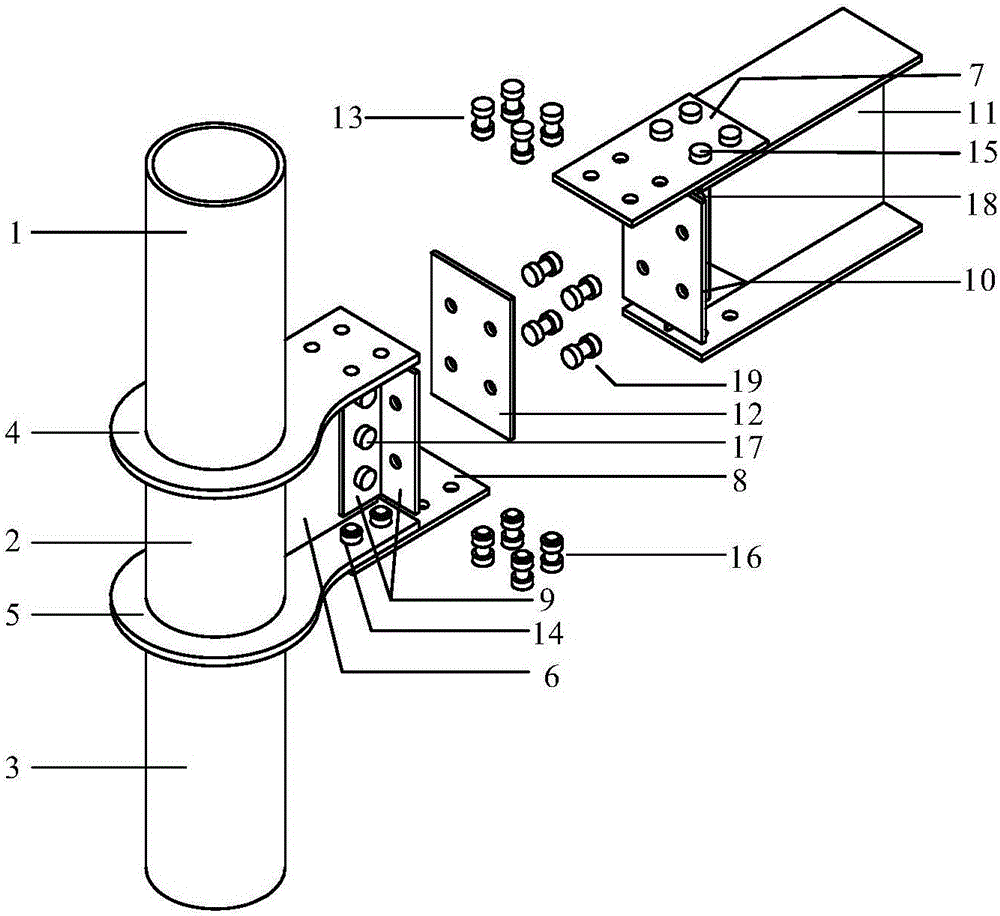

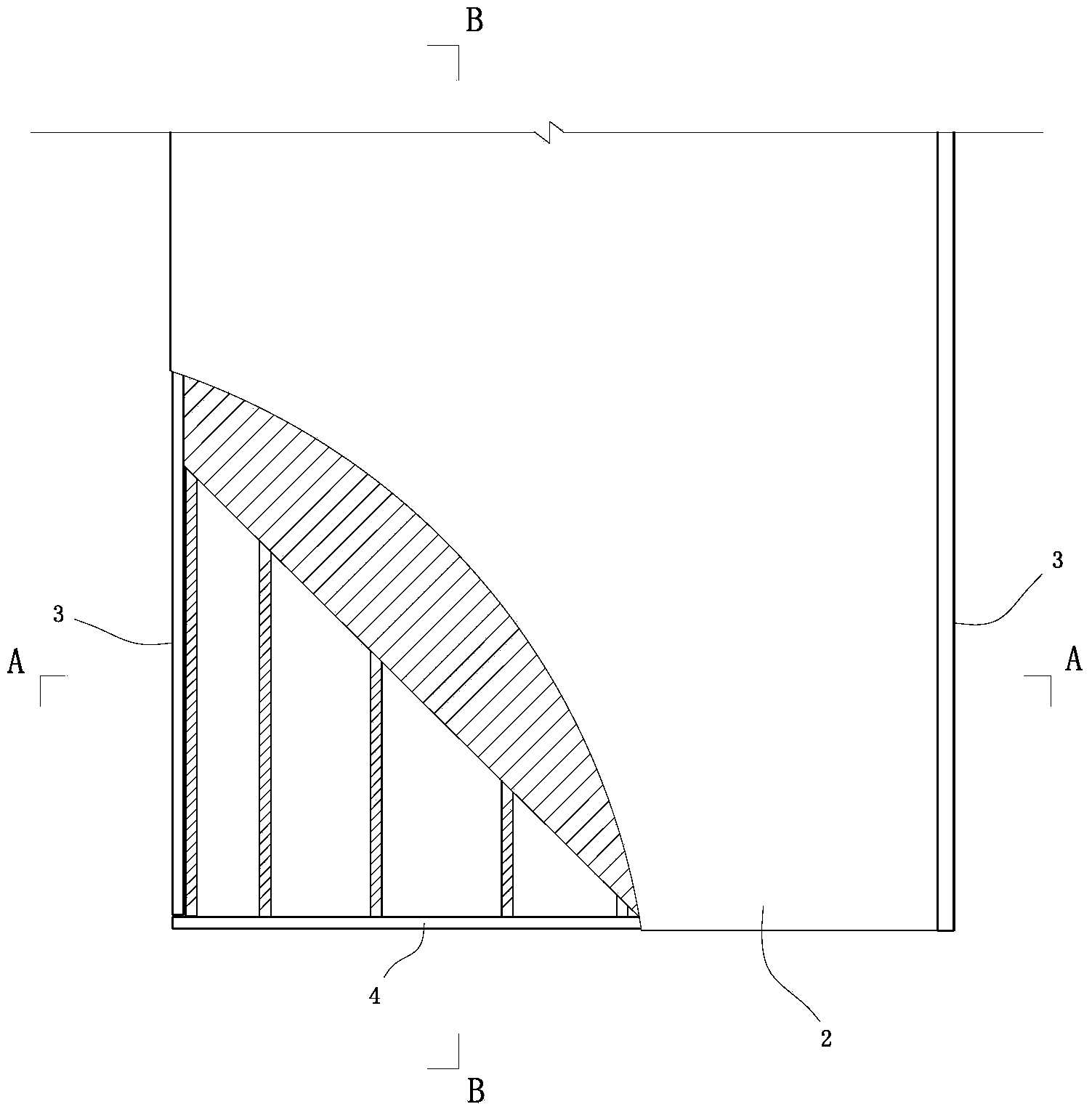

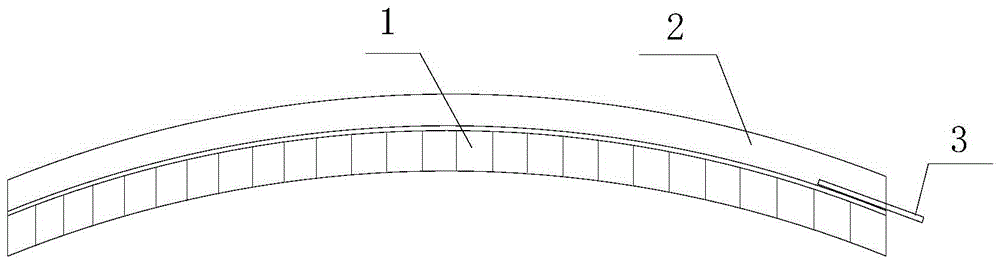

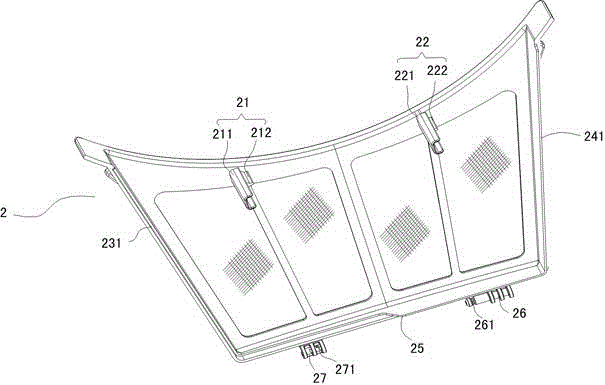

Cover plate weakening type assembly type wave web beam-column joint connection device

ActiveCN105863075AEasy and fast fastening workImprove control accuracyShock proofingShaped beamArchitectural engineering

The invention relates to a cover plate weakening type assembly type wave web beam-column joint connection device and belongs to the field of structural engineering. The assembly type wave web beam-column joint connection device is composed of a round steel pipe column with a cantilever beam section, a wave web I-shaped beam section and a connecting device between the round steel pipe column with the cantilever beam section and the wave web I-shaped beam section. Welded parts of the joint connection device are finished in a factory; weld seam accuracy and quality of the welded parts are easier to control; the round steel pipe column with the cantilever beam section and the wave web I-shaped beam section are assembled only through high-strength bolts and connecting plates on site; the fastening work of the bolts is convenient and fast; and the construction speed and construction quality are greatly improved. Meanwhile, the wave web I-shaped beam section can be built on the lower connecting plate of the round steel pipe column with the cantilever beam section, so that the construction difficulty is lowered, and on-site assembly and positioning are easy. A joint of the joint connection device is a beam-end reinforcement and dog-bone weakening combined joint; through reasonable design, double energy dissipation of bolt friction slippage and connecting plate and bolt plastic deformation can be achieved; and the joint ductility is good, and the energy-dissipating capacity and bearing capacity are high.

Owner:BEIJING UNIV OF TECH

Method for machining universal joint bearing

ActiveCN102562777AImprove pass rateEasy for mass production applicationsPivotal connectionsUniversal jointEngineering

The invention discloses a method for machining a universal joint bearing. The method comprises the following steps of: machining a spherical head rod and an outer ring, wherein the outer ring is provided with an elastic mounting groove and a splitting hole which are communicated and penetrate through the outer ring along an axial line of the mounting groove; mounting a tool in the mounting groove, wherein the tool is provided with an outer spherical surface and a through slot penetrating through an axial line of the tool, and parameters of the outer spherical surface and parameters of the mounting groove of the outer ring are matched; mounting the tool and the outer ring on a machining device in a connecting manner after a connection shaft penetrates through the through slot; carrying out finish machining on the outer side surface of the outer ring through a machining device; splitting the outer ring and the tool through the splitting hole of the outer ring; and mounting the spherical head rod and the outer ring. The method for machining the universal joint bearing, disclosed by the invention, has the following advantages that the machining precision of the outer side surface of the outer ring, which is provided with the spherical head rod, is good and the yield of the universal joint bearing can be increased.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

