Slag regulating agent for super high power large electric furnace smelting

A technology of electric furnace smelting and slag adjusting agent, which is applied in electric furnaces, furnaces, furnace types, etc., can solve the problems of uneven carbon powder spraying by carbon oxygen guns, high total iron content in furnace slag, and short duration of foamed slag. The effect of prolonging furnace life, improving yield of tapping alloy and improving dephosphorization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

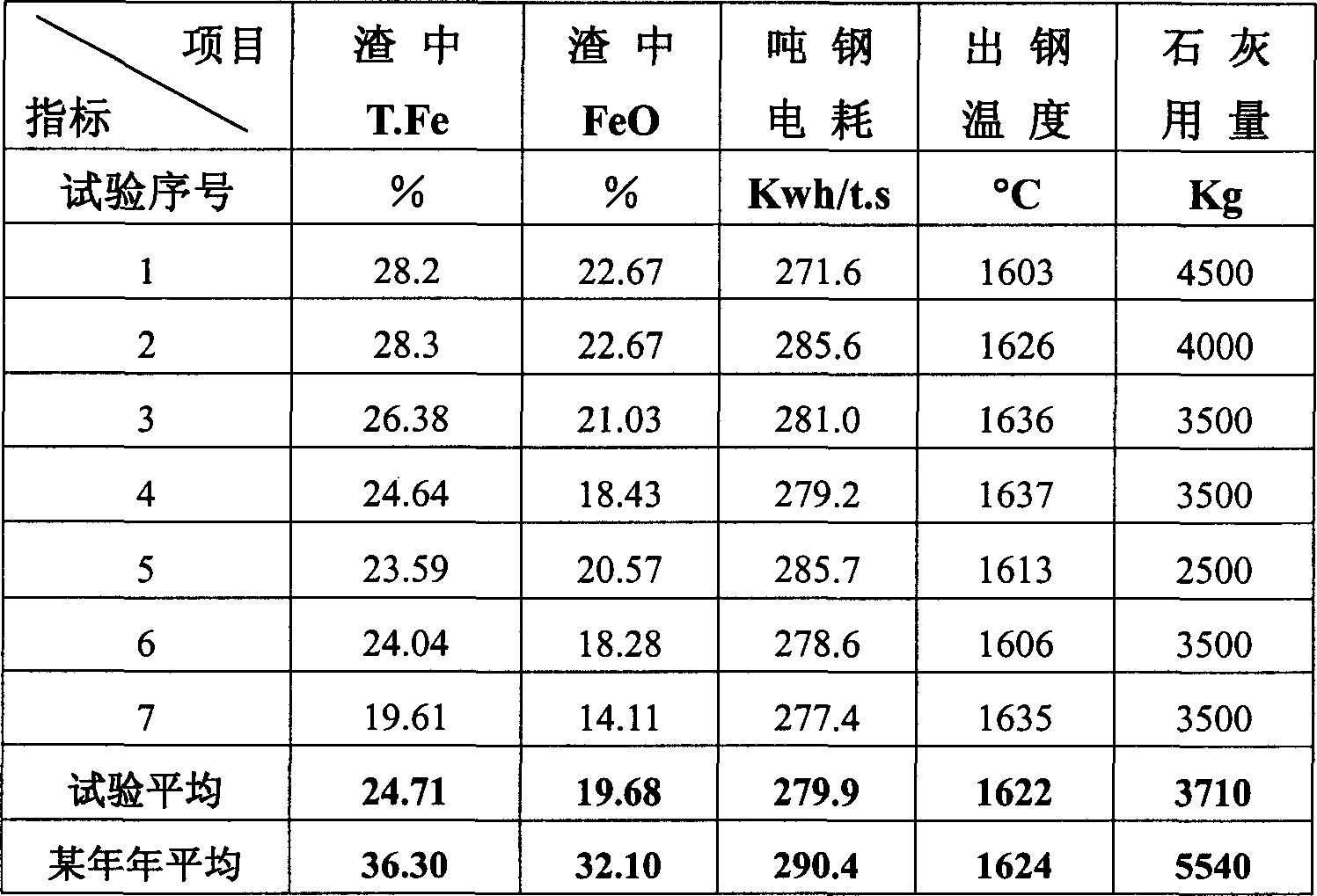

[0011] See Table 1 and Table 2. Table 1 is the summary table of test data; Table 2 is the composition of the electric furnace slag adjustment agent corresponding to the test number in Table 1.

[0012] Table 1

[0013]

[0014] Corresponding test serial number

[0015] The above-mentioned embodiment is carried out in the smelting process of a 150-ton ultra-high-power large electric furnace. About 1 ton of slagging agent is added into the furnace through the furnace top charging system in 3 to 4 batches after the power consumption is about 25000Kwh (if possible, it can be The effect is better if it is added continuously), the added slag adjusting agent is combined with the carbon powder sprayed by the slag door carbon gun to create foam slag uniformly and stably in the furnace, and reduce FeO and Fe in the slag 2 o 3 and other oxides, so that the average total iron content in the slag in the electric furnace dropped from 36.30% in a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com