Computer modularized control technology for oxygen consumption in electric arc furnace

A computer module, modular control technology, applied in the field of steelmaking, to reduce electrode consumption and smelting power consumption, and improve metal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

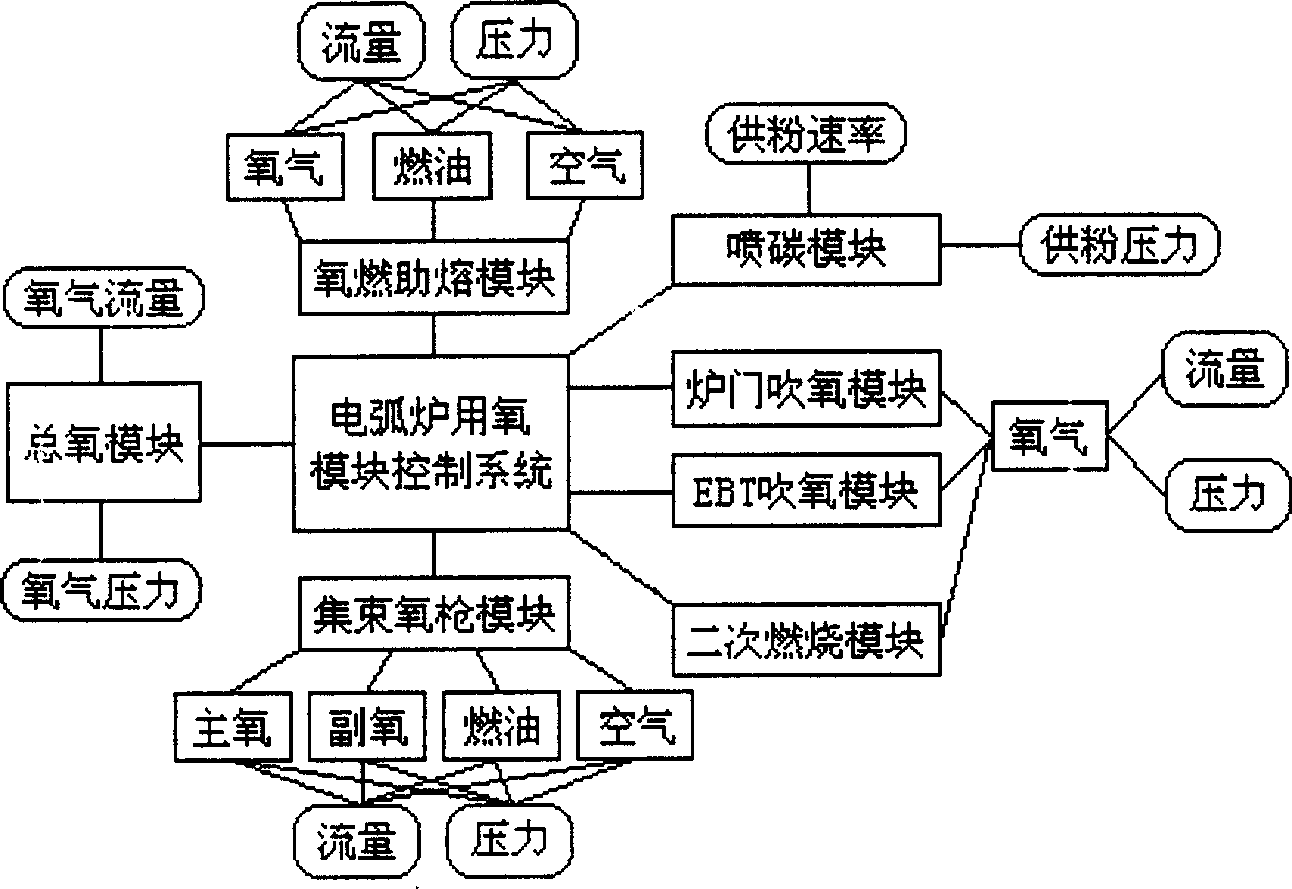

[0025] A computerized modular control technology for electric arc furnaces. According to the characteristics of oxygen use in each position of the electric arc furnace, various oxygen use methods are divided into modules for modular control. The modules include a total oxygen module, an oxygen combustion boosting module, and a furnace door Oxygen blowing module, electric furnace eccentric furnace bottom--EBT oxygen blowing module, secondary combustion module, cluster oxygen lance module and carbon injection module; control the supply of oxygen or other media in the production process by adjusting the flow and pressure of oxygen or other media ; In the control method, PID control in the negative feedback control method is adopted. figure 1 It is the configuration diagram of the computer module control system of the electric arc furnace.

