Patents

Literature

108results about How to "Reduce smelting power consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintering technology of ferrochrome mineral powder

Owner:CENT SOUTH UNIV

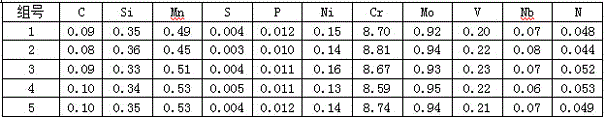

Method for smelting martensitic stainless steel P91 for boiler pipe

ActiveCN106636953AImprove melting efficiencyReduce consumptionElectric arc furnaceMartensitic stainless steel

The invention belongs to the technical field of smelting, and mainly relates to a method for smelting martensitic stainless steel P91 for a boiler pipe. The technological process of an electric arc furnace / medium-frequency induction furnace, an argon-oxygen refining furnace, an LF refining furnace, vacuum degassing, LF and continuous casting is adopted. Components for smelting the martensitic stainless steel for the boiler pipe comprise, by mass percent, 0.08%-0.12% of C, 0.30%-0.50% of Si, 0.30%-0.60% of Mn, not larger than 0.015% of P, not larger than 0.010% of S, not larger than 0.40% of Ni, 8.5%-9.5% of Cr, 0.90%-1.10% of Mo, 0.18%-0.30% of V, not larger than 0.30% of Cu, 0.03%-0.07% of N, 0.05%-0.10% of Nb, not larger than 0.020% of Al, not larger than 0.015% of [As], not larger than 0.010% of [Sn], not larger than 0.010% of [Pb], not larger than 0.010% of [Sb], not larger than 0.010% of [Bi] and the balance Fe and a small quantity of other elements. The method for smelting the martensitic stainless steel P91 for the boiler pipe aims to be low in inclusion content and delta-ferrite content and capable of achieving continuous casting production.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

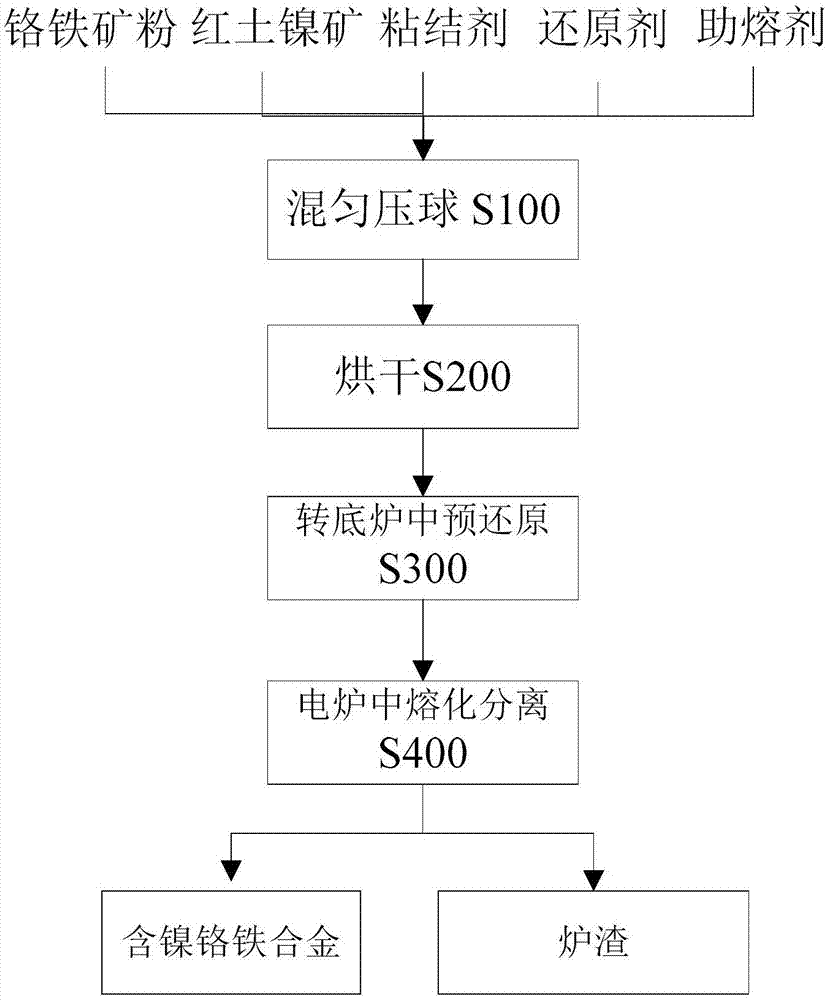

Method for smelting nickel-containing ferrochrome alloy

The invention relates to a method for smelting nickel-chromium ferroalloy, which comprises the following steps: uniformly mixing the ground laterite nickel ore with chromite powder, reducing agent, binder and fluxing agent to prepare balls The pellets are placed in a rotary hearth furnace for high-temperature reduction to obtain metallized pellets; the metallized pellets are sent to an electric furnace for high-temperature melting and separation to obtain nickel-chromium-iron alloys. The present invention uses the easy-to-form characteristics of laterite-nickel ore by mixing ingredients with chromite ore and high-magnesium laterite-nickel ore, reduces the addition of binders, and molds cheap and difficult-to-form chromite powder ore, reducing the Production cost; all raw materials are pre-mixed, the ingredients are relatively uniform, and the smelting time is shortened; the pellets are pre-reduced at high temperature in the rotary hearth furnace, which effectively reduces the power consumption of the electric furnace smelting; at the same time, due to the introduction of Ni in the laterite nickel ore, nickel-containing The ferrochrome alloy further obtained low-cost raw materials for smelting stainless steel.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

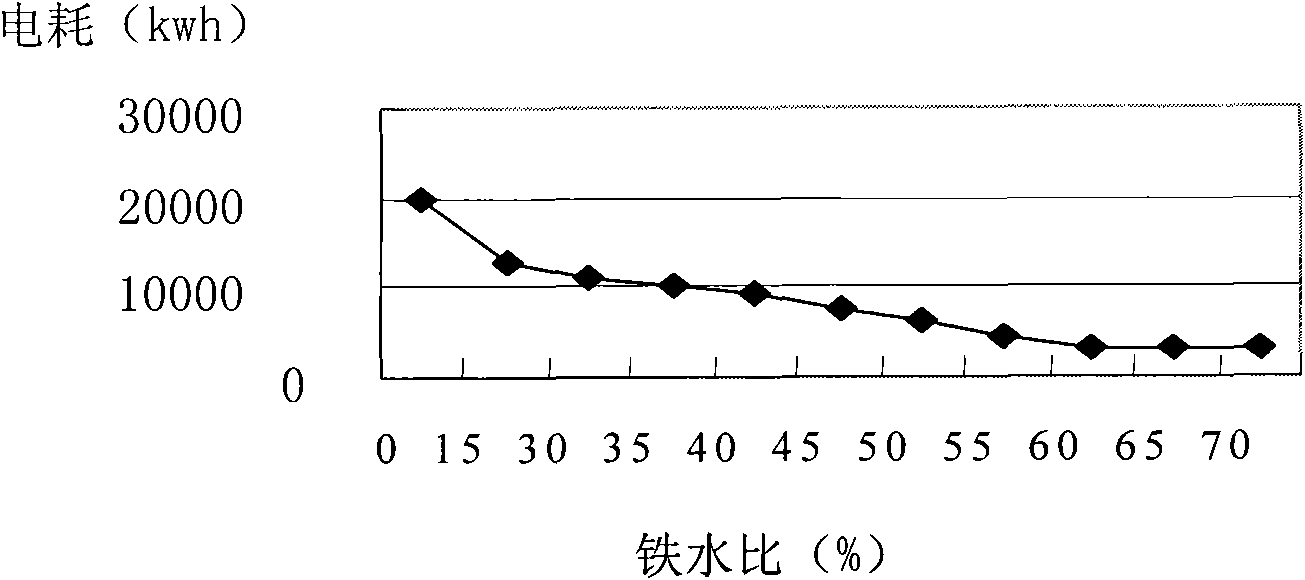

Electric furnace burden process with high efficiency and low cost

InactiveCN101660019ARaise the endpoint componentIncrease temperatureProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention relates to an electric furnace burden process with high efficiency and low cost. Main raw materials are molten iron accounting for 30-60 percent of metal adding amount, excellent scrap steel accounting for 5-10 percent of metal adding amount and low-lost scrap steel accounting for 30-35 percent of metal adding amount; auxiliary materials are lime and soft burning dolomite, wherein 3.0-3.5 percent of lime and 1.0-1.5 percent of soft burning dolomite are respectively added in each ton of molten steel; and through optimizing electric furnace slag discharge operation, using an oxygenlance and adopting power supply oxygen blowing control and other smelting processes, the electric furnace burden process greatly improves simultaneous hit rate of terminal point components and the temperature of an electric arc furnace, realizes the aims of improving the quality of the molten steel, shortening the smelting period and reducing the consumption and significantly reduces the full oxygen content of steel products at the same time. The electric furnace burden process has good application prospect for ensuring the quality of steel and reducing the production cost.

Owner:KUNMING IRON & STEEL

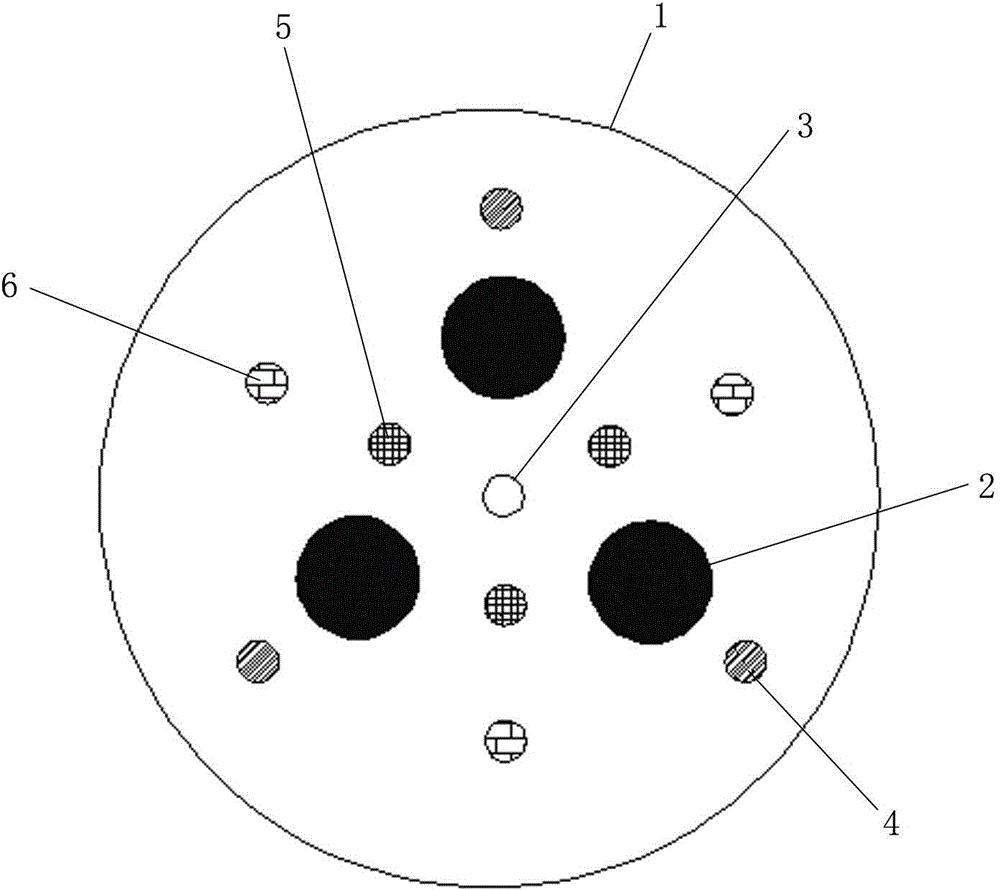

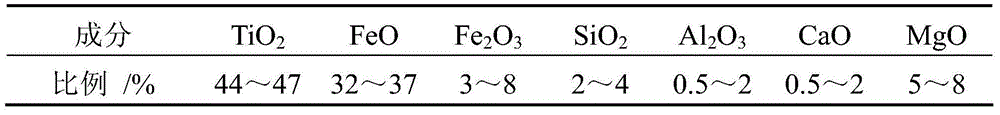

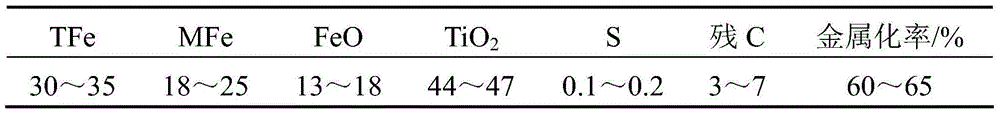

Method for preparing titanium slag by electric furnace-smelted and pre-reduced pellets

ActiveCN104087710AReduce smelting power consumptionSafe and stable operationProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention discloses a method for preparing titanium slag by electric furnace-smelted and pre-reduced pellets. The method comprises the following steps of: taking pre-reduced pellets as materials, wherein the pre-reduced pellets are obtained by pre-reducing titanium-containing magnetite concentrates, and according to the weight percentage, a metallization ratio of the pre-reduced pellets is not lower than 60wt%, and residual carbon content is 3-8wt%; adding the raw materials into an electric furnace in batches, and supplying power for smelting, wherein in an adding process, furnace voltage of the electric furnace is controlled to minus 80 to minus 120Pa; in a normal smelting process, furnace voltage of the electric furnace is controlled to plus 10 to minus 10Pa; under the condition that power delivery amount of the electric furnace reaches total feeding amount tonnage value*(1.1-1.3MWh), an electrode seat has no greater fluctuation after stably operating for 10-30 minutes, a flue smoke gas temperature is stabilized to a temperature range of + / -5DEG C for 10-30 minutes, and the temperature is lower than a smelting early-stage temperature and titanium slag grade is 72%-77%, slag tapping and iron tapping are carried out.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

