Method for smelting martensitic stainless steel P91 for boiler pipe

A technology of martensitic stainless steel and smelting methods, applied in the field of smelting, can solve the problems of high cost and unable to meet the needs of continuous casting production, and achieve the effects of short time, saving AOD time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

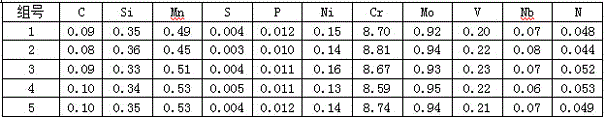

Examples

Embodiment Construction

[0017] A method for smelting martensitic stainless steel P91 for boiler tubes, using an electric furnace to smelt primary molten steel, the process flow is: electric arc furnace (EAF) / intermediate frequency induction furnace (IF) + argon oxygen refining furnace (AOD) + LF refining furnace + vacuum Degassing (VD) + LF + continuous casting (CC) + billet annealing.

[0018] The smelting process is as follows:

[0019] Step 1: Electric arc furnace smelting: the electric furnace is equipped with 60% of special steel scrap, 30% of low five-hazard pig iron, and 10% of low five-hazard sponge iron. After the sampling test, As≤0.012%, Sn≤0.010%, Pb≤0.010%, Sb≤0.005%, Bi≤0.010%, electric arc furnace tapping conditions: end point [P]≤0.003%, tapping temperature≥1640℃;

[0020] Step 2: The intermediate frequency material is composed of 7-8 tons of high-carbon ferrochromium, 0.5-0.8 tons of ferromolybdenum, and 1-2 tons of P91 material head. Before mixing, carefully check the P content to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com