Patents

Literature

38results about How to "Solve the problem of not easy disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

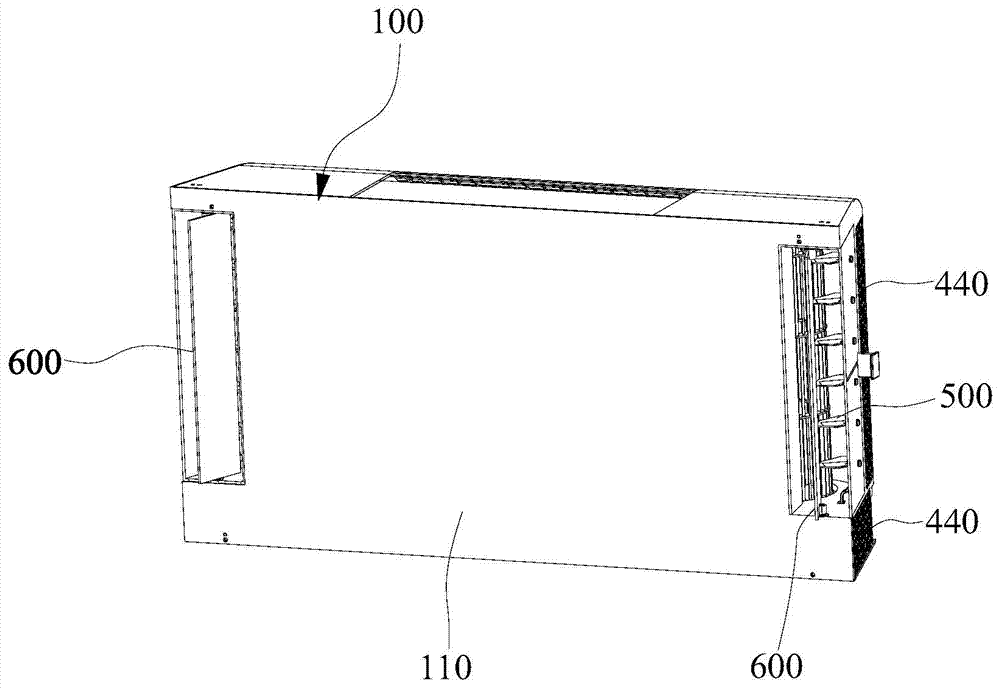

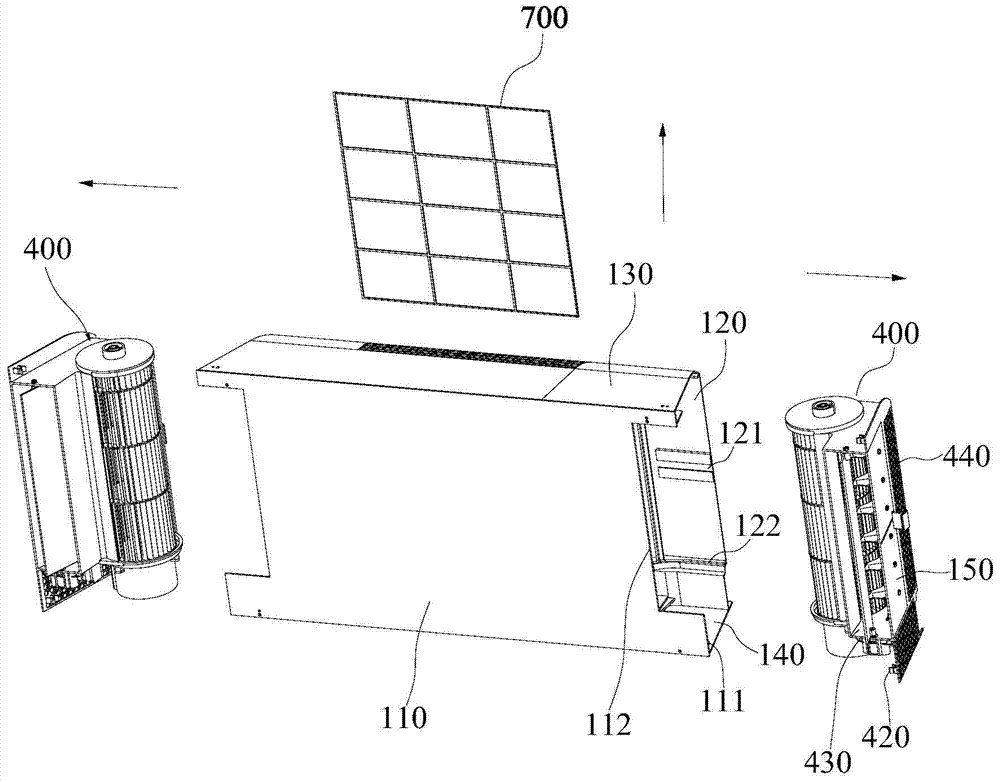

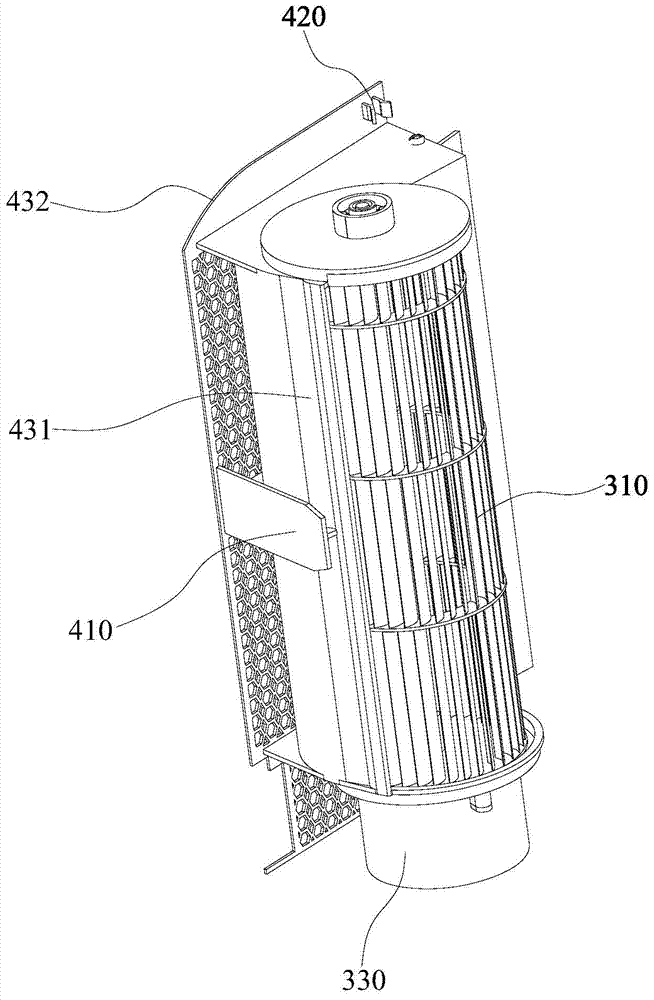

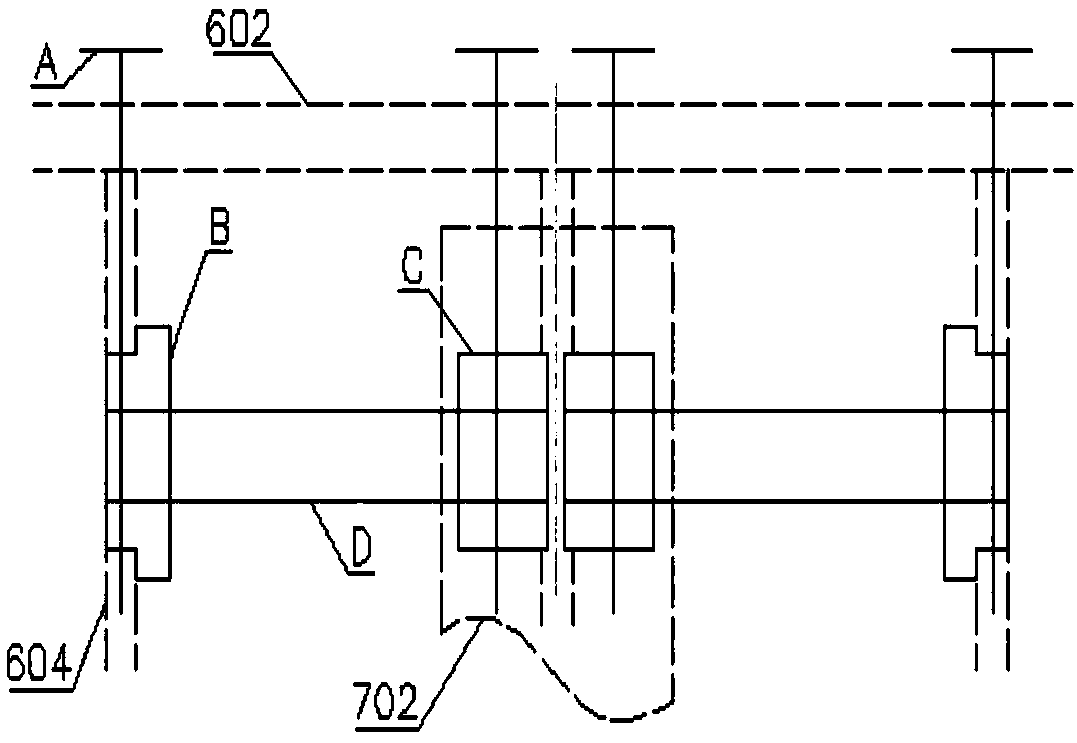

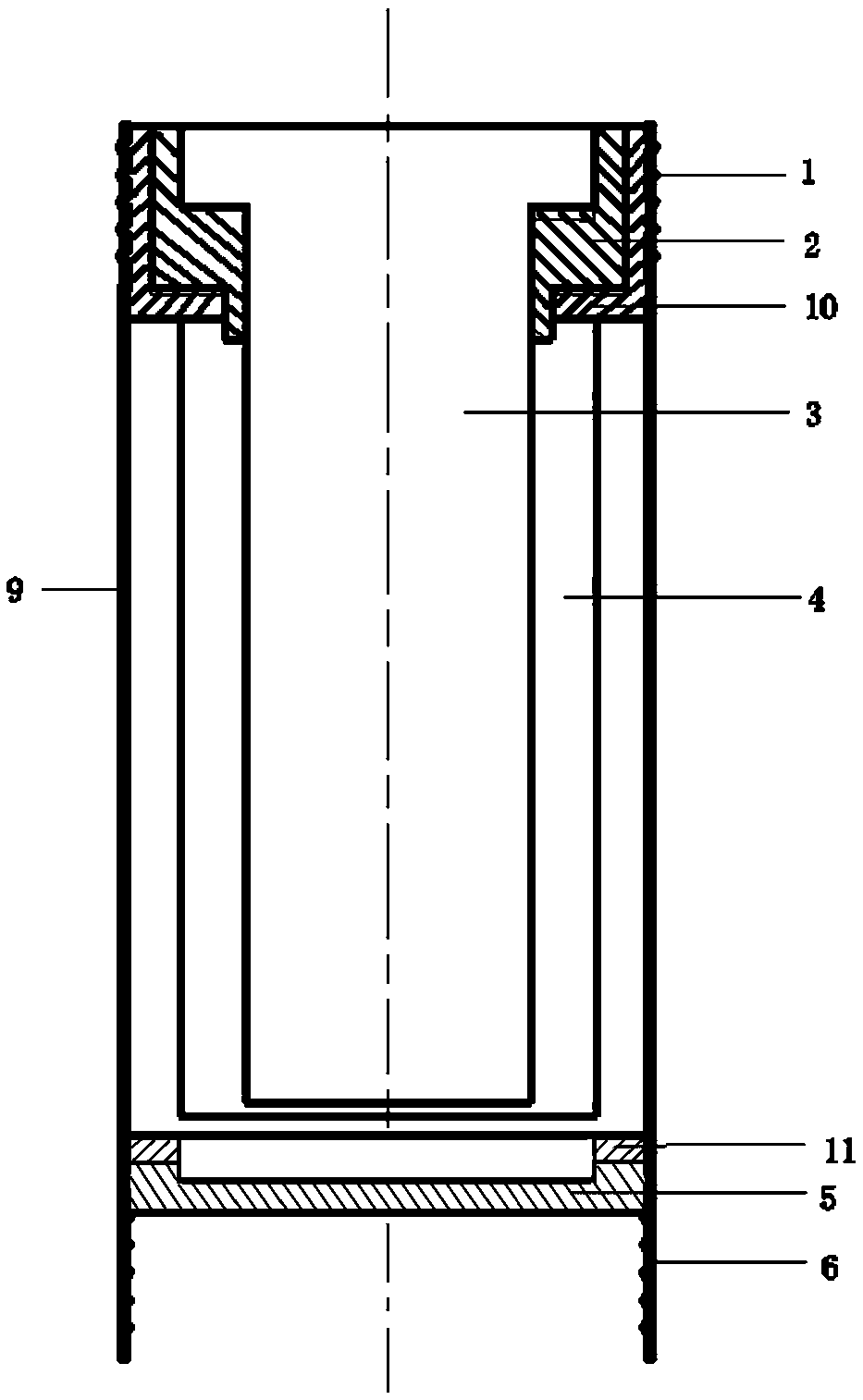

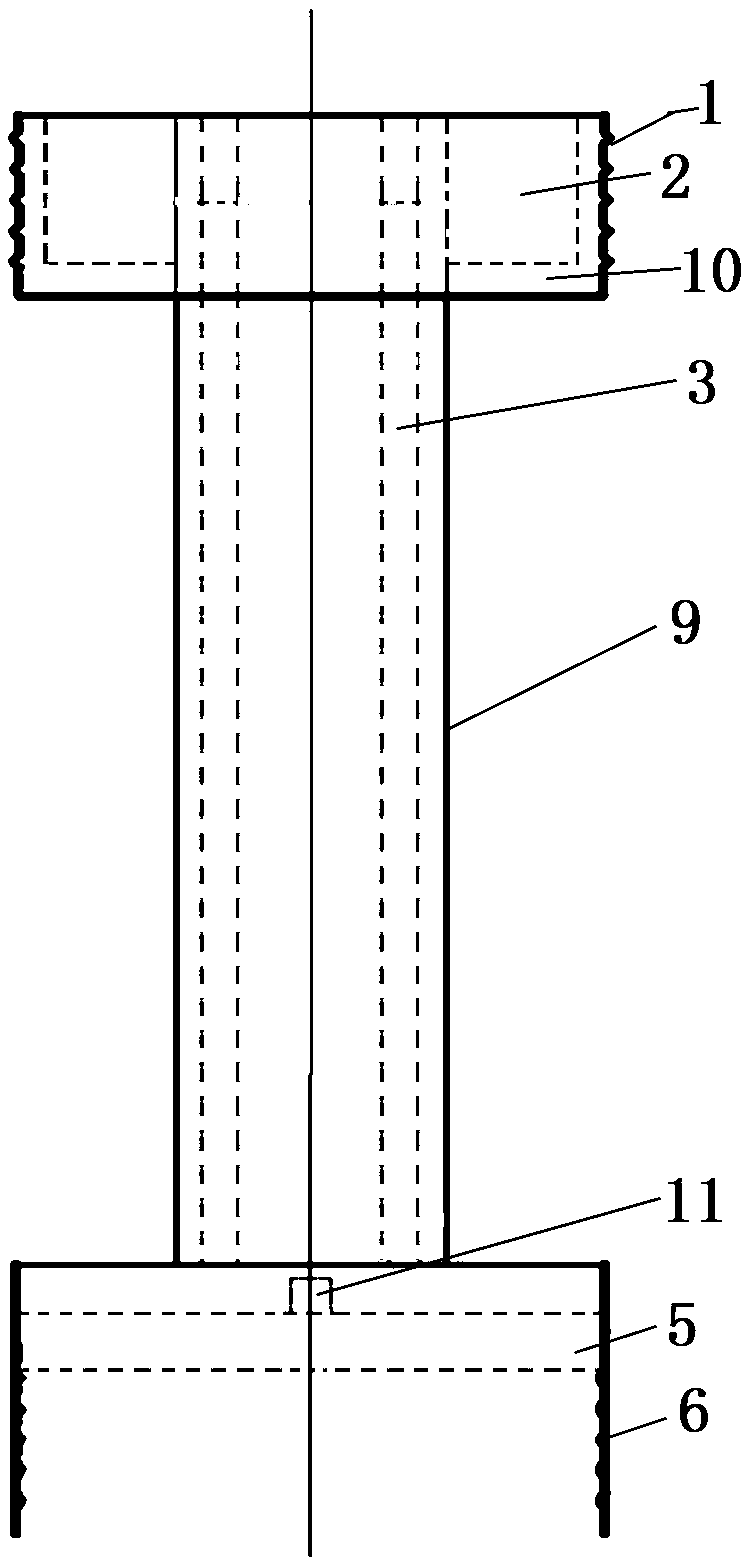

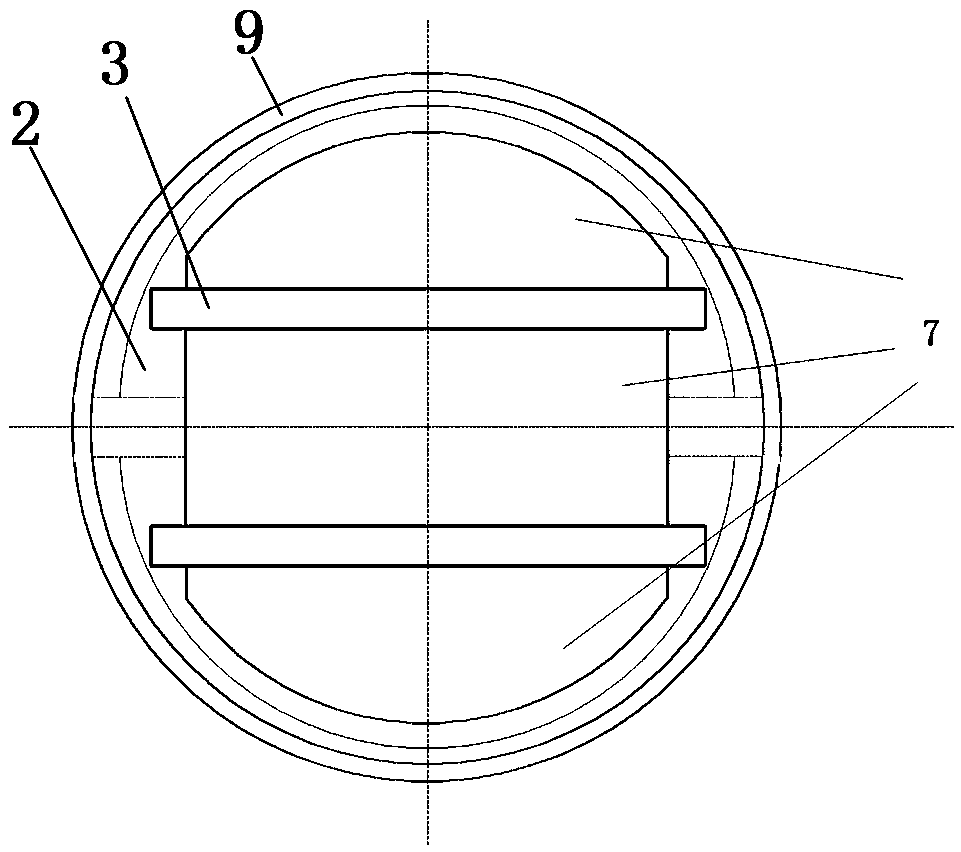

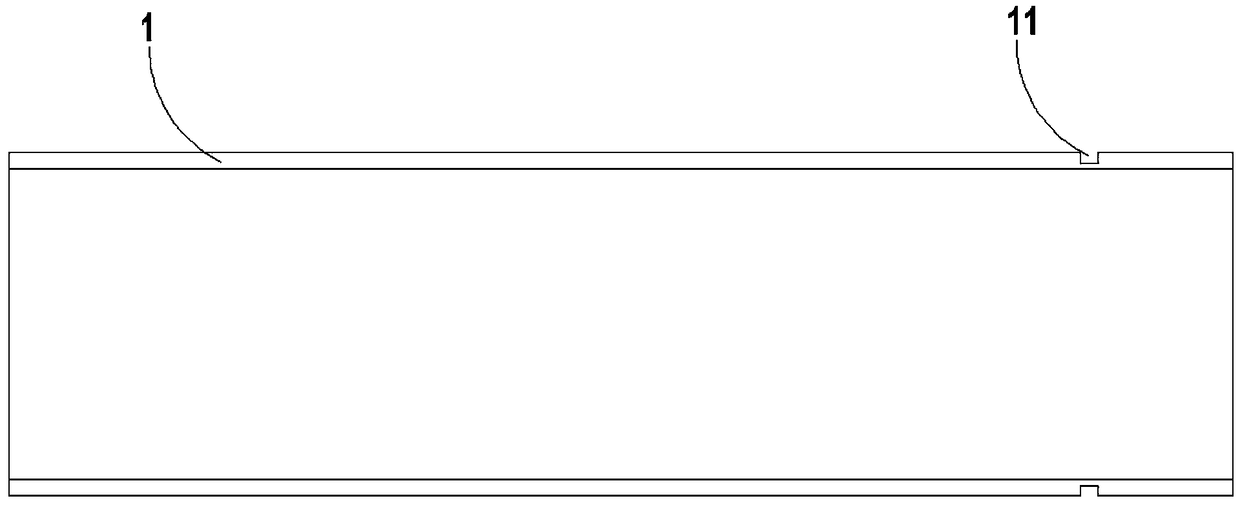

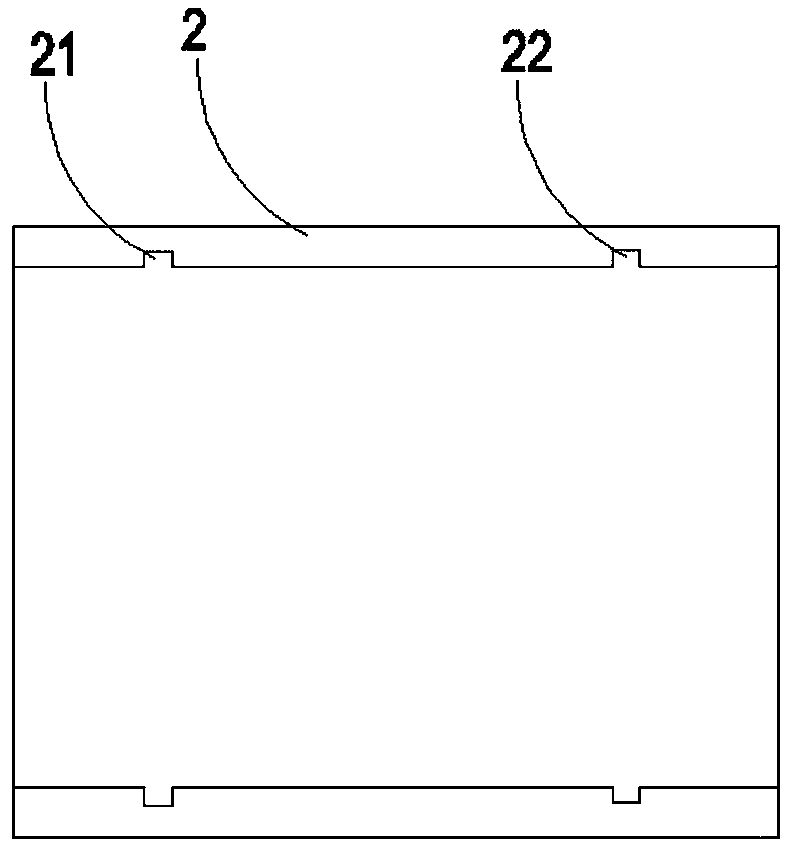

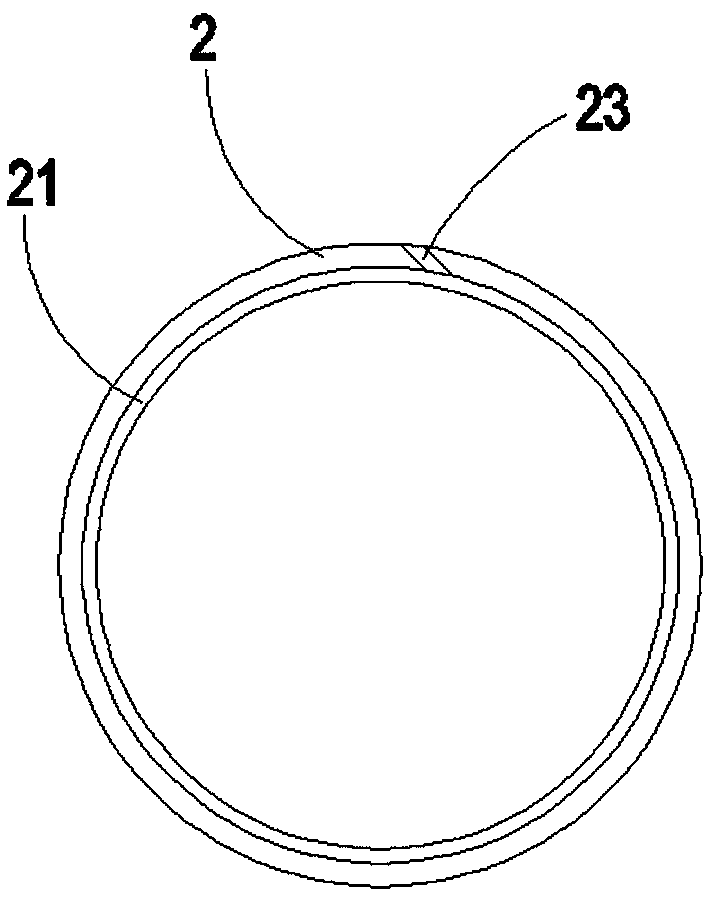

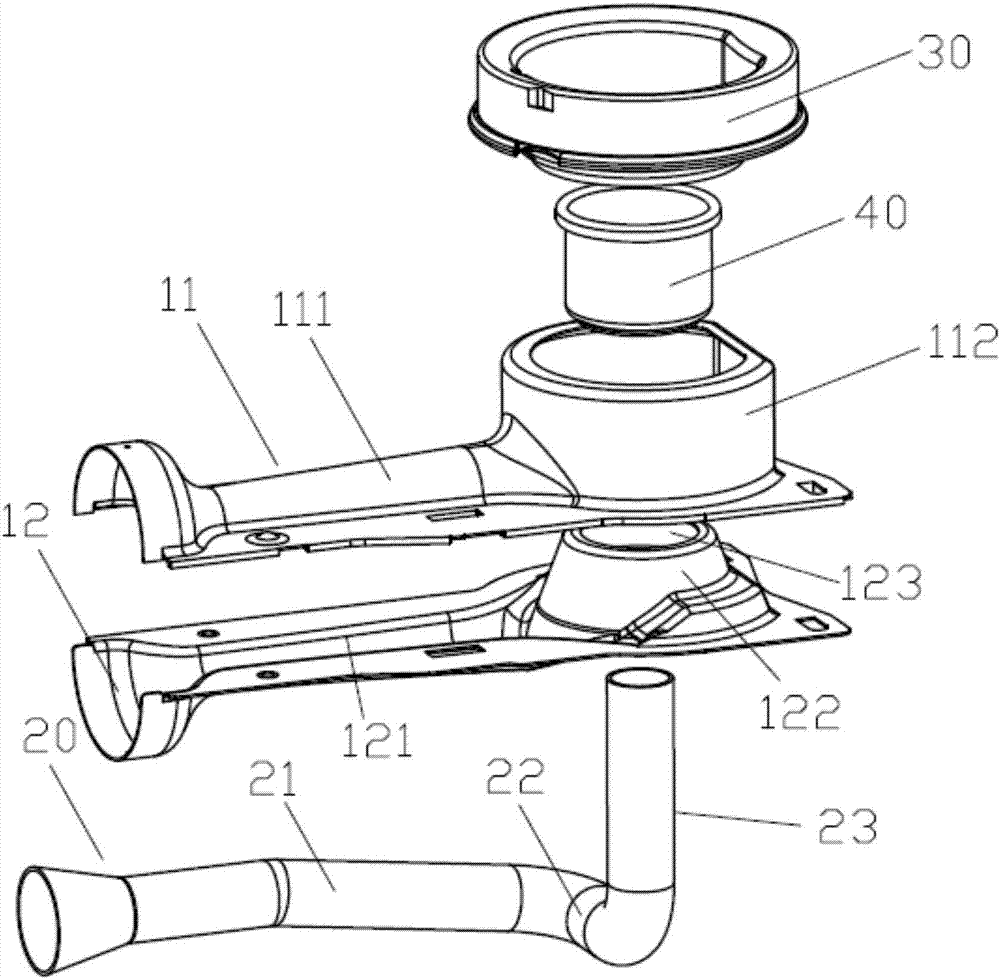

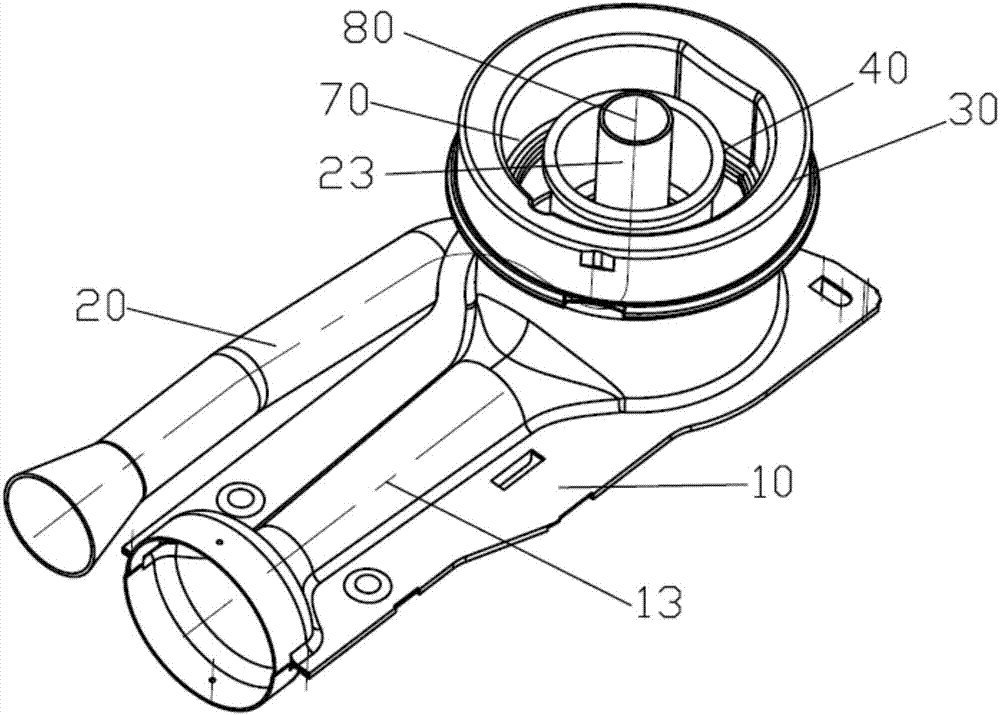

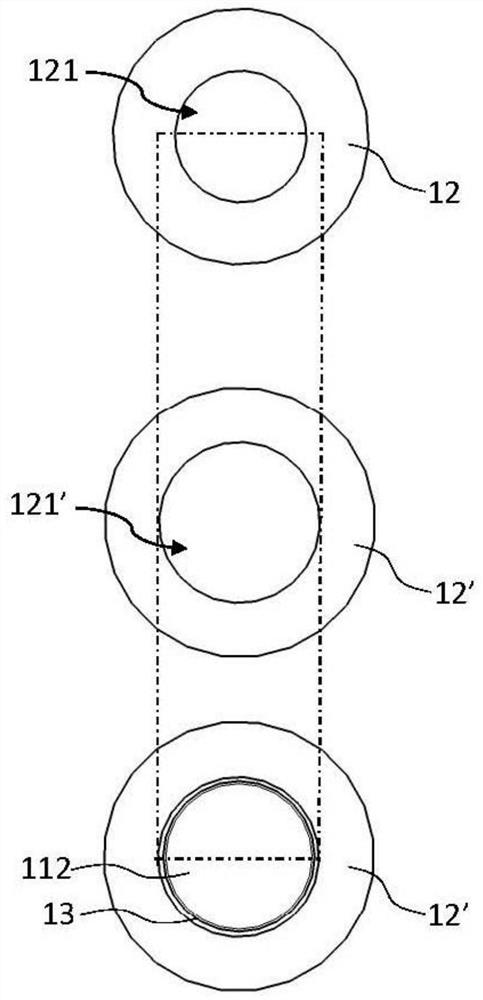

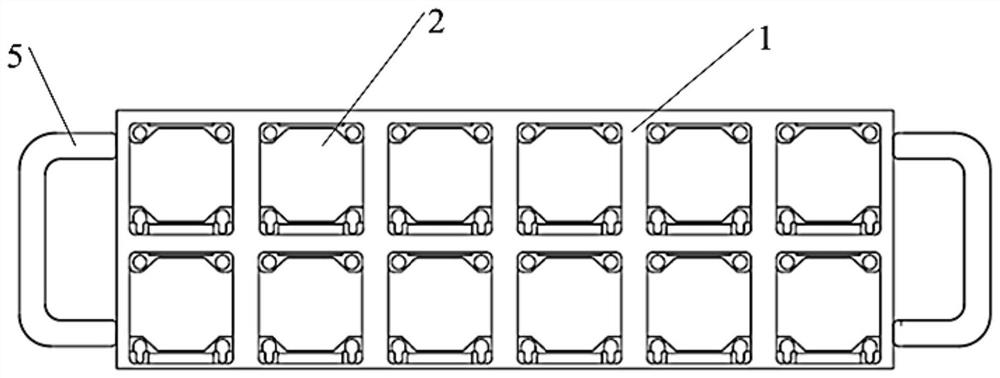

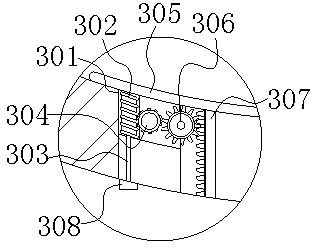

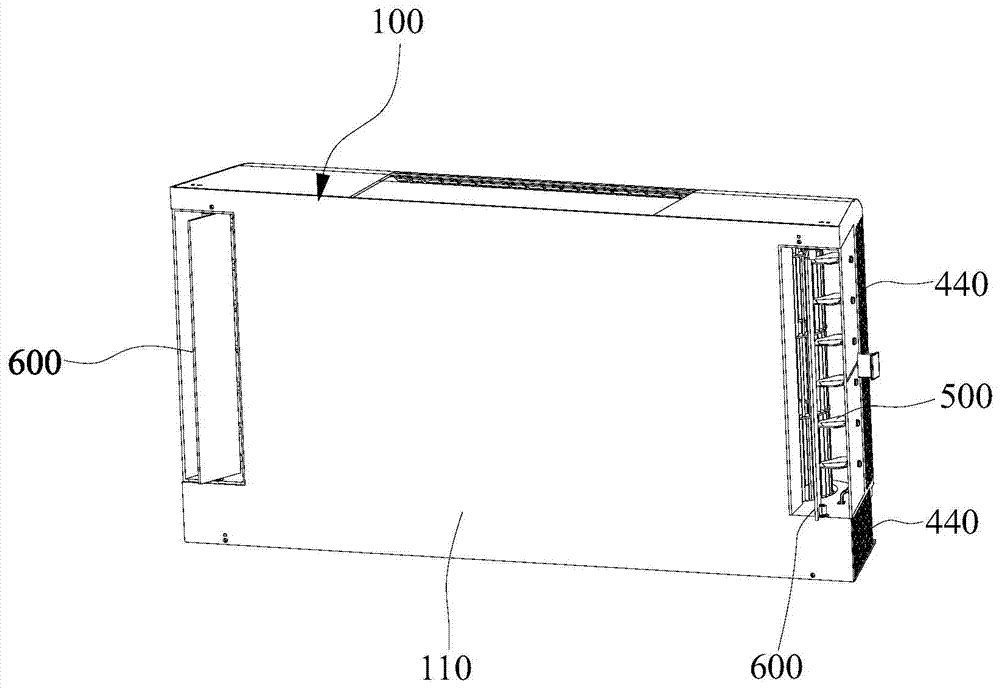

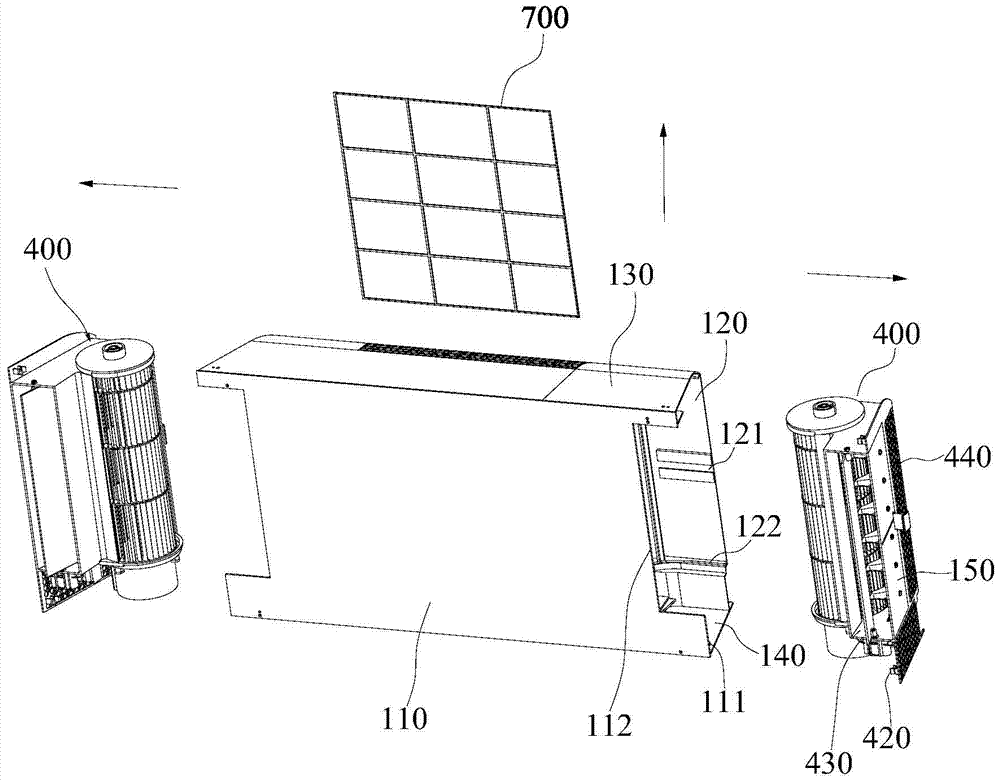

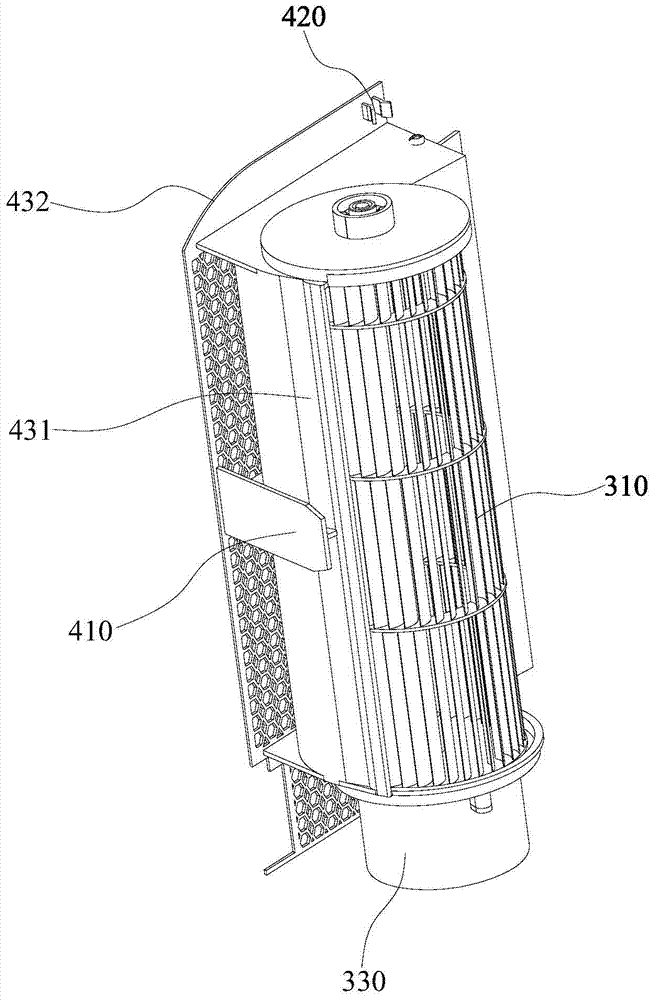

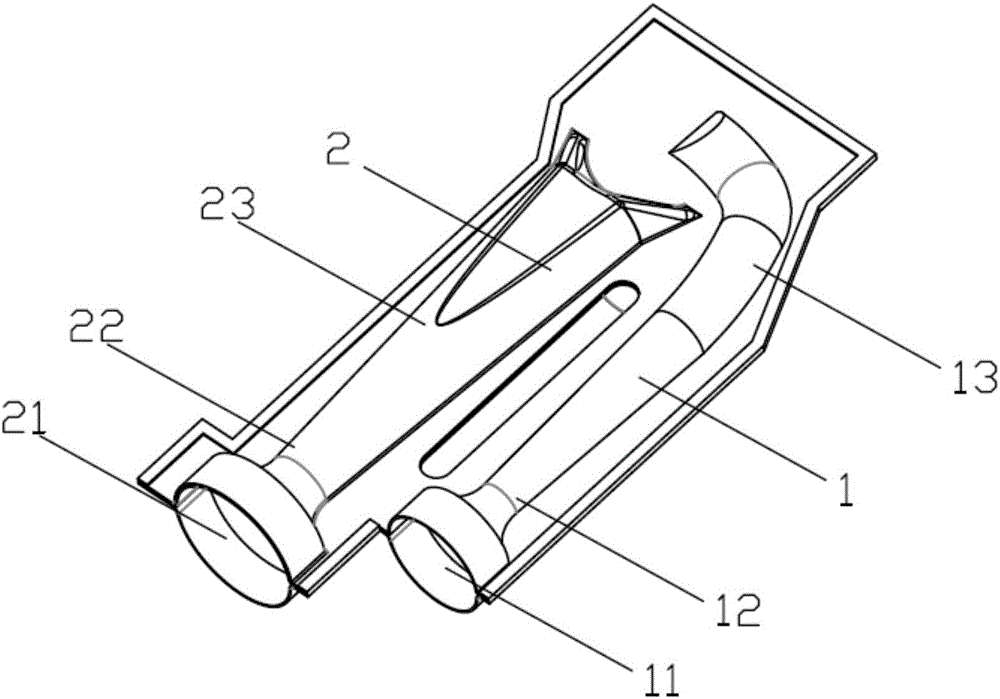

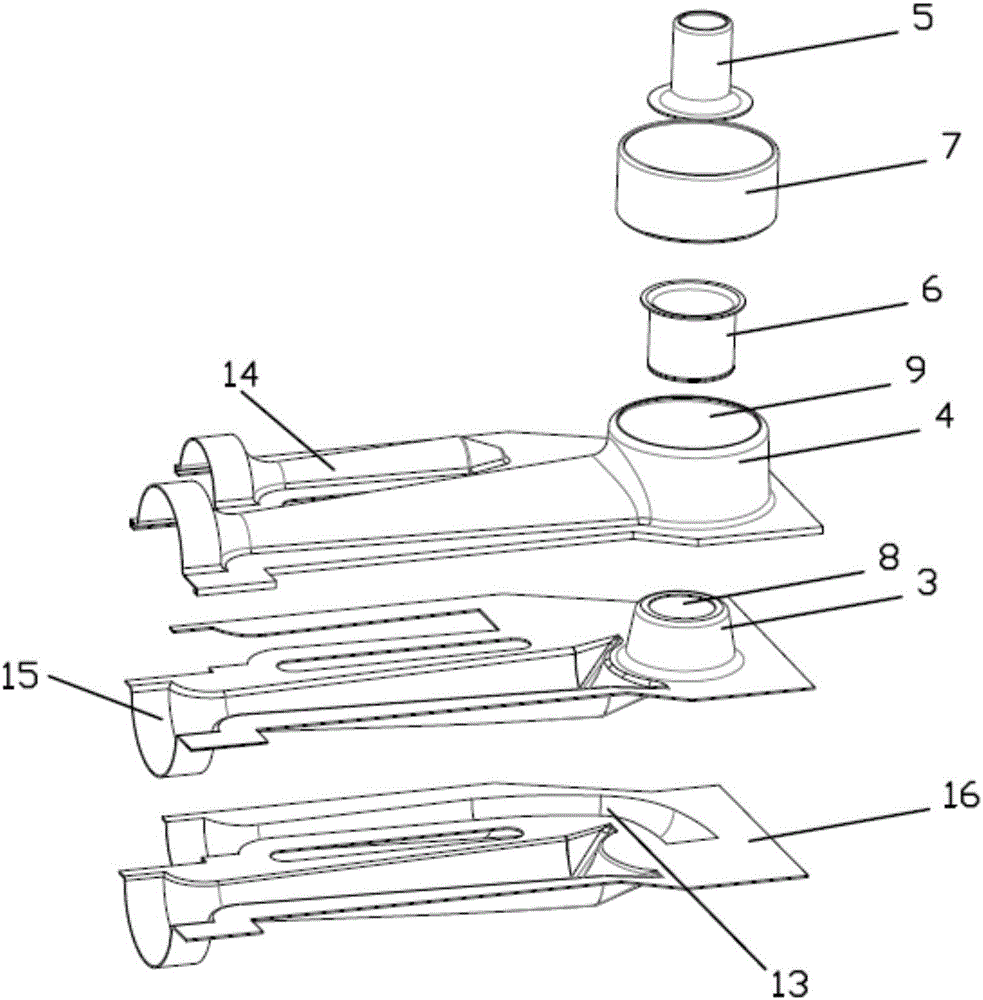

Easy-to-disassemble and wash air conditioner indoor unit

ActiveCN104501306ASolve the problem of not easy disassemblyLighting and heating apparatusHeating and ventilation casings/coversWaste managementHeat exchanger

The invention relates to the technical field of air conditioners, and provides an easy-to-disassemble and wash air conditioner indoor unit, which comprises a shell, a heat exchanger arranged in the shell, fans and air duct components, wherein the air duct components are positioned on the side edges of the heat exchanger, and are detachably connected with the shell. According to the air conditioner indoor unit, the two air duct components are detachably connected with the shell respectively, and then an ordinary user can disassemble the air duct components to wash the fans, and assembles the air duct components after the fans are washed; by such a structure, the problem of difficulty in disassembling of a conventional air conditioner indoor unit is solved, and the market competitiveness of the product is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

