Efficient crushing device for aniseed processing

A high-efficiency pulverization and crushing box technology, applied in grain processing and other directions, can solve the problems of poor pulverization effect, insufficient uniformity of large powder particles, insufficient refinement of large materials, etc., and achieve the effect of increasing the degree of refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

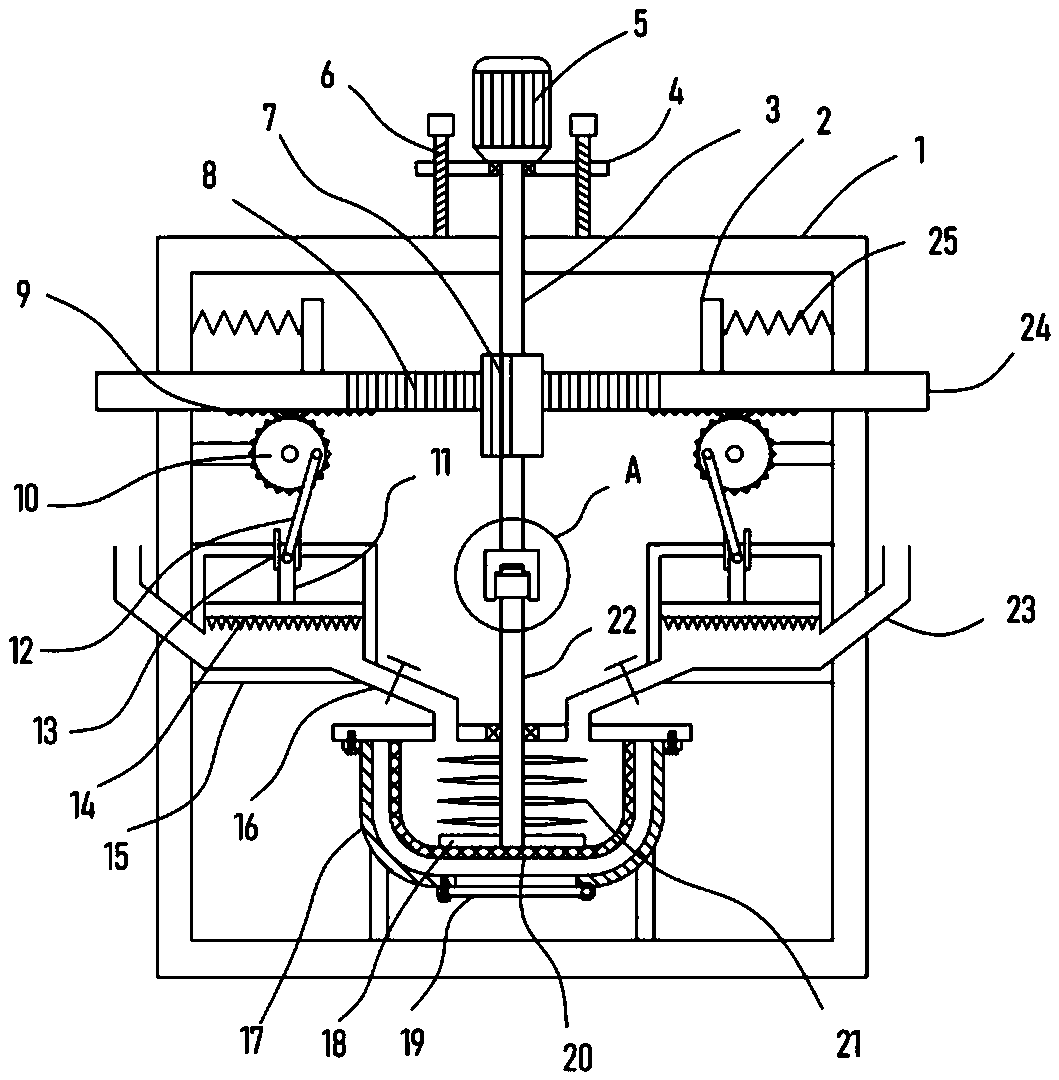

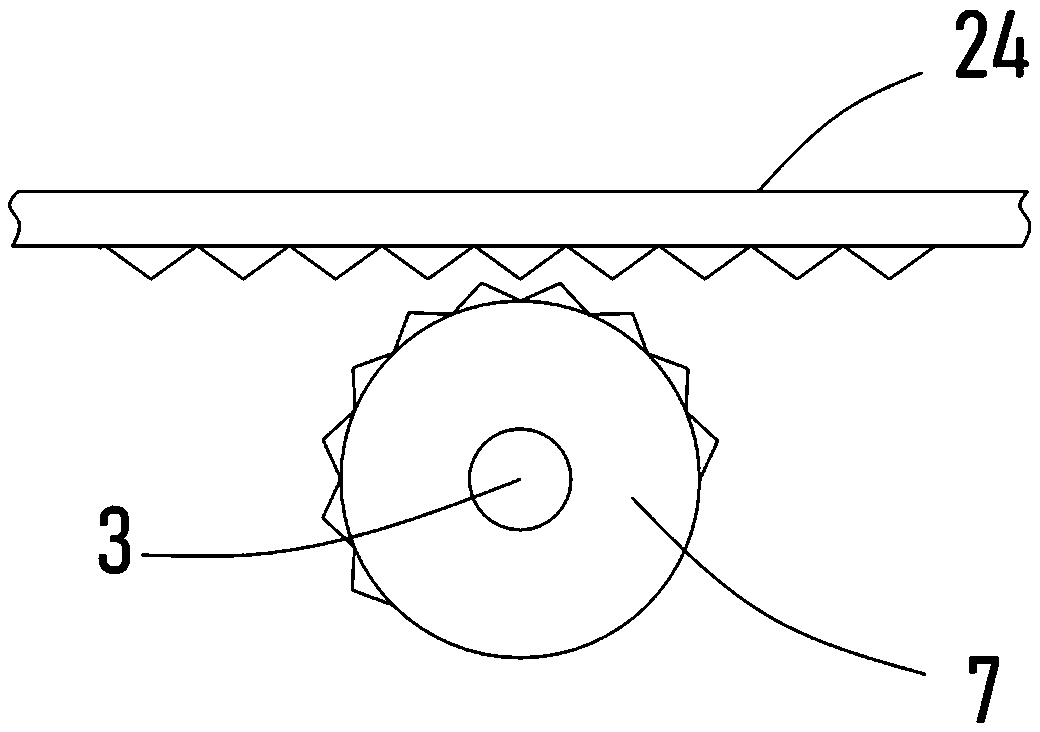

[0021] see Figure 1-3 , a high-efficiency crushing device for large material processing, including an operation box 1, a drive motor 5 is arranged on the top of the operation box 1, a drive shaft 3 is coaxially fixed to the output shaft of the drive motor 5, and an incomplete Cylindrical spur gear 7, slide plate 24 is installed slidingly in the operation box 1, is fixed with spur rack I8 meshing with incomplete cylindrical spur gear 7 on the slide plate 24, driving motor 5 drives drive shaft 3 to rotate, and drive shaft 3 drives not The complete cylindrical spur gear 7 rotates, the upper surface of the sliding plate 24 vertically fixes the limit baffle 2, and a return spring 25 is horizontally fixed between the limit baffle 2 and the inner wall of the operation box 1, and the