Patents

Literature

35results about How to "Improve the strength of sinter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintering technology of ferrochrome mineral powder

Owner:CENT SOUTH UNIV

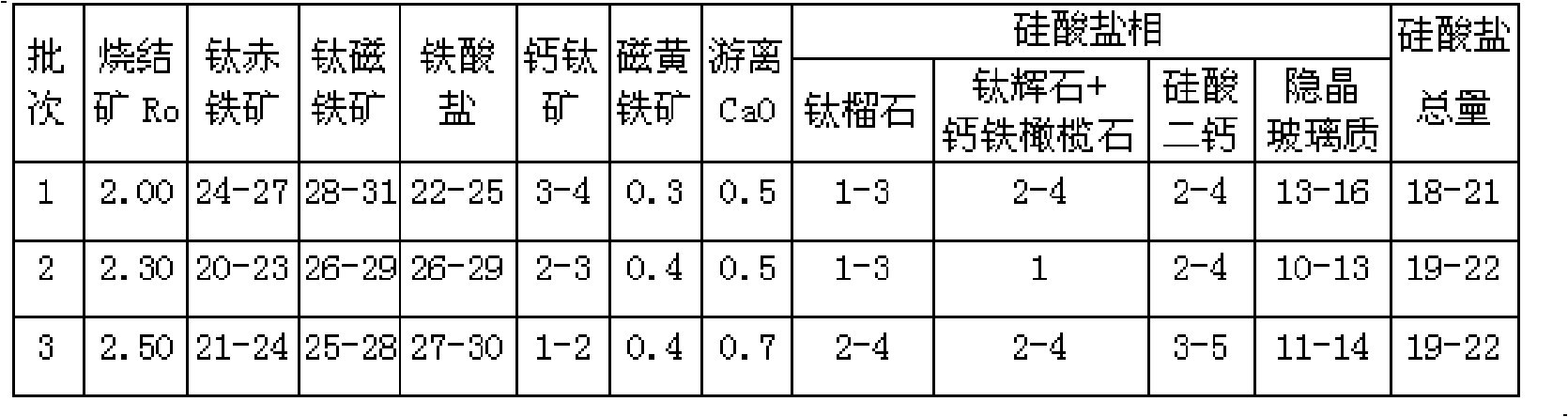

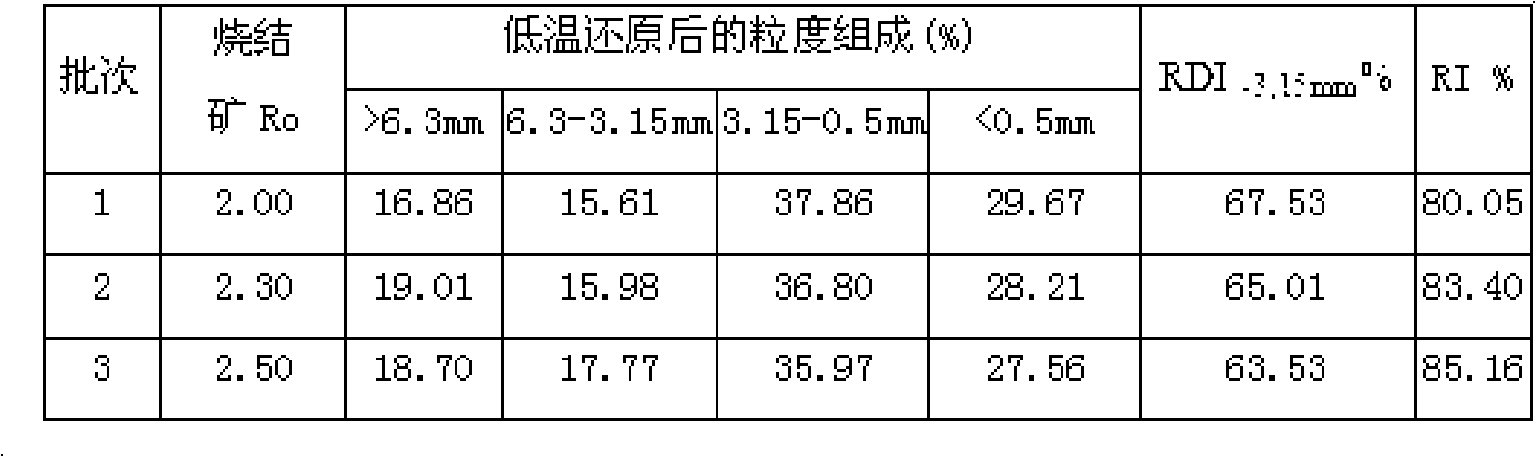

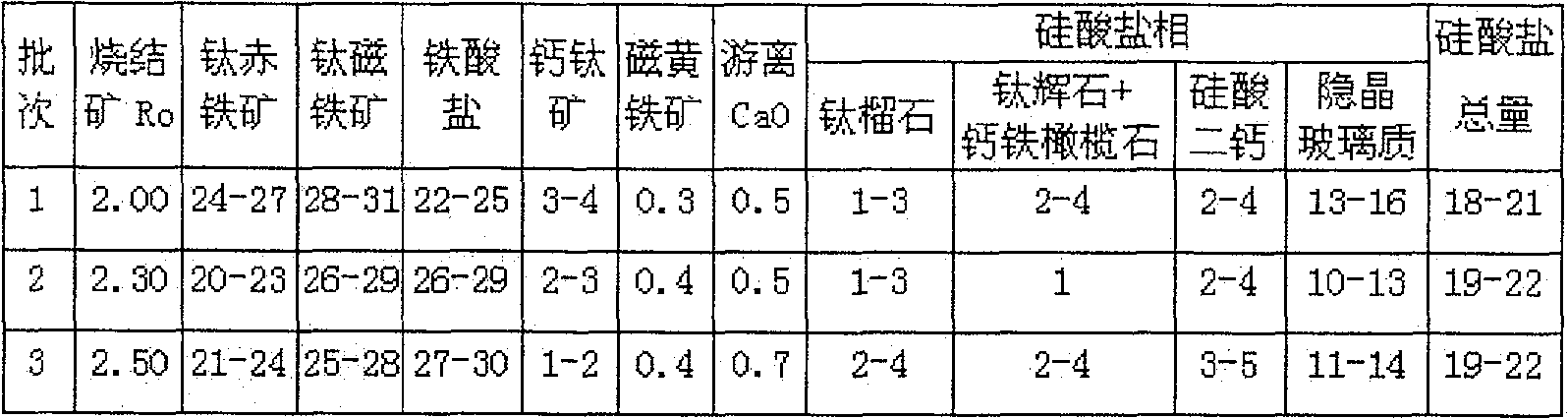

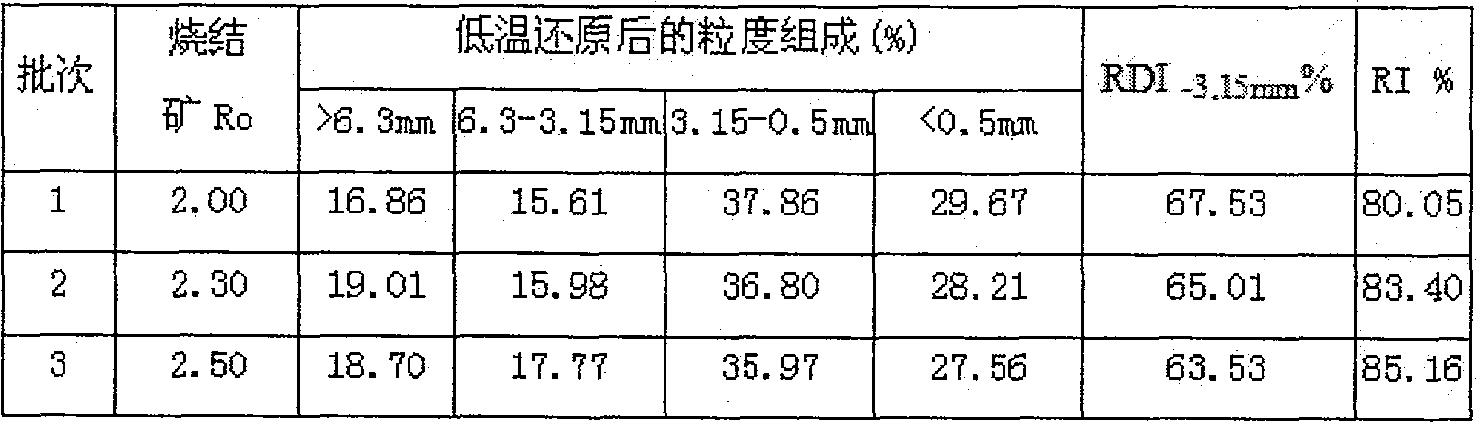

High titan type high alkalinity sinter and method for preparing same

The invention belongs to the field of metallurgy and mainly relates to a manufacture method for preparing a high titanium high pH value sintering ore by a v-ti magnetite concentrate ore. The technical problem needed to be solved is to provide a preparation method which takes the high titanium v-ti magnetite concentrate ore specially owned by Panzhihua as the material to prepare the high titanium high pH value sintering ore. The method is mainly characterized by taking the high titanium v-ti magnetite concentrate ore as the material with a sintering temperature of 1300 to 1400 DEG C. The technique of the invention applied to prepare the sintering ore is simply controlled; the high pH value sintering ore obtained by sintering is smelted; the technical economic indexes like the operating factors of a blast furnace, a coke ratio, a coal ratio, etc, and the like, are all improved. The method of the invention essentially improves the minimal components of a v-ti sintering ore, improves the intensity of the sintering ore and improves the metallurgy performance by improving the pH value of the v-ti sintering ore to 2.0 to 3.2, controlling a proper carbon addition amount and increasing the amount of a liquid phase.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