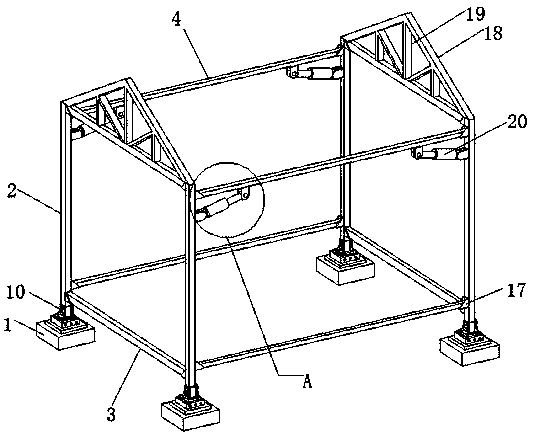

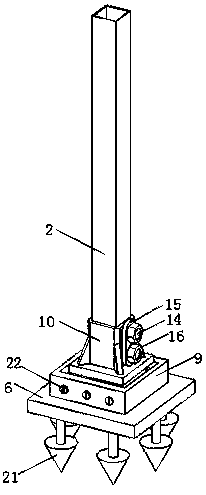

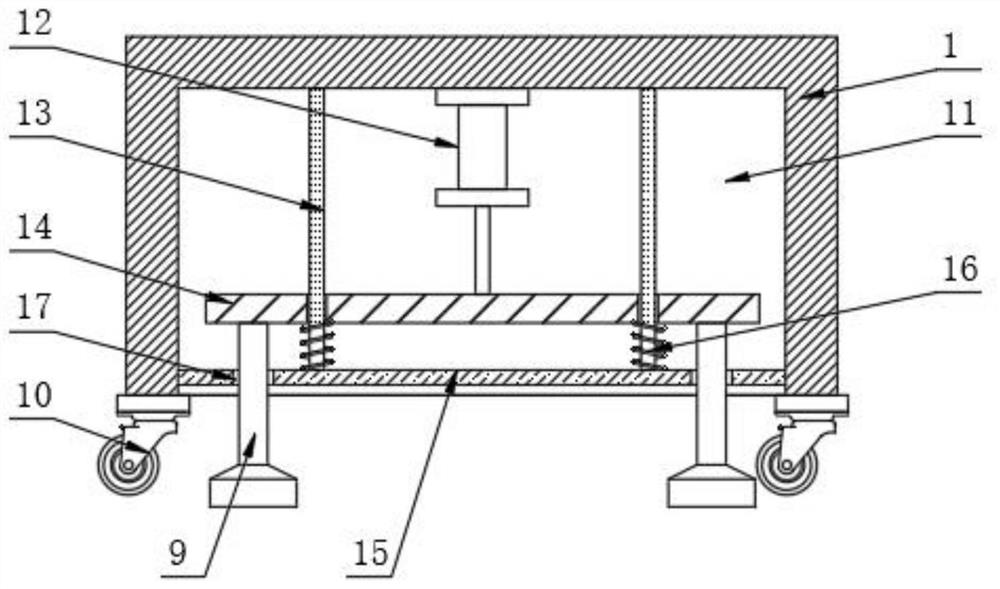

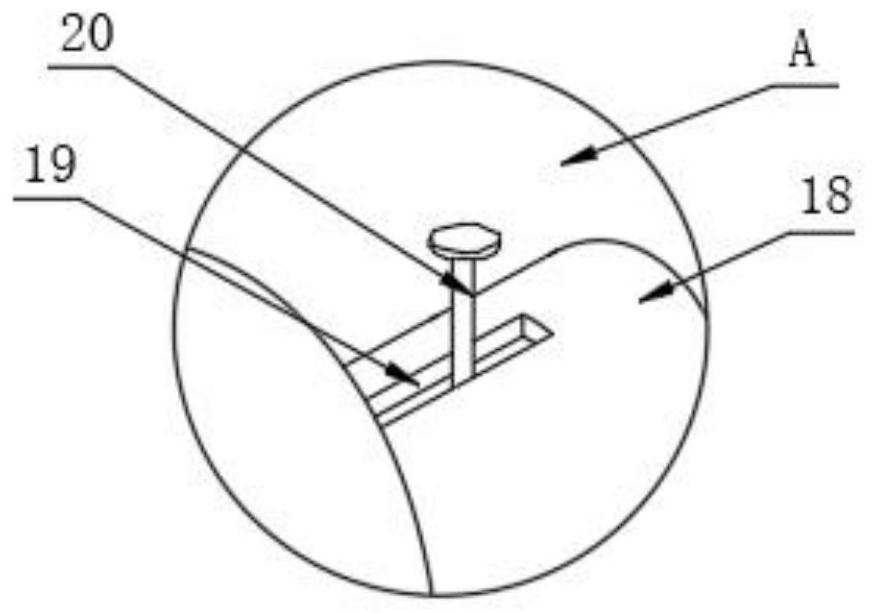

Glass reinforced plastic house building with good stability

InactiveCN111305378AReduce shockEliminate shockProtective buildings/sheltersBulkheads/pilesArchitectural engineeringHouse building

The invention relates to the technical field of house buildings, in particular to a glass reinforced plastic house building with the good stability. The glass reinforced plastic house building with the good stability comprises foundation blocks, stand columns, longitudinal beams and cross beams. A fixed plate is arranged on the upper surface of each foundation block. A rectangular block is weldedto the upper surface of each fixed plate. The upper surface of each rectangular block is provided with a rectangular groove. The bottom wall of each rectangular groove is provided with a plurality ofroller grooves. Rollers are rotatably arranged in the roller grooves. Through longitudinal sliding dampers and transverse dampers, the anti-seismic capability of a whole house frame can be greatly improved, and the glass reinforced plastic house building has the excellent stability. In addition, through a further improvement on a bolt and nut connecting mode, the problems that existing bolts get loose easily after being fixed and are not prone to dismantling after spot-welding reinforcement can be effectively solved. The glass reinforced plastic house building with the good stability is excellent in effect and high in practicality.

