Process apparatus for fixedly welding camber profile frame and positioning method thereof

A technology of positioning welding and process equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the difficult to meet the new needs of new vehicle assembly requirements, the positioner is difficult to adjust in positioning coordination, difficult to It can meet the problems of single piece and small batch production, and achieve the effect of fast assembly positioning, fast response and simple structure

Inactive Publication Date: 2010-08-18

CHENGDU AIRCRAFT INDUSTRY GROUP

View PDF6 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The welding device not only has a large space size, but also needs to occupy a large workshop space, has poor operability, and is difficult to move. It also needs to design and manufacture a large number of high-precision and very dense positioners to complete the welding of the entire frame.

Generally, the post-welding aging time takes several months, the production efficiency is low, the design and manufacturing cost is expensive, and the production cycle is long, so it is difficult to meet the needs of single-piece small-batch production.

Once the product is modified, the shape and size change, the original profile welding device can only be discarded or idle, and a new welding device must be designed and manufactured, resulting in a lot of waste

Difficult to meet new demands and assembly demands of new models

The dense locators on it are also very difficult to adjust in terms of positioning coordination, and the accuracy of adjustment is often unsatisfactory

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

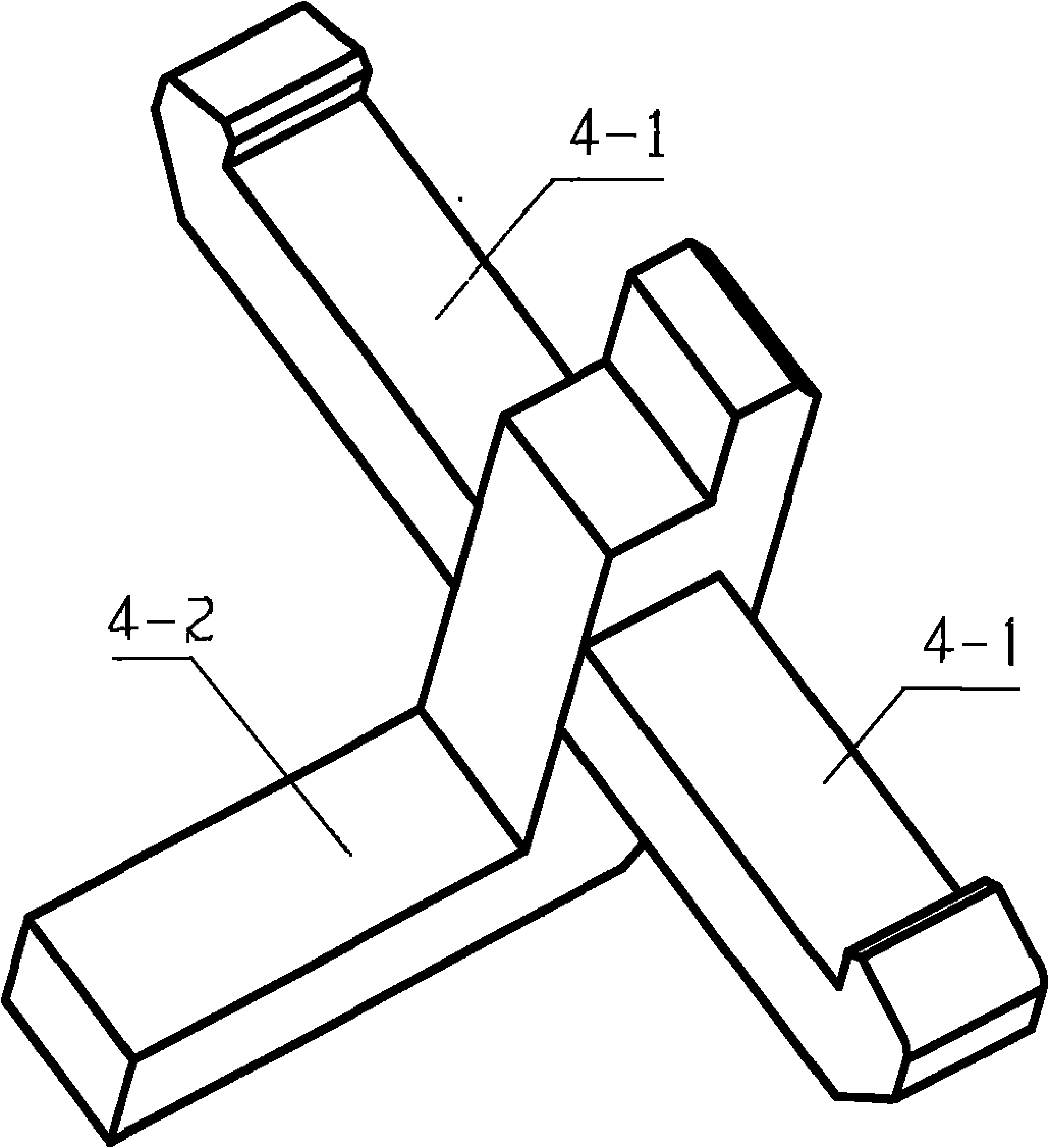

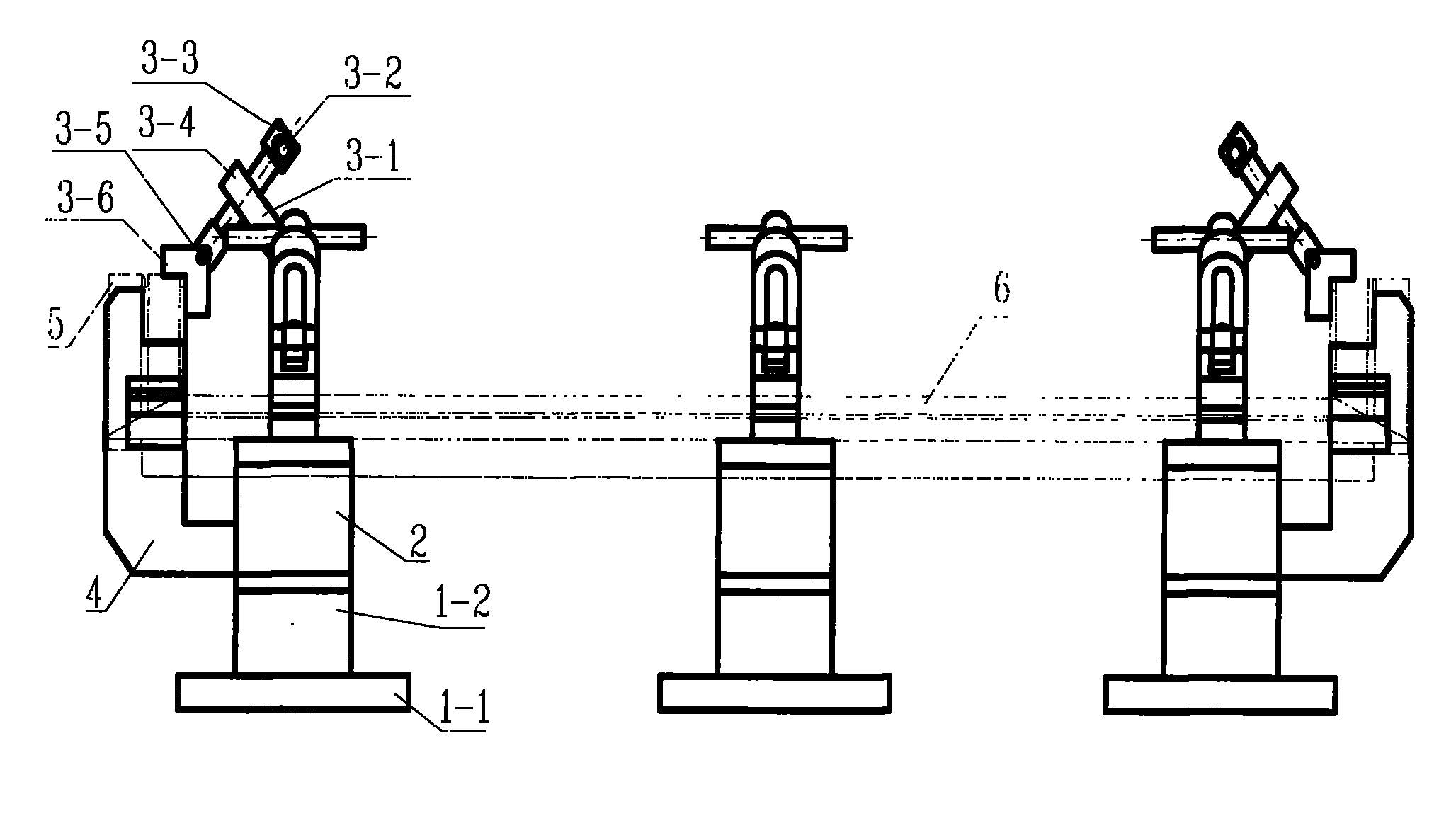

The invention discloses a process apparatus for fixedly welding a camber profile frame, comprising at least three groups of parallel welding and positioning devices for supporting rectangular frames to be welded. The welding and positioning device comprises a base module (1) movably and fixedly connected with a universal platform, the base module (1) is respectively provided