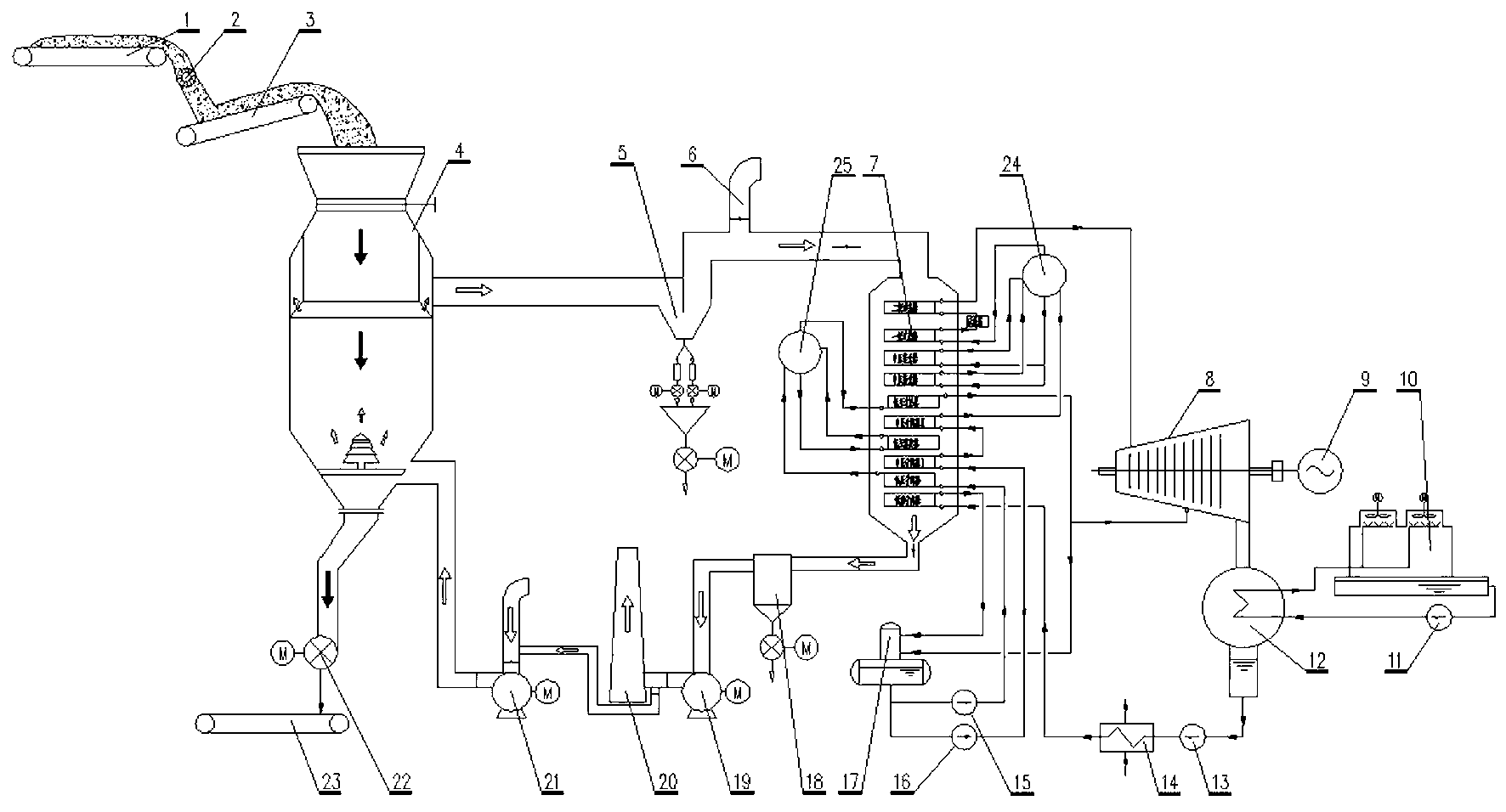

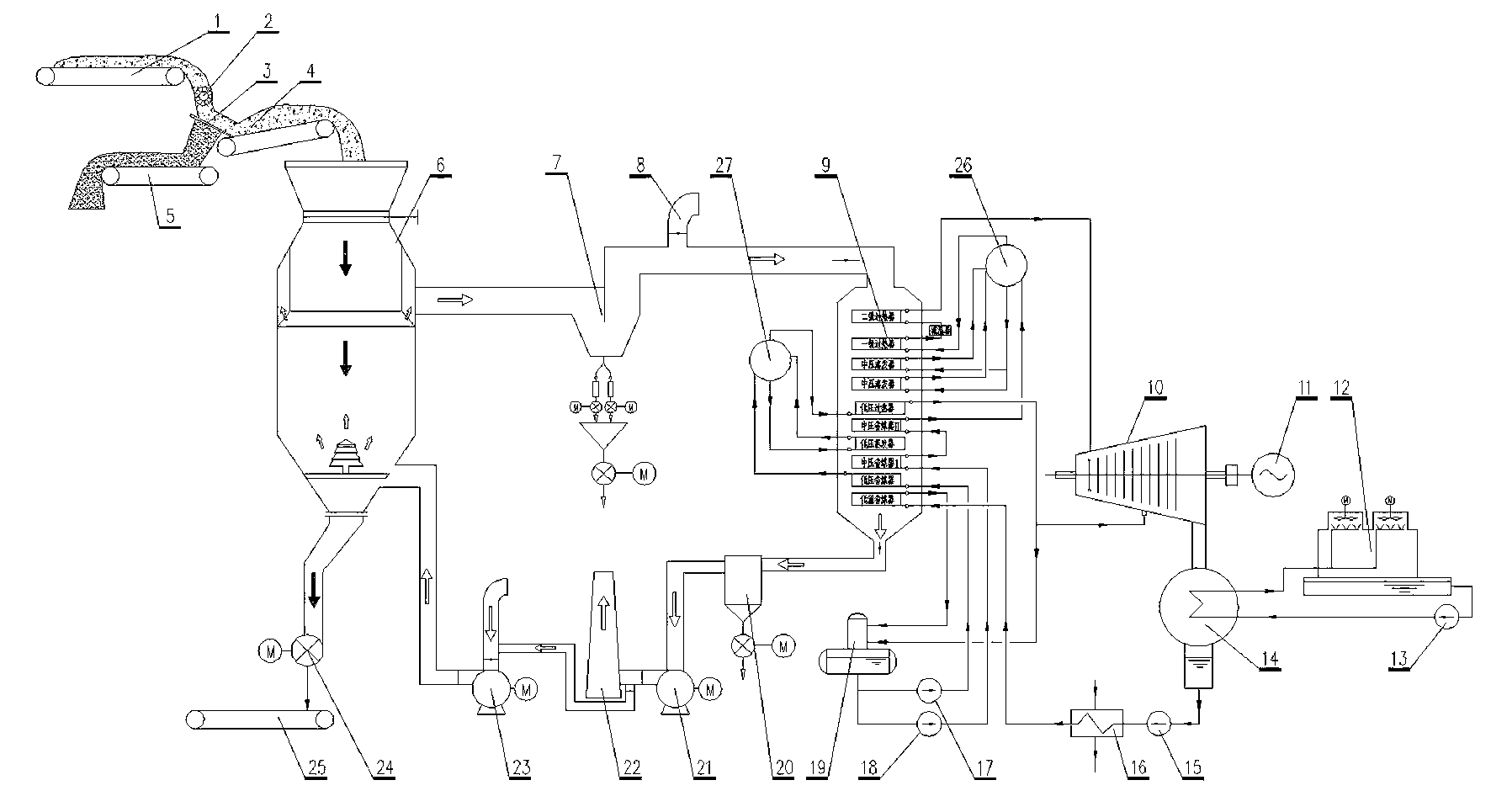

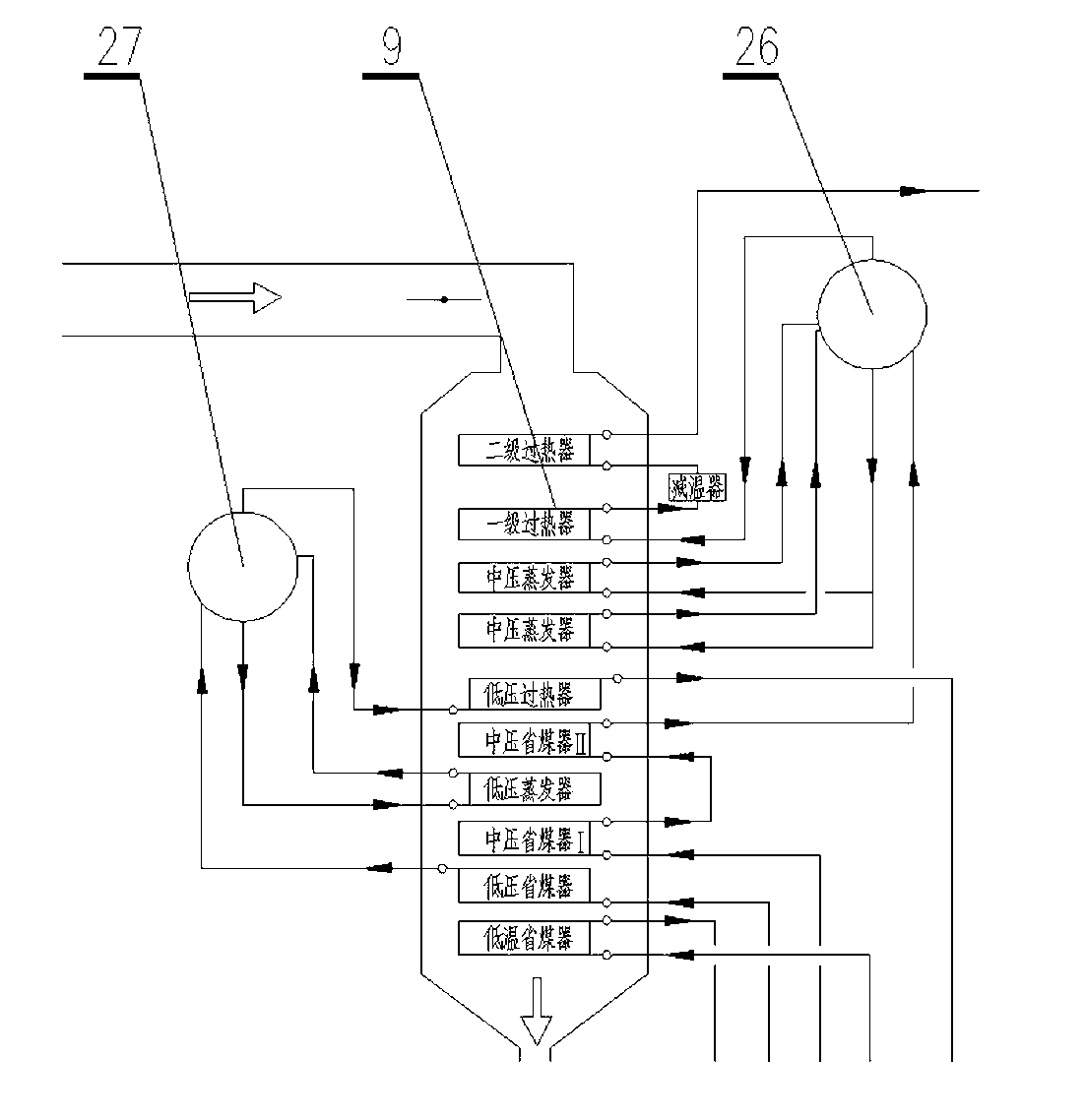

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialCogenerationMaterials science

