Patents

Literature

33results about How to "Uniform ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for smelting nickel-containing ferrochrome alloy

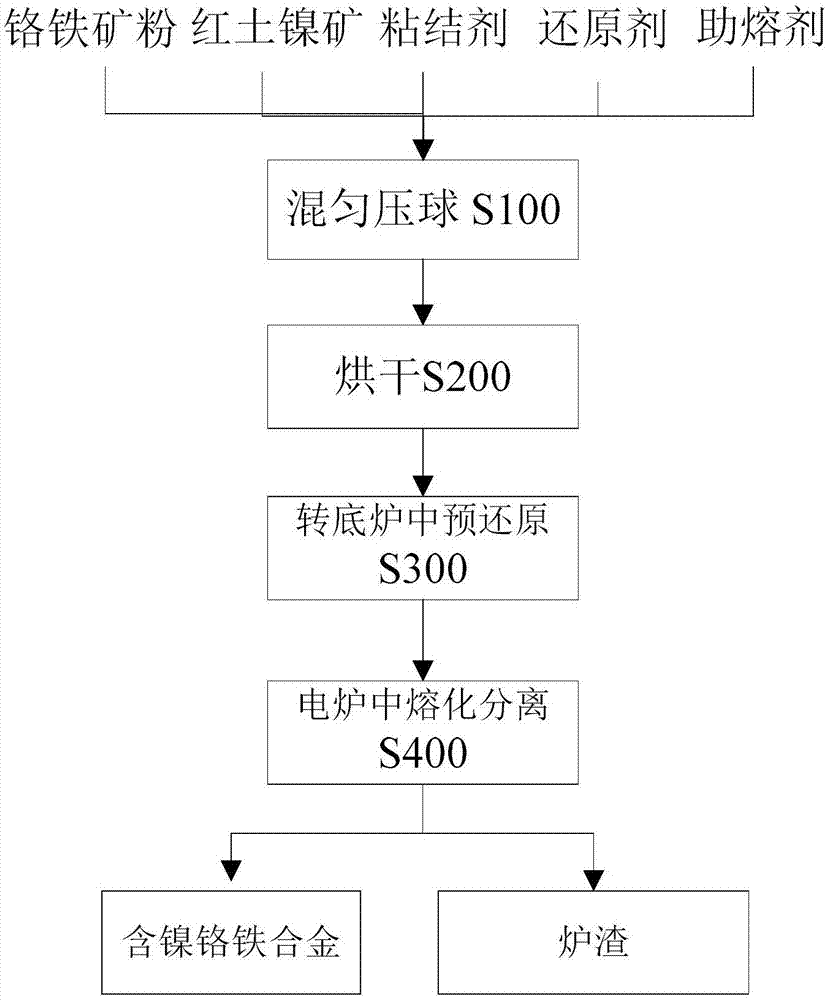

The invention relates to a method for smelting nickel-chromium ferroalloy, which comprises the following steps: uniformly mixing the ground laterite nickel ore with chromite powder, reducing agent, binder and fluxing agent to prepare balls The pellets are placed in a rotary hearth furnace for high-temperature reduction to obtain metallized pellets; the metallized pellets are sent to an electric furnace for high-temperature melting and separation to obtain nickel-chromium-iron alloys. The present invention uses the easy-to-form characteristics of laterite-nickel ore by mixing ingredients with chromite ore and high-magnesium laterite-nickel ore, reduces the addition of binders, and molds cheap and difficult-to-form chromite powder ore, reducing the Production cost; all raw materials are pre-mixed, the ingredients are relatively uniform, and the smelting time is shortened; the pellets are pre-reduced at high temperature in the rotary hearth furnace, which effectively reduces the power consumption of the electric furnace smelting; at the same time, due to the introduction of Ni in the laterite nickel ore, nickel-containing The ferrochrome alloy further obtained low-cost raw materials for smelting stainless steel.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Batching device for waterproof coating

InactiveCN110479170AIncrease collisionImprove completenessShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionEngineering

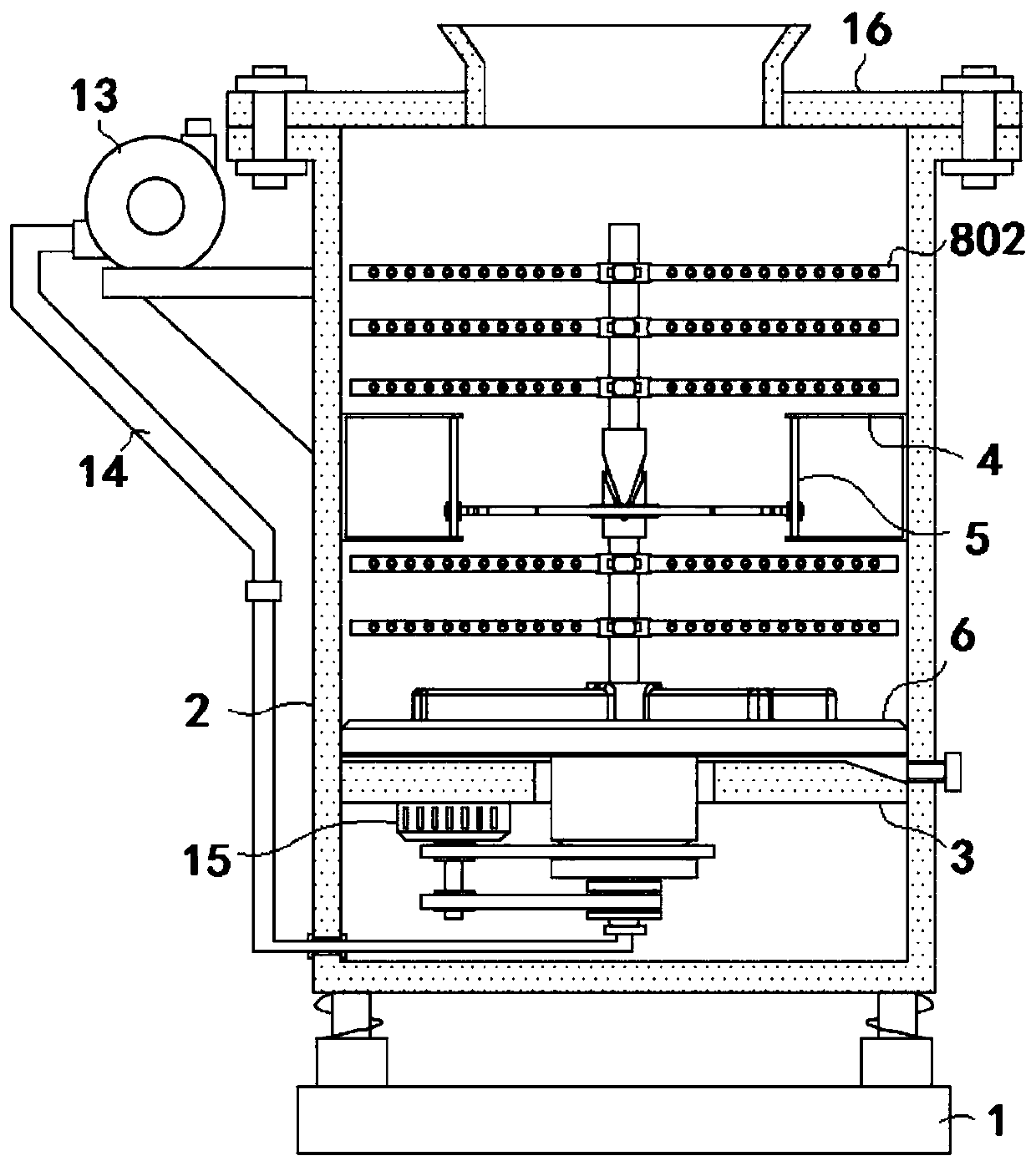

The invention discloses a batching device for waterproof coating, and relates to the technical field of waterproof coating processing. The device comprises a damping base; a batching box is fixedly connected to one surface of the damping base; a partition base and a plurality of connecting frames are fixedly connected between the inner surfaces of the batching box; guide rods are fixedly connectedbetween the inner surfaces of the connecting frames; the inner wall of the partition base is rotationally connected with a forward rotating disc through a bearing; and inner wall of the forward rotating disc is rotationally connected with an inner pipe through a bearing. Compared with a traditional waterproof coating mixing device, the batching device is characterized in that an oscillating, surging and stirring technology, a high-pressure air stirring technology and a coaxial two-way differential stirring technology are comprehensively used, during working, the circular motion of the inner pipe can be converted into linear reciprocating motion of the oscillating plate through the design of the transmission groove, and through the linear reciprocating motion of the oscillating plate, liquid generates up-down violent surging during stirring, so that the collision and staggering degree of the liquid is enhanced, and further, uniform batching is achieved.

Owner:合肥品冠环保科技有限责任公司

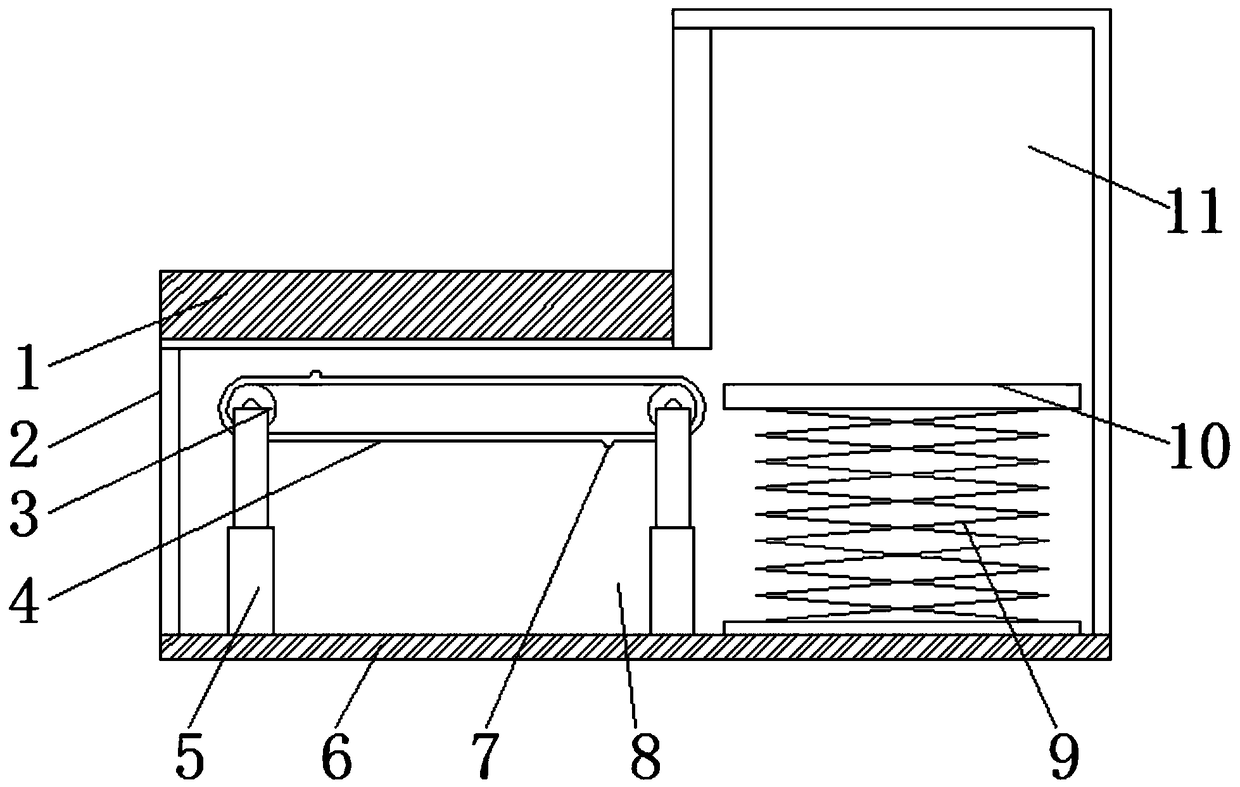

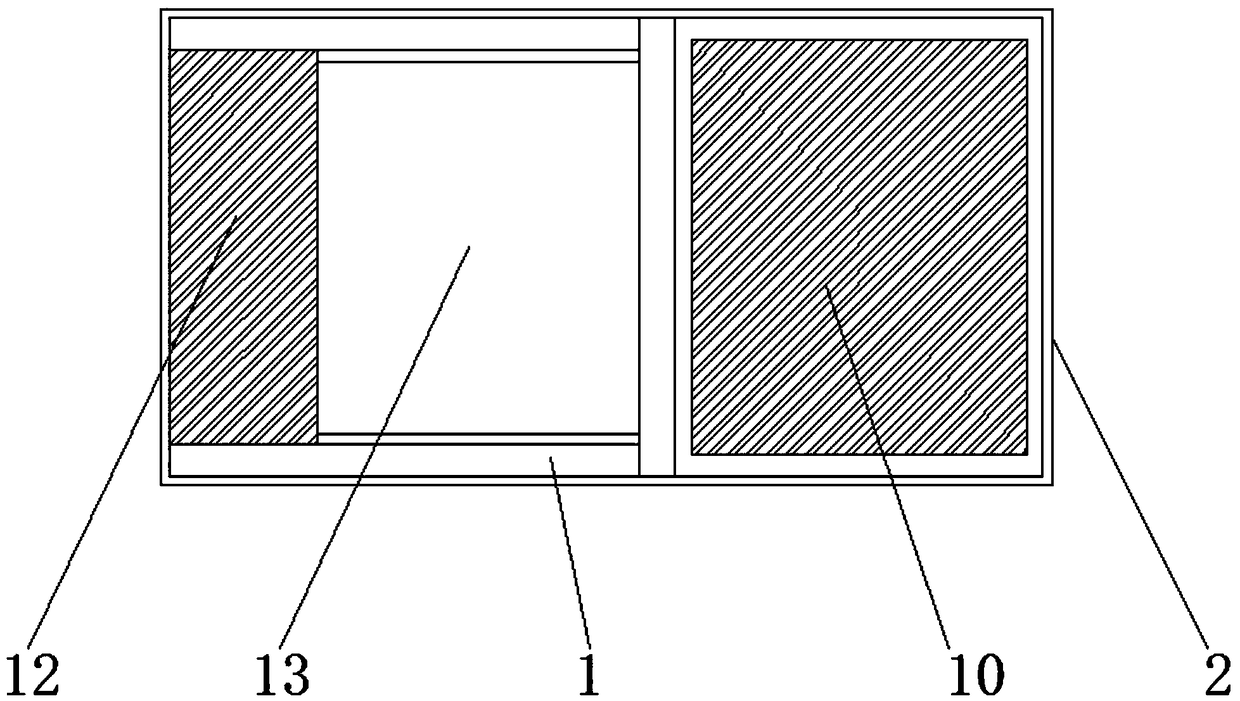

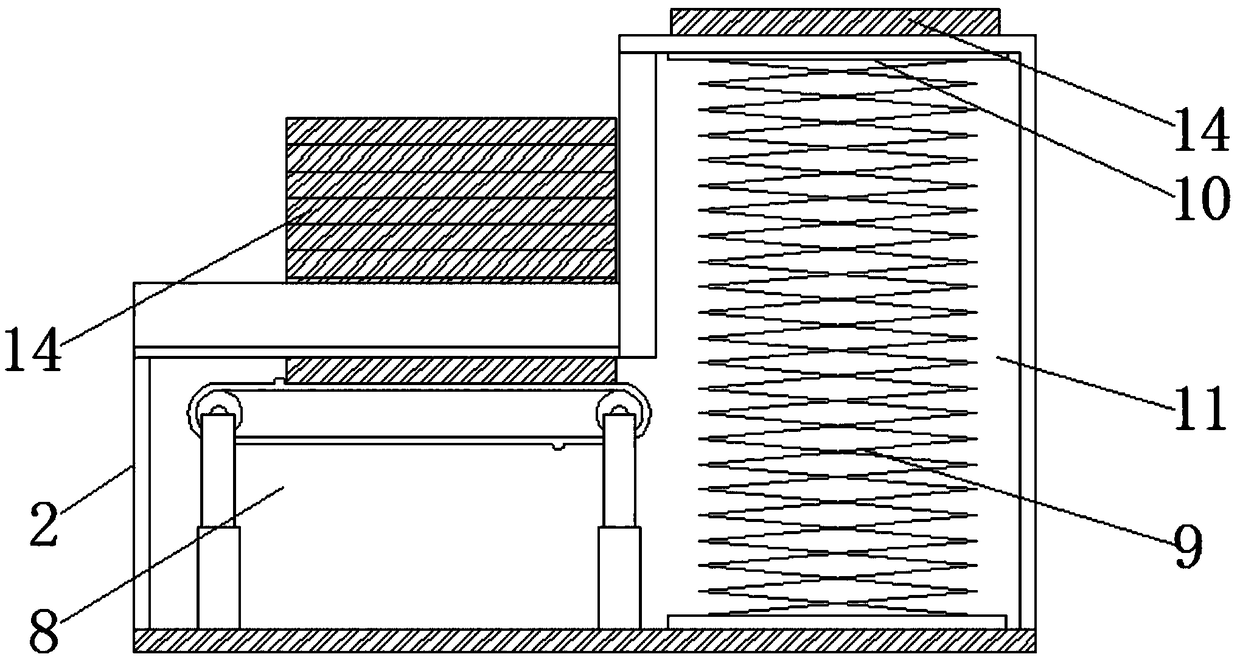

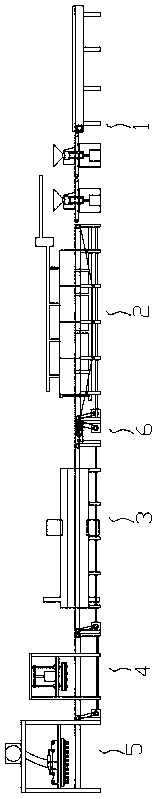

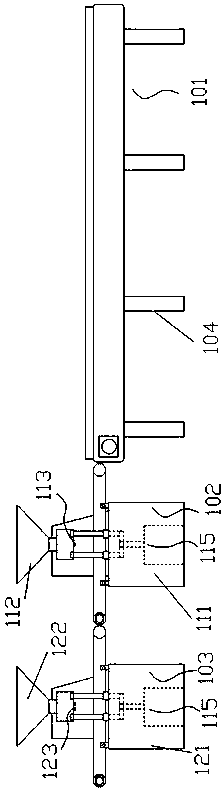

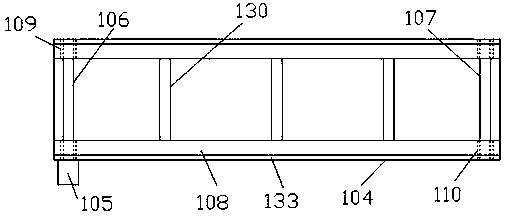

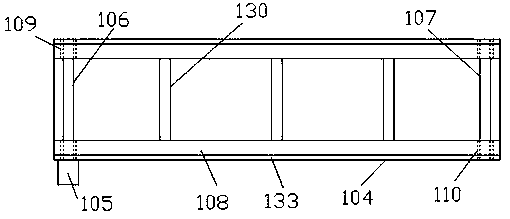

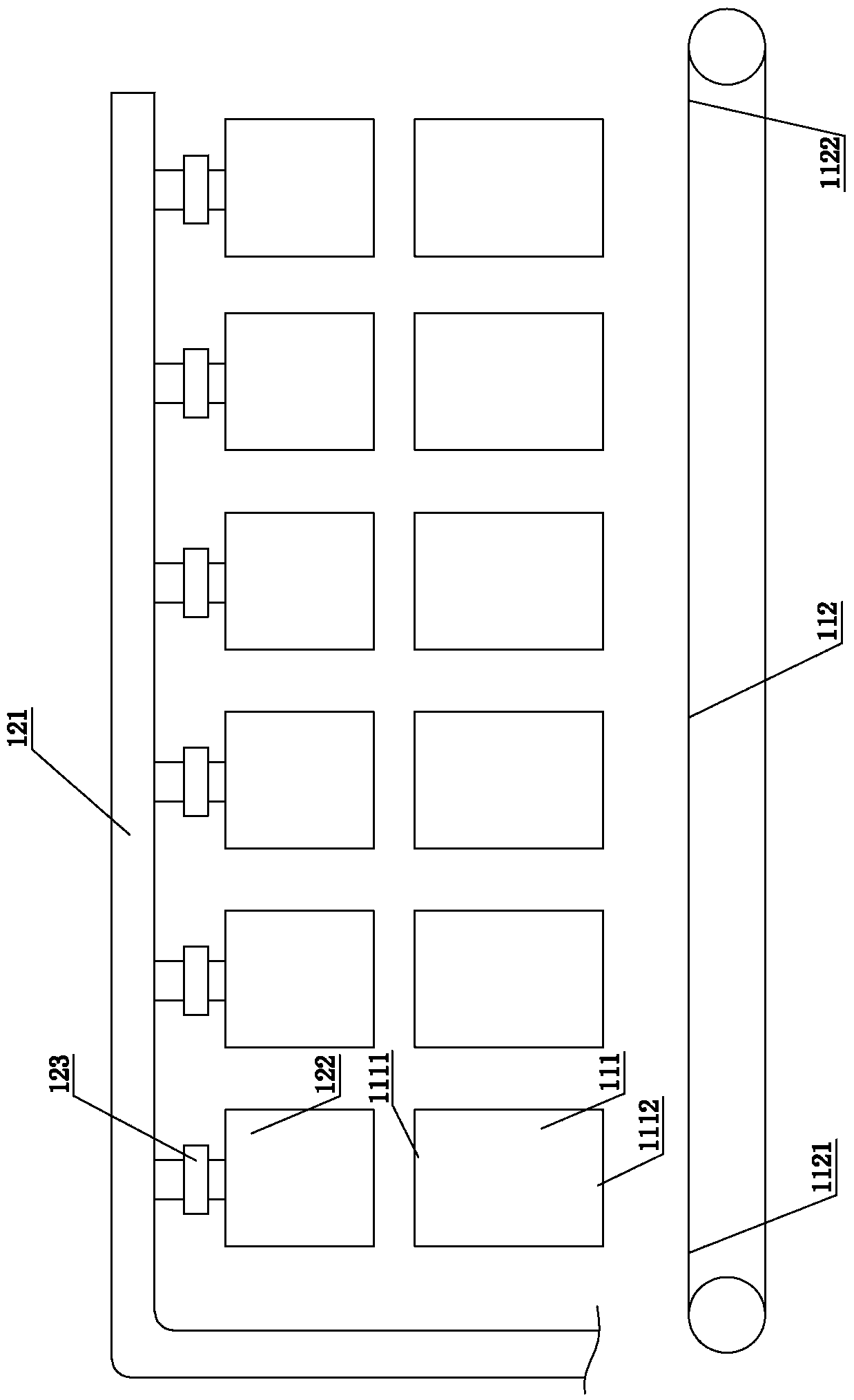

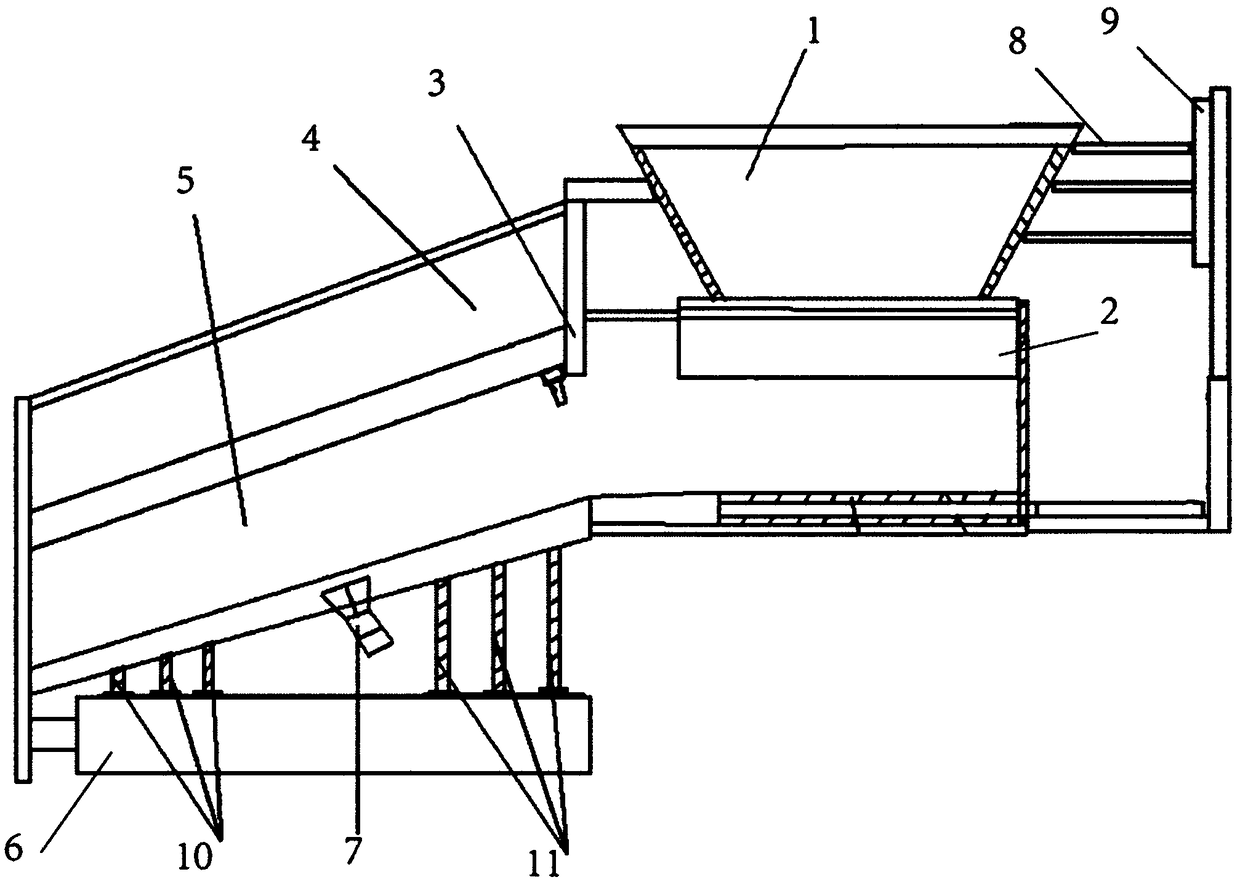

Machine tool panel automatic feeding device for woodworking

PendingCN108974959AOrdered ingredientsUniform ingredientsConveyorsDe-stacking articlesWood plankMachine tool

The invention discloses a machine tool panel automatic feeding device for woodworking. The machine tool panel automatic feeding device comprises a device body and planks, a base is arranged at the bottom of the device body, a burdening chamber is arranged above the left side of the base, electric push rods are fixedly installed on the front and back sides of the left and right portions of the bottom of the burdening chamber, a rotating roller is fixedly installed between the front and back portions of the top of each electric push rod, a feeding belt is installed among the rotating rollers ina nested manner, limiting strips are arranged on the upper and lower sides of the feeding belt, a burdening opening is formed above the feeding belt, a fixing table is arranged on the left side of theburdening opening, baffles are fixed to the front and back sides of the burdening opening and the fixing table, a feeding chamber is arranged above the right side of the base, and an electric liftingtable is installed at the bottom of the feeding chamber. According to the machine tool panel automatic feeding device, the feeding belt which is smooth in surface and is provided with the limiting strips is arranged, all planks can be singly fed, the limiting strips are in central symmetry, it is guaranteed that the planks can be orderly burdened during feeding, and even burdening is guaranteed.

