Diffraction experiment device and experiment method thereof

An experimental device and a fixed track technology, applied in the field of experimental instruments, can solve the problems of inconvenient use of diffraction experimental instruments and single experimental conditions, and achieve the effects of improving experimental adaptability, simple operation and convenient application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

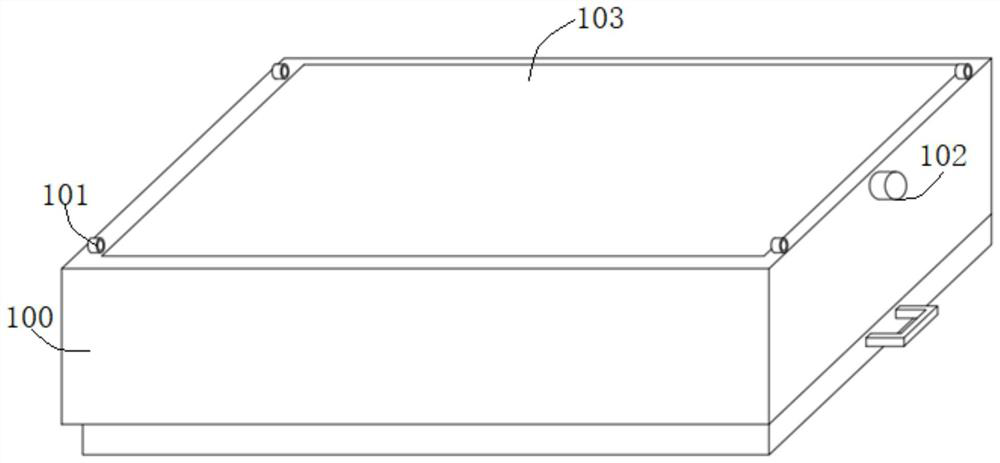

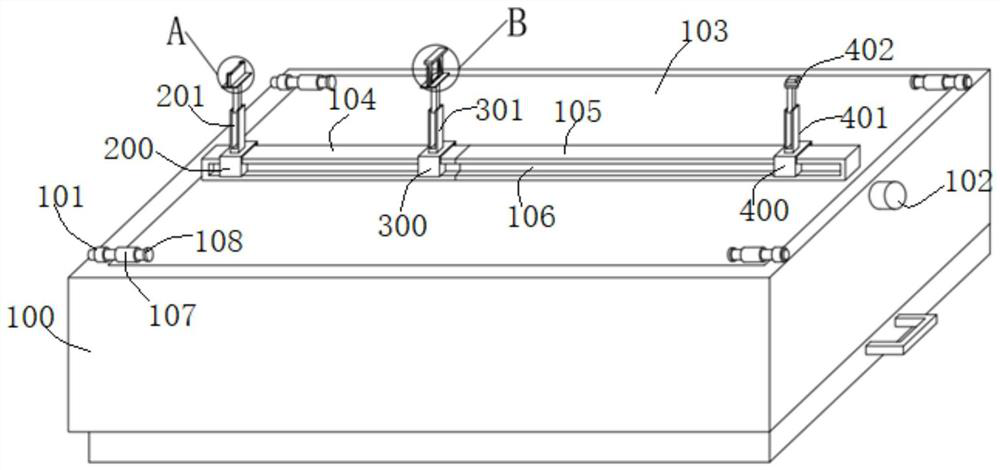

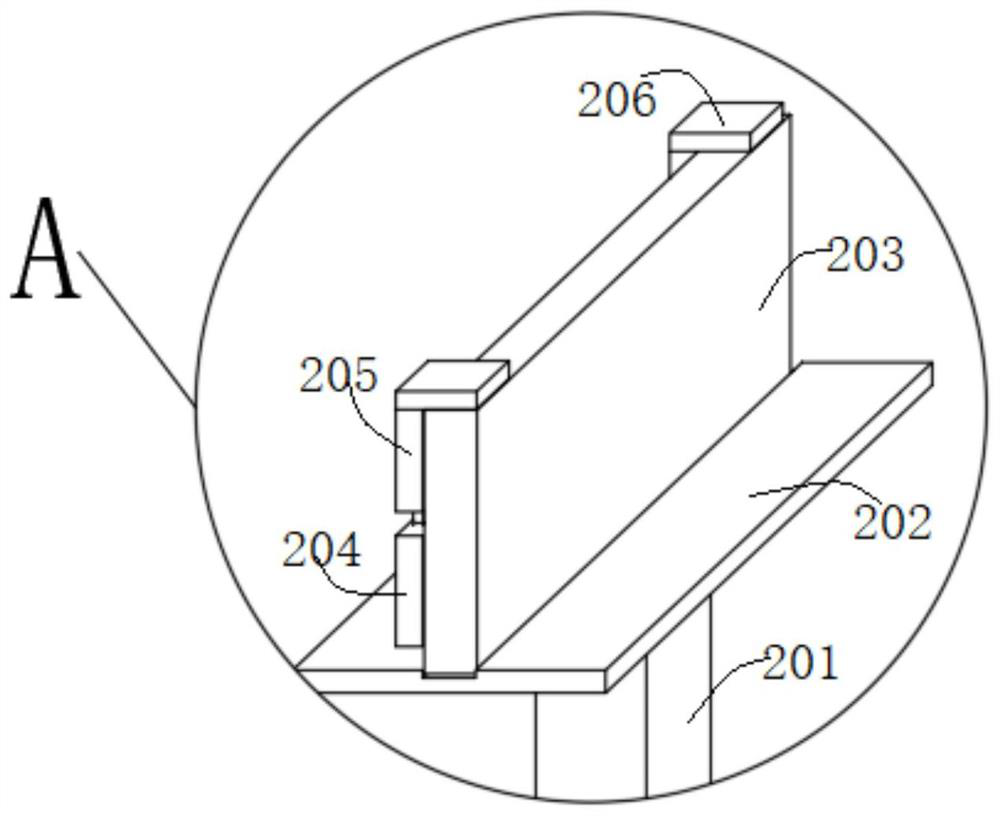

[0037] Such as Figure 1-Figure 5 As shown, a diffraction experiment device of this embodiment includes a fixed rail 104 and a movable rail 105 that are telescopically fitted and connected, and a light source assembly and a baffle that are slidably matched to the rail are sequentially arranged on the fixed rail 104 and the movable rail 105 Components and light screen components; wherein the baffle plate assembly includes a bottom plate 2 302, the two sides of the bottom plate 302 are respectively slidingly fitted with a baffle plate 1 303, and the top of the baffle plate 303 on both sides is connected to a top plate 305; between the baffle plate 1 303 on both sides The width of the gap between them can be adjusted, so that the diffraction phenomenon caused by the change of different lateral distances can be observed, which is beneficial to understand and broaden the experimental cognition.

[0038]Specifically, both sides of the fixed track 104 and the movable track 105 are pr...

Embodiment 2