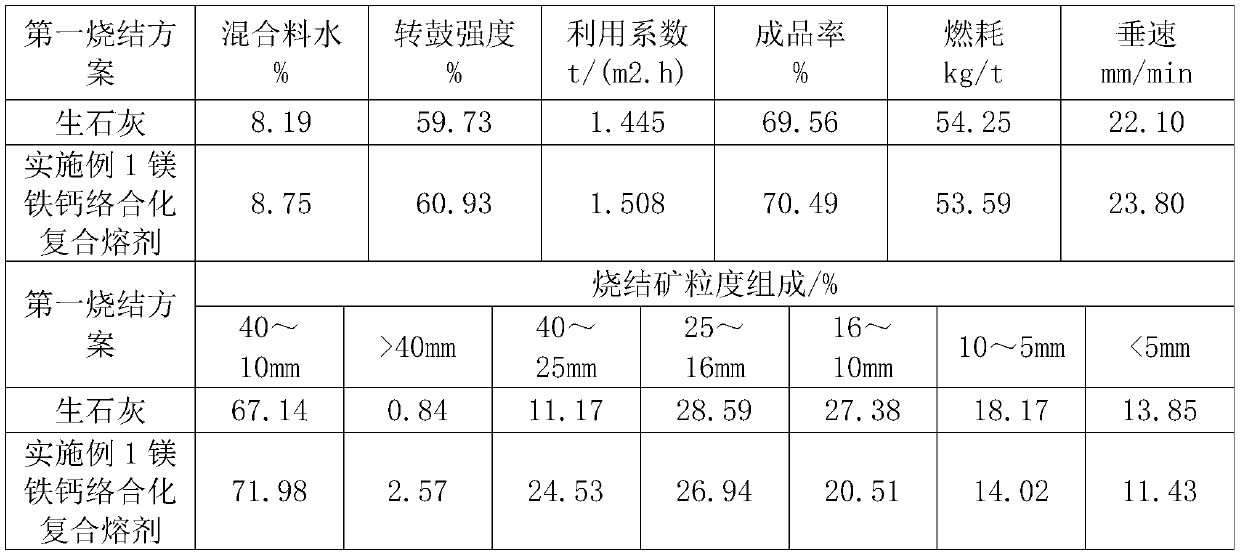

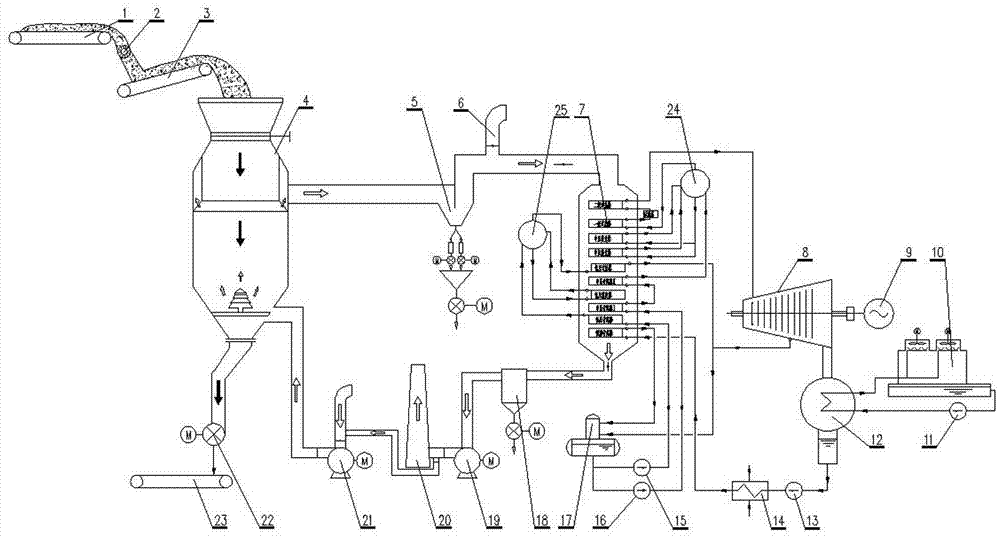

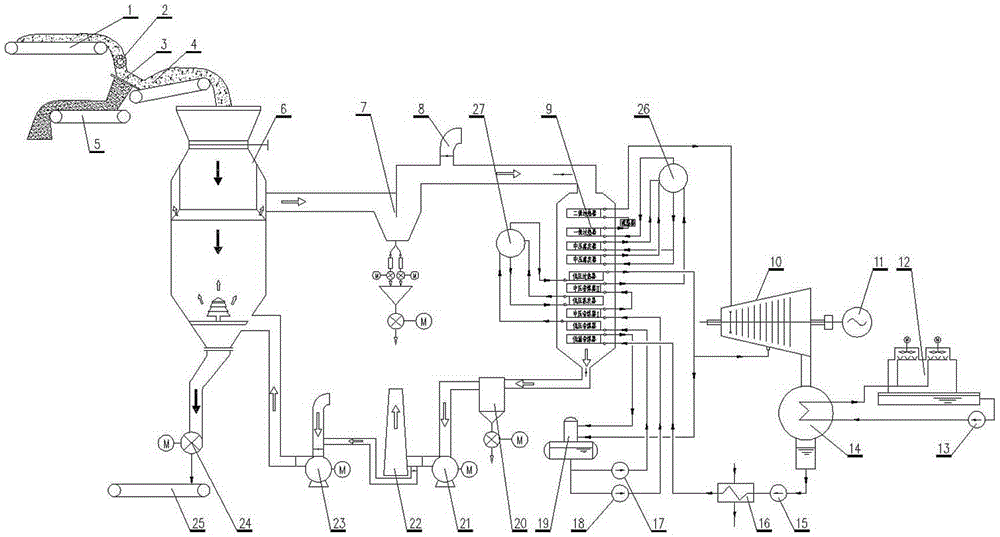

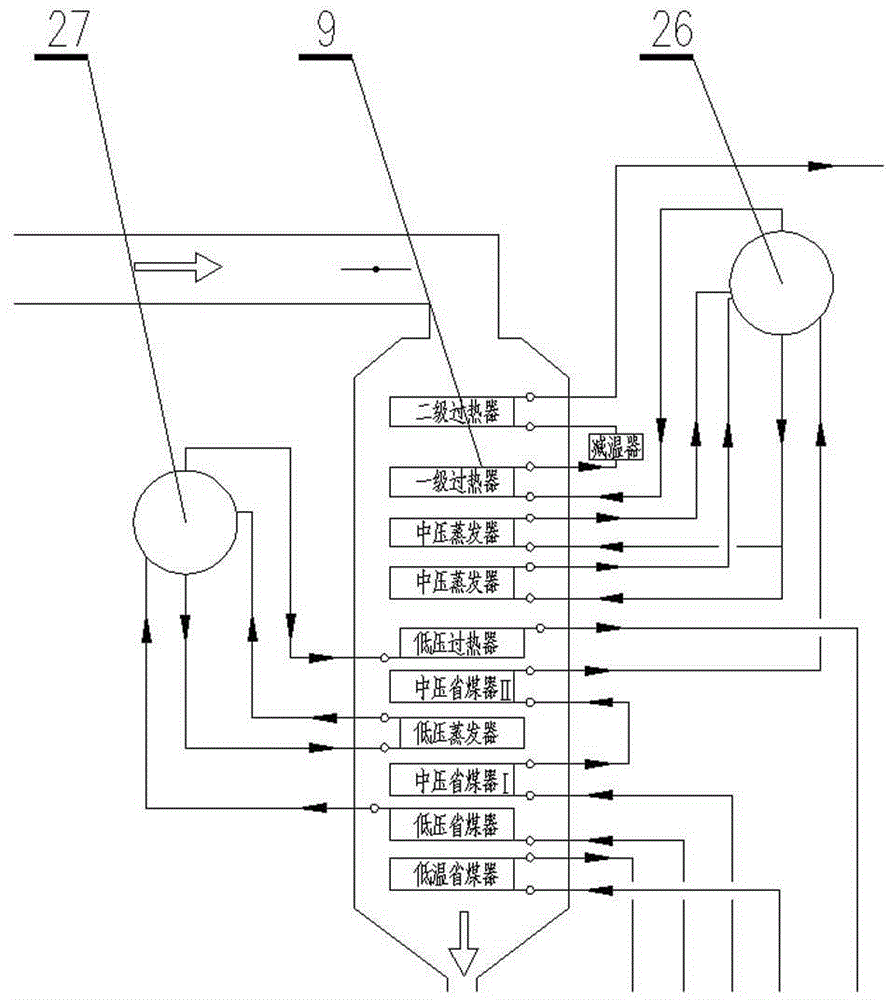

The invention discloses a device and a process for generating power through efficient recovery of waste heat of sintered ores and belongs to the technical field of cogeneration. The device comprises a sintered ore cooling system, a waste heat power generating system and a smoke system, wherein the sintered ore cooling system and the waste heat cycling power generating system are connected through the smoke system to form a loop. The process comprises the steps of 1), cooling of sintered ores; 2) the smoke system; and 3) waste heat power generating. The device and the process for generating power through waste heat have the advantages that discharged waste heat is used fully during cooling of sintered ores, the electric energy production is improved significantly, the power rate of the system is reduced significantly, and the energy-saving effect is significant.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

