Sintering process of manganese ore powder

A manganese ore powder and process technology, applied in the field of manganese ore powder sintering process, can solve the problems of poor spheroidization of fine-grained manganese ore powder, high solid fuel consumption, poor sinter strength, etc. consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

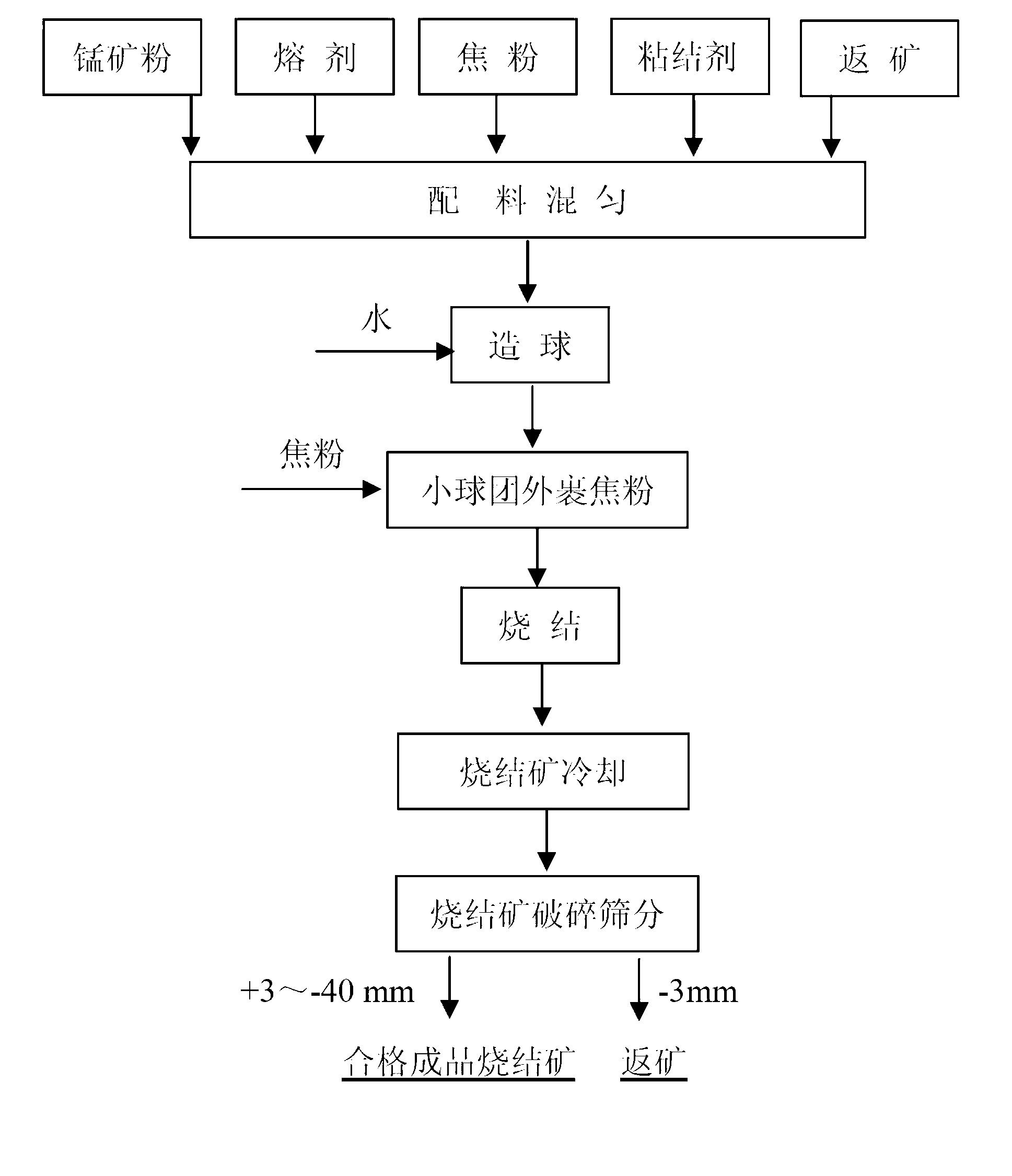

[0023] In this embodiment, manganese ore powder from a certain place is selected, and coke powder is used as fuel, wherein 60% of the coke powder is used in step (1), and 40% is used in step (2), such as figure 1 Shown technological process specifically comprises the following steps:

[0024] (1) Preparation of pellets: Mix manganese ore powder, binder, coke powder, quicklime and returned ore with water to form a mixed ore. The mass fraction of each component in the mixed ore is: binder 1.2%, coke powder 3.36%, Quicklime 4.5%, return ore 15%, pelletizing moisture 9.5%, manganese ore powder particle size composition is less than 0.074mm greater than 85.3%, binder is composed of manganate (such as potassium manganate) with a mass fraction of 30%, 10 % sodium humate, 40% polyacrylamide and 20% starch. Pellet the mixed ore on the pelletizing machine, the pelletizing time is 13 minutes, the falling strength of green pellets is 5.6 times / 0.5m, the compressive strength is 12.4N / pc, ...

Embodiment 2

[0027] In this embodiment, manganese ore powder from a certain place is selected, and coke powder is used as fuel, wherein 70% of the coke powder is used in step (1), and 30% is used in step (2), such as figure 1 Shown technological process specifically comprises the following steps:

[0028] (1) Preparation of pellets: Mix manganese ore powder, binder, coke powder, limestone and returned ore with water to form a mixed ore. The mass fraction of each component in the mixed ore is: binder 0.9%, coke powder 3.71%, Limestone 5.0%, return ore 10%, pelletizing water 8.5%, manganese ore powder particle size composition is -0.074mm greater than 85.3%, manganese ore powder grade TMn is 32.3%, binder is made of permanganate with a mass fraction of 10% Salt (such as potassium permanganate), 40% sodium humate, 30% polyacrylamide and 20% starch. Pellet the mixed ore on the pelletizer, the pelletizing time is 13min, the drop strength of green pellets is 4.9 times / 0.5m, the compressive stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com