Owner:福建省柔情旅游用品有限公司

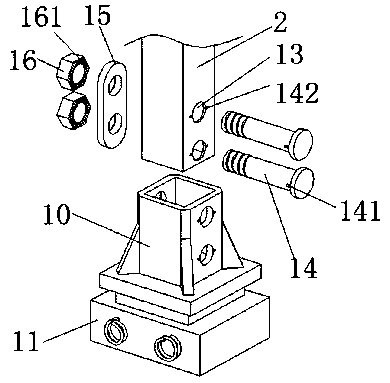

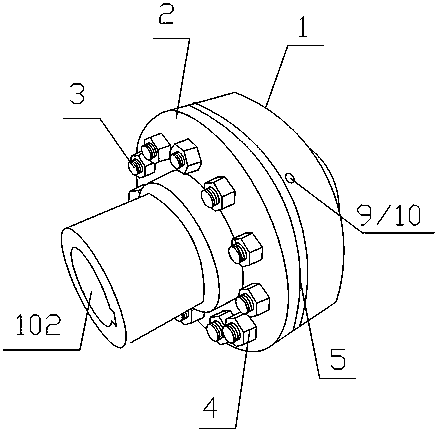

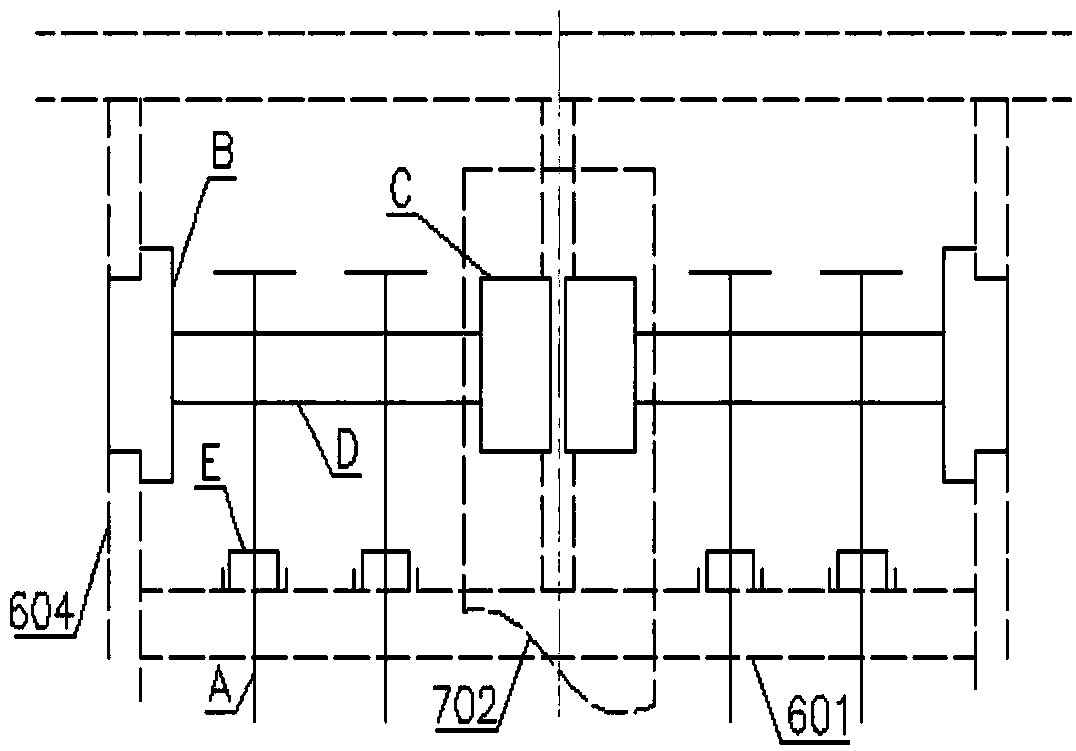

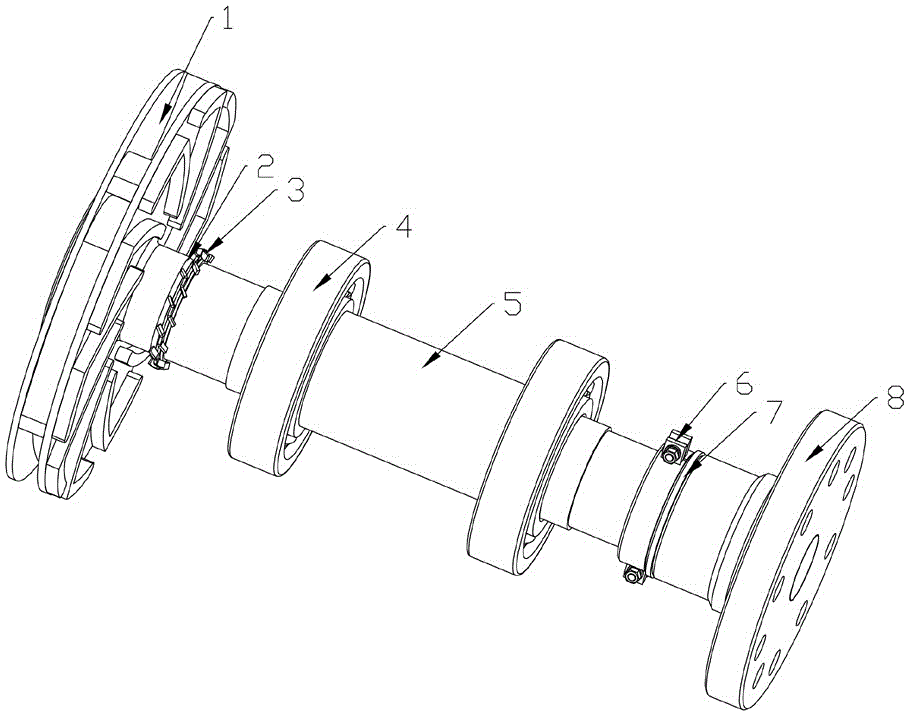

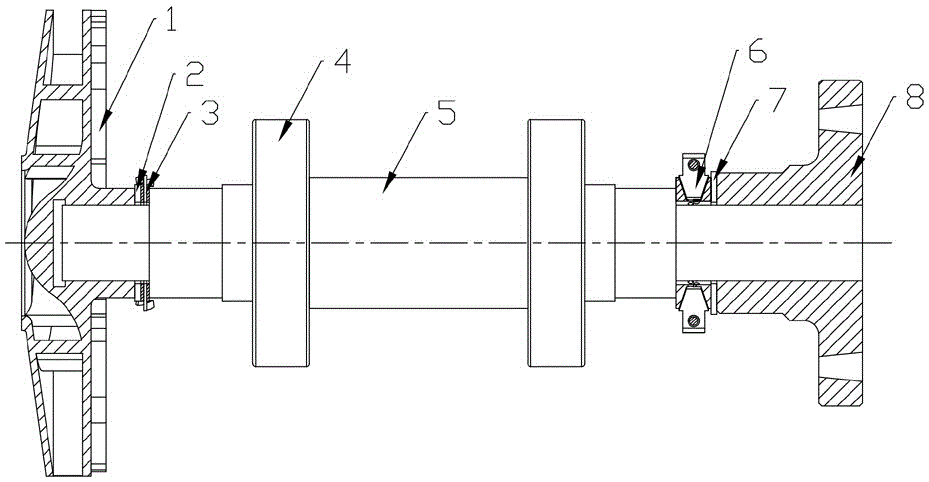

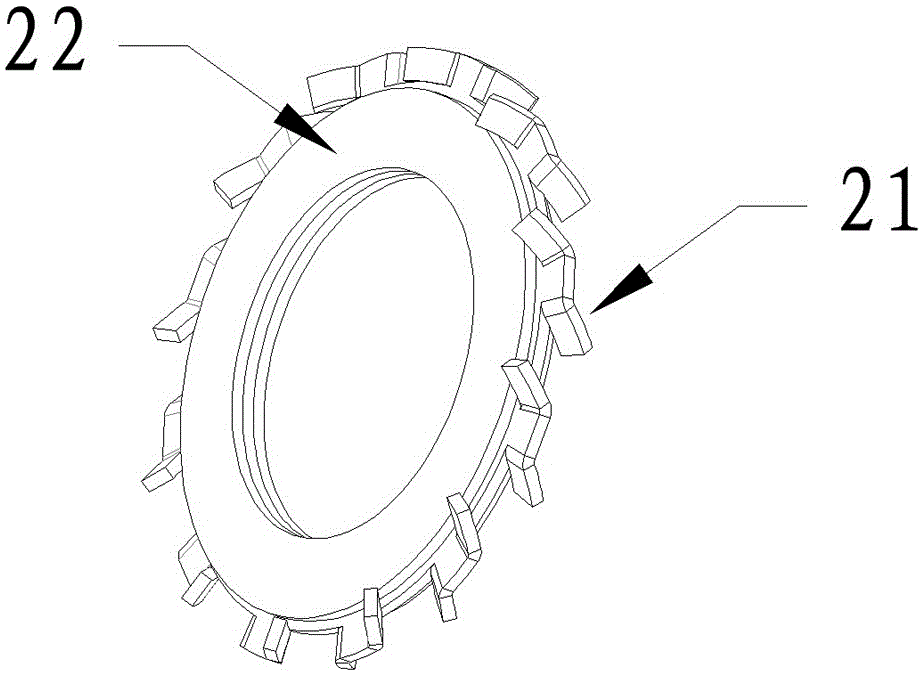

LT type elastic sleeve pin coupling

InactiveCN110094431AImprove shock resistanceMeet shockproof requirementsYielding couplingLeft halfCoupling

The invention discloses an LT type elastic sleeve pin coupling. The coupling includes a left half-coupling, a right half-coupling, multiple fastening pins, multiple fastening nuts and multiple elasticsleeves. A surface where the left half-coupling and the right half-coupling are in contact is provided with a matching positioning device, which facilitates assembly and positioning and effectively solves the problem of wrong mounting. An integral shock absorbing pad is arranged between the left half-coupling and the right half-coupling, A shockproof sleeve and a shockproof washer are arranged onthe positioning device surface, which strengthens the shockproof performance of the coupling. In addition, the connecting surface side of the left half-coupling of the coupling is also provided withan oil filling hole communicating with a shaft hole so as to oil for rust prevention. The LT type elastic sleeve pin coupling has the advantages of simple structure, reasonable arrangement and low manufacturing cost, effectively reduces the wear and rust prevention problem between a coupling shaft and the hole, and has good use value.