with a port positioning module (2) and a pressing module (3) for positioning the upper end face and the lower end face at two sides of the rectangular frame camber profile (5), the symmetrical central line of the base module (1) is further provided with a frame edge positioning module (4) used for flexibly positioning the two sides of the rectangular frame. By adopting the modularized assembly welding and positioning device with the combined structure, the large rectangular frame with the length of 10 meters and the camber profile are correctly positioned on the module, thereby realizing the replaceable performance of welding and positioning, the universalization of the platform, and the physical dimension seriation, the parameterization and the universalization of the welding and positioning module. The invention can be movably and fixedly connected with the universal platform, thereby greatly reducing the idleness ratio of tools and the space occupation during the idleness time.

Description

Process Equipment and Positioning Method for Positioning Welded Camber Profile Frame technical field The invention relates to a process equipment for welding a large camber profile frame and a positioning method thereof. Background technique Currently used in high-speed trains, especially on maglev trains, a large number of arched frames welded with special-shaped materials are formed by a combination frame of special-shaped materials with a width greater than 1 meter and a length greater than 10 meters. overall framework. It has been rolled and bent into a certain arc, and welded with a longitudinal profile more than ten meters long in the length direction to form an arched frame. The welding method commonly used in the prior art is to use a welding device composed of an integral skeleton welding structure for welding. The welding device not only has a large space size, needs to occupy a large workshop space, has poor operability, and is difficult to move, but also need...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K37/04

Inventor 饶华刘跃文

Owner CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com