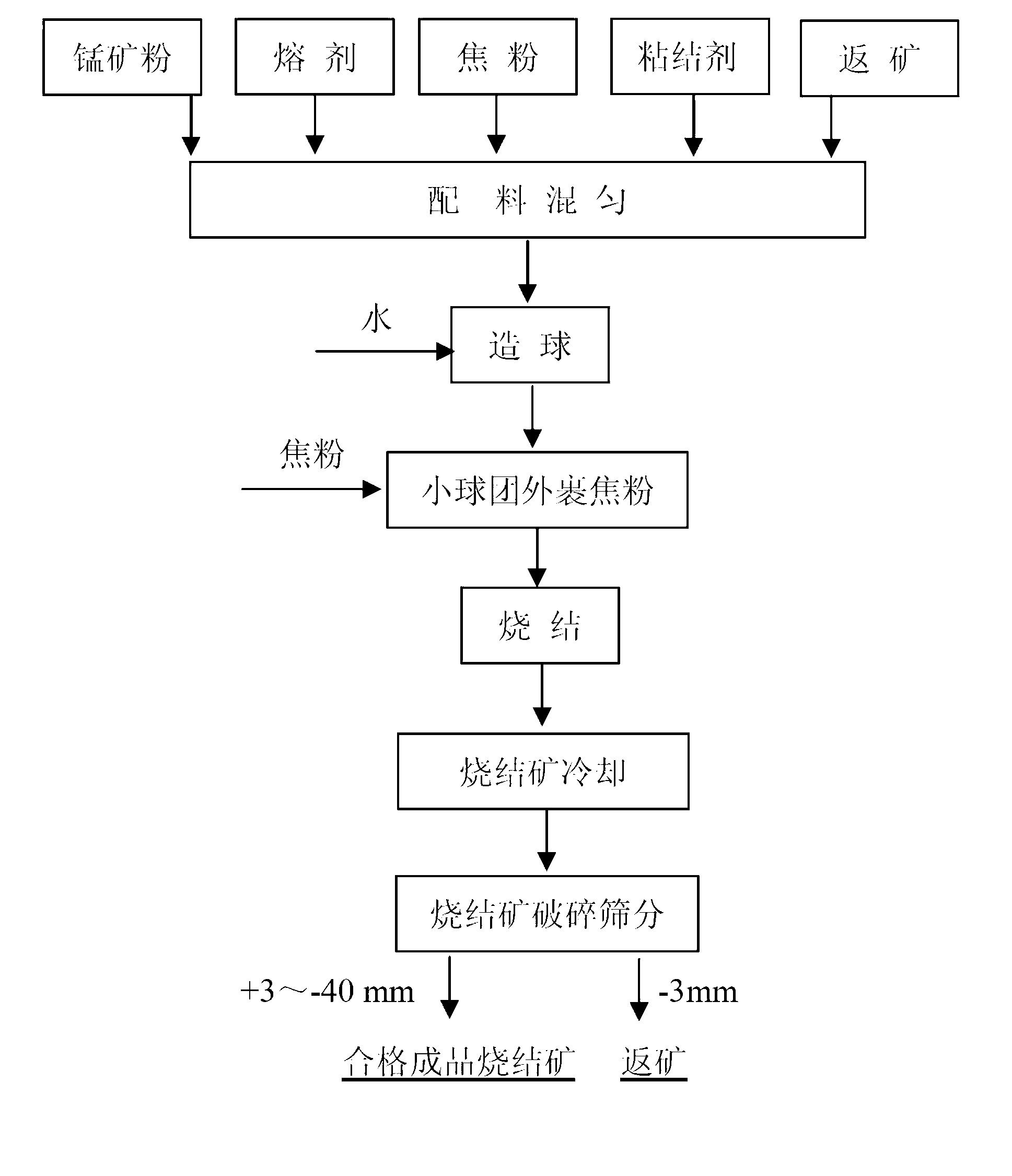

Sintering process of manganese ore powder

The invention discloses a sintering process of manganese ore powder. The process comprises the following steps of: adding water to mix manganese ore powder, a binding agent, fuel, a fluxing agent and return ore as mixed ore, wherein the binding agent is formed by mixing manganese salt and organic matter and counts for 0.6-3.0% of mass of the mixed ore, the fuel counts for 3.0-6.0% of mass of the mixed ore, the fluxing agent counts for 3.0-15.0% of mass of the mixed ore, the return ore counts for 10-30% of mass of the mixed ore and the adding amount of water counts for 5.0-15.0% of mass of the mixed ore; preparing the mixed ore as pellets; and then coating a layer of fuel on the surfaces of the generated pellets, drying and preheating, subsequently firing and sintering as hot-sintered ore; and cooling, breaking and screening the hot-sintered ore to obtain finished product sintered ore and return ore. The sintering process of manganese ore powder disclosed by the invention combines the advantages of the pelleting process and the sintering process, so that the strength and the yield of the finished product sintered ore are greatly enhanced and the energy consumption is obviously reduced.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Sintering ore additive

InactiveCN1924036AImproved low temperature reduction propertiesReduce consumptionMetallurgyEnergy consumption

The invention discloses a sintering additive, which comprises the following parts: 20wt%-60wt% composite mineralizer,10wt%-30wt% oxidizing catalyst,15wt%-40wt% oxygenation agent and 10wt%-30wt% protective. The additive can improve sintering oaring strength, which reduces energy consumption effectively.

Owner:娄底市裕德科技有限公司

Process for producing sintered ore for ironmaking through blast furnace from high-aluminum limonite

The invention discloses a process for producing sintered ore for ironmaking through a blast furnace from high-aluminum limonite. The high-aluminum limonite accounts for 60%-70% of the weight of iron-containing raw material, and fine particle magnetite concentrate accounting for 25%-35% of the weight of the iron-containing raw material is mixed into the iron-containing raw material. The process comprises the following steps of: performing blending, mixing and pelletizing treatment on the iron-containing raw material, a solvent and coke powder; performing sintering, material distribution, ignition, sintering, cooling and particle adjustment on a pelletized mixture to get a finished product of the sintered ore, determining the alkalinity of a sintered mixture according to the requirement of smelting of the blast furnace on the alkalinity, wherein the ordinary range of the alkalinity is 1.7-2.1; and mixing limestone, dolomite and quicklime into the mixture for regulating the alkalinity, wherein the mixing weight of the quicklime is 1-4%. The adding of the fine particle magnetite concentrate can effectively improve the pelletizing effect of the high-aluminum limonite, significantly improve the sintering air permeability, greatly reduce the using quantity of the coke powder, improve the metallogenic conditions during the sintering process of the high-aluminum limonite, effectively improve the quality indexes of the sintered ore and realize the application of the high-aluminum limonite in sintering production.

Owner:CENT SOUTH UNIV

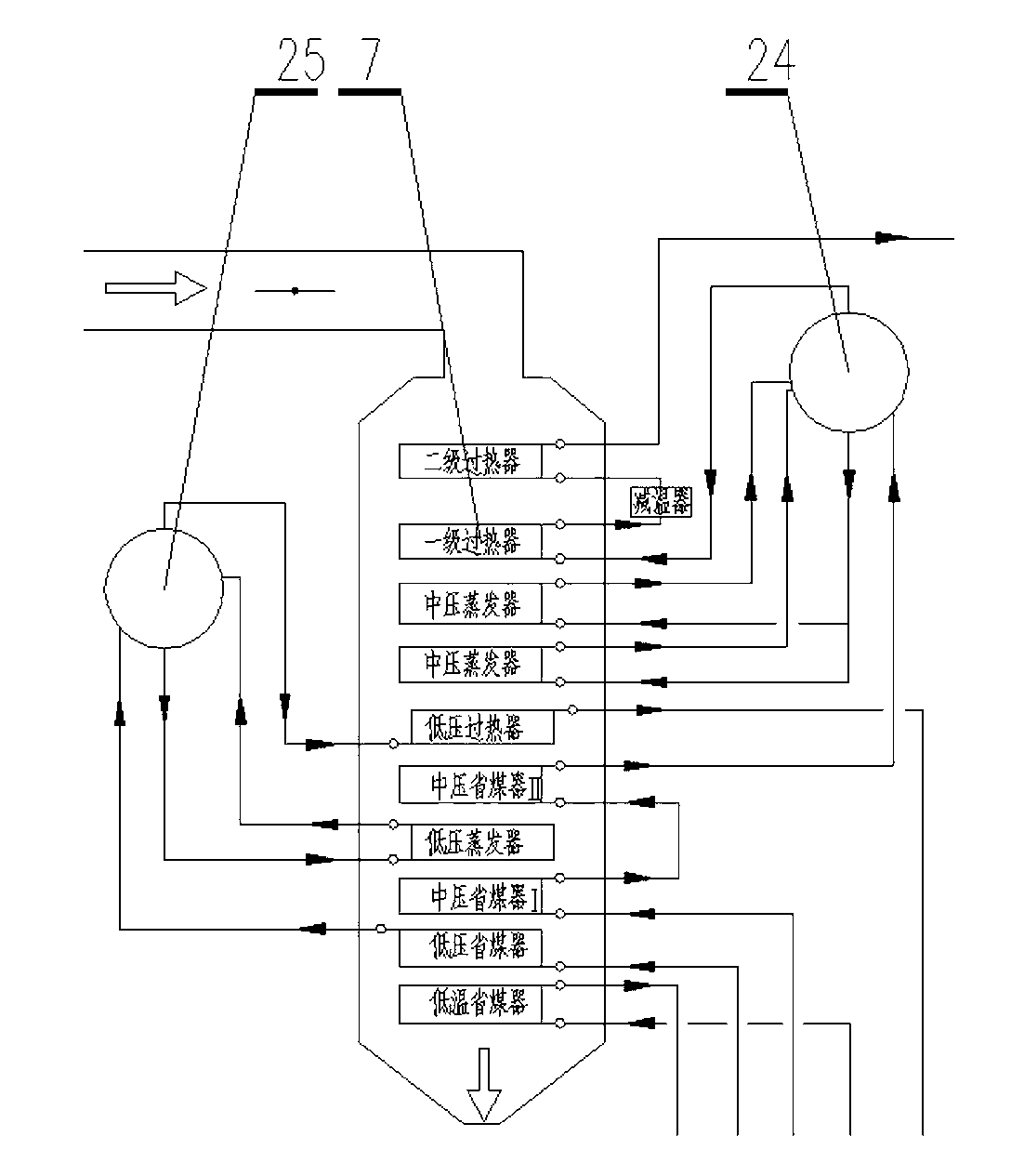

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Furnace type efficient recovery system for flue gas waste heat of cooled sinter

InactiveCN103234363AImprove qualityImprove waste heat utilization efficiencyIncreasing energy efficiencyWaste heat treatmentProcess engineeringFlue gas

A furnace type efficient recovery system for flue gas waste heat of cooled sinter comprises an air blower, a cooling furnace, a primary dust remover, an emergency blow-off valve, a waste heat boiler, a secondary dust remover, a draft fan and a chimney. An outlet of the air blower is communicated with a cooling air inlet on the lower portion of the cooling furnace. A flue gas outlet on the upper portion of the cooling furnace is communicated with the primary dust remover, the waste heat boiler, the secondary dust remover, the draft fan and the chimney through pipelines successively. The emergency blow-off valve is arranged on a pipeline between the primary dust remover and the waste heat boiler. A connection pipeline is arranged between the draft fan and the air blower. The furnace type efficient recovery system for flue gas waste heat of cooled sinter has the advantages that the sinter quality is improved, the sinter return rate is reduced, flue gas parameters are stable, the system own power consumption rate is reduced, and the energy-saving effect is apparent.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Sintering method of iron ore with added limonite

The invention provides a sintering method of iron ore with added limonite. The sintering method of the iron ore with the added limonite comprises the steps of limonite fine grinding treatment, limonite roasting treatment, batching, mixing, material distribution, material pressing and sintering with fire, wherein the granularity of the ground limonite is controlled to be below 1mm, the ground limonite is roasted at the temperature of 180-220 DEG C, the water content of the mixed material is controlled to be 7.3-7.6 wt%, and the quantity of the pressed materials in the step of material pressing is controlled to be 20-50 mm. The sintering method of the iron ore with the added limonite is capable of eliminating the explosion phenomenon in the sintering process of the coarse-grain limonite, improves the strength and the yield of sintered ore, improves the quality of the sintered ore, can reduce the content of crystal water in the limonite, is favorable for sintering, can reduce the consumption of fuel, improves the grain composition of the mixed materials, and improves the air permeability of material layers, thereby improving the yield and the quality of the sintered ore. In addition, the sintering method of the iron ore with the added limonite is capable of improving the compactness of the material layers, improves the structure of the sintered ore, controls the sintering speed at the same time, improves the metallurgical performance of the sintered ore, and is favorable for improving the techno-economic indicators of a blast furnace process.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