Owner:JIANGSU ROKEE HEAVY IND TECH

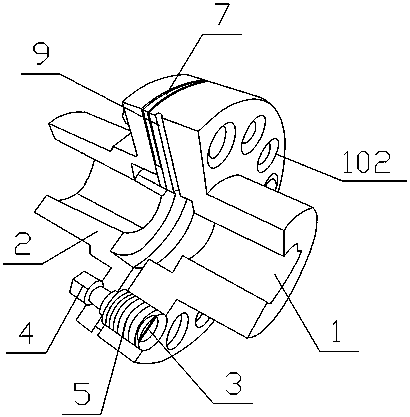

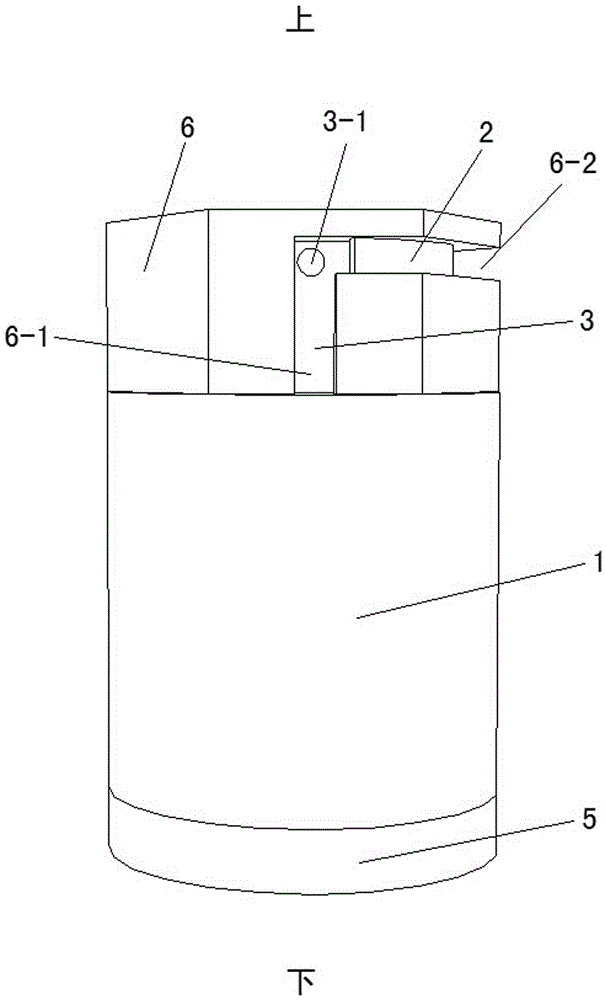

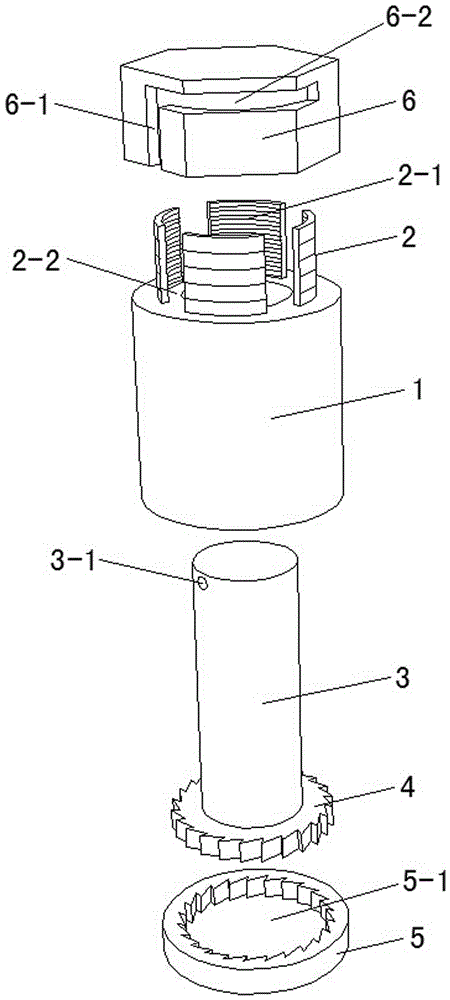

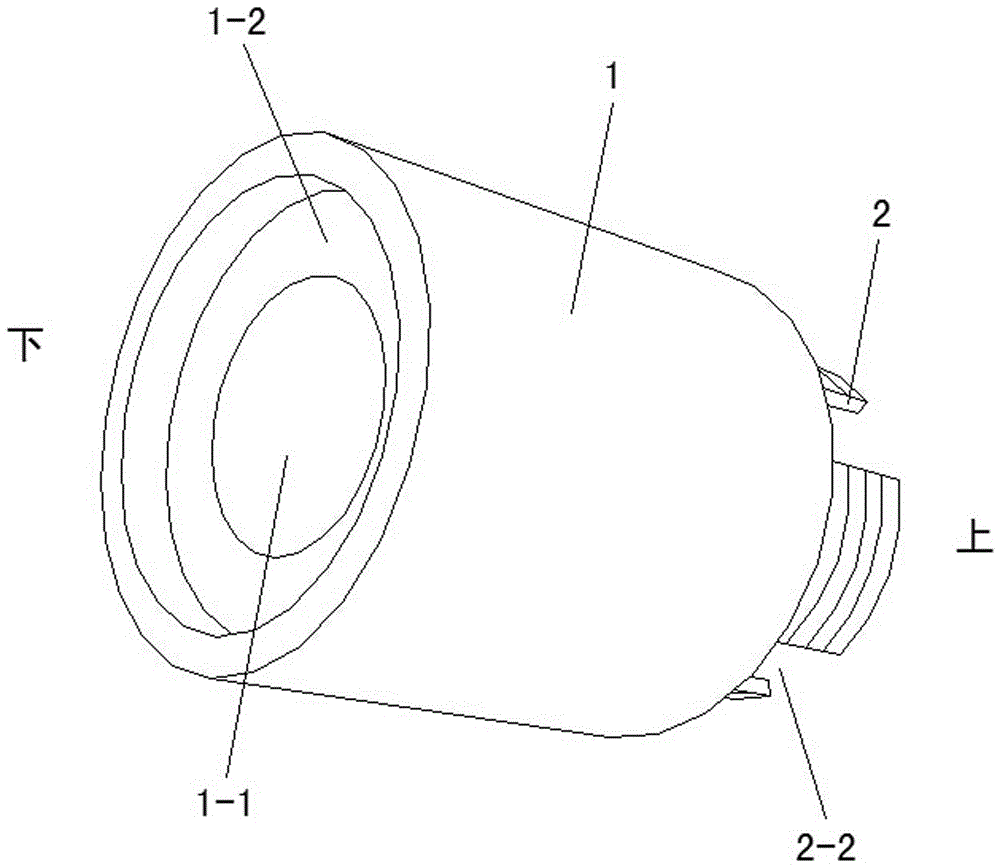

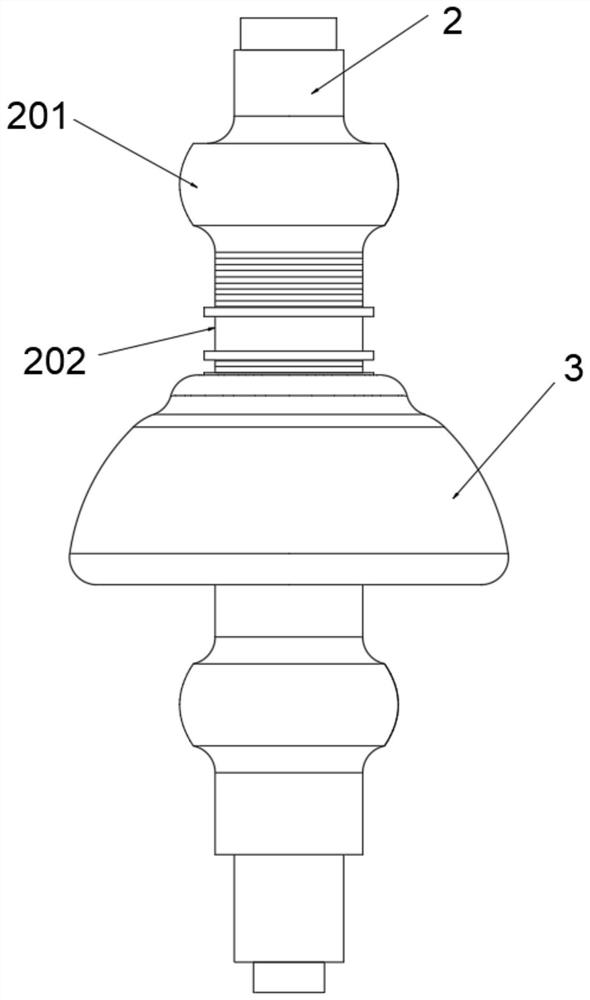

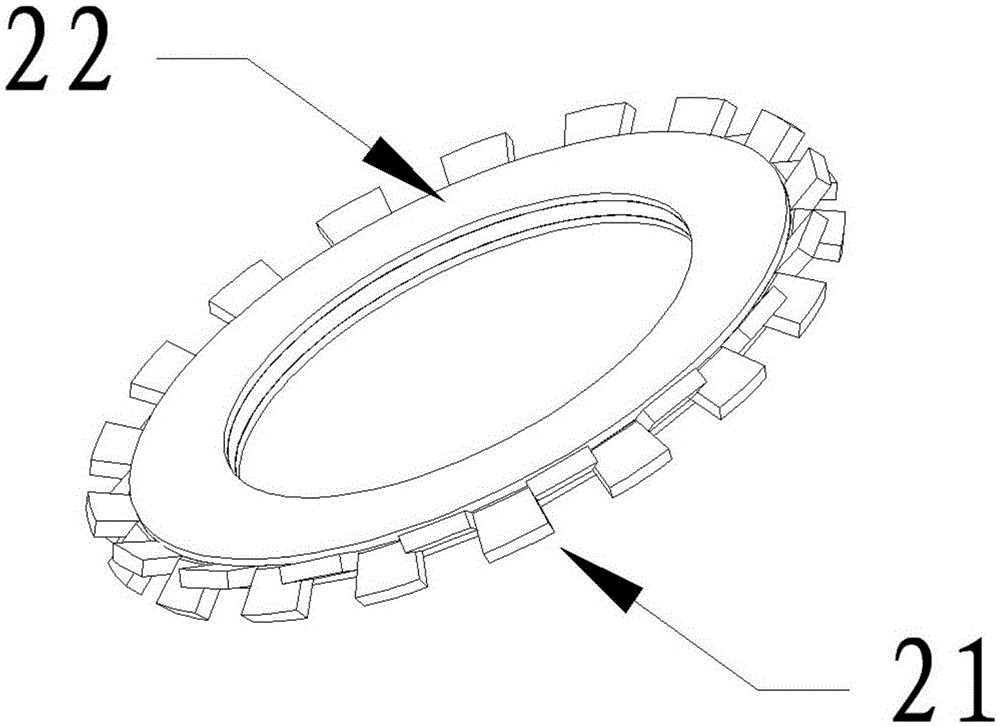

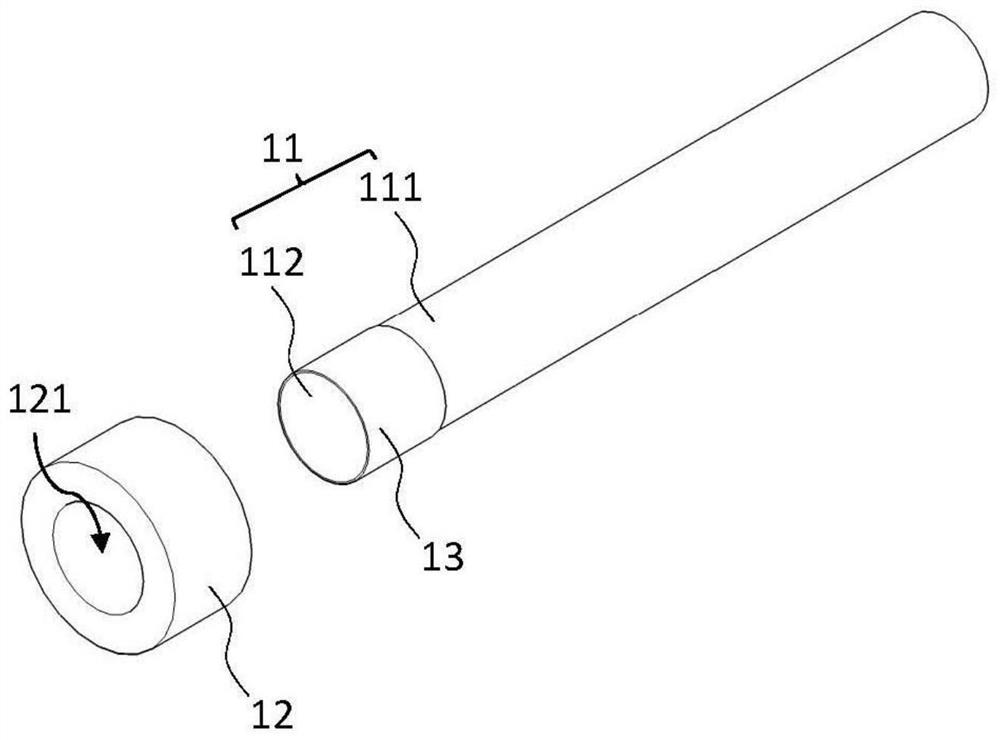

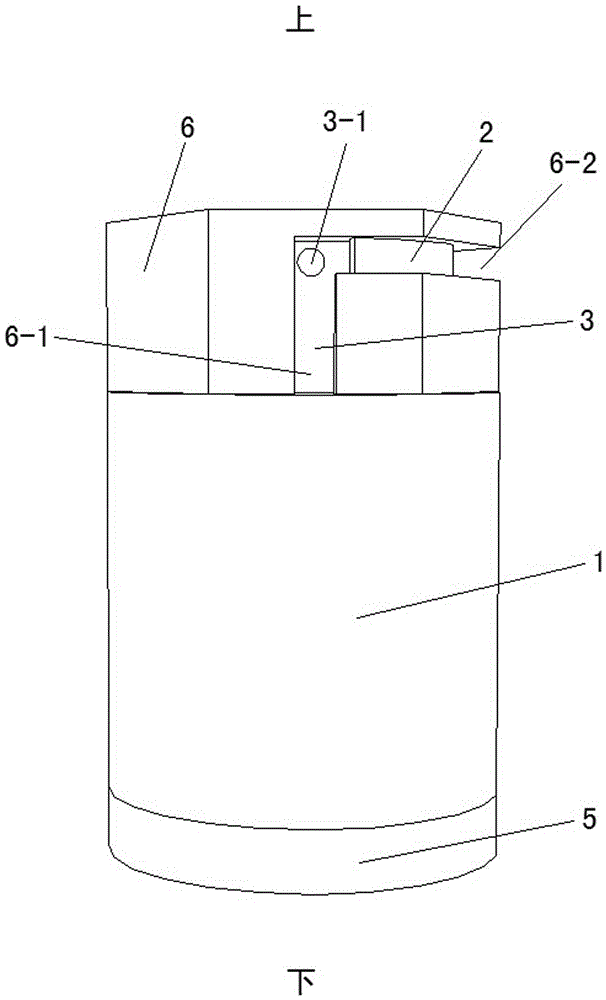

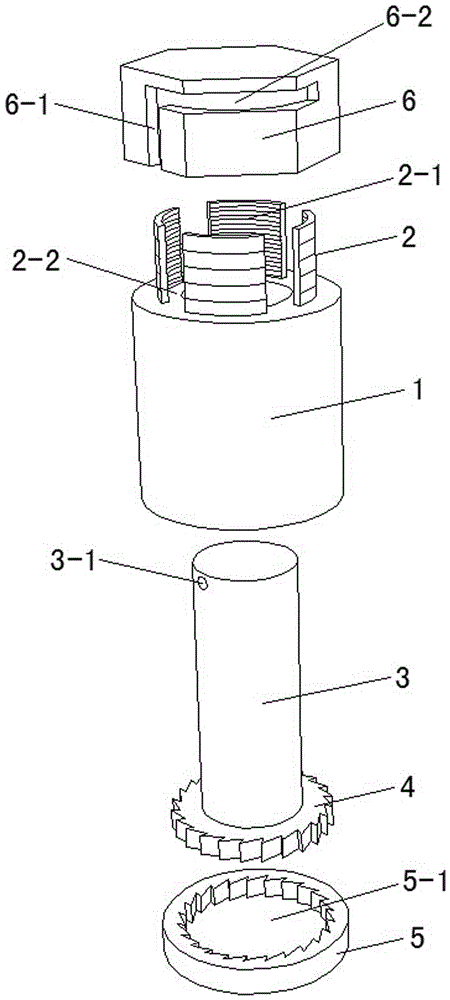

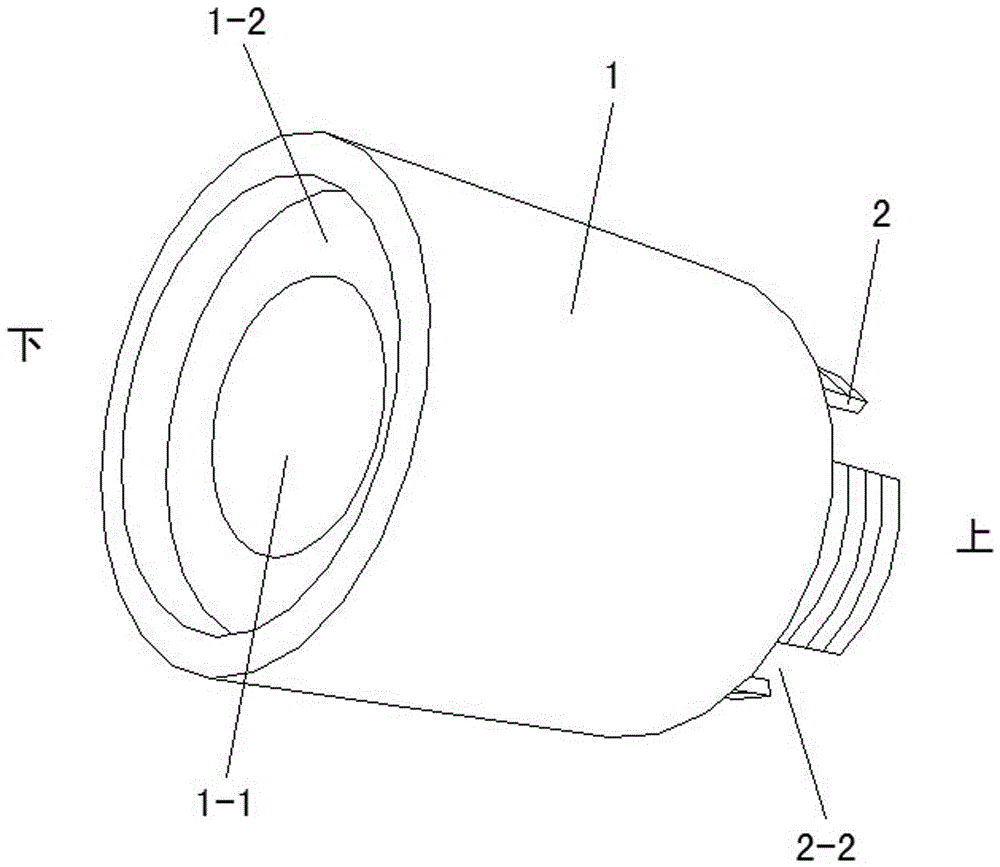

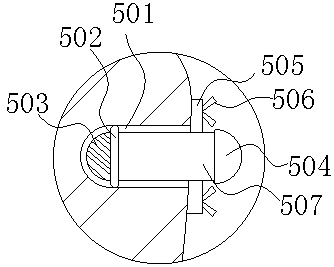

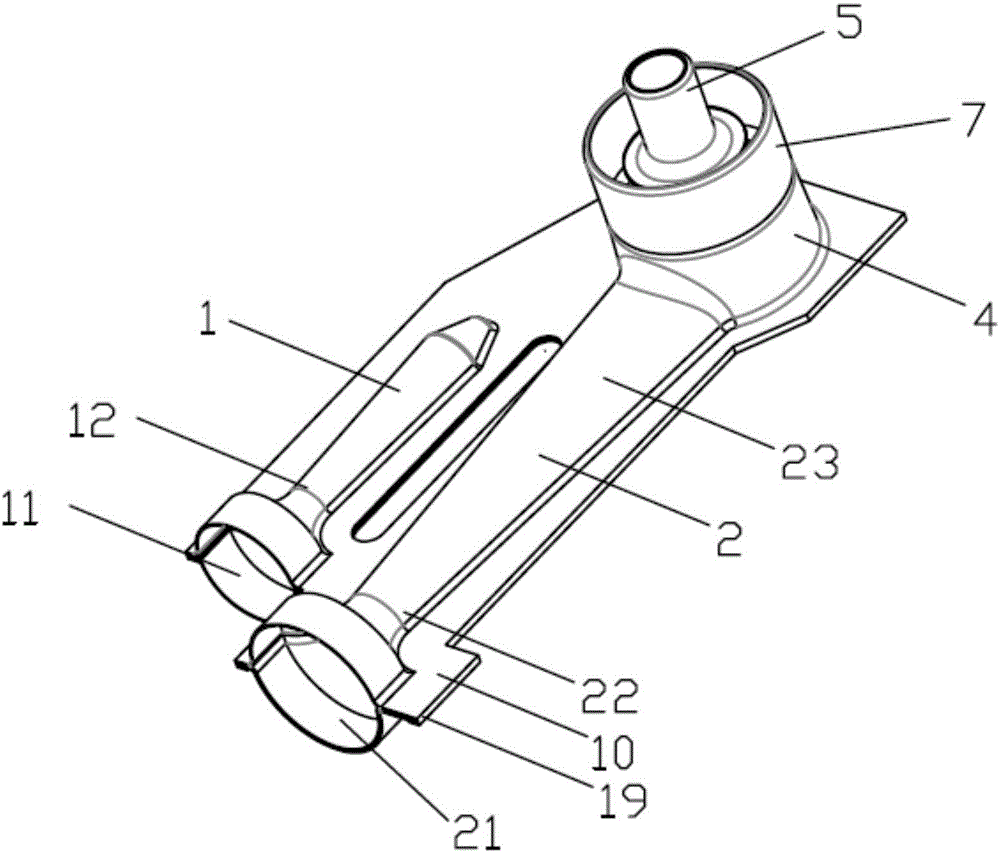

Piano string locking peg facilitating string replacement and tuning

InactiveCN107180622ASolve the problem of not easy disassemblyEasy tuning operationStringed musical instrumentsPianoEngineering

The invention relates to a piano string locking peg facilitating string replacement and tuning and relates to a piano string locking device. A small cylinder inner chamber and a large cylinder inner chamber which are communicated are coaxially formed in a cylinder body, the small cylinder inner chamber is communicated with the upper end surface of the cylinder body, the large cylinder inner chamber is communicated with the lower end surface of the cylinder body, the lower end of a rotary rod is rotationally inserted in the cylinder body, a string penetration hole is formed in the upper end of the side wall of the rotary rod, a positioning wheel is arranged in the large cylinder inner chamber, teeth are manufactured on the circumferential surface of the positioning wheel, the positioning wheel is coaxially and fixedly connected with the lower end surface of the rotary rod, a positioning groove is formed in the upper surface of a bottom plate, the upper surface of the bottom plate is fixedly connected with the lower end surface of the cylinder body, a fastening tube is provided with an external thread and coaxially fixed on the upper end surface of the cylinder body, a fastening cap is in fastening connection with the fastening tube through threads, and an opening I and an opening II are formed in the side wall of the fastening cap. A piano string mounting position is fixed in a wrapping and fastening manner, the structure is novel and practical, and string replacement and tuning are more convenient.

Owner:朱世龙

Oiling rust-proof coupling

The invention relates to the technical field of couplings, in particular to an oiling rust-proof coupling. The oiling rust-proof coupling comprises a left half coupling body and a right half coupling body. The right half coupling body is arranged on one side of the left half coupling body. The oiling rust-proof coupling further comprises a sealing end cover, and fixed through holes are formed in the sealing end cover, the left half coupling body and the right half coupling body; the sealing end cover is fixedly connected with the left half coupling body and the right half coupling body through fixed bolts; and oiling holes are formed in the sealing end cover. The oiling rust-proof coupling has a good rust-proof function, the problems that due to the fact that the oiling rust-proof coupling is not used for a long time, rusty spots are generated, and dismounting is not easy are solved, and the service life of the coupling is effectively prolonged.

Owner:镇江市润州联轴器厂

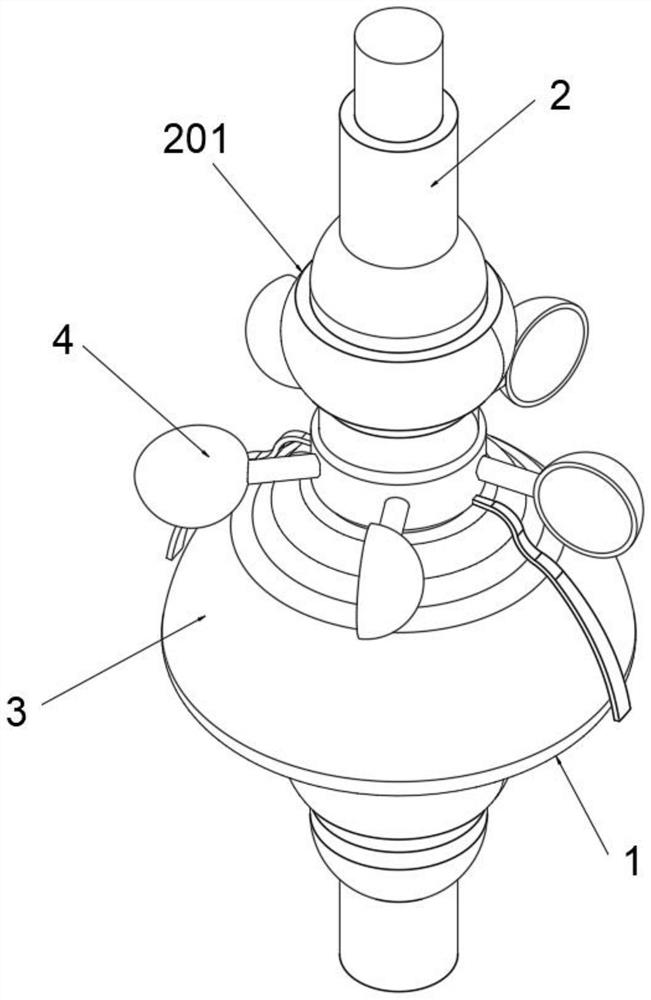

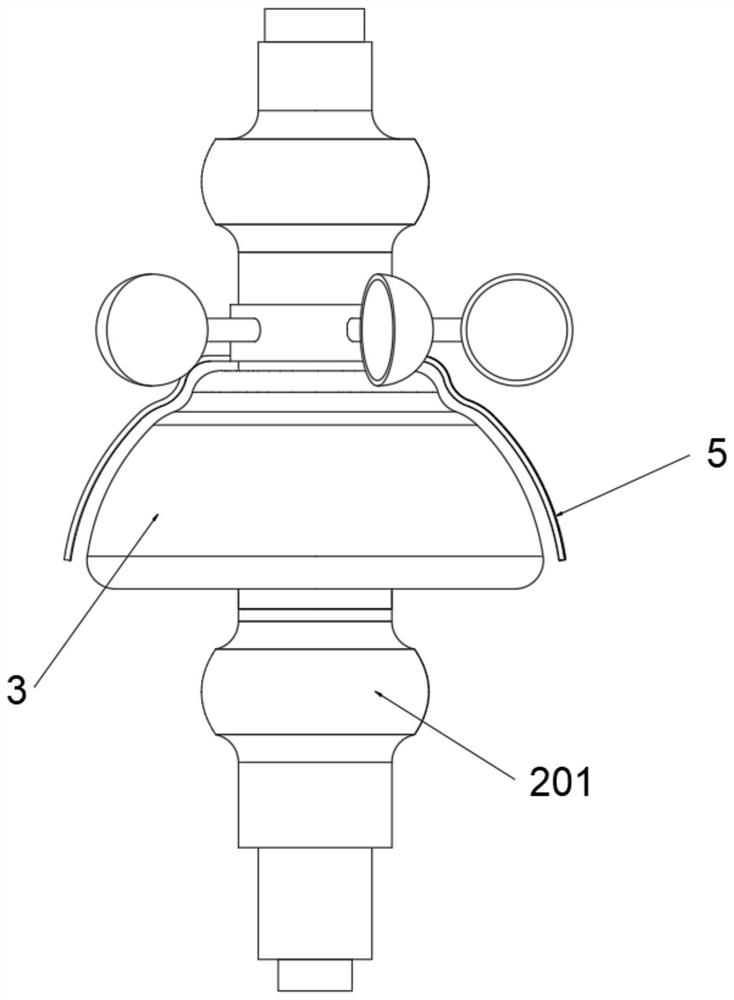

Insulator with self-cleaning effect for overhead transmission line

The invention relates to the technical field of overhead transmission line insulator cleaning, in particular to an insulator with a self-cleaning effect for an overhead transmission line, which comprises a cleaning part. At least a fixing ring is arranged in the cleaning part, installing bases are evenly and fixedly connected to the periphery of the outer side wall of the fixing ring, inserting grooves are formed in the positions, close to the edge of a right opening, of the periphery of the inner wall of each installing base, and rotating grooves are formed in the positions, close to the center, of the periphery of the inner wall of each installing base, a clamping groove is arranged in the right side of the rotating groove, a sealing side wall is arranged on the left side of the installing base, locking screw holes are formed in the edges of the left side and the right side of the inserting hole, the power piece comprises a connecting rod, a hemispherical wind cup is fixedly connected to one end of the connecting rod, and a plurality of clamping blocks are fixedly connected to the peripheral side walls, close to the edges, of the other end of the connecting rod. Through the cleaning brush which is arranged on the cleaning part and is tightly attached to the upper surface of the umbrella skirt, the cleaning brush rotates along with the fixing ring to clean the upper surface ofthe umbrella skirt, and then self-cleaning of the insulator in the using process is achieved.

Owner:YUEQING KEYI ELECTRIC GROUP

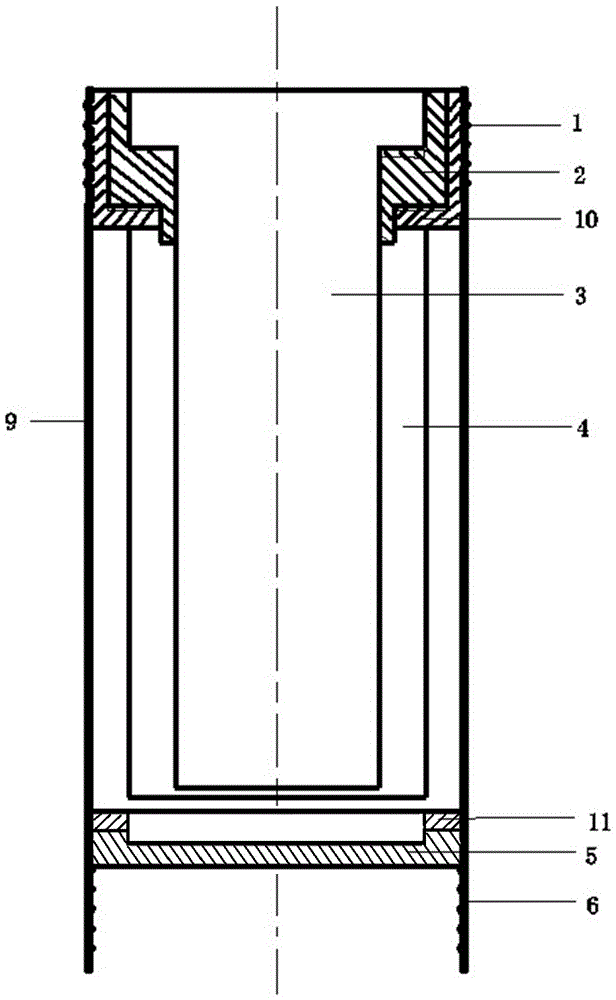

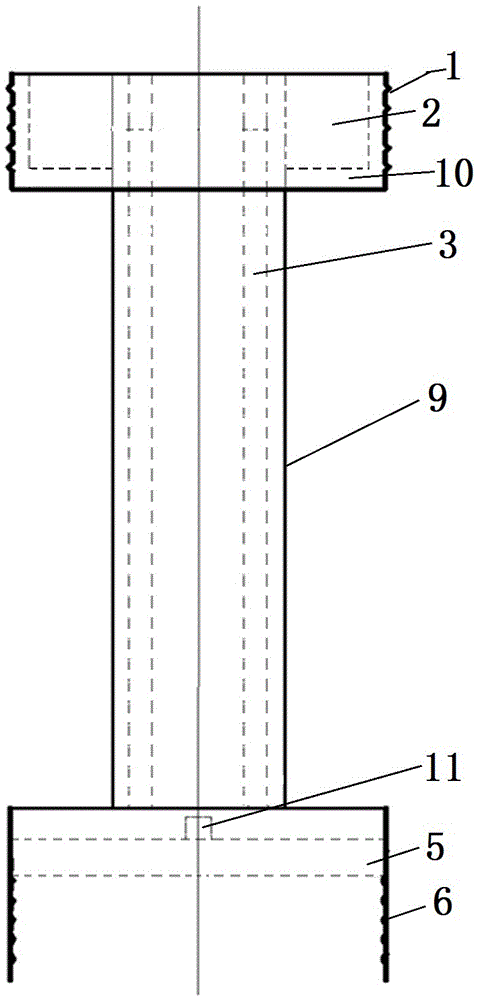

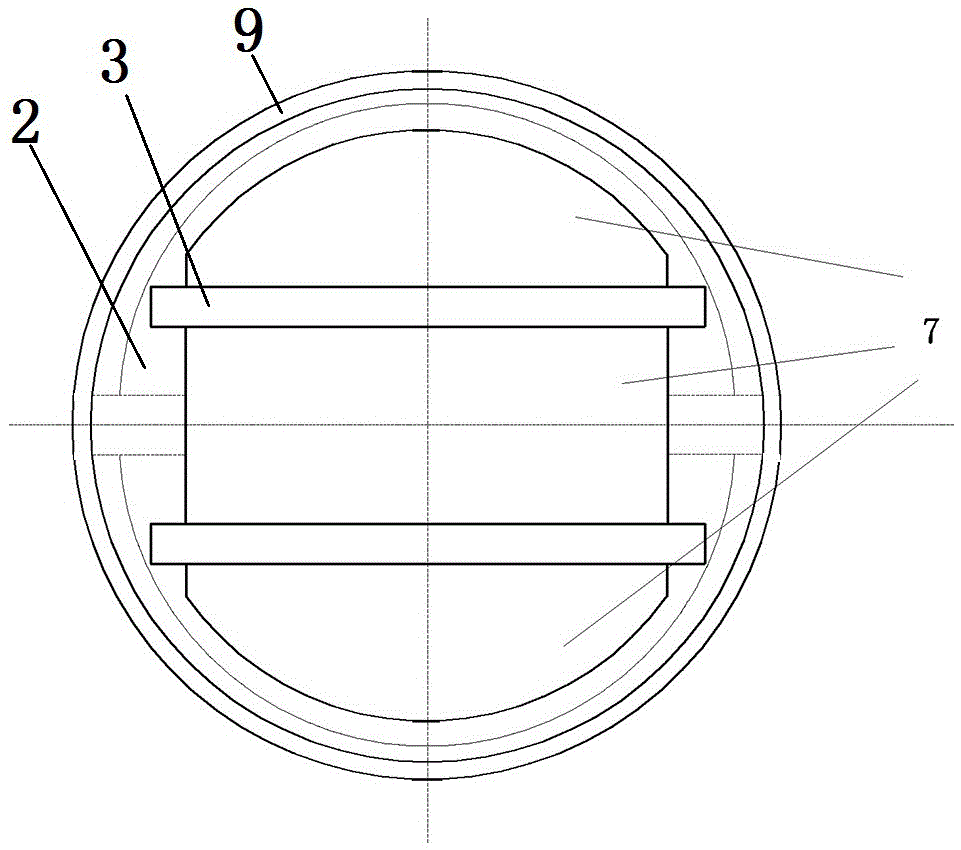

Underground corrosion monitoring device

ActiveCN106226228ASolve the problem of not being easy to disassembleSolve the problem of not easy disassemblyWeather/light/corrosion resistanceEngineeringCorrosion monitoring

The invention relates to the field of oil-gas field pipeline corrosion monitoring, in particular to an underground corrosion monitoring device. The underground corrosion monitoring device comprises a hanging piece for corrosion monitoring and a hanging piece connecting device, a shoulder portion for hanging connection is arranged at one end of the hanging piece, the hanging piece connecting device comprises a main barrel, a hanging piece limiting seat is arranged at the upper end of the main barrel, a limiting groove is formed in the hanging piece limiting seat, and the hanging piece is connected into the limiting groove in a hanging mode. The hanging piece is connected into the limiting groove of the hanging piece limiting seat through the shoulder portion arranged on the hanging piece, therefore, the condition that a metal structure of the hanging piece is destroyed due to the fact that a hanging hole is formed in the hanging piece, and the problem that the hanging piece is difficult to disassemble is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

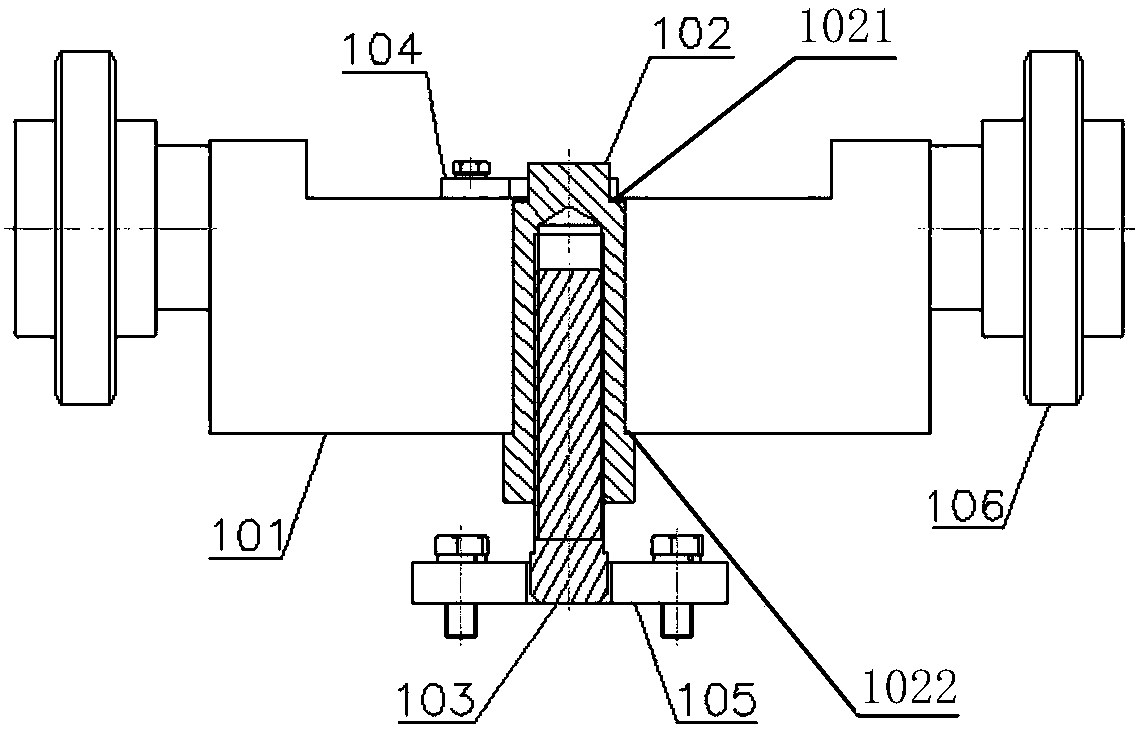

Tensioning apparatus for scraper plate material delivering system, and scraper plate material delivering system and paving machine thereof

InactiveCN107805996AImprove adaptabilitySolve the problem of not easy disassemblyRoads maintainenceVehicle frameClassical mechanics

The invention relates to a tensioning apparatus for a scraper plate material delivering system. The tensioning apparatus comprises a guide support; a tensioning thread sleeve, which is perpendicular to the length direction of the guide support; a tensioning screw, which is in screw-thread fit with the tensioning thread sleeve; and tensioning wheels, which are arranged on two sides of the guide support. The tensioning thread sleeve is axially limited on the guide support and matches with the unthreaded hole of the guide support in a loose fit mode. The head of the tensioning screw is abutted onthe rear end beam of a vehicle frame. The guide support is slidingly arranged on the support seat of the vehicle frame. The bottom of the guide support is provided with a guide slide block. Two sidesof the guide slide block are in loose fit with lateral surfaces of the support seat of the vehicle frame. By adopting a structure having a single screw and a single guide slide block, the problem that the tensioning screw of a rear-mounted tensioning apparatus is too long and is difficult to disassemble is solved; at the same time, the problem that the tensioning screw is easily deformed under the action of alternating bending stress is also solved; the adaptability of the tensioning apparatus is effectively improved, and the material delivering efficiency of the scraper plate material delivering system is improved.