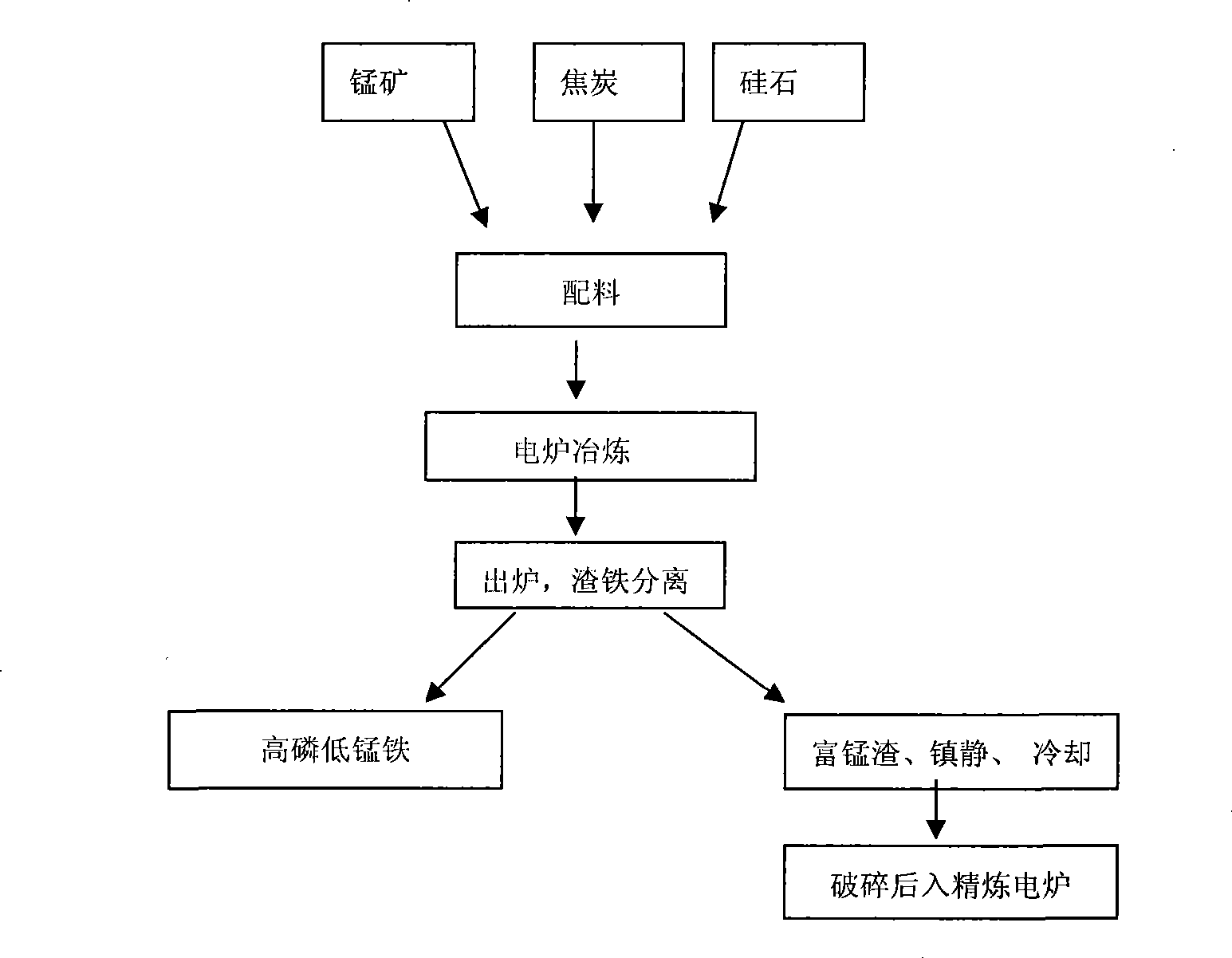

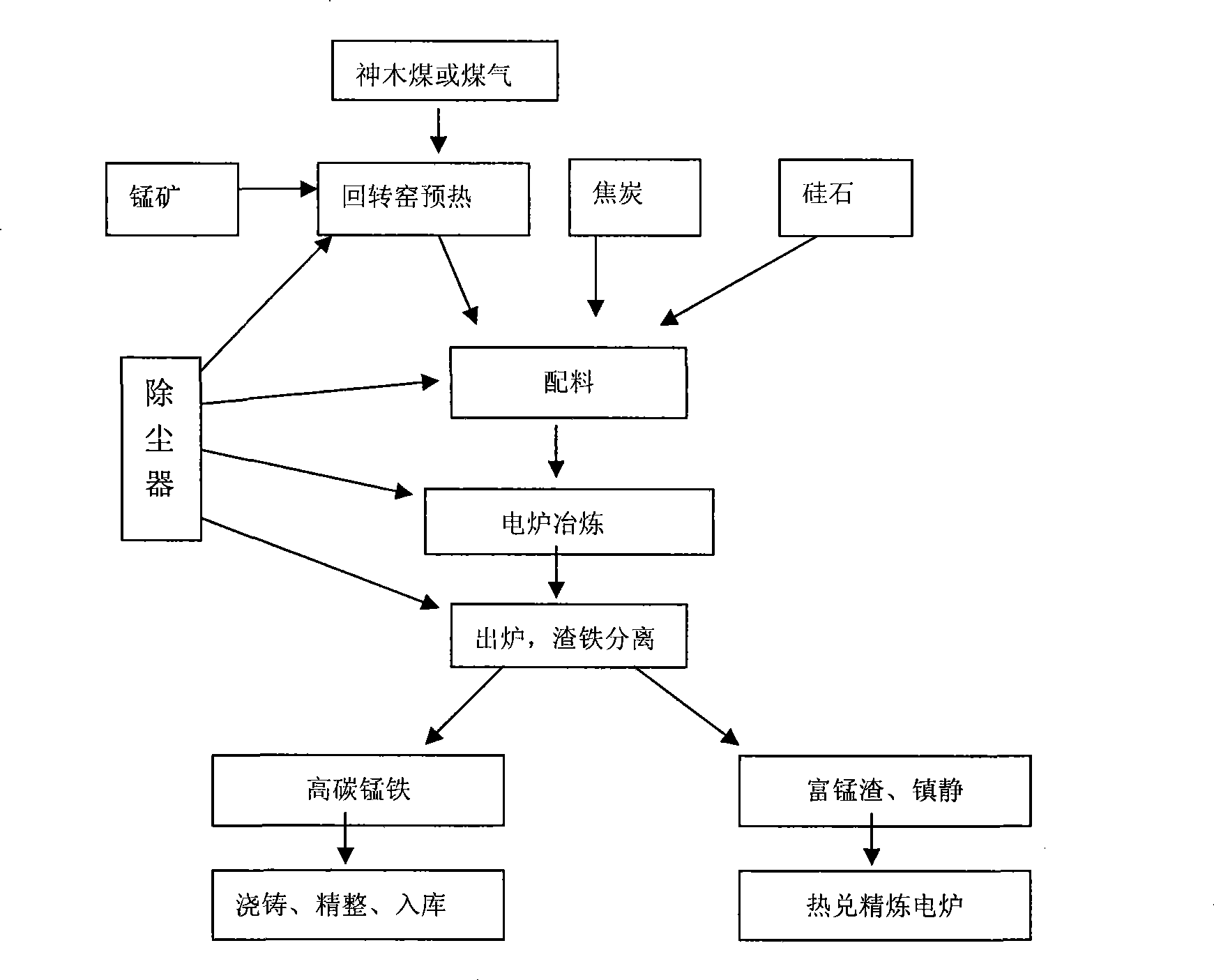

Electric furnace smelting process for manganese-rich slag

ActiveCN101481757AReduce smelting power consumptionReduce consumptionTemperature controlSmelting process

The invention belongs to the process for smelting manganese-rich slag, and particularly relates to the process for smelting the manganese-rich slag using an electric furnace. The invention, which solves the problems that the process for smelting the manganese-rich slag is energy-intensive, operationally dangerous and consumptive, is characterized in that manganese ore is pre-heated by a rotary kiln, wherein, the temperature, at which the manganese ore is pre-heated in the rotary kiln, is controlled within 900 to 1,100 DEG C; and the charging temperature of the manganese ore to be pre-heated is controlled above 600 DEG C. Compared with the prior art, the invention has the following beneficial effects: the power consumption for smelting is remarkably reduced; the production capacity of the electric furnace is expanded; the operating rate thereof is increased; the working condition is improved; and the labor productivity and the labor safety are improved.

Owner:JIAOCHENG YIWANG FERROALLOY

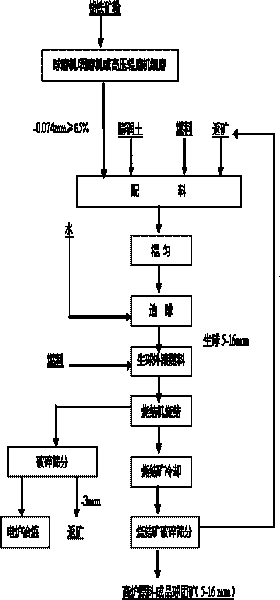

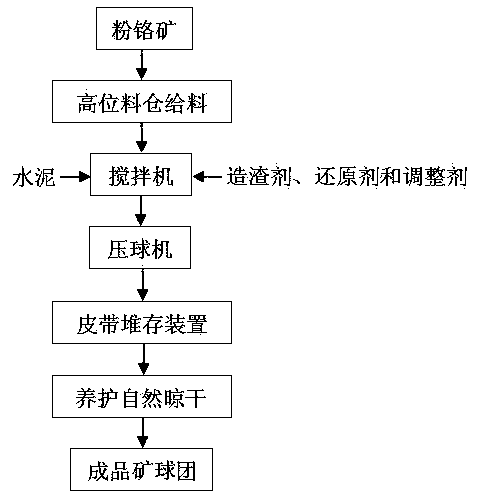

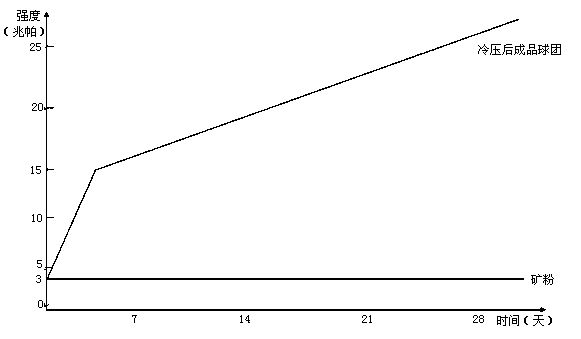

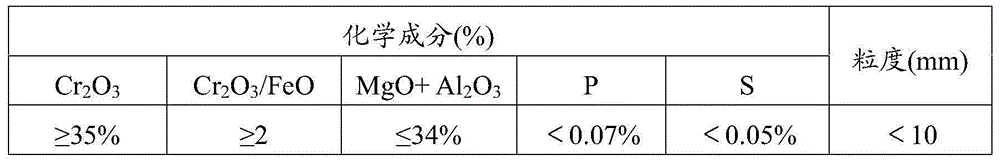

Method for preparing chrome ore pellets

The invention discloses a method for preparing chrome ore pellets and relates to a preparation method of cold-pressing pallets with raw material chrome ore (particle size of 10mm) in a ferrochrome metallurgy production process. The method is characterized by comprising the preparation process: adding a binder, a slag former, a reducing agent and a modifier to chrome ore, evenly mixing, adding water to regulate the humidity, conducting cold pressing to make pellets, then naturally curing and airing to prepare the finished pellets. The method for preparing the chrome ore pellets is simple in technique; the usage amount of auxiliary materials for producing ferrochrome can be reduced; the smelting power consumption of unit product of high-carbon ferrochrome Cr50 can be reduced; the high-carbon ferrochrome can be produced through single mineral. The method achieves the purposes of improving the production efficiency, lowering the cost and being energy-saving and consumption-reduction.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

