Quick crushing device for paint block

A crushing device and fast technology, applied in grain processing and other directions, can solve the problems of unsatisfactory paint block crushing effect and low paint crushing efficiency, and achieve the effect of comprehensive and thorough crushing, ingenious structure, and improved crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

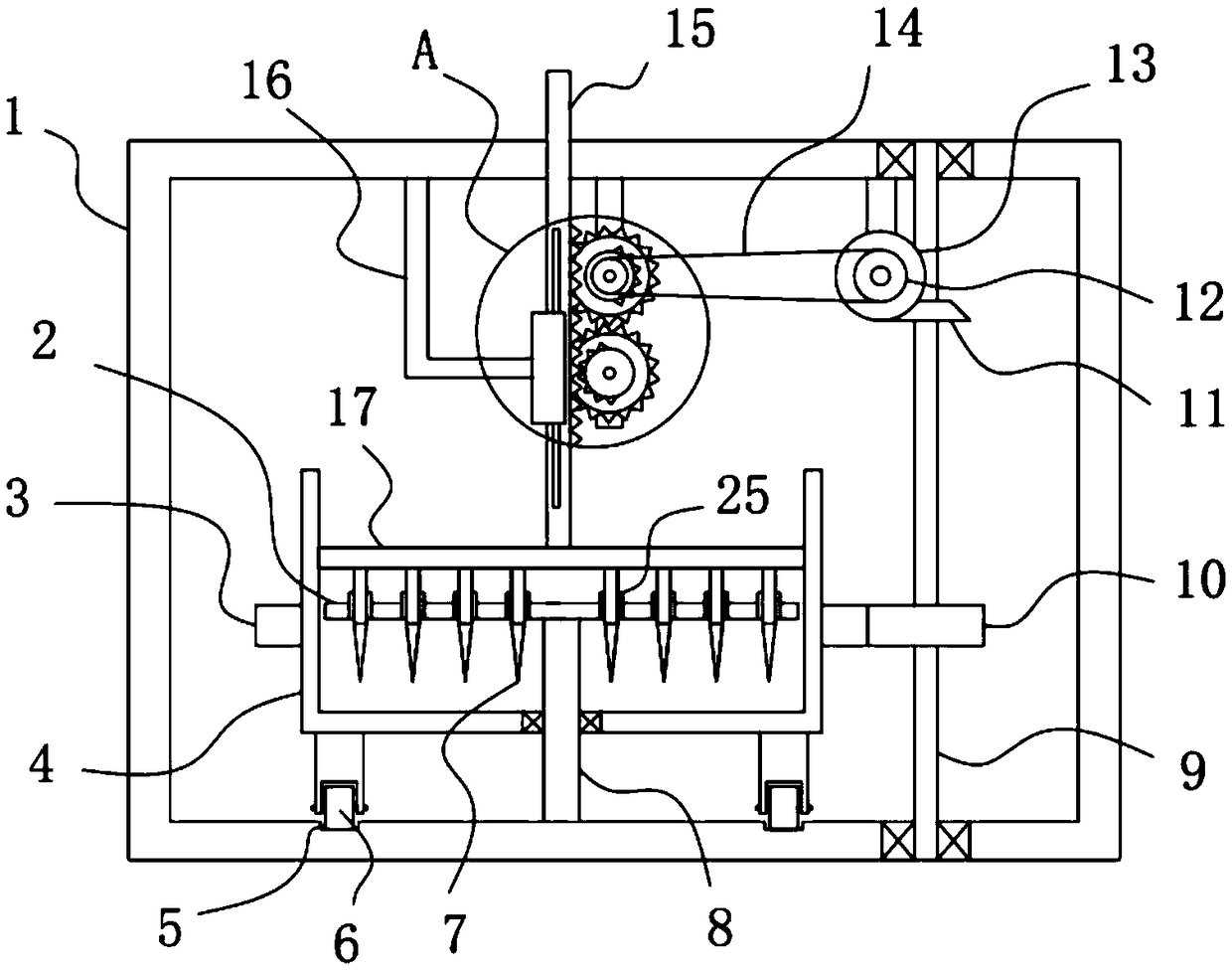

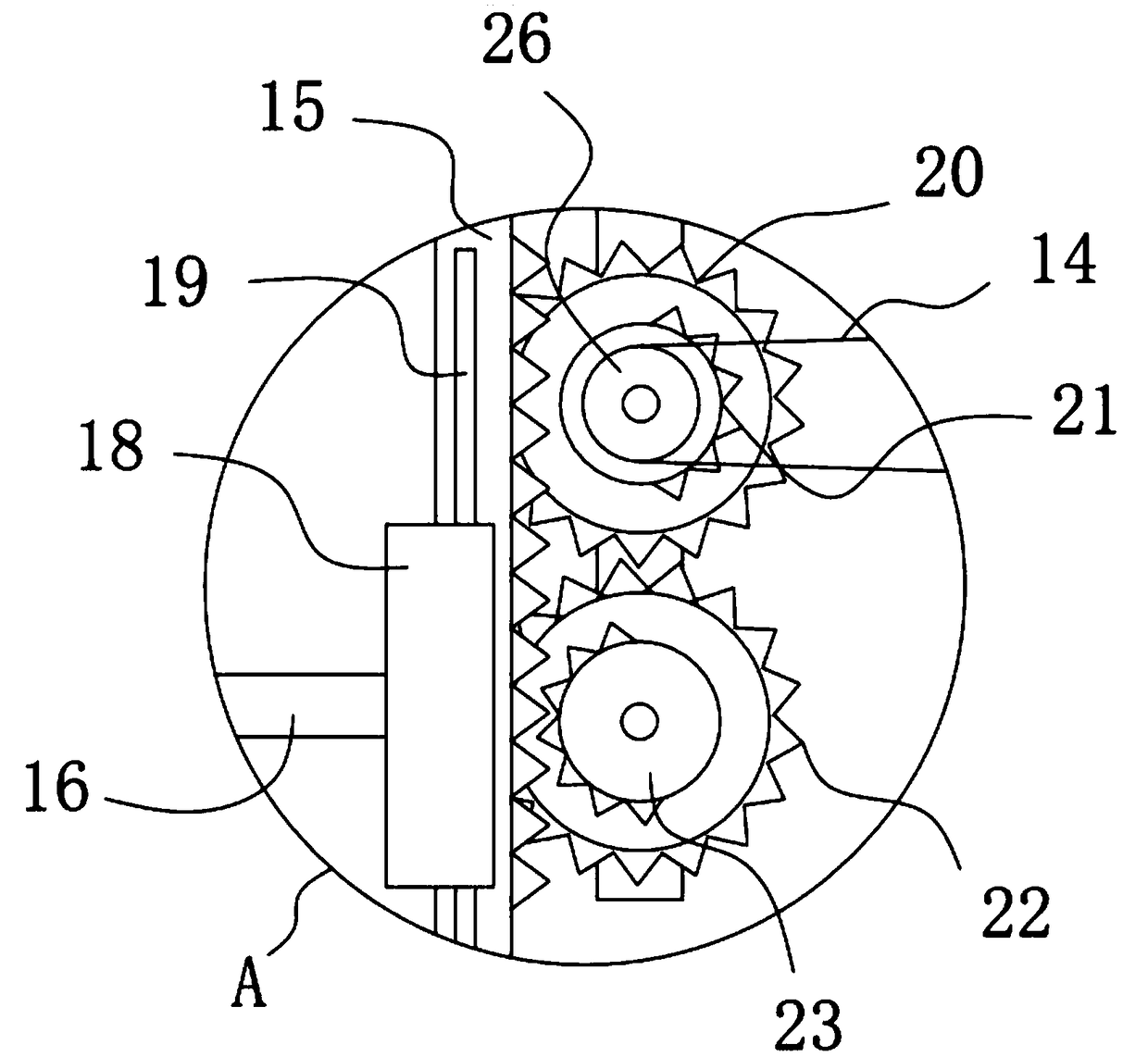

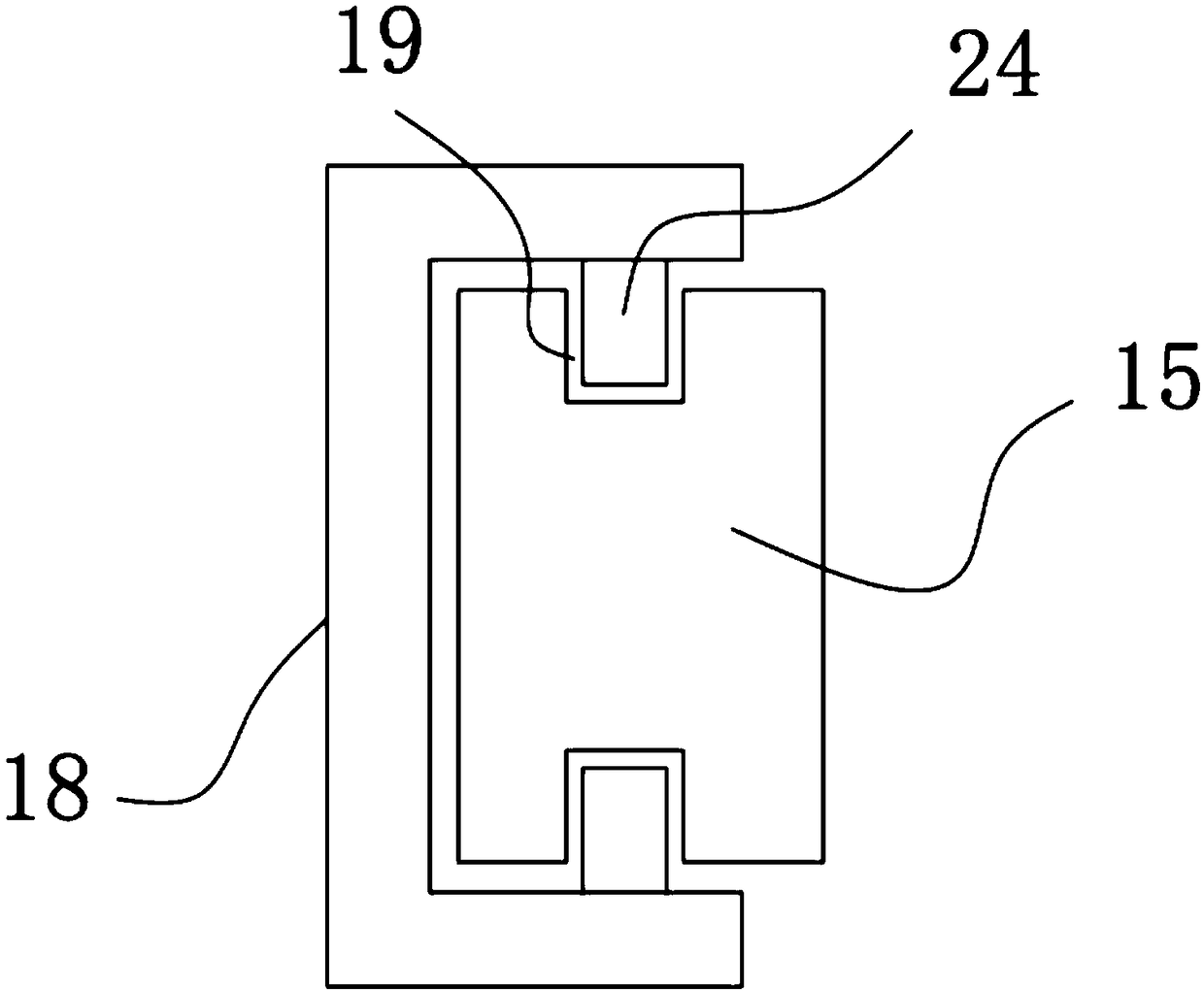

[0022] see Figure 1-4 , a quick crushing device for paint blocks, comprising an operating frame 1, a crushing barrel 4 is arranged in the operating frame 1, a fixing frame 16 is fixedly installed on the top of the operating frame 1, and a vertical sliding type is installed on the operating frame 1 Transmission rack 15, the transmission rack 15 is sleeved and connected with a limit frame 18, the right side of the transmission rack 15 is provided with a gear I20 and a gear II22 meshingly connected, and the fronts of the gear I20 and the gear II22 are coaxially fixedly installed with The incomplete gear I21 and the incomplete gear I23 