lime glass tube

A technology of glass tube and lime material, applied in the field of lime material glass tube and its preparation, which can solve the problems of small tolerance variation range of glass tube outer diameter, large variation range of outer diameter, insufficient step blowing, etc., and achieve stable and melting glass liquid The effect of high efficiency and long material resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

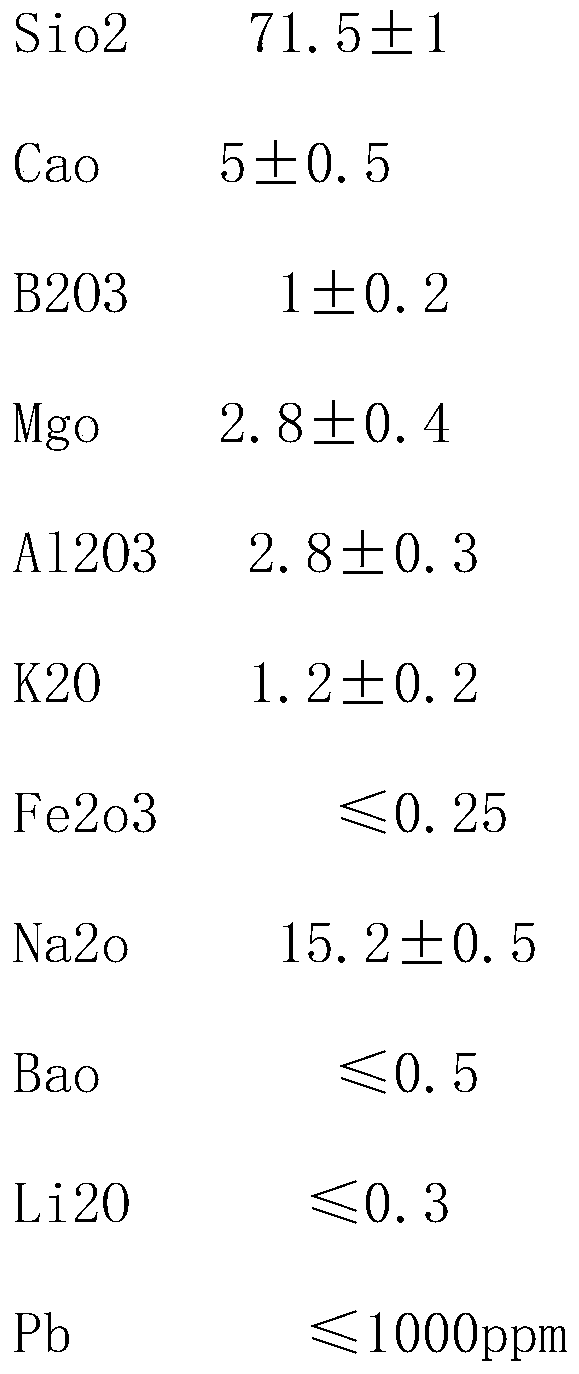

Method used

Image

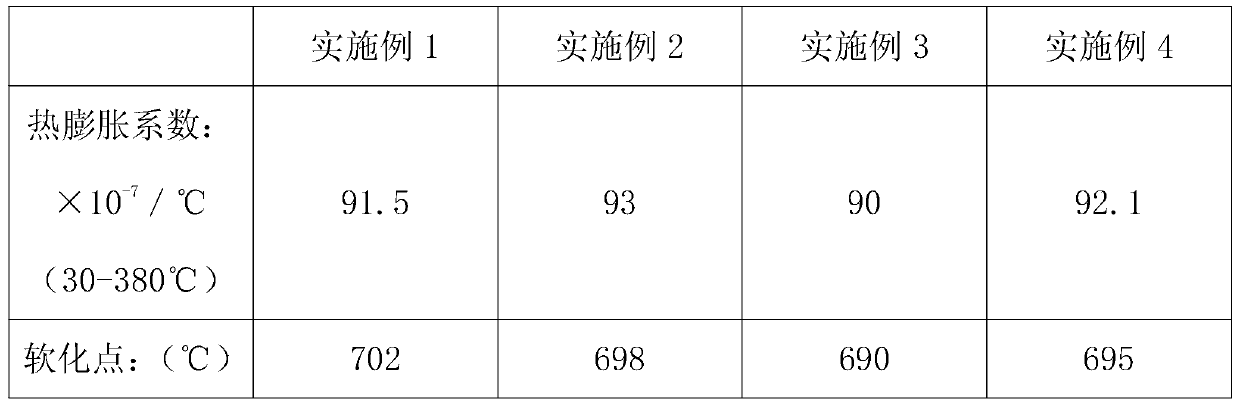

Examples

Embodiment 1

[0023] A preparation method for a lime material glass tube, comprising the following steps:

[0024] (1) Ingredients: Add the raw materials in the above parts by weight in the order of lime, soda ash, quartz sand, sodium nitrate, potassium feldspar powder, dolomite powder, calcite powder, borax sodium sulfate, tourmaline, and silicon carbide. Mix well in the mixer;

[0025] (2) Melting: Keep the temperature stable, the flame length stable, the temperature constant at 1500°C, and burn for 24 hours to fully melt the raw materials;

[0026] (3) Nucleation and crystallization: constant temperature of 1280 ° C, burning for 24 hours, the temperature is required to be stable and uniform during combustion, and the flame is full, so that the glass can be fully nucleated and crystallized;

[0027] (4) Forming: forming glass with forming equipment;

[0028] (5) Annealing: Keep the temperature at 540°C±3 for 24 hours to eliminate stress, cold frying and other phenomena.

[0029] The st...

Embodiment 2

[0032] A preparation method for a lime material glass tube, comprising the following steps:

[0033] (1) Ingredients: Add the raw materials in the above parts by weight in the order of lime, soda ash, quartz sand, sodium nitrate, potassium feldspar powder, dolomite powder, calcite powder, borax sodium sulfate, tourmaline, and silicon carbide. Mix well in the mixer;

[0034] (2) Melting: Keep the temperature stable, the flame length stable, the temperature constant at 1500°C, and burn for 24 hours to fully melt the raw materials;

[0035] (3) Nucleation and crystallization: constant temperature of 1280 ° C, burning for 24 hours, the temperature is required to be stable and uniform during combustion, and the flame is full, so that the glass can be fully nucleated and crystallized;

[0036] (4) Forming: forming glass with forming equipment;

[0037] (5) Annealing: Keep the temperature at 540°C±3 for 24 hours to eliminate stress, cold frying and other phenomena.

[0038] The st...

Embodiment 3

[0041] A preparation method for a lime material glass tube, comprising the following steps:

[0042] (1) Ingredients: Add the raw materials in the above parts by weight in the order of lime, soda ash, quartz sand, sodium nitrate, potassium feldspar powder, dolomite powder, calcite powder, borax sodium sulfate, tourmaline, and silicon carbide. Mix well in the mixer;

[0043] (2) Melting: Keep the temperature stable, the flame length stable, the temperature constant at 1500°C, and burn for 24 hours to fully melt the raw materials;

[0044] (3) Nucleation and crystallization: constant temperature of 1280 ° C, burning for 24 hours, the temperature is required to be stable and uniform during combustion, and the flame is full, so that the glass can be fully nucleated and crystallized;

[0045] (4) Forming: forming glass with forming equipment;

[0046] (5) Annealing: Keep the temperature at 540°C±3 for 24 hours to eliminate stress, cold frying and other phenomena.

[0047] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com