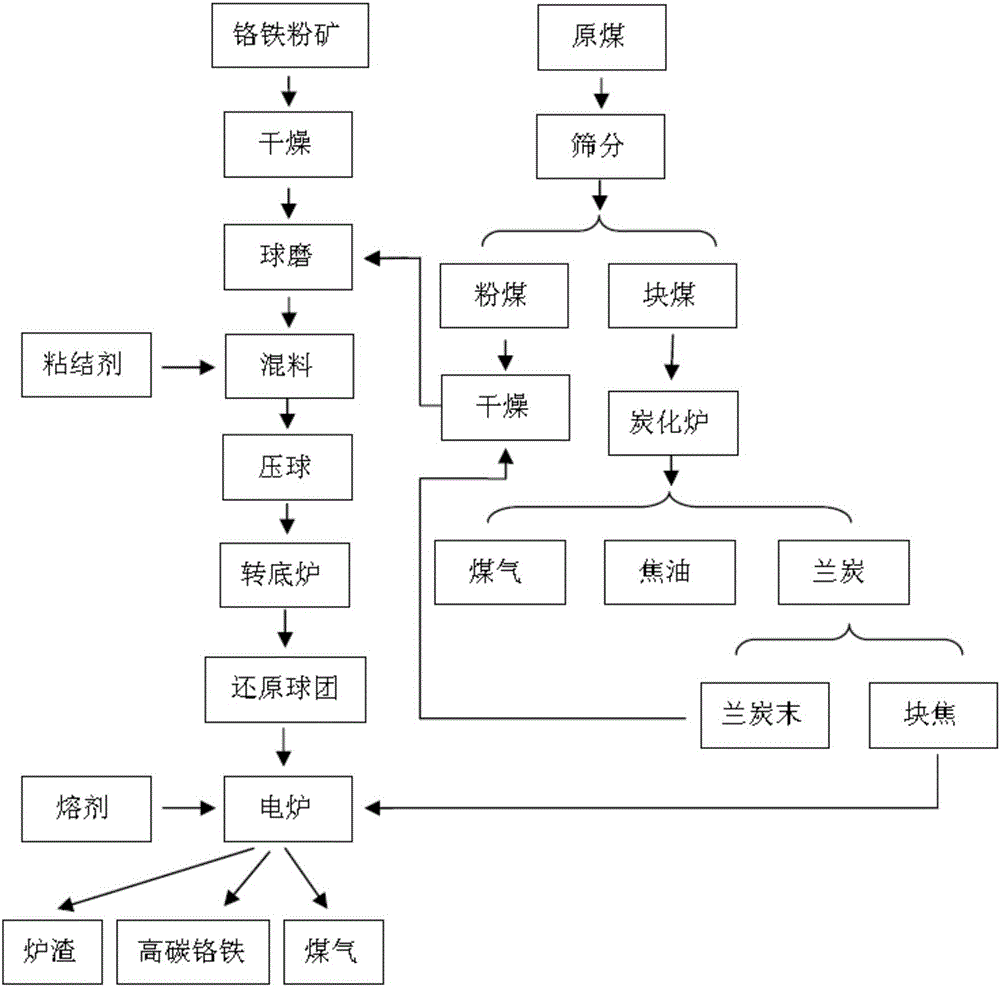

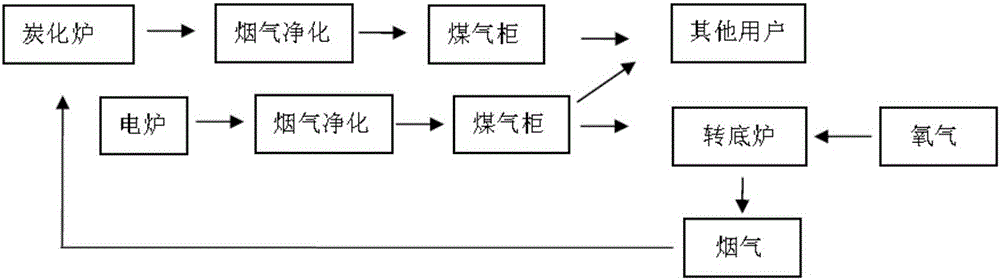

Combined production process for high-carbon ferro-chrome and semi-coke

ActiveCN105112663AImprove resource utilizationEfficient use ofSpecial form destructive distillationHearth type furnacesElectricityAdhesive

The invention provides a combined production process for high-carbon ferro-chrome and semi-coke. The combined production process for the high-carbon ferro-chrome and the semi-coke comprises the steps that coal and ferro-chrome fine ore are prepared and used as raw materials; lump coal is subjected to pyrolysis and carbonization to obtain the semi-coke; the ferro-chrome fine ore, pulverized coal and semi-coke powder are ground in a mixed mode, and adhesives and water are added to obtain green pellets; the green pellets are arranged in a rotary hearth furnace to be subjected to high-temperature roasting and reduction, and the reduced pellets are obtained; and the reduced pellets are cooled, mixed with lump semi-coke and flux, and then added into a closed electric furnace to be smelted, and high-carbon ferro-chrome producted are obtained. During the process, the electricity consumption for smelting of the electric furnace is 2400 kw*h / t.

Owner:BERIS ENG & RES CORP

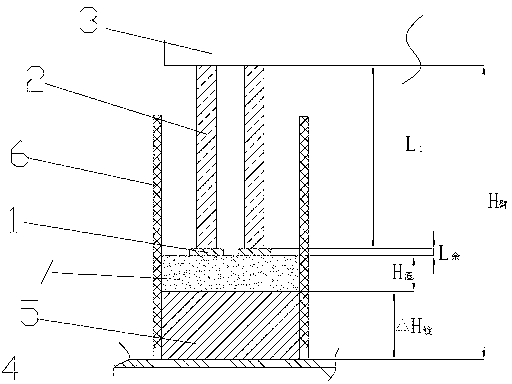

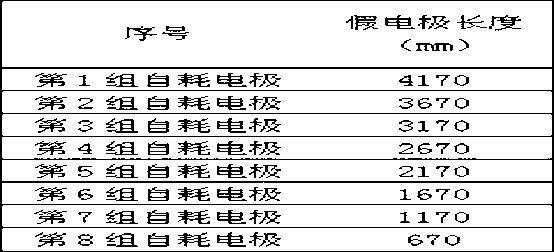

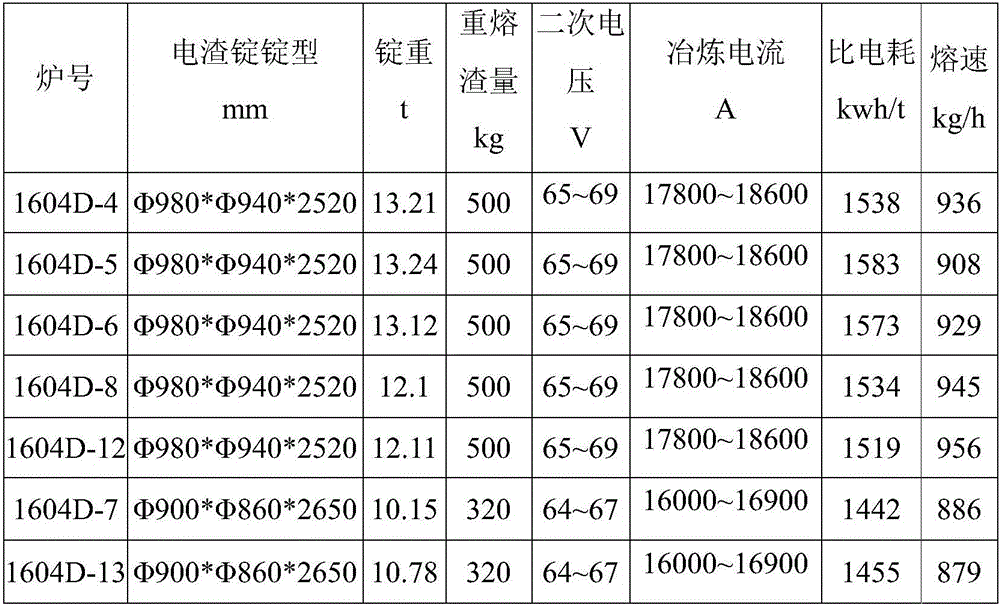

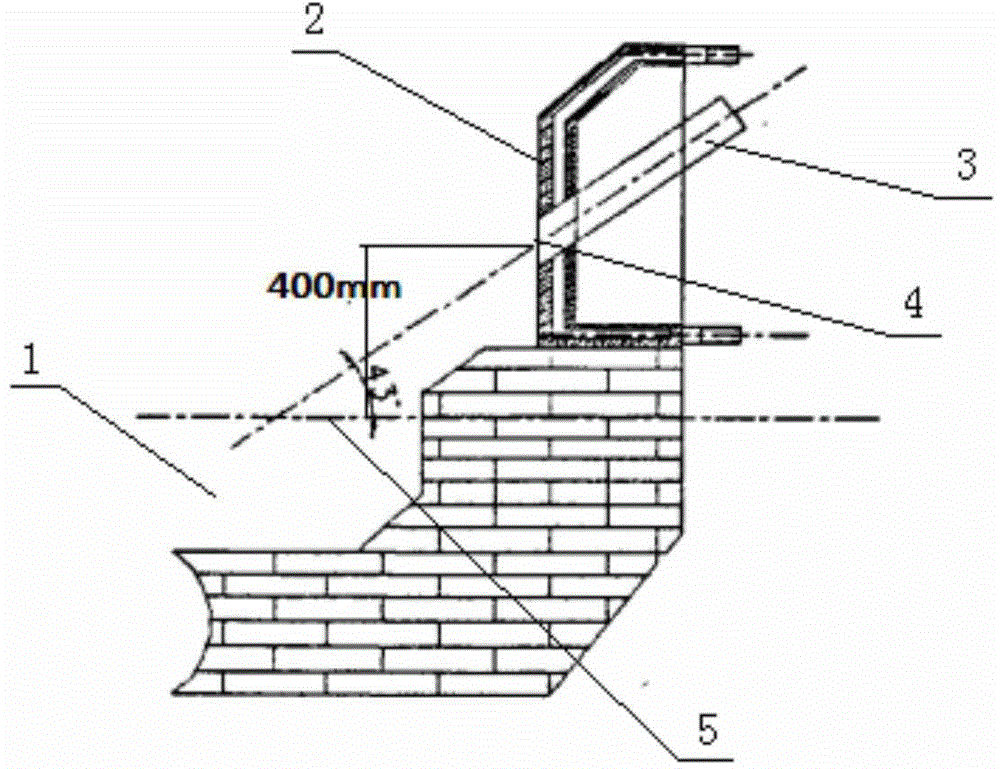

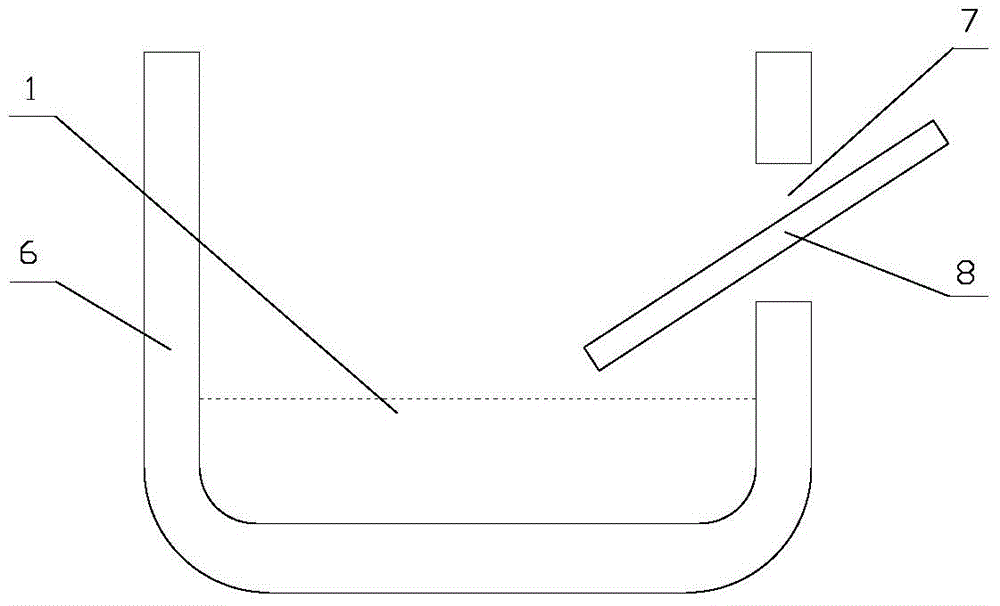

Method of accurately controlling consumable electrode remainder in electroslag remelting

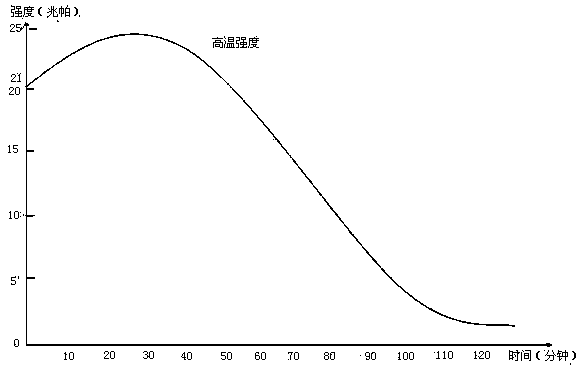

The invention discloses a method of accurately controlling consumable electrode remainder in electroslag remelting, and the method comprises the following steps: (1) designing the consumable electrode remainder length as L remainder; (2) designing the false electrode lengths of the groups of consumable electrodes: the false electrode length L1 of the first group of consumable electrodes is equal to H arm- L remainder-delta H ingot-H slag, the false electrode length Ln of the nth group of the consumable electrodes is equal to L1-(n-1)*delta H ingot, in the formula, L remainder refers to the designed remainder length of the consumable electrode, H arm refers to the vertical distance from the bottom end of the cross arm to the soleplate when the cross arm reaches the lower limit, delta H ingot refers to the added height of the electroslag ingot when each group of consumable electrodes is smelted until the cross arm reaches the lower limit, and H slag refers to the thickness of the slag; and (3) remelting the electroslag. The method disclosed by the invention has such beneficial effects as accurately controlling the consumable electrode remainder length, improving the utilization rateof the consumable electrode, avoiding the quality accident of changing the electroslag ingot component caused by adding the false electrode in the furnace by mistake, reducing the smelting electric consumption and reducing the production cost of the electroslag ingot and the like.