Owner:TIANJIN ENG MACHINERY INST

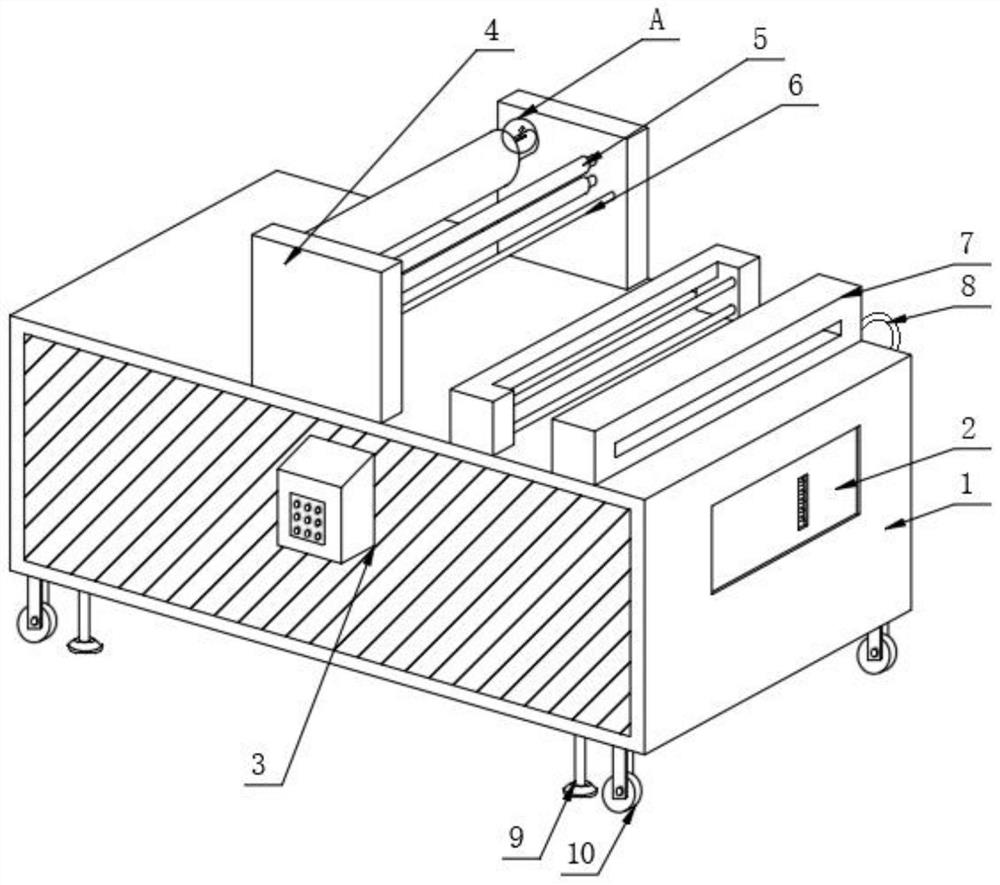

Cloth spreading machine for garment production

InactiveCN111762600AEasy to install and disassembleImprove aestheticsLiquid/gas/vapor textile treatmentTextile shapingEngineeringMechanical engineering

The invention discloses a cloth spreading machine for garment production, and particularly relates to the technical field of garment production equipment. The cloth spreading machine comprises a processing table, wherein a cloth spreading frame is arranged on the surface of the top end of the processing table; a control box is arranged on the front surface of the processing table; a steam wettingchamber is arranged on one side of the cloth spreading frame; one end of the steam wetting chamber is connected with an elastic pipe; and two sleeve seats are arranged inside the cloth spreading frame. According to the cloth spreading machine, positioning columns, the sleeve seats, sliding rods and grooves are arranged, so that rapid connection between cloth placing rollers and the sleeve seats isrealized, the installation and the disassembly are convenient, the cloth placing rollers can be replaced, and normal operation of cloth spreading is guaranteed; a steam box and the steam wetting chamber are arranged, steam fumigation is carried out on the interior of the steam wetting chamber, and through steam ironing in the steam wetting chamber, the flatness of cloth can be realized, and the attractiveness is improved; and a lifting plate, a spring I and four supporting legs are arranged, so that the lifting plate can be elastically extruded, the supporting legs are in contact with the ground, and the stability of the processing table is guaranteed.

Owner:高邮萤火贸易有限公司

Thread quick-dismantling device applied to coupling water pump

The invention discloses a thread quick-dismantling device applied to a coupling water pump. The thread quick-dismantling device comprises a water pump impeller, a bearing, a water pump shaft and a coupling. The coupling and the water pump shaft are assembled in a threaded mode, and the water pump impeller and the water pump shaft are assembled in a threaded mode. The spiral directions of threads are arranged in the automatic locking directions of working and bearing. The water pump impeller is similar to a nut and tightly presses an impeller flat washer and a copper-lead torsion compound gasket by being connected with the water pump shaft in a threaded mode. The water pump impeller is in threaded rigid connection with one end of the water pump shaft. Clamping hoop parts are arranged at the other end of the water pump shaft in a sleeving mode, the water pump shaft is sleeved with a coupling flat washer, then, the coupling which is similar to the nut is screwed in, and all parts are reasonably locked, so that the clamping hoop parts, the coupling similar to the nut and the other end of the water pump shaft are also connected in a rigid mode. According to the thread quick-dismantling device applied to the coupling water pump, the problems that the threads are continuously and automatically locked and not easy to disassemble during assembling under the loading effect can be effectively solved, and a clamping hoop gasket is provided with elliptical holes so as to enhance the axial elasticity; the thread quick-dismantling device is especially suitable for convenient disassembling of a large-size component after the large-size component is locked in a threaded mode, and the effect is particularly remarkable.

Owner:JISHOU UNIVERSITY

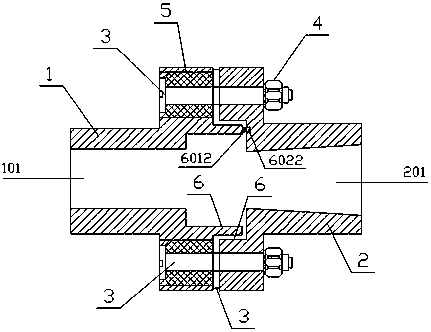

Pipeline capable of being mounted quickly

PendingCN108775462AStable structureTo achieve mutual locking and fixingCouplingsPipe connection arrangementsEngineeringHot melt

The invention discloses a pipeline capable of being mounted quickly. The pipeline comprise a first pipe body, a second pipe body and a clamping stripe, wherein a first annular groove is formed in theouter side of one end of the first pipe body; a second annular groove is formed in the inner side of one end of the second pipe body, a first through hole is also formed in the second pipe body, one end of the first through hole is connected to the second annular groove while the other end of the first through hole is connected to the outer side of the second pipe body, the end, provided with thefirst annular groove, of the first pipe body is inserted into the end, provided with the second annular groove, of the second pipe body, and the first annular groove and the second annular groove arespliced to from an accommodating cavity; one end of the clamping stripe is inserted into the accommodating cavity through the first through hole and forms an annular clamping ring according to the structure of the accommodating cavity. The pipeline disclosed by the invention is simple and convenient in mounting process and can solve the problem that in the prior art, the pipeline is mounted and connected only by a hot melt way, so that the pipeline is stable in structure, can bear a tensile force and can be used for horizontal fixed drilling and pipe drawing construction.

Owner:广东科朗管网技术有限公司

A Downhole Corrosion Monitoring Device

ActiveCN106226228BSolve the problem of not easy disassemblyAvoid destructionWeather/light/corrosion resistanceEngineeringCorrosion monitoring

The invention relates to the field of oil-gas field pipeline corrosion monitoring, in particular to an underground corrosion monitoring device. The underground corrosion monitoring device comprises a hanging piece for corrosion monitoring and a hanging piece connecting device, a shoulder portion for hanging connection is arranged at one end of the hanging piece, the hanging piece connecting device comprises a main barrel, a hanging piece limiting seat is arranged at the upper end of the main barrel, a limiting groove is formed in the hanging piece limiting seat, and the hanging piece is connected into the limiting groove in a hanging mode. The hanging piece is connected into the limiting groove of the hanging piece limiting seat through the shoulder portion arranged on the hanging piece, therefore, the condition that a metal structure of the hanging piece is destroyed due to the fact that a hanging hole is formed in the hanging piece, and the problem that the hanging piece is difficult to disassemble is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pipeline capable of being rapidly disassembled and installed

PendingCN108916513APipe structure is stableEasy to installPipe connection arrangementsDrill pipeMechanical engineering

The invention discloses a pipeline capable of being rapidly disassembled and installed. The pipeline comprises tube bodies, a fixing sleeve and clamping strips, wherein first annular grooves are formed in the outer sides of one ends of the tube bodies; second annular grooves and third annular grooves are formed in the inner sides of the two ends of the fixing sleeve, first through holes are formedin the fixing sleeve, one ends of the first through holes are connected with the second annular grooves, the other ends of the first through holes are connected with the outer side of the fixing sleeve, one ends of the second through holes are connected with the third annular grooves, the other ends of the second through holes are connected with the outer side of the fixing sleeve, the tube bodies are provided with the first annular grooves, one ends of the tube bodies are inserted into one end, with the second annular grooves, of the fixing sleeve, the first annular grooves and the second annular grooves are spliced to form containing cavities, one ends of the clamping strips are inserted into the containing cavities through the first through holes, and annular clamping rings are formedaccording to the containing cavities. The pipeline can effectively solve the problem that in the prior art, the pipeline installation connection can be realized only by adopting a hot melting mode, sothat the pipeline structure is stable and can bear tensile force, and the pipeline can be used for horizontal fixed drill pipe drawing construction.

Owner:广东科朗管网技术有限公司

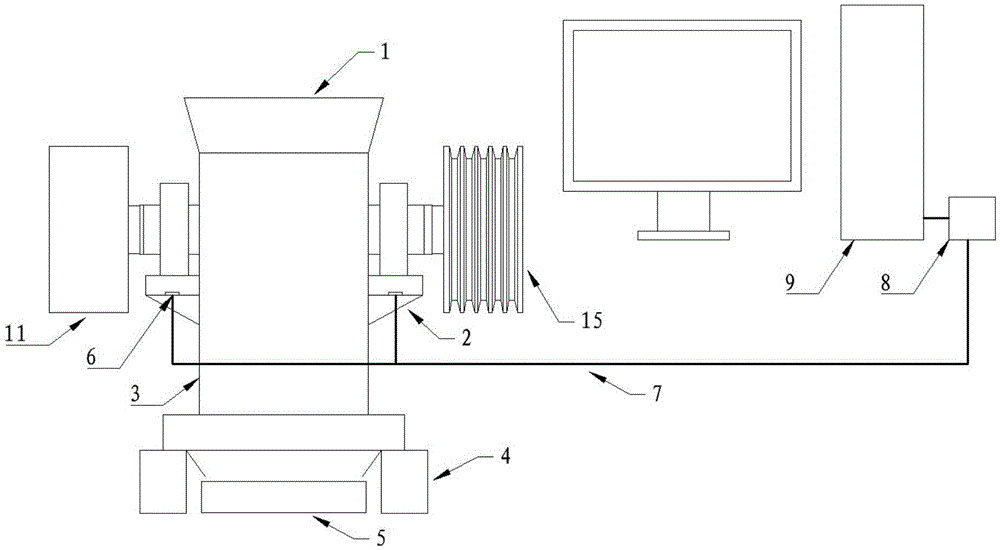

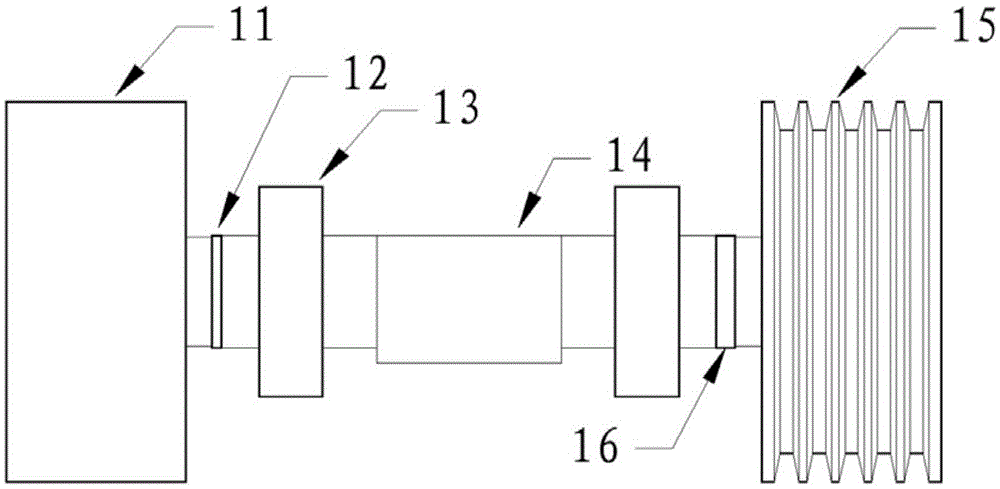

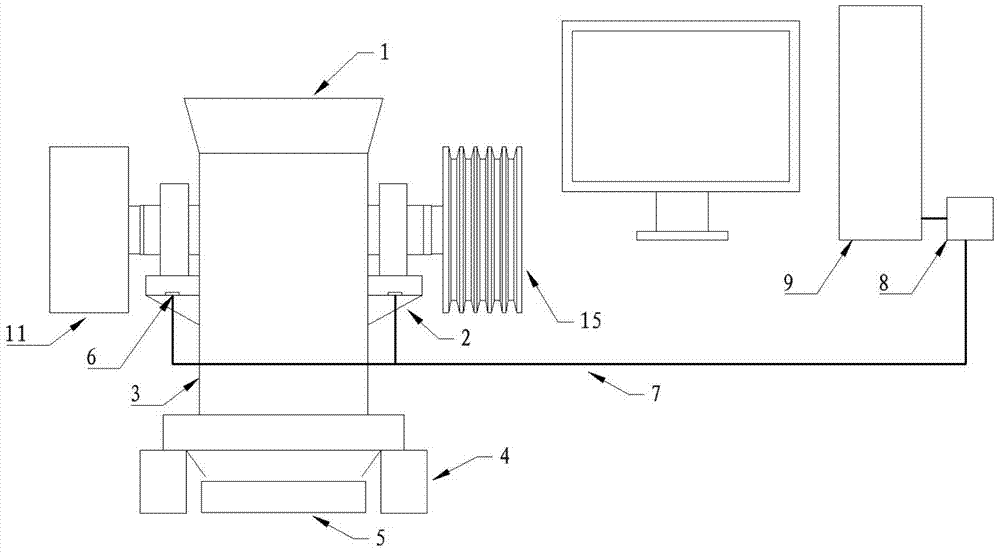

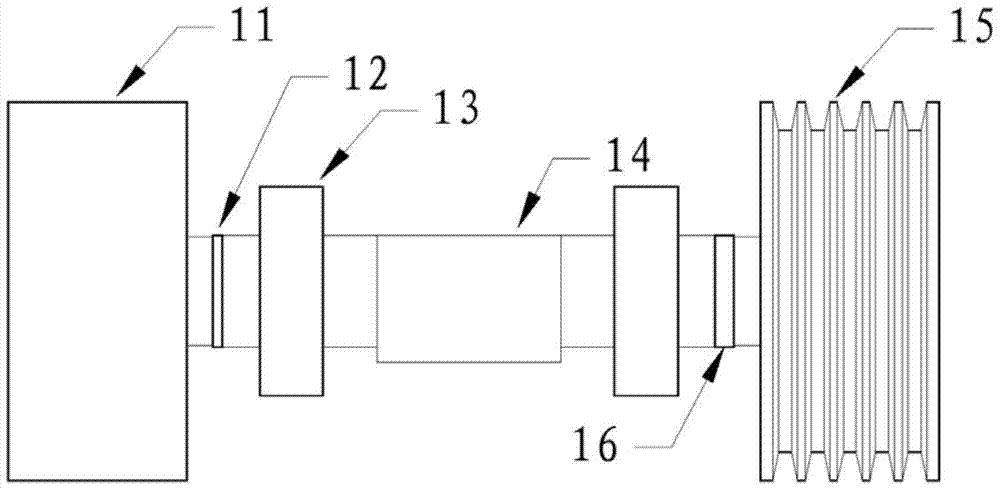

Miniature jaw crusher with monitor

The invention discloses a miniature jaw crusher. The miniature jaw crusher comprises a miniature jaw crusher body and a monitoring system, wherein the miniature jaw crusher body comprises a machine body (3), a flywheel (11) and a belt pulley (15); the flywheel (11) and the belt pulley (15) are assembled with a camshaft (14) of the machine body (3) in a normally and reversely threaded manner; the monitoring system comprises a strain sensor (6) arranged on a bearing block (2) of the machine body (3); and the strain sensor (6) is connected with a signal processor (8) through a signal line (7), carries out processing and controlling through a computer (9). By the miniature jaw crusher, the problem that threaded assembly of the jaw crusher is locked automatically and continuously and is not easy to detach can be solved effectively, the jaw crusher can be detached conveniently, meanwhile, impact load in a crushing operation process can be monitored indirectly, particularly, the miniature jaw crusher can be detached conveniently after components of the miniature jaw crusher are locked in a threaded manner, and working condition maintenance of the miniature jaw crusher can also be implemented.

Owner:江苏佳华机械科技有限公司

Device with tool head capable of being dismounted conveniently

InactiveCN107116469ASolve the problem of not easy disassemblySimple structureGrinding wheel securing apparatusEngineeringMachine tool

The invention discloses a device for conveniently disassembling a tool head, which is composed of a base, a support column, a spindle box, a rotating shaft, a chuck, a bearing seat, a beam and a grinding wheel tool head, and the support column is fixedly arranged on the base, The upper part of the support column is provided with a bearing seat, and the beam is connected between the bearing seats. A chute is provided at the lower part of the beam, and the chute is movably connected with the grinding wheel tool head. The upper side of the base is provided with a headstock, and the headstock is connected by a rotating shaft. Chuck. The invention has a simple structure, is easy to implement, and effectively solves the problem that the tool head of a traditional machine is not easy to disassemble.

Owner:SUZHOU SPARKS PRECISION MACHINERY CO LTD

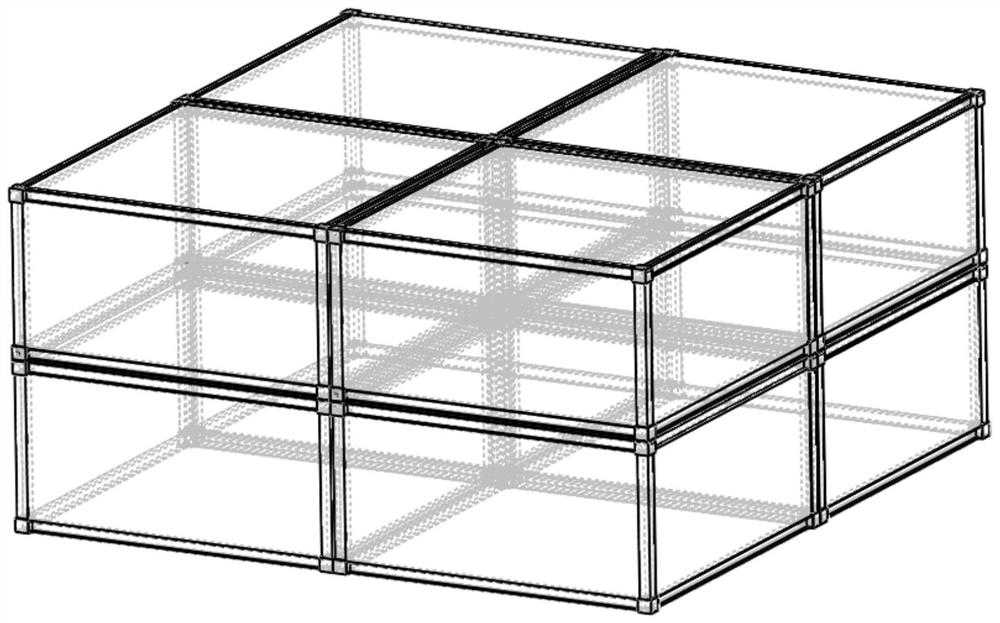

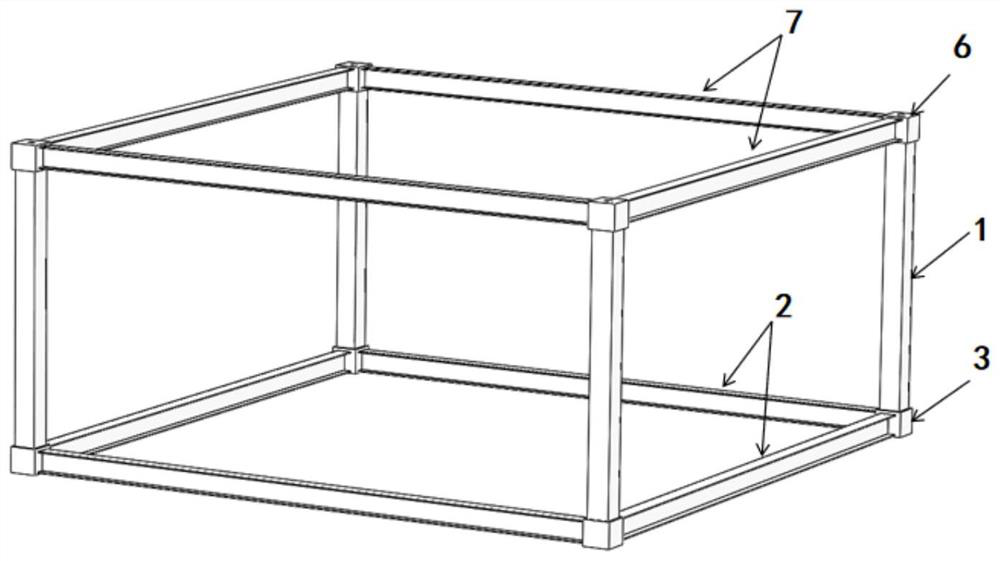

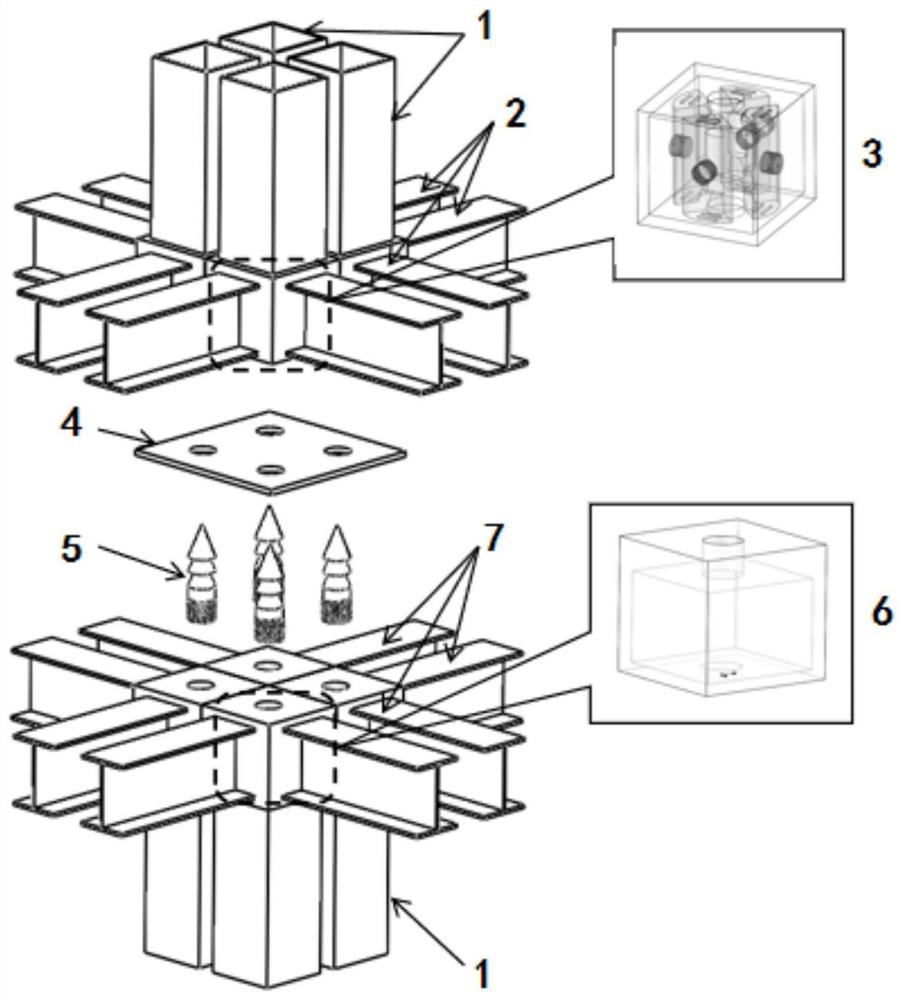

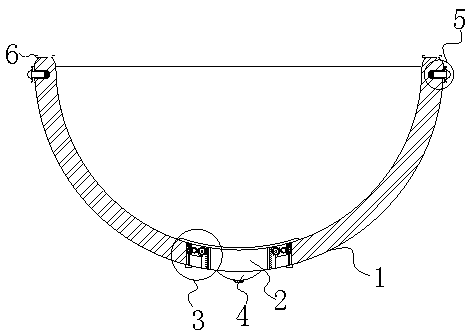

Integrated box house easy to disassemble, self-locking connection nodes

ActiveCN113863507BSolve the problem of not easy disassemblyEasy to disassembleSpecial buildingBuilding constructionsStructural engineeringIndustrial engineering

The invention discloses an easy-to-detach and self-locking connection node of an integrated box-type house, which includes a lower corner piece of an upper box-shaped unit, an upper corner piece of a lower box-shaped unit, a horizontal connecting plate and a tenon piece, and the upper box-shaped The lower corner piece of the box-type unit is connected with the upper corner piece of the lower box-type unit through the horizontal connecting plate and the tenon piece; The connecting plate cover is set on the upper corner piece of the lower box unit at the node, and is sleeved on the tenon piece. The invention also discloses an unlocking tool for the above node. The invention has strong applicability, can be used in the corner, side and middle connection areas of the integrated box-type house structure, and also realizes no welding on site, greatly improves the assembly rate and construction efficiency, and is convenient and quick to install and easy to disassemble, which is beneficial to Realize the recycling of integrated container houses, saving manpower and resources.

