Thread quick-dismantling device applied to coupling water pump

A coupling and thread technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problem of difficult disassembly, and achieve the effect of quick and convenient disassembly, remarkable effect, and enhanced bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

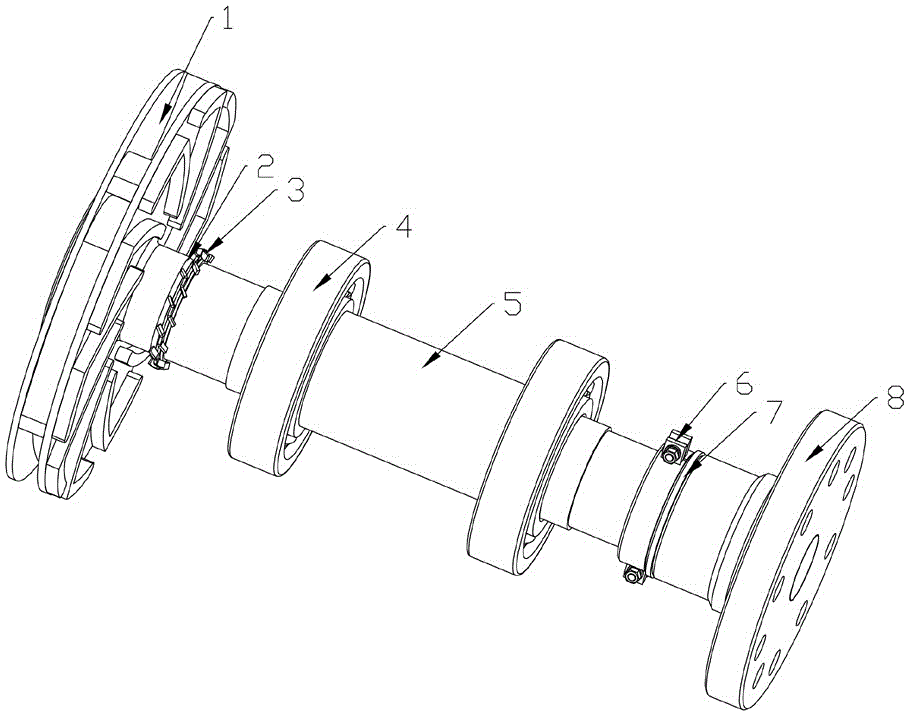

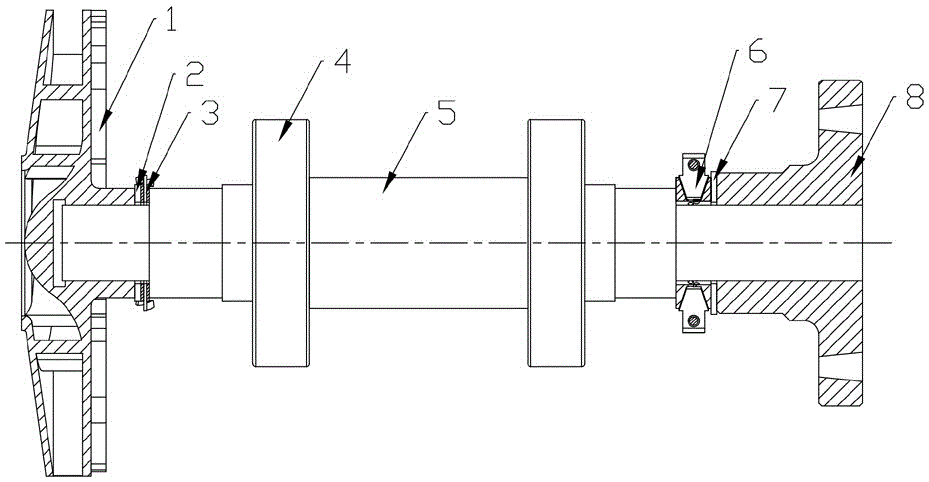

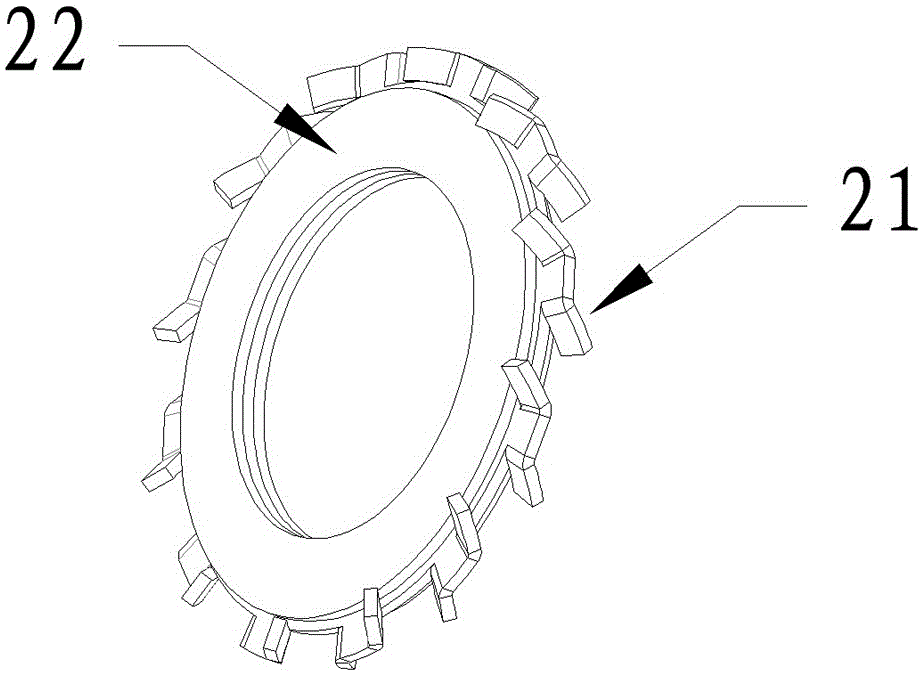

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The threaded quick release device applied to the coupling water pump shown includes the water pump impeller 1, the bearing 4, the water pump shaft 5 and the coupling 8, and the coupling 8 and the water pump shaft 5 as well as the water pump impeller 1 and the water pump shaft 5 are all threaded Assembling, the thread rotation direction is the direction that is automatically locked with the work and load; the water pump impeller 1 is threaded with the water pump shaft 5 through a similar nut, and the impeller flat washer 2 and the copper-lead torsion composite pad 3 are pressed tightly, and the water pump impeller 1 and the water pump shaft One end of 5 forms a threaded rigid connection; the clamp part 6 is inserted into the other end of the water pump shaft 5, and then the coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com