Owner:ZHEJIANG ELECTROSLAG NUCLEAR MATERIAL

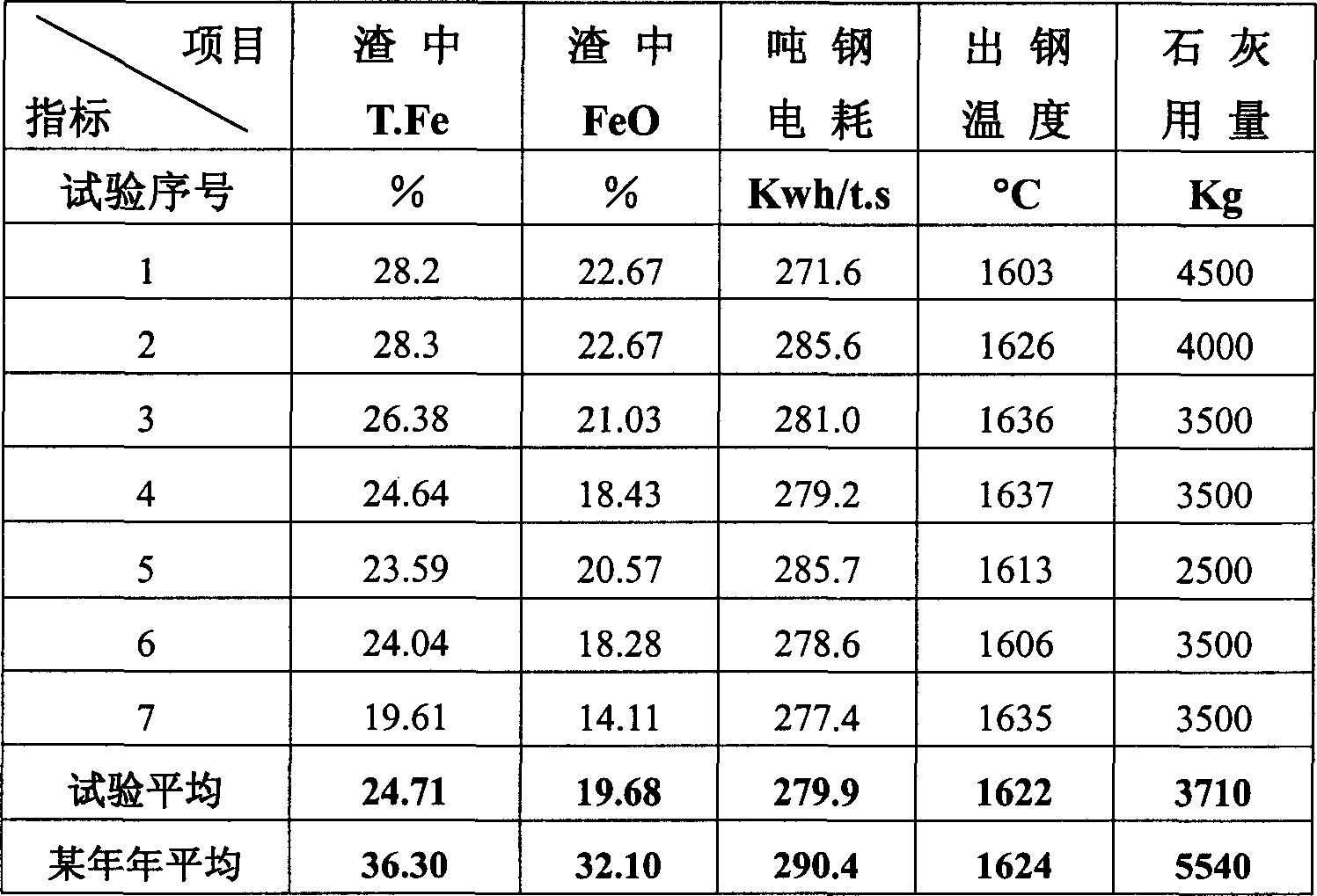

Slag regulating agent for super high power large electric furnace smelting

ActiveCN1782101AReduce iron contentTotal iron content dropped toProcess efficiency improvementElectric furnaceElectricityElectric arc furnace

The present invention relates to super high power arc furnace smelting technology, and is especially slag regulating agent for super high power large electric furnace. The present invention features that the slag regulating agent consists of C 30-35 wt%, Al 5-7 wt%, MgO 8-10 wt%, Al2O3 10-12 wt%, CaO 20-25 wt%, SiC 9-10 wt% and impurity the rest, and has bulk density of 1.8-2.0 g / cu cm. The slag regulating agent of the present invention can form homogeneous foamed slag continuously in the furnace to reduce FeO, Fe2O3, etc. in the slag layer, raise smelting yield, raise steel alloy yield, raise the heat efficiency of the furnace, lower power consumption, raise the dephosphorization capacity of the furnace and prolong the service life of the furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

Top oxygen gun blowing technology for electric furnace steel making

InactiveCN1450177AShorten smelting timeIncrease profitProcess efficiency improvementElectric furnaceSlagCopper

The present invention belong to the field of metallurgical technology, in particular, it relates to an electric furnace steel-smelting oxygen gun converting process. It is characterized by that on the furnace cover of electric furnace an opened hole is set, the size of said opened hole is 50-500 nm, the oxygen gun can be fallen downward to a distance 200-1000 mm from molten steel surface by meansof a lifting mechanism to make decarbonization and slag-forming operation, said oxygen gun adopts water-cooling mode, its jet adopts supersonic jet, its Mach number is 1.6-2.2, oxygen gun nozzle number is 1-3, oxygen gas flow rate is 800-1000 N cu.m / h. oxygen gas pressure is 0.6-1.2 MPa, and water inlet and outlet flow rate of oxygen gun is 10-60 t / h, said oxygen gun has a copper-steel composite copper head.

Owner:UNIV OF SCI & TECH BEIJING

Smelting technique of brown corundum

InactiveCN102815731AReduce smelting power consumptionImprove securityEnergy inputAluminium oxides/hydroxidesThermal insulationElectricity

The invention discloses a smelting technique of brown corundum, which comprises the following steps: 1. adding pulverized raw alumina, which satisfies the particle size requirement, into a rotary kiln or shaft kiln, and roasting to 1200 DEG C by using heat from coal gas generated by a generating furnace; 2. sending the roasted alumina material into a thermal insulation charging basket, proportionally adding a carbon material and iron chips, and transferring into a thermal insulation storage bin; and 3. sending the material in the thermal insulation storage bin in the step 2 into an electric furnace by using a feeder, continuing heating for smelting until the reaction is complete, inspecting, cooling and grading to obtain the finished product. The smelting can also be carried out after pulverizing, mixing, granulating and roasting the three raw materials. The invention can lower the power consumption for smelting and enhance the safety of the smelting technique. The smelting technique does not need to use cured alumina, but only uses raw alumina, thereby greatly lowering the raw material cost; and the material is roasted in the rotary kiln or shaft kiln, and added into the electric furnace for smelting while the material is hot, thereby utilizing the waste heat of roasting and saving the electric power.

Owner:王洪仁

Electric-arc furnace converter process for smelting steel and iron slag

ActiveCN103667590AShort smelting timeShorten smelting timeProcess efficiency improvementElectric furnaceMelting tankElectric arc furnace

The invention discloses an electric-arc furnace converter process for smelting steel and iron slag, belongs to the field of metallurgy, and aims to solve the technical problem about providing the electric-arc furnace converter process for smelting steel and iron slag with short duration of heat and low power consumption. In order to solve the technical problem, the invention provides the following technical scheme: furnace burden comprises molten iron, steel and iron slag, and steel scrap; molten iron is put into the furnace to enable the tapping of the molten iron accounts for 30-60% of that of all furnace burden; steel and iron slag is put into the furnace to enable the tapping of the steel and iron slag accounts for 35-70% of that of all furnace burden; when the steel scrap is put into the furnace for the first time, the tapping of the steel scrap accounts for 0-5% of that of all furnace burden; when the steel and iron slag is put into the furnace for the first time, the steel scrap is also put into the furnace, and the steel scrap is distributed on the steel and iron slag. With adoption of the process, the physical and chemical heat brought about by the molten iron is fully utilized to accelerate furnace burden melting and formation of the furnace burden in the furnace hearth, shorten melting time, reduce smelting power consumption, improve productivity and reduce production cost.

Owner:RUI STEEL INDAL OF PANZHIHUA GANGCHENG GROUP

Process for smelting MC5 roller by using return scraps

InactiveCN103966385AHigh recovery rateImprove cleanlinessFoundry mouldsFoundry coresIntermediate frequencyDie casting

The invention relates to a process for smelting an MC5 roller by using return scraps. The process comprises the following steps: S01, selecting the return scraps as a furnace charge for smelting the MC5 roller; S02, feeding the return scraps selected in the step S01 to a medium-frequency induction furnace to melt as the furnace charge; S03, carrying out deoxidation and desulfurization on molten steel of the return scraps smelted in the step S02 in an LF (Ladle Furnace), and accurately adjusting the components of the molten steel; S04, pumping the molten steel processed in the step S03 in a VD (Vacuum Degassing) furnace in vacuum, enabling occluded foreign substances to float upwards, and removing harmful gases; and S05, carrying out die casting by using the molten steel processed in the step S04, so as to manufacture an MC5 roller steel ingot. The invention provides a metallurgical technology for increasing alloy utilization rate in the return scraps and producing the MC5 roller by using the return scraps produced in smelting, forging and machining processes.

Owner:ZHONGYUAN SPECIAL STEEL

Method for preparing titanium carbide slag by using titanium-containing slag

InactiveCN110106364AAvoid wastingEasy to adjustProcess efficiency improvementStable stateElectricity

The invention relates to the field of titanium-containing slag smelting methods, and particularly relates to a method for preparing titanium carbide slag by using titanium-containing slag which shortens reaction time and reduces smelting power consumption. The method comprises the following steps of, a, adding titanium-containing slag into a submerged arc furnace or an electric arc furnace and increasing the temperature; and when the temperature reaches a set value, adding a carbonaceous reducing agent, and making the carbonaceous reducing agent react with the titanium-containing slag in the furnace; b, taking a flue gas temperature and a CO concentration value in the furnace as a judgment basis of a reaction control, and adjusting an input power and a feeding speed of the reducing agent according to the flue gas temperature and the CO concentration value in the furnace, thus making the CO concentration value the control reaction maintain the optimal stable state; and c, ending the feeding of the reducing agent; and when the CO concentration value gradually falls to the set concentration, starting slag tapping, ending the reaction, and obtaining the titanium carbide slag. Accordingto the method, the reaction time can be shortened, the smelting power consumption can be reduced, and the technical economy of preparing the titanium carbide slag by using the titanium-containing slag is improved; and the method is particularly suitable for the process of preparing the titanium carbide slag by using the titanium-containing slag.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for shortening sintering time of resistant material of electric furnace at time of opening new furnace

The present invention discloses a method used for shortening the sintering time of the refractory material of an electric furnace when a novel furnace is opened. Before the production of the first furnace of the newly opened furnace, a layer of petroleum coke recarbonizer is spread uniformly on the ramming material that has been arranged on the slope of the bottom of the furnace. The method can shorten the sintering time of the refractory material of the electric furnace when a novel furnace is opened, save the energy consumption of the electric furnace, and improve the quality of electric steelmaking. At the same time, the method ensures the excellent sintering effects of the refractory material on the bottom of the furnace, and prolongs the service life of the refractory material.

Owner:JIANGSU SUZHOU STEEL GRP

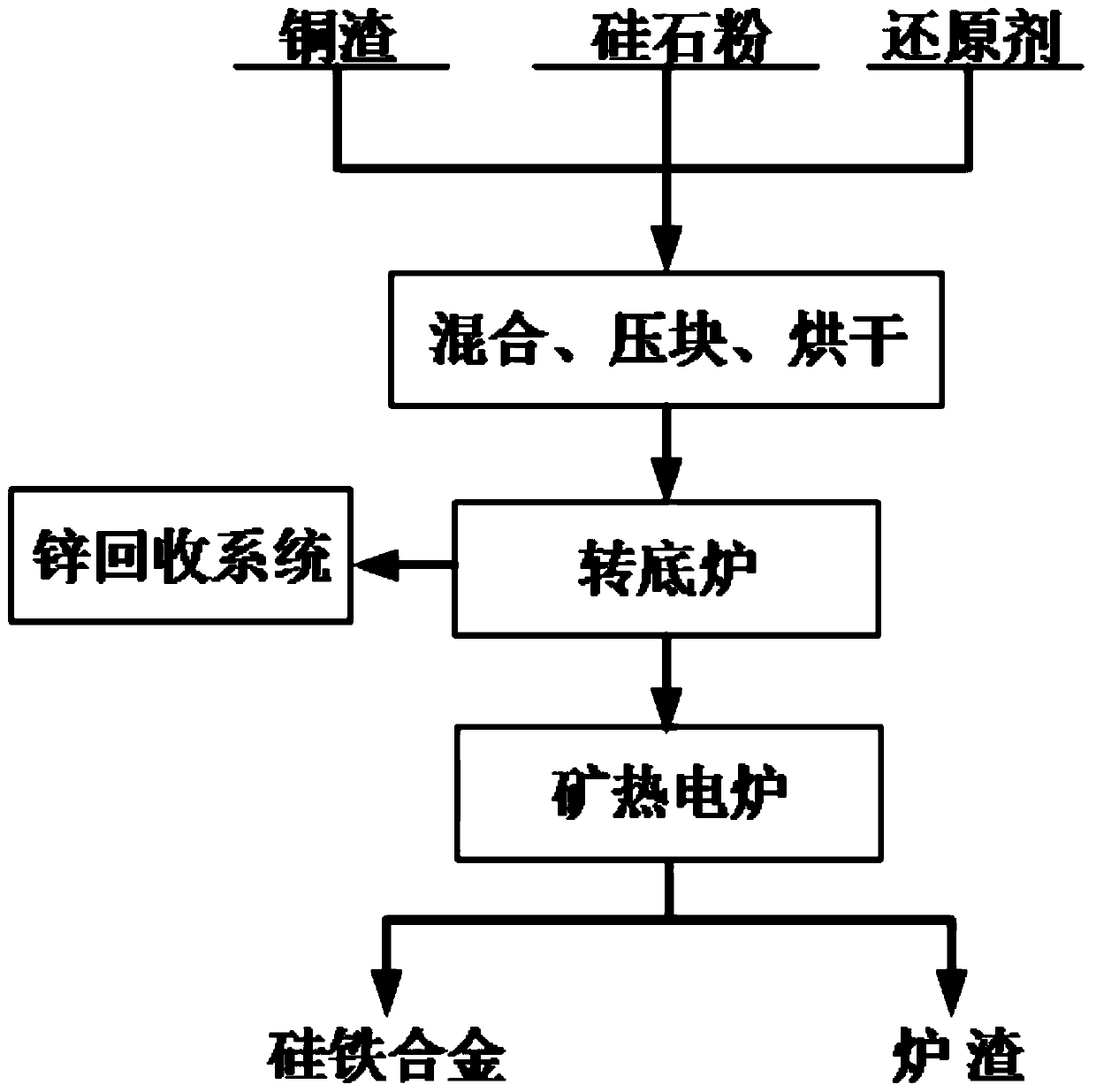

Copper slag treatment method by utilizing rotary hearth furnace direct reduction and ore-smelting electric furnace smelting reduction