Owner:TIANJIN UNIV

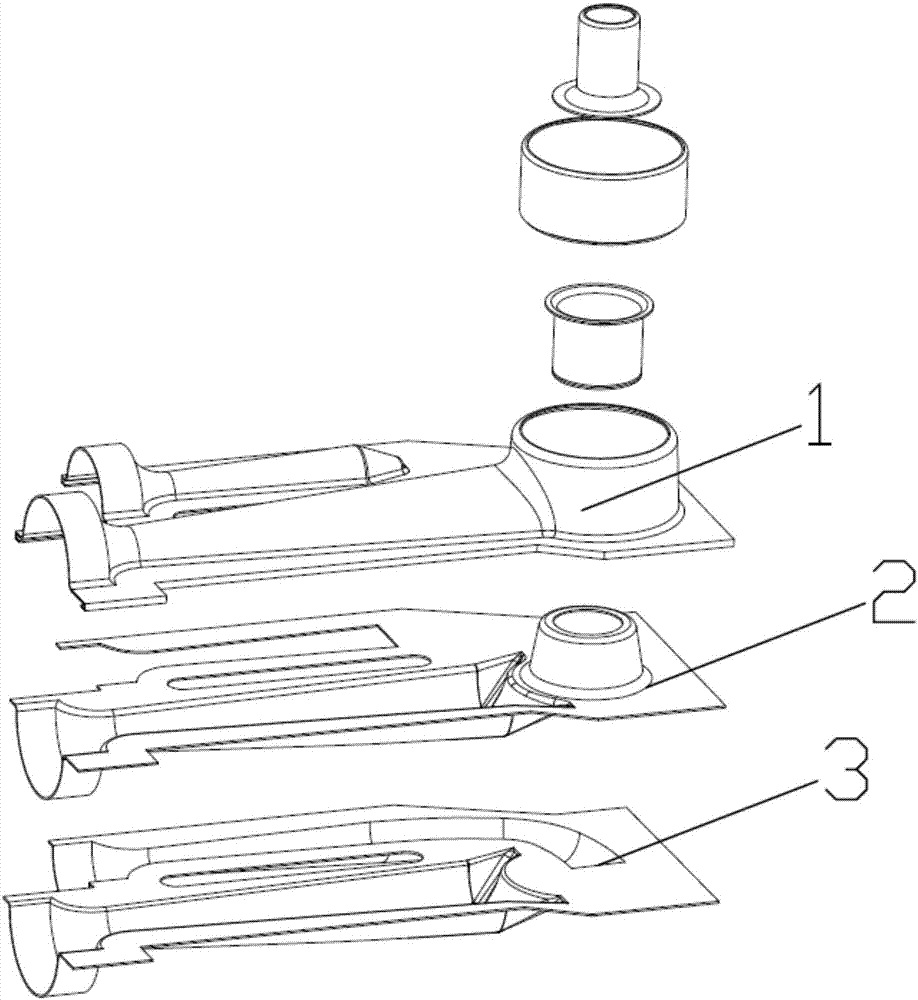

Stamping type burner of gas stove

PendingCN107448939AFacilitate mass productionLow costBurner material specificationsGaseous fuel burnerGas pipelineEngineering

The invention relates to a stamping type burner of a gas stove. The stamping type burner comprises an external ejector pipe and an internal ejector pipe, wherein the external ejector pipe comprises an upper half pipe and a lower half pipe; an upper ejector slot and an upper cavity are formed in the upper half pipe; two ends of the upper ejector slot are respectively connected with the upper cavity and a gas pipeline; a lower ejector slot and a lower cavity are formed in the lower half pipe; the lower ejector slot corresponds to the upper ejector slot; the lower cavity corresponds to the upper cavity; the upper half pipe and the lower half pipe are buckled and fixedly connected and subjected to gas-liquid sealing; when the upper half pipe and the lower half pipe are buckled, the upper ejector slot and the lower ejector slot are combined to form an ejector pipeline of the external ejector pipe; the lower cavity is located inside the upper cavity, and an exocyclic mixing cavity is formed between the lower cavity and the upper cavity; a through hole into which the internal ejector pipe penetrates is formed in the lower cavity; and the internal ejector pipe is located on the left side or the right side of the external ejector pipe. The stamping type burner of the gas stove is simple in structure, and the stamping production process is simplified.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

An anti-dropping mechanism for connecting wires of software development equipment

ActiveCN112164935BEasy to fixSolve instabilityRelieving strain on wire connectionSoftware engineeringSoftware development

Owner:陈汉英

Temperature difference assembly part, assembly method and light rigid body assembly with temperature difference assembly part

PendingCN111898168AGood structural strengthLightweight and durableGeometric CADMetal working apparatusEngineeringMechanical engineering

The invention discloses a temperature difference assembly part, which comprises a controlled part, a temperature difference assembly part, a temperature difference assembly part and a temperature difference assembly part, clamping part, at least one clamping space corresponding to the shape of the controlled part is formed in the clamping part; the clamping space has a size slightly smaller than that of the controlled part; when the temperature of the clamping part is higher than the temperature of the to-be-processed part and reaches a preset temperature difference value, the clamping space can just allow the to-be-processed part to get in and out, and when the temperature difference between the clamping part and the to-be-processed part is smaller than the preset temperature difference value, the size of the clamping space tightly clamps the to-be-processed part of the to-be-processed part; and the low heat transfer layer is arranged between the controlled part and the position, where the clamping space is formed, of the clamping part, and the low heat transfer layer has a heat conduction value lower than that of the controlled part and that of the clamping part. In addition, theinvention further discloses an assembling method of the temperature difference assembling part and a light rigid body assembly with the temperature difference assembling part.

Owner:MINTRON ENERGY TECH CO LTD

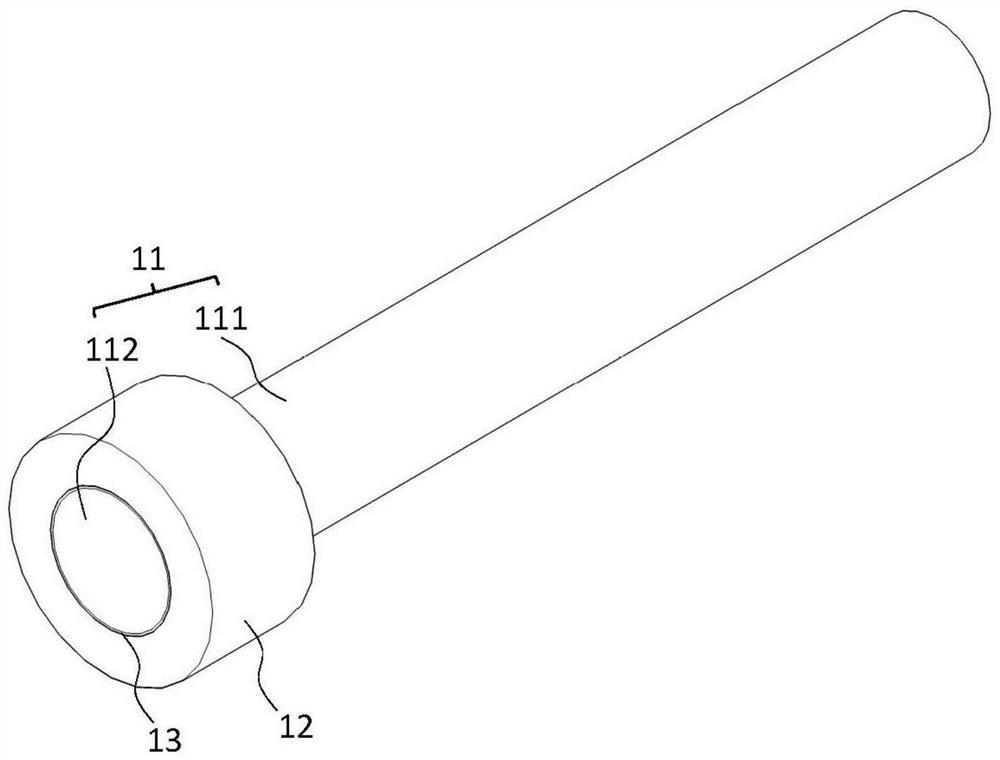

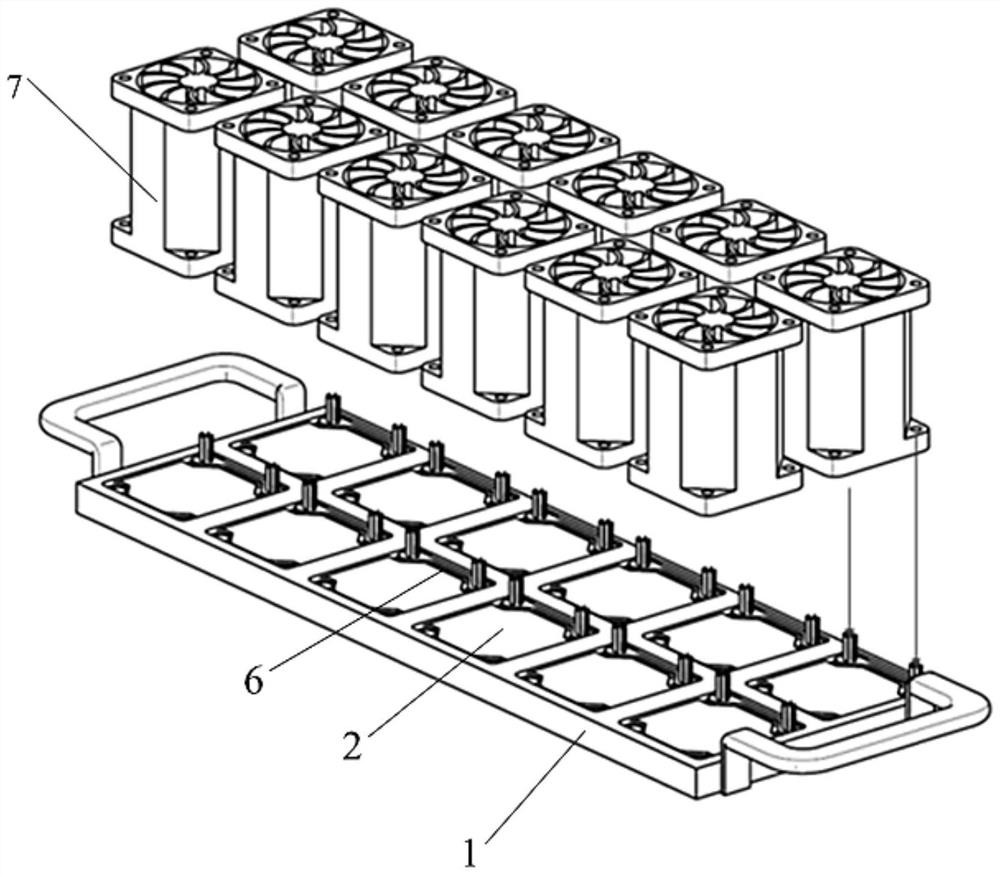

Fan module device convenient to mount and dismount and dismounting method

ActiveCN114442774AImprove installation efficiencyReduce damage rateDigital data processing detailsEnergy efficient computingComputer hardwareEngineering

The invention provides a fan module device convenient to mount and dismount, a dismounting and mounting method and a server fan mounting module. A plurality of server fan mounting platforms are arranged on the server fan mounting module; a first server fan clamping position is arranged at one end of the server fan mounting platform, and a second server fan clamping position is arranged at the other end of the server fan mounting platform; the first server fan clamping position is provided with a server fan clamping assembly; a server fan clamping assembly is connected to the server fan clamping assembly; and the fan module is arranged on the server fan mounting platform of the server fan mounting module, and is clamped on the server fan clamping assembly of the first server fan clamping position through the server fan clamping assembly. The installation efficiency between the fan module and the server fan installation module in the server can be improved, the damage rate of the server fan clamping assembly is reduced, and meanwhile the problem that the server fan clamping assembly is not easy to disassemble when the fan module is replaced can be solved.

Owner:INSPUR (SHANDONG) COMPUTER TECH CO LTD

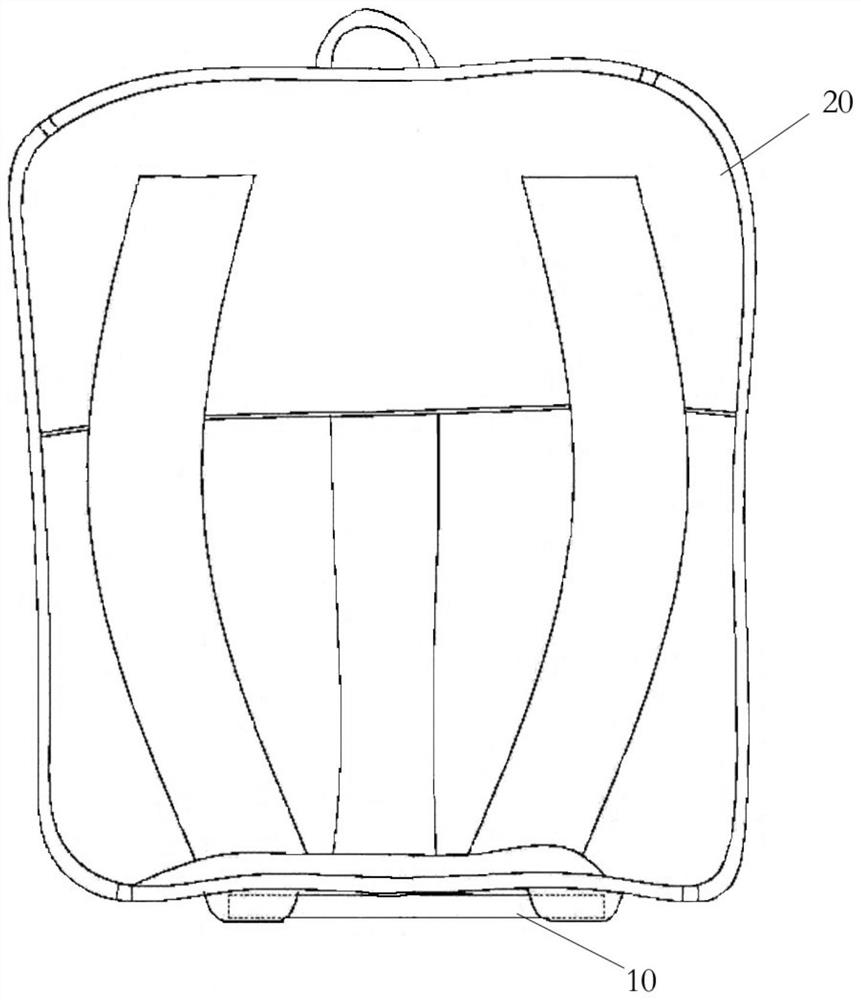

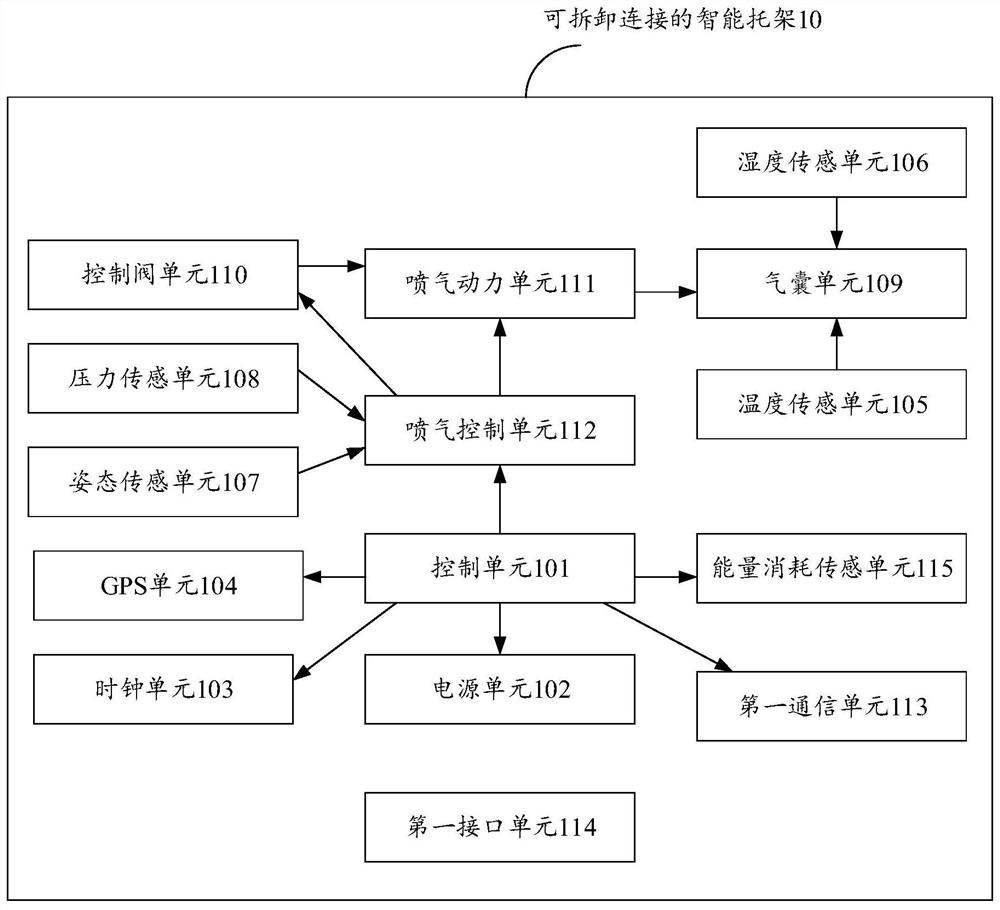

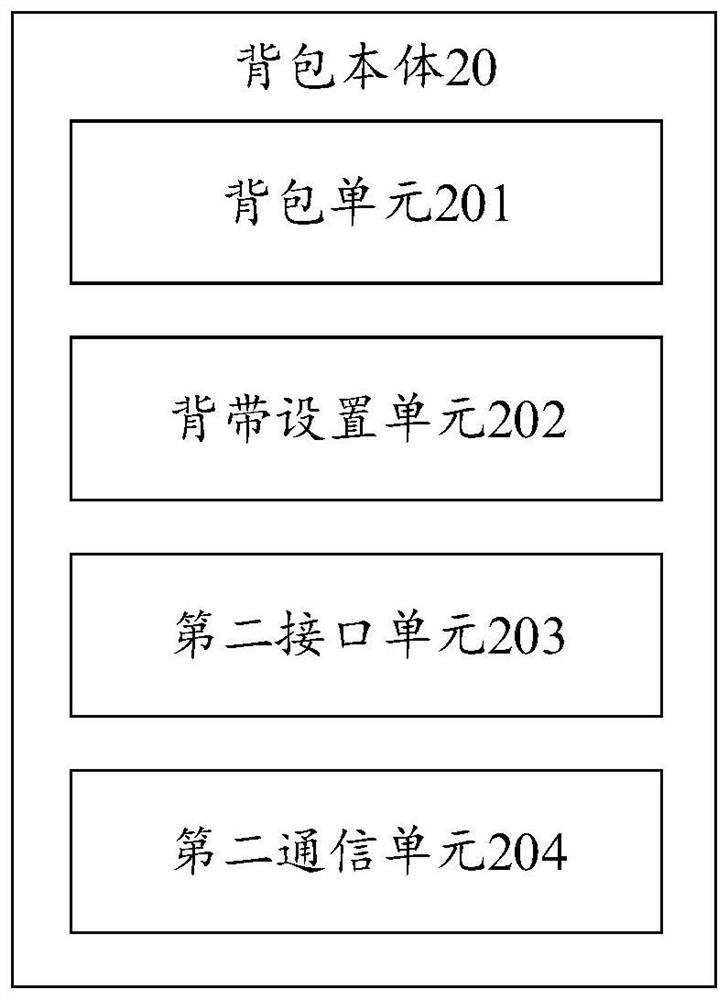

Intelligent air injection backpack and control method of intelligent air injection backpack

PendingCN113545592AReduce capacitySolve the problem of not easy disassemblyTravelling sacksPursesControl engineeringControl cell

The embodiment of the invention provides an intelligent air injection backpack and a control method of the intelligent air injection backpack. The intelligent air injection backpack comprises a backpack body and an intelligent bracket detachably connected with the backpack body, and an air injection power unit and an air bag unit connected with the air injection power unit are arranged outside the intelligent bracket. A control unit, a pressure sensing unit and a posture sensing unit are arranged in the intelligent bracket, the pressure sensing unit and the posture sensing unit are separately connected with the control unit, the gravity and the stress direction of the intelligent air injection backpack are measured through the pressure sensing unit and the posture sensing unit respectively, and then the control unit obtains air injection parameters. Whether the gravity is larger than a preset gravity threshold value or not is judged according to the air injection parameters, and if the gravity is larger than the preset gravity threshold value, the working mode of the intelligent air injection knapsack is controlled according to the stress direction, the air injection power unit and the air bag unit, so that the bearing capacity of the intelligent air injection backpack is relieved, and the intelligent air injection backpack is kept balanced.

Owner:SHENZHEN RUGUO TECH

A piano string-locking nail that is convenient for string changing and tuning

InactiveCN107180622BSolve the problem of not easy disassemblyEasy tuning operationStringed musical instrumentsPianoEngineering

The invention relates to a piano string locking peg facilitating string replacement and tuning and relates to a piano string locking device. A small cylinder inner chamber and a large cylinder inner chamber which are communicated are coaxially formed in a cylinder body, the small cylinder inner chamber is communicated with the upper end surface of the cylinder body, the large cylinder inner chamber is communicated with the lower end surface of the cylinder body, the lower end of a rotary rod is rotationally inserted in the cylinder body, a string penetration hole is formed in the upper end of the side wall of the rotary rod, a positioning wheel is arranged in the large cylinder inner chamber, teeth are manufactured on the circumferential surface of the positioning wheel, the positioning wheel is coaxially and fixedly connected with the lower end surface of the rotary rod, a positioning groove is formed in the upper surface of a bottom plate, the upper surface of the bottom plate is fixedly connected with the lower end surface of the cylinder body, a fastening tube is provided with an external thread and coaxially fixed on the upper end surface of the cylinder body, a fastening cap is in fastening connection with the fastening tube through threads, and an opening I and an opening II are formed in the side wall of the fastening cap. A piano string mounting position is fixed in a wrapping and fastening manner, the structure is novel and practical, and string replacement and tuning are more convenient.

