Technology for fabricating foaming slag in arc furnace molten pool

A technology of foam slag and electric arc furnace, applied in the direction of electric furnace, process efficiency improvement, furnace, etc., can solve the problems of pipeline wear, influence of foam slag, uneven particle size of coke powder, etc., and achieve the effect of avoiding wear and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

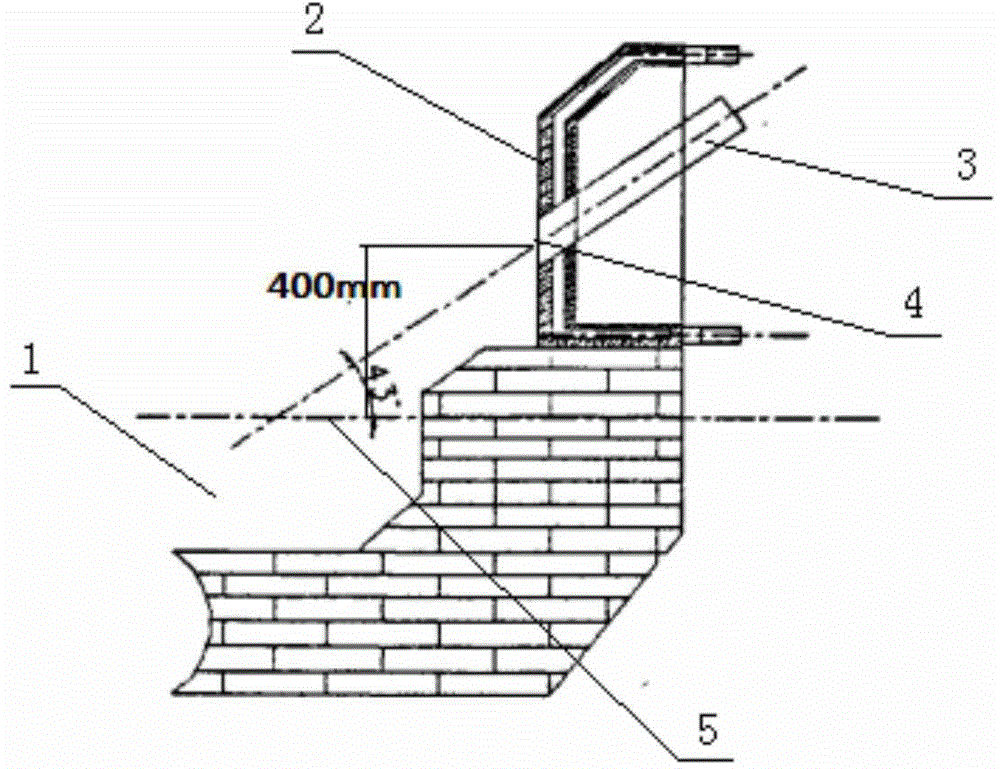

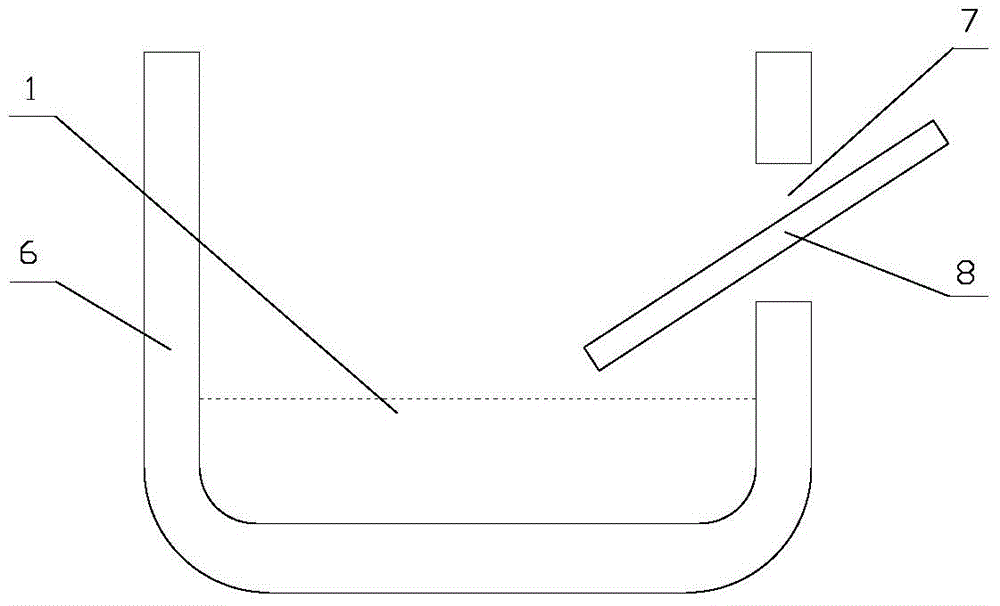

[0041] Example 1: 50 tons of electric arc furnace foam slag

[0042] (1) The metal material of the electric arc furnace is hot-charged with a ratio of 65% of molten iron. In order to create foam slag in advance, the electric arc furnace adopts the operation of leaving steel and slag. In order to obtain a good foam slag effect, when adding scrap steel, add it to the bottom or middle of the material tank Active lime 35kg / t steel and light burnt magnesium block 6kg / t steel. Add primary material (scrap steel) and mix with molten iron.

[0043] (2) The graphite-like foaming slag is sprayed at the furnace door and the rear wall of the electric furnace; when the temperature of the electric arc furnace melting pool reaches 1580°C, the graphite-like foaming slag is sprayed continuously and evenly on the slag surface of the electric furnace, and the melting stage The graphite-like blowing intensity is 15-18kg / min, and the graphite-like blowing intensity after melting is 20-25kg / min. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com