ActiveCN110669945ARealize resource utilizationReduce energy consumptionProcess efficiency improvementFerrosiliconIron alloys

The invention discloses a copper slag treatment method by utilizing rotary hearth furnace direct reduction and ore-smelting electric furnace smelting reduction. The method comprises the following steps that 1) raw materials are treated, specifically, copper slag, silica powder, a reducing agent and a binder are prepared and mixed, then are prepared into copper slag carbon-containing pellets through a pelletizing process, and the copper slag carbon-containing pellets are dried for later use; 2) rotary hearth furnace reduction and pellet coking enhancing are conducted, specifically, the copper slag carbon-containing pellets are fed into the rotary hearth furnace for reduction to obtain zinc oxide powder and metalized pellets; and 3) ferrosilicon smelting is conducted, specifically, the high-temperature metalized pellets discharged from the rotary hearth furnace are directly fed into the ore-smelting electric furnace for smelting to obtain a ferrosilicon iron alloy and the slag. Accordingto the method, an innovative process of the rotary hearth furnace reduction and ore-smelting electric furnace smelting combination is adopted, a zinc element is recycled in the rotary hearth furnaceto obtain high-value-added zinc oxide powder, the high-temperature metalized pellets discharged from the rotary hearth furnace are directly hot-loaded into the ore-smelting electric furnace for smelting, the process that traditional cold burden inlet into the furnace needs to consume electric energy for heating is omitted, and the power consumption and the raw material cost are greatly saved.

Owner:宝武集团环境资源科技有限公司

Electric furnace smelting stainless steel slagging method

InactiveCN102373313AReduce smelting power consumptionShorten smelting timeElectric furnaceProcess efficiency improvementScrapFerrosilicon

The invention relates to an electric furnace smelting stainless steel slagging method, which comprises the following steps sequentially: I electric furnace charging: materials are added into two material baskets in two times, 40+ / -4 of nickel recirculating scrap, 35+ / -4 of nickelic pig iron, 20+ / -2 of high carbon ferrochrome and 10+ / -1 of waste slag are added into the material basket 1, 10+ / -1 of nickel recirculating scrap, 45+ / -4.5 of nickelic pig iron and 15+ / -1.5 of high carbon ferrochrome are added into the material basket 2, and the material basket 1 is firstly charged; II after charging materials in the electrochemical material basket 1 are sent into an electric furnace, a first batch of pressed balls are added, and a second batch of pressed balls and lime are added for second charging; III electric furnace charging; IV electrochemical steel is sent, a third batch of pressed balls and lime are added, a furnace door oxygen lance starts to supply oxygen for fluxing, a fourth batch of pressed balls are added, a fifth batch of pressed balls are added, a sixth batch of pressed balls are added, power is transmitted, and the furnace door oxygen lance stops supplying the oxygen; and VI the power is transmitted to raise the temperature, ferrosilicon is added, and steel is tapped. In the electric furnace smelting stainless steel slagging method disclosed by the invention, stainless steel dedusting pre-reduction pressed balls are utilized to assist producing foamed slag.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

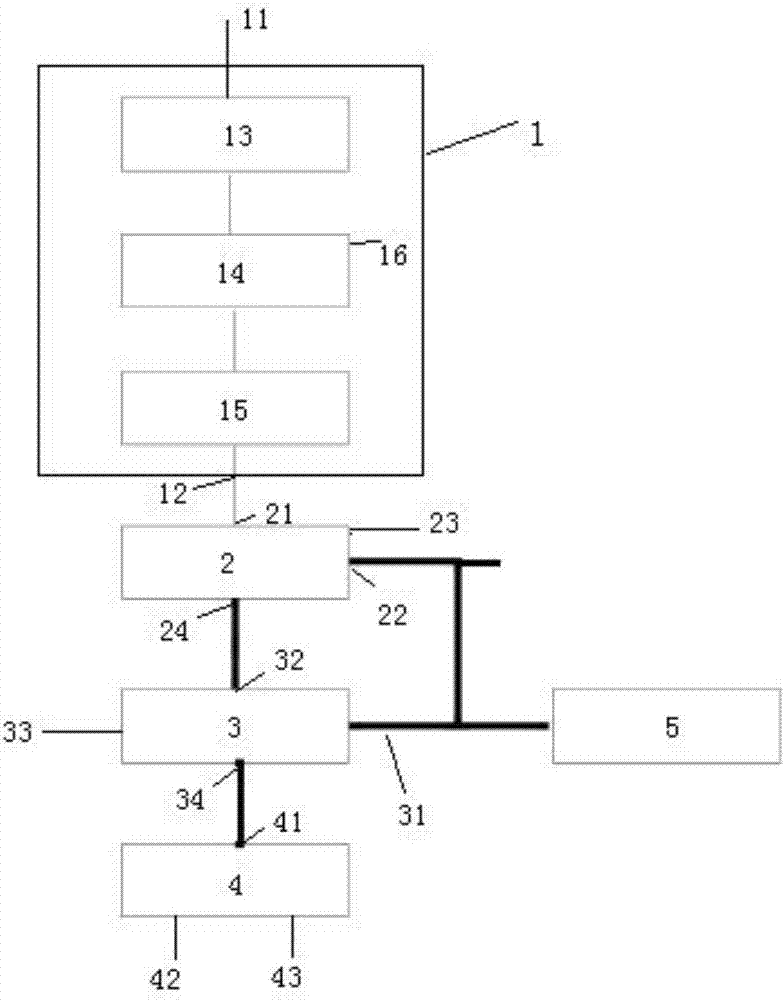

Smelting system and smelting method for mother liquid of stainless steel

InactiveCN107099659ALow costProportion adjustmentElectric furnaceProcess efficiency improvementThermal stateSlag

The invention relates to a smelting system and a smelting method for a mother liquid of stainless steel. The smelting system includes a mixing and pelletizing unit, a drying apparatus, a rotary hearth furnace, and an electric furnace. The mixing and pelletizing unit includes a raw material inlet and a pellet outlet; the drying apparatus includes a pellet inlet, a drying gas inlet, a flue gas outlet, and a dried pellet outlet; the pellet inlet is connected to the pellet outlet; the rotary hearth furnace includes a flue, a material distributing mouth, a burning nozzle, and a pre-reduced pellet outlet; the material distributing mouth is connected to the dried pellet outlet; the electric furnace includes a pre-reduced pellet inlet, an iron outlet and a slag outlet; the pre-reduced pellet inlet is connected to the pre-reduced pellet outlet. By means of the system and the method, ratio of chromite ore powder and iron ore is easy to control, and metallization ratio of thermal-state metallized pellet is high. So that a mother liquid of stainless steel, which includes required components, can be smelted in one step; the pellets are hot-delivered to the electric furnace with non-coke coal resource and hot delivery method which are low in cost, thus reducing cost and energy consumption.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

