Lithium-battery phase-change-heat-management assembling structure

An assembly structure and lithium battery technology, which is applied to battery components, secondary batteries, structural parts, etc., can solve the problems of heat accumulation that cannot be discharged in time, large temperature difference of the battery, and impact on battery performance and service life, etc., to achieve reduction Small temperature difference, lower charging and discharging temperature rise, convenient assembly and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

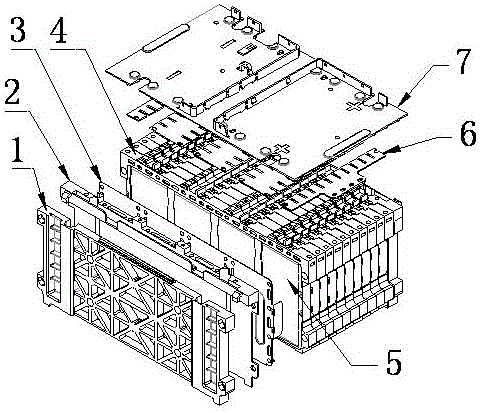

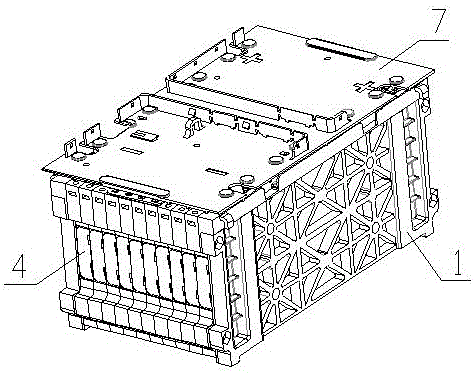

[0019] In this embodiment, a lithium battery phase change thermal management assembly structure, see figure 1 , figure 2 , including aluminum end plate 1, series copper bar 6, upper cover 7 and 10 sets of lithium batteries, each set of lithium batteries is composed of 4 pieces of soft pack batteries 5, each set of lithium batteries is fixed by a bracket 4, and the 10 brackets are connected to each other Arranged in parallel.

[0020] A phase-change aluminum plate 3 is arranged on one side of each bracket, and the surface of the entire phase-change aluminum plate 3 is provided with a phase-change material coating layer; the bracket 4 is a rectangular photo frame structure, and the bracket 4 is provided with 5 soft pack batteries. slot, 4 pieces of soft-packed batteries 5 are a group, and the 4 pieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com