Steam-huff-and-puff oil production method assisted by injection of air and carbon dioxide

A carbon dioxide and auxiliary steam technology, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of not very large energy enhancement effect, limited application scale, adverse environmental impact, etc., to improve the production rate , the effect of reducing cold damage and improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

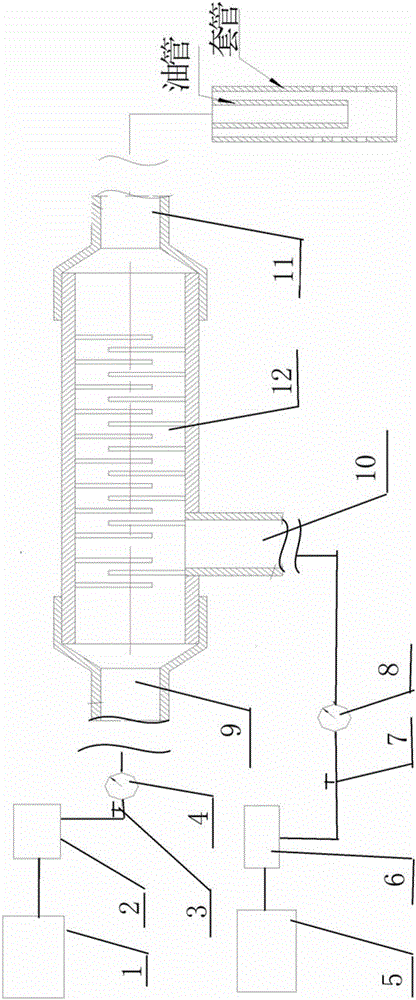

Image

Examples

Embodiment

[0046] This embodiment provides an air injection and carbon dioxide assisted steam huff and puff oil recovery method, which includes the following steps:

[0047] Step 1. Set injection and production wells and adjacent wells: take the injection and production wells as the center, and the adjacent wells in the same oil layer as the radius, and divide the surrounding adjacent wells with one well spacing, two well spacing, and three times well spacing respectively Adjacent wells on the first line, adjacent wells on the second line, and adjacent wells on the third line;

[0048] On-line measurement of oxygen content in casing gas of injection wells and adjacent wells;

[0049] Step 2. On-line determination of the oxygen content of the casing gas in the injection well is higher than the explosion point, inject carbon dioxide (or nitrogen or a mixture of carbon dioxide and nitrogen) into the injection well, and use the casing gas of the injection well to The oxygen content is lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com