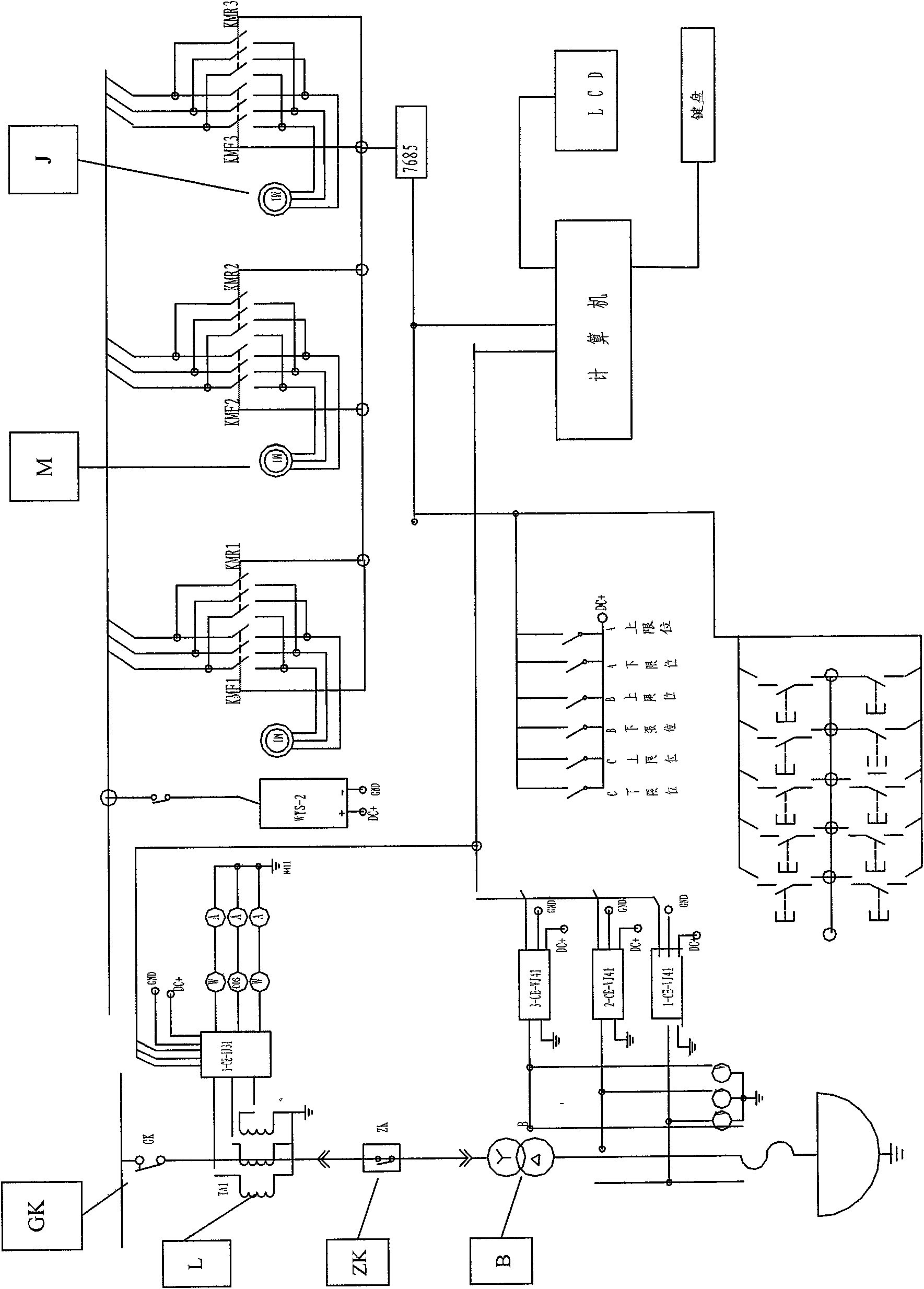

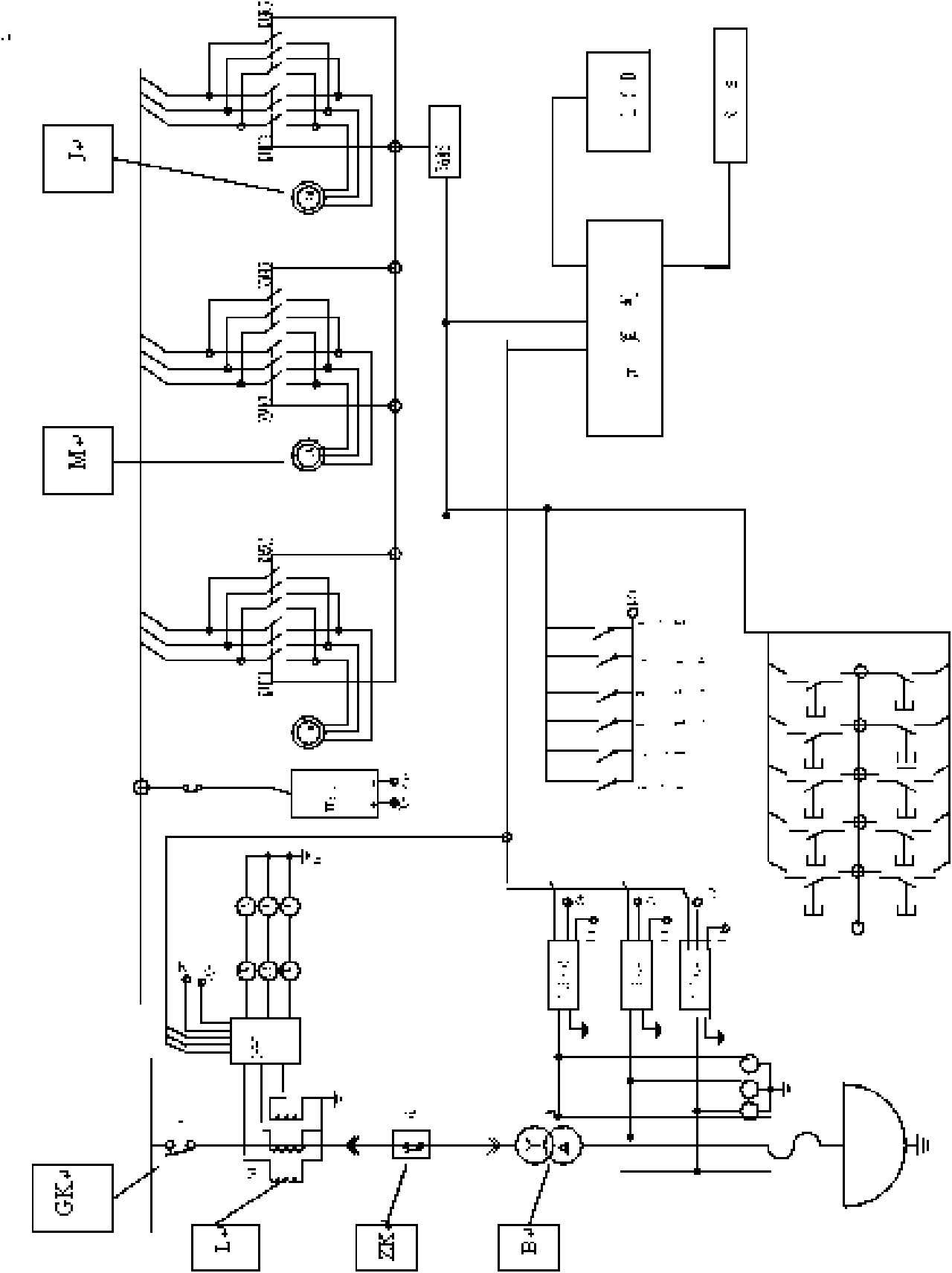

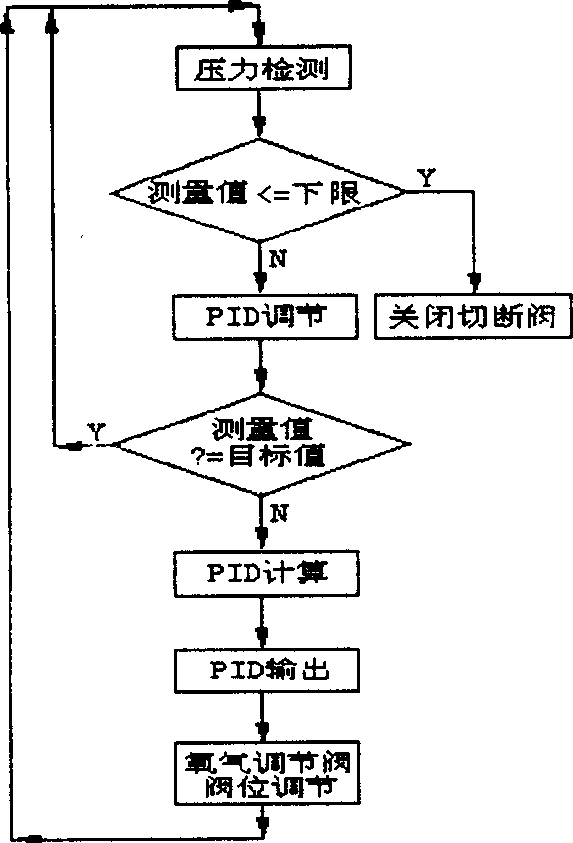

Method for clamping electrodes of automatic electrode control system of calcium carbide furnace

InactiveCN101572970AReduce smelting power consumptionIncrease productionElectric discharge heatingIncreasing energy efficiencyAutomatic Generation ControlElectric arc

The invention discloses a method for clamping electrodes of an automatic electrode control system of a calcium carbide furnace. According to the requirements of a smelted product and a process of the calcium carbide furnace on voltage, current and power, the numerical value of the current or the power is sent to a computer; a control system of the computer carries out comparison operation on a parameter value detected in real time and a set value, and then sends out a group of instructions to a control relay to drive an electric motor (or a hydraulic oil cylinder) to rotate so as to drive the electrodes to move up and down; and simultaneously, the computer calculates the vertical distance of the electrodes, and when the distance of any two-phase ends of the three-phase electrodes is greater than a given value, the electrodes are clamped. The method has the advantages that the ends of the three-phase electrodes are maintained between two given planes, the three-phase arc length and power are kept basically same, and the aims of improving electric and thermal efficiency, reducing smelting electricity consumption and improving yield are achieved.

Owner:成都高威节能科技有限公司

Method for recognizing electrode defection of yellow phosphorus stove electrode automatic control system

ActiveCN101527981AProtection from being brokenGuaranteed to proceed normallyElectric discharge heatingIncreasing energy efficiencyElectricityAutomatic control

The invention provides a method for recognizing electrode defection of a yellow phosphorus stove electrode automatic control system, comprising the following steps: pull difference value is calculated according to pull of 3 hoisting chains of each electrode; when pull difference value of any two hoisting chains is more than a given value, the polar electrode is judged to be in a deflective state, and then the polar electrode is needed to withdraw from the automatic control state , switches to a manual control state and gives a warning prompt. The positive effect of the method is: being capable of monitoring whether the electrode is deflective or not, effectively protecting the electrode from being snapped, maintaining normal operation of smelting process, so as to achieve the purpose of improving electric and thermal efficiency, reducing smelting power consumption and improving production.

Owner:南通江海港建设工程有限公司

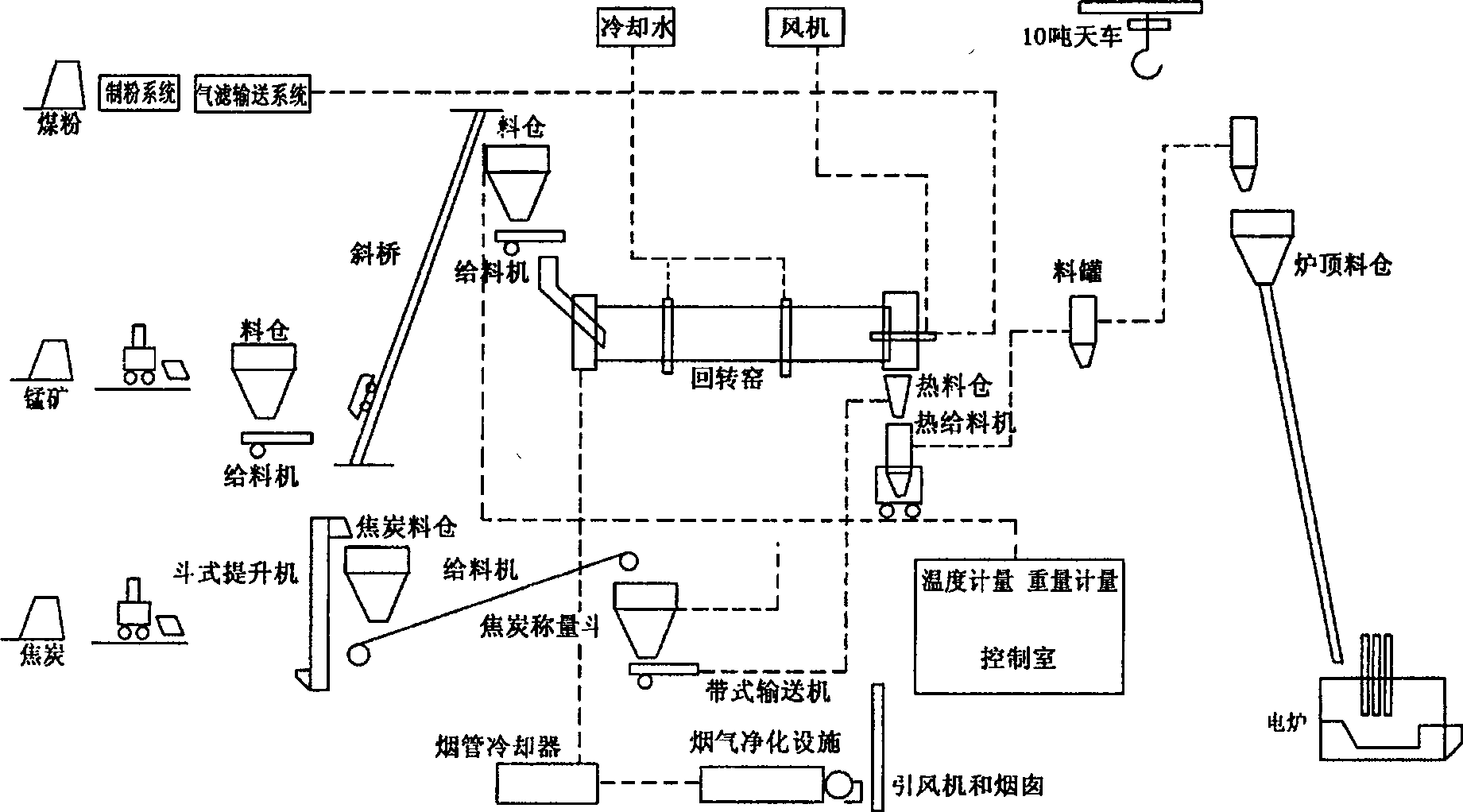

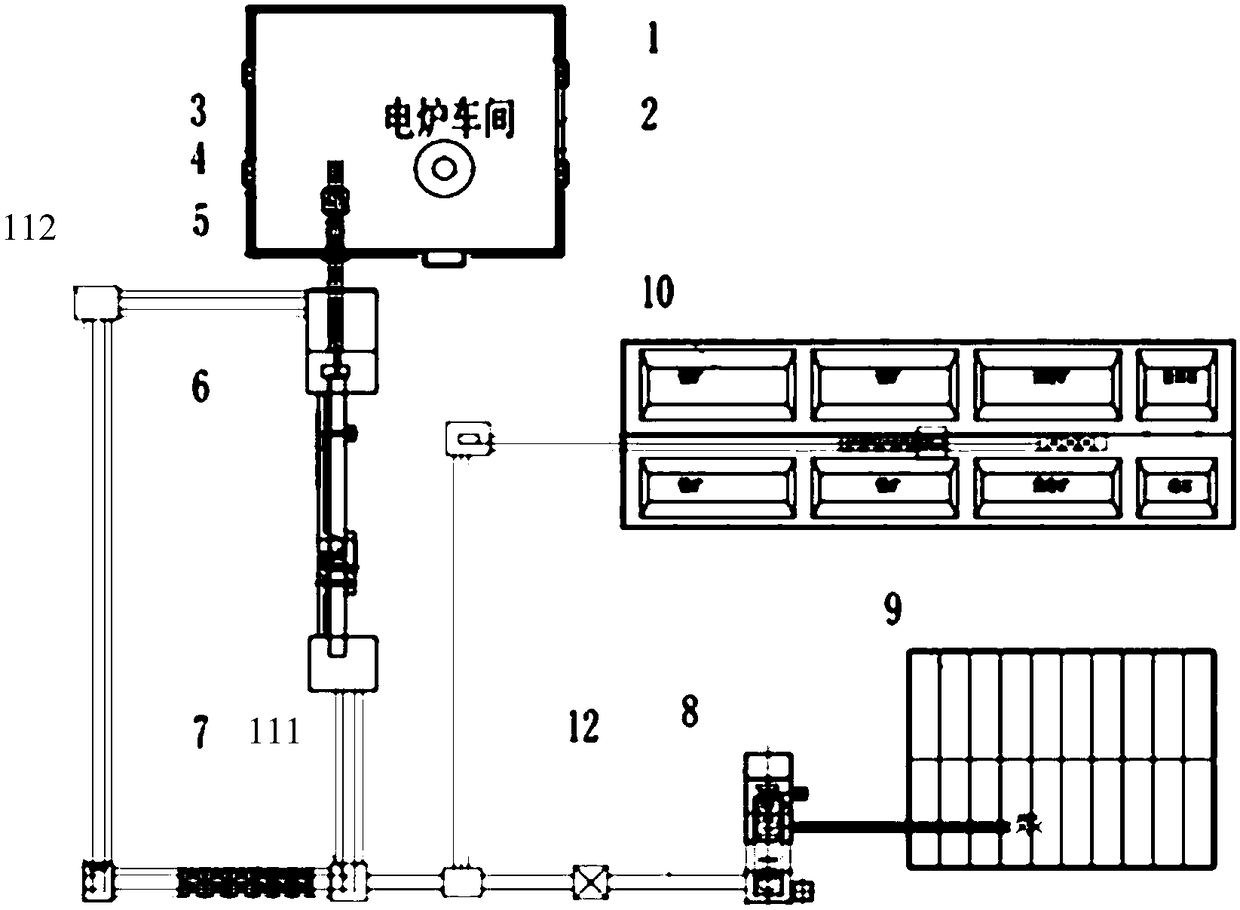

Manganese-silicon alloy production system and technology

ActiveCN108411131ARaise the furnace temperatureReduce smelting power consumptionSilicon alloyManganese

Disclosed is a manganese-silicon alloy production system. The manganese-silicon alloy production system comprise a comprehensive material shed, a coke material shed, a proportioning station, a rotarykiln, a heat-preservation material tank and an electrical furnace; the comprehensive material shed is used for storing ores, and the ores comprise various manganese ores, silica, dolomite and sinteredores; the coke material shed is used for storing coke; the proportioning station is used for proportioning the various manganese ores, the silica and the dolomite to form a first mixed material, andused for proportioning the coke and the sintered ores to form a second mixed material; the rotary kiln is used for receiving the first mixed material from the proportioning station and calcining the first mixed material, the feeding end of the rotary kiln is arranged at the kiln tail, and the discharging end of the rotary kiln is arranged at the kiln head; the heat-preservation material tank is arranged on the lower portion of the discharging end of the rotary kiln, and used for receiving and storing hot materials from the discharging end of the rotary kiln, and receiving and storing the second mixed material from the proportioning station; and the electrical furnace receives the first mixed material from the heat-preservation material tank and the second mixed material from the proportioning station, and smelts the received mixed materials. The production system is high in heat utilization rate and high in electric furnace production capacity.

