Sintering method of ferromanganese ore pellets

A sintering method and iron-manganese ore technology, which is applied in the field of metallurgy, can solve the problems that the sintering process of manganese ore is not significantly changed, and achieve the effects of improving thermal gas permeability, reducing moisture, and improving surface activity and reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

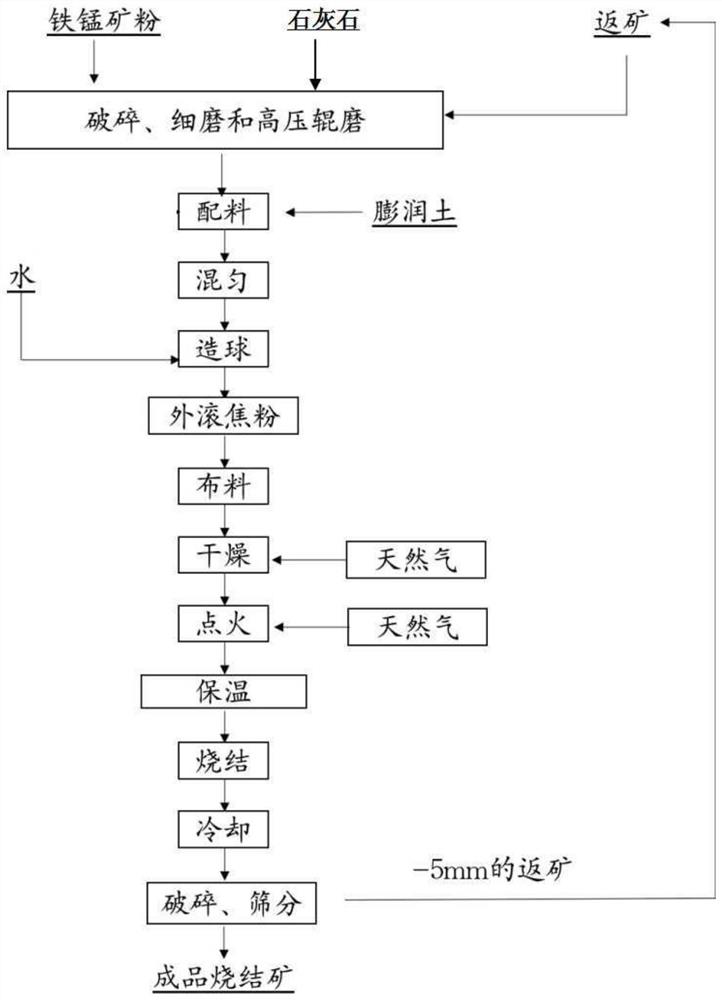

Image

Examples

Embodiment 1

[0051] The coarse-grained iron-manganese ore, limestone and returned ore are pretreated by roller crushing, ball milling and high-pressure roller milling until the particle size is less than 0.074mm, accounting for about 70%, and the specific surface area is 1575cm. 2 / g; then add bentonite, the amount of bentonite is 0.8% for mixing, and the alkalinity is controlled to 1.6%; the mixed material is pelletized, the pelletizing moisture is controlled to 8%, and the pelletizing time is 12min, and the compressive strength of the obtained green pellets is obtained. 11N / piece, drop strength 4.7 times / (0.5m), burst temperature 280℃, raw meal particle size 10-16mm, the green ball index meets or even exceeds industrial requirements; ; The mixed material is subjected to distribution, drying, ignition sintering, heat preservation, cooling, crushing and granulation to obtain the finished pellet sinter. The height of the material layer is 500mm; the drying temperature is 250°C, the drying t...

Embodiment 2

[0054] The coarse-grained iron-manganese ore, limestone and returned ore are pretreated by roller crushing - ball milling - high pressure roller milling, until the particle size is less than 0.074mm, accounting for about 70%, and the specific surface area is 1575cm 2 / g; then add bentonite, the amount of bentonite is 1.2% for mixing, and the alkalinity is controlled to 1.6; the mixed material is pelletized, the pelletizing moisture is controlled to 8%, the pelletizing time is 12min, and the compressive strength of the obtained green pellet is 12.3 N / piece, drop strength 5.1 times / (0.5m), burst temperature 320°C, raw meal particle size 10-16mm, the green ball index meets or even exceeds industrial requirements; ; The mixed material is subjected to distribution, drying, ignition sintering, heat preservation, cooling, crushing and granulation to obtain the finished pellet sinter. The height of the material layer is 750mm; the drying temperature is 300°C, the drying time is 3min; ...

Embodiment 3

[0057] The coarse-grained iron-manganese ore, limestone and returned ore are pretreated by roller crushing, ball milling and high-pressure roller milling until the particle size is less than 0.074mm, accounting for about 70%, and the specific surface area is 1575cm. 2 / g; then add bentonite, the amount of bentonite is 1.2% for mixing, and the alkalinity is controlled to 1.6; the mixed material is pelletized, the pelletizing moisture is controlled to 8%, the pelletizing time is 12min, and the compressive strength of the obtained green pellet is 12.3 N / piece, drop strength 5.1 times / (0.5m), burst temperature 320°C, raw meal particle size 10-16mm, the green ball index meets or even exceeds industrial requirements; ; The mixed material is subjected to distribution, drying, ignition sintering, heat preservation, cooling, crushing and granulation to obtain the finished pellet sinter. The height of the material layer is 1000mm; the drying temperature is 300°C, the drying time is 3min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com