Owner:泰州环溪家居有限公司

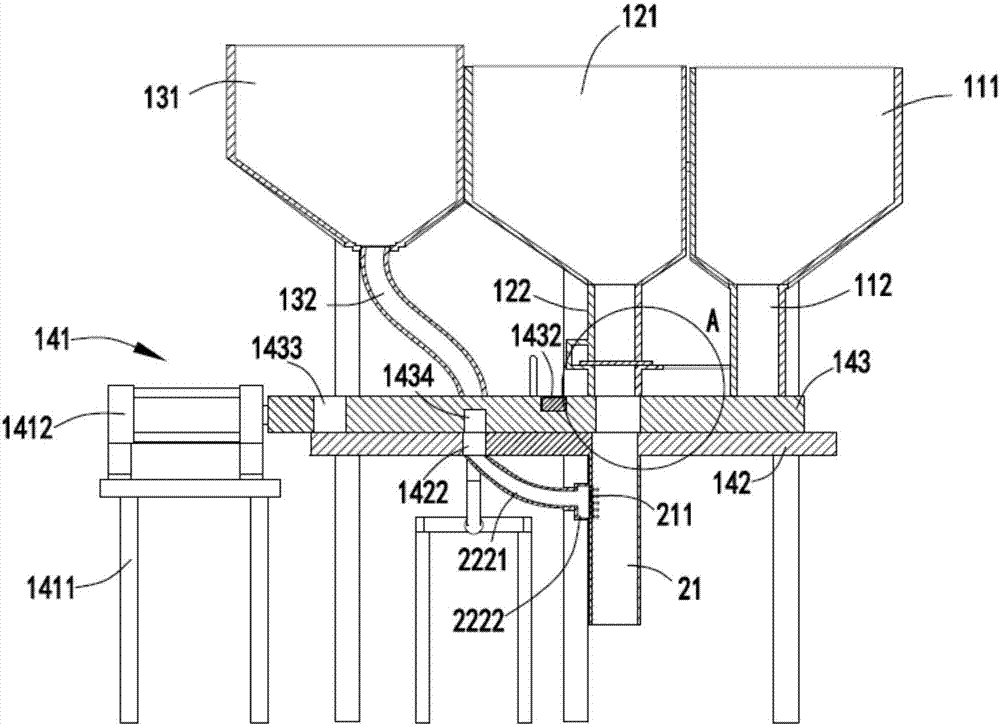

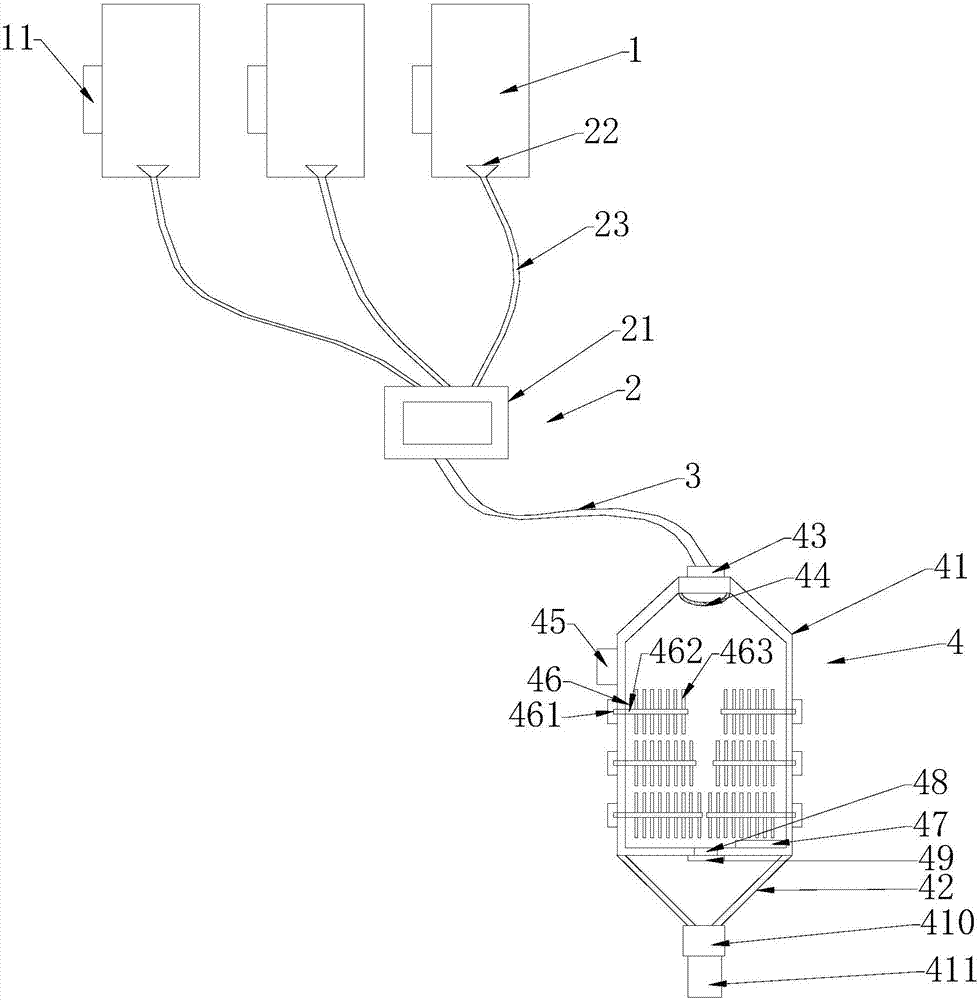

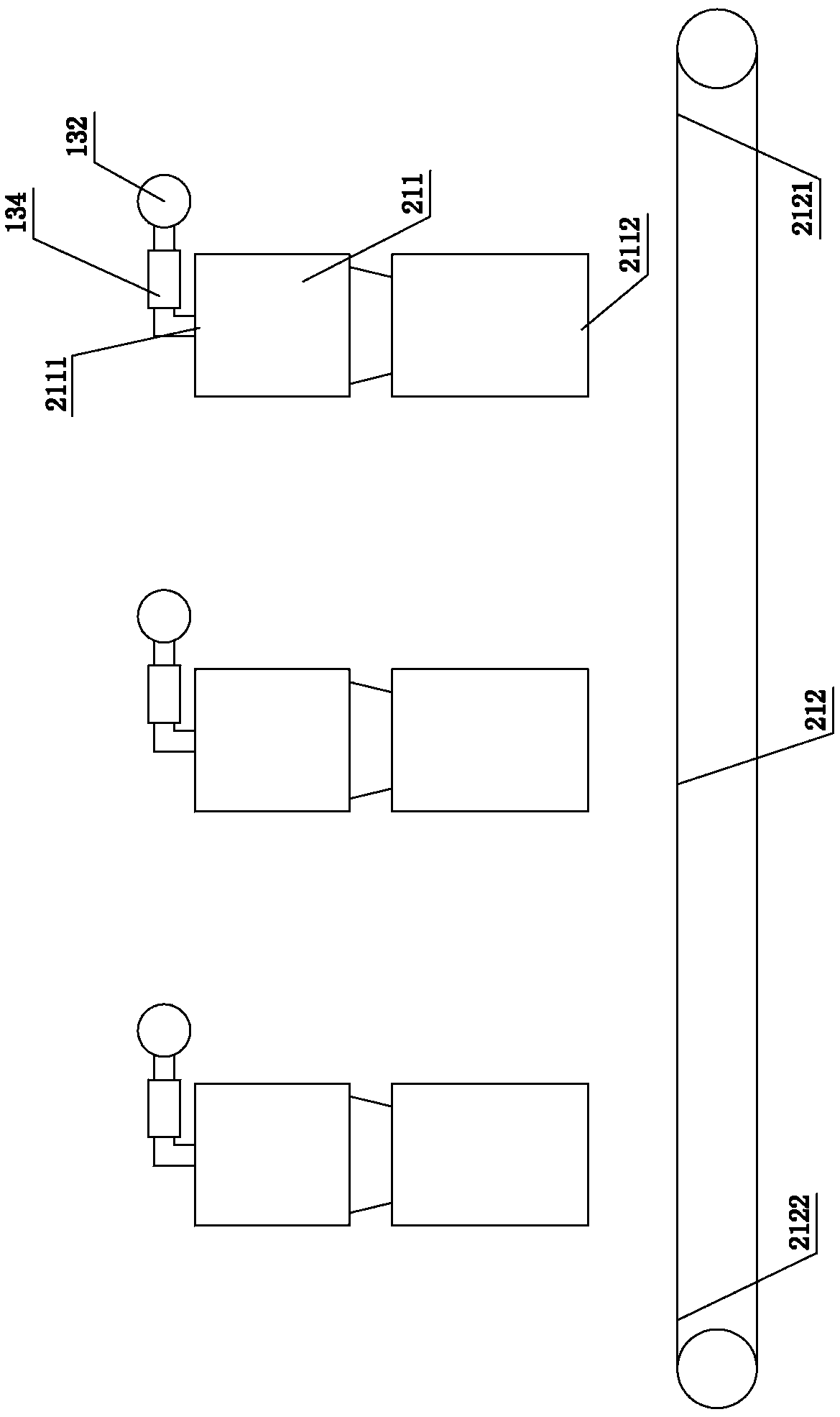

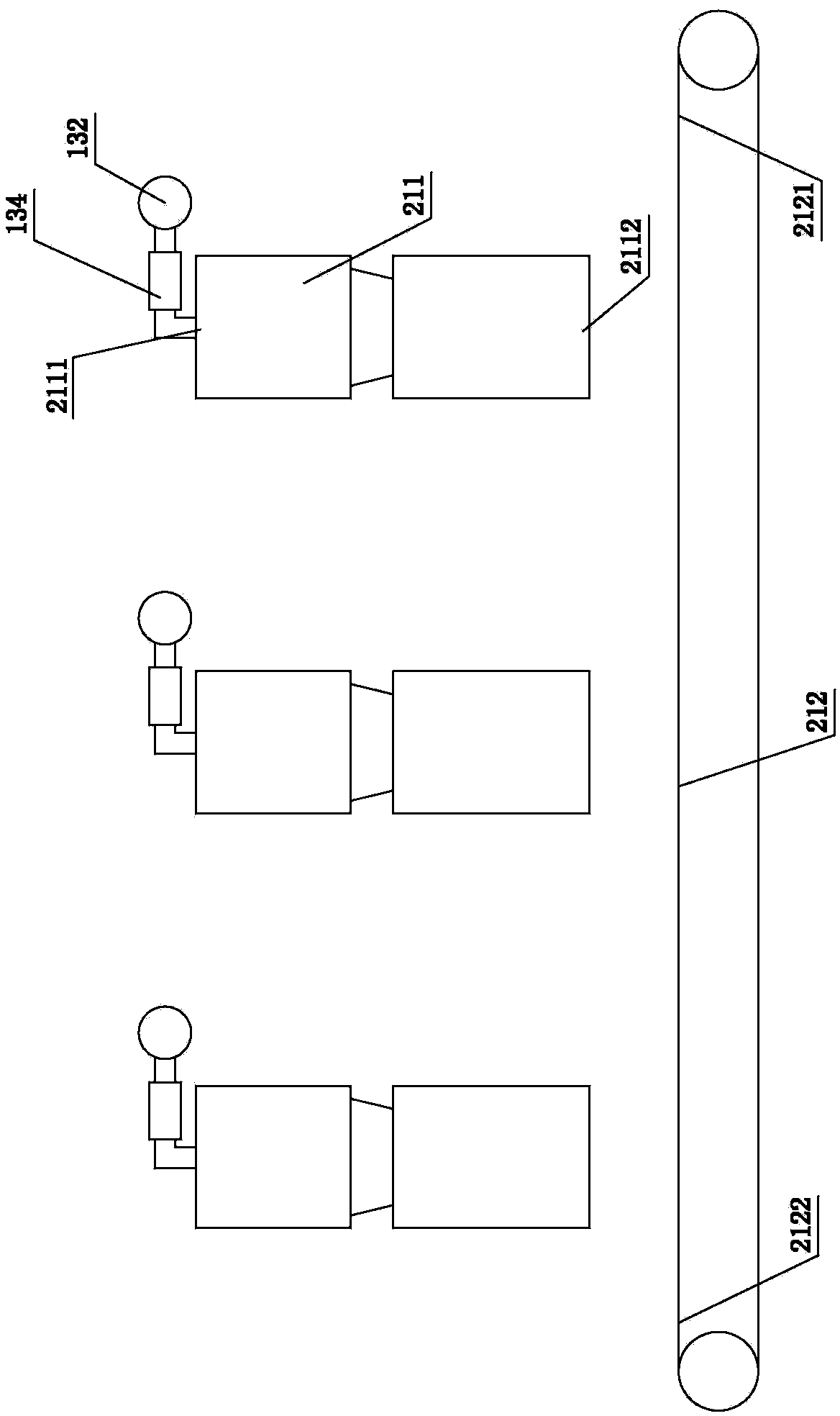

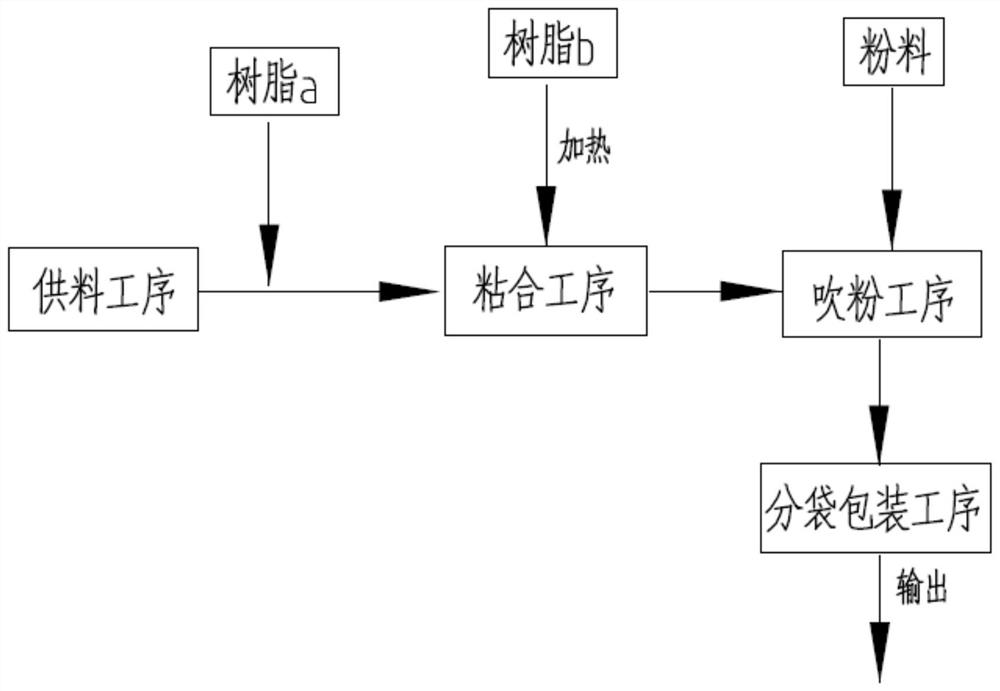

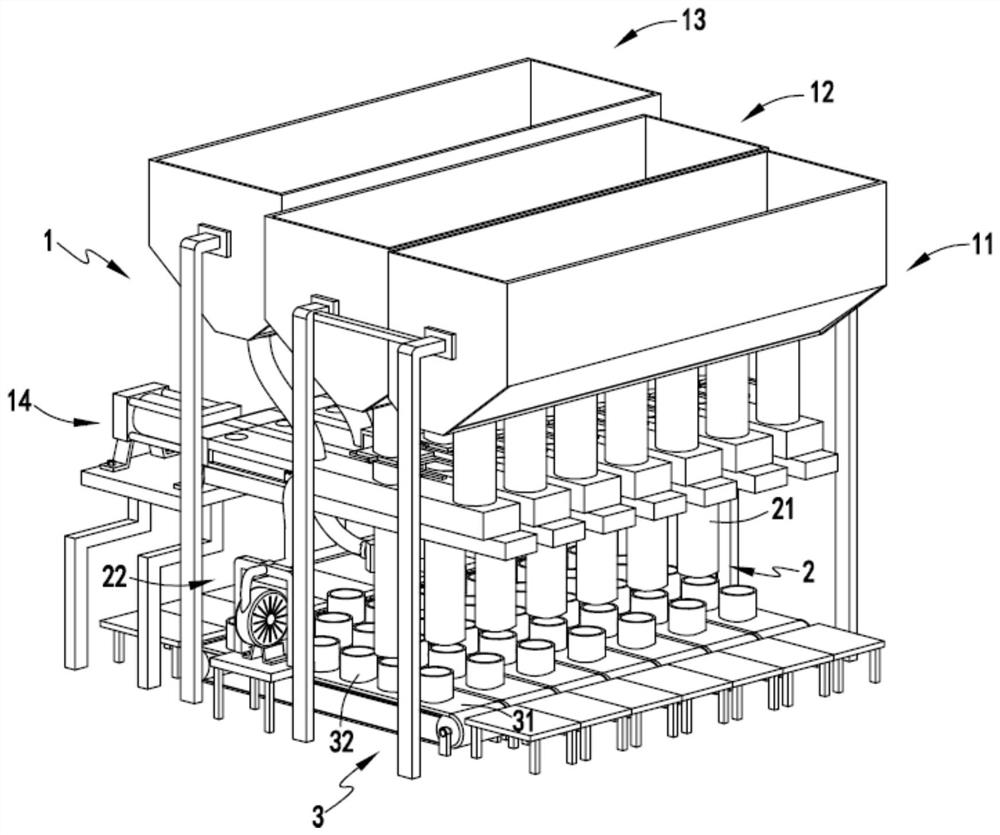

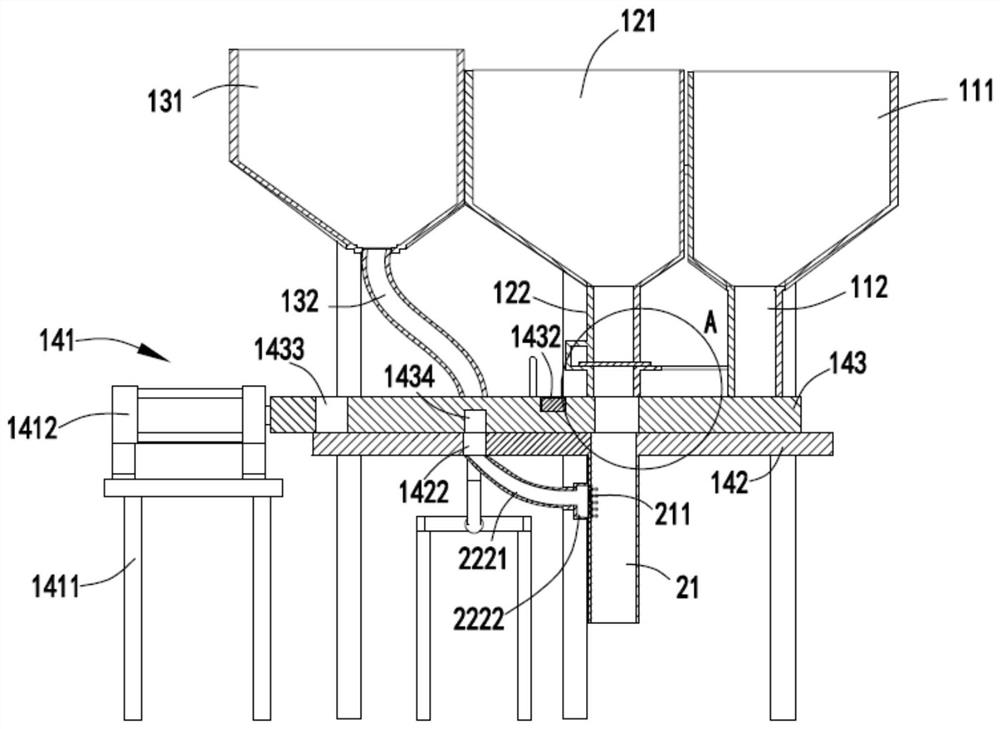

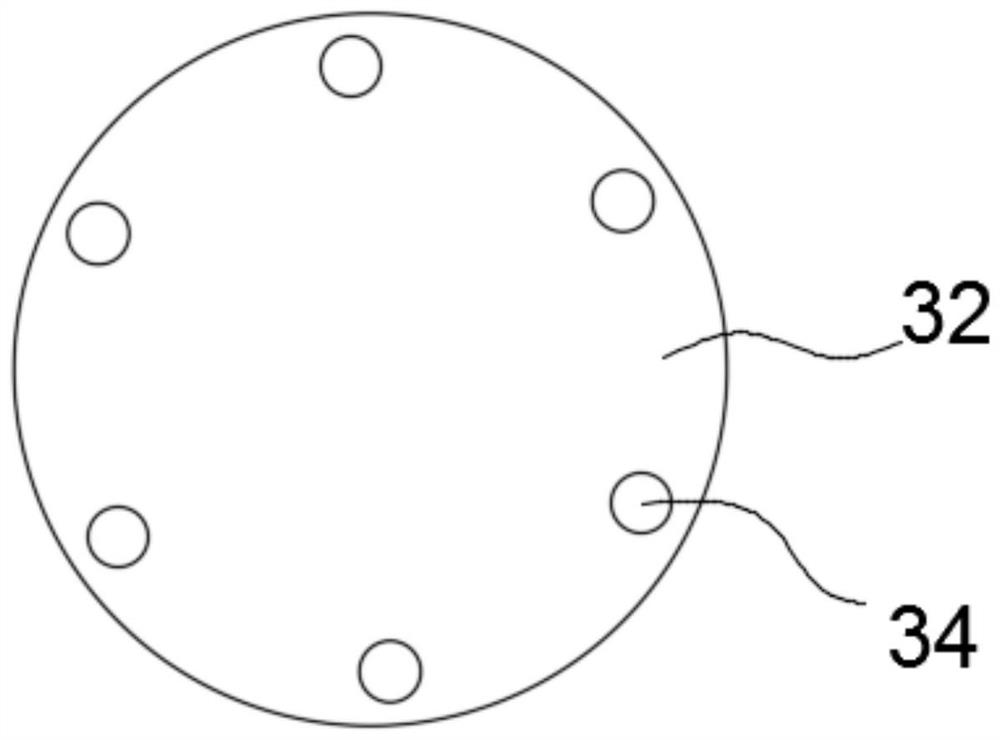

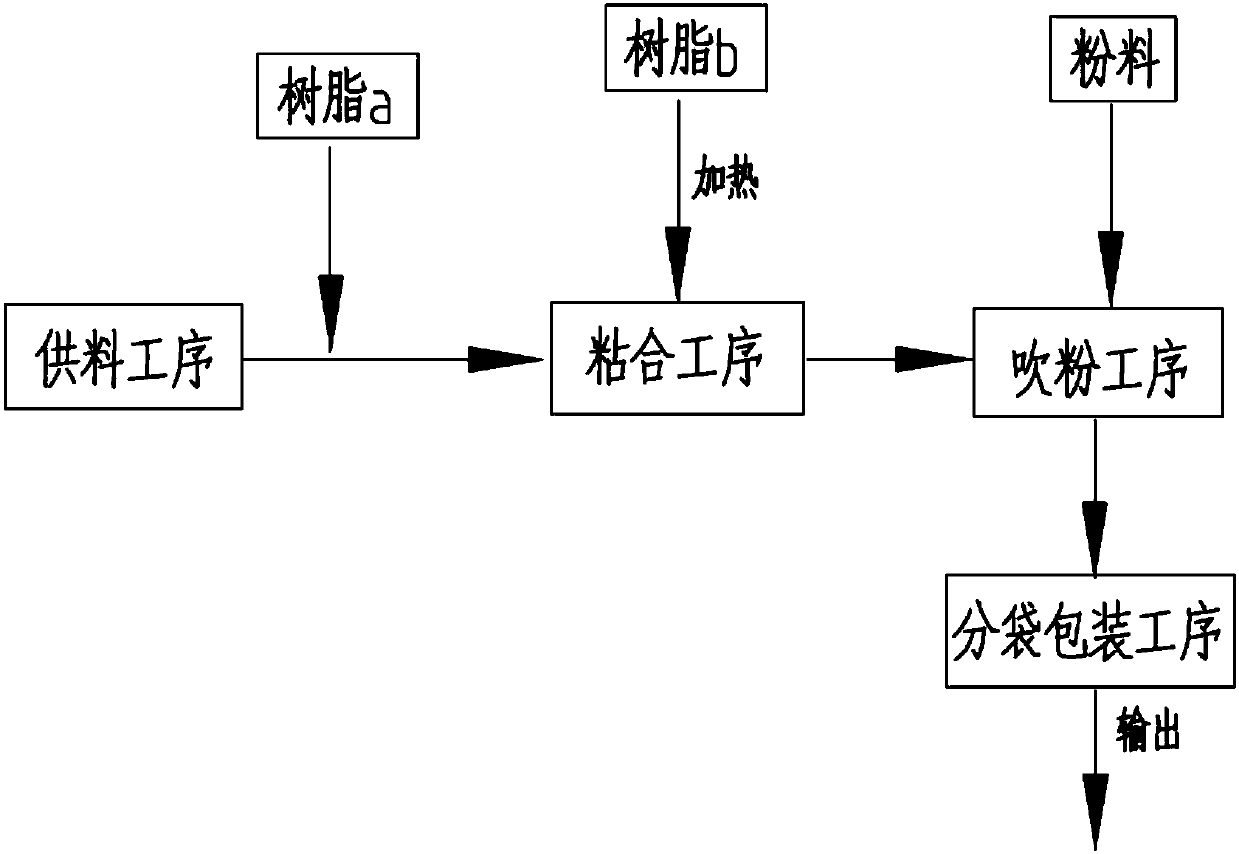

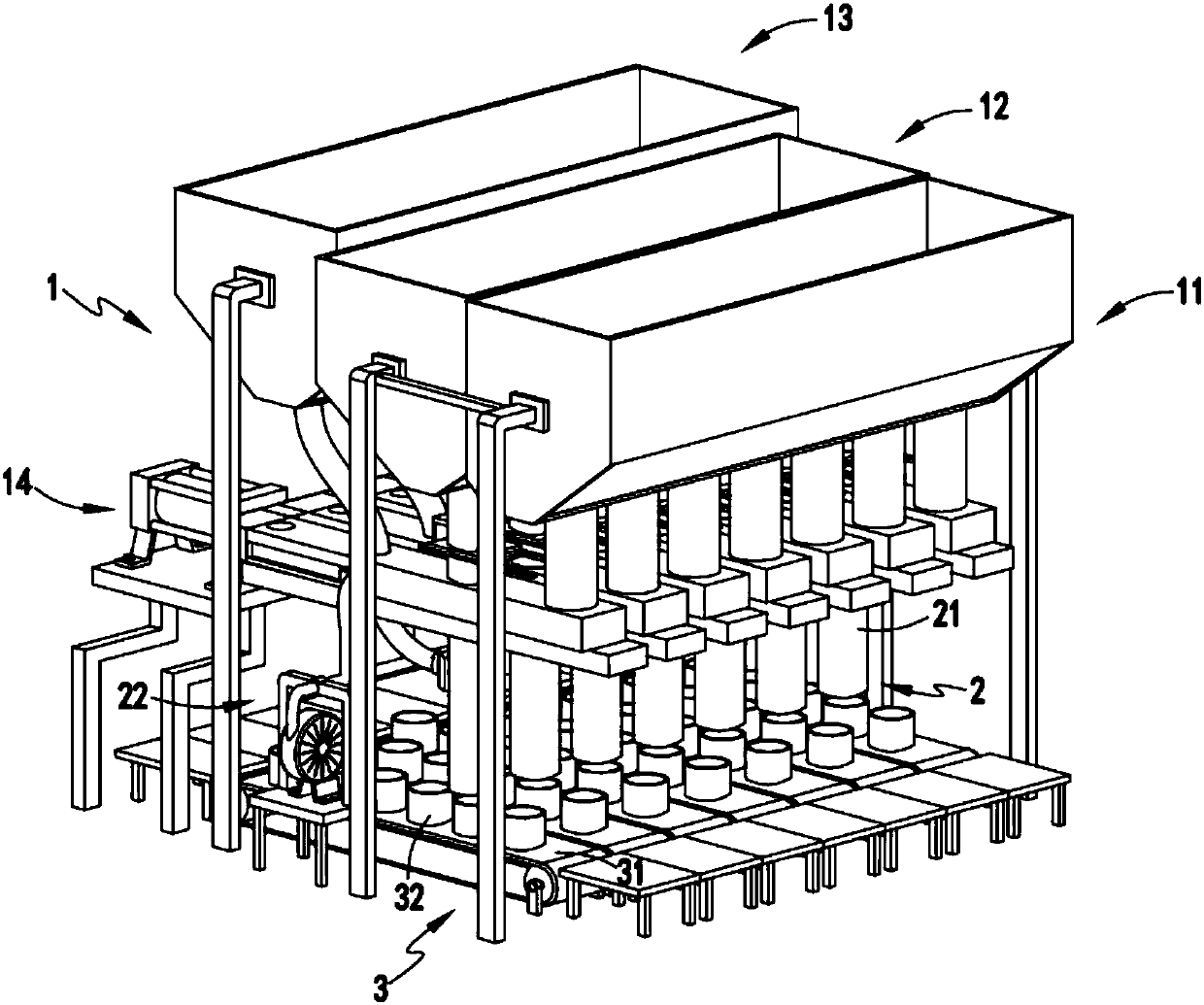

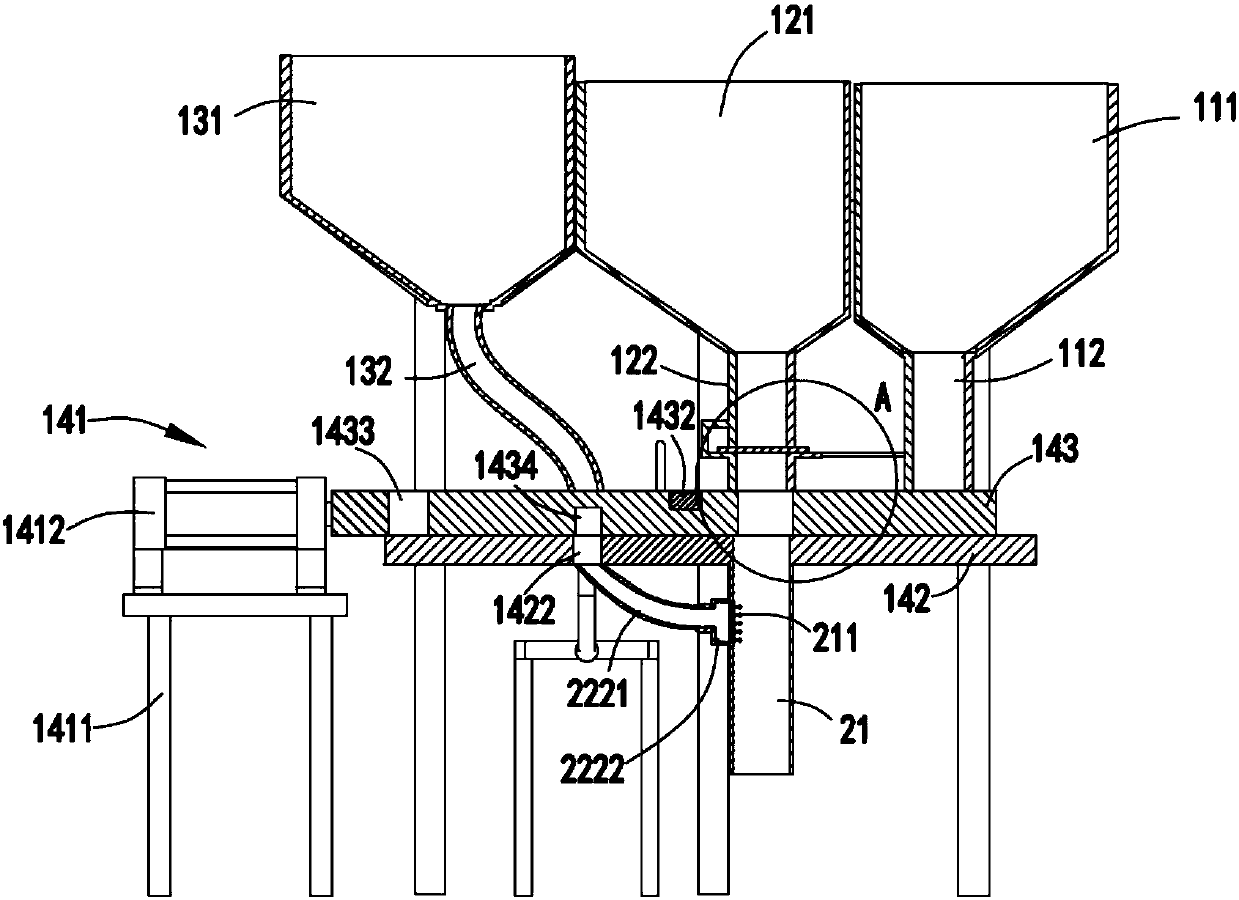

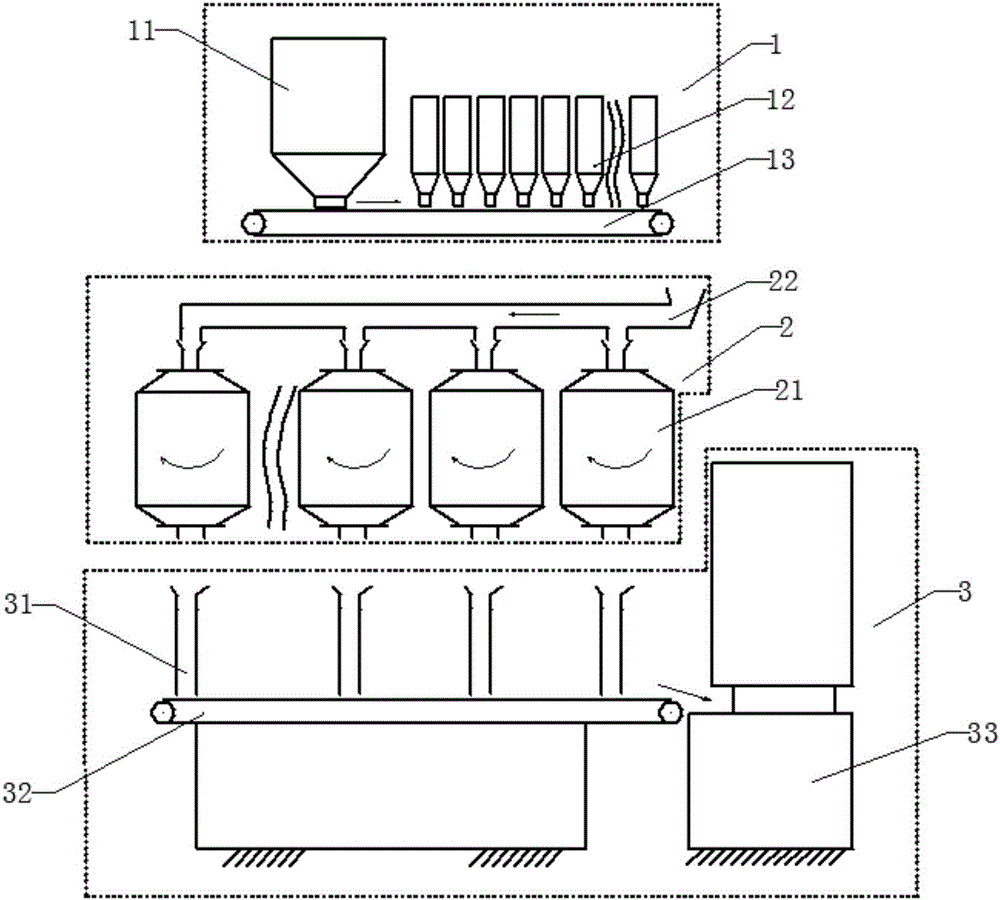

Efficient constant-proportion mixing production system for paint

InactiveCN107469730AEvenly bondedGuaranteed rationingTransportation and packagingMixer accessoriesMixed materialsEngineering

The invention relates to an efficient constant-proportion mixing production system for paint. The system comprises a material feeding part, a mixing part and a subpackaging part. The material feeding part comprises a feeding device a, a feeding device b, a feeding device c and a transferring mechanism used for controlling materials in the feeding device a, the feeding device b and the feeding device c to be quantitatively conveyed and heating materials in the feeding device b in the conveying process; the mixing part is arranged below the material feeding part and comprises blending barrels and a powder blowing mechanism arranged on one side of the blending barrels, the materials conveyed by the transferring mechanism are bonded in the blending barrels, and quantitative powder is blown into the blending barrels by the powder blowing mechanism to be mixed with the materials; the subpackaging part is arranged below the mixing part and used for subpackaging mixed materials obtained after blending in the blending barrels and then outputting the mixed materials. The system solves the problems that in the blending process of road marking paint, the blending proportion is difficult to control, mixing is not uniform, and the material disproportion of different regions in packaged mixed materials influences the quality of the marking paint in follow-up use.

