Power supply module of electrical vehicle and connection method

A technology for power supply modules and electric vehicles, applied in electric vehicles, battery/battery traction, circuits, etc., can solve the problems of small contact resistance, low heat generation efficiency, small contact resistance heat generation efficiency, and low heat generation efficiency, and achieve safe connection methods Reliable, effective, low contact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

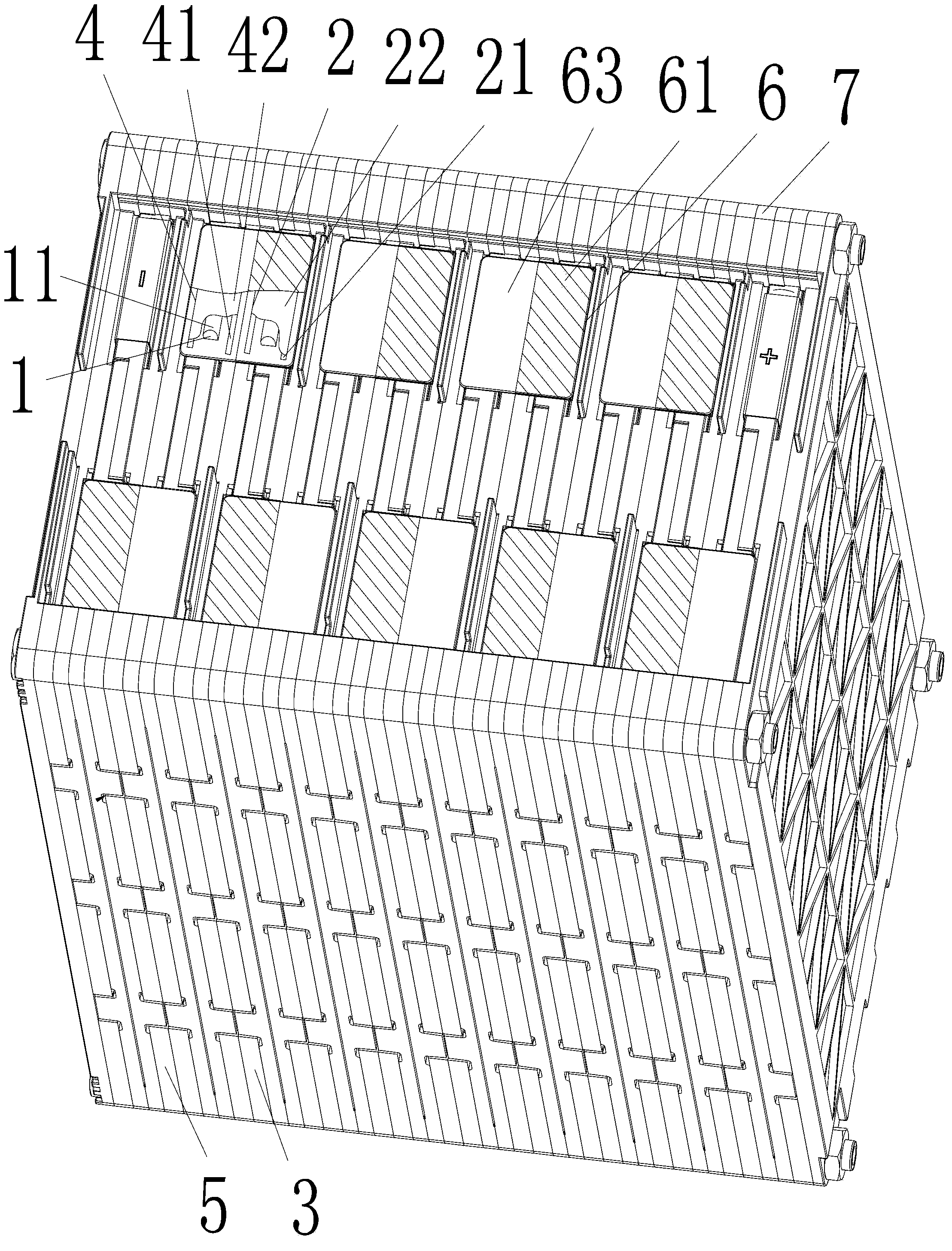

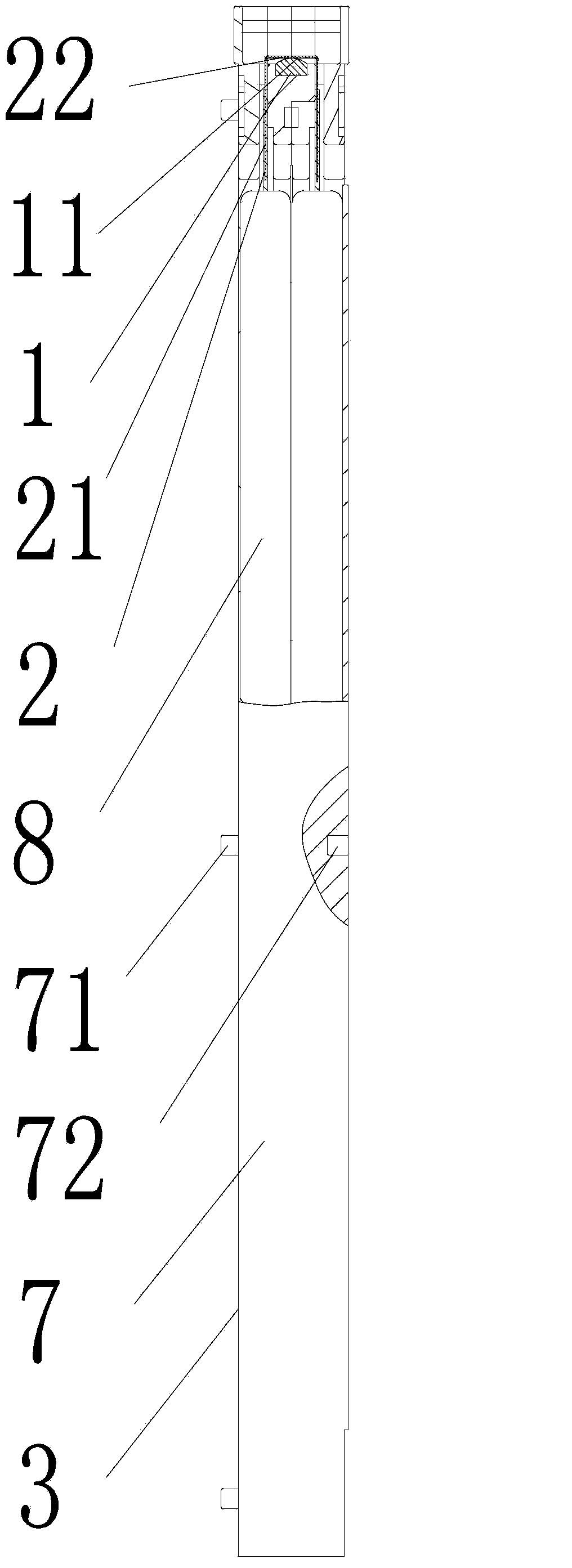

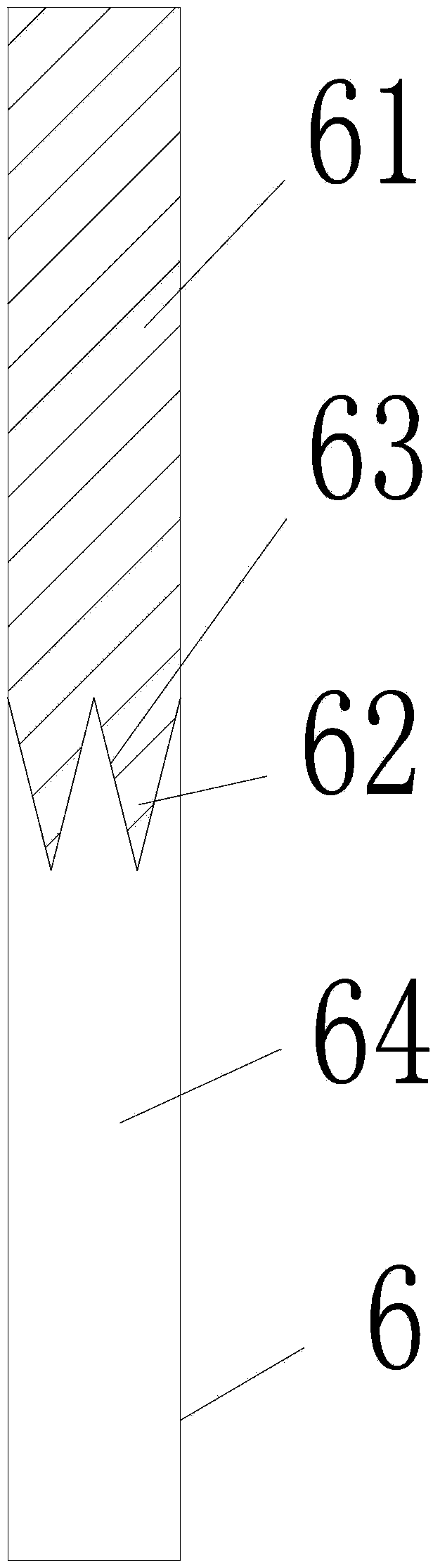

[0019] as attached figure 1 , attached figure 2 , attached image 3 Shown: an electric vehicle power module, including five positive battery units 3 with a fixed frame 7 and two aluminum tabs 2 with one end protruding from one side of the fixed frame 7, arranged at intervals with the positive battery unit 3 Five negative battery cells 5 with a fixed frame 7 and two copper tabs 4 with one end protruding from one side of the fixed frame 7, nine busbars for connecting the positive battery unit 3 and the negative battery unit 5 in series Row 6; one aluminum tab 2 of two adjacent positive battery units 3 and one copper tab 4 of negative battery unit 5 are respectively welded to a bus bar 6 . One end face of the fixed frame 7 is provided with six positioning pins 71; the other end face of the fixed frame 7 has six positioning holes 72 clearance fit with the positioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com