Ozone microbubble catalytic oxidation device and application thereof

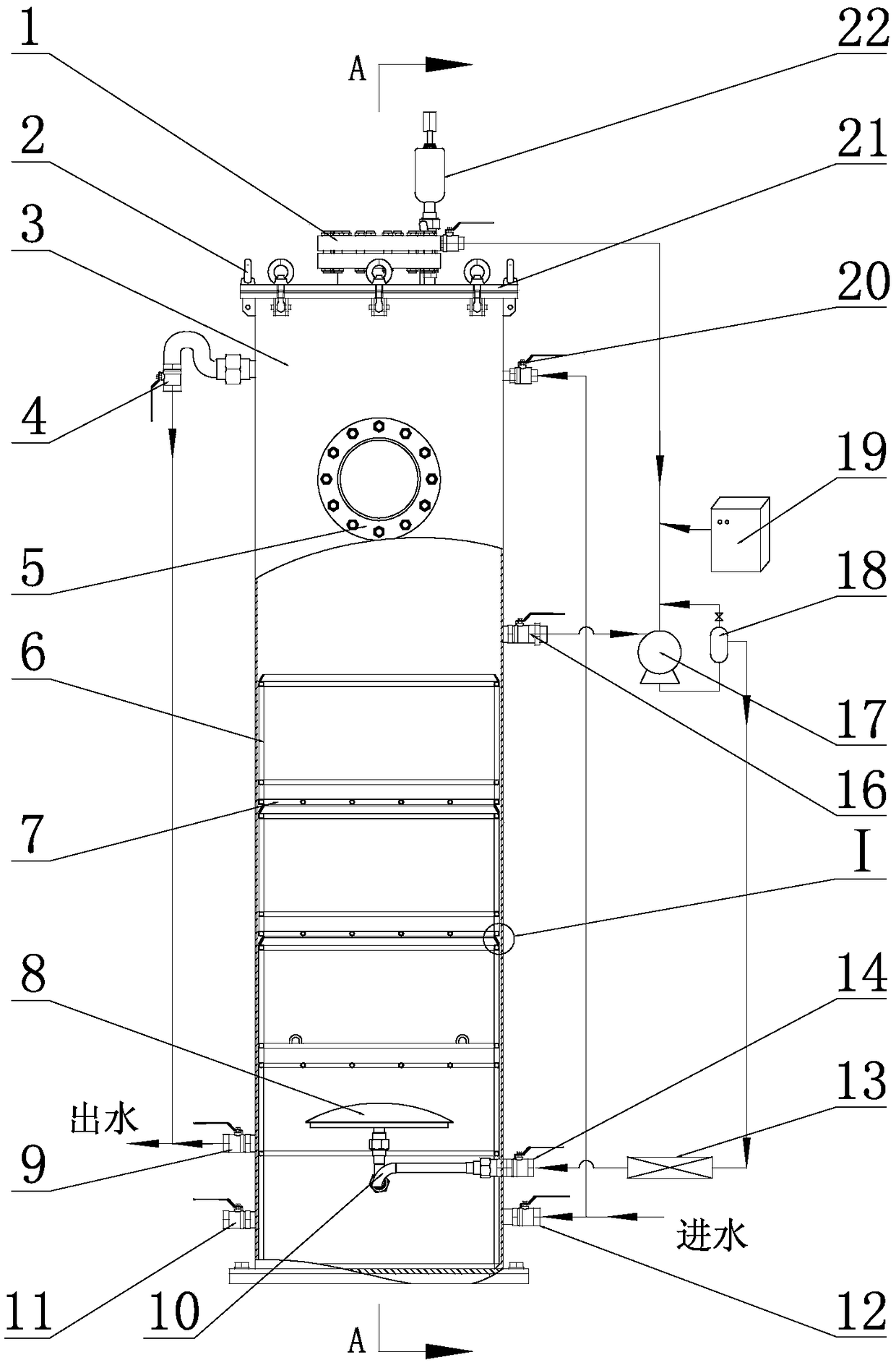

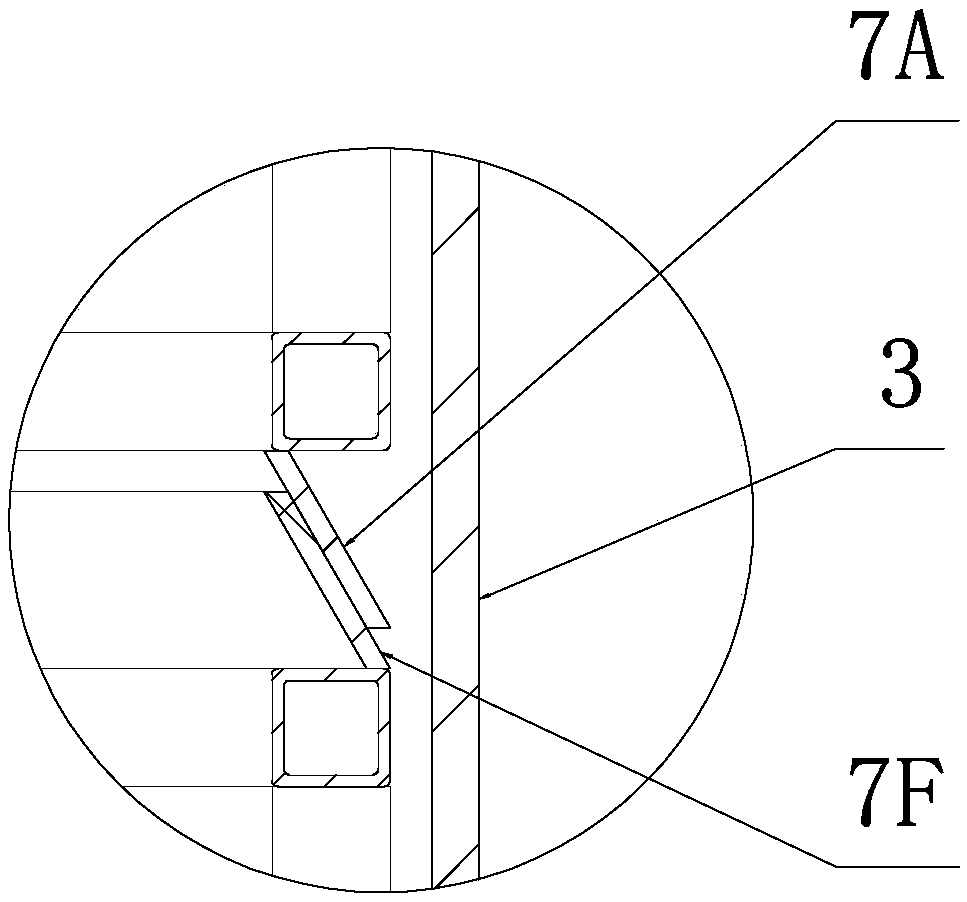

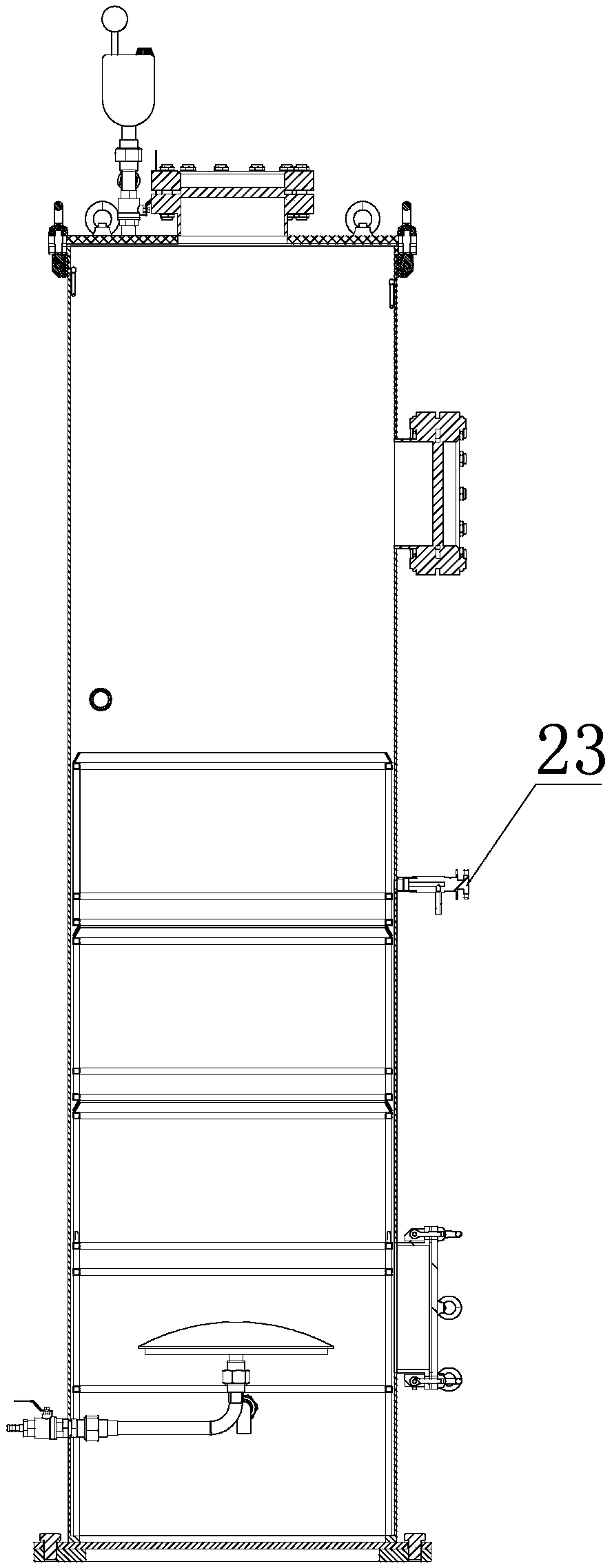

PendingCN108689481ACompact structureEasy to disassemble and repairWater/sewage treatment apparatusWater/sewage treatment by oxidationOzone generatorsSewage treatment

The invention belongs to sewage treatment in environmental protection engineering, and in particular, relates to an ozone microbubble catalytic oxidation device and an application thereof. The ozone micro-bubble catalytic oxidation device comprises a tower body, an ozone generator and a catalytic unit. The tower body is equipped with water inlets and water outlets. The water inlets include an upper water inlet arranged at the upper part of the side wall of the tower body and a lower water inlet arranged at the lower part of the side wall of the tower body, the water outlets include an upper water outlet arranged at the upper part of the side wall of the tower body and a lower water outlet arranged at the lower part of the side wall of the tower body. The ozone generator conveys a gas-liquid mixture to a microbubble generator through a gas-liquid mixing pump, and the output end of the microbubble generator is connected with an inlet of a circulating pipeline of the microbubble generatorbelow the tower body; the catalytic unit adopts at least two layers of catalyst boxes in longitudinal interval and horizontal arrangement, the catalyst boxes are arranged in the tower body through brackets, and an outlet, arranged on the side wall of the tower body above the catalytic unit, of the circulating pipeline of the microbubble generator is connected with the gas-liquid mixing pump. Thetechnical problem of low ozone utilization rate of the prior art is effectively solved, and the ozone microbubble catalytic oxidation device has the advantages of compact structure, high ozone utilization rate and the like.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

Positive crankcase ventilation ("PCV") valve mounting structure

ActiveUS20160123199A1Lower control costsMinimize the numberCombustion enginesCrankcase ventillationCylinder headCrankcase

A positive crankcase ventilation (PCV) valve mounting structure has a blow-by gas passage with an upstream-side passage portion and a down-stream-side passage portion positioned in a cylinder head and an intake manifold, respectively. The blow-by gas passage may receive the PCV valve therein such that an upstream side portion of a valve case of the PCV valve is positioned within the upstream-side passage portion and that a downstream side portion of the valve case is positioned within the down-stream-side passage portion when the cylinder head and the intake manifold are joined together. A gasket may seal the cylinder head to the intake manifold and may include a seal portion positioned between the valve case of the PCV valve and at lest one of the cylinder head and the intake manifold.

Owner:AISAN IND CO LTD

Transformer iron core capable of improving assembly efficiency

ActiveCN104810140AImprove product qualityReduce lossesTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The invention relates to a transformer iron core capable of improving the assembly efficiency. The transformer iron core comprises one or more sequentially overlaid laminated layers, wherein each of the overlaid laminated layers comprises upper yoke laminates, lower yoke laminates, middle pillar laminates and side pillar laminates on two sides which are the same in number of laminates; the upper yoke laminates comprise one or more than one upper yoke piece, a triangular notch is formed in the middle section of the upper yoke piece, and the triangular notch on each upper yoke piece is longitudinally misplaced and stepped along the central line of the triangle; the left side end edge of each upper yoke piece is transversely misplaced and is longitudinally overlapped with the side pillar laminate and the middle pillar piece to step; the upper and lower ends of each of the middle pillar pieces of the middle pillar laminate respectively form triangular parts and are longitudinally misplaced and stepped; the upper and lower end edges of the side pillar piece of the side pillar laminate on each side obliquely extend and are longitudinally misplaced and longitudinally overlapped with the upper and lower yoke pieces to step; process holes convenient for assembling and positioning are formed on the upper and lower yoke pieces, the middle pillar pieces and side pillar pieces. The transformer iron core provided by the invention is simple to operate and convenient to assemble, the assembly efficiency is improved and the labor cost is lowered.

