Method for smelting nickel-containing ferrochrome alloy

A ferroalloy, nickel-chromium technology, applied in the field of nickel-chromium ferroalloy smelting, can solve the problems of inability to ensure the uniformity of material distribution, high energy consumption and production costs, and low metal content, so as to shorten smelting time, reduce smelting power consumption, and batching uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The Cr of the chromite powder that present embodiment uses 2 o 3 The content of TFe (total iron) is 41.24%, and the content of TFe (total iron) is 21.0%. The content of Ni in lateritic nickel ore is 1.70%, and the content of MgO is 19.17%.

[0037] Take 100 parts of chromite powder, 40 parts of laterite nickel ore, 25 parts of semi-coke, 3 parts of bentonite, and 8 parts of silica, and control the ratio of magnesium to aluminum to 0.91. The particle size of laterite nickel ore ground to below 100 mesh accounts for 83%; the particle size of semi-coke with carbon content above 75% to below 200 mesh accounts for 90%; the particle size of silica ground to below 200 mesh accounts for 83%. than 92%.

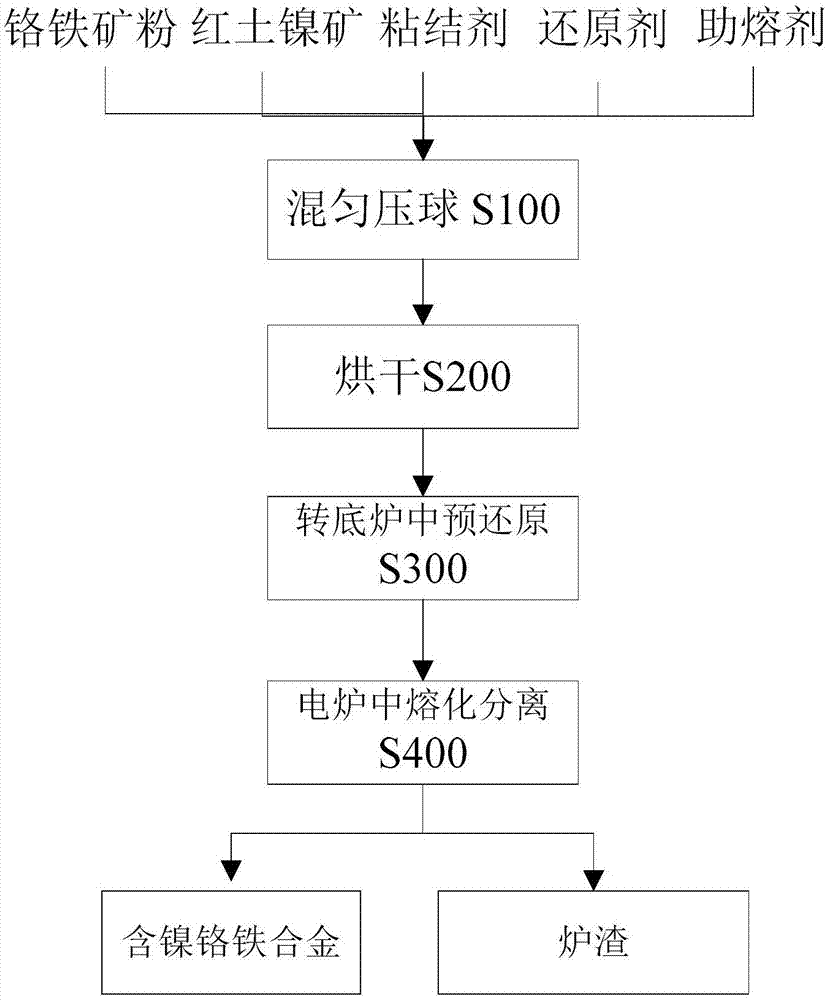

[0038] Such as figure 1 As shown, in step S100, the above-mentioned raw materials are mixed according to the above-mentioned proportions, and after mixing evenly, water is added to make the water content of the mixed raw materials 7%, and then the pellets are obtained by briq...

Embodiment 2

[0040] The Cr of the chromite powder that present embodiment uses 2 o 3 The content is 41.24%, the TFe (total iron) content is 21.0%, the Ni content of lateritic nickel ore is 1.70%, and the MgO content is 19.17%.

[0041] Take 100 parts of chromite powder, 100 parts of laterite nickel ore, 18 parts of semi-coke, 1 part of bentonite, and 10 parts of silica, and control the ratio of magnesium to aluminum to 1.20; grind the laterite nickel ore to a particle size below 100 mesh, accounting for 83% ; The semi-coke with a carbon content of more than 75% is ground to a particle size below 200 mesh, accounting for 90%; the particle size of silica ground to a particle size below 200 mesh accounts for 92%.

[0042] Such as figure 1 As shown, in step S100, the above-mentioned raw materials are mixed according to the above-mentioned proportions, and after mixing evenly, water is added to make the water content of the mixture 10%, and then briquetting is performed to obtain pellets. In...

Embodiment 3

[0044] The Cr of the chromite powder that present embodiment uses 2 o 3 The content of TFe (total iron) is 41.24%, and the content of TFe (total iron) is 21.0%. The content of Ni in lateritic nickel ore is 1.70%, and the content of MgO is 19.17%.

[0045] Take 100 parts of chromite powder, 60 parts of laterite nickel ore, 10 parts of semi-coke, 2 parts of bentonite, and 6 parts of silica, and control the ratio of magnesium to aluminum to 1.06. The particle size of the laterite nickel ore that is ground to below 100 mesh accounts for 80%; the particle size of semi-coke with a carbon content of more than 75% that is ground to below 200 mesh accounts for 80%; the particle size of silica that is ground to below 200 mesh accounts for 80%. than 80%.

[0046] Such as figure 1 As shown, in step S100, the above-mentioned raw materials are mixed according to the above-mentioned proportions, and after mixing evenly, water is added to make the water content of the mixed raw materials 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com