matched by the transmission rack 15, the teeth of the incomplete gear I21 and the incomplete gear I23 face oppositely, and the front of the incomplete gear I21 is coaxially fixed with a driven pulley 26, so The operation frame 1 is internally rotatable with a bevel gear II13, and the bevel gear II13 is frontally rotatably provided with a driving pu...

Embodiment 2

[0025] On the basis of Embodiment 1, in addition, a driven shaft 9 is rotatably arranged in the operating frame 1, and a drive gear 10 is fixedly mounted on the surface of the driven shaft 9, and a drive gear 10 is sleeved and fixedly mounted on the surface of the crushing bucket 4. The outer ring gear 3 meshingly connected; the surface of the driven shaft 9 is sheathed and fixedly installed with a bevel gear I11 meshingly connected with the bevel gear II13.

[0026] The rotation of the bevel gear II13 drives the bevel gear I11 meshed with it to rotate, the bevel gear I11 drives the driven shaft 9 to rotate, the driven shaft 9 drives the drive gear 10 to rotate, and the drive gear 10 is driven by the external ring gear 3 meshed with it The crushing barrel 4 rotates, and then drives the rotation of the block paint inside the crushing barrel 4 to realize uniform spreading, ensure the full and comprehensive crushing effect of the crushing blade 7 on the block paint, and greatly im...

Embodiment 3

[0028] On the basis of Embodiment 2, in addition, the bottom of the operating frame 1 is vertically fixed with a rotating shaft 8 extending to the inside of the crushing bucket 4, and the upper end of the rotating shaft 8 is fixed with a transverse partition 2 below the crushing disc 17. A set plate 25 vertically corresponding to the crushing blade 7 is evenly and fixedly installed on the partition plate 2 .

[0029] When the crushing blade 7 moves up and down to crush the paint block, the crushing blade 7 penetrates the cover plate 25 up and down, and the side wall of the crushing blade 7 is attached to the inner side wall of the cover plate 25 to realize the adhesion of the cover plate 25 to the crushing blade 7 scrape off the paint to ensure the cleanliness of the surface of the broken blade 7 and ensure a sufficient crushing effect on the paint block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com