Owner:DONGGUAN GUANGHUA IND

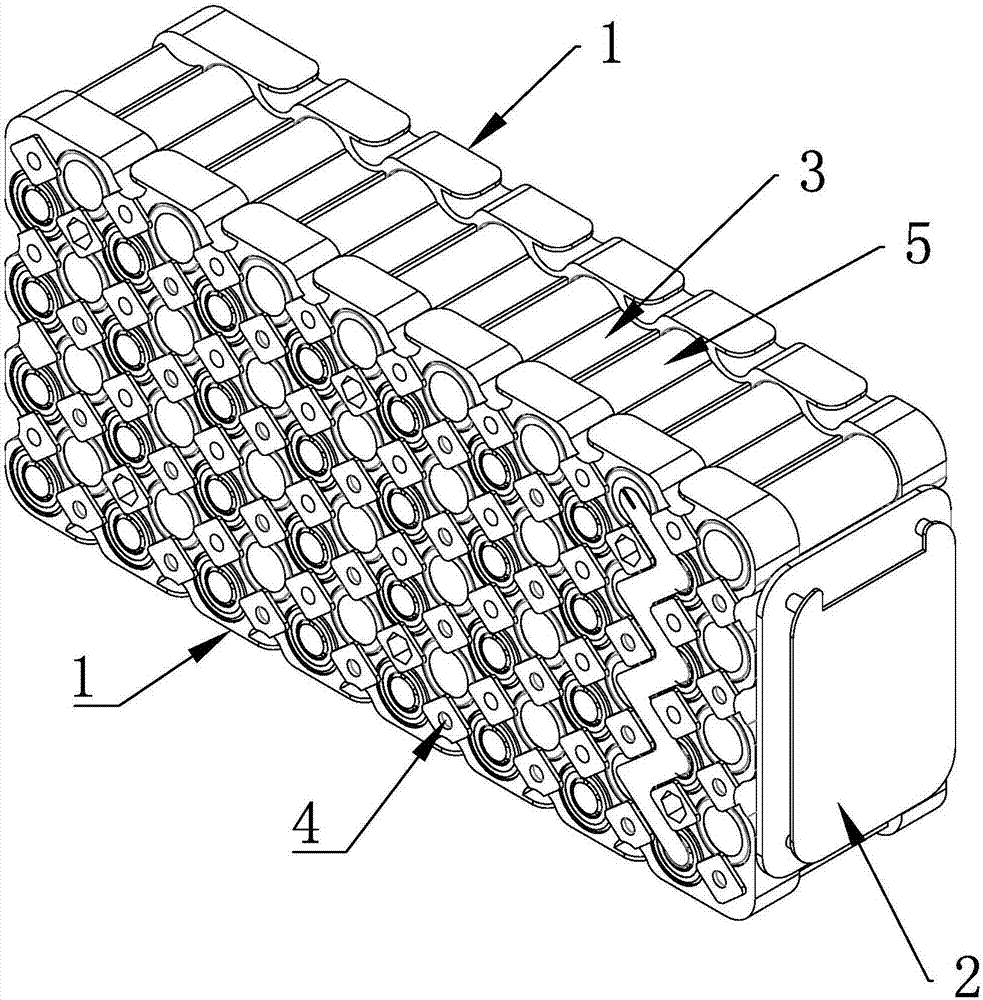

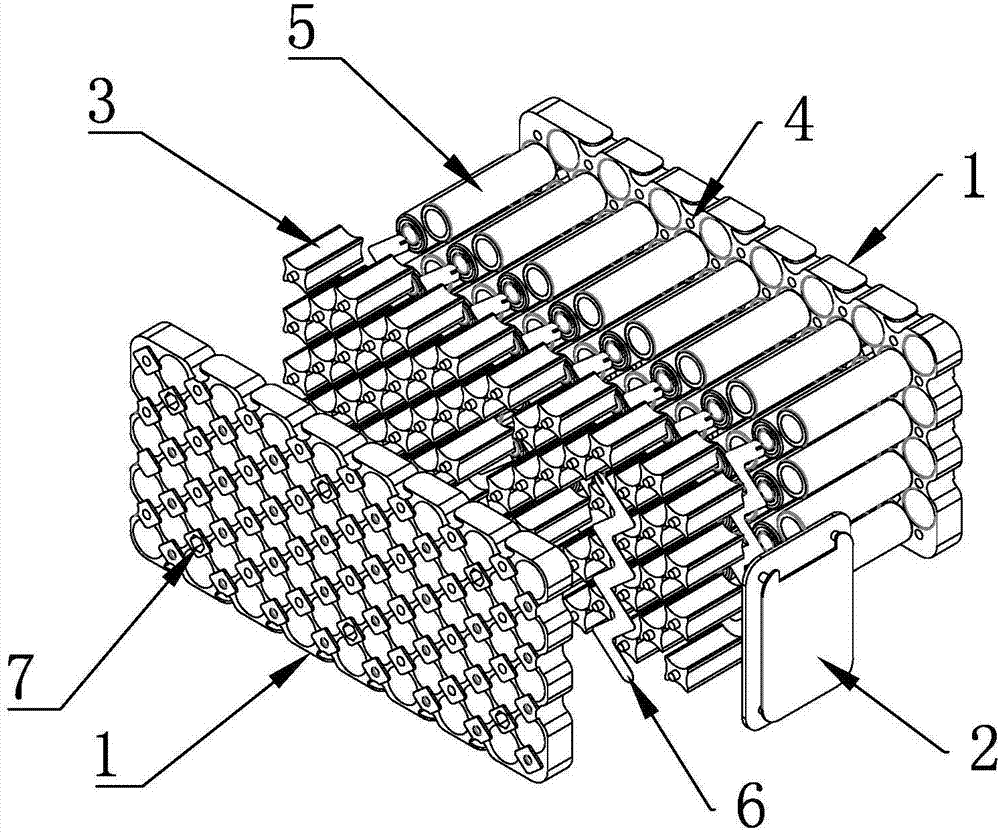

Assembly structure for management of transformation heat of bicycle lithium battery

ActiveCN107017447ASmall temperature differenceReduce charge and discharge temperature riseSecondary cellsCell component detailsHeat conductingEngineering

The invention relates to an assembly structure for management of transformation heat of a bicycle lithium battery, which comprises two pairs of plastic supports of which inner surfaces are correspond to each other, a plurality of battery cells which are roughly parallel to each other and clamped between the two plastic supports, and a plurality of transformation heat conducting columns which are inserted in gaps of adjacent battery cells. In the scheme of the invention, heat generated by the charging and discharging process of the battery cells is directly absorbed and stored by the transformation heat conducting columns; heat absorbed by the transformation heat conducting columns is transmitted to the external environment in the process of temperature rising of the transformation heat conducting columns, so that the temperature of the battery cells and the possibility of temperature aggregation inside a battery pack are both reduced.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

Brazing method for high-temperature alloy assembly of aero-engine

InactiveCN105478945AGuaranteed Brazing RequirementsEasy to processSoldering apparatusTurbineFiller metal

The invention provides a brazing method for a high-temperature alloy assembly of an aero-engine. The method comprises the first step of cleaning, the second step of brazing filler metal filling, the third step of first-time brazing, the fourth step of machining, the fifth step of second-time brazing and the sixth step of machining finishing. The two-time brazing technology is adopted, the requirement for brazing of high and low-pressure turbine outer ring fan-shaped section assemblies is guaranteed, and the brazing deformation is small; and meanwhile component machining is convenient, component brazing is good, component assembling and positioning are convenient, and the brazing quality of engine components is guaranteed.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Ship metal hose welding support device convenient to weld and position

InactiveCN110900101AEasy alignmentPrevent rotationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMarine engineering

The invention discloses a ship metal hose welding support device convenient to weld and position. The ship metal hose welding support device includes a bottom plate, balls, a connecting plate and a hose body, a fixing plate is fixedly installed on the top surface of the right end of the bottom plate, the inside of the fixing plate is provided with a first storage slot, a pull rod is installed inside the fixing plate, the pull rod passes through the top surface of the fixing plate, the fixing plate is connected to a rotating shaft through the balls, the rotating shaft penetrates through the left surface of the fixing plate to be fixedly connected to a circular plate, a first lead screw is mounted on the circular plate, the first lead screw penetrates the circular plate, and a slider is installed on the outer surface of the first lead screw. By means of the ship metal hose welding support device convenient to weld and position, the circular plate rotates through rotation of the rotatingshaft on the fixing plate, meanwhile, the rotating shaft can be positioned through clamped connection of a limiting shaft and a limiting hole, the phenomenon that the rotating shaft rotates by itselfis avoided, and the stability of subsequent welding work by workers is facilitated.

Owner:王冬暄

LT type elastic sleeve pin coupling

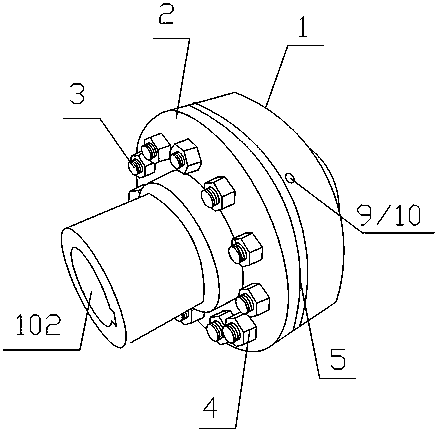

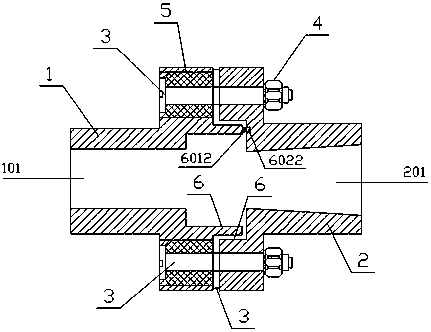

InactiveCN110094431AImprove shock resistanceMeet shockproof requirementsYielding couplingLeft halfCoupling

The invention discloses an LT type elastic sleeve pin coupling. The coupling includes a left half-coupling, a right half-coupling, multiple fastening pins, multiple fastening nuts and multiple elasticsleeves. A surface where the left half-coupling and the right half-coupling are in contact is provided with a matching positioning device, which facilitates assembly and positioning and effectively solves the problem of wrong mounting. An integral shock absorbing pad is arranged between the left half-coupling and the right half-coupling, A shockproof sleeve and a shockproof washer are arranged onthe positioning device surface, which strengthens the shockproof performance of the coupling. In addition, the connecting surface side of the left half-coupling of the coupling is also provided withan oil filling hole communicating with a shaft hole so as to oil for rust prevention. The LT type elastic sleeve pin coupling has the advantages of simple structure, reasonable arrangement and low manufacturing cost, effectively reduces the wear and rust prevention problem between a coupling shaft and the hole, and has good use value.

Owner:JIANGSU ROKEE HEAVY IND TECH

Front test bed structure of motorcycle shifting fork checking fixture

InactiveCN103033108ARealize detectionShorten the lengthAngles/taper measurementsMechanical thickness measurementsEngineeringControl theory

The invention discloses a front test bed structure of a motorcycle shifting fork checking fixture. The structure is characterized by comprising a lower supporting block, a middle supporting block and an upper supporting block which are sequentially arranged in a stacked mode from bottom to top. The thickness of the middle supporting block is consistent with that of the end portion of the front end of a motorcycle shifting fork arm, and the length of the middle supporting block along the front-back direction of a bottom plate is smaller than that of the upper supporting block and that of the lower supporting block along the front-back direction of the bottom plate so that a detection cavity used for detecting the thickness of the end portion of the motorcycle shifting fork arm is formed in a rear portion position between the upper supporting block and the lower supporting block. The rear portion of the upper supporting block is further provided with a shifting fork concave portion detection block installation hole. The structure achieves test and locating of the front end concave portion and the fork arm of the shifting fork for two times, achieves test of a plurality of parameters of the shifting fork through match with a rear test bed, and has the advantages of being convenient to process and manufacture, capable of improving processing efficiency and saving processing materials, convenient to assemble and locate, compact and small in structure, and the like.

