Method for dephosphorizing by blowing lime powder in electric furnace

A lime powder and electric furnace technology, applied in electric furnaces, lime production, furnaces, etc., can solve the problems of high lime consumption and unstable production rhythm, and achieve the effects of reducing lime consumption, improving lime utilization rate, and reducing smelting power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

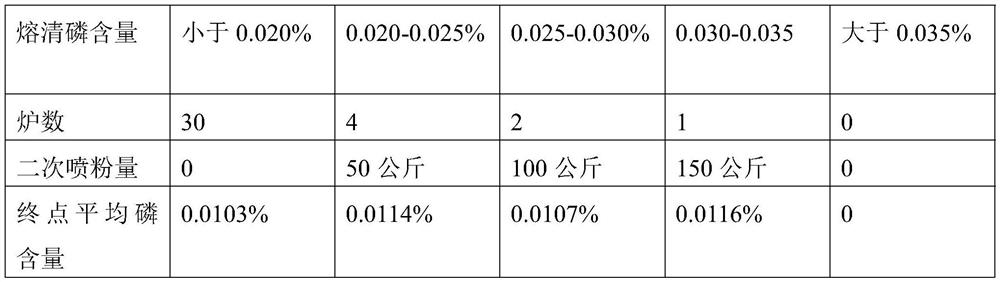

[0017] The type of steel smelted in an electric furnace is 42CrMoA, and 1.2 tons of lime is added from the ingredients along with the iron and steel material. In the early stage of smelting, it is operated according to the high-iron ratio oxygen supply model. After the end, turn on the decarburization heating mode. When the temperature is higher than 1540 ° C, the molten oxygen is taken for analysis. A total of 37 heats were tested

[0018]

Embodiment 2

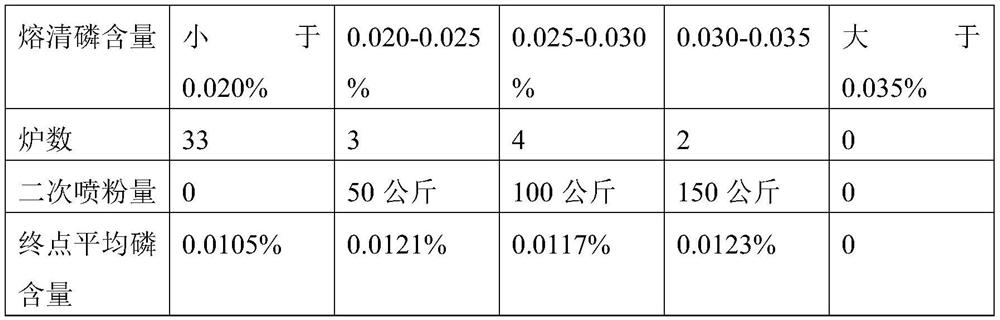

[0020] The type of steel smelted in an electric furnace is 22CrMoH, and 1.0 tons of lime is added from the ingredients along with the iron and steel material. The early stage of smelting is operated according to the high-hot metal ratio oxygen supply model. When the temperature reaches 1470-1495 ° C, the low-oxygen mode is turned on and 200 kg of lime powder is injected; After the end, turn on the decarburization heating mode. When the temperature is higher than 1540 ° C, the molten oxygen is taken for analysis. A total of 42 heats were tested

[0021]

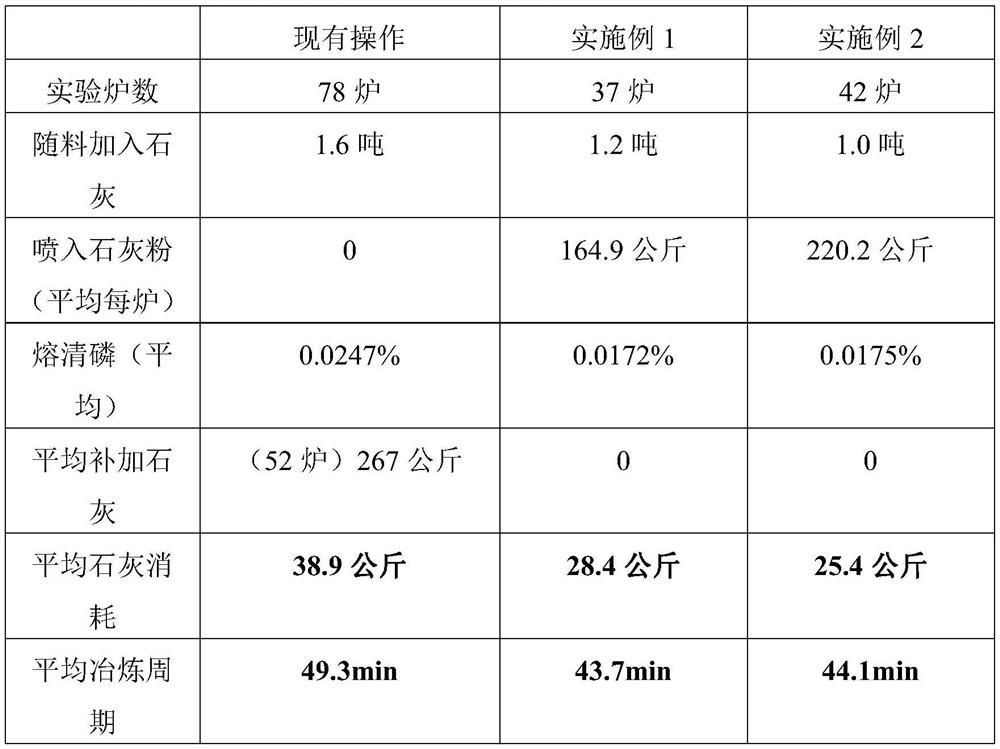

[0022] Experimental data obtained by embodiment 1 and embodiment 2 and prior existing production process data analysis contrast

[0023]

[0024] It can be seen from the above table that the present invention adopts the lime powder injection process to effectively improve the dephosphorization efficiency of the electric furnace, reduce lime consumption, and eliminate the influence of additional lime on the production rhy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com