[0043] A kind of diffraction experimental device of this embodiment is basically the same as that of Embodiment 1. Furthermore, the baffle plate assembly also includes a baffle plate 2 304, and through grooves are opened on the opposite walls of the two baffle plate 1 303, and the baffle plate 2 304 Correspondingly embedded in the through groove, and the second baffle 304 on both sides can be relatively far away from or close to, the bottom of the second baffle 304 is flush with the bottom of the first baffle 303, and the height of the top of the second baffle 304 is lower than the top of the first baffle 303 high. Such as Figure 4 As shown, the second baffle plate 304 can move inside and outside the through groove of the first baffle plate 303. The first baffle plate 303 can specifically adopt the shape of a right-angled trapezoid in cross-section, and open a through groove on its inclined surface. Move inside and outside the surface, and the bottom of baffle plate 2 304 is...

Embodiment 3

[0045] A kind of diffraction experimental device of this embodiment is basically the same as the above-mentioned embodiment, and further, the baffle plate assembly also includes a baffle plate three (not shown in the figure), and the baffle plate three is located at the front side or the rear side of the baffle plate one 303, And the width of the third baffle is sufficient to cover the gap between the first 303 on both sides; the third baffle is movable along the height direction of the first 303 baffle. Specifically, the baffle plate 3 can be suspended under the top plate 305 through bolt fastening, that is, the bolts are screwed from the upper part through the top plate 305 and connected with the baffle plate 3 below, and the up and down height of the baffle plate 3 can be adjusted by rotating the bolts , and the top surface of the baffle plate 3 is also connected with a soft shielding curtain, one side of which is connected to the top plate 305, and one side is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com