Assembly structure for management of transformation heat of bicycle lithium battery

A technology for assembling structure and lithium battery, applied in battery pack parts, secondary batteries, structural parts, etc., can solve the problems of battery pack life reduction, temperature imbalance, difficult heat accumulation, etc., to reduce the charge and discharge temperature rise, Long service life, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

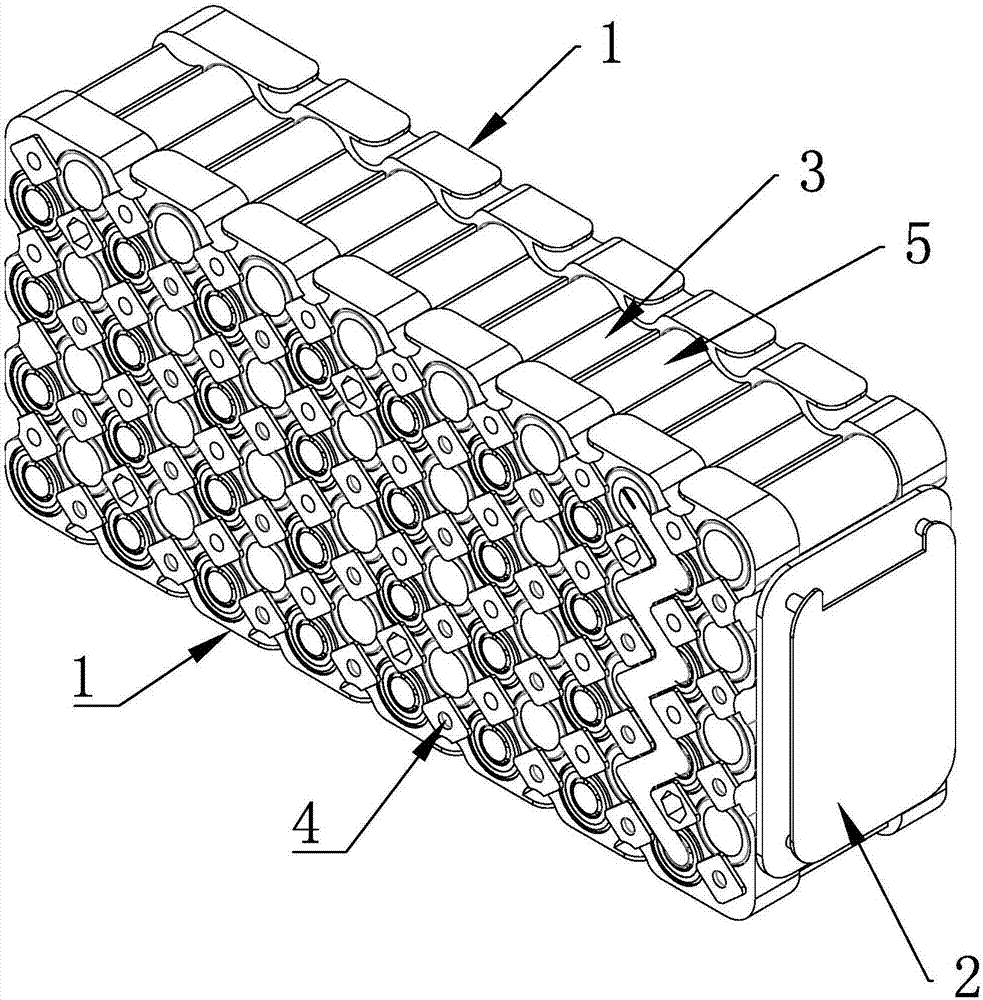

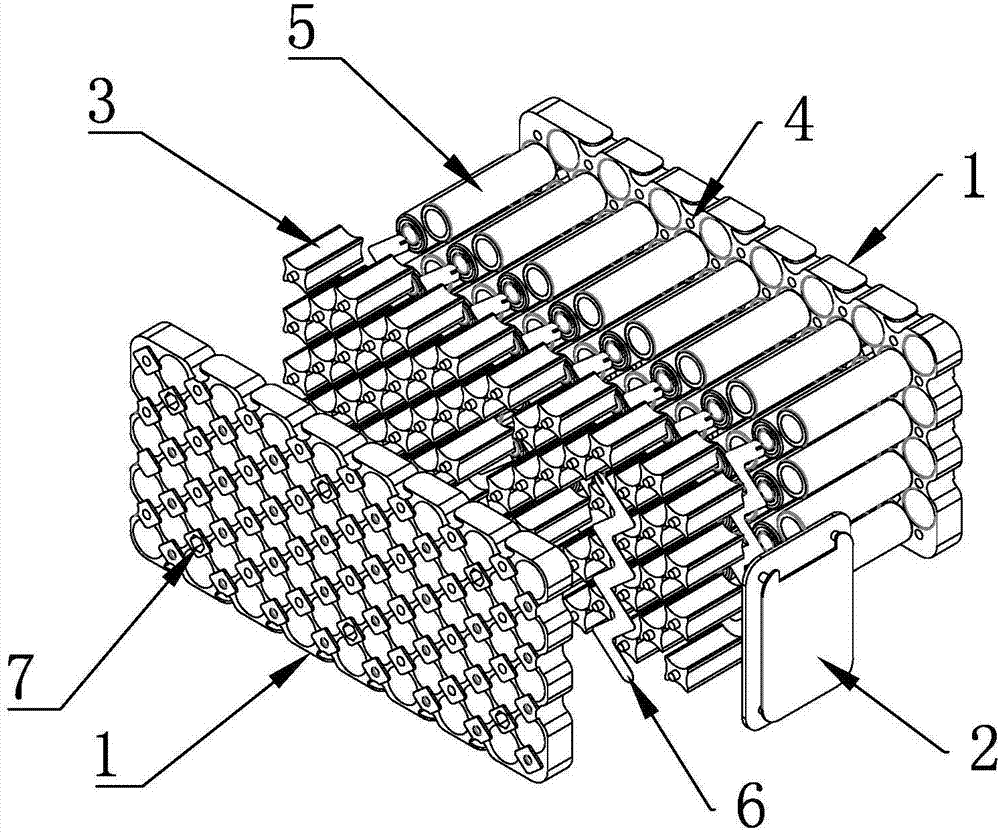

[0023] Embodiment: The bicycle lithium battery phase change thermal management assembly structure of the present invention, as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 As shown, it includes: two pairs of plastic brackets 1, the main