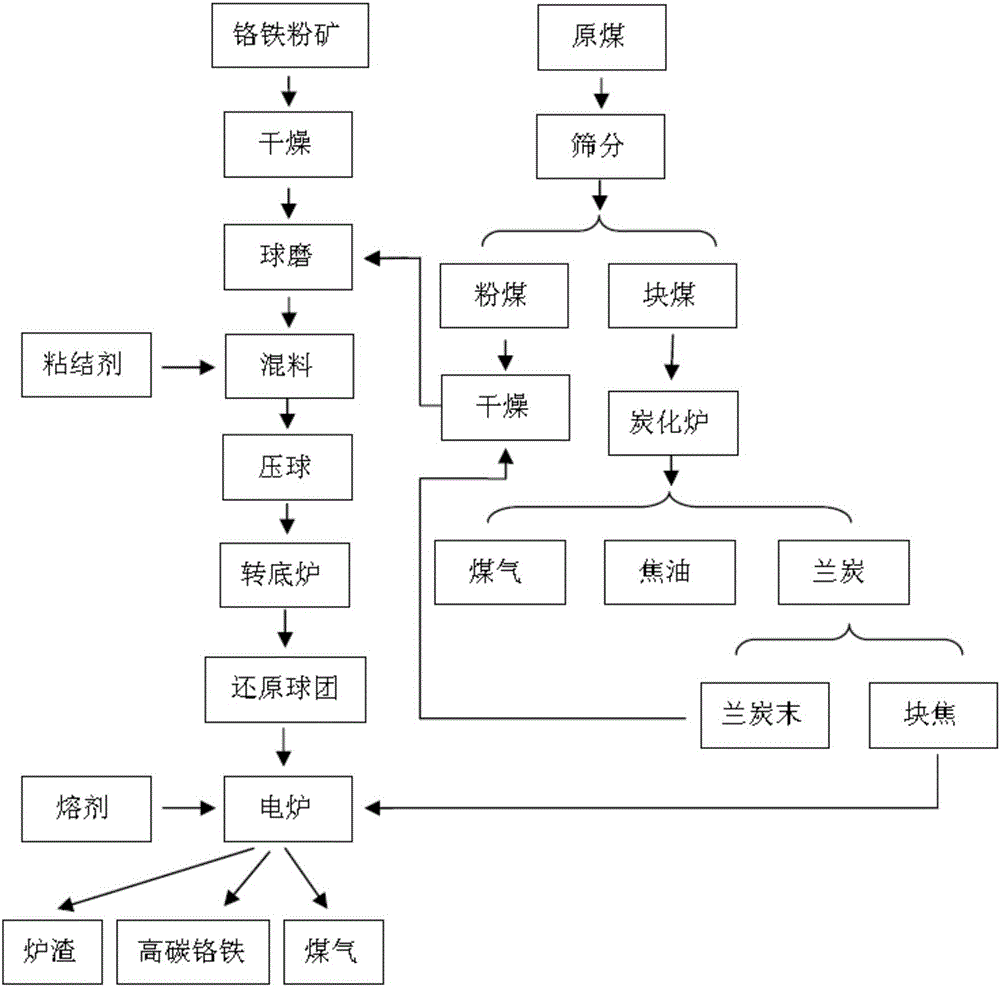

Combined production process for high-carbon ferro-chrome and semi-coke

A high-carbon ferrochromium, co-production technology, applied in the petroleum industry, special forms of dry distillation, furnace types, etc., can solve the problems of unutilized excess gas, ineffective and repeated transportation of coal resources, and reduced utilization of pyrolysis raw materials, etc. The effect of reducing smelting power consumption, reducing energy consumption and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] (2) Preparation of blue charcoal

[0057] Lump coal with a particle size of 30-80mm is sent into a carbonization furnace to produce semi-coke by pyrolysis and carbonization, wherein the temperature of pyrolysis and carbonization is 950-1100°C.

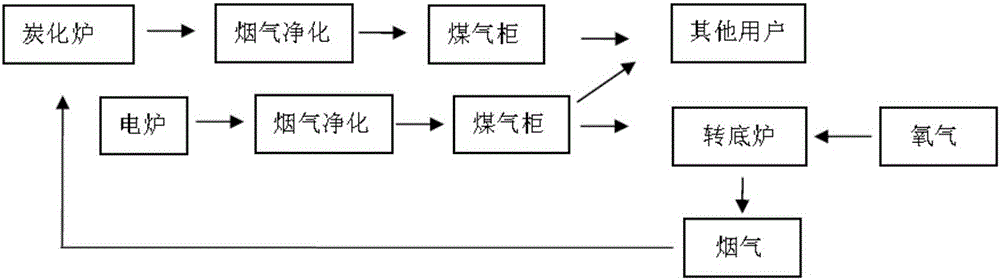

[0058] In the present invention, the carbonization furnace adopts an internal heating carbonization furnace, and the heat required by the carbonization furnace comes from the high-temperature flue gas of the rotary hearth furnace. The heat of the conventional internal heating carbonization furnace comes from the high-temperature flue gas generated by the combustion of a large amount of returned furnace gas. Conventional internal heating carbonization furnaces generally use air to support combustion, and the N in the flue gas after combustion 2 The volume fraction is about 70%, so the nitrogen content in the final semi-coke tail gas is relatively high (N 2 The volume fraction is about 40%). Because nitrogen is an inert gas, th...

Embodiment

[0105] The implementation of the method and the use of the equipment of the present invention will be described below through specific examples. It should be understood by those skilled in the art that this should not be construed as limiting the scope of the claims of the present invention. Example

[0106] The low metamorphic coal used in this example is long-flame coal, and both long-flame coal and ferrochrome fine ore are conventional commercially available raw materials, and their chemical compositions are shown in Table 6 and Table 7, respectively, and the percentages are by weight.

[0107] Table 6 Chemical composition of long flame coal

[0108] Element

Ash

Volatile matter

Total sulfur

%

3.7

5.8

35.7

54.4

0.4

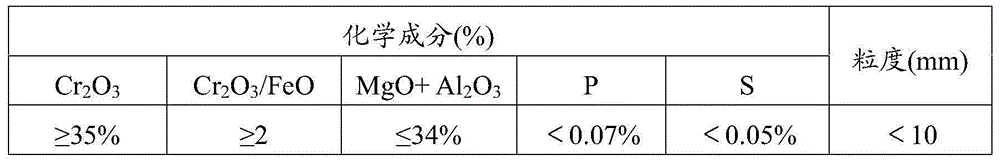

[0109] Table 7 Chemical composition of chromite fine ore

[0110] name

Cr 2 o 3

FeO

SiO 2

Al 2 o 3

MgO

CaO

h 2 o

P

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com