Pallet for printed-circuit board wave-soldering furnaces

A printed circuit board and wave soldering technology, which is used in printed circuits, printed circuit manufacturing, and assembling printed circuits with electrical components. The effect of adjusting the time of the wave soldering track, reducing the storage space and management difficulty, and reducing the production cycle and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

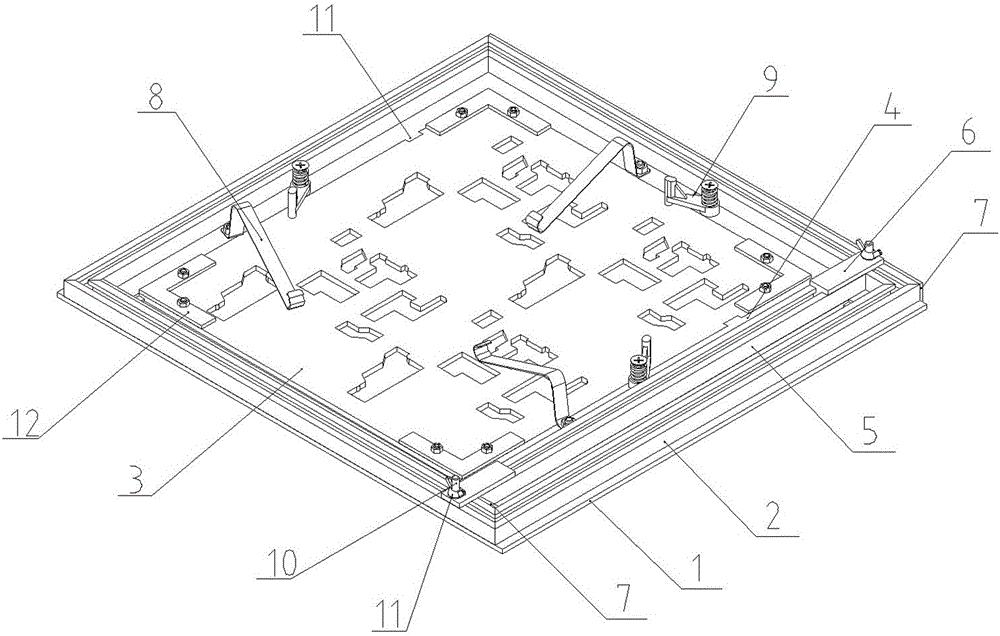

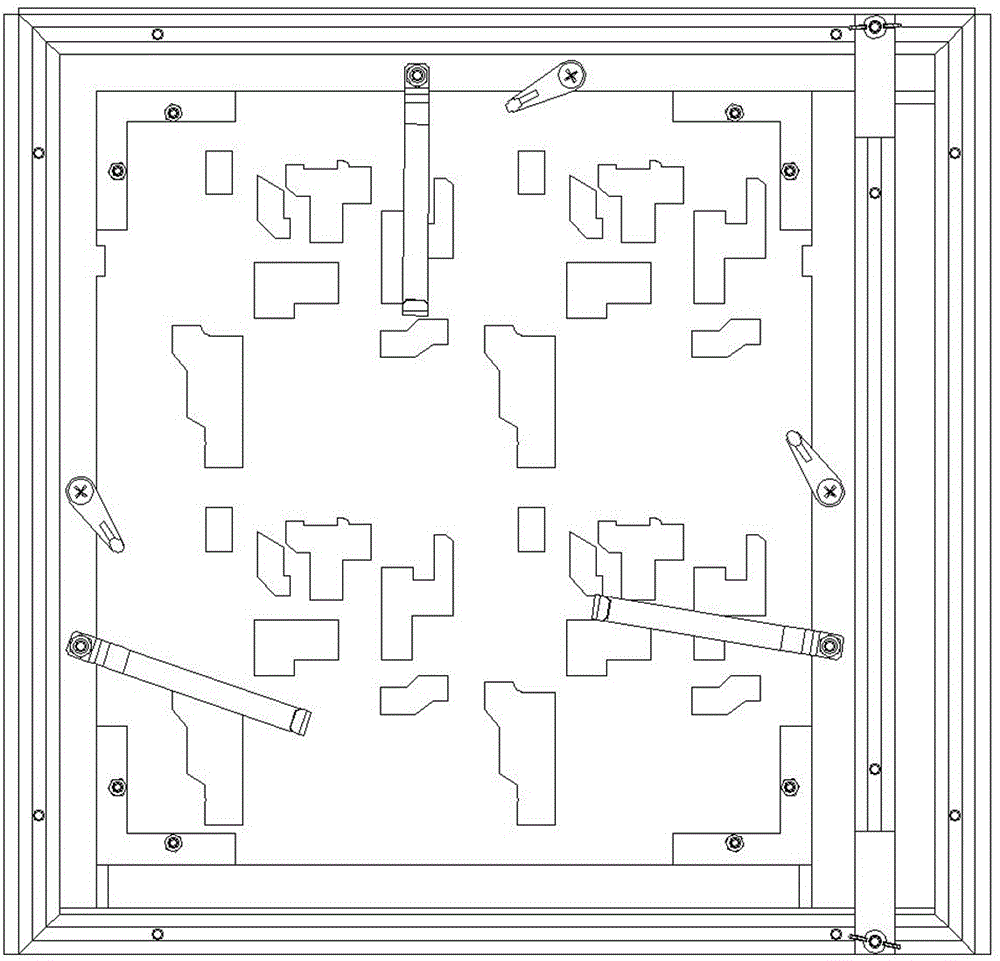

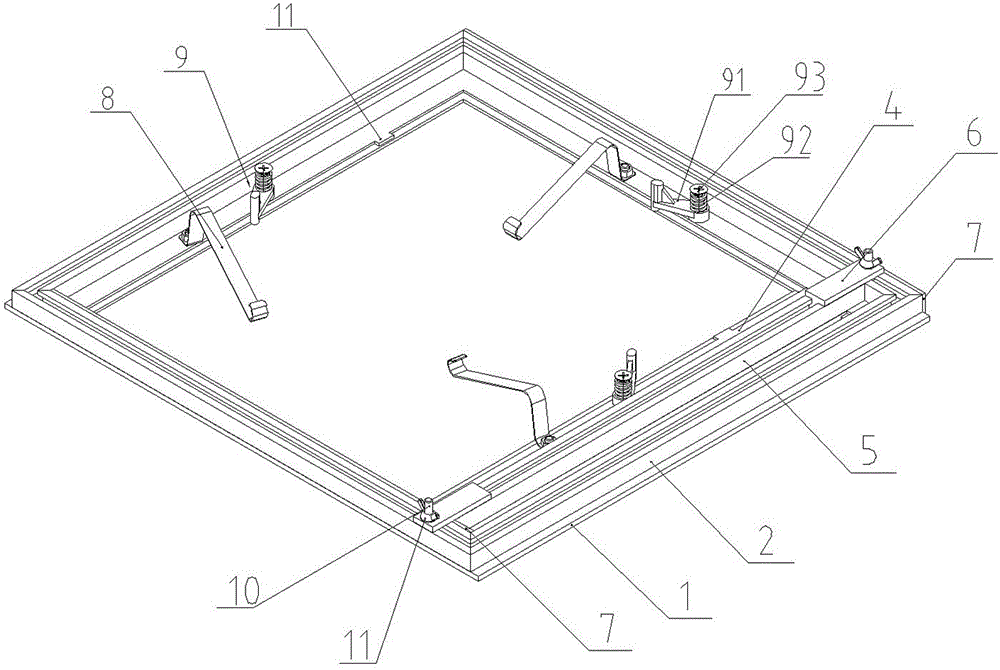

[0024] Such as Figure 1 to Figure 3 As shown, this embodiment discloses a printed circuit board wave soldering furnace tray, including a main rectangular bottom plate 1, a rectangular vertical frame 2, a special bottom plate 3, a moving bottom plate 4, a moving bracket 5, a fixed block 6, and a synthetic stone Article 7, printed circuit board buckle 8, special bottom plate buckle assembly 9.

[0025] The rectangular vertical frame 2 is surrounded by profiles with T-shaped grooves along the length direction, and each profile is arranged with the opening of the T-shaped groove facing upwards, and synthetic stone strips 7 of corresponding sizes are respectively installed on the inner wall and outer wall of the profile on one opposite side.

[0026] A rectangular hole is opened on the rectangular bottom plate 1, and the rectangular upright frame 2 is connected to the upper surface of the rectangular bottom plate 1 and the periphery of the rectangular hole. The widths of the soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com