Owner:朱世龙

Titanium alloy seal head convenient to disassemble

InactiveCN111377134AEasy to disassembleSolve the problem of not easy disassemblySealingGear wheelEngineering

The invention provides a titanium alloy seal head convenient to disassemble, and relates to the field of seal heads. The titanium alloy seal head convenient to disassemble comprises a sealing device,wherein the surface of the sealing device comprises a disassembling mechanism, the disassembling mechanism is arranged at the position located at the bottom of the sealing device, and the disassembling mechanism internally comprises control grooves, threaded rods, a through rod, a first gear, a first sucker and a second gear. According to the titanium alloy seal head convenient to disassemble, through cooperative arrangement of the control grooves, the threaded rods, the through rod, the first gear, the first sucker, the second gear, a tooth block and a fixing block, the fixing block is rotated to drive the through rod, then the threaded rod is driven to rotate, the first gear and the second gear are driven to rotate, therefore, the tooth block is driven to move upwards, the first sucker is pushed, the sealing device is disengaged from the first sucker, and the titanium alloy seal head is disassembled, so that the effect of conveniently disassembling the seal head is achieved, and theproblem that an existing titanium alloy seal head is not easy to disassemble is solved.

Owner:江苏联宏机械设备有限公司

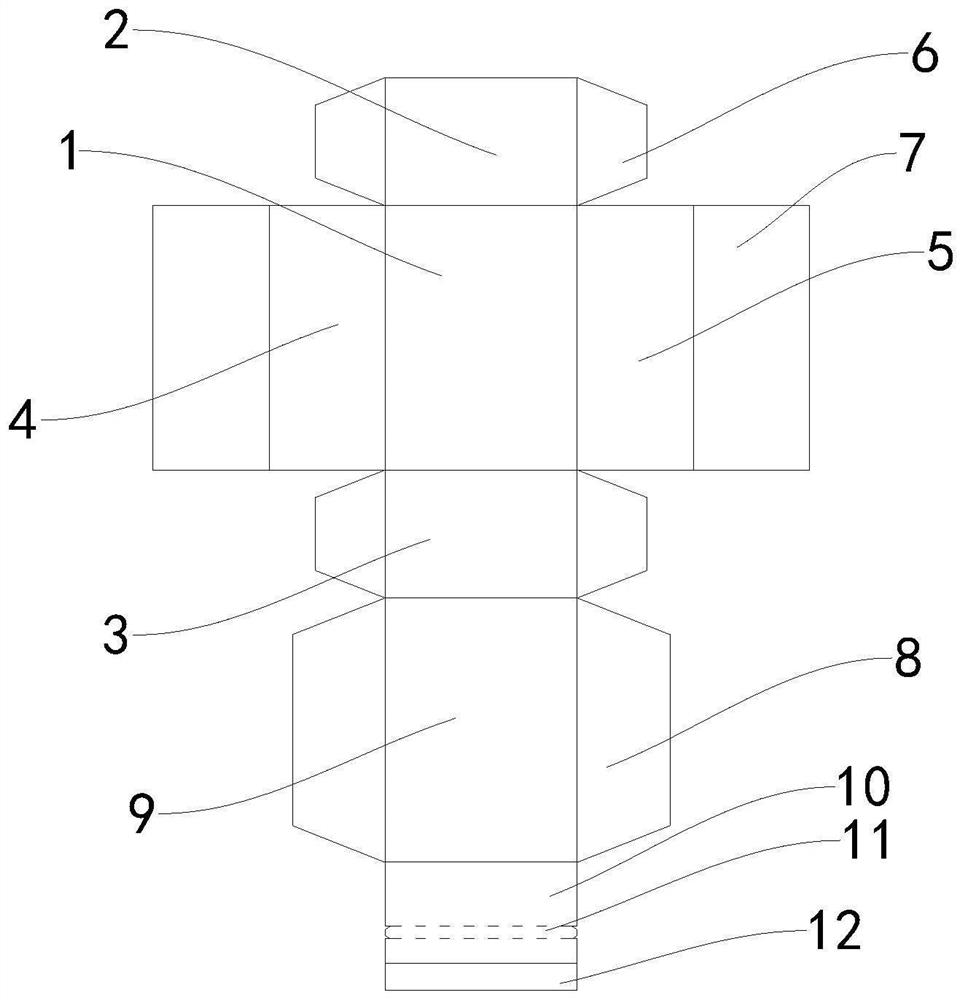

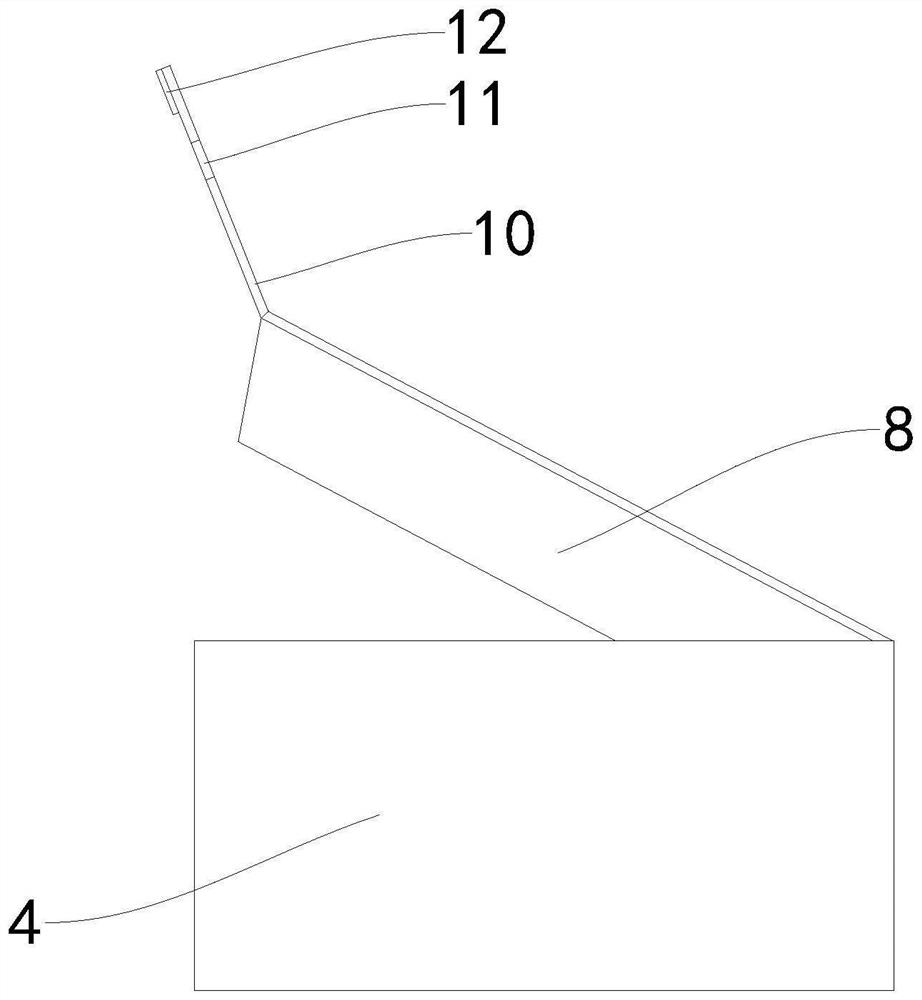

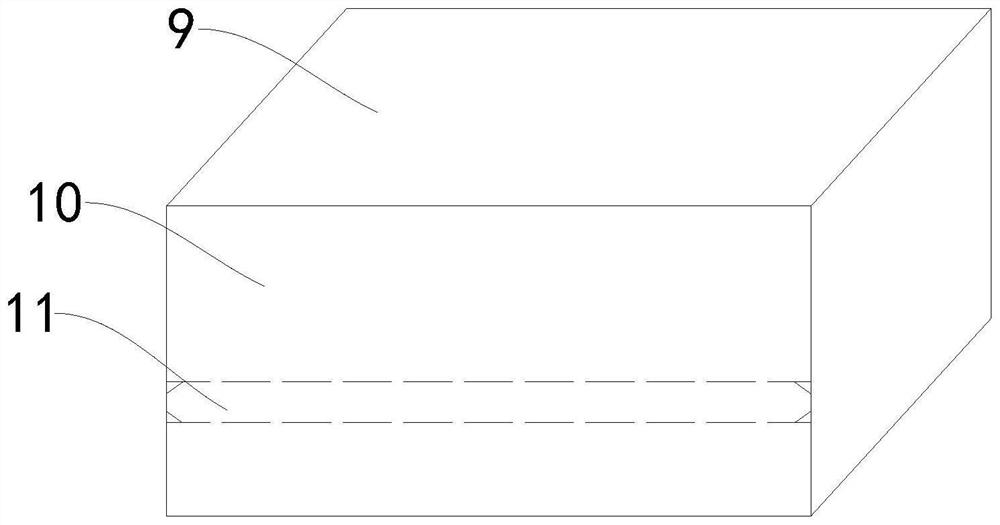

Logistics box convenient to disassemble

The invention provides a logistics box convenient to disassemble, and relates to the technical field of logistics packaging. The logistics box comprises a logistics box body and a packaging assembly. The logistics box body is provided with a containing cavity, the containing cavity is used for storing articles to be transported, the logistics box body is provided with a taking and placing opening connected with the containing cavity, and the taking and placing opening is used for allowing the articles to pass through; the packaging assembly comprises a sealing plate hinged to the taking and placing opening, the sealing plate is used for sealing the taking and placing opening, the sealing plate is hinged to a packaging plate, the packaging plate is used for connecting the logistics box body and the sealing plate, and the packaging plate is provided with a connecting structure used for connecting the logistics box body. An easy-to-tear tape is arranged on the packaging plate between the connecting structure and the logistics box body and is used for separating the packaging plate bodies on the two sides of the easy-to-tear tape. The problem that a logistics box is not easy to disassemble is solved.

Owner:SUZHOU MAIDIAN COLOR PRINTING

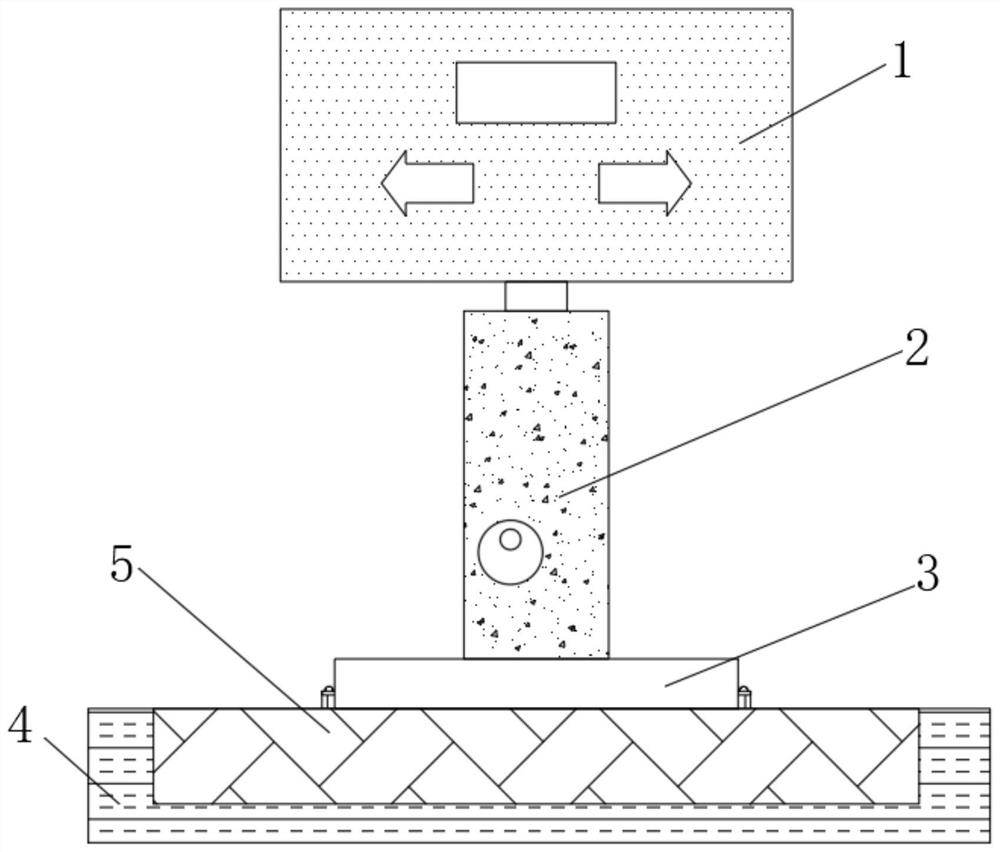

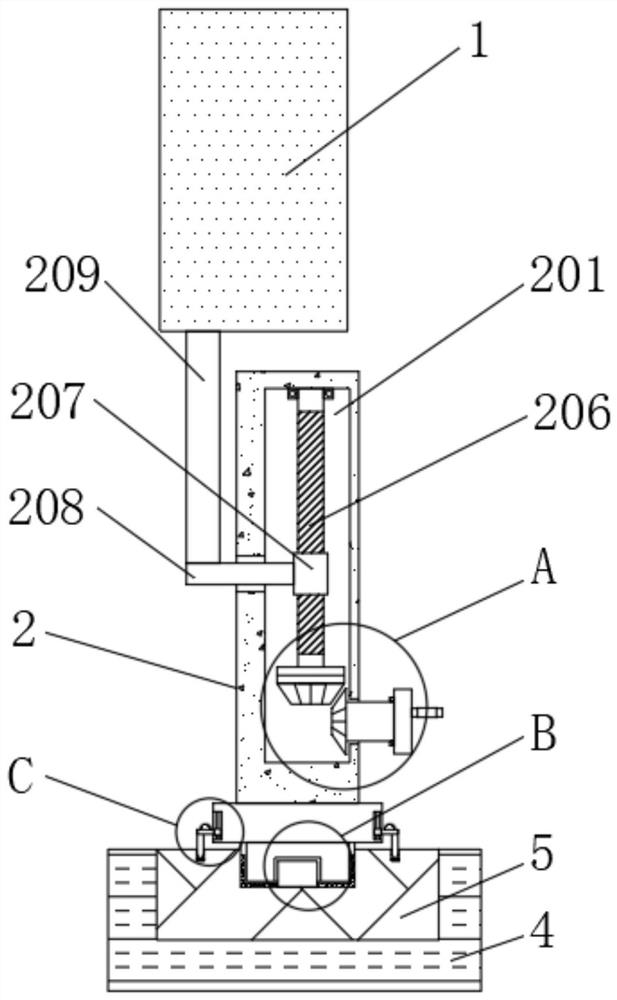

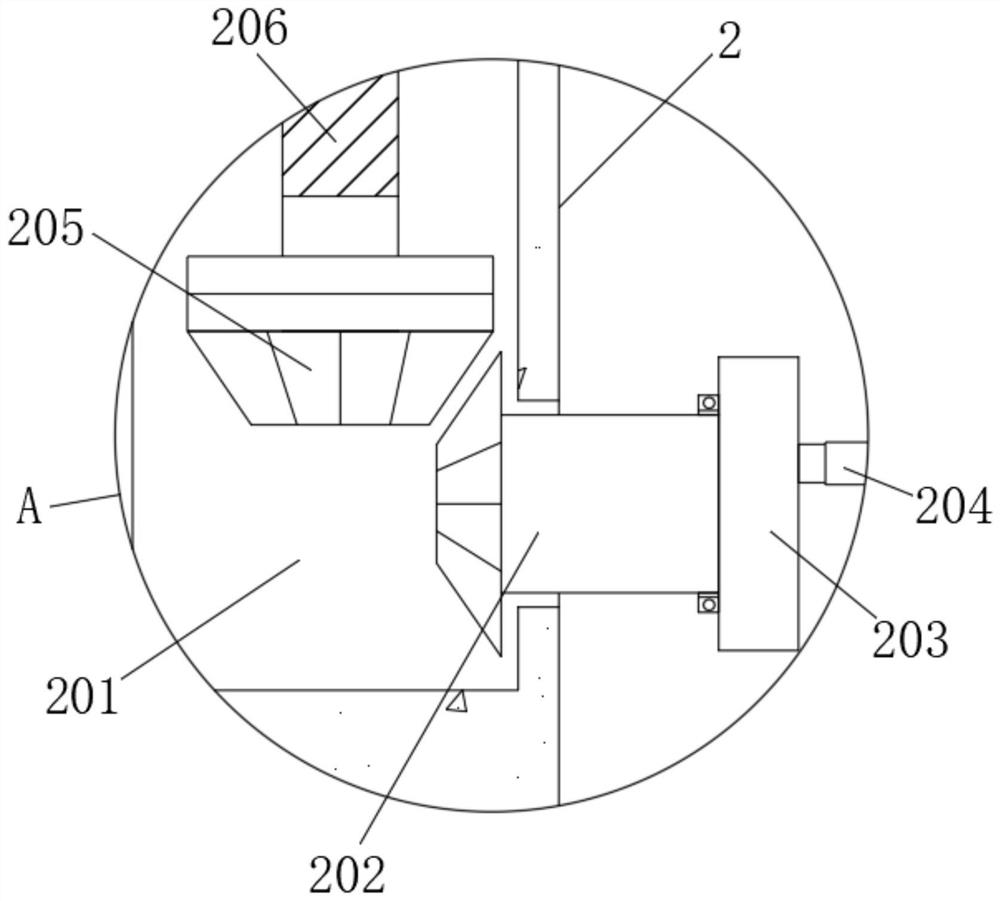

Indication board for port logistics management and control

PendingCN112419873AIncrease the adjustable rangeImprove efficiencyTraffic signalsRoad signsLogistics managementGear wheel

The invention relates to the field of sign devices, in particular to an indication board for port logistics management and control. The comprises a sign device body, a supporting frame is arranged below the sign device body, the bottom end of the supporting frame is fixedly connected with a device base, the device base is movably installed on a fixed plate, and the fixed plate is arranged in the ground; a groove is formed in the supporting frame, a first bevel gear is arranged at the bottom end of the groove, a handle is fixedly connected to the first bevel gear, a second bevel gear is arranged above the first bevel gear, and the first bevel gear and the second bevel gear are meshed with each other. The logistics management and control indicating board solves the problems that an existinglogistics management and control indicating board is fixed in height and cannot be adjusted in height, the adjusting interval of the device is increased, the use efficiency of the device is improved,the practicability of the device in the use process is ensured, the use effect is improved, and the integrity of the device is ensured.

Owner:徐晓宁

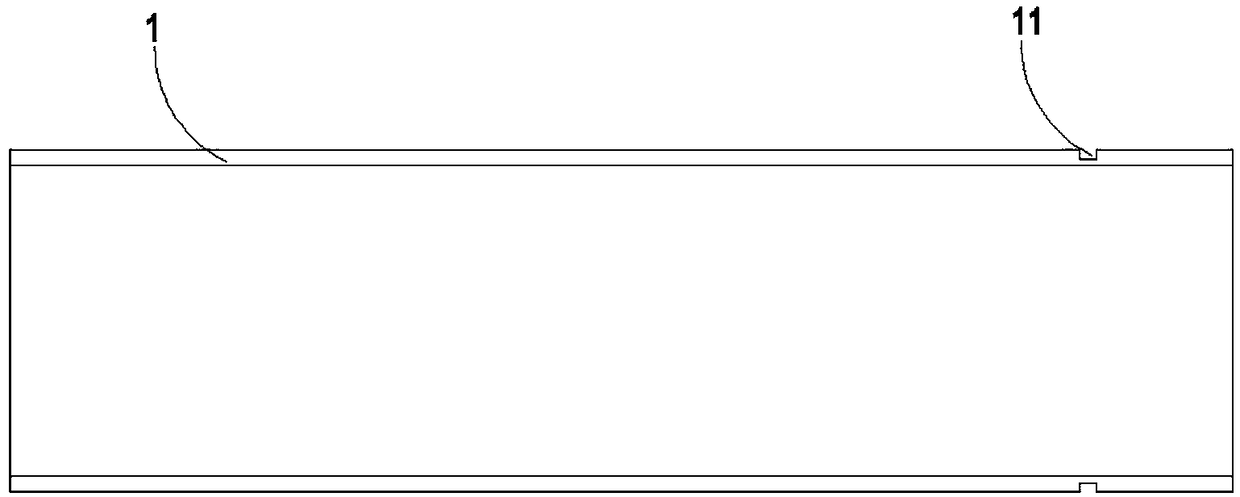

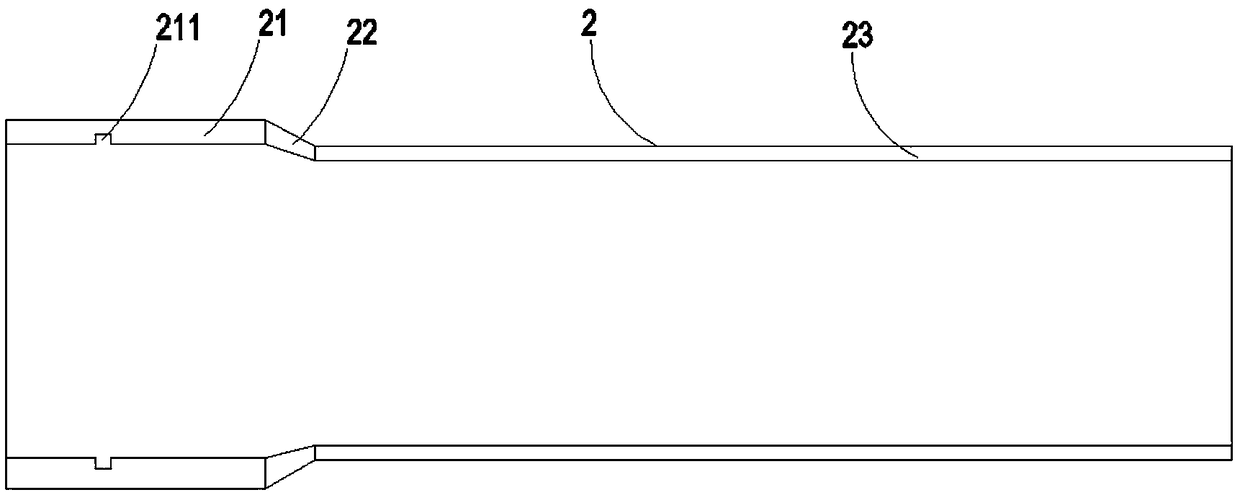

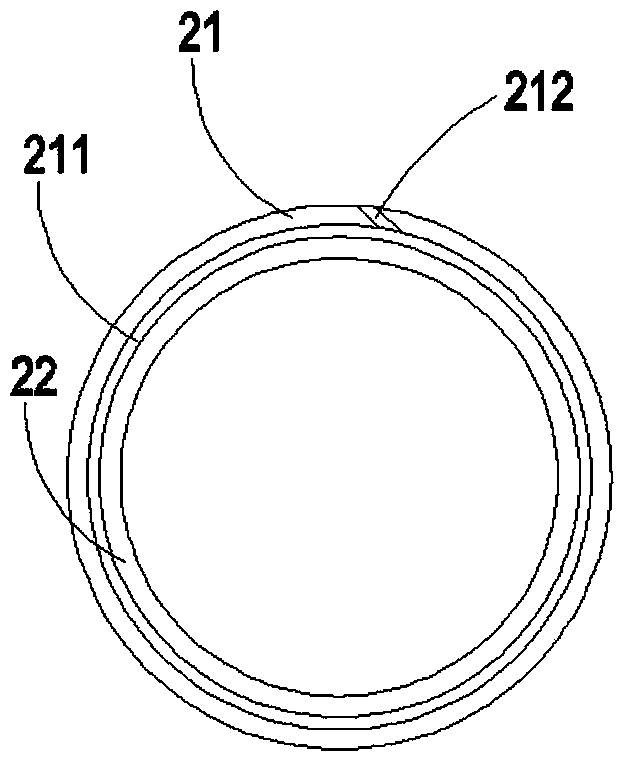

Detachable and washable air conditioner indoor unit

ActiveCN104501306BSolve the problem of not easy disassemblyLighting and heating apparatusHeating and ventilation casings/coversPlate heat exchangerWaste management

The invention relates to the technical field of air conditioners, and provides an easy-to-disassemble and wash air conditioner indoor unit, which comprises a shell, a heat exchanger arranged in the shell, fans and air duct components, wherein the air duct components are positioned on the side edges of the heat exchanger, and are detachably connected with the shell. According to the air conditioner indoor unit, the two air duct components are detachably connected with the shell respectively, and then an ordinary user can disassemble the air duct components to wash the fans, and assembles the air duct components after the fans are washed; by such a structure, the problem of difficulty in disassembling of a conventional air conditioner indoor unit is solved, and the market competitiveness of the product is improved.

