Method for preparing titanium slag by electric furnace-smelted and pre-reduced pellets

A technology for electric furnace smelting and titanium slag, applied in the field of electric furnace smelting titanium slag, can solve the problems of deteriorating furnace conditions, high power consumption, unfavorable long-term smelting, etc., and achieves the effects of safe and stable operation and low smelting power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

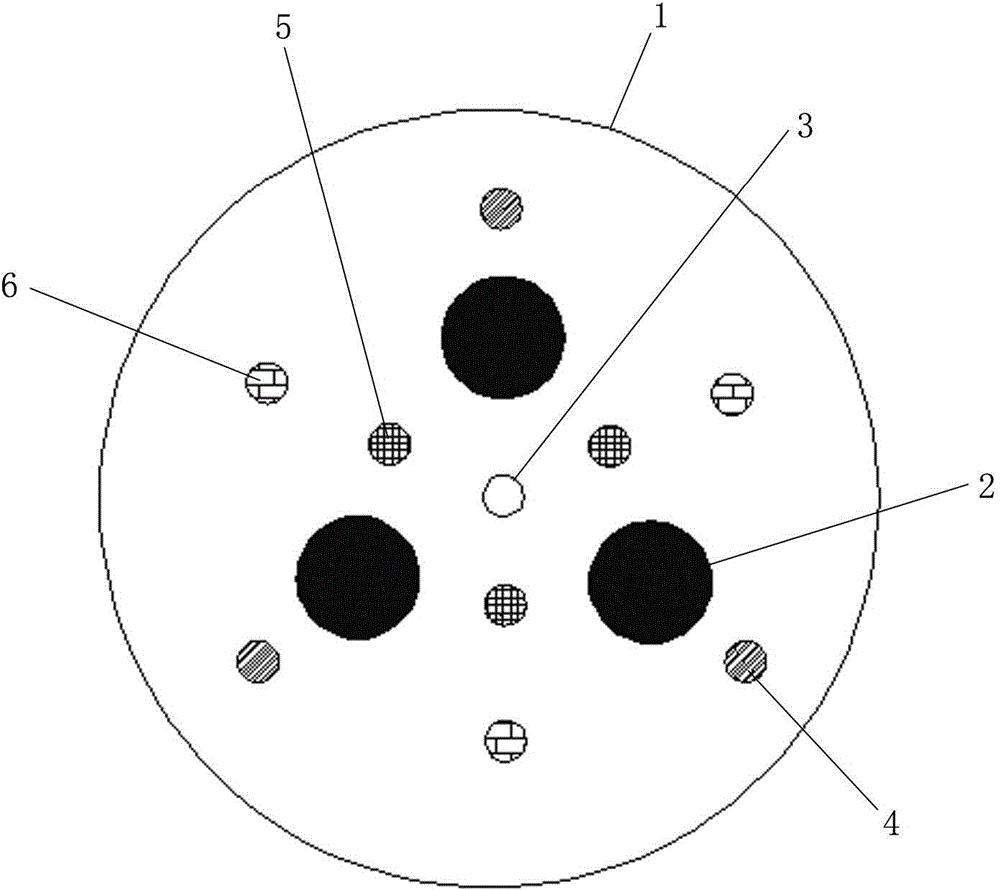

[0008] Hereinafter, the method for preparing titanium slag by smelting pre-reduced pellets in an electric furnace according to the present invention will be described in conjunction with exemplary embodiments.

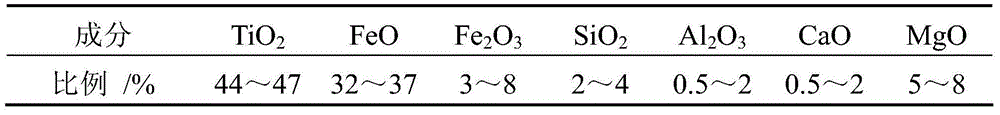

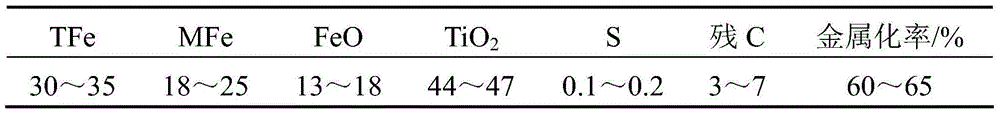

[0009] In an exemplary embodiment of the present invention, the method for preparing titanium slag by smelting pre-reduced pellets in an electric furnace includes the following steps: using pre-reduced pellets as a raw material, the pre-reduced pellets are obtained by pre-reducing titanium-containing magnetite concentrate The metallization rate is not less than 60wt% and the residual carbon content is 3-8wt% in terms of weight percentage; the raw materials are added to the electric furnace in batches and smelted with power supply; wherein, during the feeding process, the furnace pressure of the electric furnace is controlled It is -80~-120Pa, preferably -90~-110Pa. In the normal smelting process, the furnace pressure of the electric furnace is controlled to be +10~-10Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com