Heat radiating module

A technology of heat dissipation module and heat dissipation fin, applied in cooling/ventilation/heating transformation, instrument cooling, instrument and other directions, can solve the problems of increasing production cost, removing clean chamfers, increasing processes, etc., to achieve convenient assembly and positioning, The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

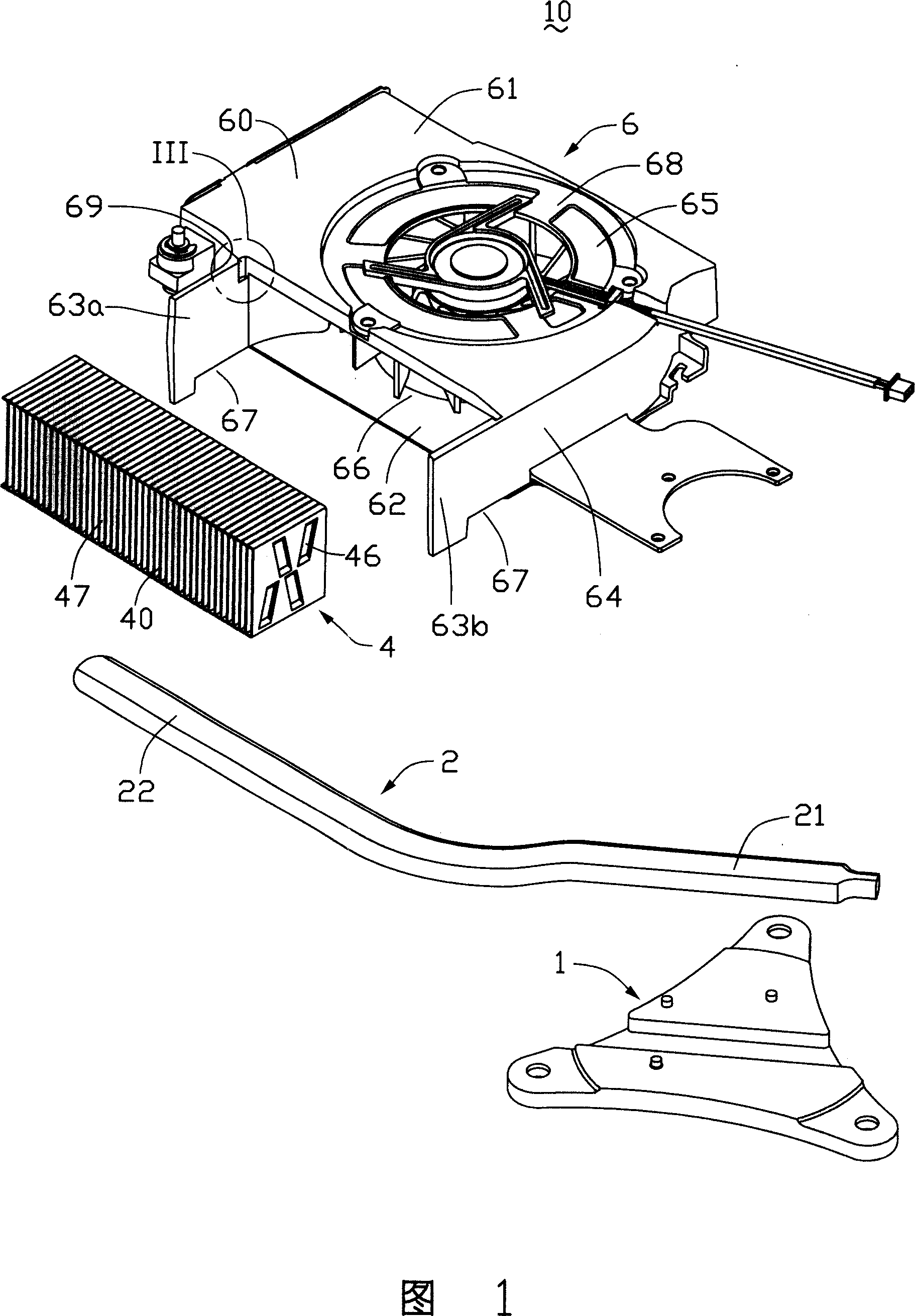

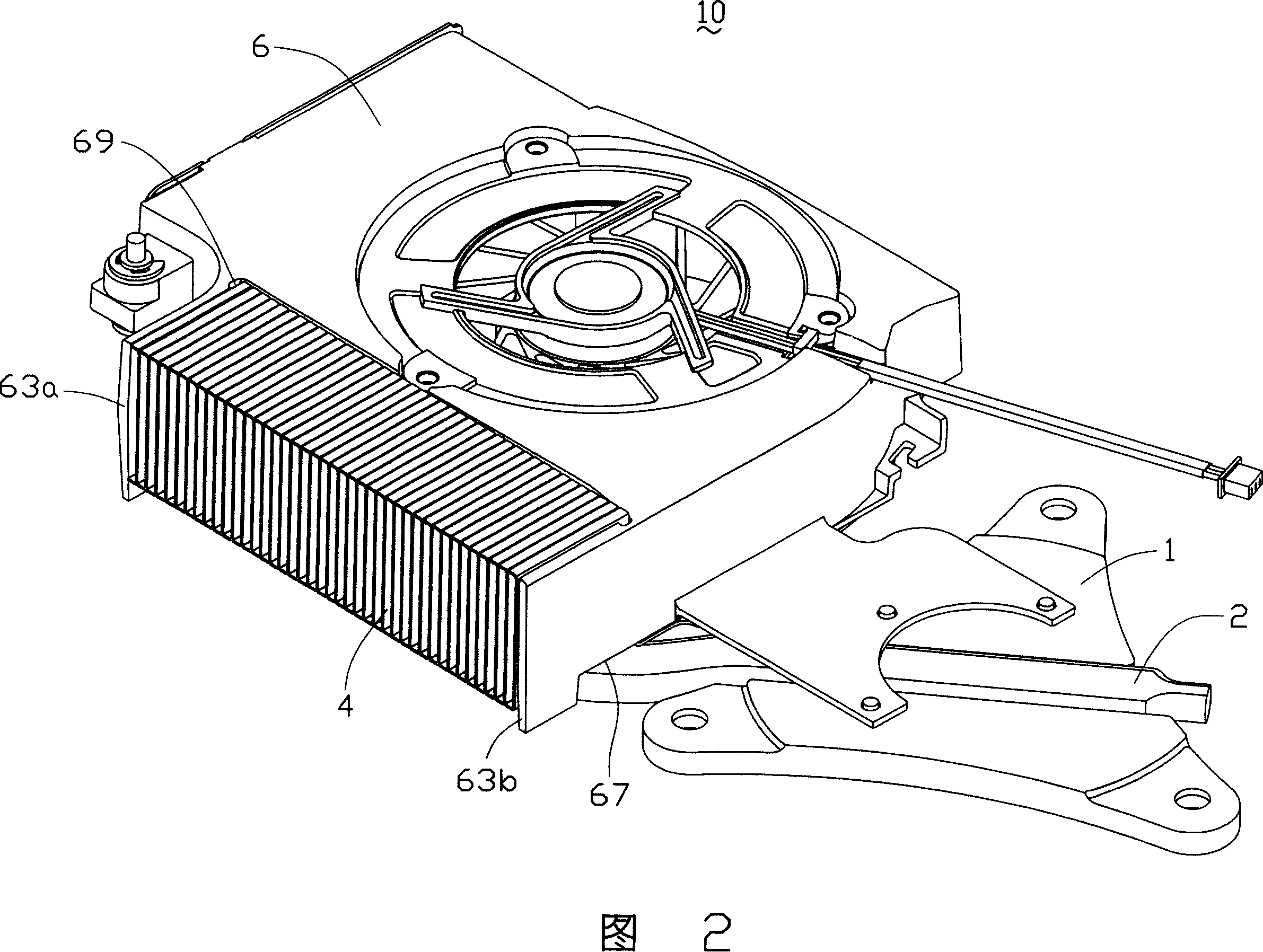

[0013] As shown in FIGS. 1 and 2 , the cooling module 10 includes a vapor chamber 1 , a heat pipe 2 , a fin set 4 and a centrifugal fan 6 . Wherein the fin set 4 is placed at the side end of the centrifugal fan 6 .