Owner:CHANGXING HENGDA ELECTRONICS MATERIAL CO LTD

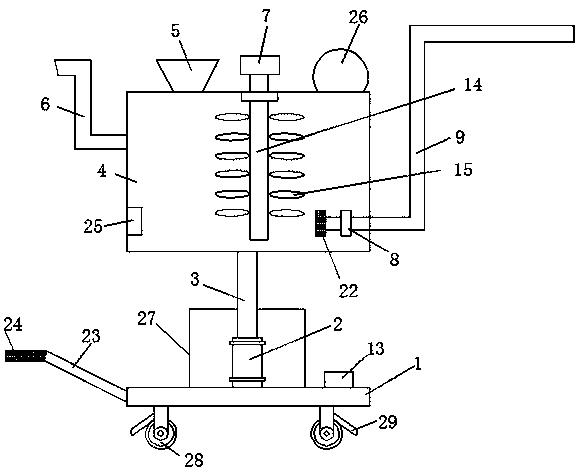

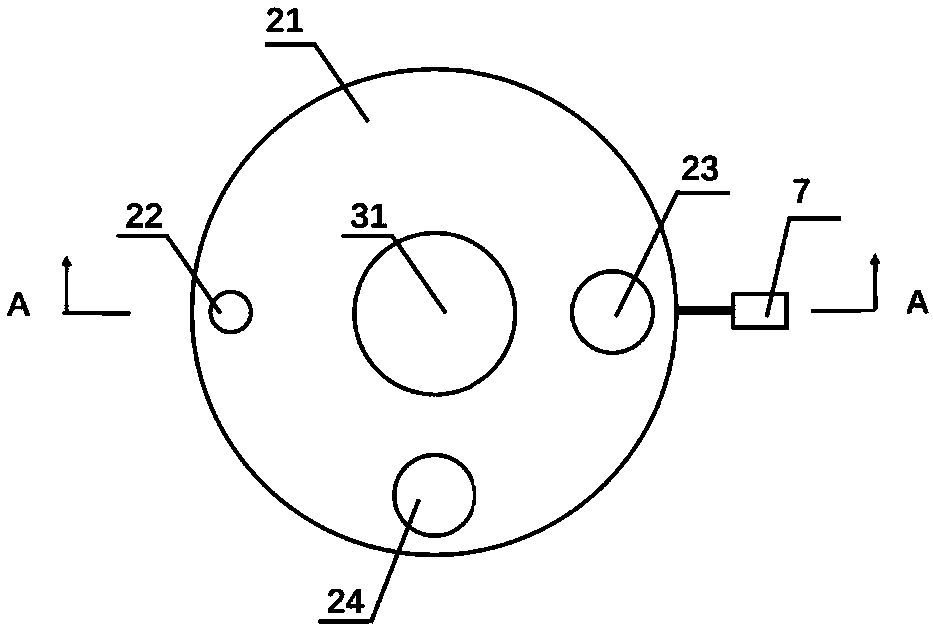

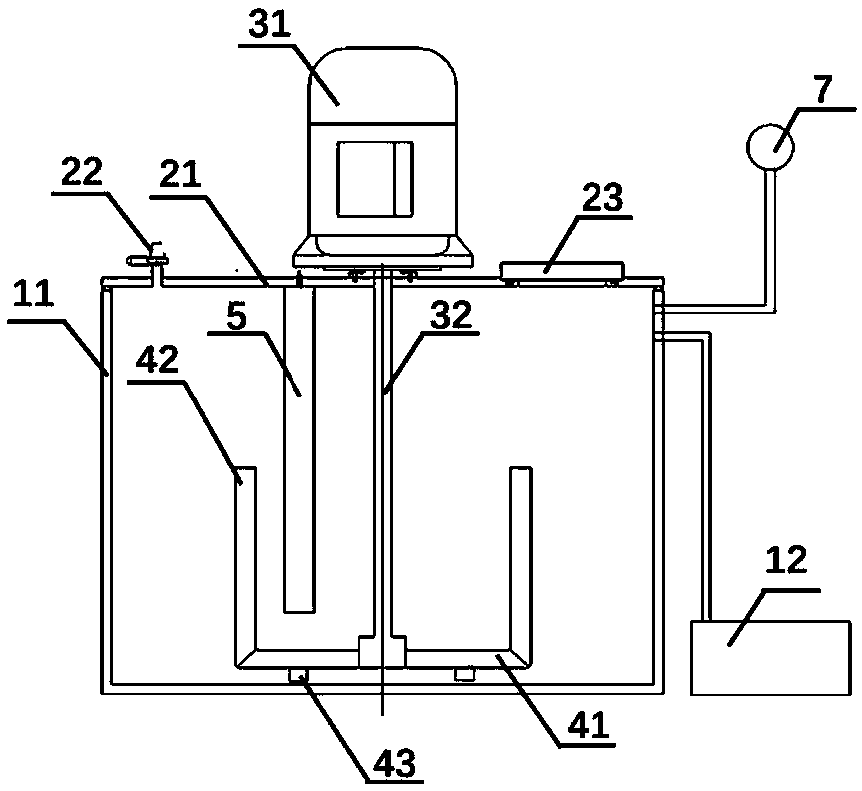

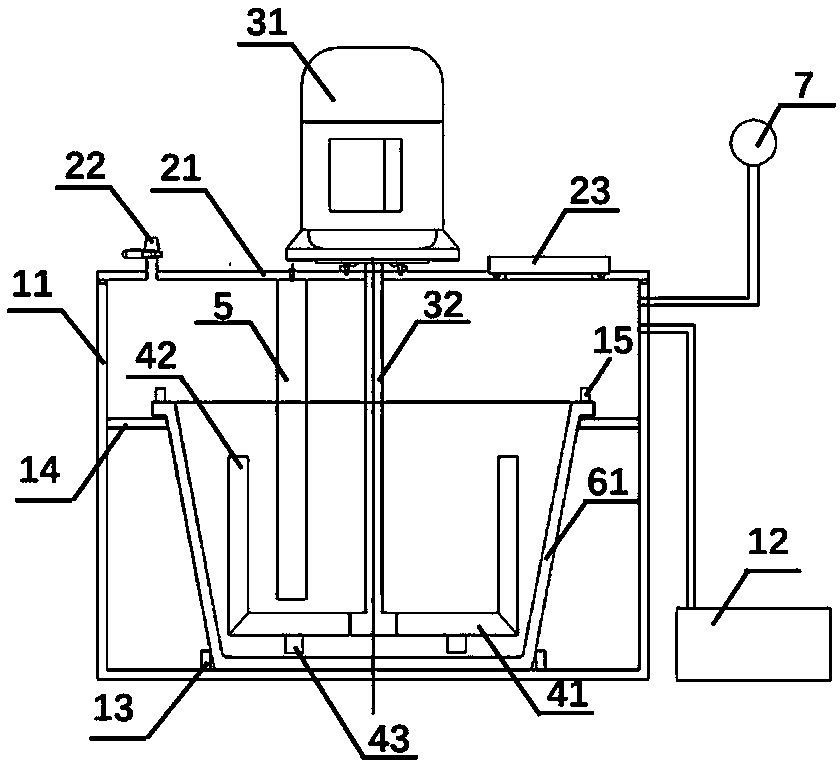

Batching device for processing and pulping of new energy lithium battery

InactiveCN112473499AGuaranteed accuracyRealize the effect of quantitative batchingElectrode manufacturing processesRotary stirring mixersWater storage tankElectric machine

The invention discloses a batching device for processing and pulping of a new energy lithium battery. The batching device comprises a base, wherein a mounting frame, a stirring tank and a water storage tank are fixedly mounted at the top of the base; a rotating opening is formed in the top of the stirring tank; a stirring shaft is arranged in and rotatably connected with the rotating opening; a plurality of stirring rods are fixedly mounted at the end, extending into the stirring tank, of the stirring shaft; a driving motor is fixedly mounted at the top of the stirring tank; transmission wheels are fixedly mounted at the driving end of the driving motor and the end, extending out of the base, of the stirring shaft; a transmission belt is arranged between the two transmission wheel and is in transmission connection with the two transmission wheels; and a rotating shaft is rotationally connected to the mounting frame. The device of the invention relates to the technical field of new energy lithium battery processing, and has the advantages of simple structure, convenient operation, flexibility and capability of uniformly stirring ingredients, improving stirring effect, conveniently cleaning the stirring tank and guaranteeing cleanness and no residue in the stirring tank.