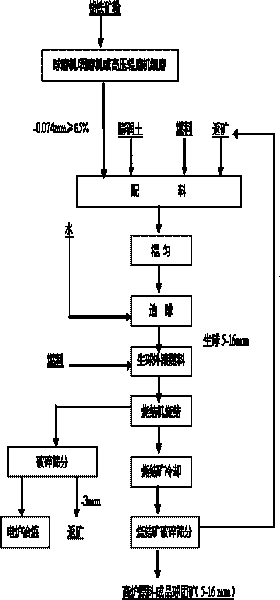

Sintering method of fine Baima vanadium-titanium magnetite concentrate

The invention discloses a sintering method of fine Baima vanadium-titanium magnetite concentrate. The sintering method comprises the sequential steps of burdening, mixing with water, pelletizing, igniting and sintering, spraying CaCl2 solution and blast furnace processing, wherein based on mass, the water content in the mixed material in the water mixing step is 7.2-7.5%; the carbon content in the mixed material is 4.8-5.0%; the material layer height when igniting and sintering is 640-700 mm; and the mass concentration of the sprayed CaCl2 solution is 1.5-3%. Through optimizing of the sintering technical parameters, comprehensively improving of the water content of the sintering mixed material, the carbon content in the mixed material and the height of the material layer, the grain composition and the sinter components of the mixed material when the fine Baima vanadium-titanium magnetite concentrate is sintered are greatly improved; the sintering atmosphere, flux mineralization, sintering heat system and mineral crystallization in the sintering process are effectively strengthened, so as to improve the sinter product yield and quality, and enable the yield and the quality of the sinter and the metallurgical performance to be greatly improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Sintering ore with uniform grain size and production method thereof

The invention belongs to the technical field of steel metallurgy, and particularly relates to a sintering ore with uniform grain size and a production method thereof. According to the mass ratio in araw material, a main material comprises 5wt% - 10wt% of Brazil Coarse Fines, 10wt% - 15wt% Brazilian Blended Fines, less than or equal to 25wt% of PB Fines, less than or equal to 25wt% of Newman Fines, less than or equal to 15wt% of Mac Fines, less than or equal to 20wt% of Jimblebar Fines, less than or equal to 15wt% of Indian Fines, less than or equal to 25wt% of FMG Blended Fines, less than orequal to 25wt% of Western Fines, less than or equal to 15wt% of Super Special Fines, less than or equal to 15wt% of Yandi Fines, less than or equal to 15wt% of Robe River Fines; and an auxiliary material comprises 15wt% of return fines, 4wt% - 5wt% of dolomite fines, 6.4wt% - 7.5wt% of pale gray, 2wt% - 4wt% of limestone fines, 2.2wt% - 2.3wt% of coal fines and 2.1wt% - 2.2wt% of coke fines.

Owner:TIANJIN TIANGANG UNITED SPECIAL STEEL CO LTD

Sintering method of Mei Shan iron concentrate

The invention relates to a sintering method of Mei Shan iron concentrate. The method mainly solves the technical problems of low strength and low yield of sintered ores produced by the Mei Shan iron ore concentrate with sintered return ores in the prior art. According to the technical scheme, the sintering method of the Mei Shan iron concentrate comprises the following steps of 1), preparing the ores, specifically, calculating the preparation mass ratio of the Mei Shan iron ore concentrate, iron ore powder, the sintered return ores, fluxes and solid fuel according to the technical quality indexes of the sintered ore; 2), preparing a Mei Shan iron ore concentrate prefabricated grain small ball; 3), preparing a sintered basic mixed material; 4), preparing a sintered comprehensive mixed material; and 5), carrying out material distribution on the sintered comprehensive mixed material on a sintering trolley, carrying out ignition and air draft sintering processes on the sintered comprehensive mixed material to produce a finished product sintered ore. The sintered ore produced by the method has the advantages of being excellent in metallurgical performance, simple in process, low in costand the like; the method improves the strength of the sintered ore with the Mei Shan iron concentrate and related technical economic indexes.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

