Metallurgy sintering synergist as well as preparation method and application thereof

A sintering synergist and synergist technology, applied in the field of metallurgical sintering, can solve the problems of insufficient consideration of the reducibility of sinter, insufficient consideration of the sintering process, high cost of use, etc., to achieve good granulation effect, improvement of reducibility, Optimize the effect of slag system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

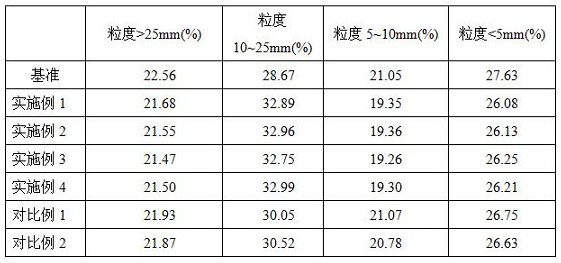

Examples

Embodiment 1

[0025] A metallurgical sintering synergist is prepared from the following raw materials in mass percentage: steel slag 55%, polyethylene glycol 1%, fluorite 3%, potassium permanganate 1%, hydrogen peroxide 1.5%, ammonium metavanadate 2%, waste activated carbon 1%, and the rest is water.

[0026] The steel slag comprises the following components: calcium oxide 34.63%, TFE 18.15%, silica 13.55%, magnesium oxide 11.36%, aluminum oxide 5.93% and MnO 1.35%.

[0027] Wherein, the waste activated carbon is the activated carbon produced in the sintering flue gas desulfurization and denitration process.

[0028] Wherein the fixed carbon content of the waste activated carbon is 80% wt.

[0029] In this embodiment, the preparation method of the synergist comprises the following steps:

[0030] (1) The steel slag is dried and crushed. The particle size of the crushed steel slag is - 1mm, accounting for 95% and - 0.1mm, accounting for 65%;

[0031] (2) Weigh polyethylene glycol, fluorite, pota...

Embodiment 2

[0034] A metallurgical sintering synergist is prepared from the following raw materials in terms of mass percentage: steel slag 58%, polyethylene glycol 1%, fluorite 3.5%, potassium permanganate 1%, hydrogen peroxide 2%, ammonium metavanadate 2.5%, waste activated carbon 1.2%, and the rest is water.

[0035] The steel slag comprises the following components: calcium oxide 34.63%, TFE 18.15%, silica 13.55%, magnesium oxide 11.36%, aluminum oxide 5.93%, MnO 1.35%.

[0036] Wherein, the waste activated carbon is the activated carbon produced in the sintering flue gas desulfurization and denitration process.

[0037] Wherein the fixed carbon content of the waste activated carbon is 80% wt.

[0038] In this embodiment, the preparation method of the synergist comprises the following steps:

[0039] (1) The steel slag is dried and crushed. The particle size of the crushed steel slag is - 1mm, accounting for 95% and - 0.1mm, accounting for 65%;

[0040] (2) Weigh polyethylene glycol, fluo...

Embodiment 3

[0043] A metallurgical sintering synergist is prepared from the following raw materials in mass percentage: steel slag 59%, polyethylene glycol 1.1%, fluorite 3.5%, potassium permanganate 1.1%, hydrogen peroxide 2%, ammonium metavanadate 2.7%, waste activated carbon 1.3%, and the rest is water.

[0044] The steel slag comprises the following components: calcium oxide 34.63%, TFE 18.15%, silica 13.55%, magnesium oxide 11.36%, aluminum oxide 5.93%, MnO 1.35%.

[0045] Wherein, the waste activated carbon is the activated carbon produced in the sintering flue gas desulfurization and denitration process.

[0046] Wherein the fixed carbon content of the waste activated carbon is 80% wt.

[0047] In this embodiment, the preparation method of the synergist comprises the following steps:

[0048] (1) The steel slag is dried and crushed. The particle size of the crushed steel slag is - 1mm, accounting for 95% and - 0.1mm, accounting for 65%;

[0049] (2) Weigh polyethylene glycol, fluorite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com