Owner:李永华

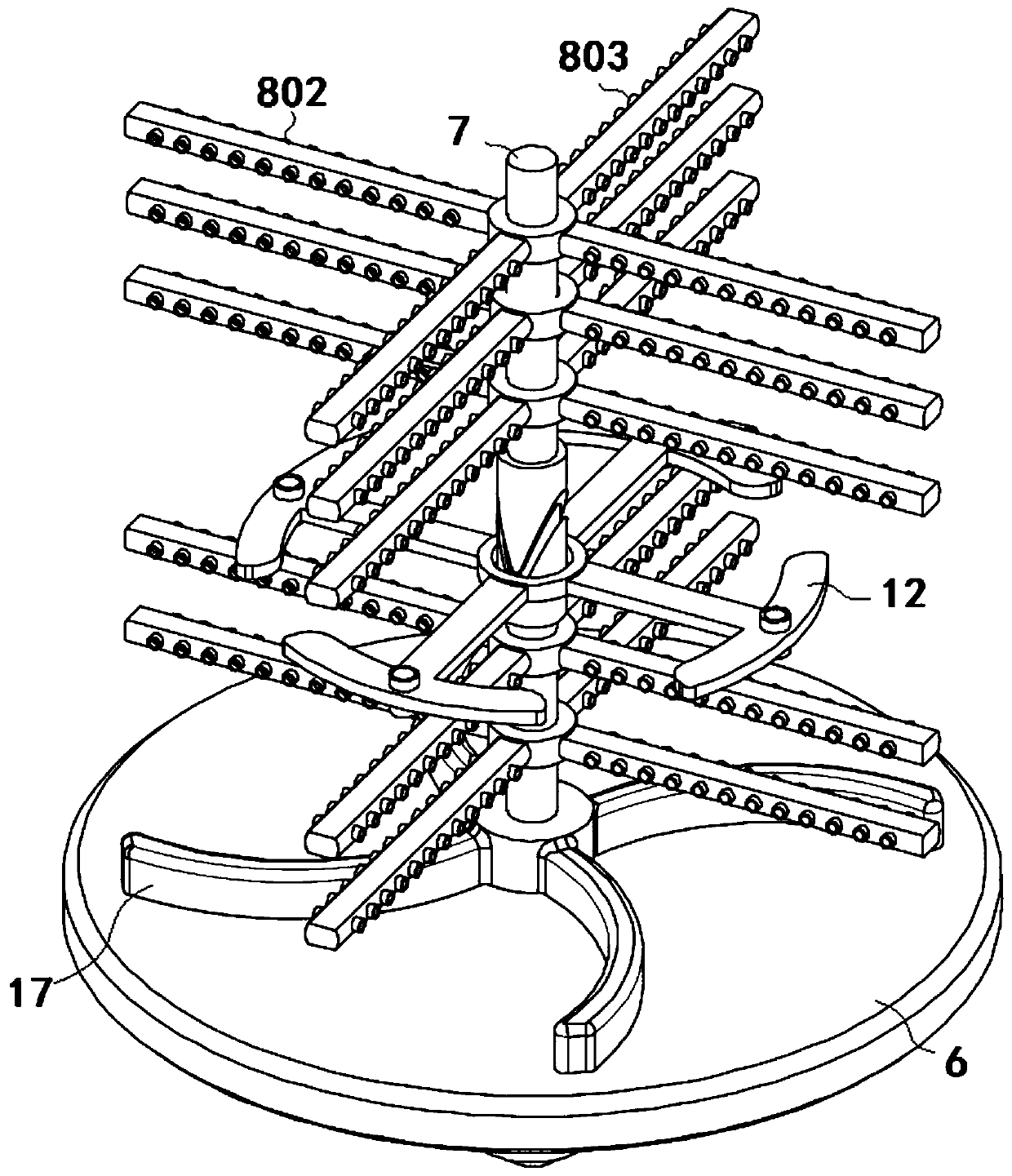

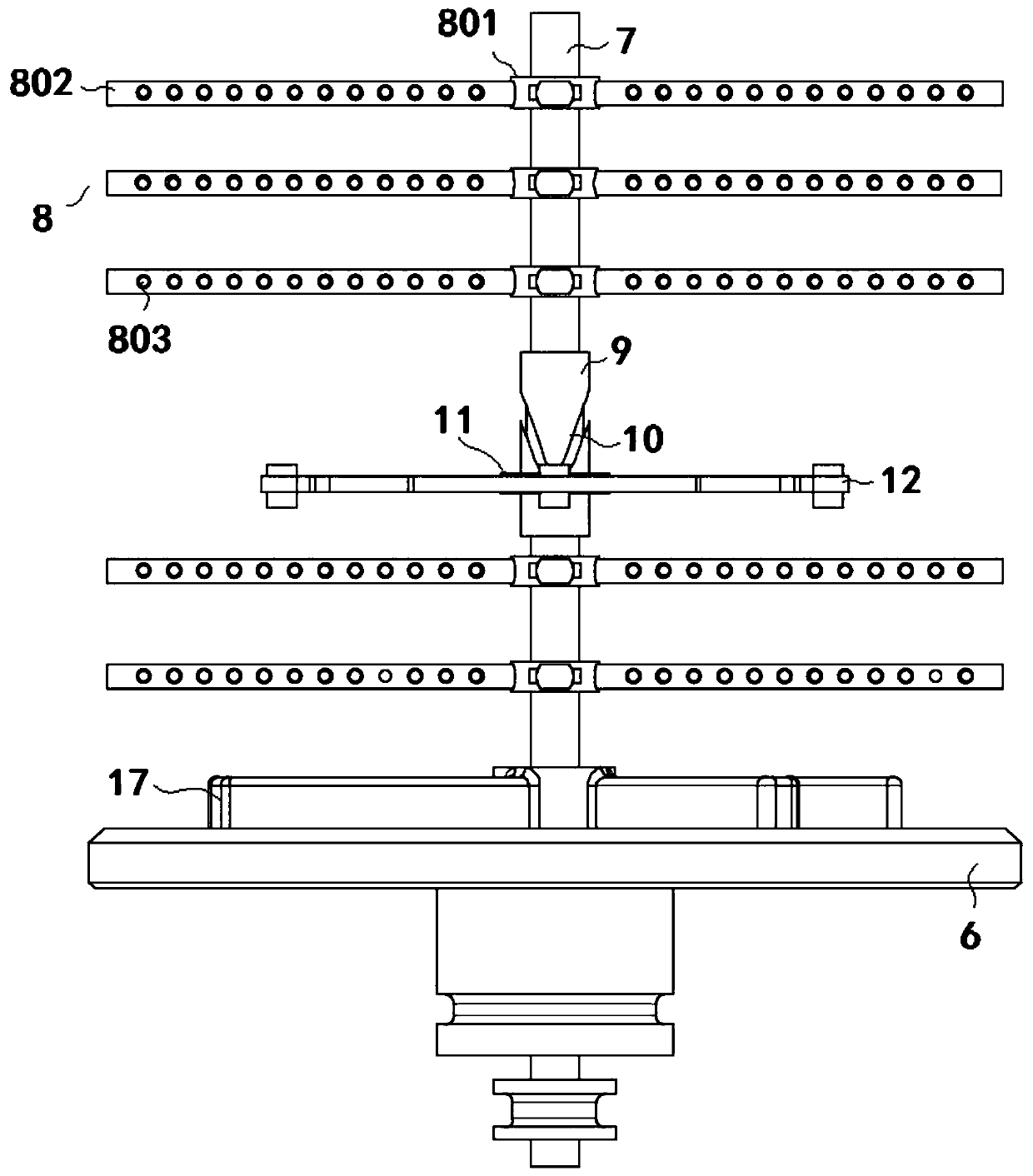

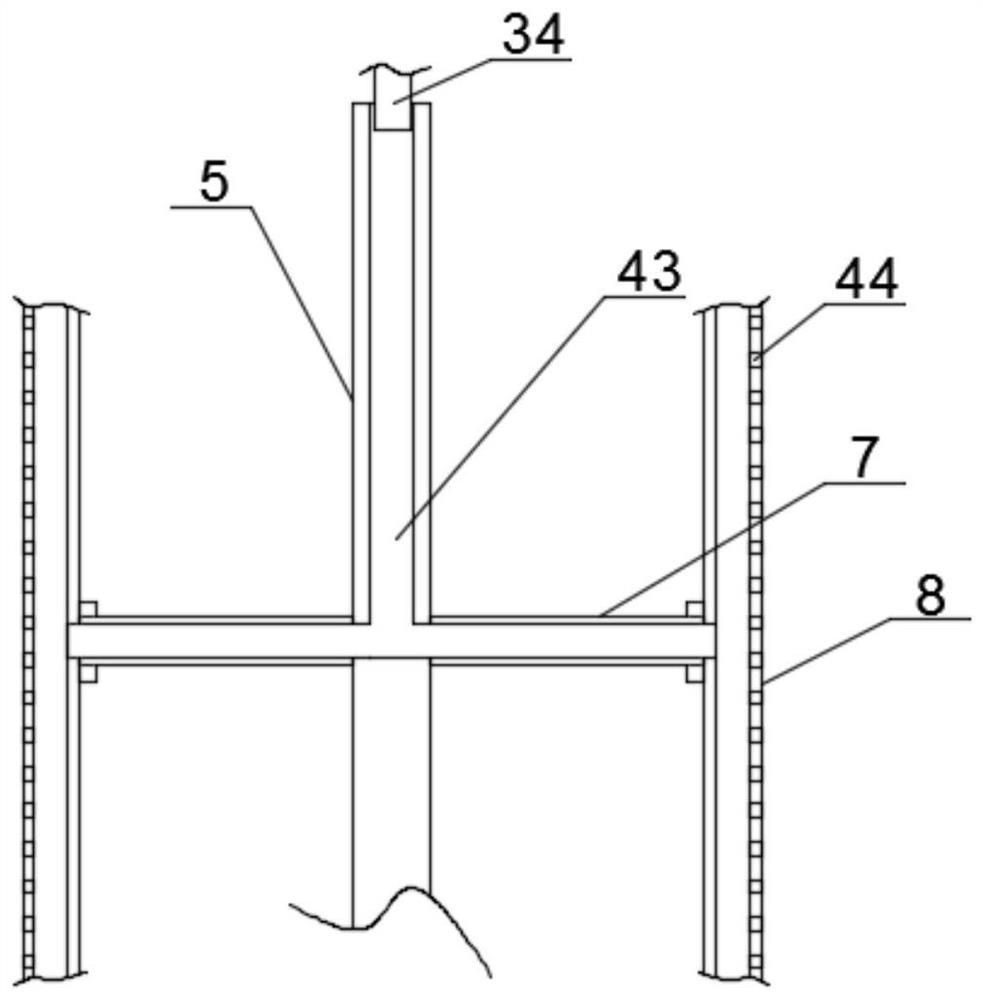

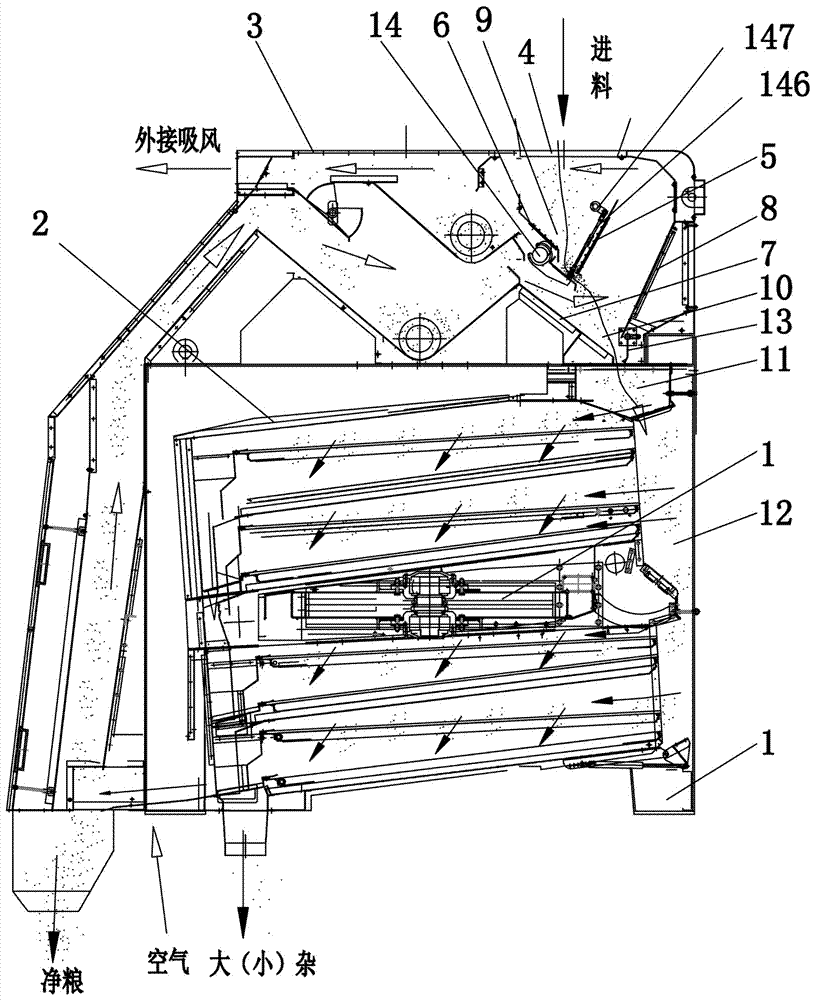

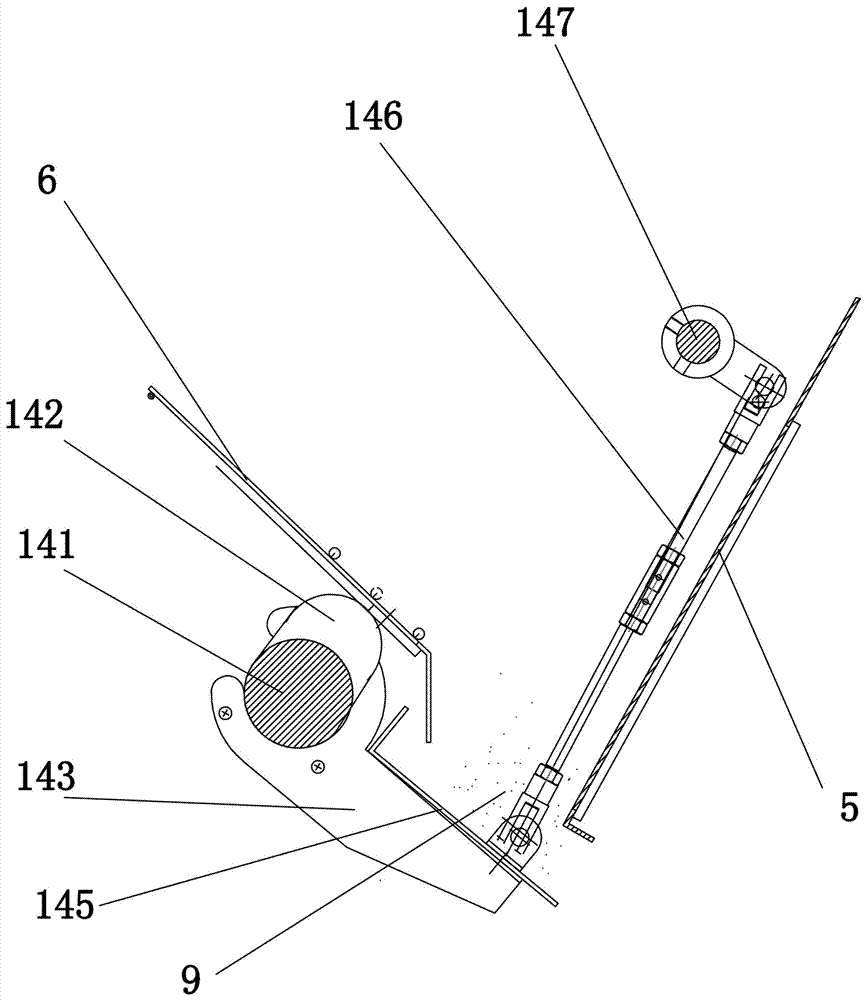

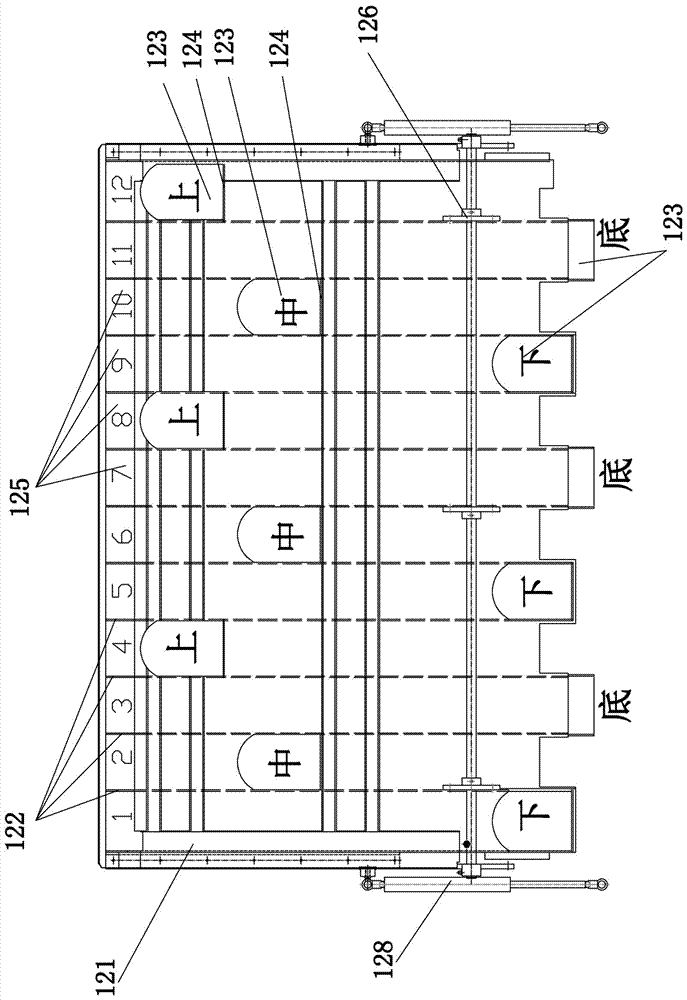

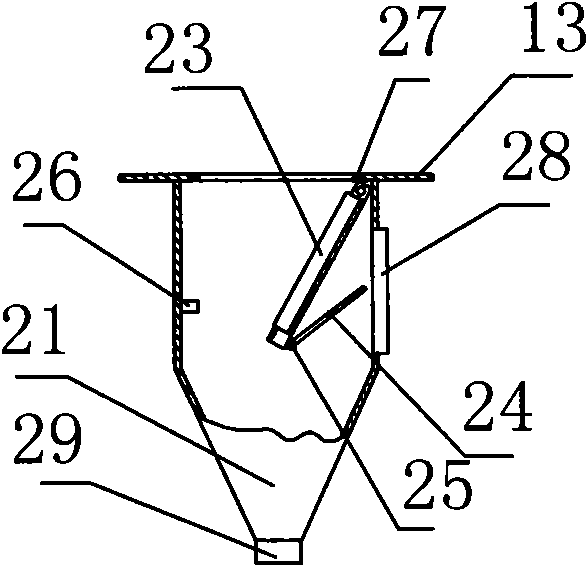

Uniform material distribution device for rotary combined multi-layer screen

ActiveCN107282395AUniform ingredientsInto the uniformSievingScreeningEngineeringMaterial distribution

The invention relates to a uniform material distribution device for a rotary combined multi-layer screen. The uniform material distribution device comprises a rack, a screen body hung on the rack, and a feeding shell at the upper end of the rack, wherein a feed inlet is formed in the feeding shell; an upper material uniformization plate and an upper material guide plate in the feeding shell form an upper feeding channel of which the section is funnel-shaped; a lower material guide plate and a lower baffle plate in the feeding shell form a lower feeding channel of which the section is funnel-shaped; an opening in the upper end of the upper feeding channel corresponds to the feed inlet; an opening in the lower end of the upper feeding channel corresponds to an opening in the upper end of the lower feeding channel; an opening in the lower end of the lower feeding channel corresponds to a feed hopper arranged on the screen body; the feed hopper communicates with a uniform material distributor arranged on the side surface of the screen body; a plurality of vertical discharge channels are arranged in the uniform material distributor; and the discharge channels communicate with different screen grids. According to the uniform material distribution device, uniform distribution of grain materials is achieved, the grain materials uniformly enter the different screen grids, the multiple layers of screen grids screen the grain materials at the same time, and screening efficiency is improved.

Owner:COFCO ENG MAOSHENG EQUIP (HENAN) CO LTD

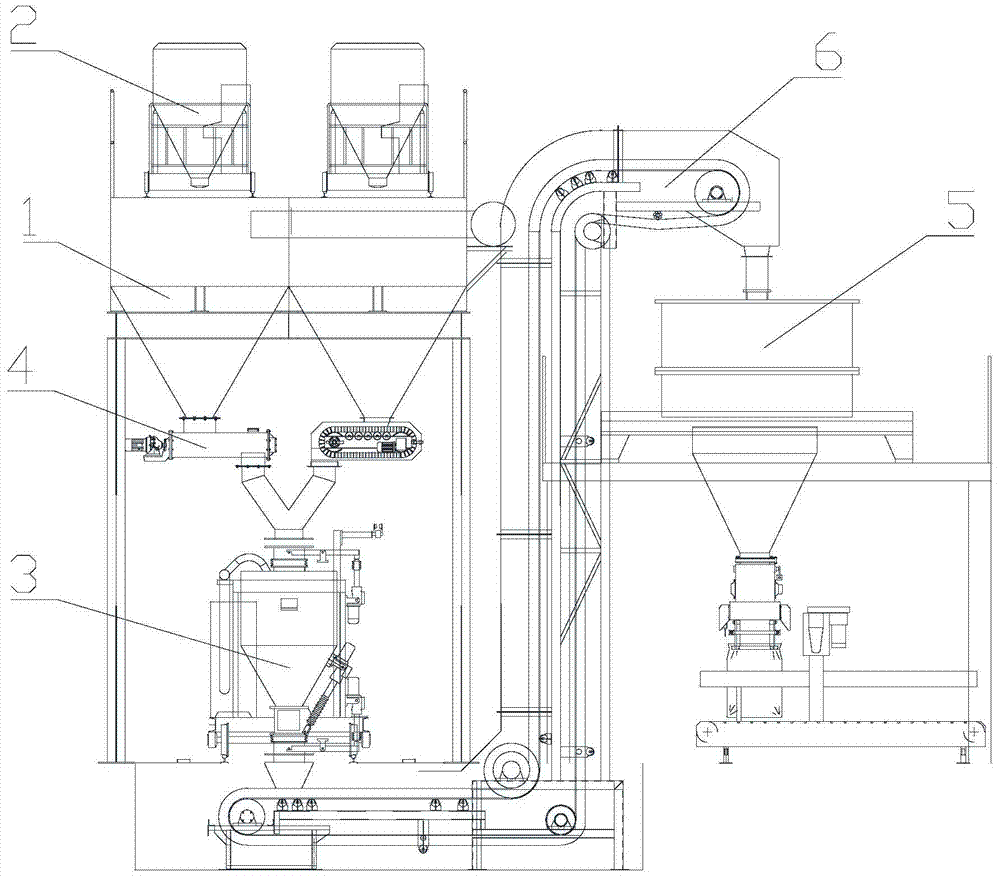

Glass coloring and mixing small material automatic batching device

The invention discloses an automatic blending device of a glass coloring mixed material. The automatic blending device comprises a raw material scale group, a feeding conveyor belt group, a first bucket elevator, a second bucket elevator, a first discharging conveyor belt group, a second discharging conveyor belt group and coloring material scales. The feeding conveyor belt group is connected with a feeding opening of the first bucket elevator and a feeding opening of the second bucket elevator respectively; two discharging openings of the first bucket elevator are connected with first discharging conveyor belt group and the second discharging conveyor belt group respectively; two discharging openings of the second bucket elevator are connected with the input end of the first discharging conveyor belt group and the input end of the second discharging conveyor belt group respectively; one coloring material scale is arranged above the first discharging conveyor belt group, and the other coloring material scale is arranged above the second discharging conveyor belt group. When the automatic blending device of the glass coloring mixed material conducts blending for two glass kilns, cross contamination of raw materials can be avoided in the blending process, the blended material is good in uniformity, and weighing accuracy of a coloring agent is high.

Owner:DAYE HUAXING GLASS

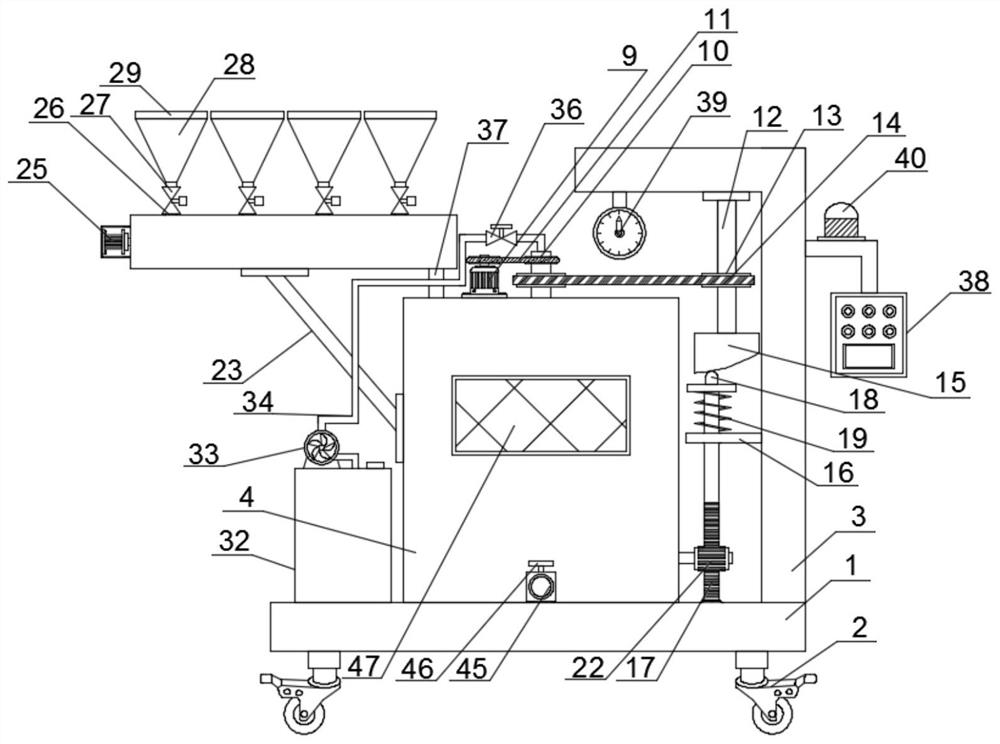

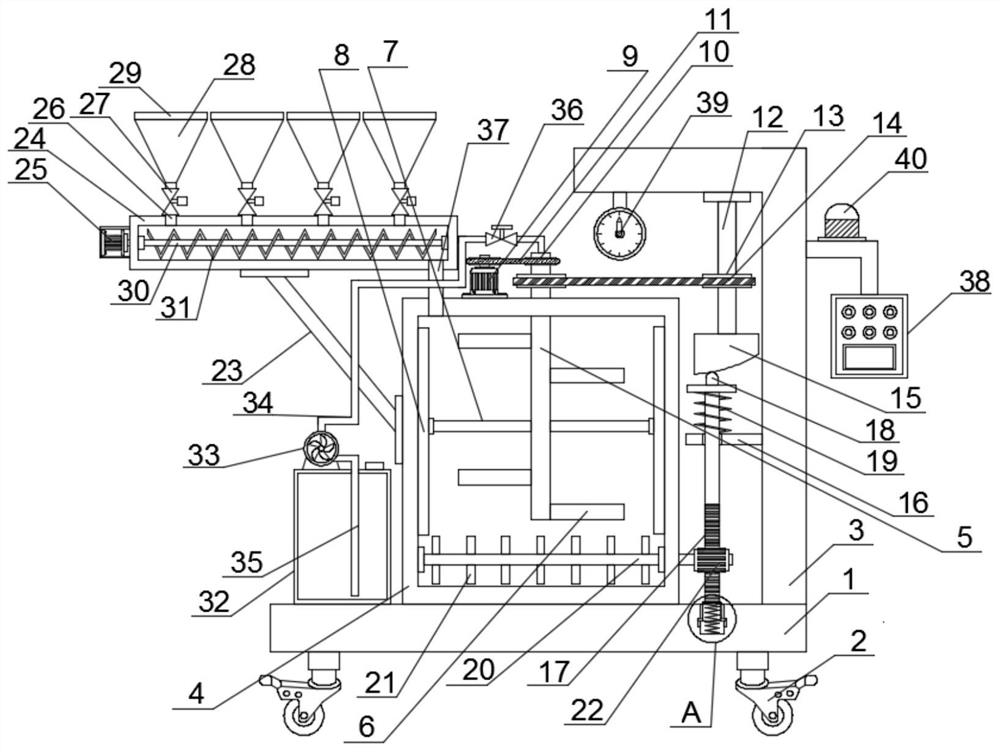

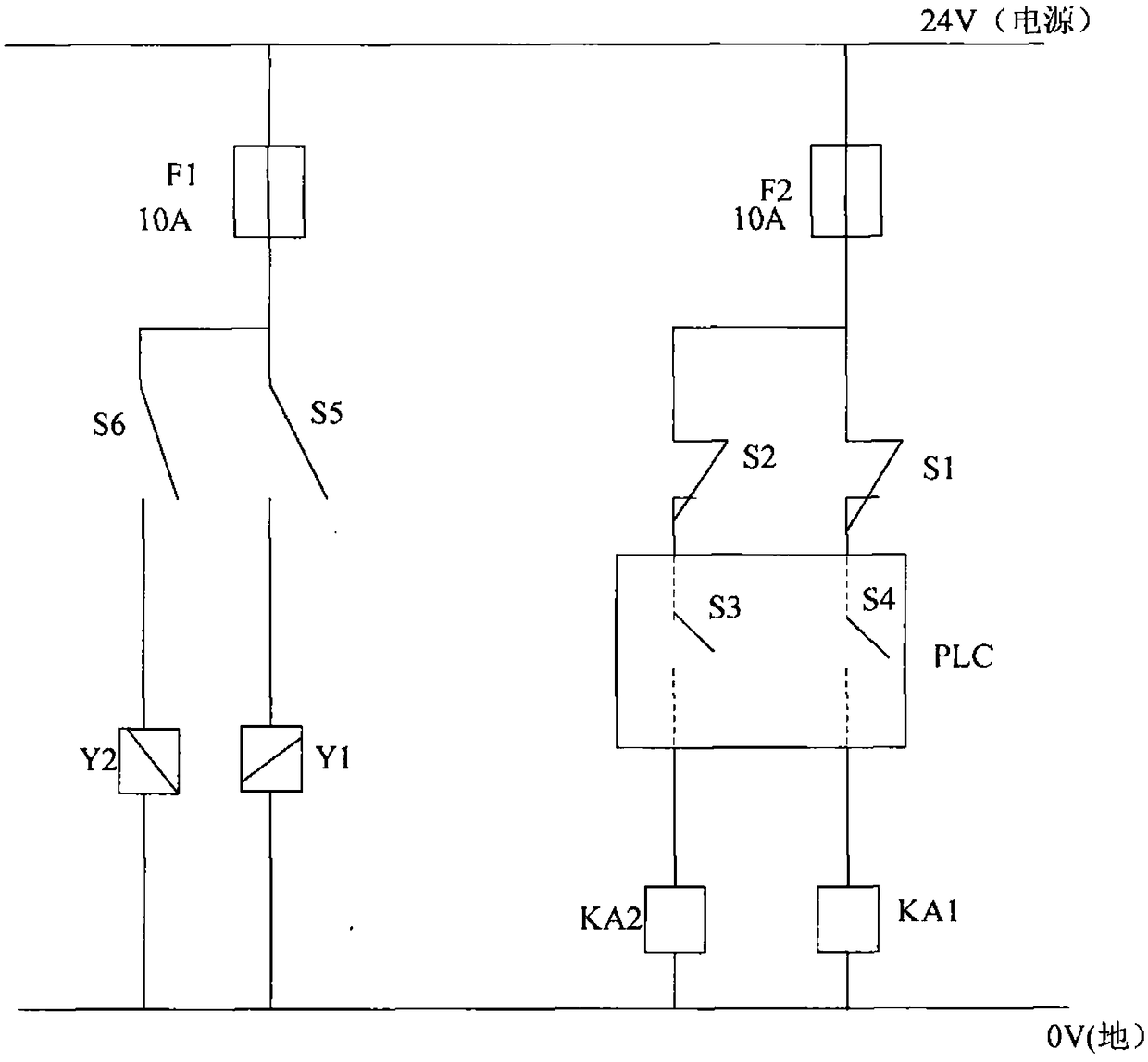

Full-automatic material blending and toner adding machine and assorted toner thereof

