LT type elastic sleeve pin coupling

A technology of pin coupling and elastic sleeve, applied in the direction of elastic coupling, coupling, mechanical equipment, etc., can solve the problems of easy collision, scrapped parts, not easy to disassemble, etc., so as to prolong the service life and improve the Service life, easy assembly and positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments:

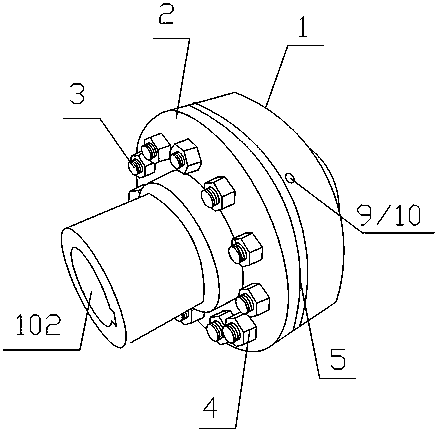

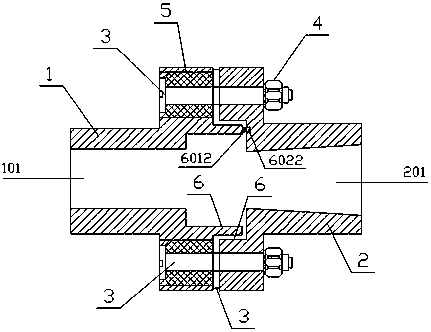

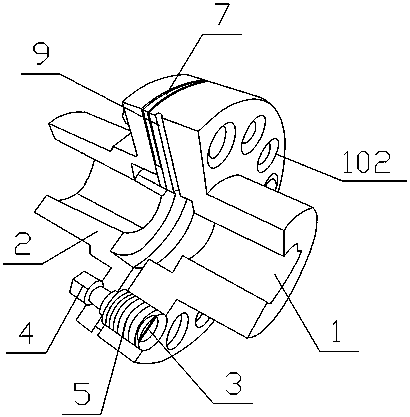

[0025] A LT-type elastic sleeve pin coupling, refer to Figure 1 to Figure 8 , including left half coupling 1, right half coupling 2, several fastening pins 3, several fastening nuts 4 and several elastic sleeves 5; said left half coupling 1 and right half coupling The connectors 2 are all T-shaped. Several elastic sleeve placement holes 103 are evenly arranged around the left shaft hole 102 on the connecting surface 101 of the left half coupling, and the connecting surface 201 of the right half coupling surrounds the left shaft hole 202 and Bolt holes 203 are set at the positions corresponding to the elastic sleeve placement holes 103 of the left half coupling; 5 through and through the bolt hole 201 of the right half coupling 2 is connected with the fastening nut 4, and the contacting side of the left half coupling 1 and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com