incomplete cylindrical spur gear 7 intermittently and slides The spur rack I8 on the plate 24 engages, and under the elastic force of the return spring 25, the sliding plate 24 drives the spur rack II9 t...

Embodiment 2

[0026] On the basis of Embodiment 1, in addition, the top of the operation box 1 is horizontally provided with an adjustment plate 4, the driving motor 5 is fixed on the adjustment plate 4, and the adjustment screw 6 is threaded on the adjustment plate 4, and the adjustment screw 6 lower end It is pivotally connected with the operation box 1.

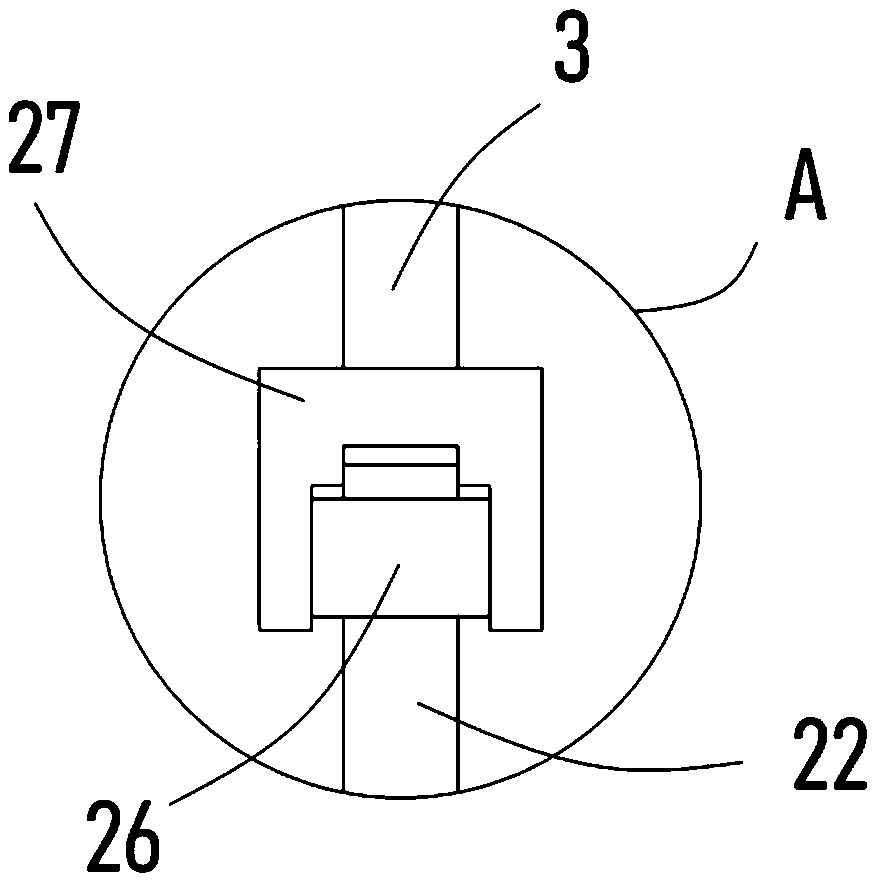

[0027] Further, the lower end of the driving shaft 3 is fixedly mounted with a clamping groove block 27 , and the upper end of the driven shaft 22 is fixedly mounted with a transmission block 26 which is clamped and matched with the clamping groove block 27 . Turning the adjusting screw 6 can drive the adjusting plate 4 to move downward together with the driving motor 5, and the driving shaft 3 moves downward to realize the transmission cooperation between the clamping groove block 27 and the transmission block 26, and then realize the driving shaft 3 driving the driven shaft 22 to rotate , and then the cutting blade 21 is rotated, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com