Owner:BERIS ENG & RES CORP

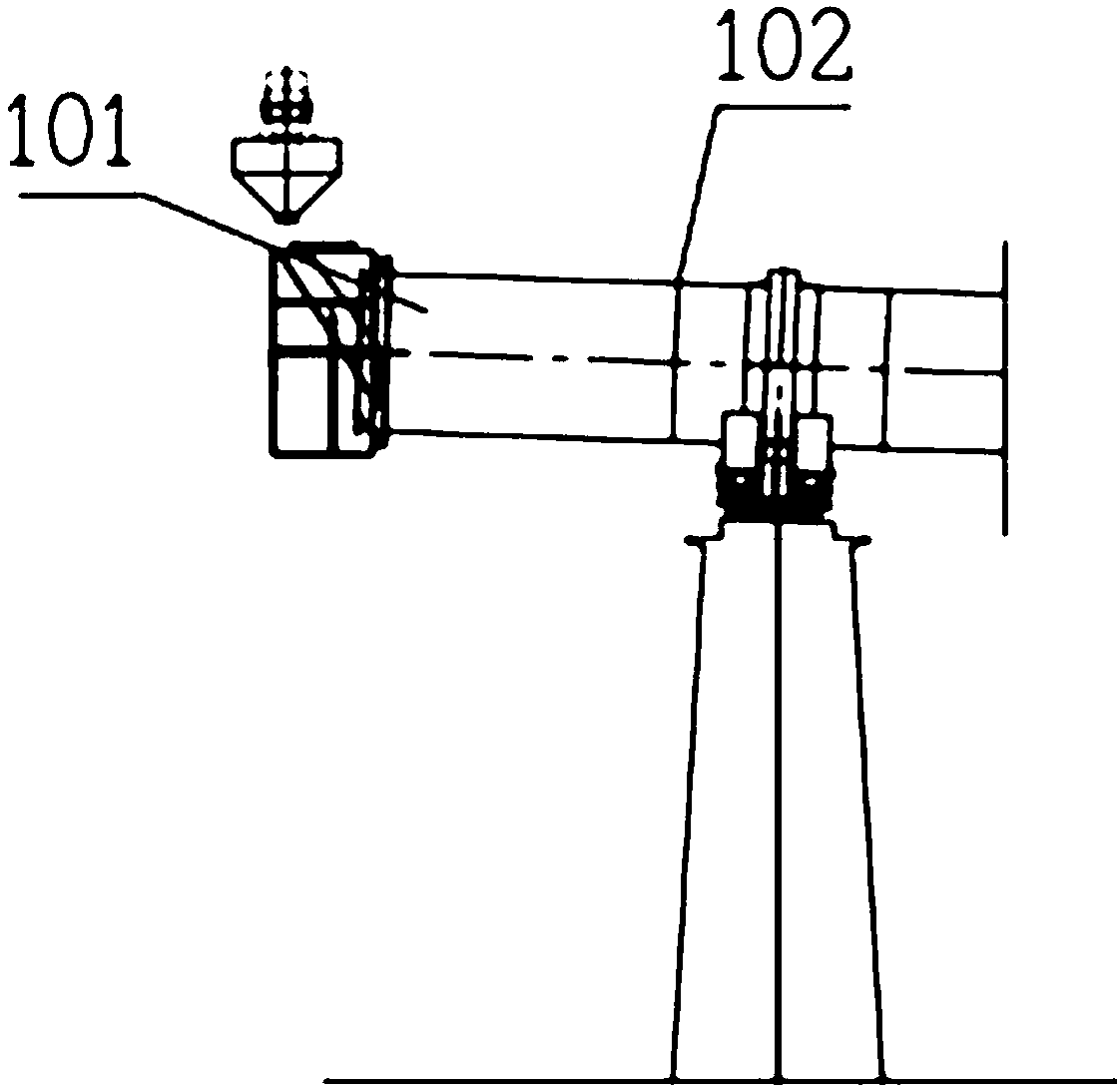

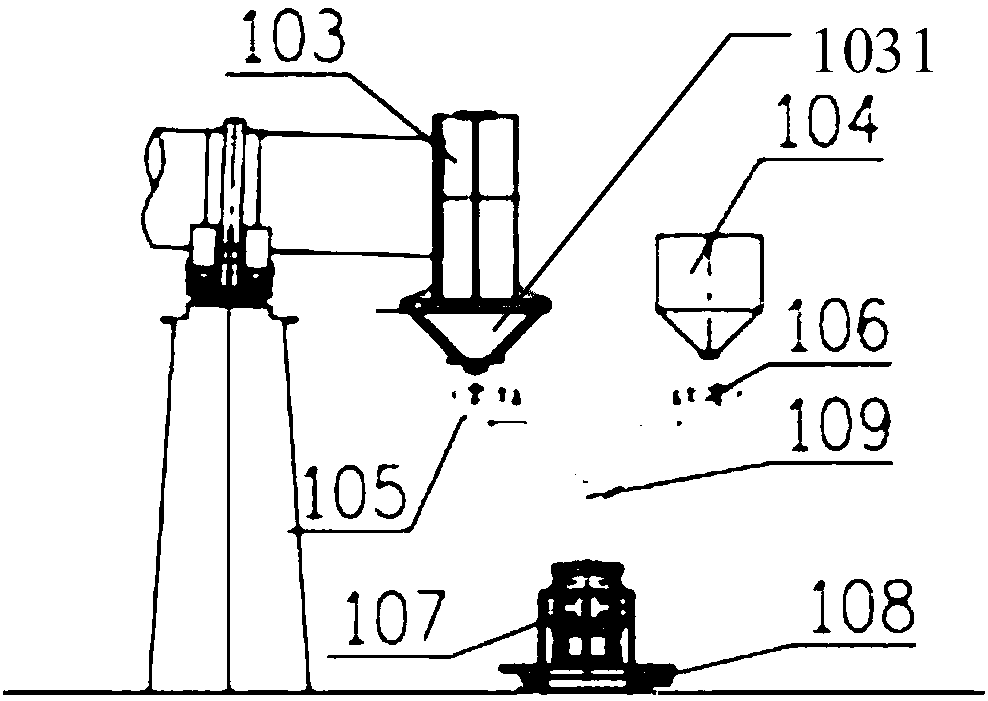

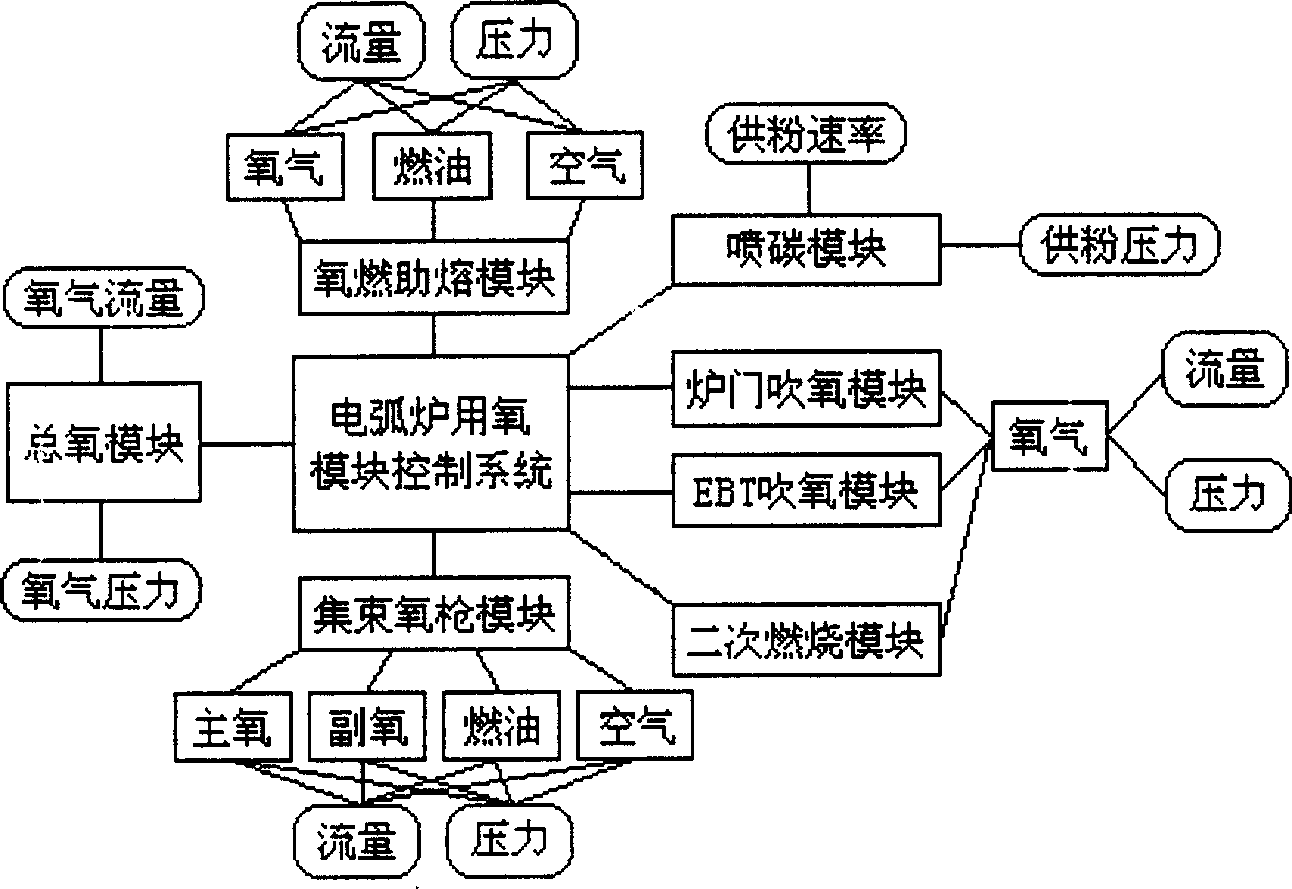

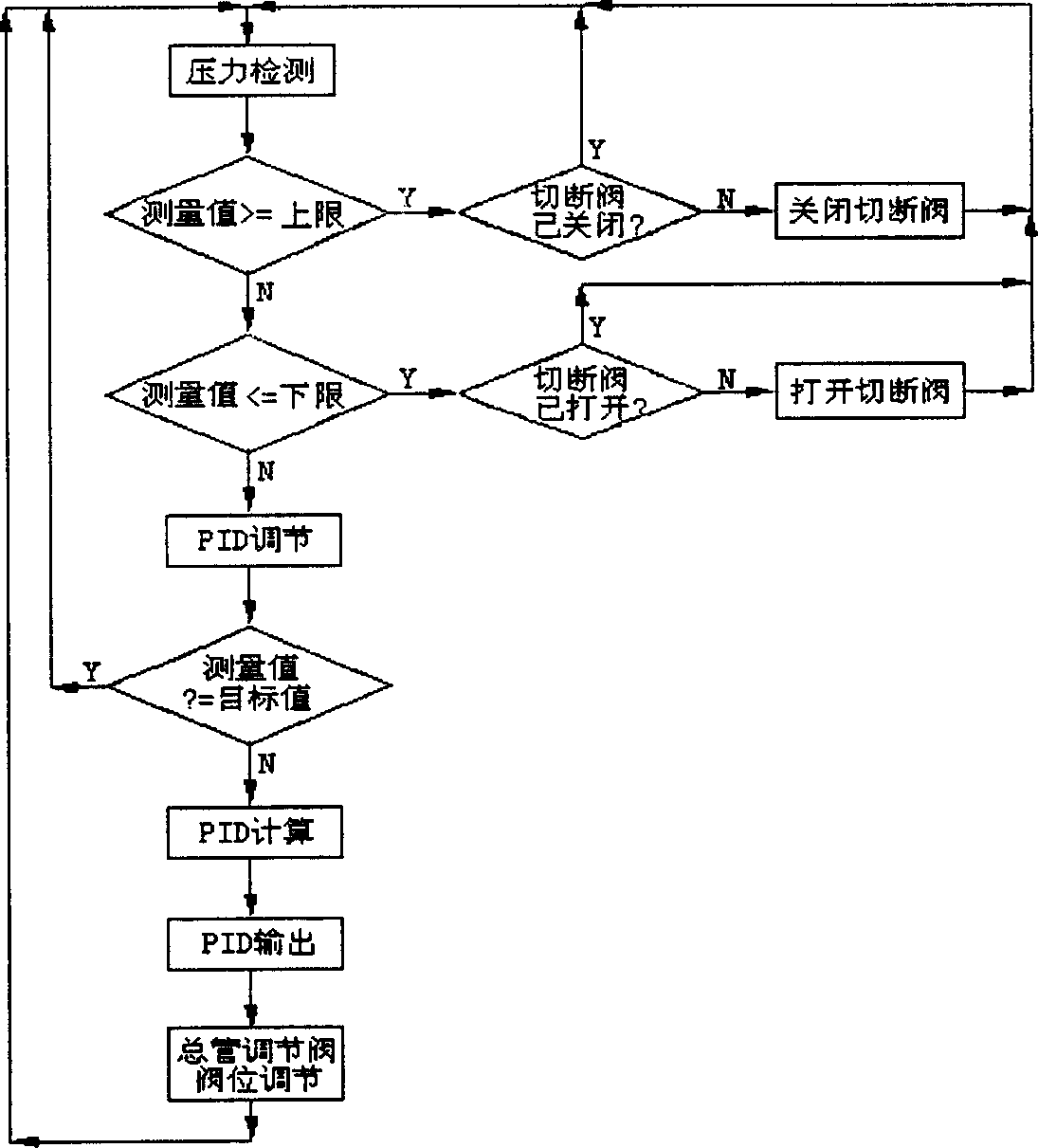

Computer modularized control technology for oxygen consumption in electric arc furnace

InactiveCN1385665ASolve the problem of oxygen balance injectionHigh yieldLighting and heating apparatusSimulator controlElectric arc furnaceCombustion

The present invention relates to a computer modular control technique for oxygen consumption of electric arc furnace. It is characterized by that various oxygen consumption modes are divided into several modules: total oxygen module, oxygen combustion fluxing module, furnace door oxygen-blowing module, electric furnace ecentric furnace-bottom-EBT oxygen-blowing module, secondary combustion module, bunched ouxygen gun module and carbon-jetting module. Said invention utilzies the regulation of flow rate and pressure of oxygen gas and other medium, controls their supply method, adopts PID control and combines it with computer time-sharing control technique of oxygen consumption to reduce oxygen consumption by 10-20%, raise metal yield rate by 1-2%, reduce electrode consumption by 0.3-0.5 kg / t and reduce electric consumption by 35-50 k wt / t.