InactiveCN106881787AImprove liquidityImprove processing fluidityElectric machineryProcess engineering

The invention belongs to the field of plastic processing, particularly relates to a full-automatic material blending and toner adding machine and an assorted toner thereof, and overcomes the defects of large size, large occupied space, high cost, time waste, electricity waste and trouble in cleaning in the prior art. The full-automatic material blending and toner adding machine comprises a material blending barrel, a toner barrel, a material mixing hopper and a PLC, wherein the material blending barrel is arranged above the material mixing hopper; a material feeding switch device is arranged at the bottom of the material blending barrel; the toner barrel is communicated with the material blending barrel; a toner stepping motor is arranged on the toner barrel; a photoelectric detection switch is arranged in the material mixing hopper; the material feeding switch device, the toner stepping motor and the photoelectric detection switch are respectively connected with the PLC through lines in a control manner. The full-automatic material blending and toner adding machine can be conveniently and directly connected to production machinery such as an injection molding machine and a blowing machine and has the advantages of simple structure, relatively small size and saving of labors and lands; meanwhile, the toner barrel is independently arranged, stirring cleaning is not needed, and time and energy are saved; furthermore, the PLC automatically controls material feeding and color matching to enable the material feeding and color matching to be stable and accurate; therefore, a product has the advantages of uniform color and high yield.

Owner:董玉峰

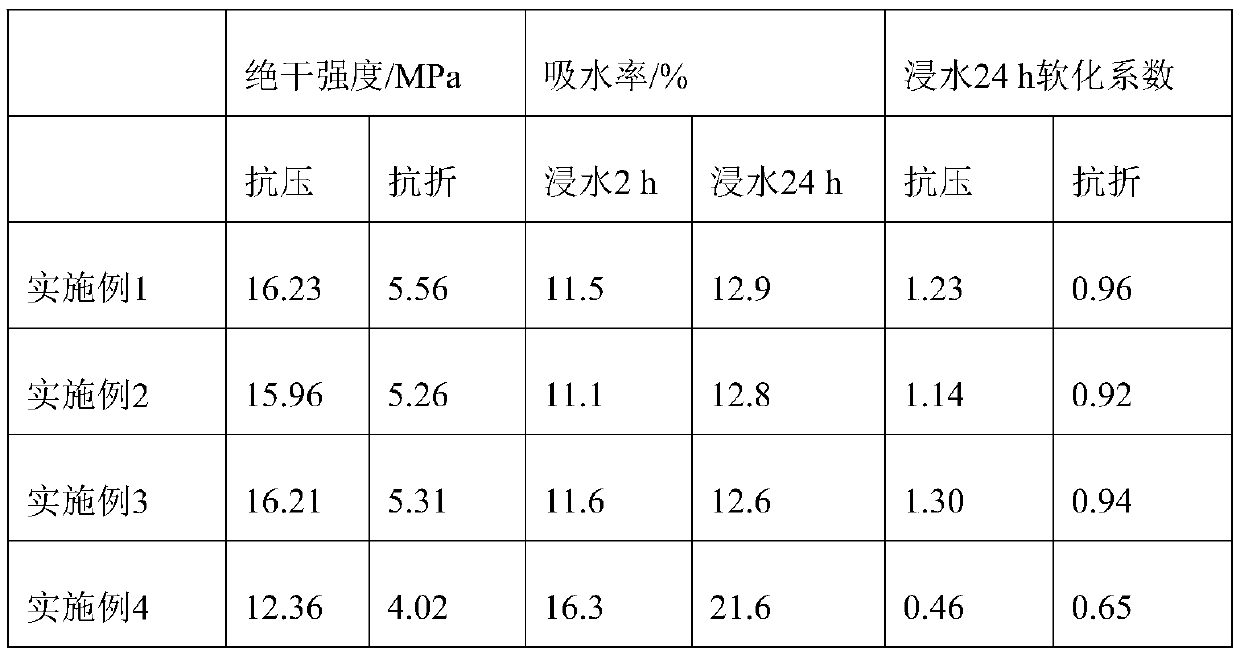

A water-resistant machine-sprayed gypsum-based material and its preparation method

The invention belongs to the technical field of building materials and in particular relates to a water-resisting machine-sprayed gypsum-based material and a preparation method thereof. A mixed waterrepellent is used and silicone acrylic emulsion forms a firm cross-linked net film on a gypsum hole wall; the film is attached on surfaces of an inner hole and a pore of a gypsum hardened body, so that surface properties of the hole and the pore are changed and the hydrophilic property is changed into the hydrophobic property; even if the contact angle theta of the surface of the inner hole and the pore of the gypsum hardened body is greater than 90 degrees and water cannot automatically seep into capillary pores, so that the waterproof performance of a phosphorus gypsum building block is improved, the growth of a crystal can be changed; the growth of the crystal in the direction of a long axis is inhibited; the growth of the crystal in the direction of a short axis is enhanced and the crystal becomes short and flat; the porosity between the crystals is reduced and the density is increased, so that the water-proof and water-resisting effects of gypsum are improved.

Owner:深圳摩盾环保新材料有限公司

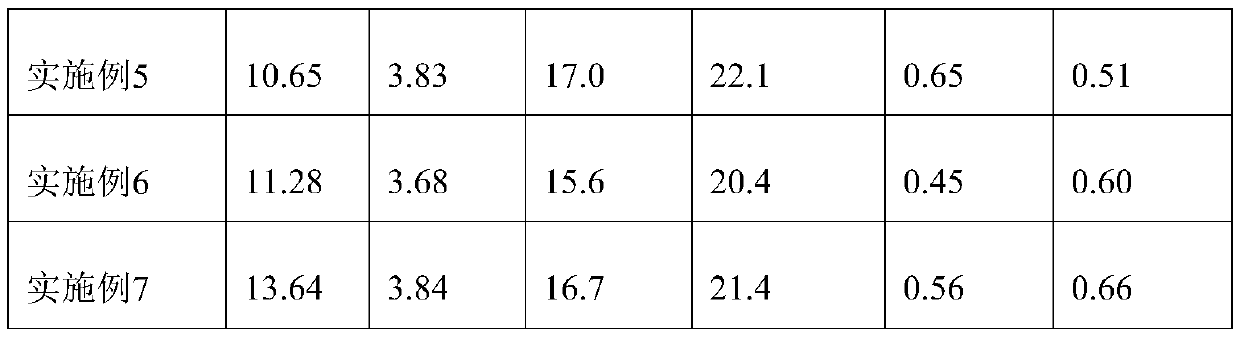

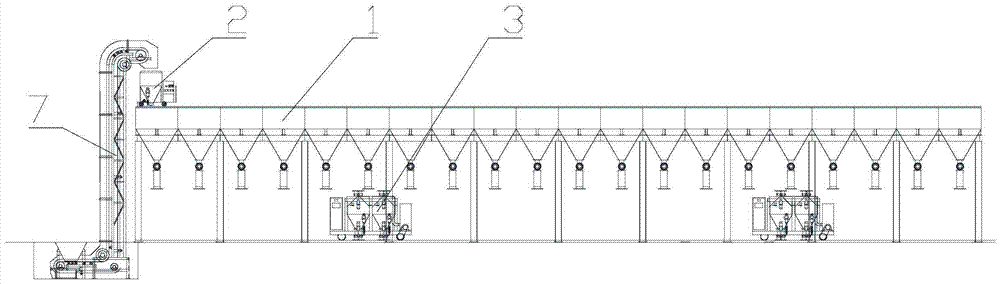

Castable batching device

The invention discloses a castable batching device. The castable batching device comprises batching bins arranged in rows, wherein at least two batching bins are arranged in each row; a feeding car is arranged above the batching bins; a batching car is arranged below the batching bins; the feeding car and the batching car are both moved in the arrangement direction of the batching bins in each row; a discharge port of the feeding car can be corresponding to feed ports of the batching bins; a weighing conveying belt is arranged between discharge ports of the batching bins and a feed port of the batching car; the discharge ports of the batching bins are corresponding to one end of the weighing conveying belt; the other end of the weighing conveying belt can be corresponding to the feed port of the batching car; the batching device further comprises a mixer; a second lifter is arranged between the discharge port of the batching car and a feed port of the mixer; the discharge port of the batching car is corresponding to a feed port of the second lifter; and a discharge port of the second lifter is corresponding to the feed port of the mixer. The castable batching device has the advantages of high automation degree, low labor intensity, high working efficiency and uniform mixing and batching.

Owner:ZHEJIANG RUITAI REFRACTORY TECH

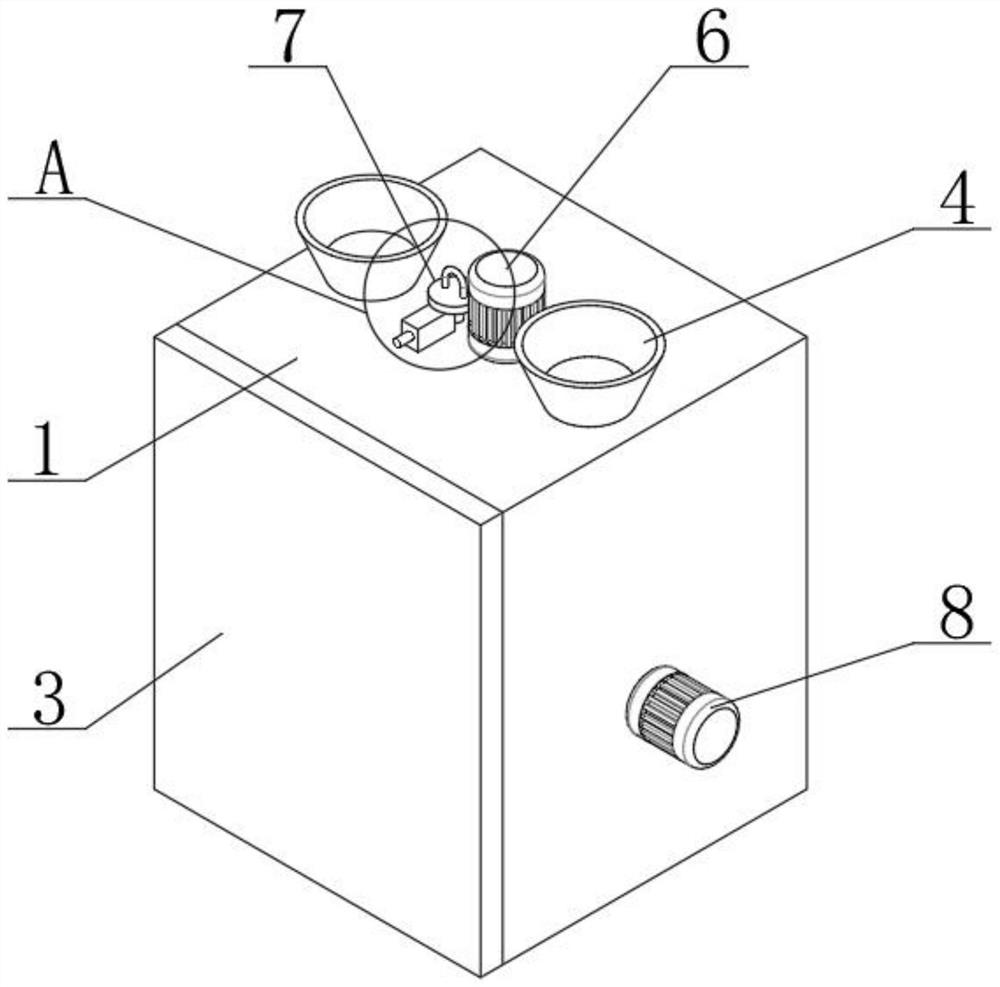

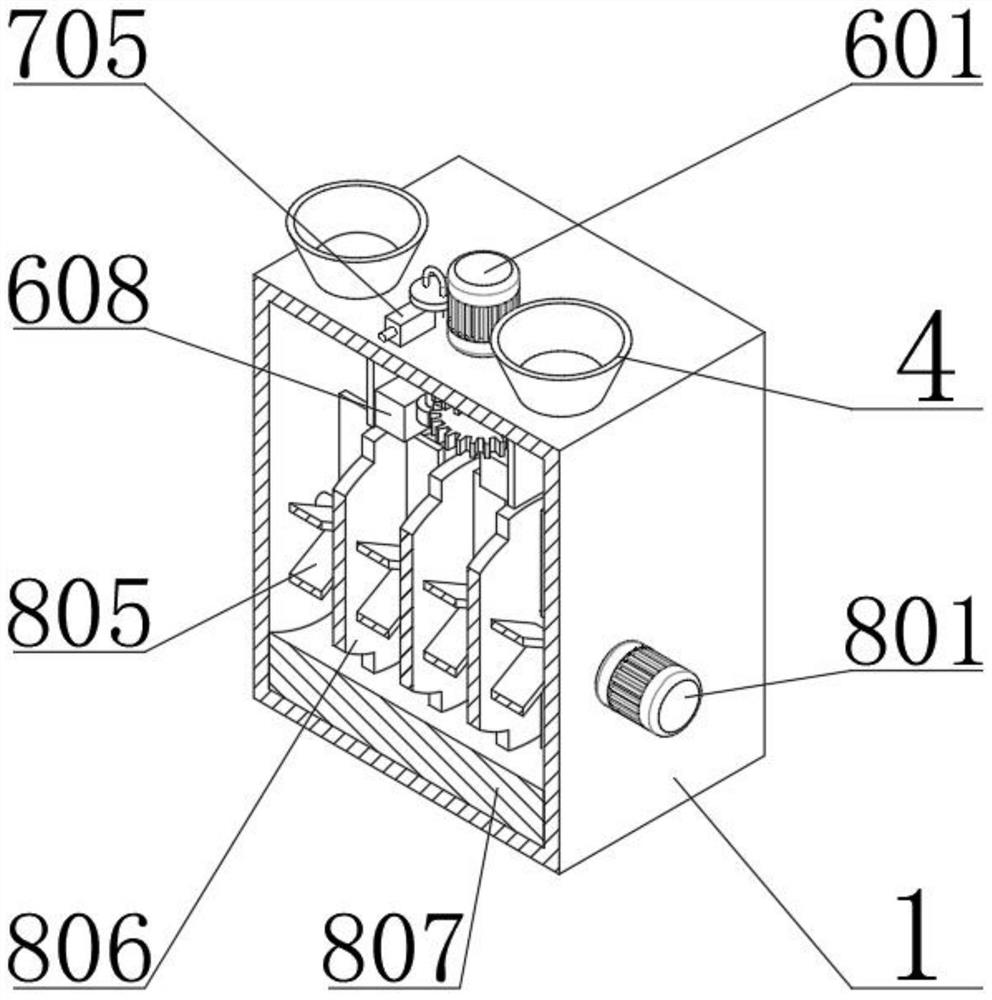

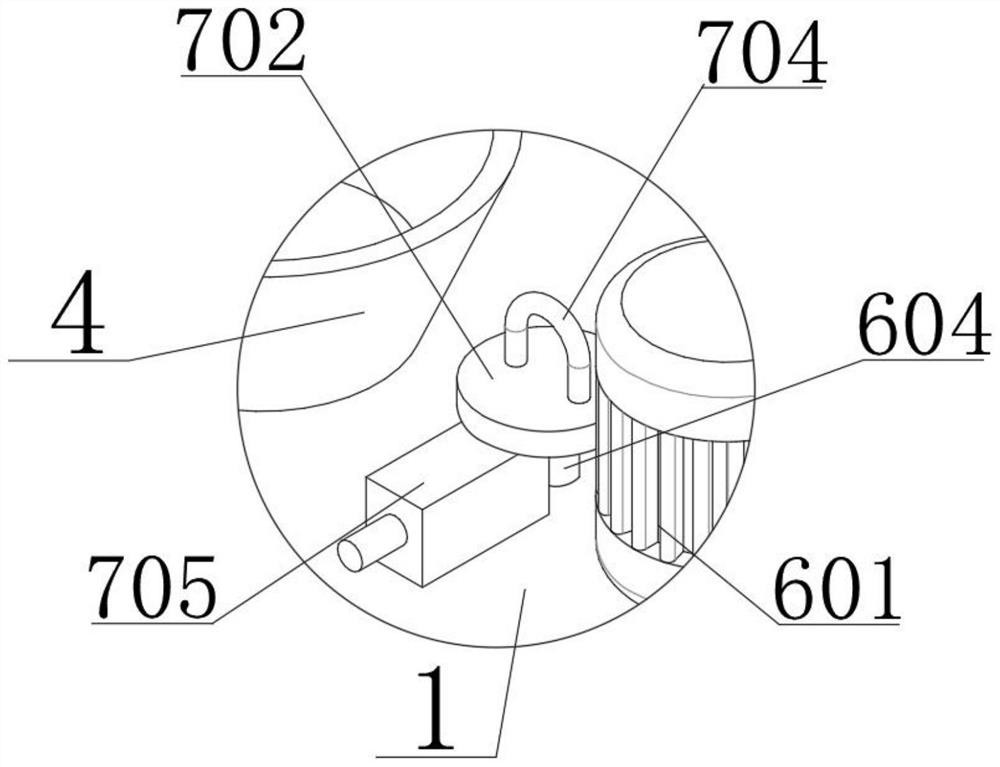

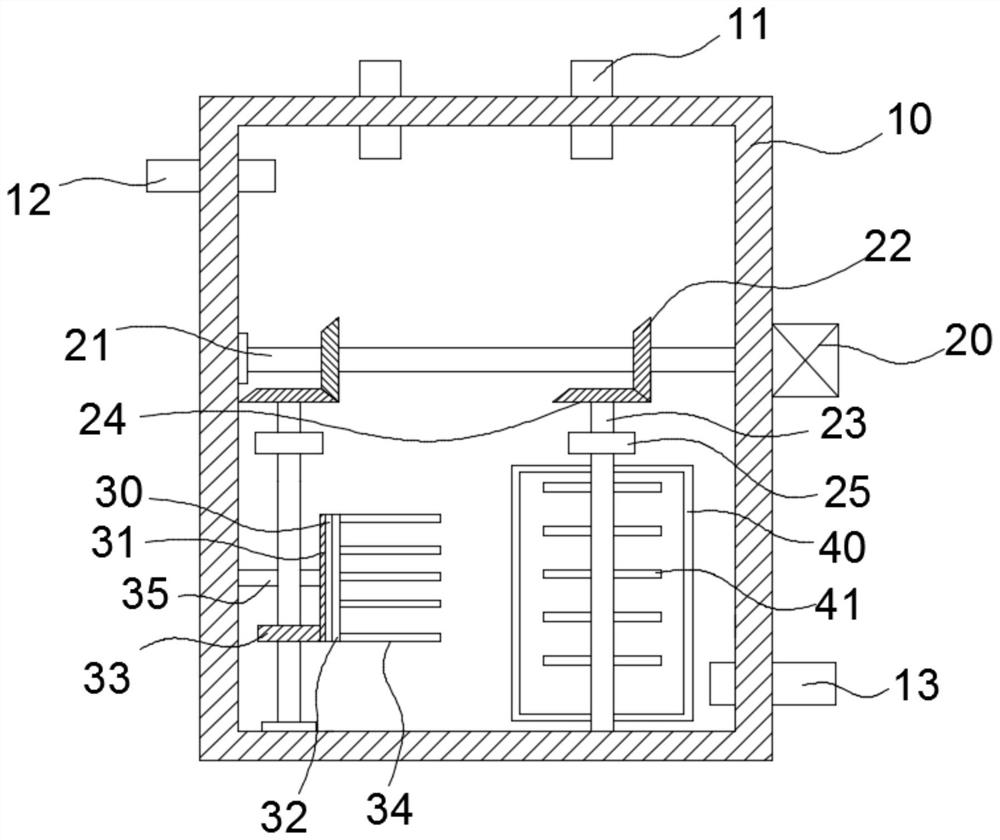

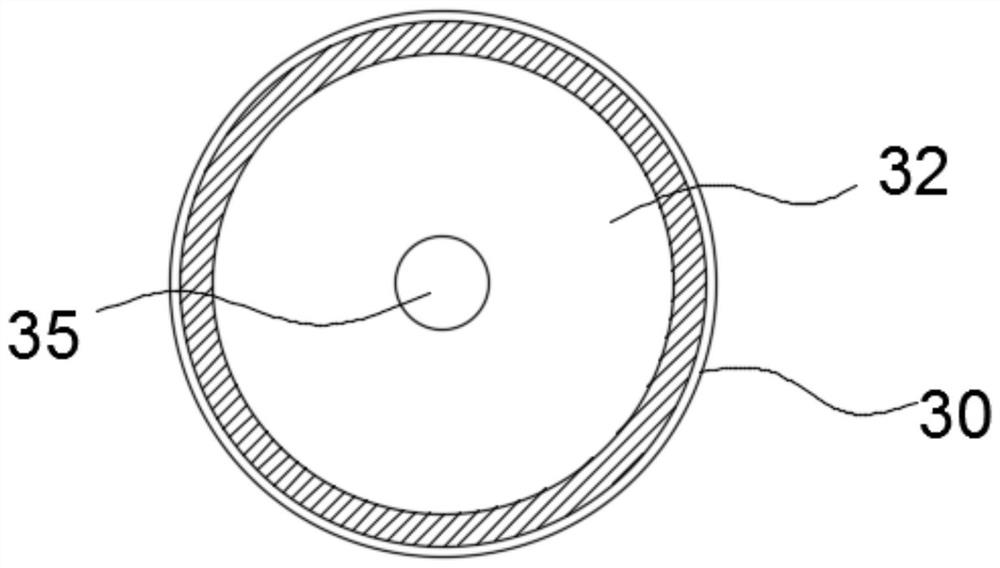

Device and method for preparing digestion-free protein with active protein and soybean protein as raw materials

PendingCN111772031AEvenly mixedShorten the mixing timeRotary stirring mixersTransportation and packagingFree proteinActive protein

The invention relates to the technical field of health-care food, in particular to a device and method for preparing digestion-free protein with active protein and soybean protein as raw materials. The device comprises a box body, a discharging hopper and a box door, wherein the box door is installed on the front side of the box body, and the discharging hopper arranged in a bilateral symmetry mode is installed on the top end face of the box door; a uniform discharging device is installed in the center of the top end of the box body; a speed regulation control device is installed on the innerside of the uniform discharging device; and a stirring device is installed on the inner side of the bottom end of the box body. By virtue of the uniform discharging device, the active protein and thesoybean protein can be discharged uniformly, therefore, the mixing uniformity is ensured, the stirring time is shortened, and a relatively good production effect is ensured.

