Venturi microbubble generator and application of generator in catalytic ozonation

A micro-bubble generator and ozone catalytic oxidation technology are applied in the directions of oxidized water/sewage treatment, fluid mixer, chemical instruments and methods, etc. The degree of refinement, refinement and crushing effect are enhanced, and the effect of improving the uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The present invention will be further described below in conjunction with the examples, but it should not be interpreted as a limitation of the present invention. The protection scope of the present invention is based on the contents recorded in the claims. protection scope of the present invention.

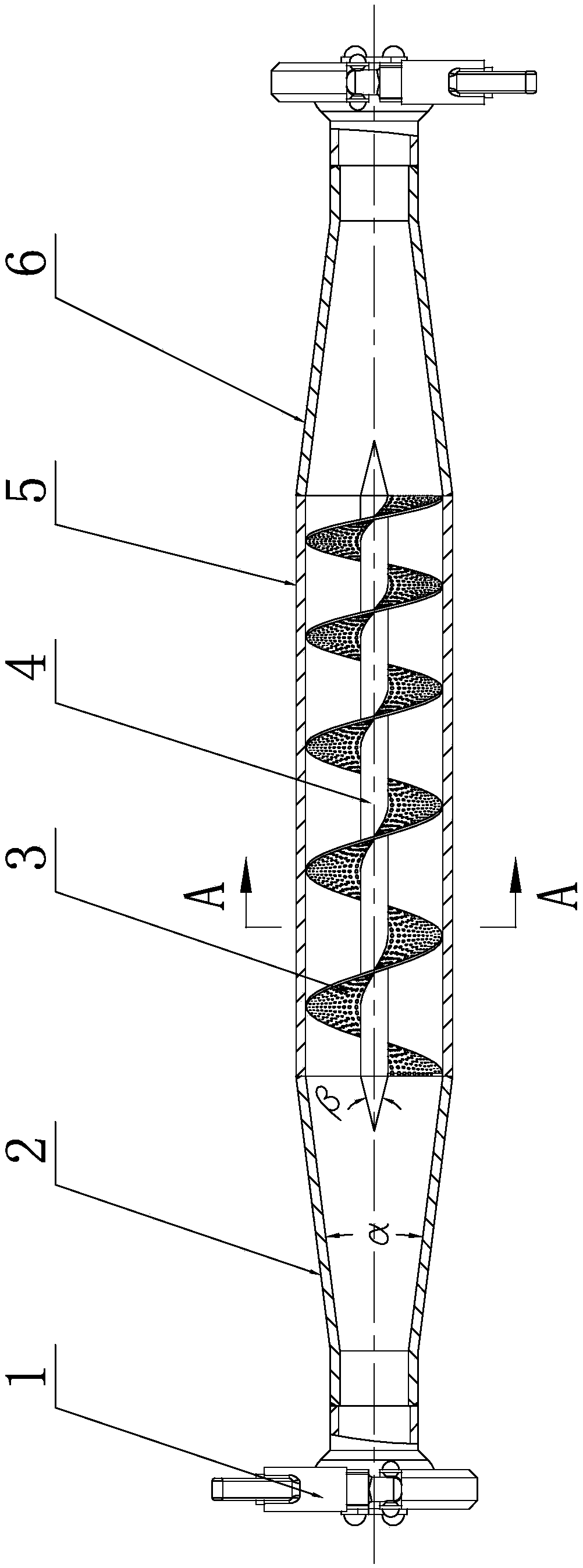

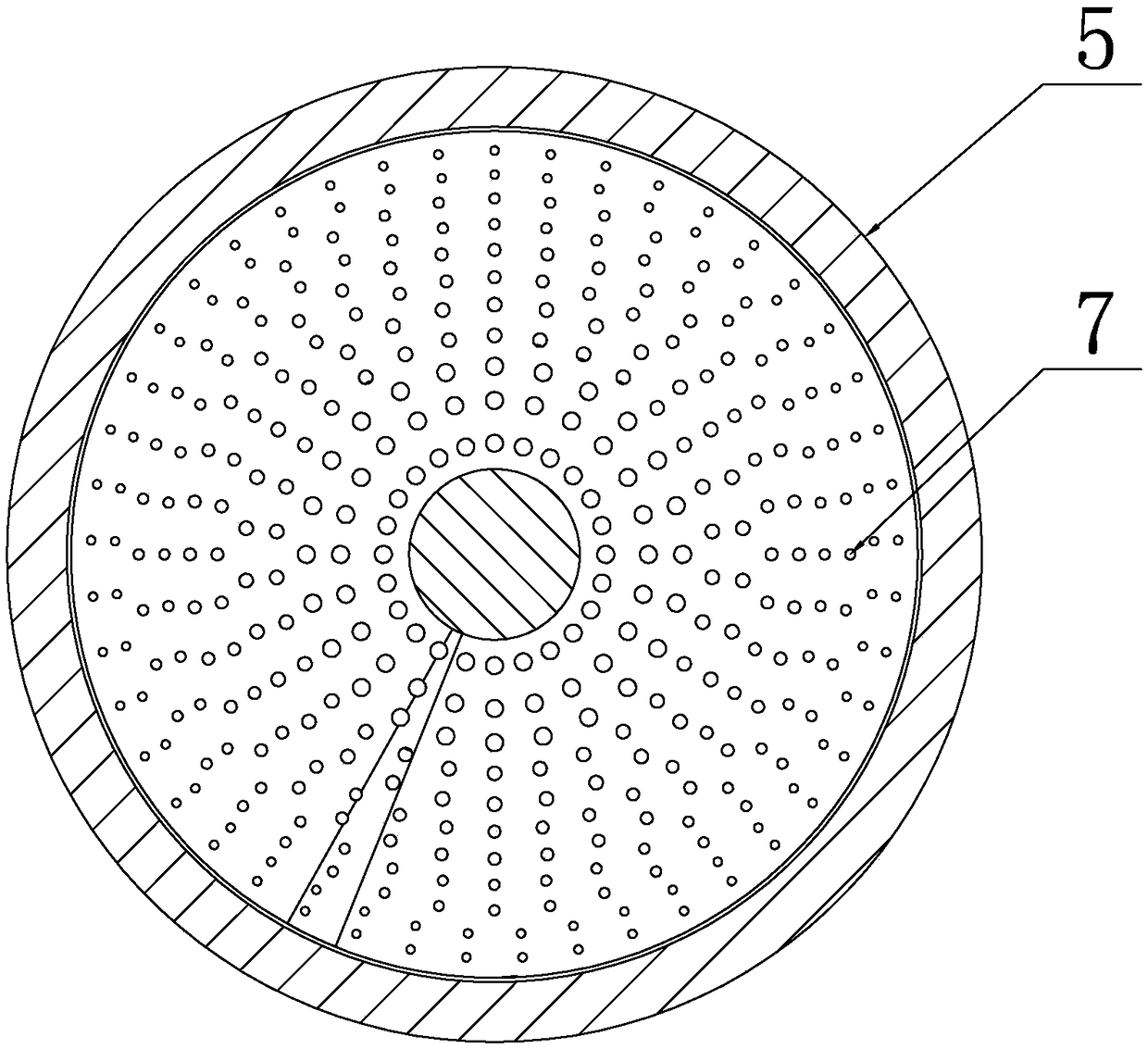

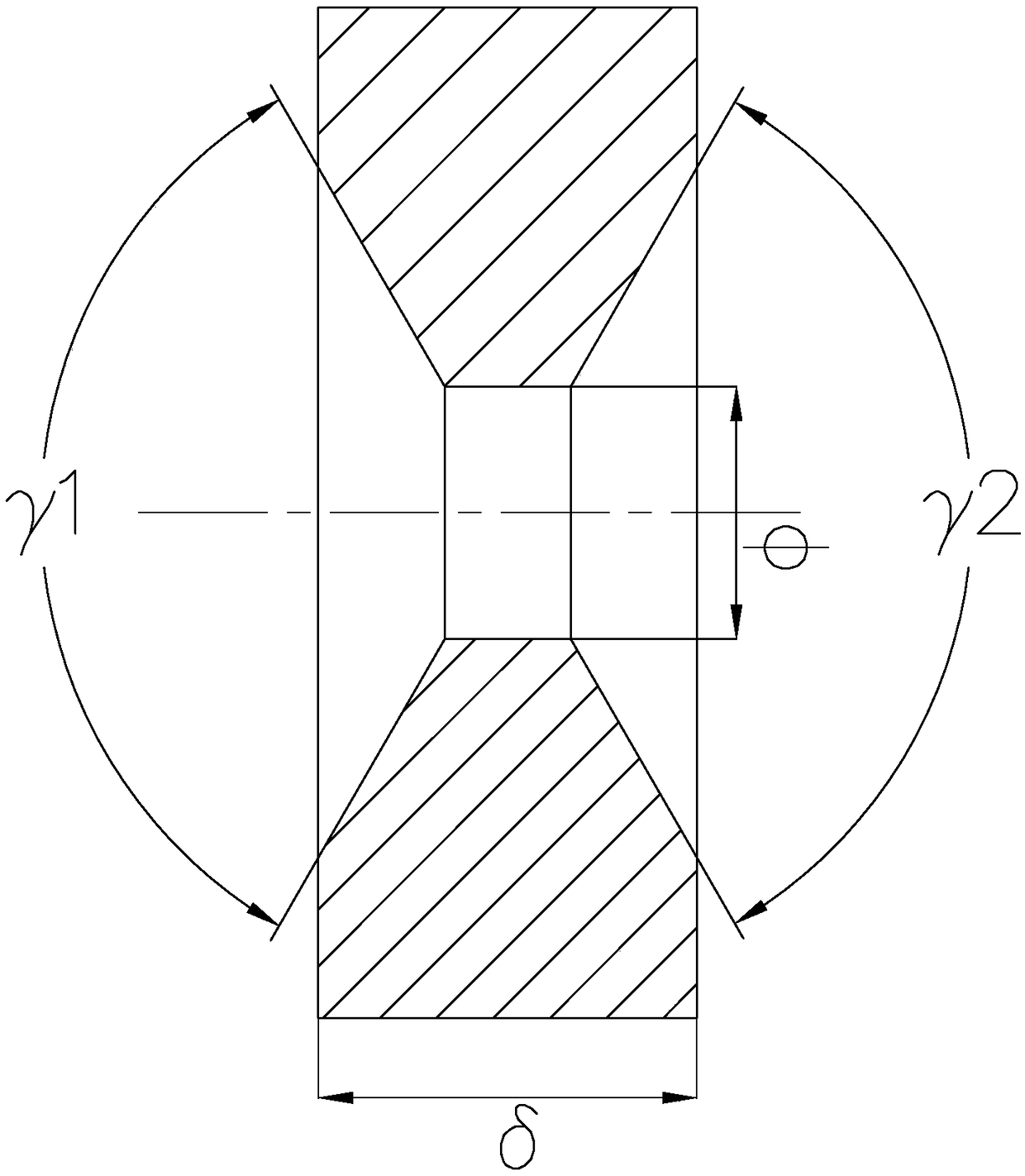

[0037] The overall structure of this embodiment is as shown in the figure, which includes a main pipe 5 with an inlet and an outlet at both ends. At the output end of the pump, the outlet of the main pipe 5 is output through the second venturi tube 6. The first venturi tube 2 and the second venturi tube 6 include an inlet section, a constriction section, a throat and a diffusion section connected in sequence from the outside to the inside. 5 is fixed with a screw blade 3 in the same direction as the material travels. There is an opening 7 on the screw blade 3. The diameter of the opening 7 decreases sequentially from the inside to the outside along the radial direction. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com