Owner:力帆科技(集团)股份有限公司

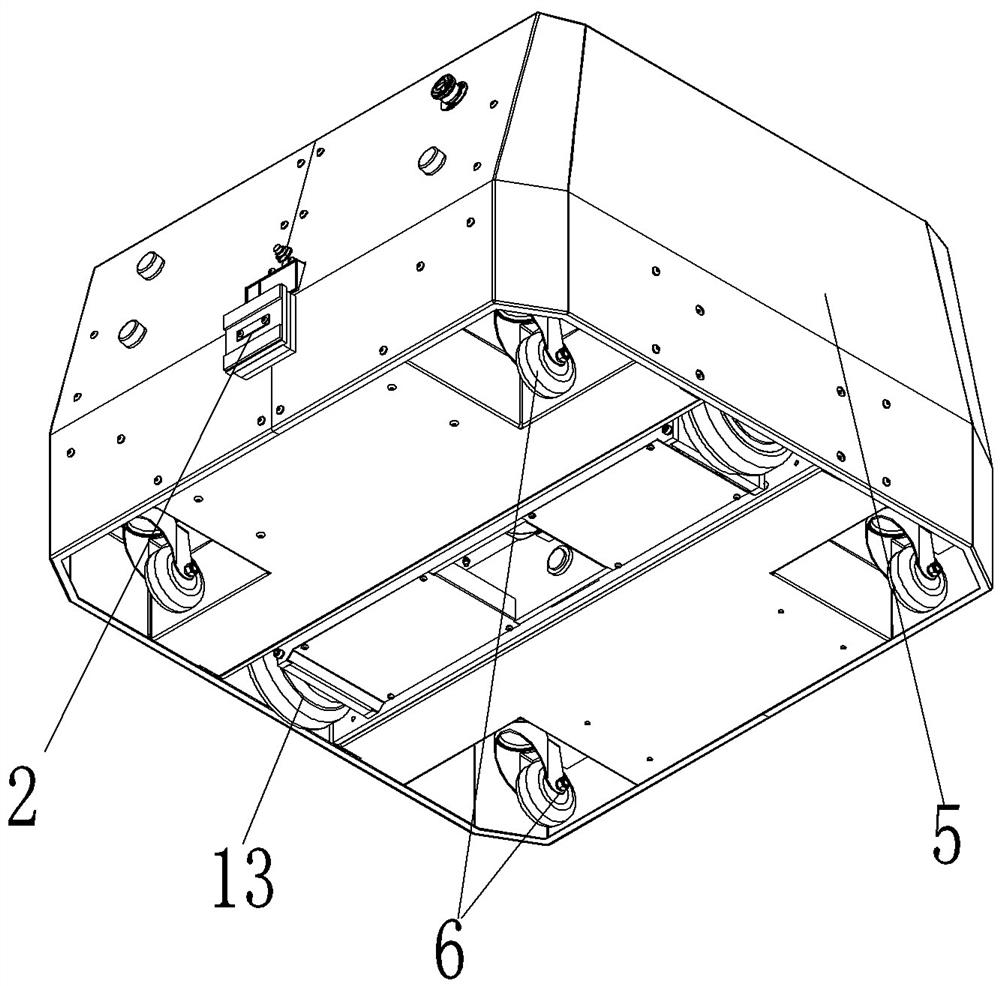

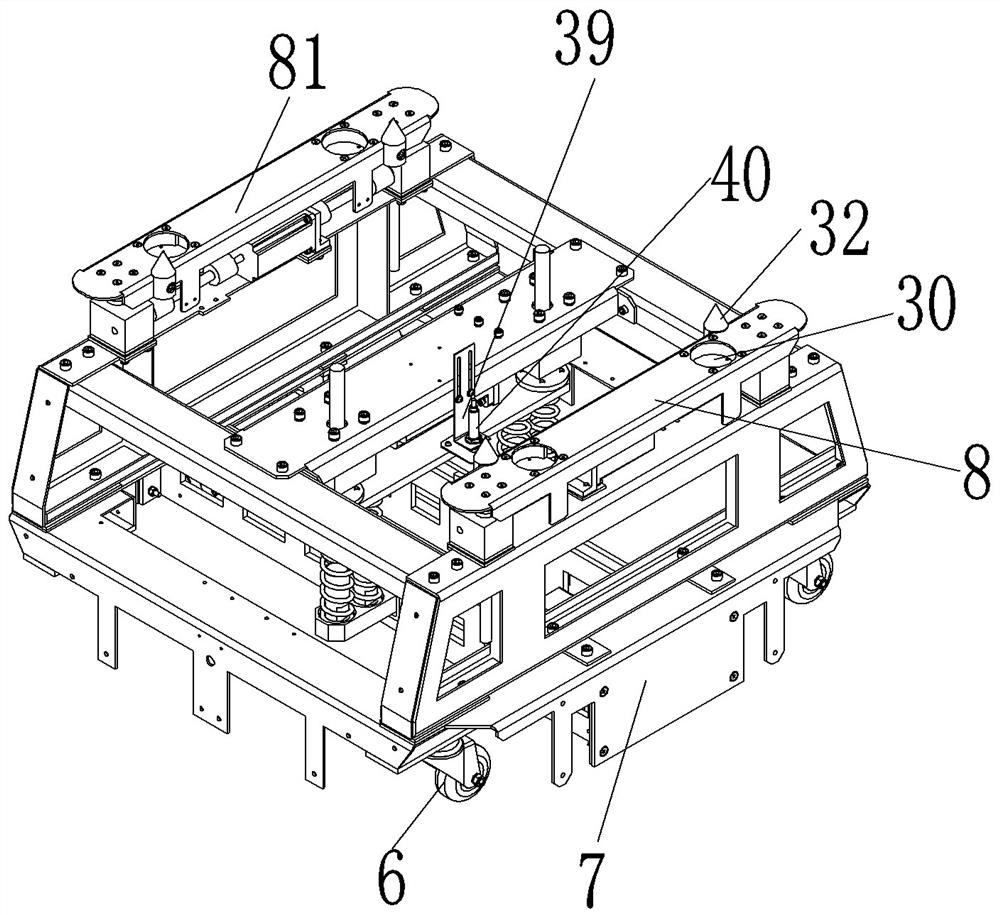

Automatic guide trolley

ActiveCN111674490AGuaranteed ground pressureEasy to support independentlyVehiclesDrive wheelStructural engineering

Owner:YUNNAN ZHUOPEI TECH

Lead wire cover and mounting method thereof

ActiveCN105207399AAvoid problems with operating space constraintsEasy to assemble and locateSupports/enclosures/casingsUltimate tensile strengthElectrical and Electronics engineering

Owner:GREE ELECTRIC APPLIANCES INC +1

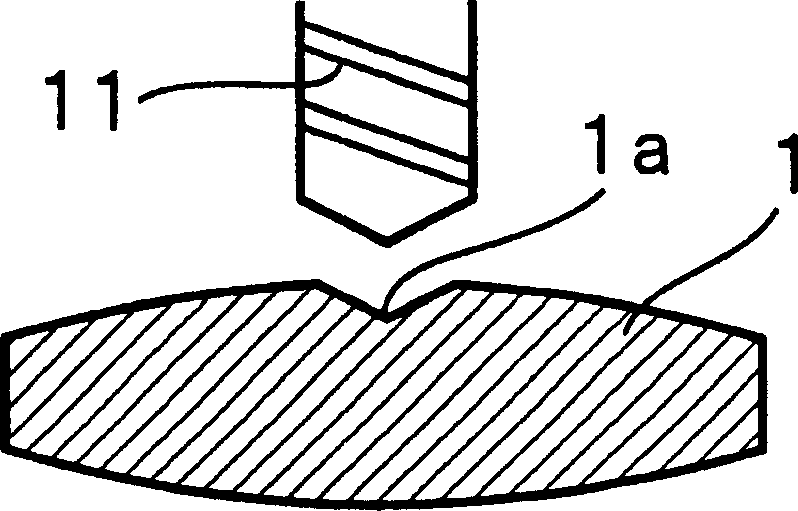

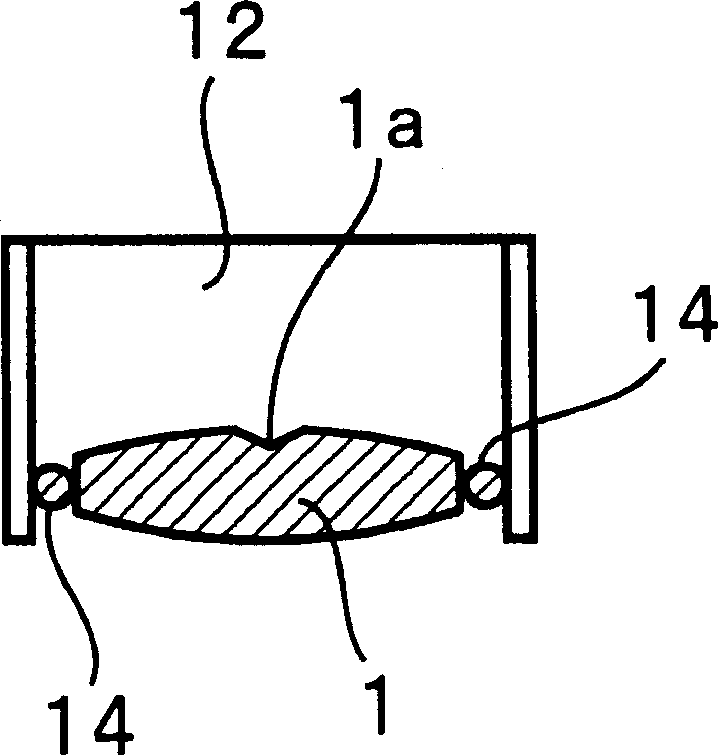

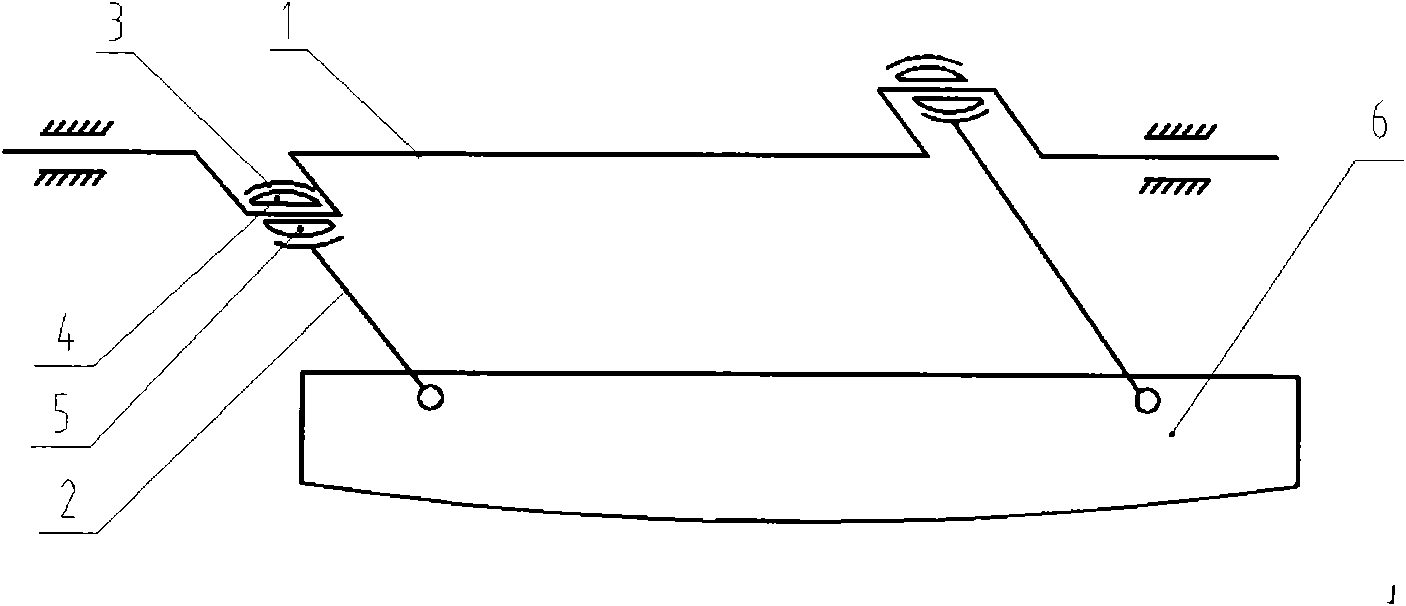

Optical element, optical system and manufacture method thereof, optical device

InactiveCN1825141AEasy to locate and assembleEasy to set upOptical articlesMountingsRefractive indexEngineering

An optical element has a marker provided in the form of an optical fault at a predetermined location in the effective optical area thereof for positioning. The optical fault is a marker 1a provided at a specific location on the effective optical area of the optical element 1 preferably in the form of a projection, a recess, a tinted portion, a different refraction portion, an air bubble, or a particle on or in the optical element 1 . More preferably, the marker 1a is located at or around the center of the optical element 1 and its area size is not greater than 0.4% of the effective optical area of the lens 1.