Owner:UNIV OF SCI & TECH BEIJING

Automatic control method for electrode with low single phase electrode power in yellow phosphorus furnace

ActiveCN101808438ARealize automatic controlIncrease input powerElectric discharge heatingIncreasing energy efficiencyAutomatic controlEngineering

The invention discloses an automatic control method for an electrode with low single phase electrode power in a yellow phosphorus furnace. The method comprises the following steps of: collecting the parameter value of the electrode in the yellow phosphorus furnace in real time; converting into a direct current voltage analogue signal; converting into a digital signal by an A / D sampling plate to be operated and processed by a computer; when the single phase electrode is positioned in lower limit and has low power, outputting a signal to a lifting mechanism of an adjacent interference phase electrode of the single phase electrode by the computer; and inserting an adjacent interference phase electrode. The invention has the advantages that the inserting of the adjacent interference phase electrode of the electrode with low power is controlled by the computer, and the current of the adjacent interference phase electrode is increased, therefore the input power of the adjacent interference phase electrode is increased to drive the power of the electrode in the lower limit and with low power to quickly raise, then the three-phase power is balanced, the electric and thermal efficiencies are enhanced, the smelting electric consumption is decreased, the output is enhanced, and the electrode automatic control for low single phase electrode power in a yellow phosphorus furnace is effectively realized.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Steel for fluid end of fracturing pump, and preparation process thereof

InactiveCN106702285AImprove cleanlinessReduce smelting power consumptionEnergy consumptionElectric arc furnace

The invention discloses steel for a fluid end of a fracturing pump, and a preparation process thereof. A continuous cast round billet of steel with T.O of not greater than 0.0015%, for the fluid end of the fracturing pump, can be produced, and then electroslag remelting (ESR) is carried out; the specific technical scheme of the electroslag remelting comprises two modules for smelting preparation for a consumable electrode and electroslag remelting for the consumable electrode; and the following technical route is adopted: electric arc furnace primary smelting, LF refining, RH vacuum refining, round billet continuous casting, billet continuous casting, electroslag remelting and ESR ingot obtaining. The invention provides steel for a fluid end of a fracturing pump, and an electroslag remelting process thereof. The components are redesigned, electric process parameters are correspondingly adjusted, and an electroslag remelting process capable of controlling the contents of gas elements in the steel and low in energy consumption is developed.

Owner:马鞍山旭阳机械有限公司

Technology for fabricating foaming slag in arc furnace molten pool

ActiveCN104131134AGood effectAvoid wear and tearProcess efficiency improvementElectric furnaceAlkalinityElectric arc furnace

The invention discloses a technology for fabricating foaming slag in an arc furnace molten pool. The technology comprises the following steps: using a powder spraying tank and a powder spraying tank conveying pipeline to spray carbon powder containing powder material for producing foaming slag, into an arc furnace, controlling the slag alkalinity, FeO content, and molten pool temperature, wherein the carbon powder containing powder material for producing foaming slag is a graphite-like material, the fixed carbon content is not less than 80%, the water content is not more than 0.5%, the particle size is less than 3 mm; and continuously and evenly spraying the graphite-like material to the slag surface in the arc furnace to produce foaming slag when the temperature of the arc furnace molten pool reaches 1550 to 1600; wherein the spraying pressure is 0.3 to 0.5 MPa, the spraying strength is 15 to 25 kg / min, and the spraying amount is 6 to 7 kg / t. The graphite-like powder material is adopted to avoid the wear on the powder spraying tank conveying pipeline. Under an iron / water ratio of 30 to 75%, foaming slag operation during the whole process can be achieved, and the using amount of graphite-like material is reduced by 20% or more, compared to that of carbon powder. The graphite-like material is safer than the coke, and the service life of the conveying pipeline is prolonged.

Owner:LAIWU IRON & STEEL GRP

Method of preparing low-calcium-and-magnesium titanium slag from Panzhihua titanium concentrate

InactiveCN106191428AHigh reactivityEasy to operateTitanium dioxideProcess efficiency improvementCalcium contentCooling down

The invention belongs to the field of chemical metallurgy, and particularly relates to a method for preparing low-calcium-and-magnesium titanium slag from Panzhihua titanium concentrate. According to the technical scheme for solving technical problems, the method comprises the following steps that a, the Panzhihua titanium concentrate is subjected to ball-milling, and oxidized at the temperature of 700-850 DEG C, pickled, filtered, washed and dried to obtain pretreated ore; b, pelletizing is conducted after the pretreated ore is evenly mixed with an excessive amount of a reductant, pellets are subjected to reduction at the temperature of 1,000-1,300 DEG C, and metallic pellets are prepared; and c, the metallic pellets are smelted, slag is discharged after smelting is completed and crushed after being cooled down, and then the low-calcium-and-magnesium titanium slag is obtained. According to the method for preparing the low-calcium-and-magnesium titanium slag from the Panzhihua titanium concentrate, the grade of TiO2 is promoted to 85% or above from around 46%; and further, the titanium slag is low in calcium content and magnesium content, moderate in granularity, and capable of being used as the raw material for preparing titanium dioxide by use of a chlorination boiling method.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for smelting chromium-containing ferronickel through laterite nickel ore

The invention discloses a method for smelting chromium-containing ferronickel through laterite nickel ore. Nickel sulphide ore, a chromium-containing material and stainless steel smelting waste slag with a certain proportion are added into the laterite nickel ore, a rotary kiln pre-reduction-electric furnace process is adopted for smelting, a chromium-containing ferronickel product is used for producing 300-series austenitic stainless steel, the nickel sulphide ore and the chromium-containing material can serve as a part of a nickel source and a chromium source to improve the nickel and chromium grade in an alloy smelting product, other components in the nickel sulphide ore and the chromium-containing material are matched with multiple components in other stainless steel smelting waste slag to serve as a slag forming constituent to adjust the furnace slag smelting property, the reduction condition of chromium oxides can be improved, and separation of metal and slag can be reinforced. The method can improve the chromium grade and the chromium recycling rate in the ferronickel product, the smelting energy consumption can be greatly reduced, multiple metallurgical waste slag in the stainless steel production process can be sufficiently used, secondary resource recycling can be achieved, enterprise production cost is reduced, and the environment pollution brought by the metallurgical waste slag can be removed.

Owner:CENT SOUTH UNIV

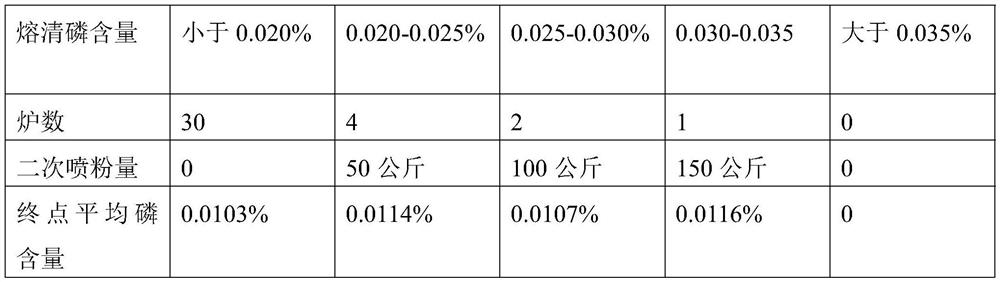

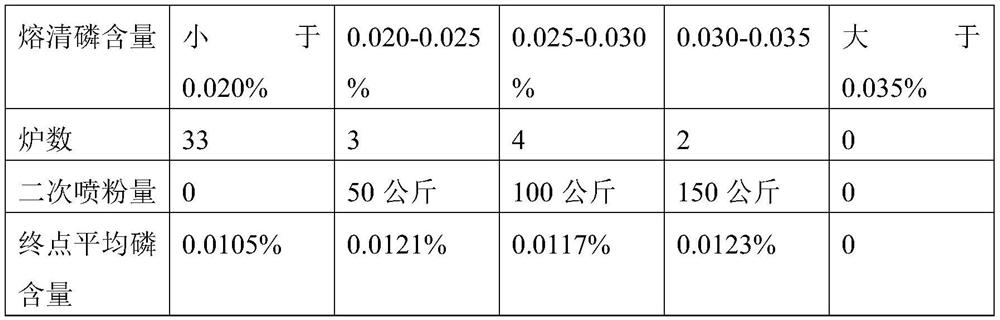

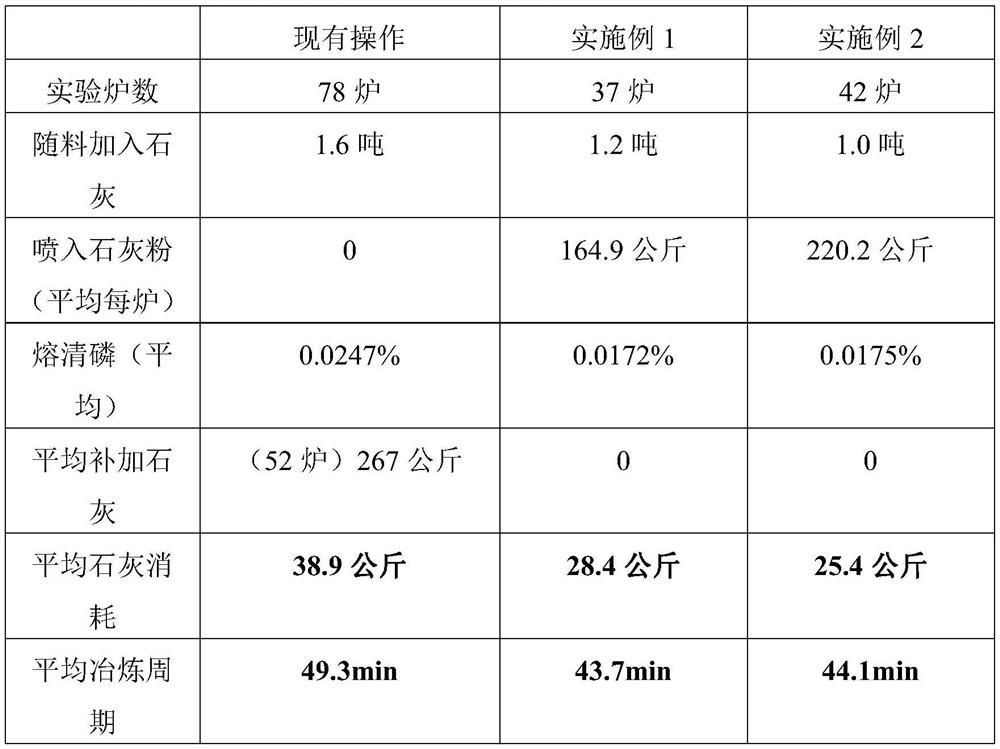

Method for dephosphorizing by blowing lime powder in electric furnace

InactiveCN112301184AWork around constraintsSolve the requestElectric furnaceProcess efficiency improvementSteelmakingMaterial consumption

The invention relates to the field of electric furnace steelmaking, in particular to a method for dephosphorizing by blowing lime powder. The method comprises the following steps: in the early stage of smelting, when the smelting temperature in an electric furnace is 1470-1500 DEG C, starting a low-oxygen mode, and blowing the lime powder with the particle size of 0-10mm into the electric furnace;and after powder blowing is finished, adjusting the oxygen supply amount to 5000-5500 Nm < 3 > / h, and conducting stirring for dephosphorization. According to the method, lime consumption is effectively reduced, so that the increase of steel and iron material consumption and smelting power consumption caused by high lime consumption is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

Electrode automatic control method for high single-phase electrode power of yellow phosphorus furnace

ActiveCN101808437ASmall currentReduce input powerElectric discharge heatingIncreasing energy efficiencyAutomatic controlEngineering

The invention discloses an electrode automatic control method for high single-phase electrode power of a yellow phosphorus furnace. The method is realized in a way that: real-time parameter values of the electrode in the yellow phosphorus furnace are collected and converted into a direct-current voltage analog signal, and the direct-current voltage analog signal is converted into a digital signal by an A / D sampling board, the digital signal is computed by a computer; when the single-phase electrode is in the upper limit position and the power is high, the computer outputs a signal to an elevating mechanism of the adjacent interference phase electrode, so that the adjacent interference phase electrode ascends. The computer is utilized to control the interference phase electrode adjacent to the high power electrode to ascend, thereby reducing the current of the adjacent interference phase electrode and reducing the input power of the adjacent interference phase; and thus, the power of the high power electrode in the upper limit position is driven to decrease as soon as possible, thereby achieving the triphase power balance, enhancing the electric and thermal efficiency, reducing the smelting power consumption, enhancing the yield, and efficiently realizing automatic control on the electrode when the power of the single-phase electrode in the yellow phosphorus furnace is high.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com