Owner:讷河市笙得利农业科技发展有限公司

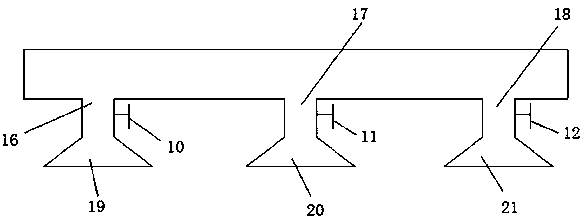

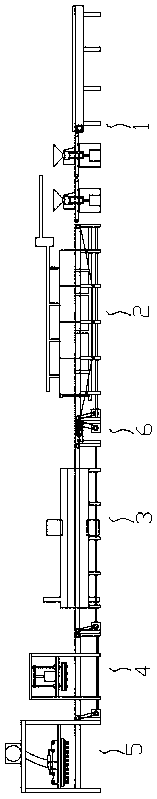

Steamed cake production line

PendingCN111345430AAchieve productionIncrease productivityFood shapingProcess engineeringMaterial resources

The invention relates to a steamed cake production line. The steamed cake production line comprises a conveying assembly line for circularly conveying cake mold plates, wherein the conveying assemblyline comprises a cake paste injection molding device; a tunnel type cake steamer, a steamed cake moisture control oven, a steamed cake hot-stamping device and a steamed cake negative-pressure adsorption demolding and transferring device which are sequentially arranged in a mold conveying direction; a vibration device for preventing sinking of steamed cakes after discharge is mounted at an output end of the tunnel type cake steamer; and a packaging assembly line is arranged at an output end of the conveying assembly line in parallel. The steamed cake production line realizes industrial cake production, has high production efficiency, can realize uniform matching and saves labor and material resources.

Owner:FUJIAN AIXIANGQIN FOOD

Automatic fertilization device based on computer control

InactiveCN108738616AUniform ingredientsAvoid wastingRotary stirring mixersTransportation and packagingDrive motorHigh pressure water

The invention discloses an automatic fertilization device based on computer control. The device comprises a bottom plate, a pneumatic cylinder, a pneumatic lifting rod, a batching bucket, a feeding port, a water inlet pipe, a driving motor, a high pressure water pump, a liquid spraying pipe, a first flow control valve, a second flow control valve, a third flow control valve and a PLC; the top of the bottom plate is provided with the pneumatic cylinder, the pneumatic cylinder sleeves the pneumatic lifting rod, a lifting end of the pneumatic lifting rod is fixedly connected with the batching bucket, the upper end of the top of the batching bucket is provided with the driving motor, an output shaft of the driving motor is provided with a stirring shaft extending to the bottom end of the innerportion of the batching bucket, the stirring shaft is provided with a plurality of stirring blades, the batching bucket is internally provided with the liquid spraying pipe extending to the outer portion of the batching bucket, a water outlet end of the liquid spraying pipe is provided with a first water spraying port, a second water spraying port and a third water spraying port separately, the first water spraying port is provided with the first flow control valve, the second water spraying port is provided with the second flow control valve, and the third water spraying port is provided with the third flow control valve.

Owner:黄春生

Production process for steamed cake

The invention relates to a production process for a steamed cake. The production process comprises the following steps: placing a cake mold tray onto a conveying assembly line, and placing a paper support into each mold cavity of the cake mold tray; conveying a cake paste prepared in advance into a cake paste injection molding device, and injecting the cake paste into each paper support on the cake mold tray; conveying the cake mold tray into a tunnel type cake steaming furnace, and heating the cake paste through high-temperature steam so as to form steamed cakes; vibrating the cake mold traythrough a vibration device used for preventing the steamed cakes from shrinking, and allowing air to enter the bottom part of the interior of each mold cavity so as to uniformly cool the steamed cakes; drying excessive moisture in the steamed cakes by an oven through cake steaming moisture control; taking prepared steamed cakes out of the cake mold tray through a steamed cake negative-pressure adsorption demolding transfer device, and transferring the steamed cakes to a packaging assembly line; and performing cooling and packaging on the steamed cakes. The production process for the steamed cake provided by the invention realizes industrial cake production and is high in production efficiency.

Owner:FUJIAN AIXIANGQIN FOOD

Preparation method of ferrochromium-molybdenum alloy

The invention relates to a preparation method of a ferrochromium-molybdenum alloy. The preparation method comprises the following steps that (1), molybdenum ore containing sulfur and cobalt is finelyground; (2), the finely ground molybdenum ore is uniformly mixed with ferrochromium fine ore and a fortifier, water is added, pelletizing moulding treatment is carried out so as to obtain pellets, andthe pellets are dried; (3), the dried pellets are uniformly put in a rotary hearth furnace for high-temperature reduction, and thus metallized pellets are obtained; and (4), the metallized pellets are ground again, a whole precipitant is added, the high-temperature reduction is carried out again, high-temperature smelting separation is carried out, and thus the ferrochromium-molybdenum alloy is obtained.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

Vacuum preparing device and application method

PendingCN108514834AGuaranteed vacuum environmentPlay a blocking roleRotary stirring mixersTransportation and packagingPulp and paper industryVacuum pump

The invention discloses a vacuum preparing device and an application method. The vacuum preparing device comprises a cylinder body and a cylinder cover, a sealing piece is arranged on the contact facebetween the cylinder body and the cylinder cover, one side of the cylinder body is connected with a vacuum pump, and the mode is used for achieving the vacuum environment of the preparing device. A motor is arranged on the cylinder cover, a rotating shaft of the motor penetrates through the cylinder cover, extends into a cavity, and is connected with a stirring paddle, and the stirring paddle extends in the direction of the side edge of the cylinder body and is used for stirring raw materials. A stirring stopping part is also arranged on the cylinder cover, and the stirring evenness of raw materials is improved. The application method of the vacuum preparing device includes the following steps that 1, the motor is started; 2, the raw materials are put into the preparing device; 3, the cylinder cover covers the cylinder body, and the vacuum pump is started; 4, the raw materials are fully stirred; 5, the motor is stopped; 6, a valve is started; 7, the prepared raw materials are taken out.

Owner:SUZHOU AONITE SILICON CARBIDE CERAMIC TECH CO LTD

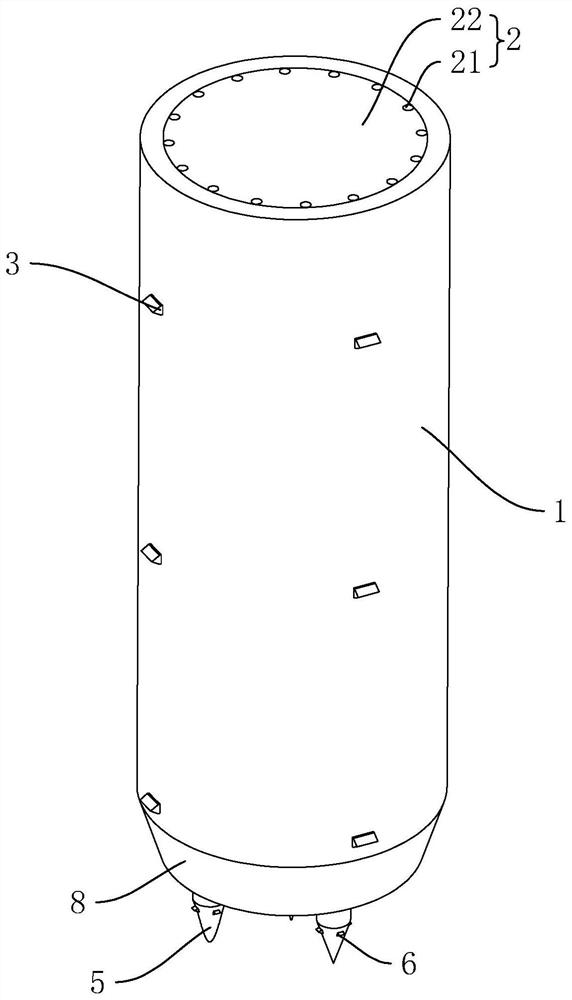

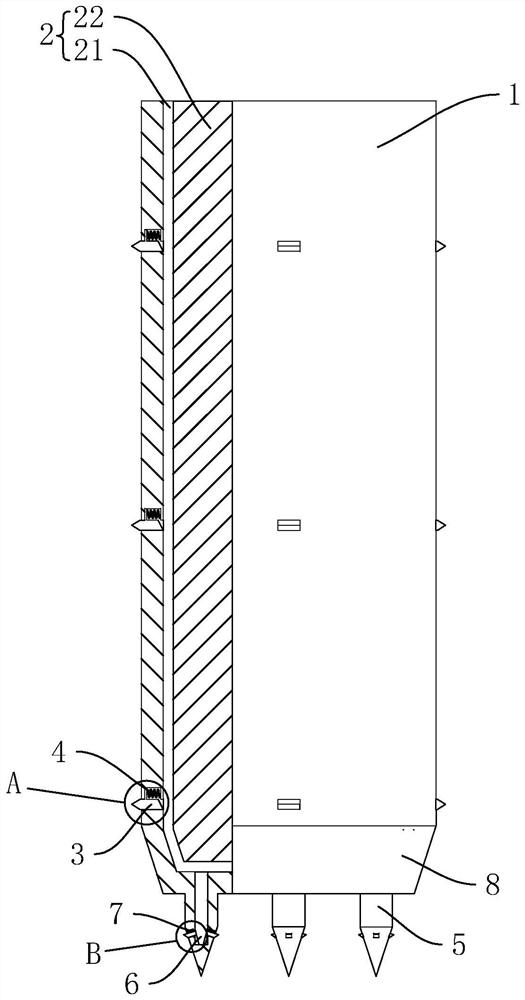

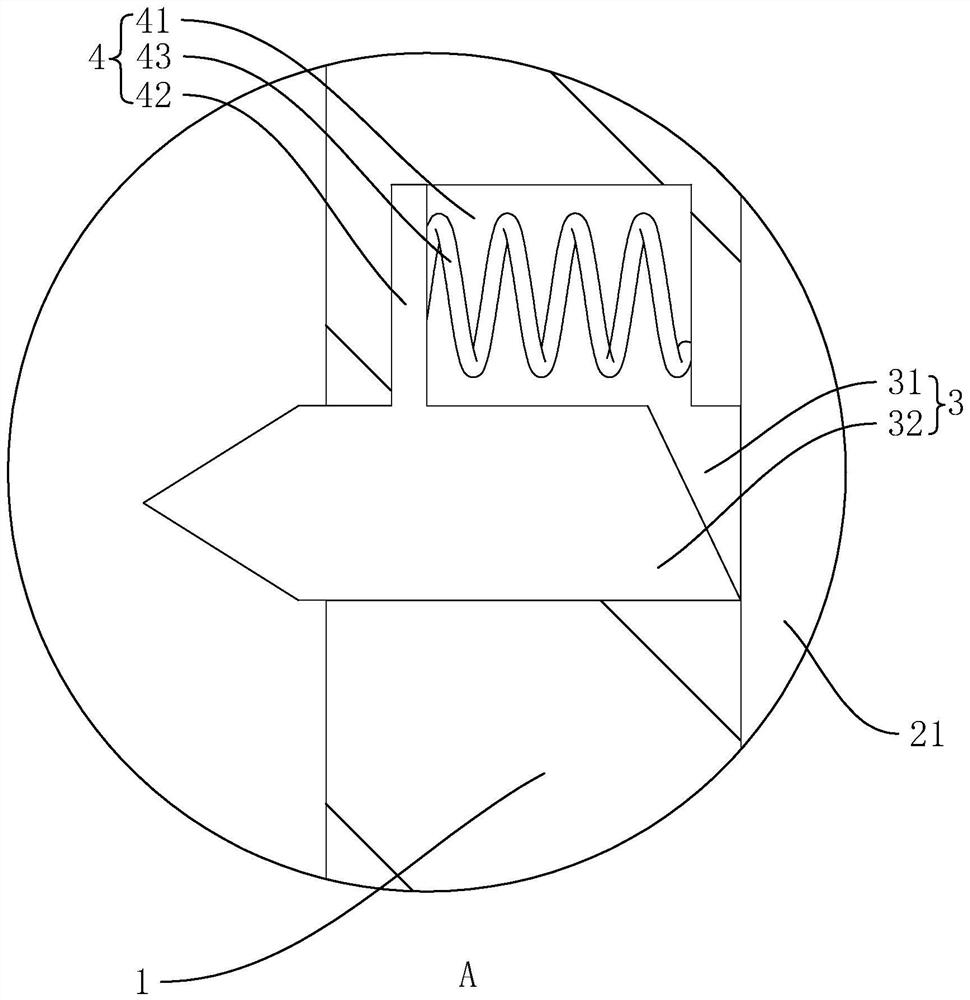

Cast-in-place pile and construction method thereof

PendingCN113802550AHigh strengthImprove connection strengthBulkheads/pilesArchitectural engineeringStructural engineering

The invention relates to a cast-in-place pile. The cast-in-place pile comprises a pile body and a concrete column poured in the pile body, a plurality of sets of reinforcing assemblies are arranged in the circumferential direction of the pile body, and the reinforcing assemblies are arranged in the length direction of the pile body; each reinforcing assembly comprises a reinforcing groove and a reinforcing block, the reinforcing grooves are formed in the pile body in the mode of being perpendicular to the pile body, and the reinforcing blocks are slidably arranged in the reinforcing grooves; and one ends of the reinforcing blocks abut against the outer side wall of a concrete column, the other ends of the reinforcing blocks stretch out of the pile body, and the reinforcing blocks slide in the direction close to or away from the concrete column. The cast-in-place pile has the effect of improving the connection strength of the cast-in-place pile fixed to the ground.