Owner:SANYO ELECTRIC CO LTD

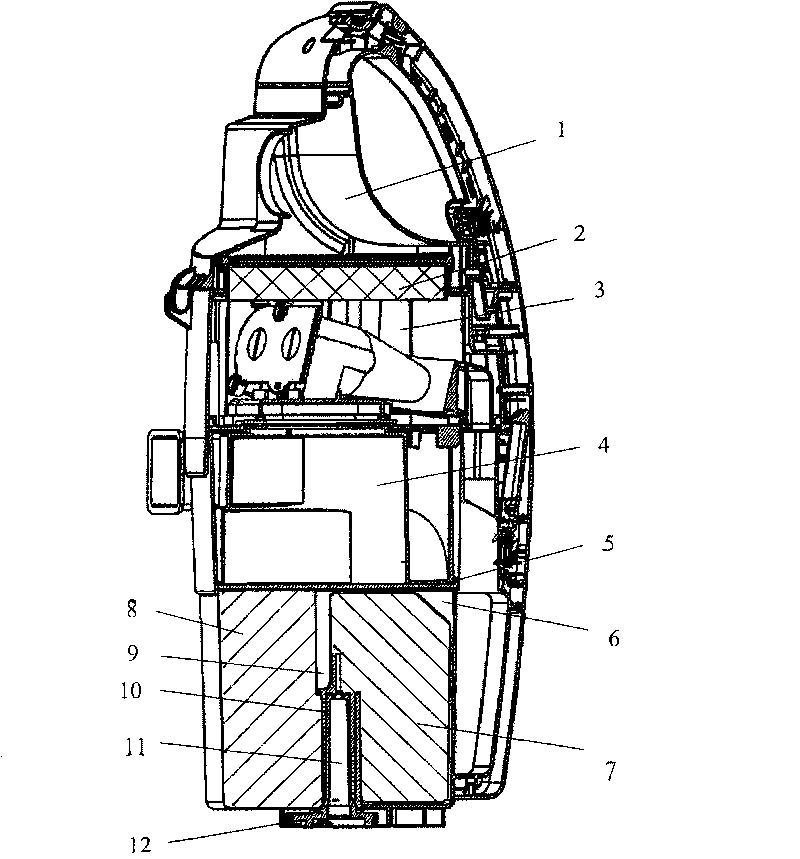

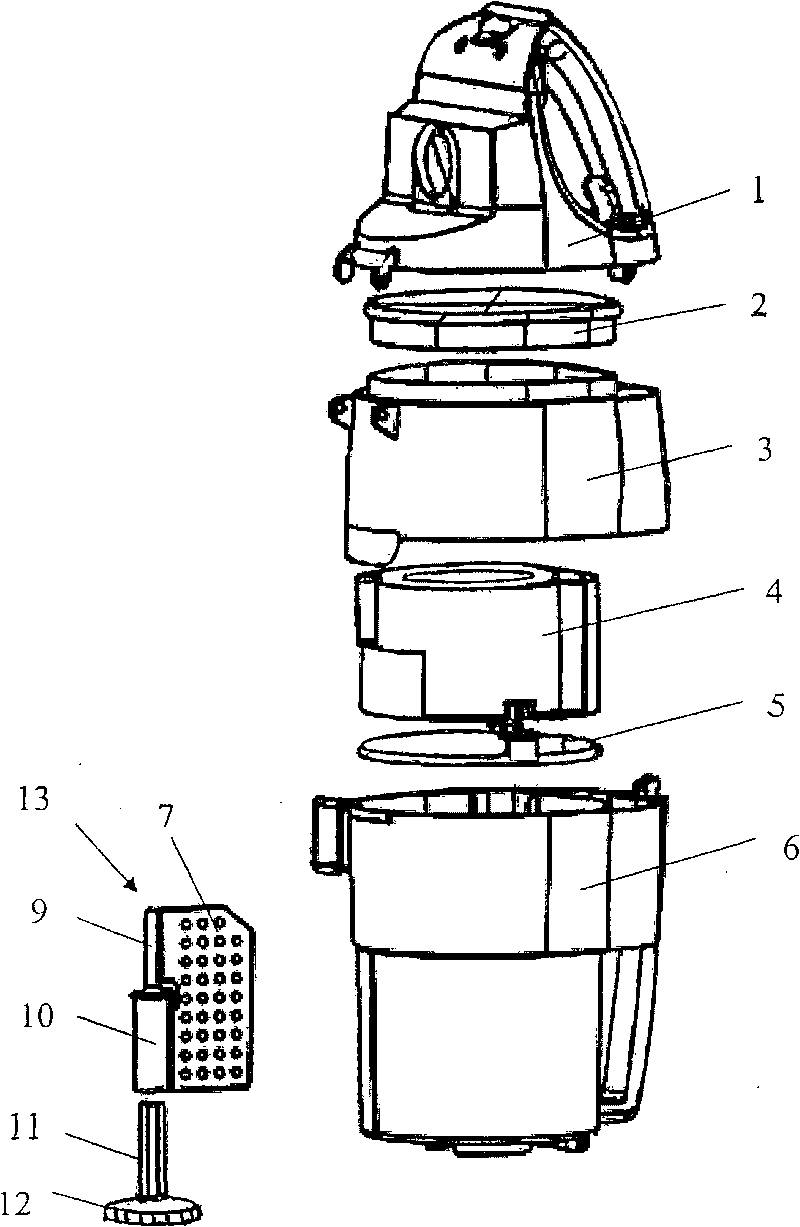

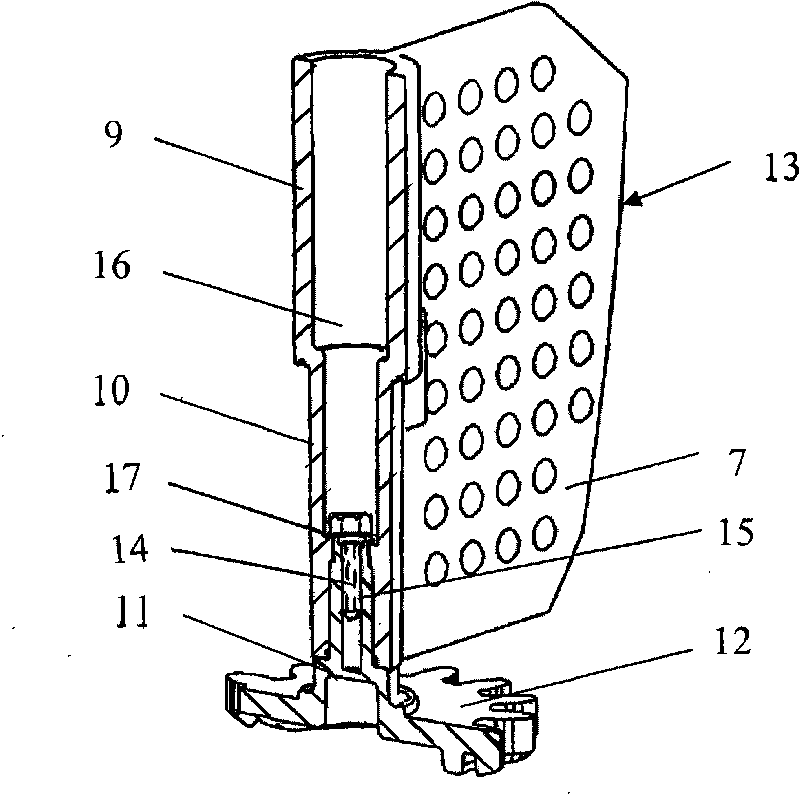

Compression plate connecting structure of dust-connecting bucket component

The invention discloses a compression plate connecting structure of a dust-collecting bucket component, comprising a compression plate, and an upright column which is fixedly connected with one side of the compression plate; a connecting shaft with a polygon hole, which is connected with the lower end of the upright column; a polyhedron gear shaft whose lower end is provided with a gear, which is matchedly connected with the polygon hole of the connecting shaft; a screw, which connects the upright column and the gear shaft; the upper end of the upright column is closed, the inside of the lower end is provided with a thread hole; the middle of the gear shaft is provided with a through hole; the lower end of the connecting shaft is provided with a concave opening, and the part of the lower end of the gear shaft which corresponds to the concave opening forms a convex table, and when the gear shaft is matched with the connecting shaft, the convex table of the gear shaft is matched with the concave opening of the connecting shaft for locating; the screw enters into the upright column through the lower end of the through hole of the gear shaft and is connected with and fastened with the thread hole of the upright hole, and connects the gear shaft and the upright column. The invention leads the air flow to be smooth, and reduces the noise of the air flow, and leads the assembling of the gear shaft and the connecting shaft to be convenient, and greatly saves labor hour.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

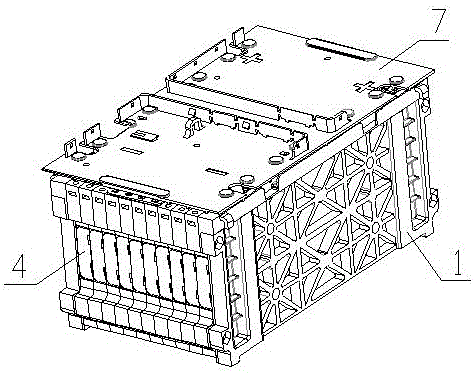

Rapidly cooled lithium battery module

PendingCN107579179AReduce the temperatureExtended service lifeSecondary cellsCell component detailsEscape rateEngineering

The invention discloses a rapidly cooled lithium battery module which comprises a temperature probe, a connecting plate, a lithium battery pack, an aluminum shell, a semiconductor refrigerator, a heatradiator and a fan, wherein the semiconductor refrigerator is sandwiched between the aluminum shell and the heat radiator; the refrigeration surface of the semiconductor refrigerator contacts the lower surface of the aluminum shell; the semiconductor refrigerator is matched with the temperature probe. As the lithium battery pack is mounted inside the aluminum shell, the lithium battery pack can be effectively protected, the structure is stable and reliable, single lithium batteries are sandwiched between aluminum fins and side walls of the aluminum shell respectively; the temperature of the lithium battery pack can be monitored by the temperature probe above the connecting plate; when the temperature is too high, the semiconductor refrigerator starts to refrigerate, and the temperature ofthe lithium battery pack is rapidly reduced by the semiconductor refrigerator through the aluminum shell and the aluminum fins, so that the service life of the lithium battery pack is prolonged, thelithium battery pack is prevented from explosion because of too high temperature, thermorunaway can be delayed, and the escape rate of operators can be greatly increased.

Owner:山东遥米新能源科技有限公司

Thread scrap filter and clothes dryer with same

ActiveCN104153171AReduce in quantityShorten the timeTextiles and paperLaundry driersIndustrial engineeringScrap

The invention discloses a thread scrap filter and a clothes dryer with the thread scrap filter. The thread scrap filter comprises two half boxes assembled mutually, and filter nets are arranged on the two half boxes. The two half boxes are the same in structure and mutually assembled to form the overall thread scrap filter through connecting structures. Meanwhile, the clothes dryer comprises the thread scrap filter of the structure. According to the thread scrap filter, because the two half boxes of the same structure are adopted for mutual assembly in a matched mode, only one die needs to be developed, the number of dies is decreased, the developing time of the die is shortened, the developing cost of the die is reduced, meanwhile, the varieties of parts are reduced, production processes are reduced, examination time is shortened, the production efficiency of the parts is improved, and the manufacturing cost is further reduced.

Owner:HAIER GRP CORP +1

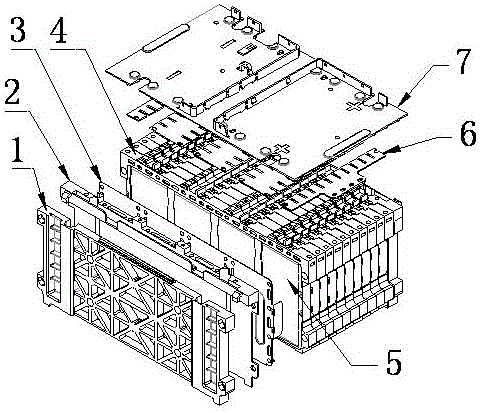

Power supply module of electrical vehicle and connection method

ActiveCN104051682AReduce contact resistanceIncrease contact resistanceBattery isolationPropulsion by batteries/cellsContact impedanceBusbar

The invention relates to the technical field of vehicle power supply, and particularly relates to a power supply module of an electrical vehicle and a connection method. The power supply module includes: a plurality of positive cell units, wherein each positive cell unit is provided with a fixing frame and two aluminium tabs which stretch out from one side edge of the fixing frame; a plurality of negative cell units which are arranged at intervals with the plurality of positive cell units, wherein each negative cell unit is provided with a fixing frame and two copper tabs which stretch out from one side edge of the fixing frame; and a plurality of busbars which are used for connecting the positive cell units with the negative cell units in series. Each aluminium tab of each positive cell unit and each adjacent copper tab of each adjacent negative cell unit are respectively welded to each busbar. The power supply module of the electrical vehicle has small contact impedance at a connecting position, is not easy to heat, is high in efficiency, is free from loosening during an operation process and is good in safety. The connection method of the power supply module of the electrical vehicle is safe and reliable.

