Method for preparing chrome ore pellets

A technology for pellets and chrome ore is applied in the field of preparing powder chrome ore pellets, which can solve the problems of energy consumption, increase cost, and high smelting power consumption, and achieve the effects of improving production efficiency, reducing dosage and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

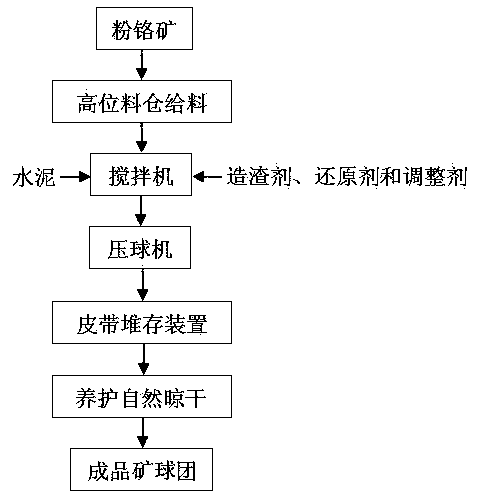

Method used

Image

Examples

Embodiment 1

[0034] Example 2

Embodiment 2

[0036] Example 3

Embodiment 3

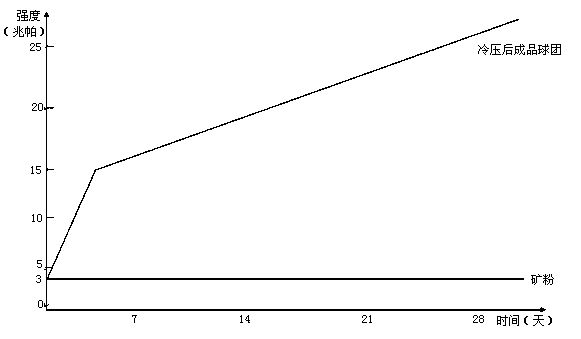

[0038] The finished ball obtained in the above embodiments of the present invention, the normal temperature strength test data are as follows: figure 2 .

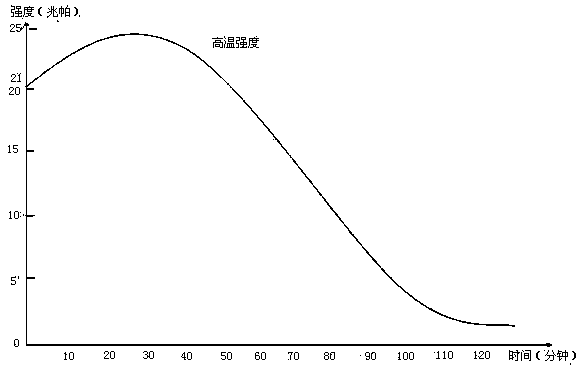

[0039] The finished ball obtained in the above embodiments of the present invention, the high-temperature strength test data are as follows: image 3 .

[0040]The finished balls obtained in the above embodiments of the present invention are smelted in a submerged arc furnace, and the power consumption of the smelting of Cr50 per unit product in the production of ferrochrome is shown in Table 1.

[0041] Table 1

[0042] name Cr50 unit product smelting power consumption Remark Embodiment 1 finished ball 2725 KW*H / t Reach the first / second level of cleaner production indicators Embodiment 2 finished ball 2830 KW*H / t Reached the third level of clean production index Embodiment 3 finished ball 2650 KW*H / t Reach the first / second level of cleaner production indicators

[0043] Each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com