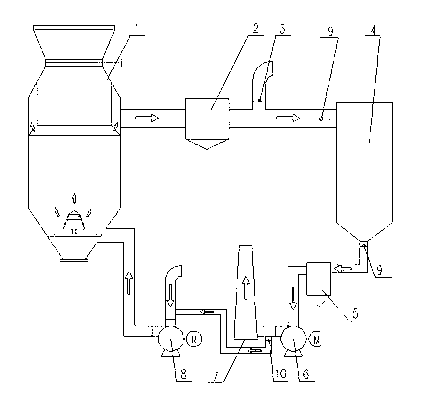

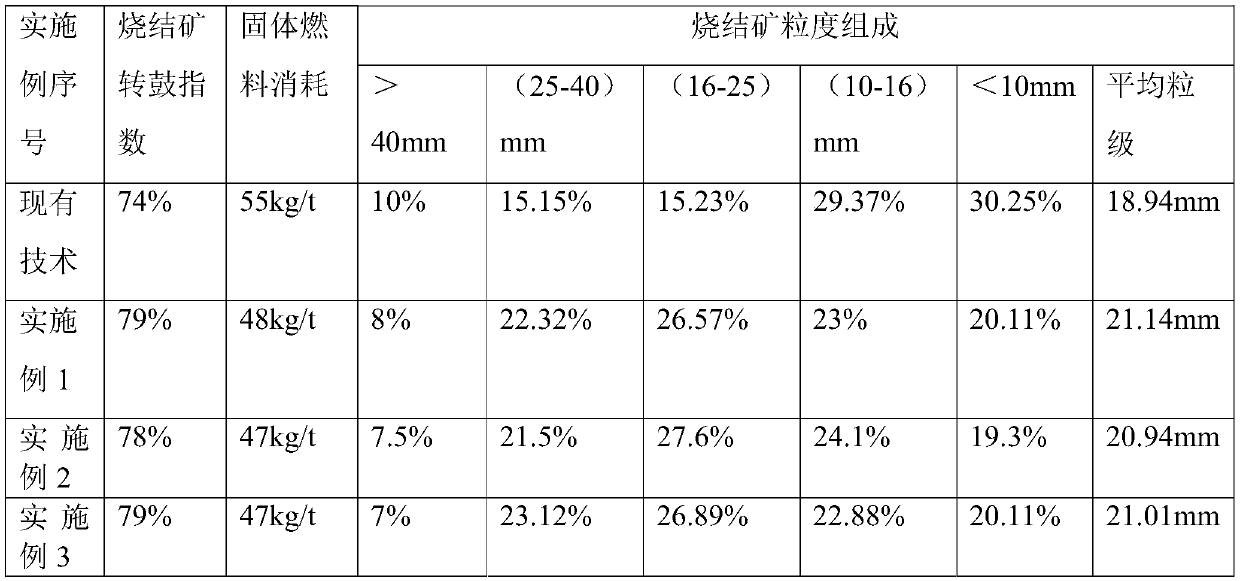

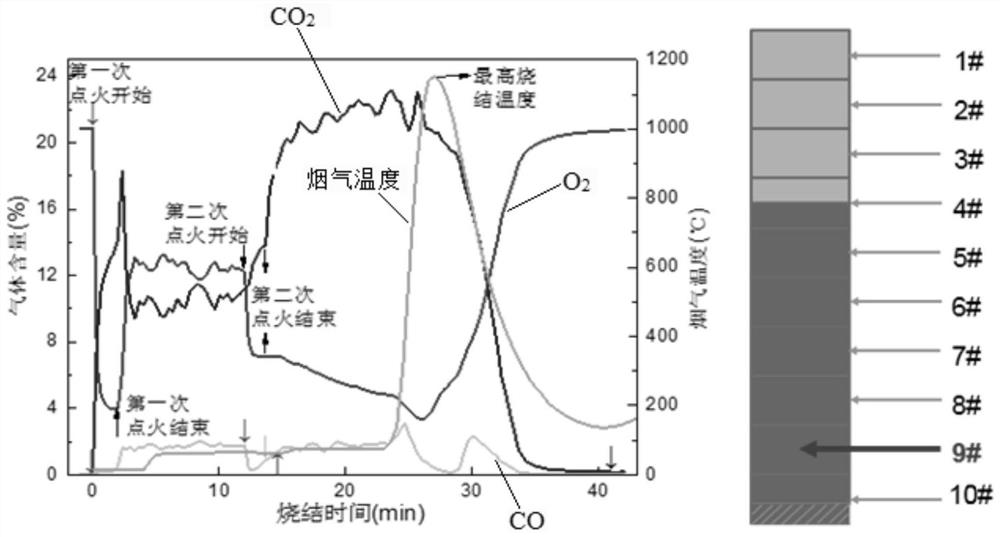

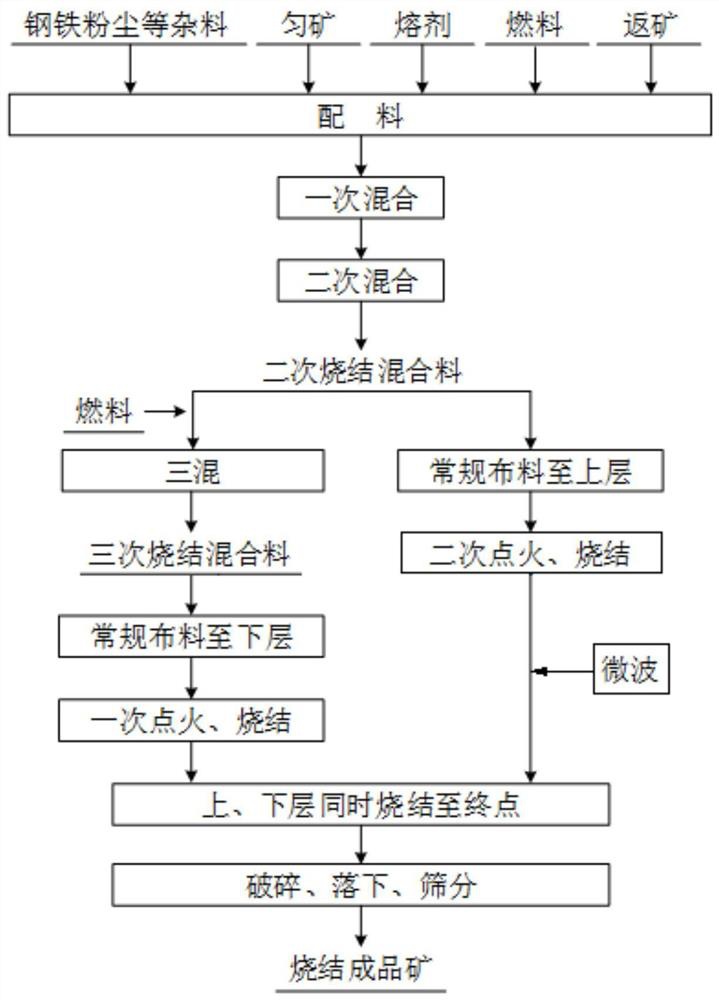

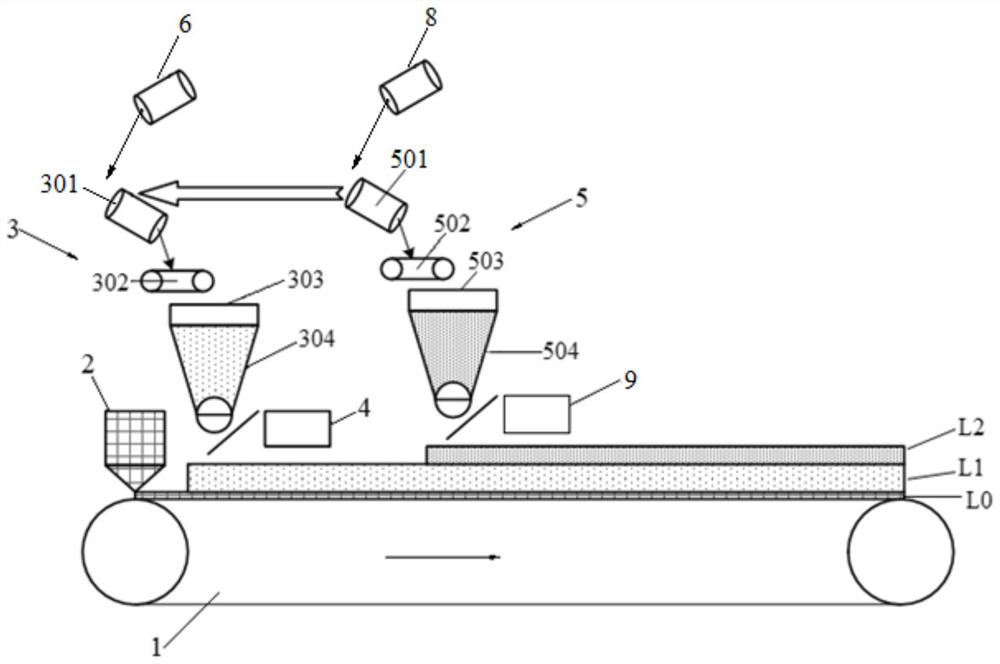

Double-layer sintering method and sintering device

ActiveCN112410544AIncrease production capacitySolve technical problemsHeat conservationBedding Material

The invention relates to a double-layer sintering method, which comprises the following steps: 1) proportioning an iron-containing raw material, a flux and a fuel, and preliminarily mixing the proportioned materials to obtain a sintered preliminary mixture; 2) adding fuel into the preliminary sintering mixture, and mixing again to obtain a sintered remixed mixture; 3) paving a bedding material ona sintering trolley, paving the sintered remixed mixture on the bedding material to obtain a first distribution layer, and then performing primary ignition sintering on the first distribution layer; and (4) paving the sintered preliminary mixture on the first distribution layer to obtain a second distribution layer, carrying out secondary ignition sintering on the second distribution layer, and providing an external heat source for heating and heat preservation of the second distribution layer. According to the double-layer sintering method and sintering device provided by the invention, the fuel is innovatively distributed in the material layer according to the mode that the upper layer content is low and the lower layer content is high, so that the oxygen amount consumed by the upper layer sintered mixture is reduced, it is guaranteed that the lower layer sintered mixture can obtain the sufficient oxygen amount, and the problems that according to an existing double-layer sintering process, the lower layer sintering oxygen content is insufficient, and the sintering ore strength is poor are solved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Additive for improving sinter reducibility, high-reducibility sinter and preparation method thereof

The invention belongs to the technical field of steel metallurgy sintering and discloses an additive for improving sinter reducibility, high-reducibility sinter and a preparation method thereof. The additive for improving sinter reducibility is made by mixing a boron-containing compound, hydrogen peroxide, permanganate and water, wherein the contents of the boron-containing compound, hydrogen peroxide and the permanganate are, by mass percent, 0.05%-5%, 0.1%-10% and 0.03%-3% correspondingly, and the balance is water. The method for preparing the high-reducibility sinter comprises the steps that common sinter obtained through sintering is broken and is then cooled in a ring cold machine, the trolley pitch diameter speed is lowered, the blast volume is adjusted, and when the surface temperature of the sinter reaches 400 DEG C-600 DEG C, the additive is sprayed on the surface. Through the additive and the method, other properties are not influenced while the sinter reducibility can be improved effectively, and the foundation is laid for blast furnace intensified smelting.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Additive for saving energy in process of sintering iron ore

The invention discloses an additive for saving energy in the process of sintering iron ore. The additive is aminoethanol, which has a common name of ethanolamine. The using amount of the ethanolamine is 0.06 to 0.3 percent of the mass of coke powder for sintering. During use, the ethanolamine is dissolved in water to be prepared into a solution; adding the aqueous solution into the coke powder, mixing uniformly in advance; and mixing with blended ore and a fusing agent, and pelletizing for sintering. The additive can improve the combustion efficiency of the coke powder in the sintering process, reduce consumption of solid fuel, and improve the yield and quality of the sintered ore. The additive has the characteristics of wide sources, low cost, environmental friendliness and the like.

Owner:CENT SOUTH UNIV

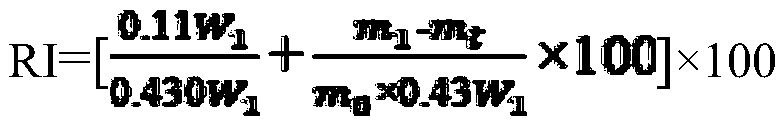

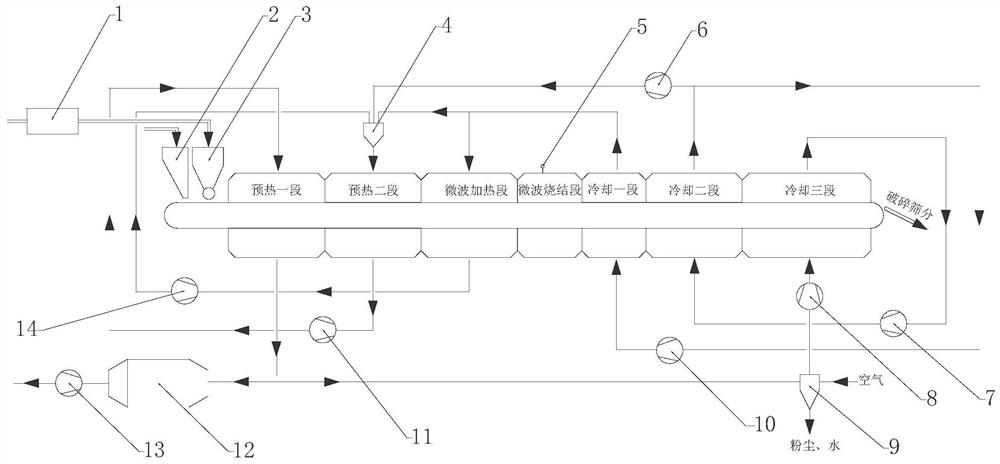

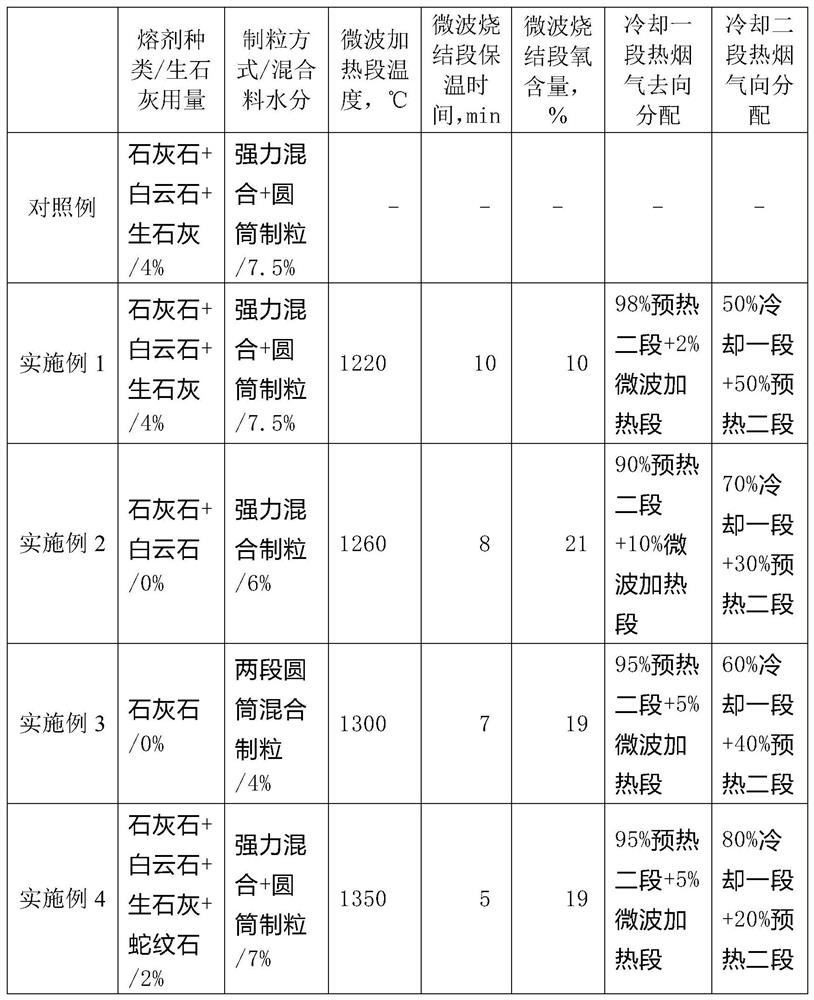

A kind of iron ore microwave sintering method

The invention discloses a microwave sintering method for iron ore. Iron ore, flux, returned ore and iron-containing solid waste are batched, mixed and granulated, and then directly loaded into the sintering machine with the paved bottom material by means of round roller feeding. On the trolley; the sintering trolley filled with the mixture will go through the first stage of preheating, the second stage of preheating, the microwave heating stage, the microwave sintering stage, the first stage of cooling, the second stage of cooling and the third stage of cooling according to the set moving speed. The mixture is preheated, heated, sintered and cooled to form ore, and then crushed and screened to obtain the finished sintered ore. By adopting the invention, no fuel is used, most of the flue gas can be recycled, and the problem of pollutant discharge in the iron ore sintering process can be completely solved, energy consumption can be reduced, and green production can be realized.