Owner:WANXIANG 123 CO LTD

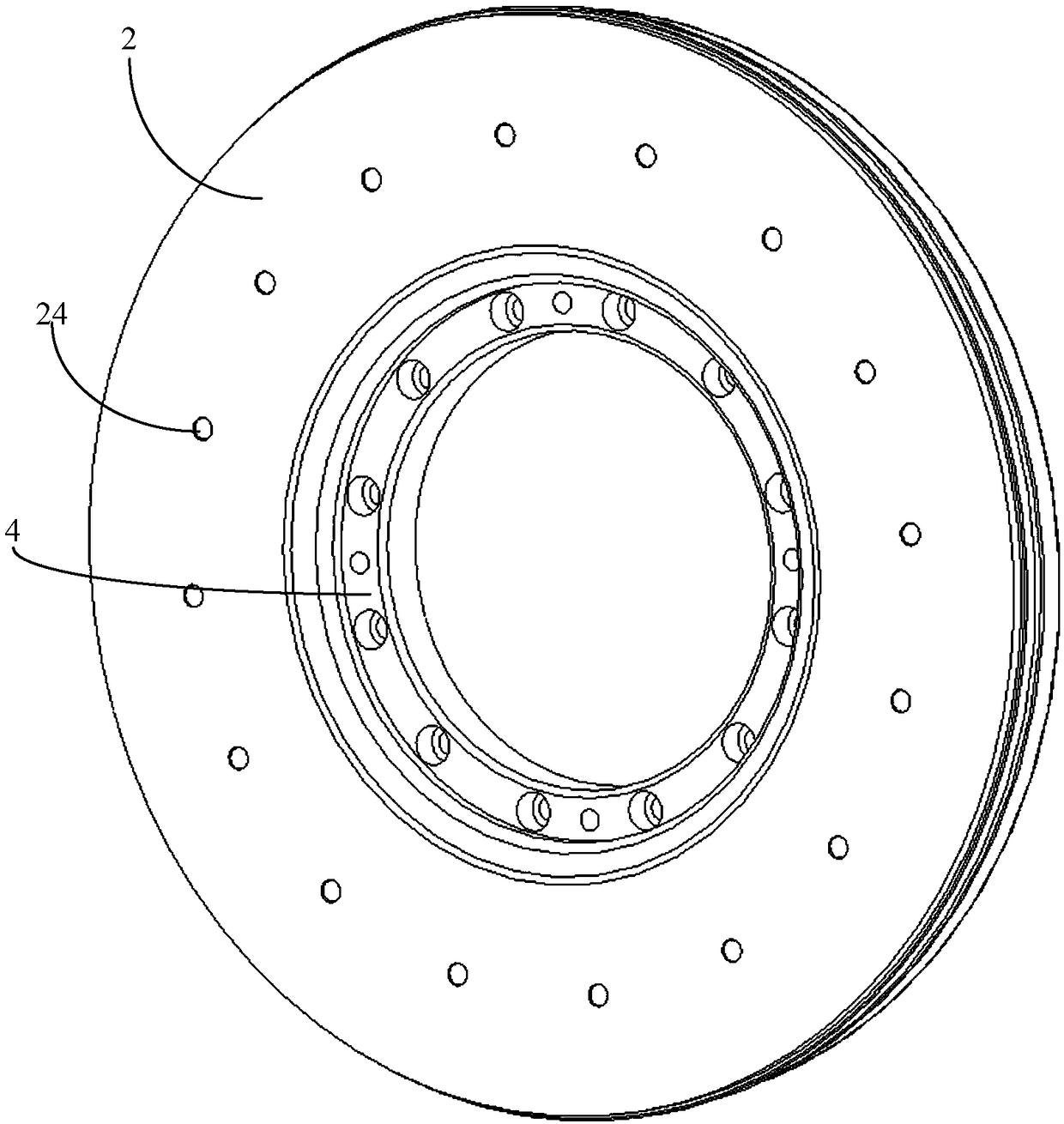

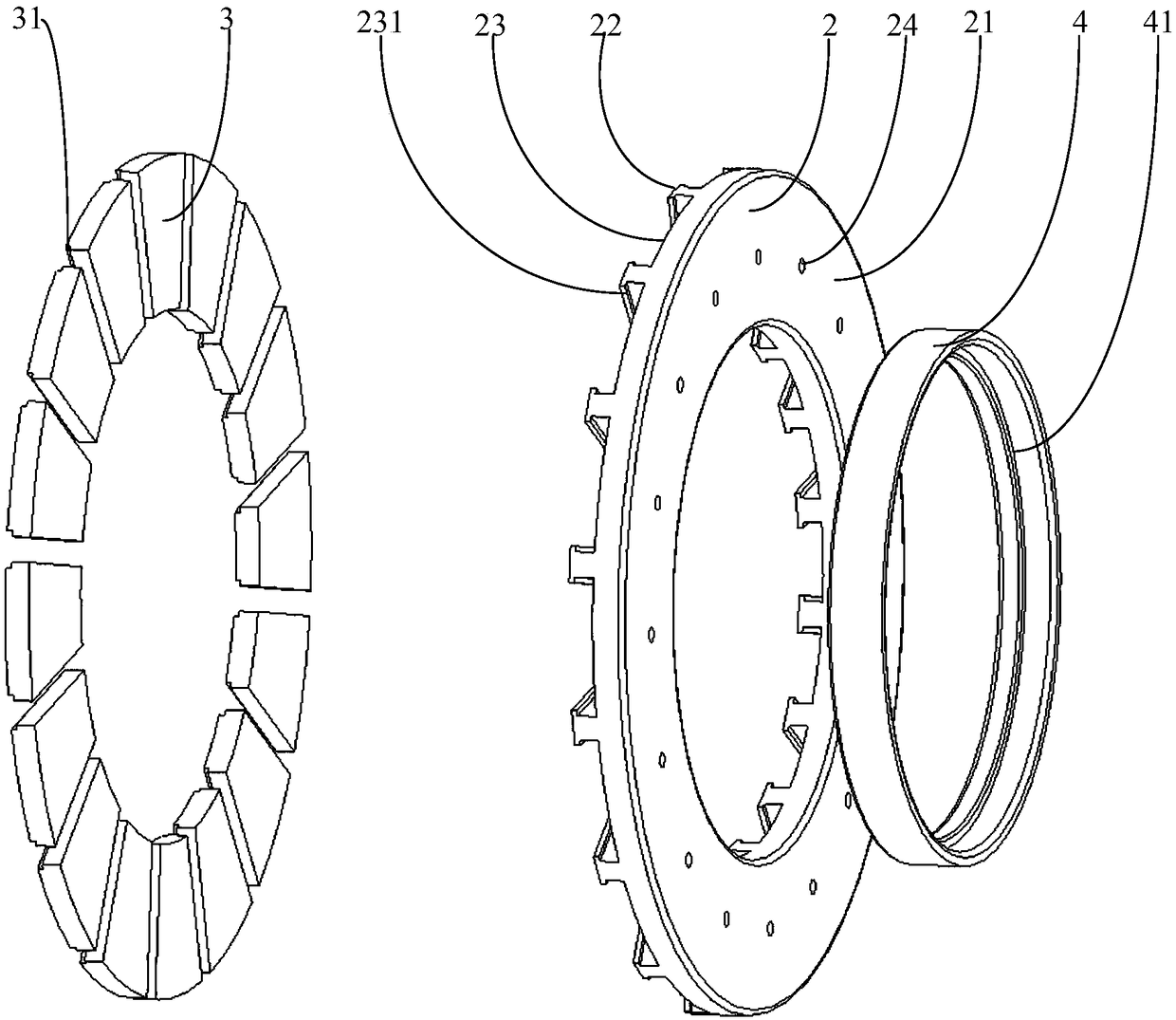

Rotor disk assembly and disk motor

PendingCN109193984AGuaranteed installation accuracyPrevent looseningMagnetic circuit rotating partsMagnetEngineering

The invention provides a disc motor and a rotor disc assembly, wherein the rotor disc assembly comprises a fixed disc, an annular iron core, a plurality of permanent magnets and a fixed ring. The fixed disk is provided with an annular mounting groove, and the annular mounting groove is provided with an annular inner side wall, an annular outer side wall and a bottom wall. The annular iron core isinstalled in the annular mounting groove, the annular iron core has a first end face and a second end face, and the second end face of the annular iron core is concave with a plurality of limiting grooves. The plurality of permanent magnets are embedded and installed in the plurality of limiting grooves, each limiting groove is adapted to correspond to the shape of the permanent magnets to preventthe permanent magnets from moving along the axial direction of the annular iron core, and each of the plurality of permanent magnets has a proximal end and a distal end. The fixing ring abuts againsta proximal end of the plurality of permanent magnets. The invention can facilitate assembling of the rotor disk assembly by an assembler and avoid loosening of the permanent magnet relative to the fixed disk.

Owner:仪坤动力科技(上海)有限公司

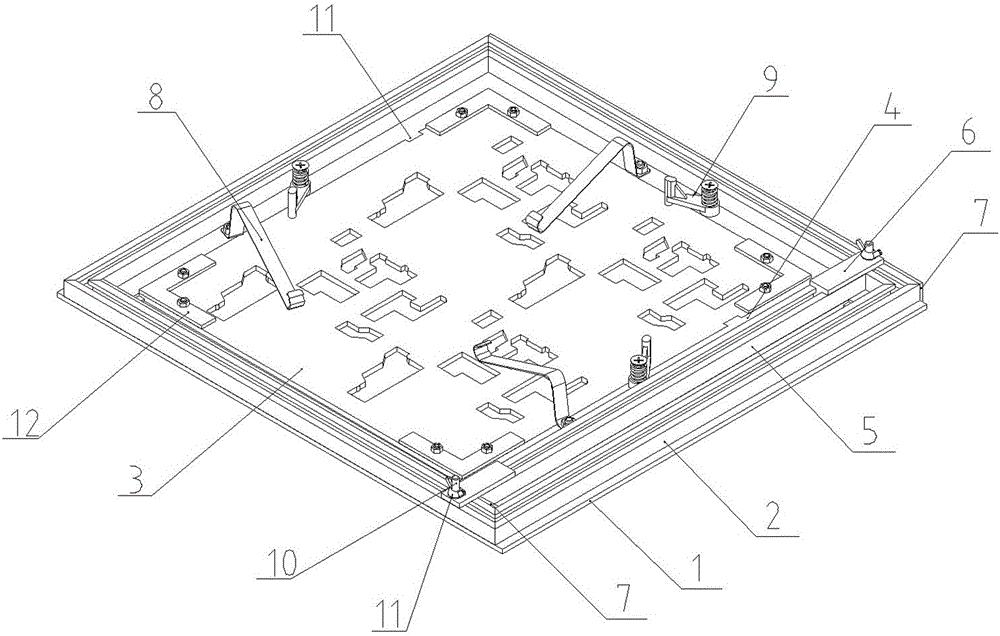

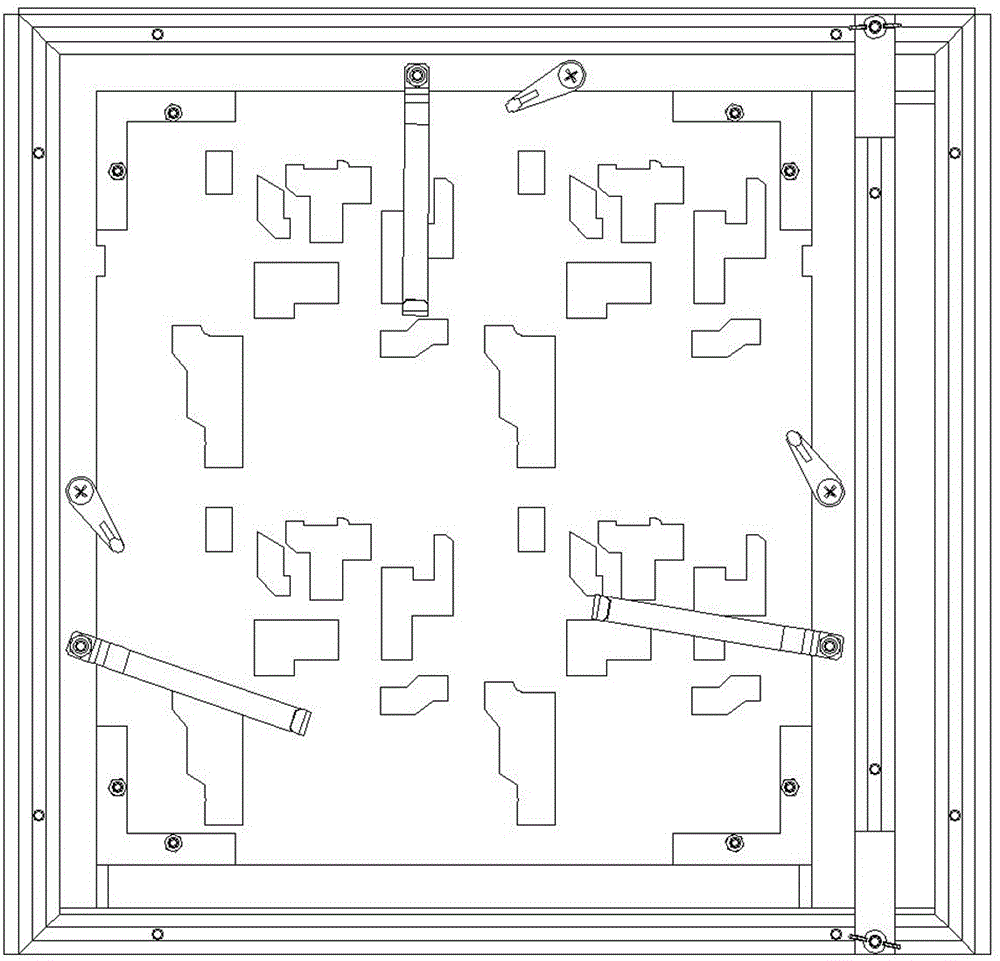

Pallet for printed-circuit board wave-soldering furnaces

ActiveCN105142360AEasy to assemble and locateEasy to replacePrinted circuit assemblingProduction departmentComputer engineering

The present invention discloses a pallet for printed-circuit board wave-soldering furnaces including a rectangular bottom plate, a rectangular vertical frame and a rectangular special purpose bottom plate. The rectangular bottom plate is provided with a rectangular hole, the rectangular vertical frame connects the upper surface of the rectangular bottom plate and the periphery of the rectangular hole, the special purpose bottom plate is assembled in the rectangular hole of the rectangular bottom plate, and a printed-circuit board is arranged on the special purpose bottom plate and is fixed on the special purpose bottom plate through a limiting stopper and a printed-circuit board pressing buckle. The plan view size of the special purpose bottom plate is less than the size of the rectangular hole of the rectangular bottom plate, and a size adjusting component is connected between a pair of opposite edges of the rectangular vertical frame. The size adjusting component includes a movable bottom plate and a sliding holder, wherein, the sliding holder is connected to the upper side of the movable bottom plate so as to move in the rectangular hole of the rectangular bottom plate by the cooperation of the corresponding edge of the special purpose bottom plate. One pallet is suitable for printed-circuit boards with various sizes. The special purpose bottom plate can be adjusted according to various plate types, and a production department is only required to manage and store the special purpose bottom plate so that the storage space and the management difficulty are greatly reduced, the pallet production cycle is shortened and the pallet production cost is saved.