Owner:德清县亿胜建设有限公司

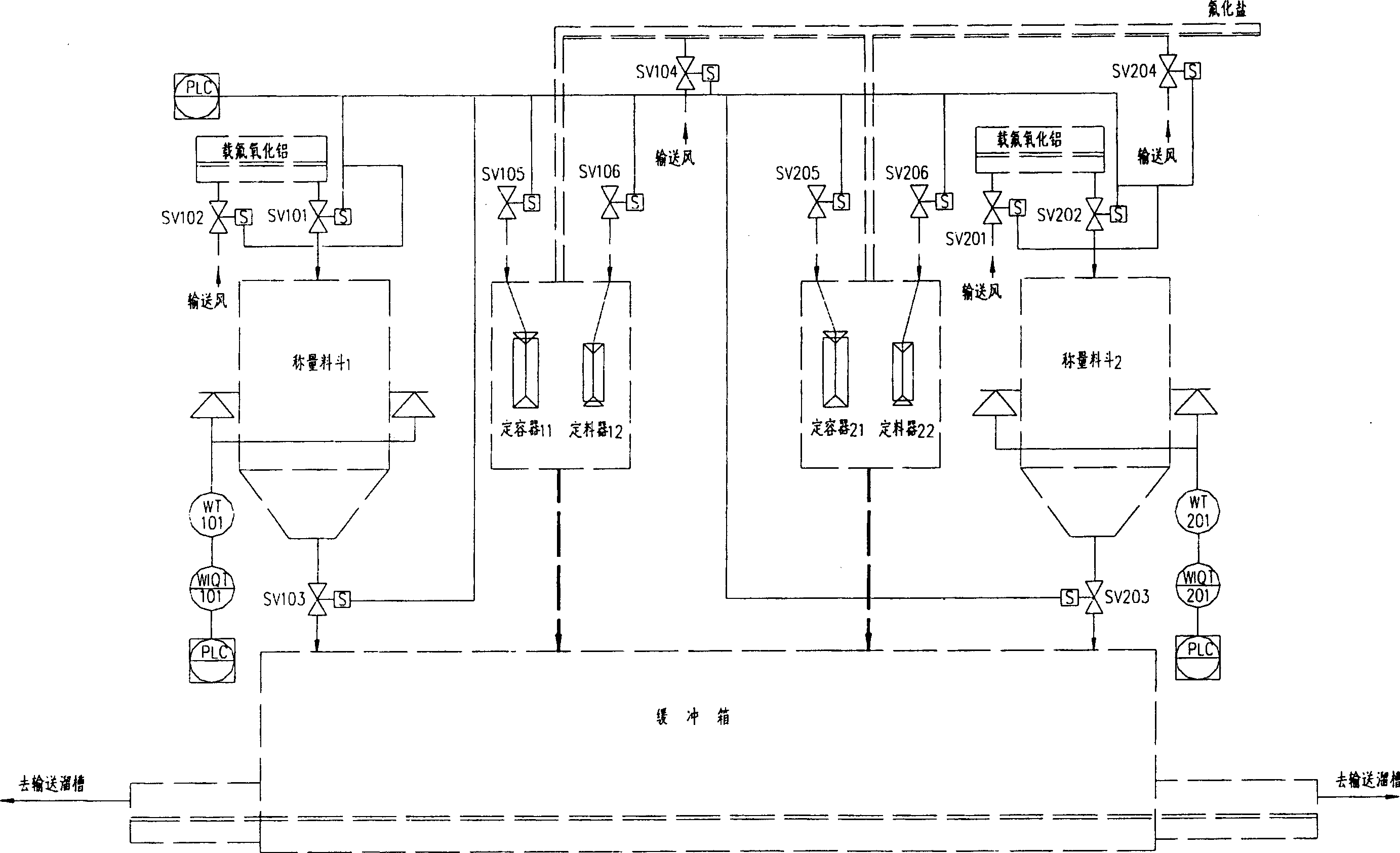

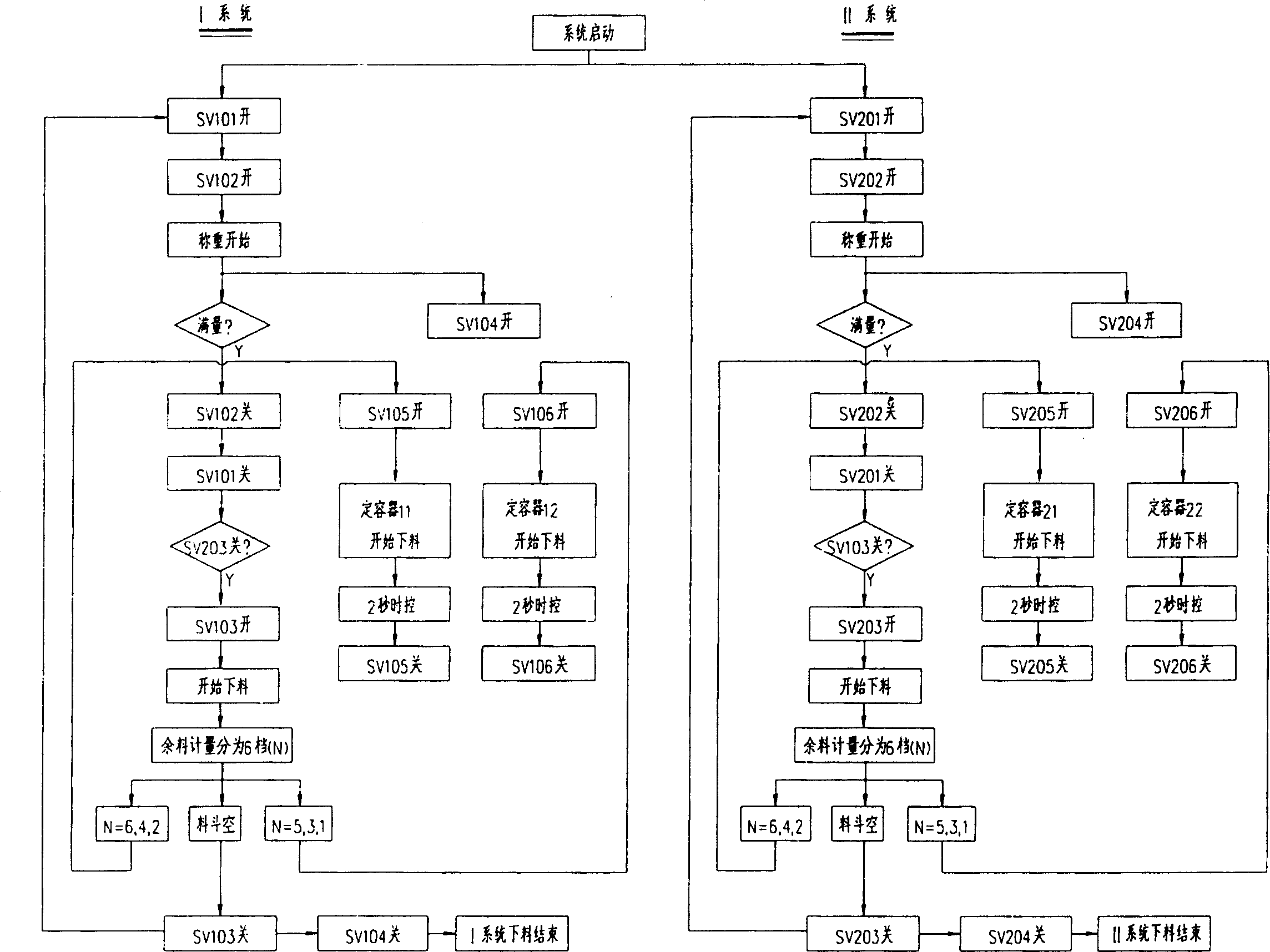

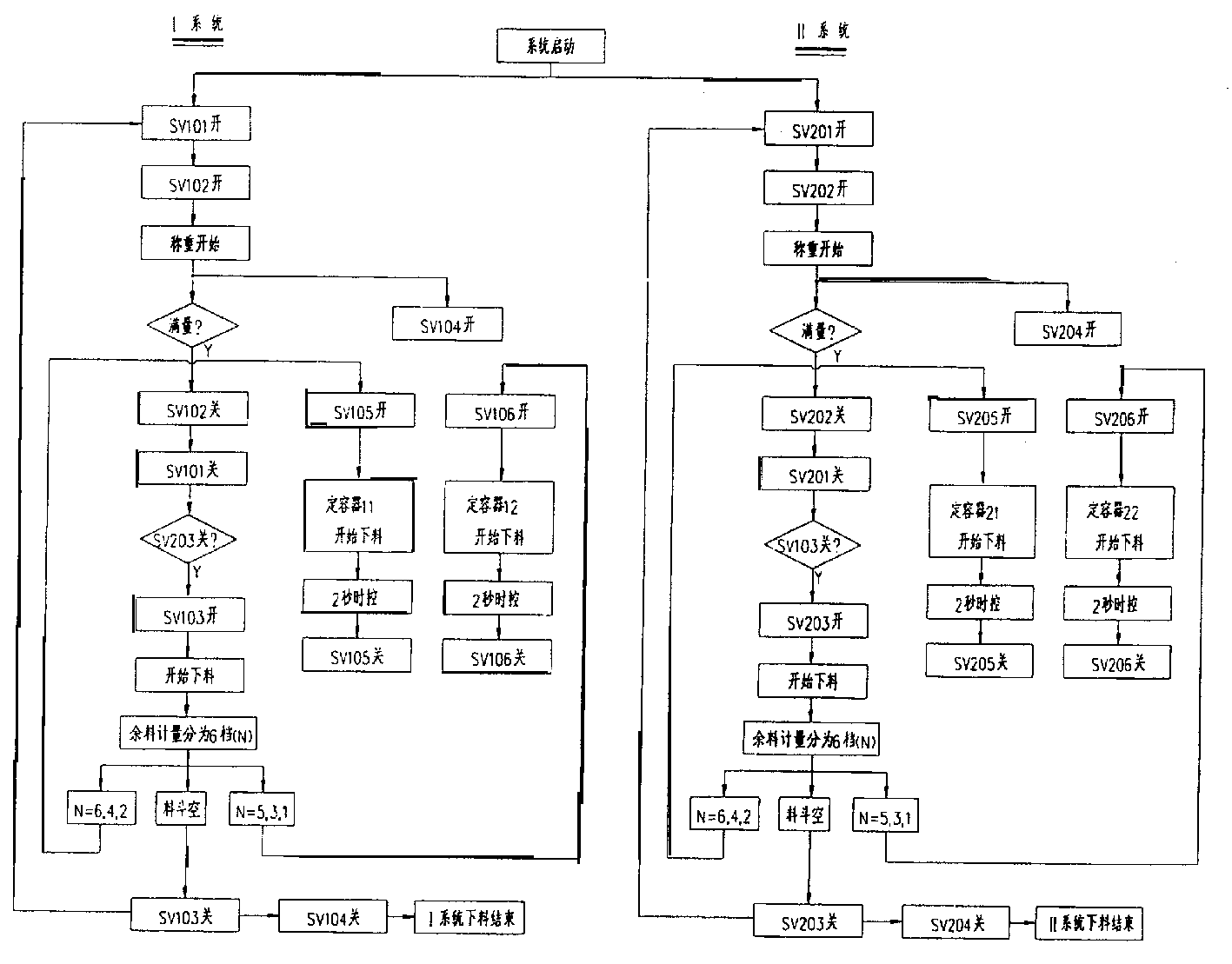

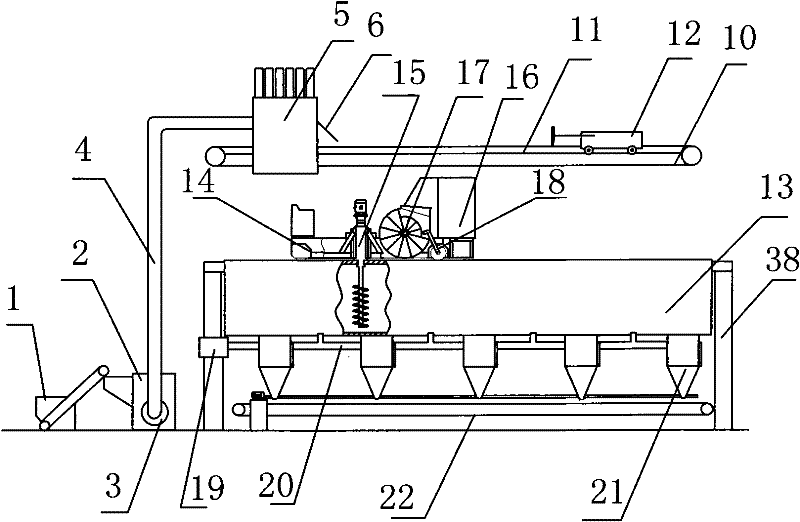

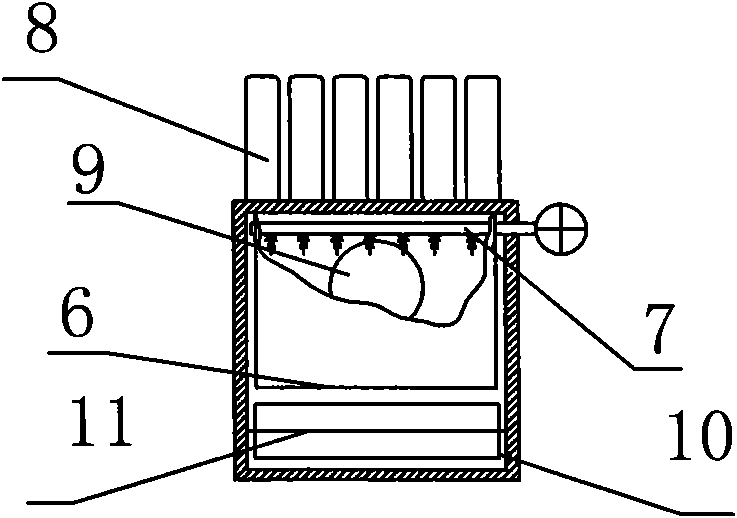

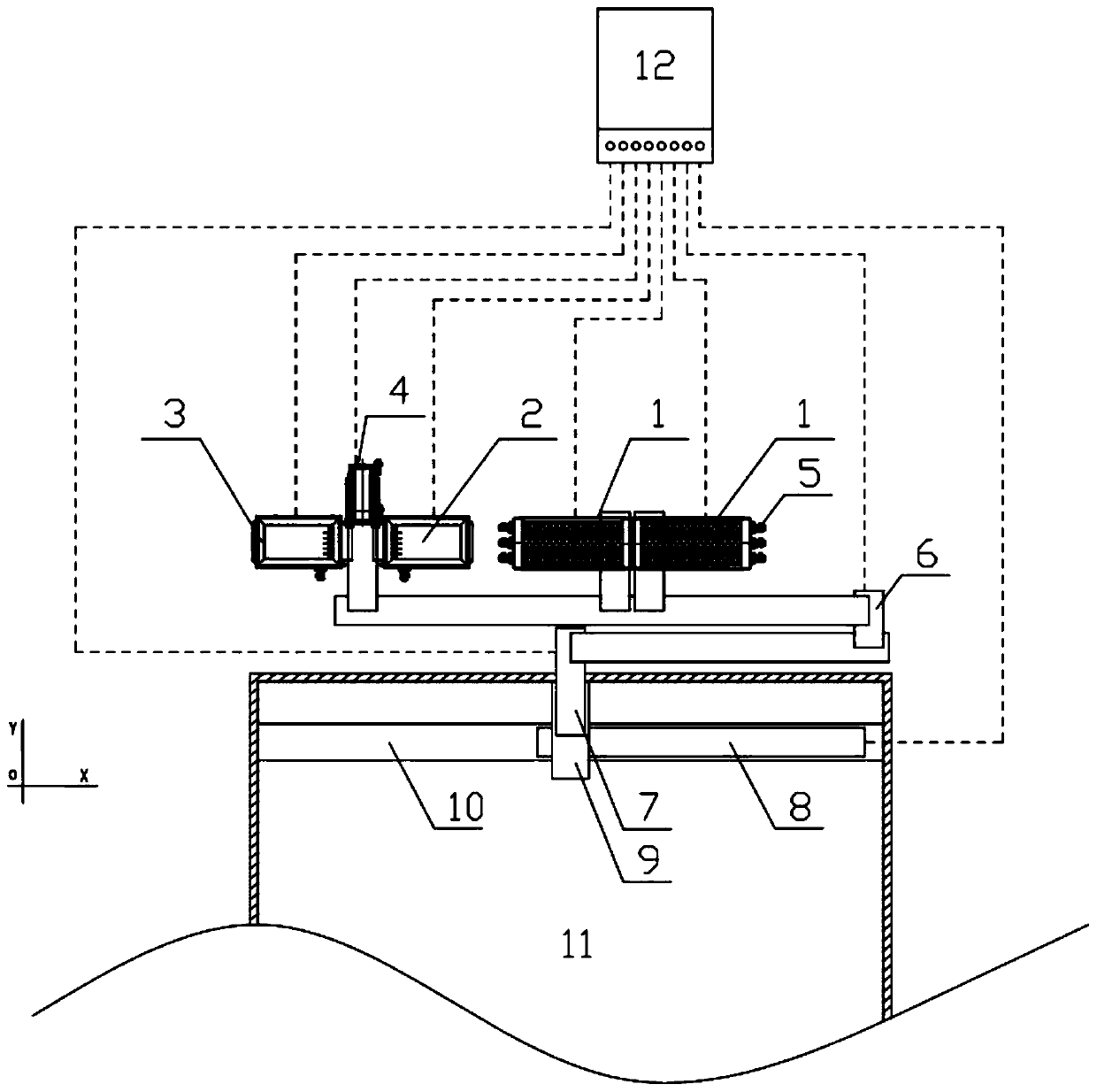

Auto-control system for electrolysis ingredient of aluminum

InactiveCN1238568CContinuous deliverySolve the problem that continuous discharge cannot be realizedElectrolysisAdditive ingredient

An autoamtic charge control system for preparing electrolytic aluminium features that its main control unit is a programmable controller or an industrial controller, a static metering mode is used for higher precision, and the charge systems A and B are controlled by it to work alternatively, so forming a continuous charge procedure. Its advantage is high charge uniformity.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Equipment for processing culture medium

InactiveCN101828483BGood for healthQuality improvementCultivating equipmentsHorticultureProcess equipmentEngineering

The invention discloses equipment for processing a culture medium, which relates to processing equipment of a crop culture medium and mainly comprises a smashing device, a stirring box and a blanking box, wherein the discharging end of the smashing device is connected to a smashed material conveying belt arranged above the stirring box through a dust-collecting box; an electric traveling crane provided with a spiral stirring shaft and a burdening mechanism is arranged on the stirring box; an oxygenation mechanism and the blanking box are arranged below the stirring box; and the blanking box is also internally provided with a kick-out rod and a spiral material pusher. The invention integrates and completes various processes for raw material processing in one device, thereby avoiding the transferring among the processes and achieving low investment cost; due to automatic integration, mechanized flow process is easily realized, scale production is easily formed, manpower is saved, and the production efficiency is improved by over 60 percent; the material is uniformly burdened, and the quality of the produced culture medium is stable; and the blanking box is bagged smoothly with high efficiency.

Owner:LUOYANG JIAJIALE AGRI PROD DEV

Automatic distributing device

InactiveCN107199669AUniform ingredientsImprove efficiencyElectromagnetic pulseMechanical engineering

The invention provides an automatic distributing device. A sucking mechanism is connected with storage boxes. A distributing mechanism is connected with the sucking mechanism and comprises a distributing chamber and a discharging chamber, the distributing chamber is located over the discharging chamber, a communicating opening is formed between the distributing chamber and the discharging chamber and provided with an electromagnetic pulse valve, the top of the distributing chamber is provided with a feeding inlet, the inner side of the distributing chamber is provided with a plurality of stirrers, the outer side of the distributing chamber is provided with a motor, and the stirrers are connected with the motor through wires. According to the automatic distributing device, the distributing chamber is internally provided with the multiple stirrers, the numbers of stirring rods on the stirrers in the different positions are different, the number of the lower stirring rods is the largest due to the fact that materials are deposited on the lower portion, thus, the uniformity of the lower materials is facilitated, and the product quality is ensured.

Owner:TIANJIN HONGXIANG PLASTIC PROD

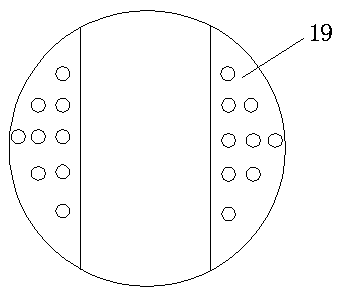

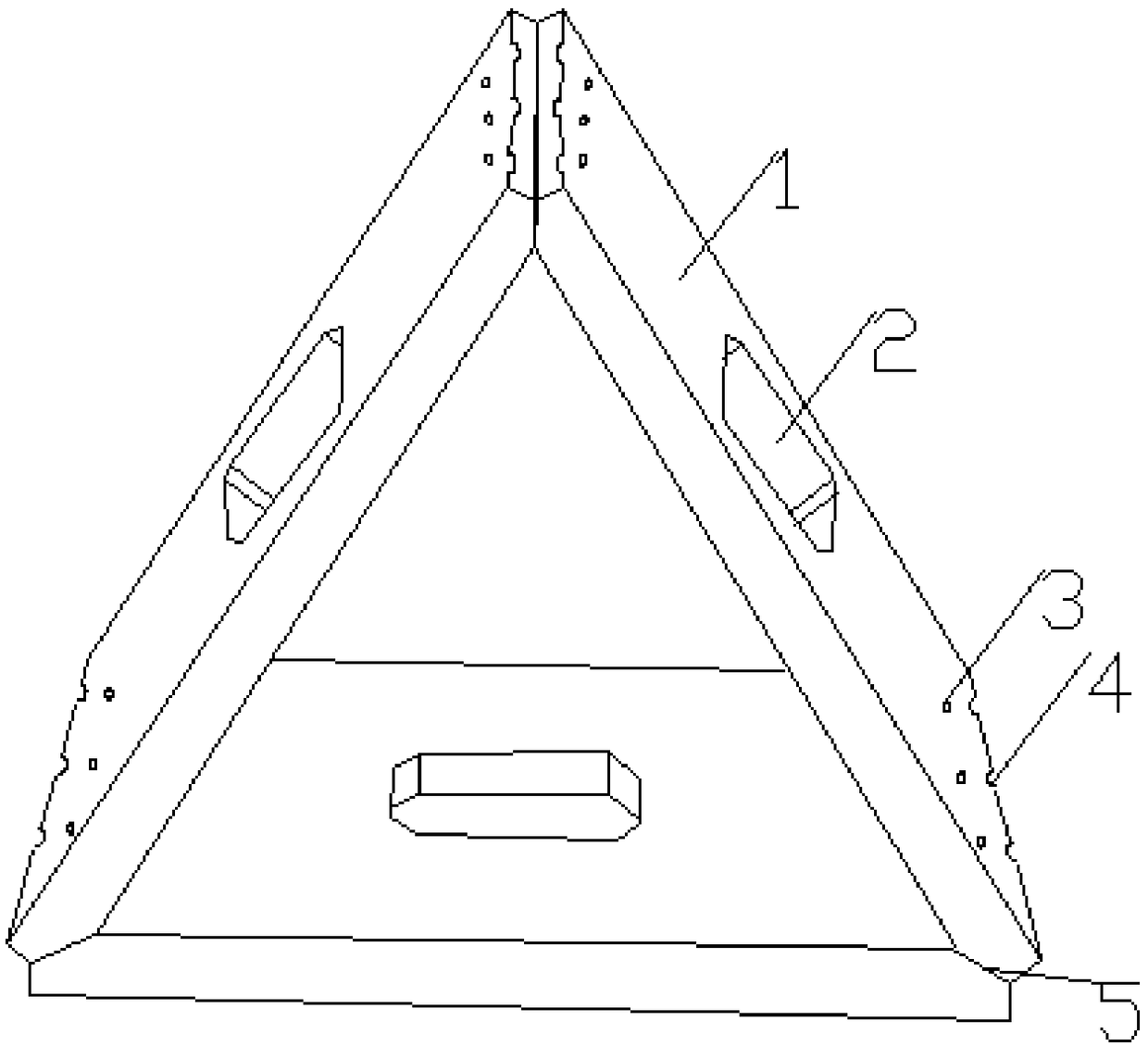

Assembled triangular prism artificial fish reef and preparation method thereof

PendingCN108513938AIncrease through-holeEasy to inhabitClimate change adaptationCeramic shaping apparatusCement boardPrism

The invention relates to the technical field of marine pasture artificial fish reef, in particular to an assembled triangular prism artificial fish reef and a preparation method thereof. The assembledtriangular prism artificial fish reef comprises three identical rectangular cement boards, and the end portions of the rectangular cement boards are connected in sequence to form a triangular prism shape; the centers of the rectangular cement boards are provided with guiding through holes. The assembled triangular prism artificial fish reef and the preparation method thereof have the advantages that the guiding through holes have large area and are mutually communicated, the through-hole property of the reef body is improved, and benefit is provided for the inhabitation and growth of reef fishes; any one of the faces of the fish reef can be used as a releasing bottom face during the release, thereby greatly providing convenience for the release; the bottom faces serve as base structures,thereby ensuring the stability of the reef body, and reducing the settlement rate of the reef body; the incident flow area of the reef body is increased, the overturning resistance of the reef body isimproved, and the regulation influence range of upwelling and back vortex of the reef body is enlarged, the flat-type rectangular cement boards are transported conveniently and assembled on site, andthe production targets of factorization, batch and standardization can be achieved.