Owner:BAOSHAN IRON & STEEL CO LTD

High-temperature sintering technology for nickel mineral powder

The invention discloses a high-temperature sintering technology for nickel mineral powder. The nickel mineral powder is composed of raw materials including, by weight percent, 35%-50% of the nickel mineral powder, 8%-10% of carbon powder, 10%-15% of iron powder, 0.6%-3% of a bonding agent, 3%-5% of fuel and 8%-15% of a fluxing agent. Compared with the prior art, the high-temperature sintering technology has the beneficial effects that a sintering method for the nickel mineral powder is simple in technological method and convenient to operate, additives such as waterborne macromolecules, furfural residues and coal ash are added in the fine grinding stage of the nickel mineral powder, an obvious grinding assisting effect is achieved, the activity of the mineral powder is effectively excited, and the reaction temperature of the mineral powder is reduced. Meanwhile, a segmented heating method is adopted in the high-temperature sintering process, the strength of sintered ore is improved, the yield of the sintered ore is increased, and consumption of solid fuel is reduced.

Owner:TONGLING ANDONG CAST STEEL

Metallurgy sintering synergist as well as preparation method and application thereof

ActiveCN114438312ASuppress generationReduce chalkingRecycling and recovery technologiesActivated carbonSlag

The invention discloses a metallurgical sintering synergist as well as a preparation method and application thereof. The synergist is prepared from the following raw materials in percentage by weight: 35-65% of steel slag, 0.1-2% of polyethylene glycol, 2-8% of fluorite, 0.05-2.5% of potassium permanganate, 0.5-8% of hydrogen peroxide, 1-5% of ammonium metavanadate, 0.5-2% of waste activated carbon and the balance of water. By optimizing the compound substances and using the synergist, the rotary drum quality of the sintered ore can be improved, the vertical sintering speed can be increased, the particle size composition of the sintered ore can be improved, RDI + 3.15 can be improved, the reduction degree and the molten drop performance can be improved, and the energy consumption can be reduced.

Owner:云南科兴环保科技有限公司

Sintering process of iron ore powder pellets

ActiveCN114540615AHigh strengthIncrease capillary forceProcess efficiency improvementMaterial distributionUltimate tensile strength

The invention discloses a sintering process of iron ore powder pellets, which fully utilizes the heat storage effect of a material layer and the characteristics that the upper temperature of the material layer is low and the lower temperature of the material layer is high in the sintering process, and adopts a three-layer material distribution mode to ensure the uniformity of the temperature of the material layer, so that the fuel at the lower part of the material layer is less, the fuel at the middle part is higher and the fuel at the upper part is more; the temperature of the whole material layer is uniform. Through layered material distribution, material layer fuel is regulated and controlled to be matched with the temperature, so that the consolidation effect of sintered ore is improved, and solid energy consumption is reduced. The hydrophilic performance of the raw materials is improved through a raw material pretreatment process, and then the air permeability of the raw materials is improved through a pelletizing process; and in the sintering link, the moisture of the sintered material is reduced through the drying process, the phenomenon that the moisture is too high in the sintering process is avoided, and the thermal-state air permeability in the sintering process is improved. The dynamic conditions of mass transfer and heat transfer in the sintering process are improved, the oxidizing atmosphere in the sintering process is improved, reasonable blending of solid-phase consolidation and liquid-phase consolidation of pellet sintering is promoted, and the strength of sintered ore is improved.

Owner:CENT SOUTH UNIV

A kind of metallurgical sintering synergist and its preparation method and application

ActiveCN114438312BSuppress generationReduce chalkingRecycling and recovery technologiesActivated carbonSlag

The invention discloses a metallurgical sintering synergist and a preparation method and application thereof. By weight percentage, the synergist is prepared from the following raw materials: steel slag 35~65%, polyethylene glycol 0.1~2%, fluorite 2~8%, potassium permanganate 0.05~2.5%, hydrogen peroxide 0.5~ 8%, ammonium metavanadate 1~5%, waste activated carbon 0.5~2%, and the balance is water. The invention can improve the quality of the sintered ore drum, improve the vertical sintering speed, improve the particle size composition of the sintered ore, and improve the RDI by optimizing the compound material and the use of the synergist. +3.15 , improve the reduction degree and droplet performance, reduce energy consumption.

Owner:云南科兴环保科技有限公司

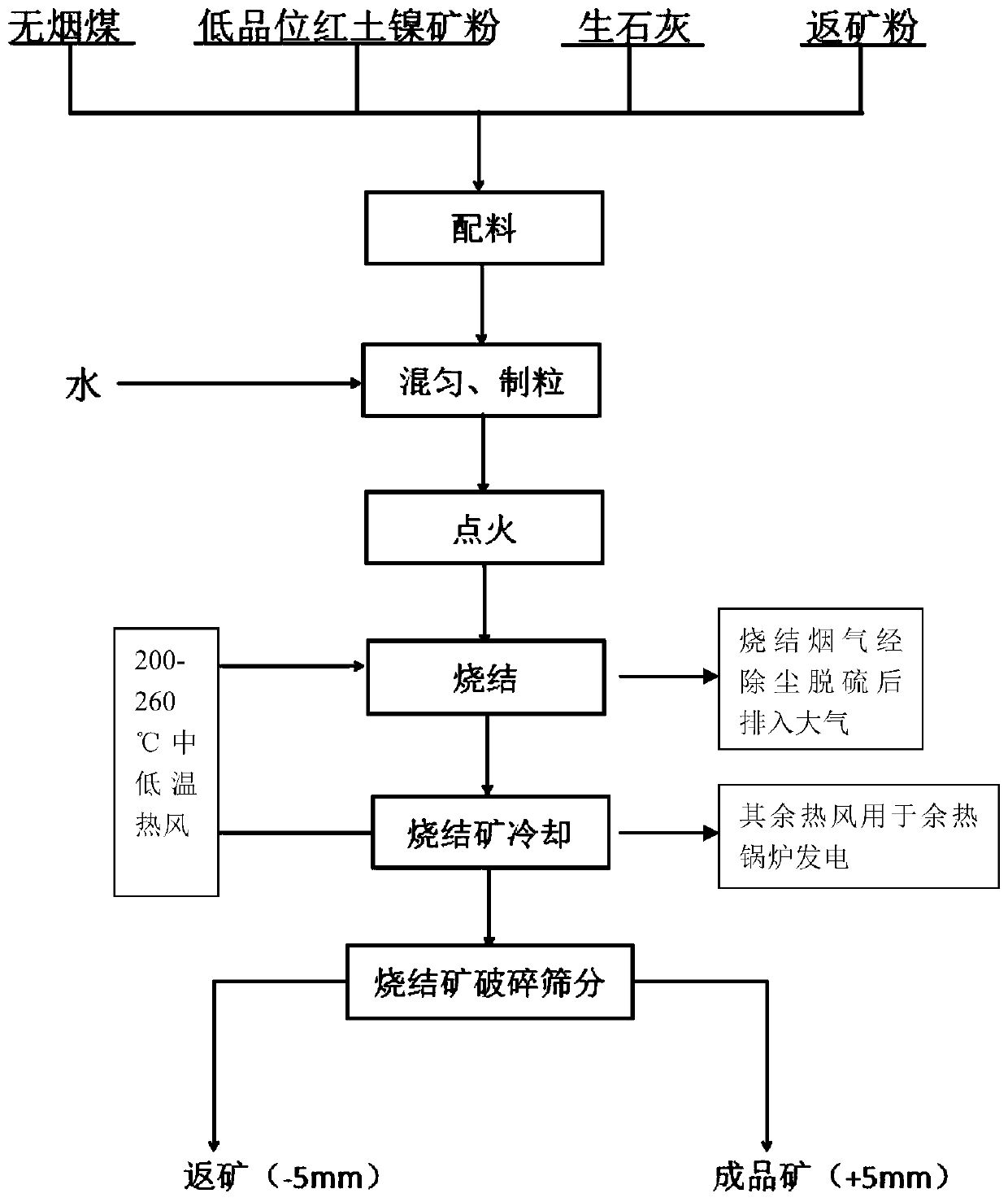

A kind of sintering method of laterite nickel ore

The invention discloses a laterite-nickel ore sintering method based on medium and low temperature cooling hot-blast air. The sintering method comprises the following steps: mixing laterite-nickel ore, ore returning powder, fuel and quicklime to obtain a mixture; adjusting the moisture of the mixture to be 16wt%-18wt%, and pelletizing the mixture in a mixed manner to obtain sintered material; igniting and sintering the sintered material to obtain hot sinter; during the sintering process, feeding hot-blast air lower than 300 DEG C into a sintering machine burden surface fume hood; carrying outheat exchange on cold-blast air and hot sinter to obtain hot-blast air and cold sinter; and crushing and screening the cold sinter to obtain sinter of finished product. According to the method, the medium and low temperature hot-blast air below 300 DEG C is returned to the sintering machine, so that the minerogenetic condition of the sinter is improved and the laterite-nickel ore sintering strength is improved; and in addition, the effective utilization of cooled hot exhaust gas of the sinter is realized, solid burnup is reduced, and emission of CO2 is reduced.

Owner:CENT SOUTH UNIV

High titan type high alkalinity sinter and method for preparing same

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

A production method of super-thick material layer oxygen-enriched sintering

ActiveCN108330275BSolve the problem that it is not easy to enter the material layerReduce fuel consumptionDecompositionMixed materials

The invention relates to an ultra-thick material layer oxygen-enriched sintering production method. The method comprises the steps that two times of material distribution and two-time ignition is carried out, an upper-layer sintering mixture and a lower-layer sintering mixture are correspondingly provided with an oxygen generator, the sintering raw material and the fuel are subjected to primary uniform mixing and secondary mixing granulation to prepare a sintered mixture A, and an oxygen preparation agent solution is additionally added during the primary uniform mixing and the secondary mixinggranulation; the sintering raw material and the fuel are subjected to the primary uniform mixing and the secondary mixing granulation to prepare a sintered mixture B, and the oxygen preparation agentsolution is additionally added during the primary uniform mixing and the secondary mixing granulation; the sintering mixture A is added to a sintering trolley through a first distributor on the machine head of the sintering machine; the oxygen preparation agent solution in the sintering material in the lower direction of the first distributor is sprayed; and the sintering mixed material B is added to the surface of sintered ore, and an oxygen preparation agent solution is sprayed on the sintering material surface. The method has the advantages that oxygen is generated by high-temperature decomposition of the oxygen generator, and the oxygen is uniformly enriched at different parts of the sintered material layer; and the strength of the sintered ore is improved, and the fuel consumption ofthe sintered solid is reduced.

