Crankshaft and connecting rod spherical hinging mechanism

A spherical articulation and connecting rod technology, applied in the direction of pivot connection, connecting rod bearing, etc., can solve the problems of increasing equipment operating costs, reducing production efficiency, shortening service life, etc., to extend service life, improve assembly accuracy, and reduce friction. the effect of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

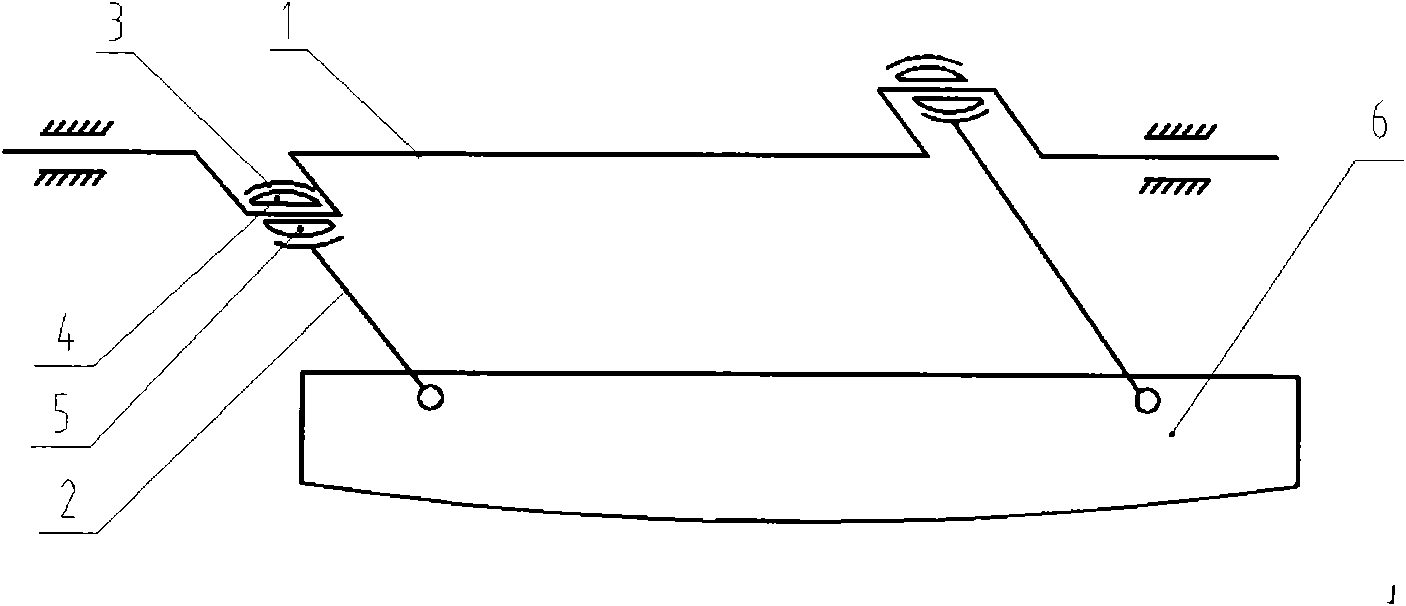

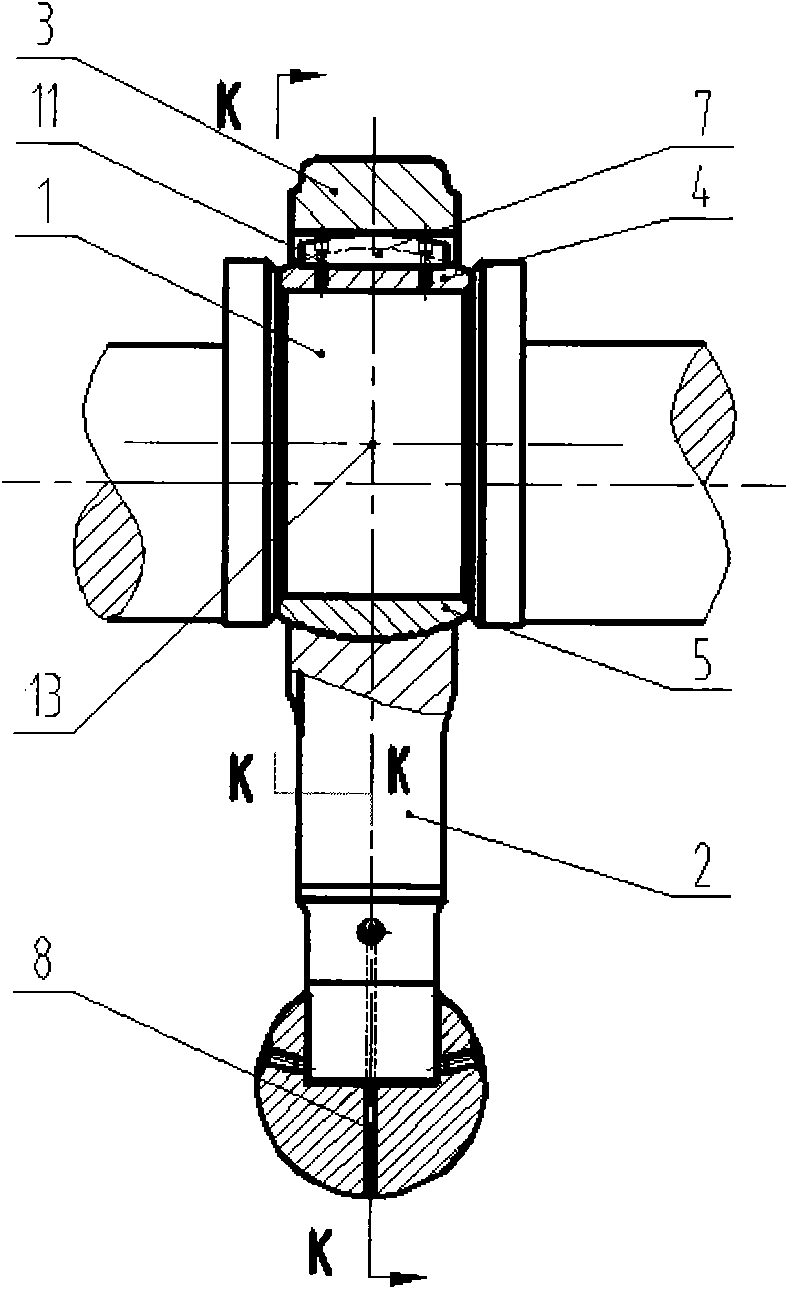

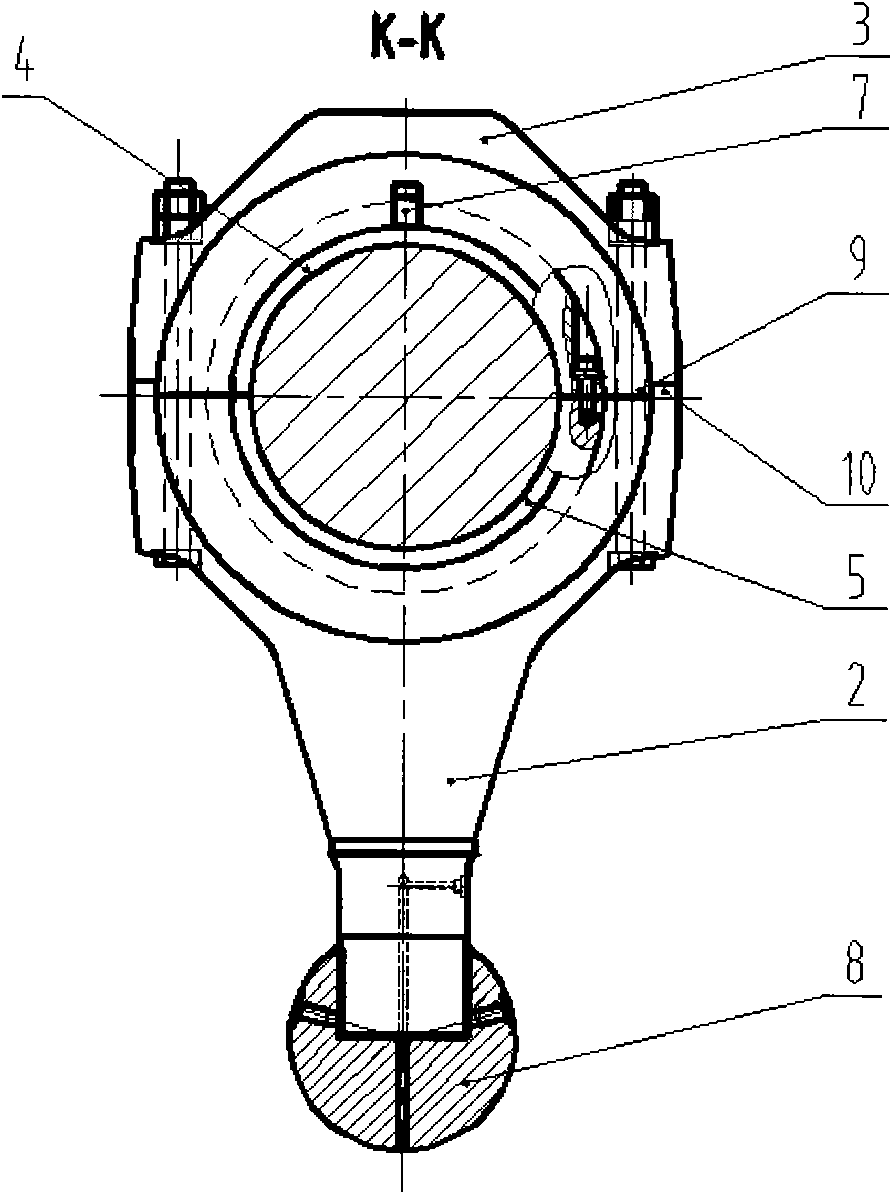

[0012] Such as Figure 2-4 As shown, including crankshaft 1, connecting rod 2, connecting rod cover 3, upper and lower hemispherical sleeves 4, 5, a cuboid is installed between the upper hemispherical sleeve 4 and the contact surface of connecting rod cover 3, and the upper surface axial direction is The circular arc key 7 is connected with the bolt 11 between the arc key 7 and the upper hemispherical cover 4, and the connecting rod 2 lower ends are connected with the connecting rod ball 8. Both sides of the fork-shaped connecting rod 2 upper ends are formed with concave slits 10 and convex slits 9 formed on both sides of the lower end of the connecting rod cover 3 are fitted. When the crankshaft 1 rotates, it drives the connecting rod 2 to swing up and down, and the connecting rod cover 3 and the upper hemispherical sleeve 4 can only swing around the center of rotation 13 and cannot rotate relative to each other in the axial direction.

[0013] In the patent No. "ZL200510012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com