Owner:北京同仁堂健康(大连)海洋食品有限公司

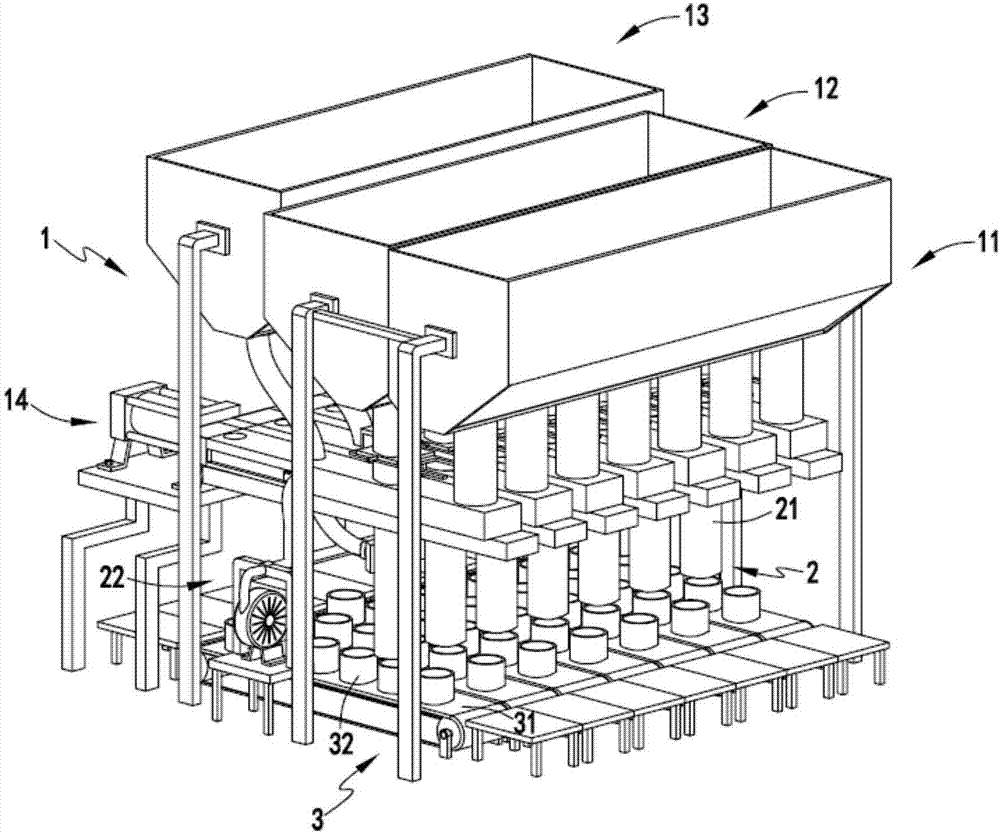

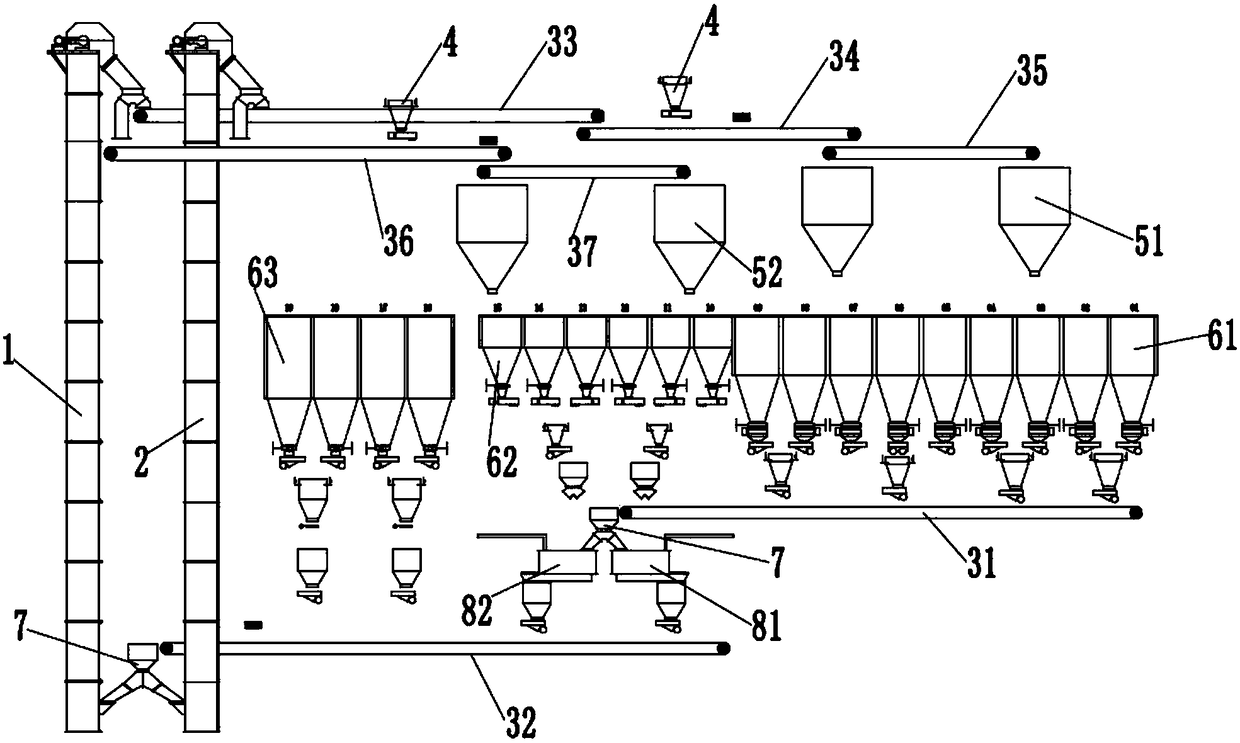

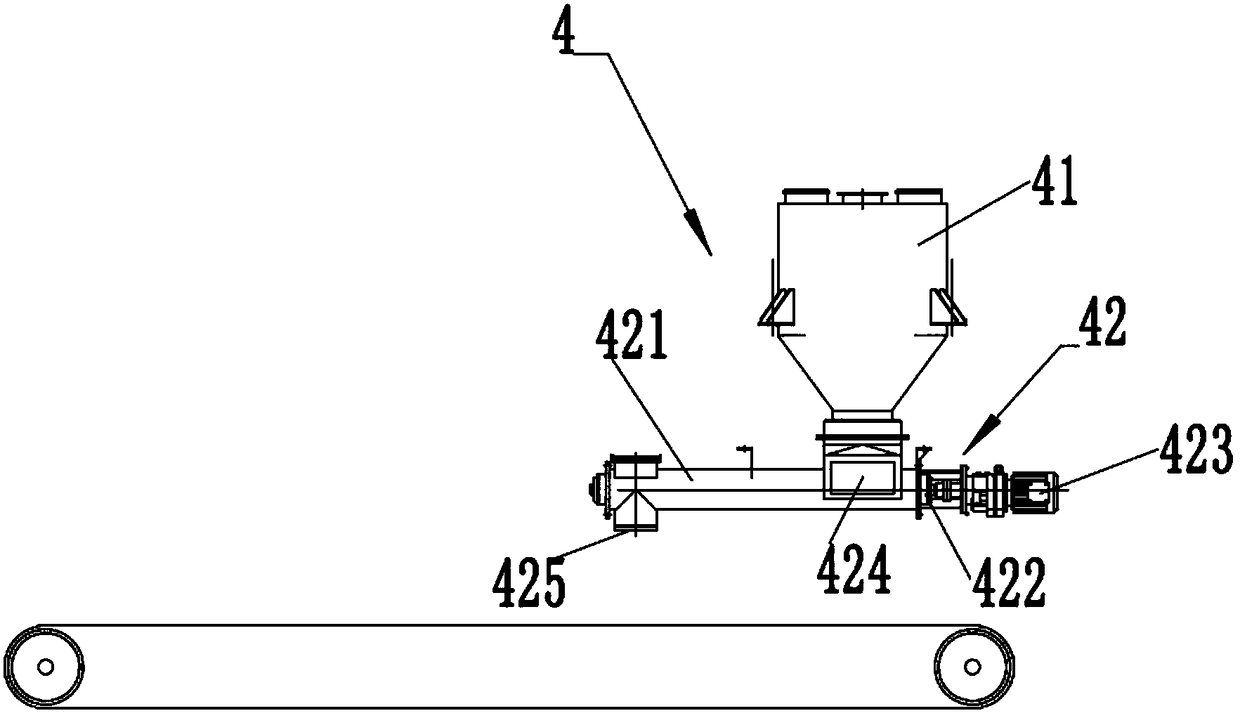

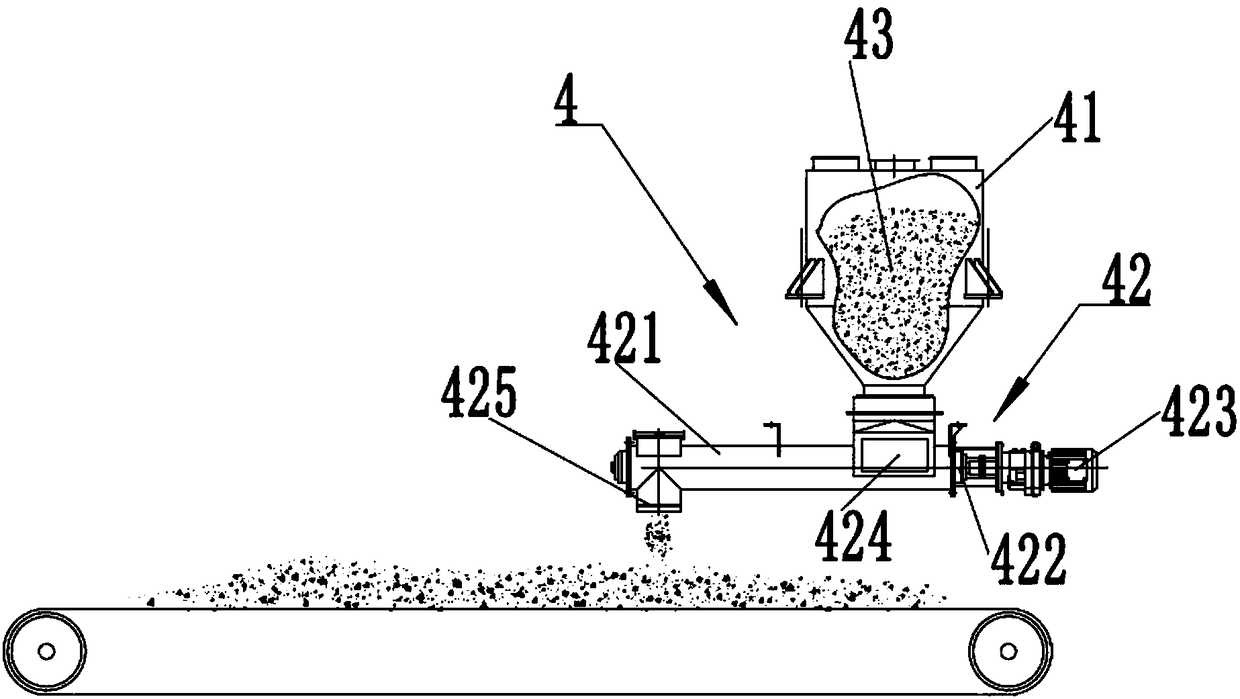

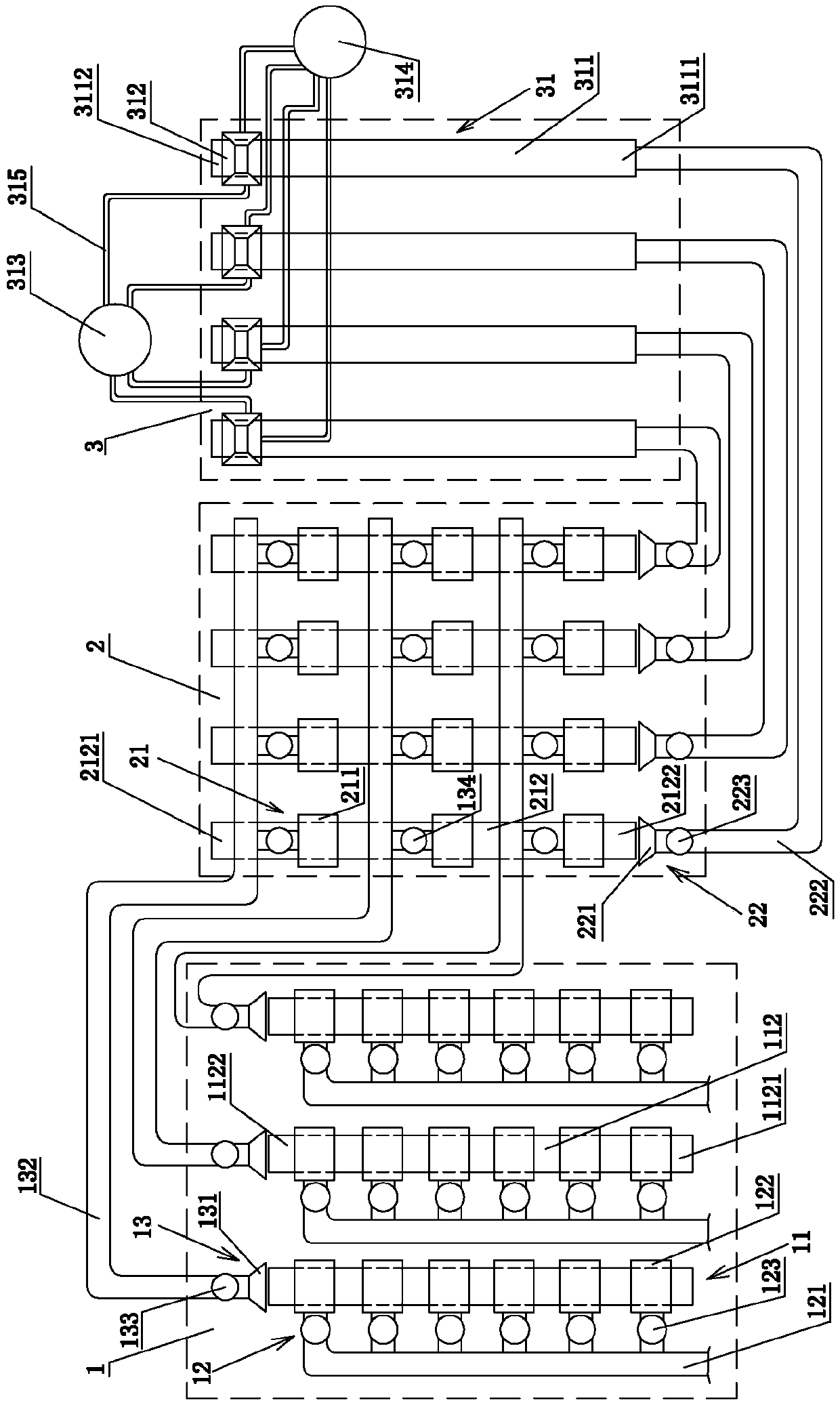

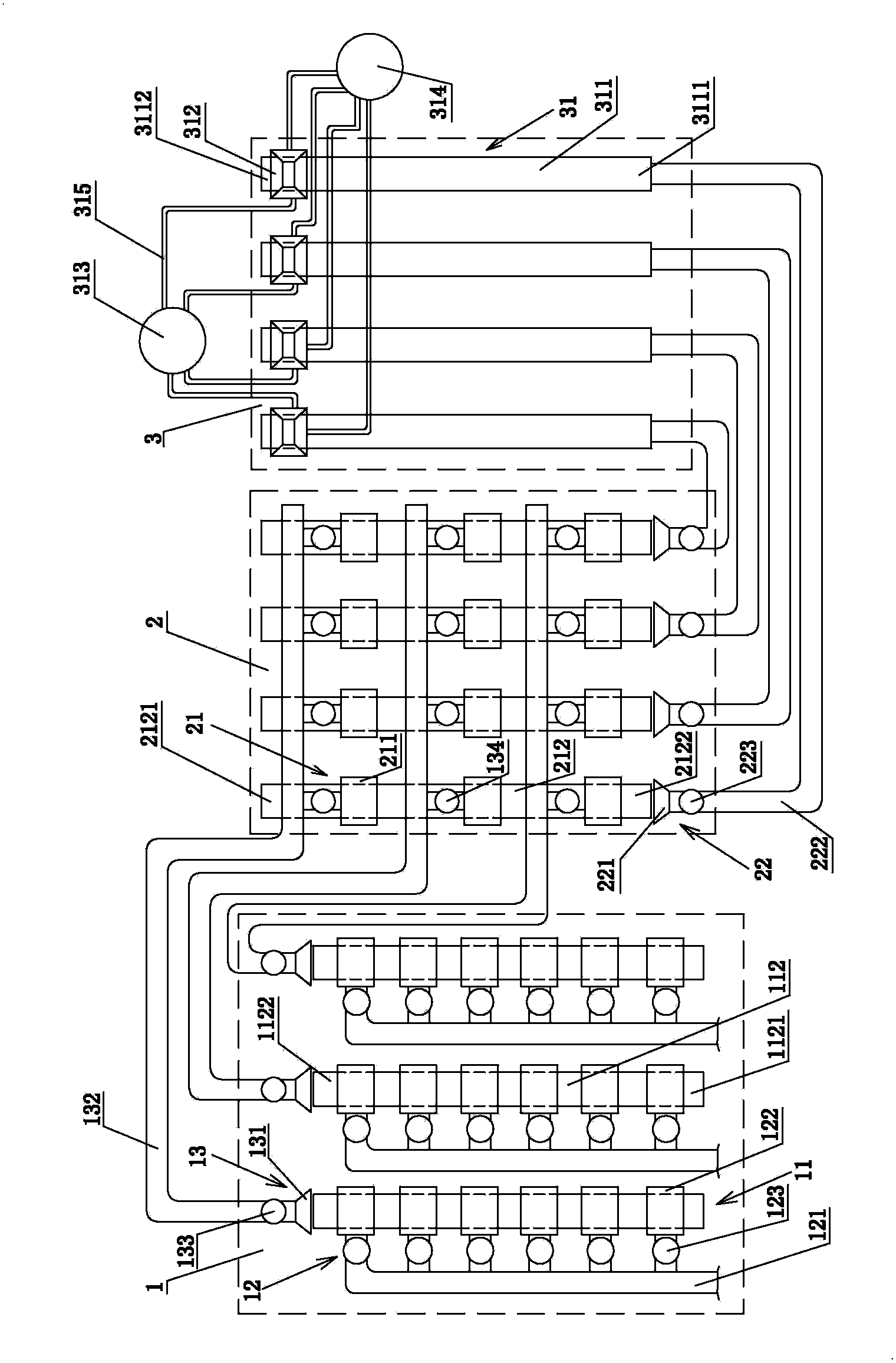

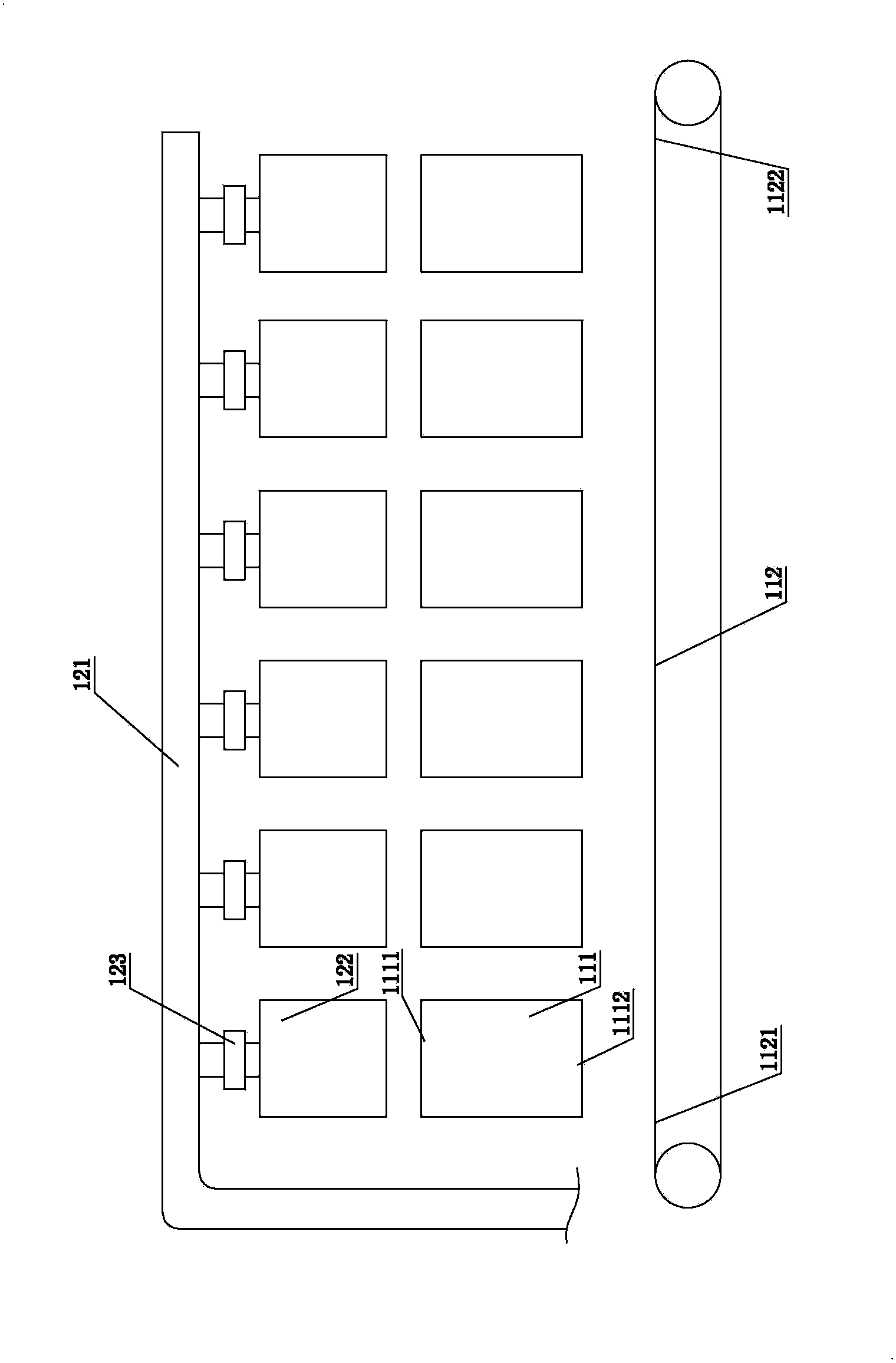

Multi-level batching equipment applied to the production of recycled polypropylene

The invention discloses multistage dispensing equipment applied to production of regenerative polypropylene. The multistage dispensing equipment comprises a first-stage dispensing device, a second-stage dispensing device and a third-stage dispensing device, wherein the first-stage dispensing device comprises a plurality of first dispensing lines for mixing first-stage materials into second-stage materials, the second-stage dispensing device comprises a plurality of second dispensing lines for mixing second-stage materials into third-stage materials, the third-stage dispensing device comprises a plurality of third dispensing lines for mixing third-stage materials into fourth-stage materials by adding an additive; and each first dispensing line is used for sending the first-stage materials to the first dispensing line through a first feeding mechanism for mixing and dispensing the materials, each first dispensing line is used for feeding the second-stage materials to the plurality of dispensing lines through a second feeding mechanism for mixing and dispensing the materials; and each second dispensing line is used for feeding the third-stage materials to each corresponding third dispensing line through a third feeding mechanism for mixing and dispensing the materials. By adopting the multistage dispensing equipment, when dispensing is performed, the automatic dispensing is realized, and the dispensing efficiency is increased; and the materials are more uniformly dispensed through three stages of mixing, and thus the quality of the polypropylene fibers is improved.

Owner:福建三宏再生资源科技有限公司

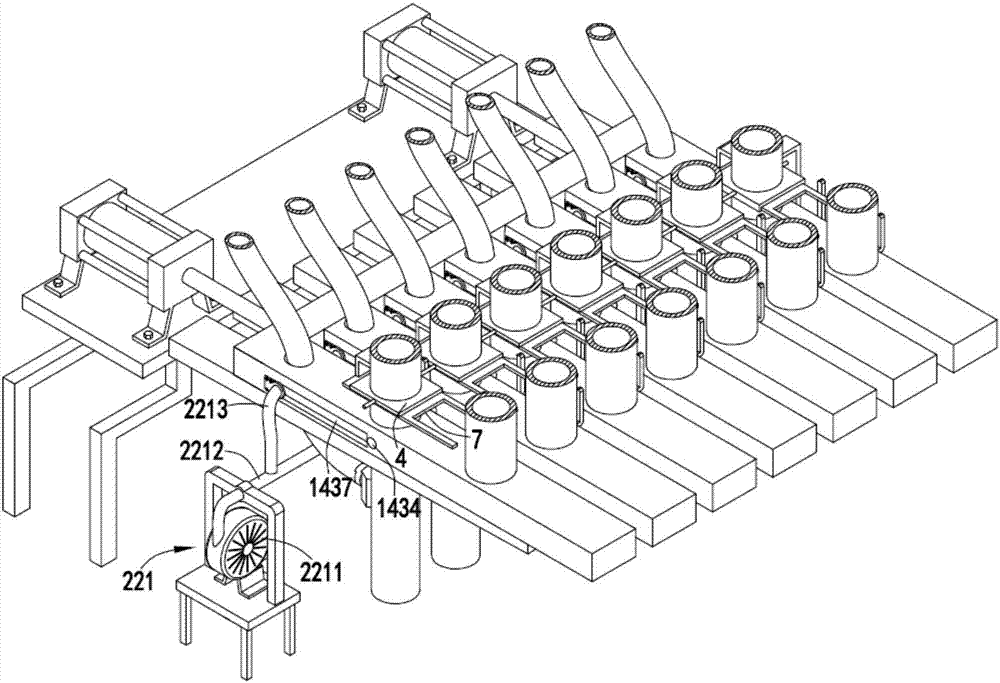

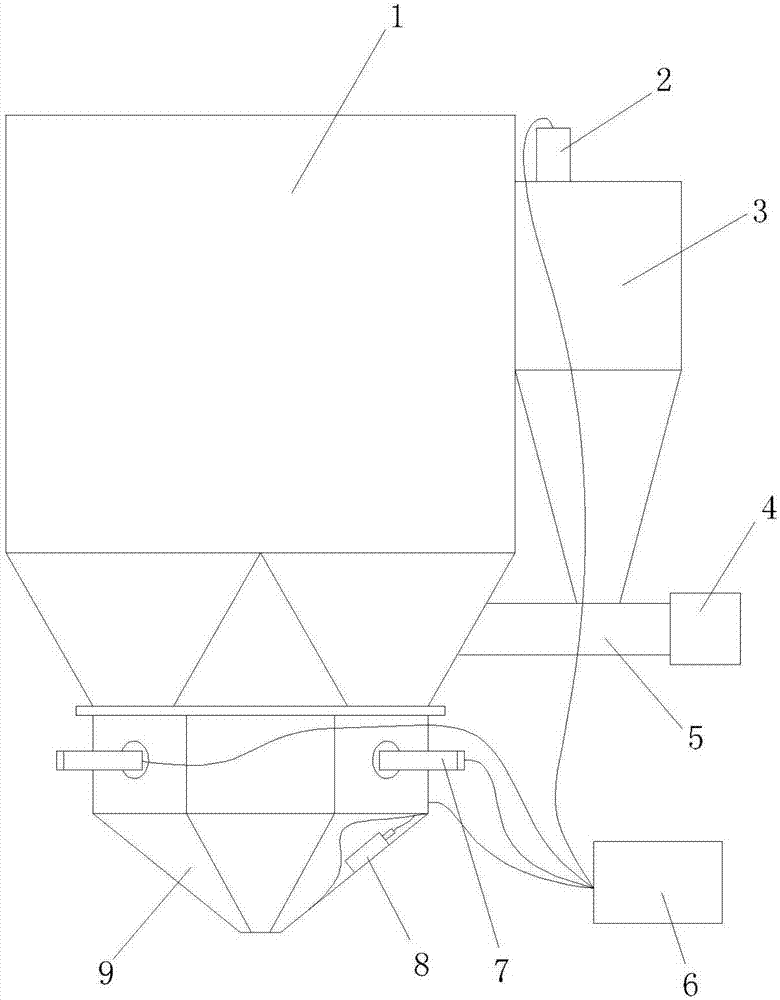

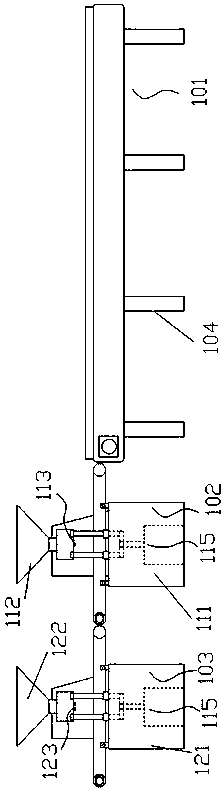

Full-automatic organic fertilizer feeding and distribution device and control method

PendingCN110563496AFully automatedUniform ingredientsBio-organic fraction processingOrganic fertiliser preparationBiogasScrew conveyor

The invention relates to a full-automatic organic fertilizer feeding and distribution device, which comprises a feeding apparatus, a distribution apparatus, a fermentation tank and a central controller. The feeding apparatus is mainly composed of biogas residue bins, an auxiliary material bin, a material returning bin, an inoculant bin, spiral conveyors and a belt conveyor. The biogas residue bins, the auxiliary material bin, the inoculant bin and the material returning bin are all provided with weighing equipment, the bottoms of the biogas residue bins, the auxiliary material bin, the inoculant bin and the material returning bin are all equipped with the spiral conveyors, which are connected to the belt conveyor. The belt conveyor is connected to the distribution apparatus, and the distribution apparatus is mainly composed of a telescopic belt conveyor, an upper frame beam, a forward and reverse rotation belt conveyor and a lower frame beam. The upper frame beam and the lower frame beam form a double-layer cross-shaped frame beam structure; and the telescopic belt conveyor is arranged in the upper frame beam. The invention has the beneficial effects that: control signals of the feeding apparatus, the distribution apparatus and other equipment are accessed into a control system, thus realizing automatic feeding and distribution of all materials.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

A castable batching device

InactiveCN104118061BUniform ingredientsStir wellMixing operation plantEngineeringUltimate tensile strength

The invention discloses a castable batching device. The castable batching device comprises batching bins arranged in rows, wherein at least two batching bins are arranged in each row; a feeding car is arranged above the batching bins; a batching car is arranged below the batching bins; the feeding car and the batching car are both moved in the arrangement direction of the batching bins in each row; a discharge port of the feeding car can be corresponding to feed ports of the batching bins; a weighing conveying belt is arranged between discharge ports of the batching bins and a feed port of the batching car; the discharge ports of the batching bins are corresponding to one end of the weighing conveying belt; the other end of the weighing conveying belt can be corresponding to the feed port of the batching car; the batching device further comprises a mixer; a second lifter is arranged between the discharge port of the batching car and a feed port of the mixer; the discharge port of the batching car is corresponding to a feed port of the second lifter; and a discharge port of the second lifter is corresponding to the feed port of the mixer. The castable batching device has the advantages of high automation degree, low labor intensity, high working efficiency and uniform mixing and batching.

Owner:ZHEJIANG RUITAI REFRACTORY TECH

Multistage dispensing equipment applied to production of regenerative polypropylene

The invention discloses multistage dispensing equipment applied to production of regenerative polypropylene. The multistage dispensing equipment comprises a first-stage dispensing device, a second-stage dispensing device and a third-stage dispensing device, wherein the first-stage dispensing device comprises a plurality of first dispensing lines for mixing first-stage materials into second-stage materials, the second-stage dispensing device comprises a plurality of second dispensing lines for mixing second-stage materials into third-stage materials, the third-stage dispensing device comprises a plurality of third dispensing lines for mixing third-stage materials into fourth-stage materials by adding an additive; and each first dispensing line is used for sending the first-stage materials to the first dispensing line through a first feeding mechanism for mixing and dispensing the materials, each first dispensing line is used for feeding the second-stage materials to the plurality of dispensing lines through a second feeding mechanism for mixing and dispensing the materials; and each second dispensing line is used for feeding the third-stage materials to each corresponding third dispensing line through a third feeding mechanism for mixing and dispensing the materials. By adopting the multistage dispensing equipment, when dispensing is performed, the automatic dispensing is realized, and the dispensing efficiency is increased; and the materials are more uniformly dispensed through three stages of mixing, and thus the quality of the polypropylene fibers is improved.

Owner:福建三宏再生资源科技有限公司

High-efficiency fixed-ratio mixing production process for coatings

The invention relates to an efficient fixed-proportion mixing production technology of a paint. The production technology comprises the following production steps: A, feeding: resin a and resin b at required proportion are conveyed sequentially and quantitatively to a bonding station through a material groove formed in a transfer plate, and powder requiring proportioning is conveyed to a powder storage device located at a powder blowing station; B, bonding: the resin b is heated synchronously while the resin a in the step A is transferred to the position below the resin b at the bonding station, the resin a and the resin b are bonded when falling synchronously, and a mixture is formed; C, powder blowing: in the process that the mixture in the step B falls down from the bonding station, thepowder in the powder storage device is blown to the mixture, and mixed paint is formed; D, sub-packaging: the mixed paint in the step C is packaged in separate bags and output sequentially. The problems of uneven paint ratio and insufficient mixing in the conventional production technology are solved.

Owner:临泉鹏成机电技术有限公司

Spreading machine convenient for material unloading

The invention discloses a spreading machine convenient for material unloading. The spreading mechanism comprises a spreading guide rail rotationally arranged at one side of a vehicle body; the spreading guide rail is glidingly provided with a spreading assembly; the spreading guide rail is glidingly provided with a compaction assembly used for compacting and shaping the side wall after the spreading; one end, far away from the vehicle body, of the spreading guide rail is provided with a support assembly used for supporting the end part of the spreading guide rail onto the bottom of a slope. The material unloading is convenient; the spreading is convenient; the construction efficiency is improved.

Owner:江苏恒昌铸造科技有限公司

Raw material batching device for producing high-performance asphalt wearing layer

PendingCN114836229AFully mixedEvenly mixedRotary stirring mixersTransportation and packagingCircular discElectric machinery

The invention discloses a high-performance asphalt wearing layer production raw material batching device, which comprises: a batching box, the top of the batching box is provided with a feed inlet, and the right side of the bottom of the batching box is provided with a discharge outlet; a rotating shaft is transversely arranged in the middle of the interior of the batching box, the right end of the rotating shaft is connected with a motor arranged on the outer wall of the right side of the batching box, and driving assemblies are arranged at the two ends of the outer surface of the rotating shaft correspondingly. The motor rotates to drive the connecting shaft to rotate, the connecting shaft drives the two vertical shafts to rotate, the vertical shafts drive the discs to rotate, the mixing rods achieve transverse mixing, the stirring rods and the mixing frames achieve vertical mixing, the mixing effect is good, raw materials in the batching box can be fully mixed, mixing is uniform, the mixing effect is good, and batching is uniform.

Owner:路菲特(广州)新材料科技有限公司

Efficient fixed-proportion mixing production technology of paint

The invention relates to an efficient fixed-proportion mixing production technology of a paint. The production technology comprises the following production steps: A, feeding: resin a and resin b at required proportion are conveyed sequentially and quantitatively to a bonding station through a material groove formed in a transfer plate, and powder requiring proportioning is conveyed to a powder storage device located at a powder blowing station; B, bonding: the resin b is heated synchronously while the resin a in the step A is transferred to the position below the resin b at the bonding station, the resin a and the resin b are bonded when falling synchronously, and a mixture is formed; C, powder blowing: in the process that the mixture in the step B falls down from the bonding station, thepowder in the powder storage device is blown to the mixture, and mixed paint is formed; D, sub-packaging: the mixed paint in the step C is packaged in separate bags and output sequentially. The problems of uneven paint ratio and insufficient mixing in the conventional production technology are solved.

Owner:临泉鹏成机电技术有限公司

Coloring system for ceramic raw material

The invention relates to a coloring system for a ceramic raw material. The coloring system comprises a dosing module, a mixing module and a forming module which are vertically arranged mutually, wherein the dosing module comprises a base charging bucket and multiple sets of color pigment feeding devices; an upper conveying device is arranged under the base charging bucket and multiple sets of color pigment feeding devices; the mixing module comprises multiple sets of stirring devices; a splitting conveying device is arranged above the multiple sets of stirring devices; the forming module comprises a plurality of storage hoppers, a lower conveying device and a pressing device. Under the power driving or gravity effect, the base material and the color pigment are accurately dosed, uniformly mixed and formed as required. The coloring system can be used for solving the problems of much more overstock fixed assets of the ceramic manufacturer, higher workload and longer time of product conversion and the manpower, consumption of water and electric resources due to cleaning work for the equipment.

Owner:FOSHAN DONGCHENGHUI TECH HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com