Owner:ANGANG STEEL CO LTD

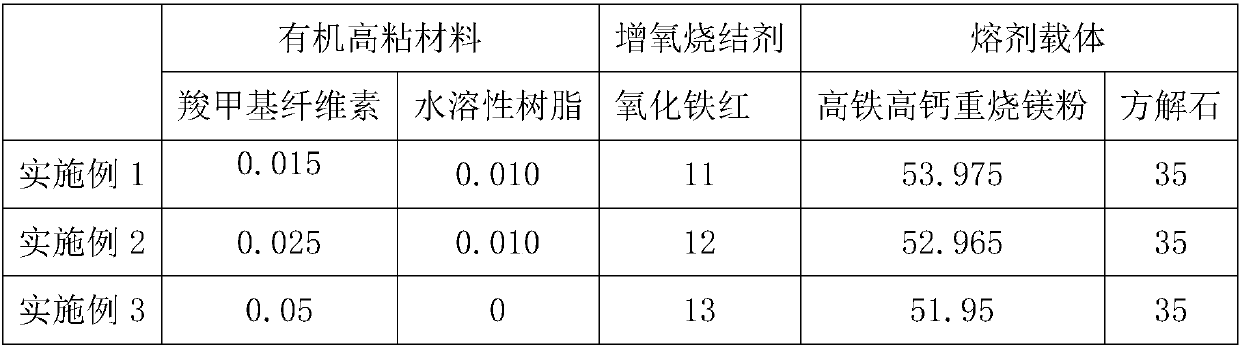

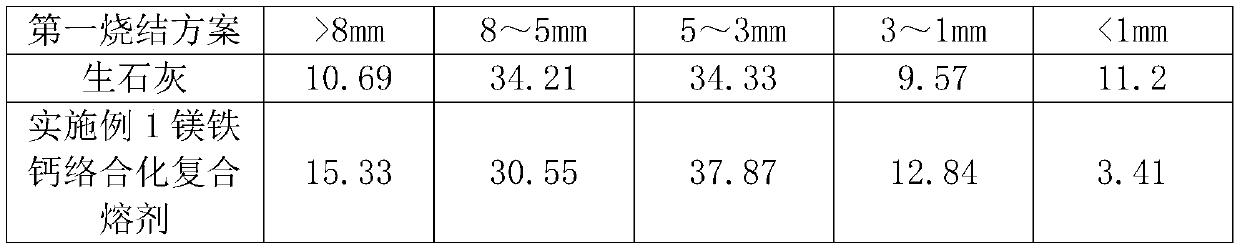

A kind of compound auxiliary agent and its preparation method and application

The invention relates to the field of sintered ore production adopting vanadium titano-magnetite, and particularly provides a compound additive, a preparation method thereof and application of the compound additive in sintered ore production adopting the vanadium titano-magnetite. The compound additive contains, by weight, 1-5% of Ig, 70-90% of CaO, 0.1-4% of MgO, 0.01-5% of SiO2 and 0.1-1% of B2O3. The preparation method comprises the step that active lime, an organic binding agent, a selective mineralizer and a selective additive are blended and subjected to mixing. The compound additive is applied to the sintered ore production process adopting the vanadium titano-magnetite, the current situation that in the traditional sintered ore production process with the vanadium titano-magnetite as the main raw materials, pelleting and sintering are difficult is avoided, the proportion of reasonable particle sizes in the pelleting process is increased, liquid phase generation in a low temperature stage of the sintering process is promoted, sintering is strengthened, the strength of sintered ore is improved, and the yield rate of the sintered ore is increased.

Owner:攀钢冶金材料有限责任公司

Sintering ore additive

InactiveCN100408703CImproved low temperature reduction propertiesReduce consumptionMetallurgyEnergy consumption

The invention discloses a sintering additive, which comprises the following parts: 20wt%-60wt% composite mineralizer,10wt%-30wt% oxidizing catalyst,15wt%-40wt% oxygenation agent and 10wt%-30wt% protective. The additive can improve sintering oaring strength, which reduces energy consumption effectively.

Owner:娄底市裕德科技有限公司

Superlow temperature sinter and mineralization energy-saving additive

InactiveCN1288257CPromotes the formation of the binder phase SFCAImprove burn rateCombustionSintering

The present invention discloses an ultra-low temperature sintering mineralization energy-saving additive. It contains (wt%) 10-60% of ultra-low temp. mineralizer, 10-30% of oxygenation agent, 10-40% of melting agent, 10-40% of catalyst and 0-30% of pore-forming agent. Said invention is a powder agent made up by mixing all the above-mentioned materials. Said invented additive has the actions of catalytic improving combustion, inhibiting 2CaO2 and SiO2 undesirable transformation in the sintering process, promoting main binding phase SFCA formation of sintering ore, inhibiting low-temperature reduction pulverization action and raising catalytic sintering process, etc.

Owner:董素华 +1

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362BIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialThermodynamicsCogeneration

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

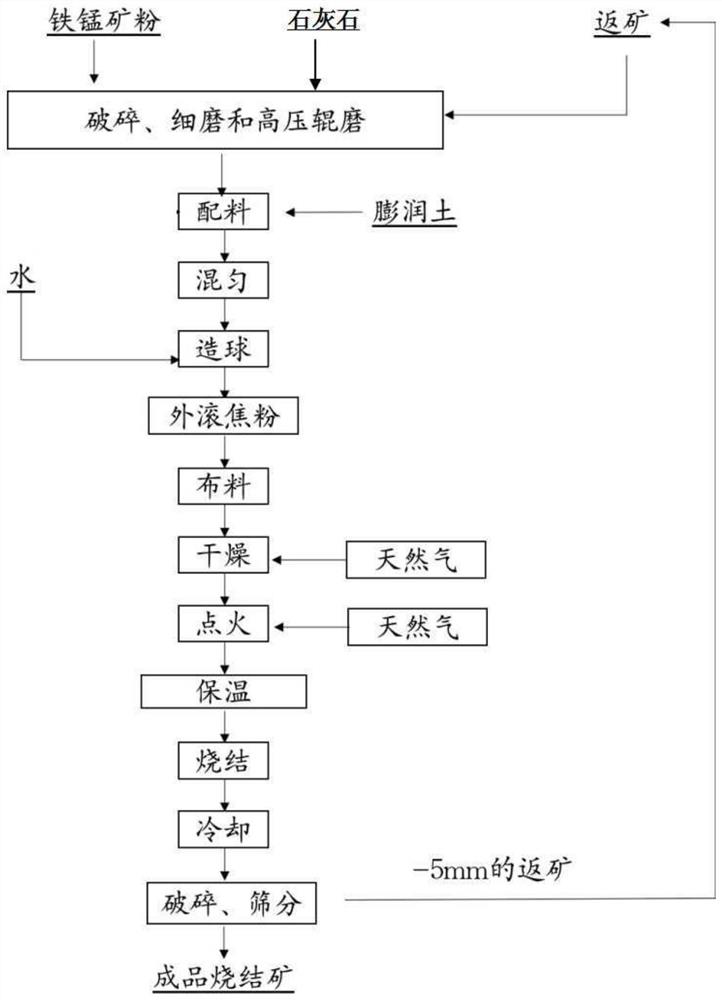

Sintering method of ferromanganese ore pellets

ActiveCN114574695AHigh specific surface areaImprove surface activityProcess efficiency improvementGrain treatmentsSolid fuelMixed materials

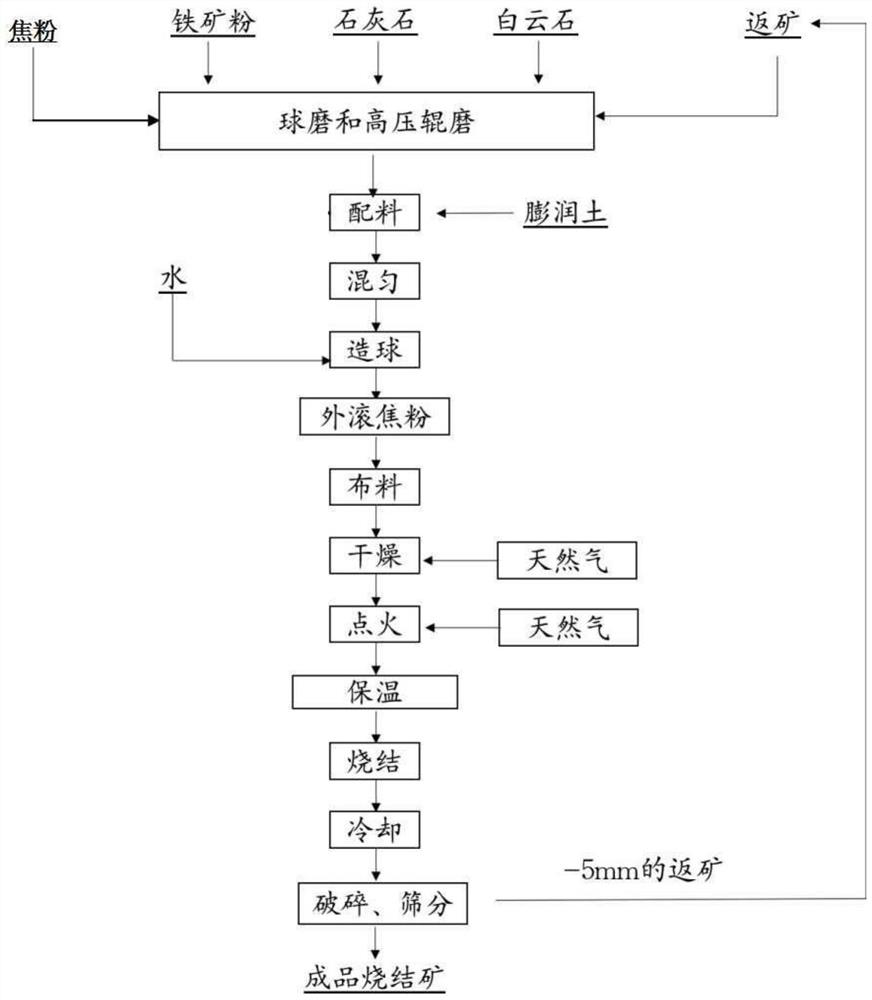

The sintering method comprises the following steps: S1, carrying out crushing and ball-milling treatment on coarse-grained ferromanganese ore, limestone and return mine, and then carrying out high-pressure roller milling to obtain a pretreated raw material; s2, after the pretreated raw materials are subjected to optimized ore blending, a binder is added and mixed uniformly, and a mixture is obtained; s3, pelletizing the mixture obtained in the step S2; s4, carrying out external rolling on the green pellets to obtain a solid fuel, so as to obtain a uniformly mixed material; and S5, distributing the uniformly mixed material, and then sequentially performing drying, ignition sintering, heat preservation, cooling, crushing and size stabilization to obtain finished pellets. In order to solve the problem that a liquid phase is difficult to form in the ferromanganese ore sintering process, a ball milling and high-pressure roller milling combined treatment process is utilized, the specific surface area of the ferromanganese ore is increased, the surface activity and reaction activity of the ferromanganese ore are improved, migration and activation of atoms in the high-temperature sintering process are promoted, the forming ability of a sintering liquid phase is improved, and the liquid phase amount is increased, so that the liquid phase consolidation effect of the ferromanganese ore is promoted; the sintering strength is improved.

Owner:CENT SOUTH UNIV

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364BIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialThermodynamicsProcess engineering

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com