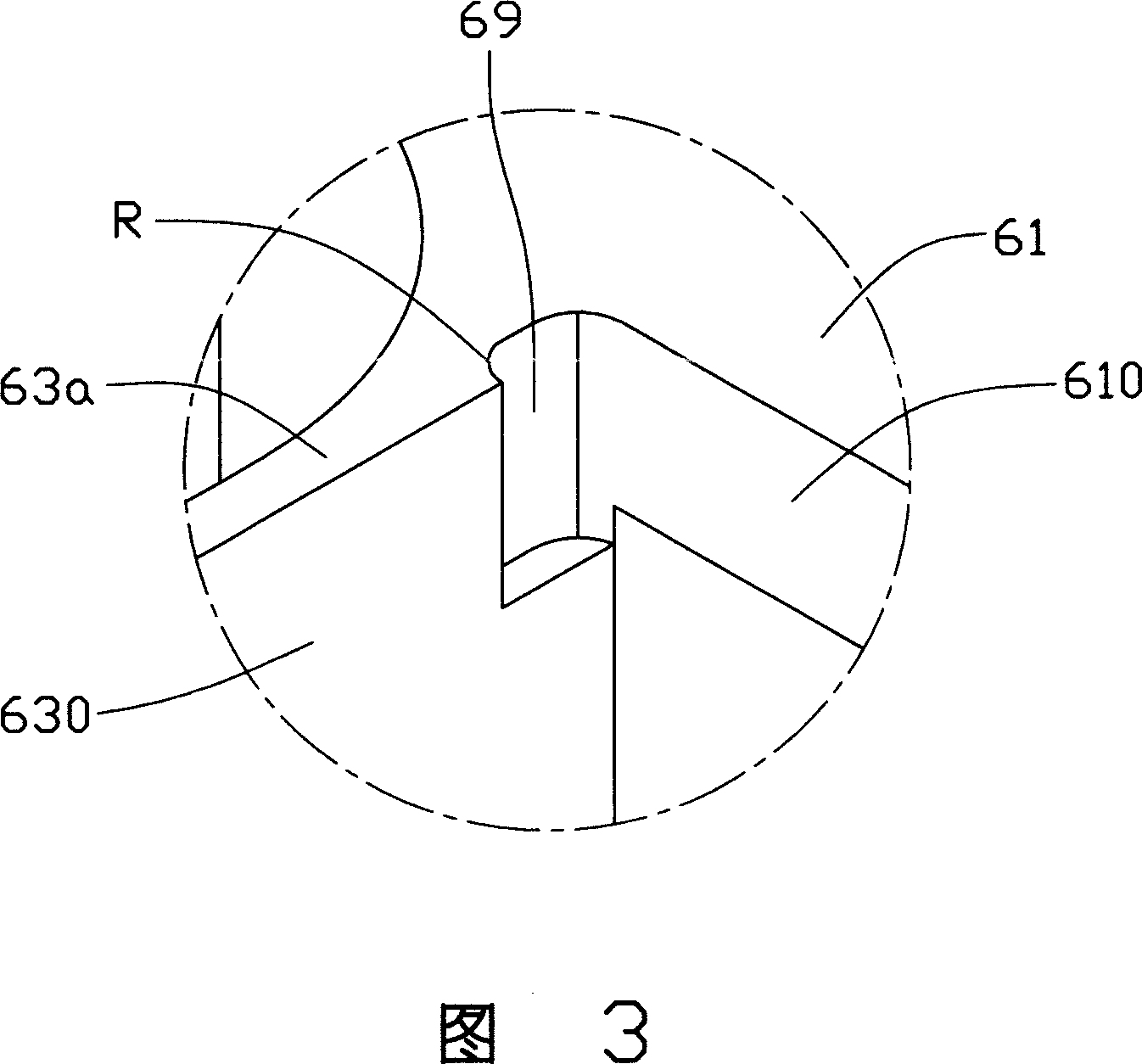

[0014] The fan 6 includes a fan frame 60 and a fan wheel set 68 disposed in the fan frame 60 . The fan frame 60 is integrally formed by injection molding. The fan frame 60 includes a top board 61 , a bottom board 62 and a side board 64 connected between the top board 61 and the bottom board 62 . Wherein, the top plate 61 , the bottom plate 62 and the side plate 64 jointly form a space for accommodating a fan wheel set 68 for generating airflow. The top plate 61 and the bottom plate 62 are arranged in parallel, and are respectively arranged on the upper and lower sides of the fan wheel set 68. A circular air inlet 65 is formed at the central position of the top plate 61 and the bottom plate 62, that is, facing the fan wheel set 68. The side plate 64 forms an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com