Owner:WASION GROUP HLDG

Lithium-battery phase-change-heat-management assembling structure

InactiveCN106785204ASmall temperature differenceReduce charge and discharge temperature riseSecondary cellsCell component detailsHeat managementTemperature difference

The invention discloses a lithium-battery phase-change-heat-management assembling structure. The problem that as heat gathering of lithium batteries in the working process cannot be discharged in time, and the temperature gathering conditions of different parts are different, the temperature difference of the batteries is large is solved. The lithium-battery phase-change-heat-management assembling structure comprises an aluminum end plate and series copper bars, and is characterized in that all the lithium batteries are fixed through supports which are mutually parallel one by one respectively, phase-change aluminum plates are arranged on one sides of all the supports, heat generated in the charging-and-discharging process of soft-rolling cells is directly absorbed and stored by the phase-change aluminum plates, and in the temperature increasing process of the phase-change aluminum plates, absorbed heat is transmitted to the outside through the phase-change aluminum plates to reduce the temperature and the temperature clustering performance of the soft-rolling cells. The structure is stable and reliable, all the soft-rolling cells have the independent phase-change aluminum plates, temperature increasing of charging and discharging of the grouped lithium batteries is greatly reduced, and the temperature difference of the soft-rolling cells is reduced, the performance of the lithium batteries in using is improved, and the service life of the lithium batteries in using is prolonged.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