Owner:GD MIDEA AIR CONDITIONING EQUIP CO LTD

Stamping type stove burner and manufacturing method thereof

The invention relates to a stamping type stove burner which comprises inner ejecting pipes, outer ejecting pipes, an inner annular cavity, an outer annular cavity, an inner burner cap base, a furnace end connecting piece, a furnace end, an inner burner cap and an outer burner cap. The inner ejecting pipes include the upper, middle and lower inner ejecting pipes. The outer ejecting pipes include the upper, middle and lower outer ejecting pipes. The upper inner ejecting pipe, the upper outer ejecting pipe and the outer annular cavity are subjected to board stamping and integrated molding to form an upper half pipe. The middle inner ejecting pipe, the middle outer ejecting pipe and the inner annular cavity are subjected to board stamping and integrated molding to form a middle pipe. The lower inner ejecting pipe and the lower outer ejecting pipe are subjected to board stamping and integrated molding to form a lower half pipe. The upper half pipe, the middle pipe and the lower half pipe are buckled, subjected to hydraulic and gas sealing and fixedly connected together. The inner burner cap is connected to the inner annular cavity. The inner burner cap is arranged on the inner burner cap base. The furnace end connecting piece is connected to the outer annular cavity. The furnace end is arranged on the furnace end connecting piece. The outer burner cap is arranged on the furnace end. The burner is safe, environmentally friendly and easy to carry.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

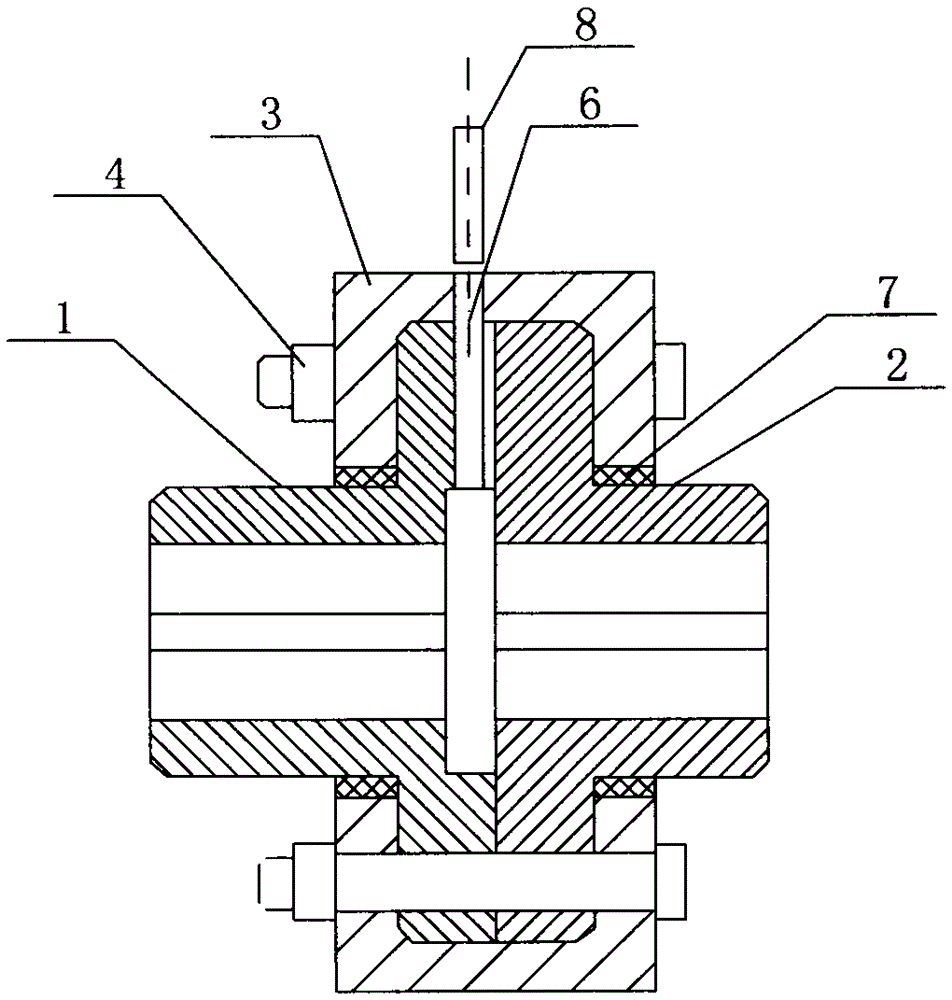

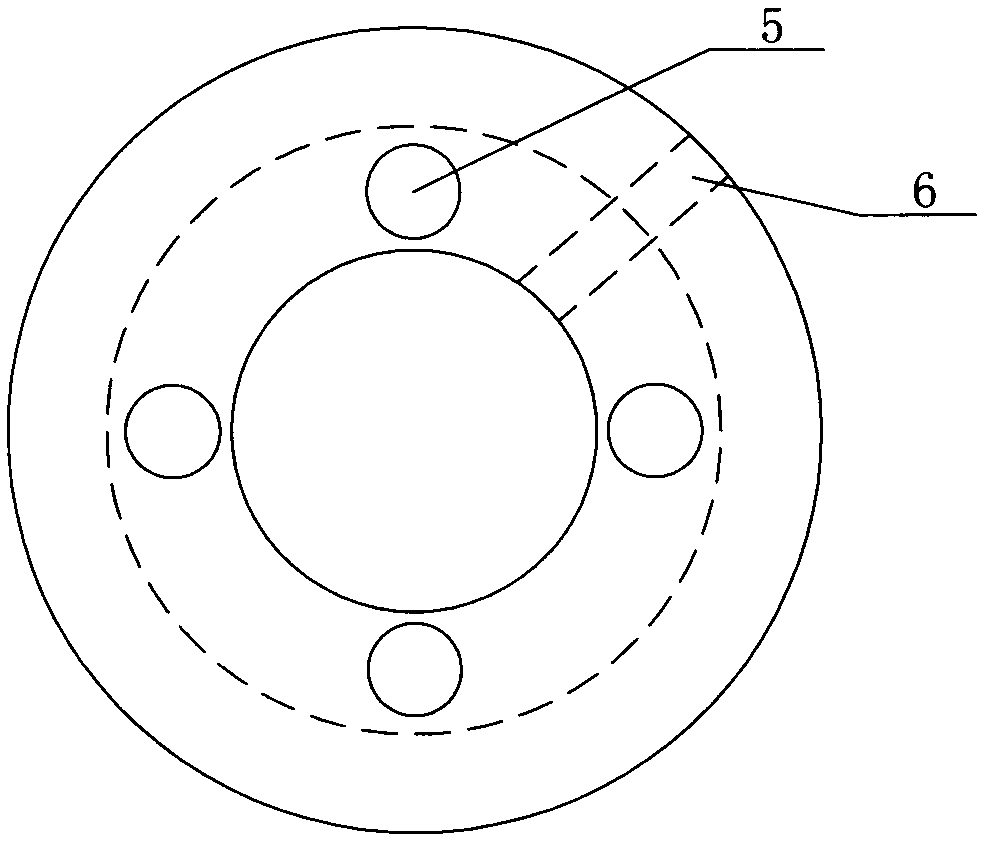

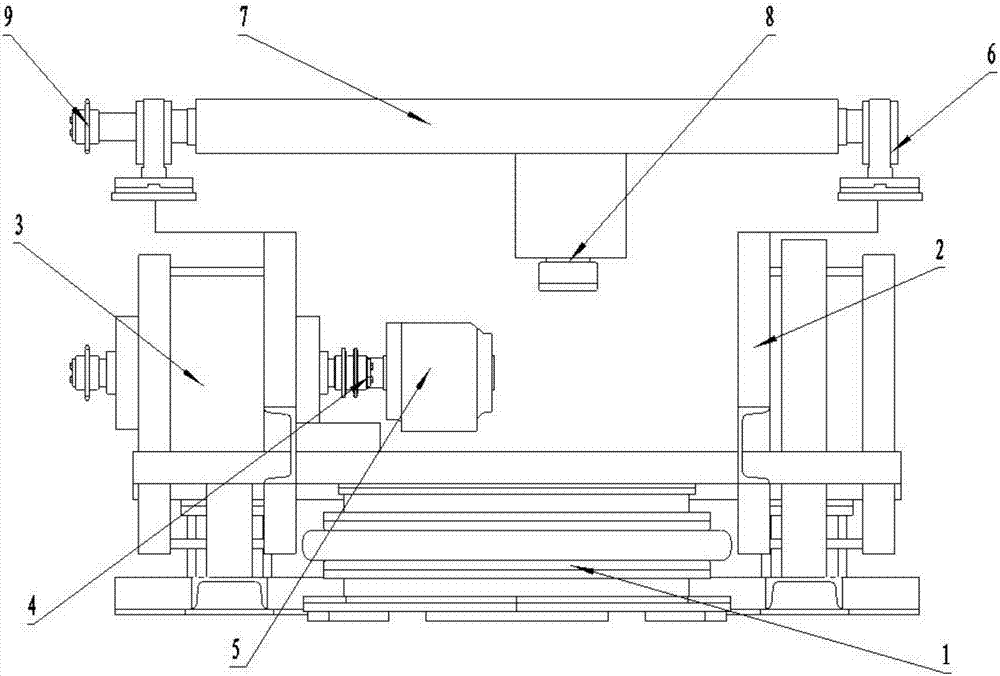

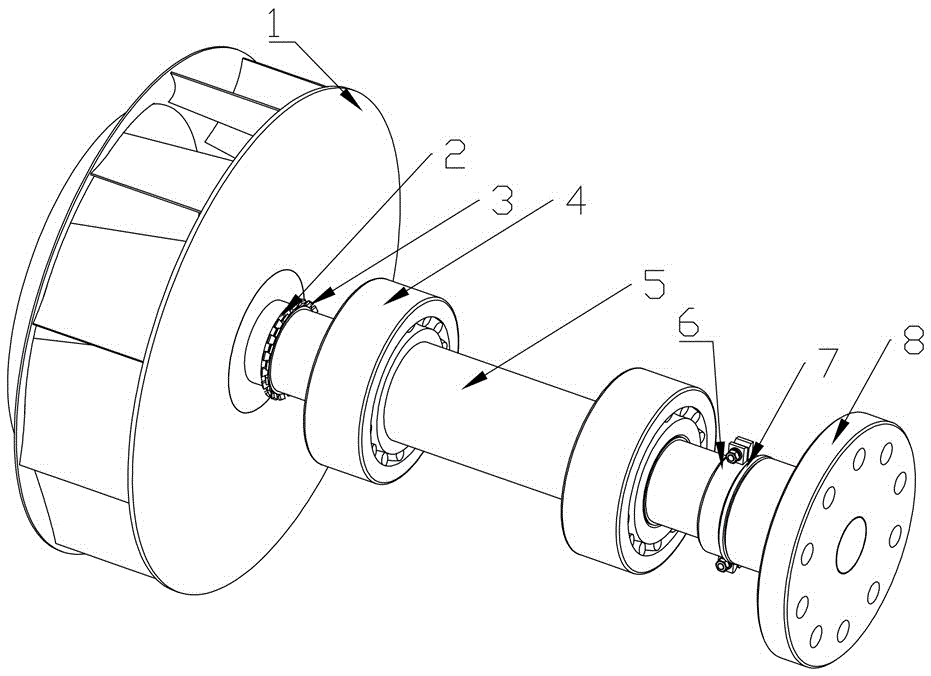

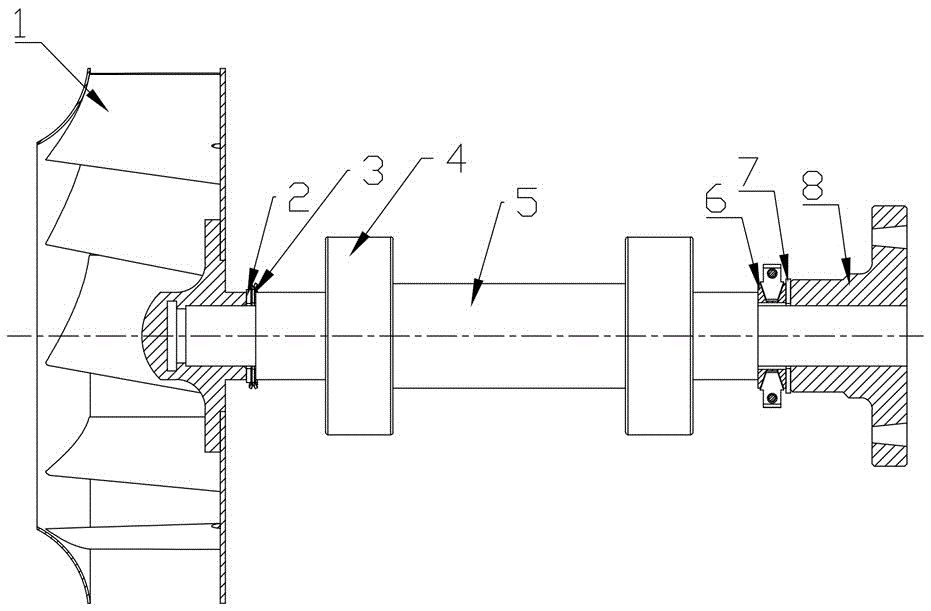

A miniature jaw crusher with monitoring

ActiveCN105536918BSolve the problem of continuous automatic locking and difficult disassemblySolve the problem of not easy disassemblyGrain treatmentsMonitoring systemEngineering

The invention discloses a miniature jaw crusher. The miniature jaw crusher comprises a miniature jaw crusher body and a monitoring system, wherein the miniature jaw crusher body comprises a machine body (3), a flywheel (11) and a belt pulley (15); the flywheel (11) and the belt pulley (15) are assembled with a camshaft (14) of the machine body (3) in a normally and reversely threaded manner; the monitoring system comprises a strain sensor (6) arranged on a bearing block (2) of the machine body (3); and the strain sensor (6) is connected with a signal processor (8) through a signal line (7), carries out processing and controlling through a computer (9). By the miniature jaw crusher, the problem that threaded assembly of the jaw crusher is locked automatically and continuously and is not easy to detach can be solved effectively, the jaw crusher can be detached conveniently, meanwhile, impact load in a crushing operation process can be monitored indirectly, particularly, the miniature jaw crusher can be detached conveniently after components of the miniature jaw crusher are locked in a threaded manner, and working condition maintenance of the miniature jaw crusher can also be implemented.

Owner:江苏佳华机械科技有限公司

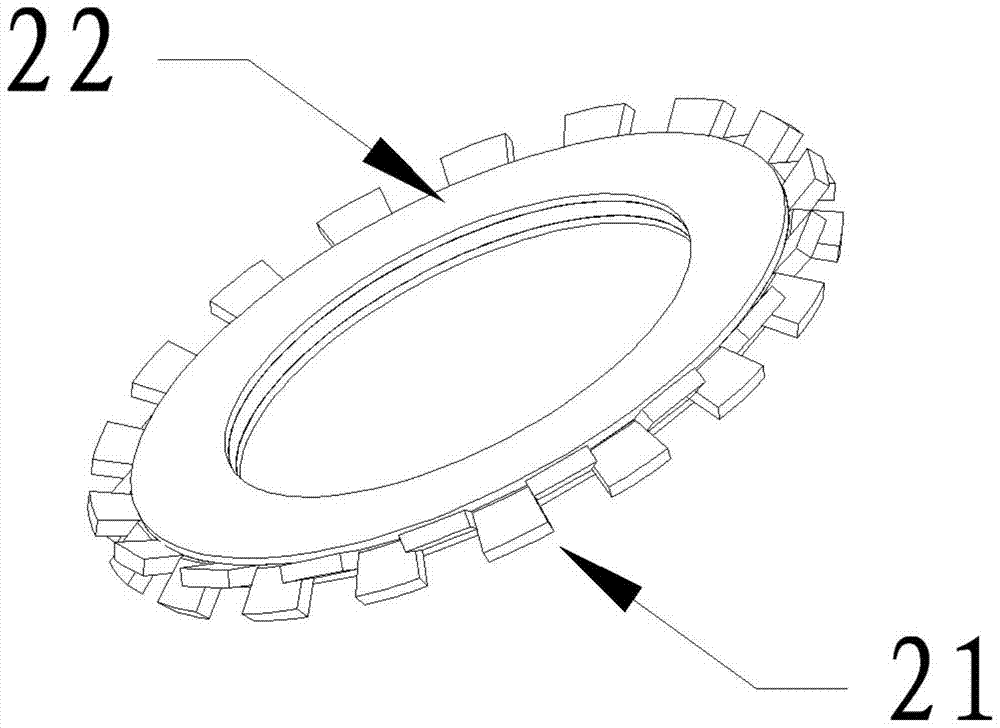

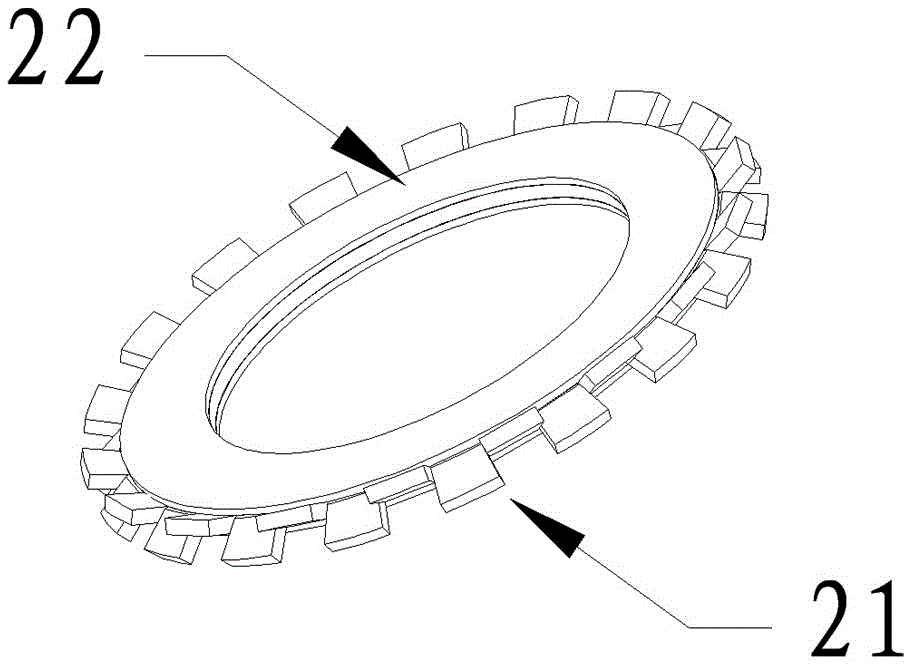

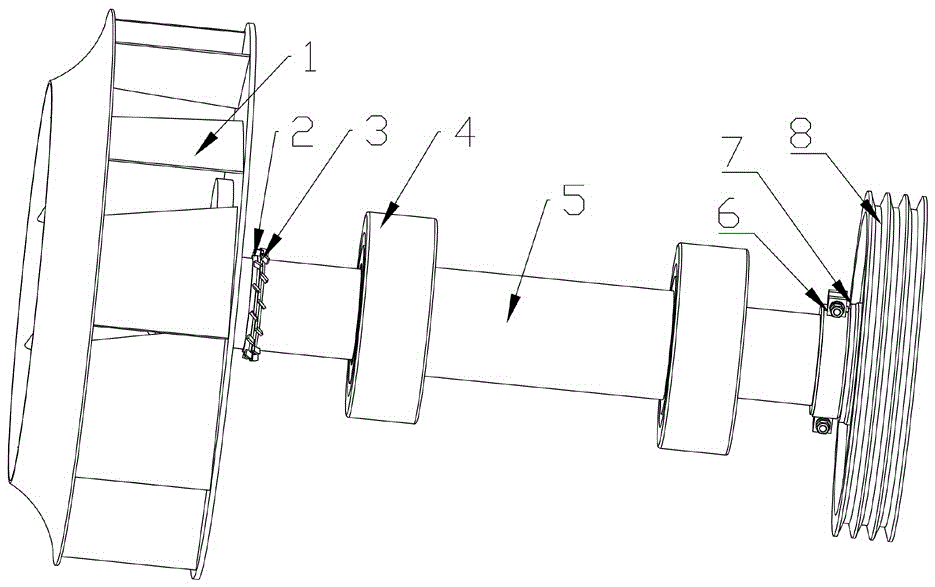

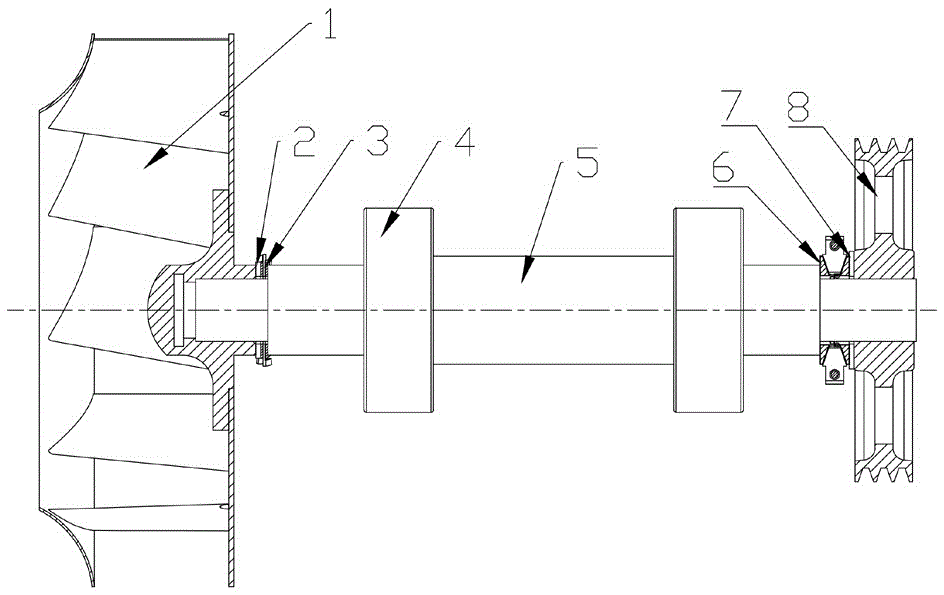

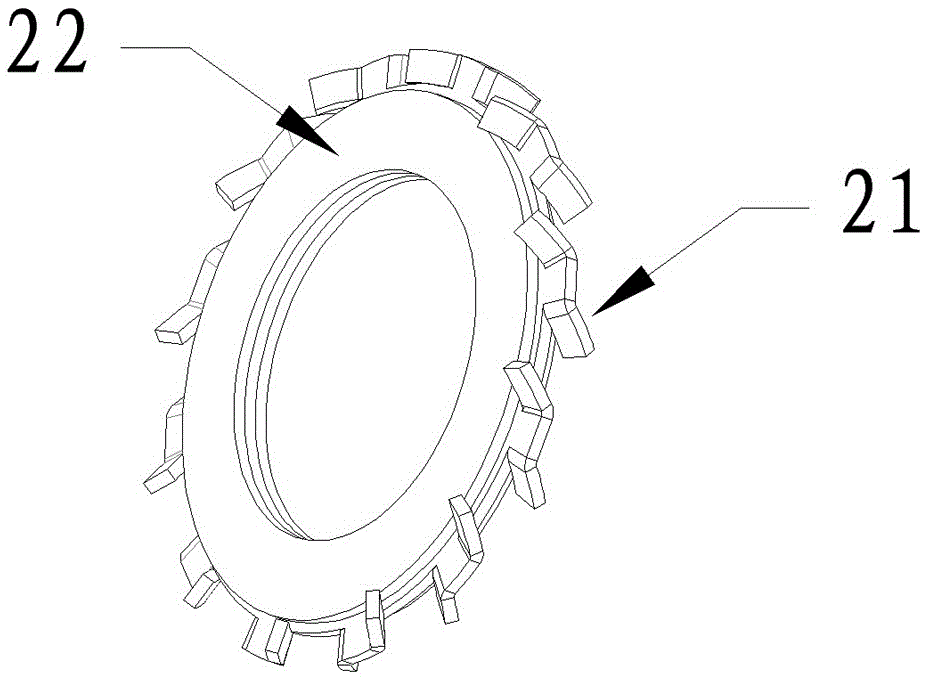

Thread fast-dismounting device applied to coupler fan

The invention discloses a thread fast-dismounting device applied to a coupler fan. The thread fast-dismounting device comprises a fan impeller, a bearing, a fan shaft and a coupler. The coupler and the fan shaft are assembled through a thread, and the fan impeller and the fan shaft are assembled through a thread; and the thread turning direction is the direction of automatic locking along with work and bearing. The fan impeller is similar to a nut, is in threaded connection with the fan shaft and enables an impeller flat washer and a copper lead reverse-folding composite pad to be pressed, and the fan impeller is in threaded rigid connection with one end of the fan shaft; a clamping part is sleeved with the other end of the fan shaft, and then the coupler flat washer is sleeved with the fan shaft and then is screwed into the coupler similar to a nut; and total locking is carried out reasonably, and the clamping part and the coupler similar to the nut are in rigid connection with the other end of the fan shaft. According to the device, the problem that under the load effect, a thread assembly is continuously and automatically locked and is not prone to being disassembled can be effectively solved, the device is particularly suitable for convenient and rapid disassembling of a large component obtained after thread locking, and the effect is particularly obvious.

Owner:JISHOU UNIVERSITY

Thread quick detaching device for fan of belt pulley

The invention discloses a thread quick detaching device for a fan of a belt pulley. The thread quick detaching device for the fan of the belt pulley comprises a fan impeller, a bearing, a fan shaft and the belt pulley, wherein the belt pulley and the fan shaft are assembled in a threaded manner; the fan impeller and the fan shaft are assembled in a threaded manner; a thread turning direction is a direction in which automatic locking is implemented along with operation and load bearing; the fan impeller which is similar to a nut is in threaded connection with the fan shaft and tightly presses an impeller flat washer and a copper-plastic reverse bending composite gasket; the fan impeller is rigidly connected with one end of the fan shaft in a threaded manner; a clamp part sleeves the other end of the fan shaft; a belt pulley flat washer sleeves the fan shaft and then the belt pulley which is similar to a nut is screwed in, and all parts are locked reasonably, so that the clamp part and the belt pulley which is similar to the nut are rigidly connected with the other end of the fan shaft. By the thread quick detaching device, the problem that thread assembly is automatically locked continuously and is not easy to detach under the effect of a load can be solved effectively, and an oval hole is formed in a clamp gasket so as to improve axial elasticity; and the thread quick detaching device is particularly suitable for conveniently detaching large components after threaded locking, and the effect is particularly remarkable.

Owner:JISHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com