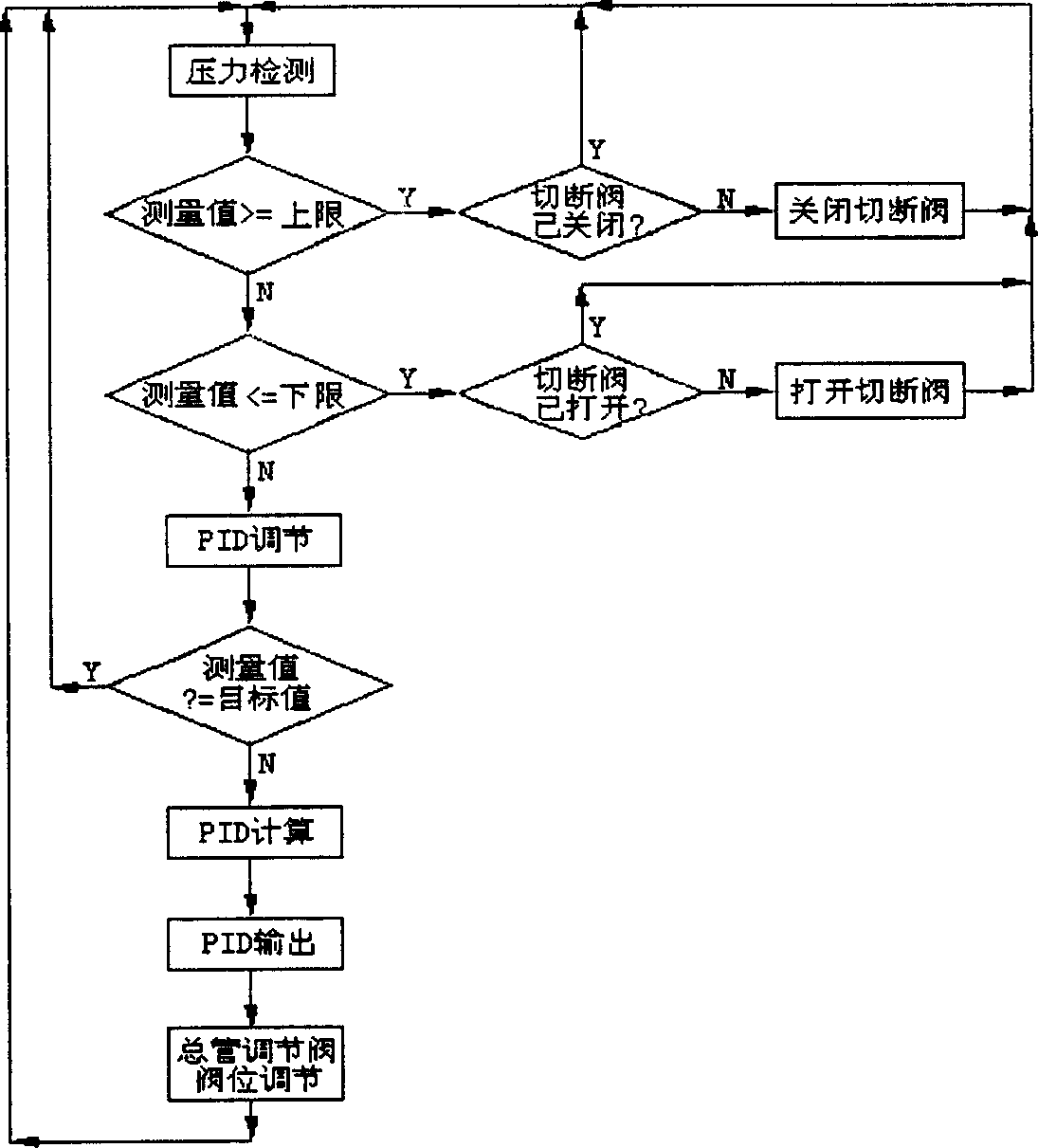

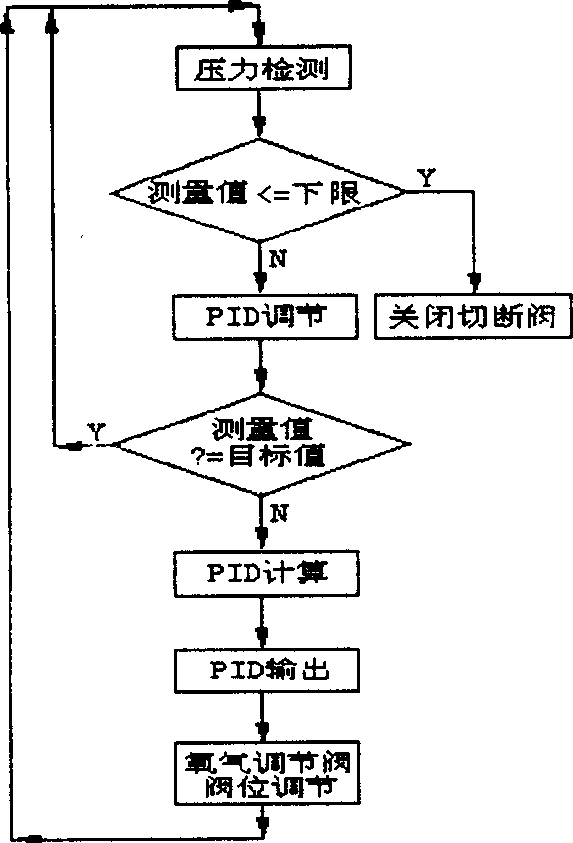

[0026] The total oxygen module control is to set the oxygen pressure of the oxygen main pipe according to the production needs. When the tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com