body of which is a flat plate structure, and the inner surfaces of the two pairs of plastic brackets 1 are opposite; several battery cells 5 clamped between the two plastic brackets 1, and the battery cells 5 are generally parallel to each other; Nickel sheets 6 connected in series; and several phase-change heat-conducting pillars 3 inserted in the gaps between adjacent electric cores 5 . The four adjacent battery cells 5 are distributed at the four corners of the quadrangle.

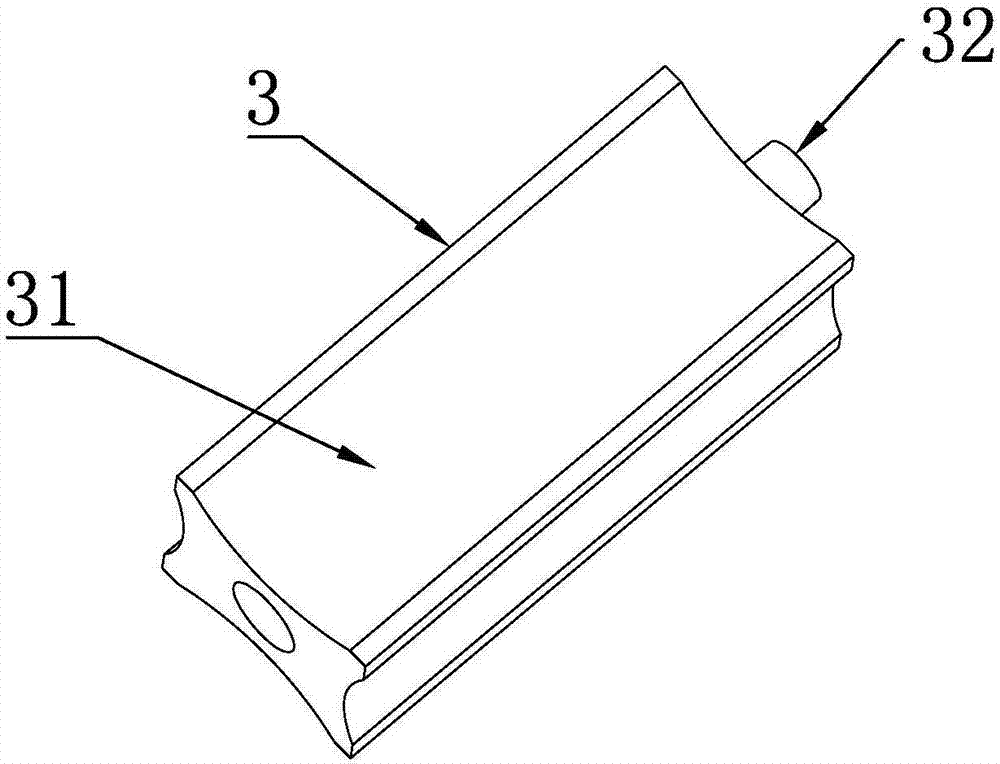

[0024] The phase-change heat-conducting column 3 is a columnar body, and the side wall has four concave arc-shaped surfaces 31 , and the arc-shaped surfaces 31 are adapted to the surface of the electric core 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com