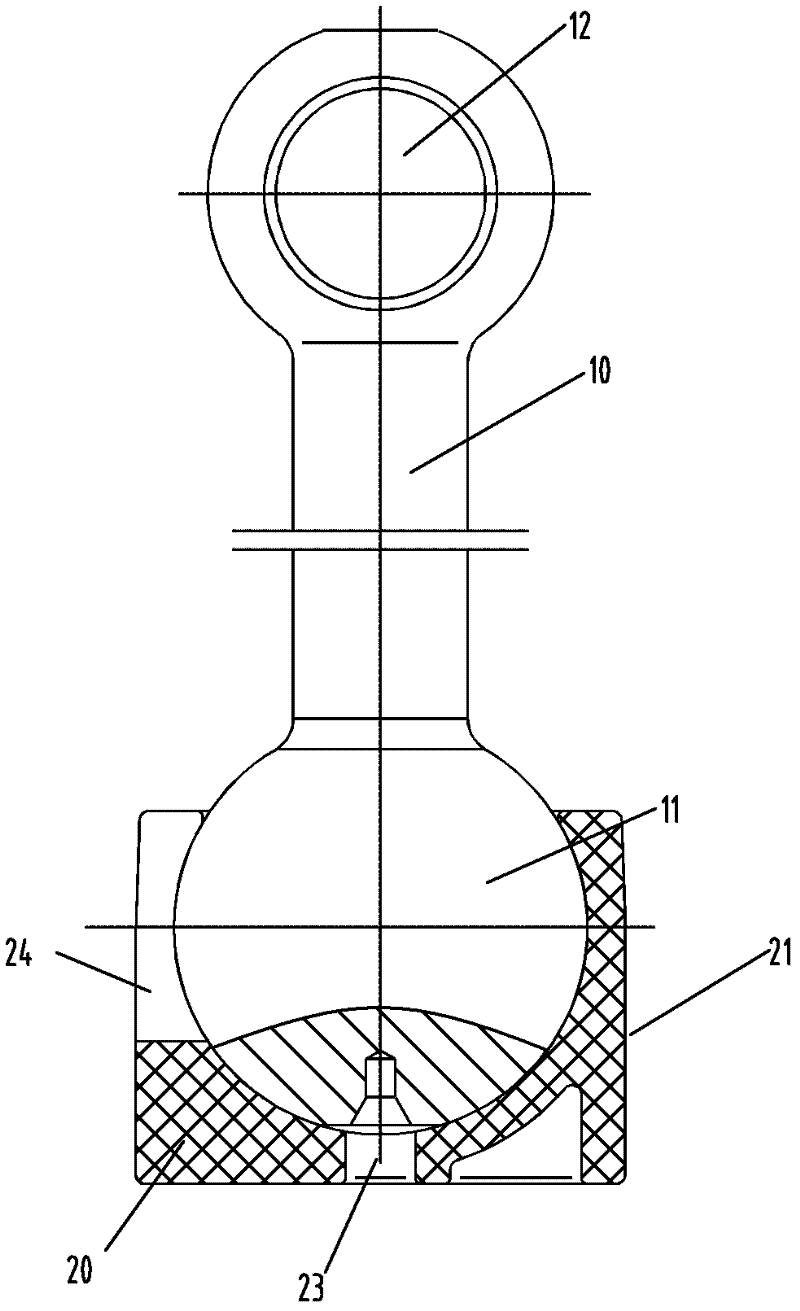

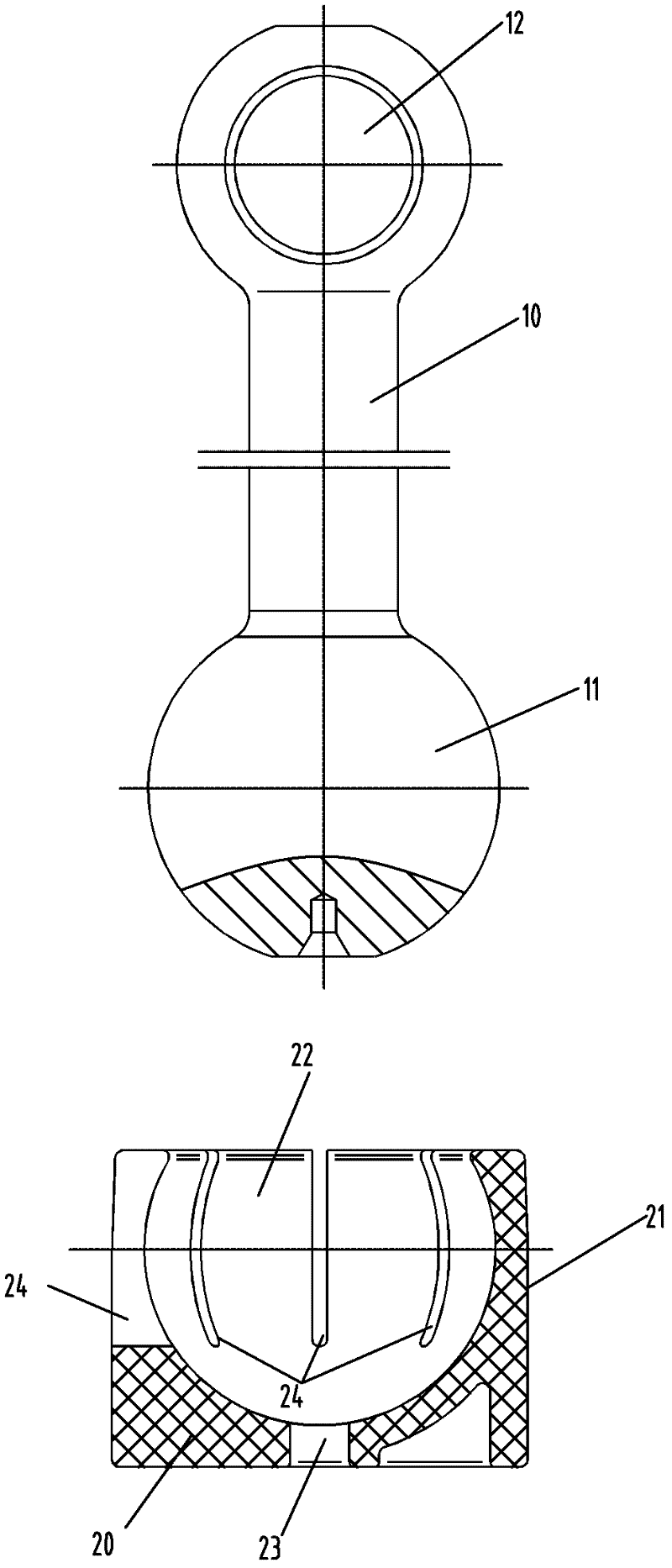

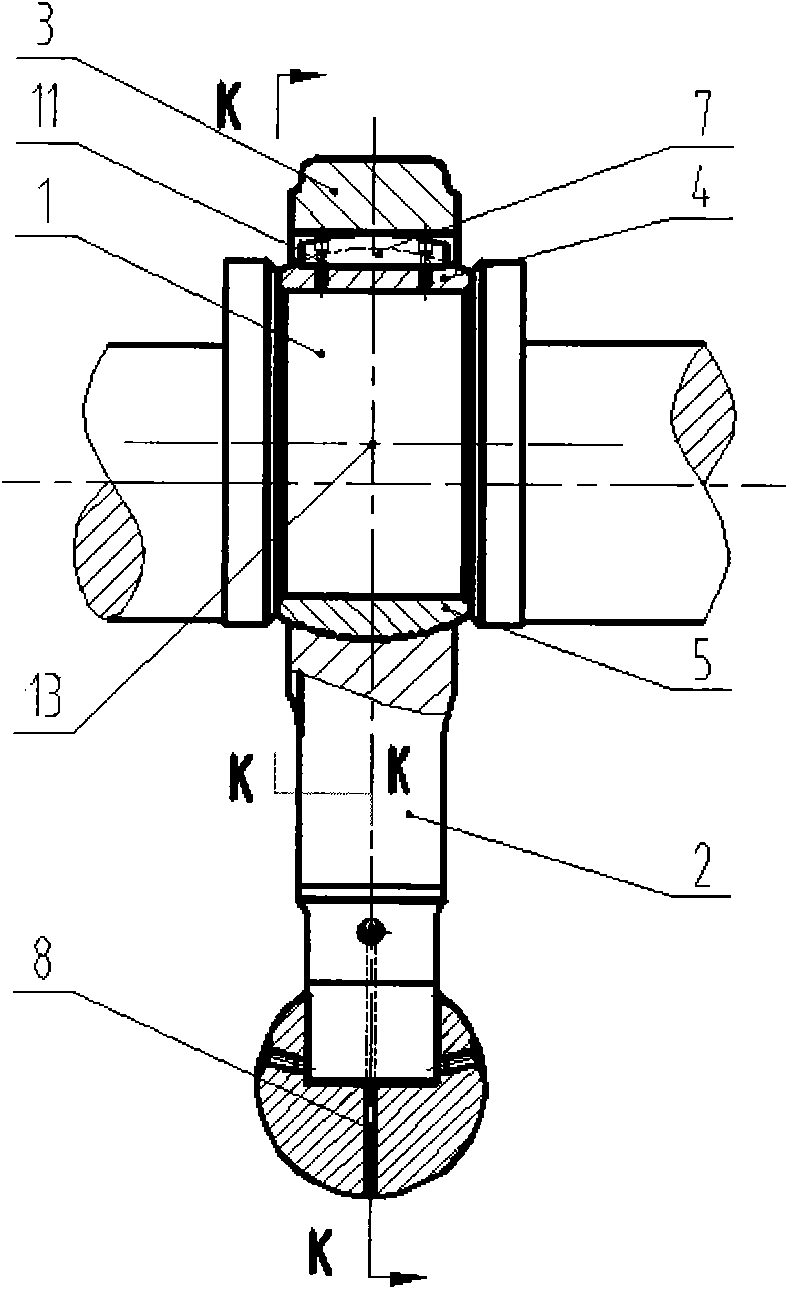

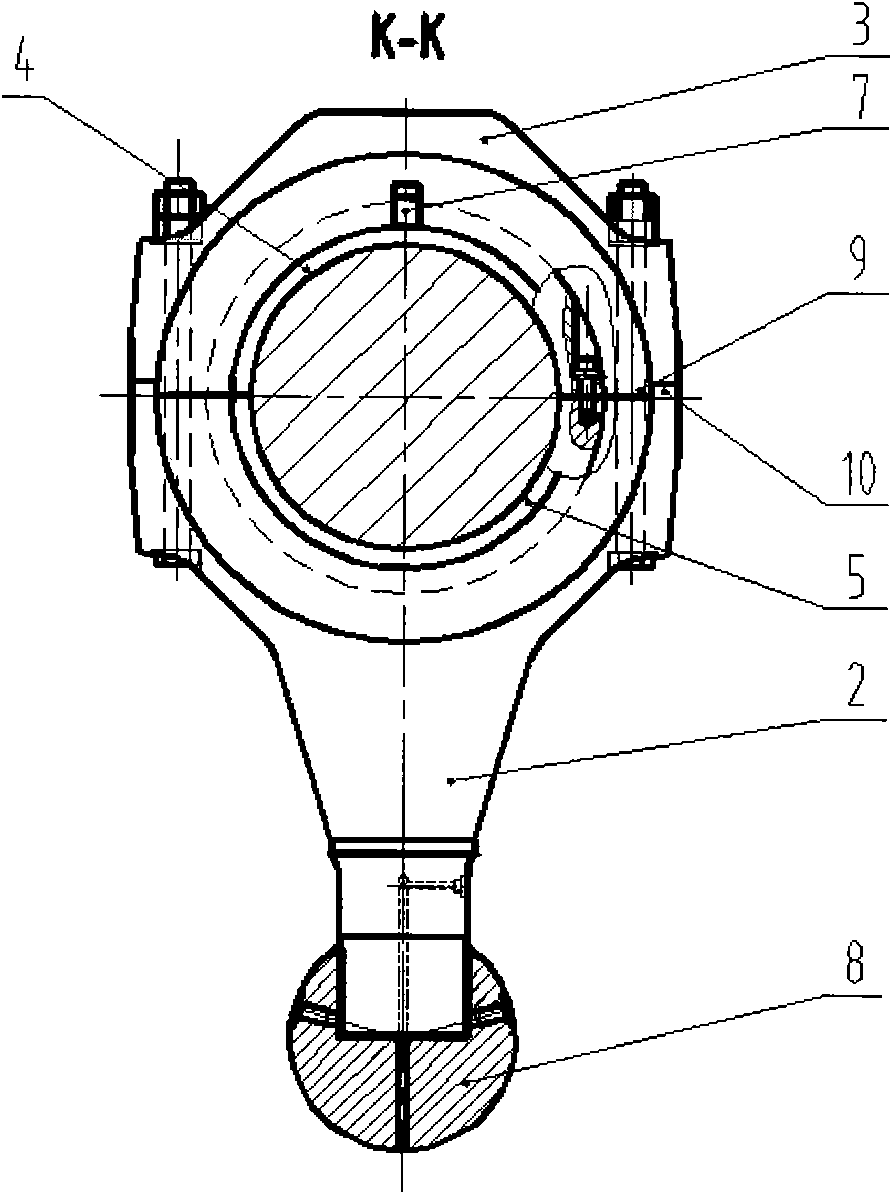

Crankshaft and connecting rod spherical hinging mechanism

InactiveCN101832329ALittle frictional movementExtended service lifeConnecting rod bearingsPivotal connectionsKinematic pairCrankshaft

The invention discloses a crankshaft and connecting rod spherical hinging mechanism, which belongs to the technical field of mechanical transmission. The mechanism comprises a crankshaft, a connecting rod, a connecting rod cover, an upper semi-spherical sleeve and a lower semi-spherical sleeve, and is characterized in that: an arc key capable of preventing the upper semi-spherical sleeve and the connecting rod cover from moving relatively is arranged between the contact surfaces of the connecting rod cover and the upper semi-spherical sleeve; the arc key is rectangular, and the upper surface of the arc key is in an arc shape in an axial direction; and in addition, concave and convex steps which are engaged are formed between the contact surfaces of the upper end of the fork-shaped connecting rod and the connecting rod cover. The mechanism has the advantages of preventing rotation between the upper and lower semi-spherical sleeves and the connecting rod cover and the connecting rod, making the upper and lower semi-spherical sleeves, the connecting rod cover and the connecting rod only swing around a turning center, effectively reducing friction motion between spherical surfaces and prolonging the service life of spherical kinematic pairs.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

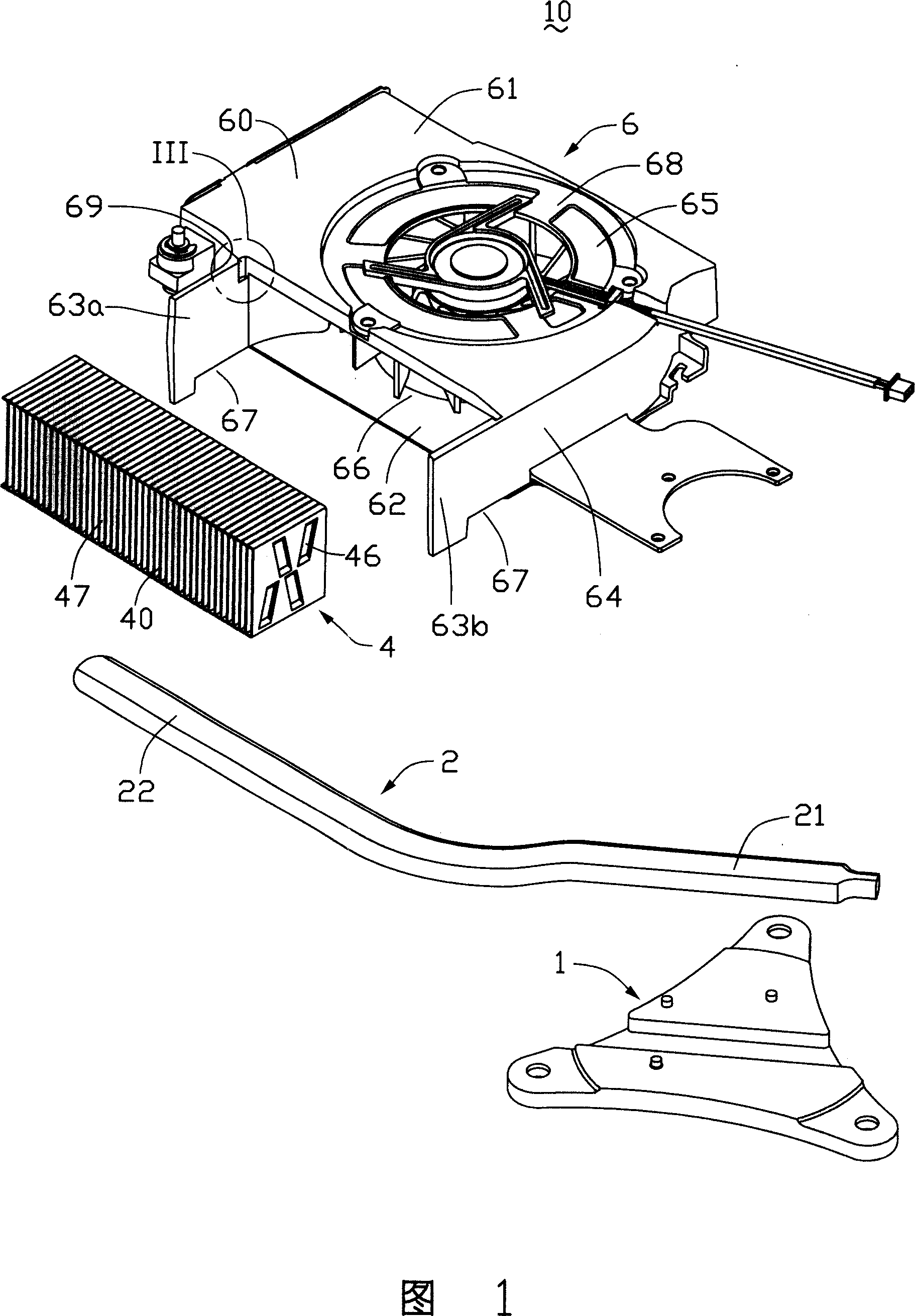

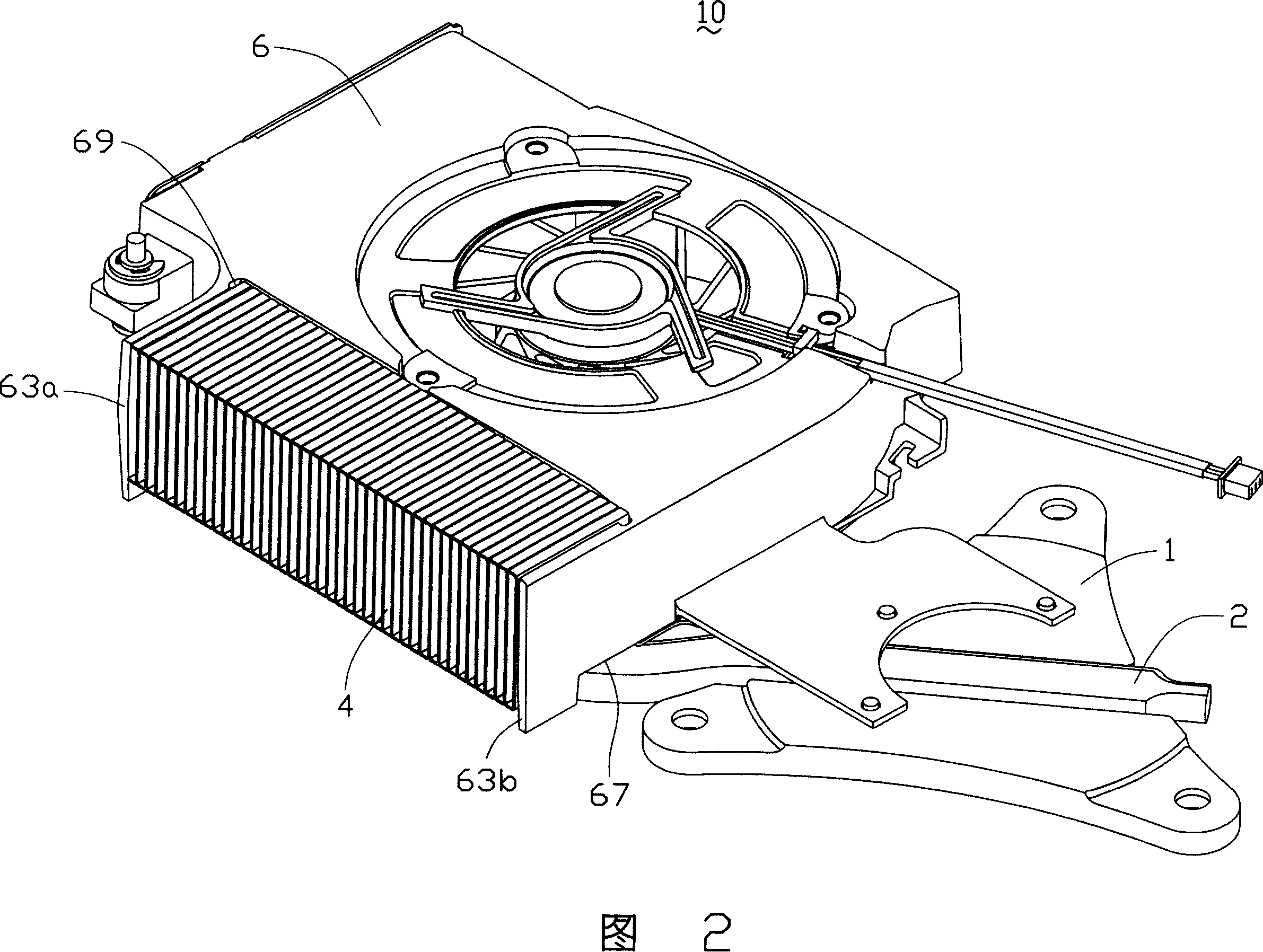

Heat radiating module

InactiveCN101098609AAvoid interferenceEasy to assemble and locateInstrumental cooling apparatusCooling/ventilation/heating modificationsAgricultural engineeringTroffer

A heat radiator module comprises a fin group and a fan, wherein the fan comprises a fan frame and a fan wheel group in the fan frame. One side of the fan frame is provided with an air outlet, the fin group is provided at the air outlet, the fan frame extends at least one baffle plate outwards at the air outlet, the connection between the baffle plate and the fan frame is provided with a groove to avoid interference between the fin group and the fan in assembly, with simple assembly and positioning.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com