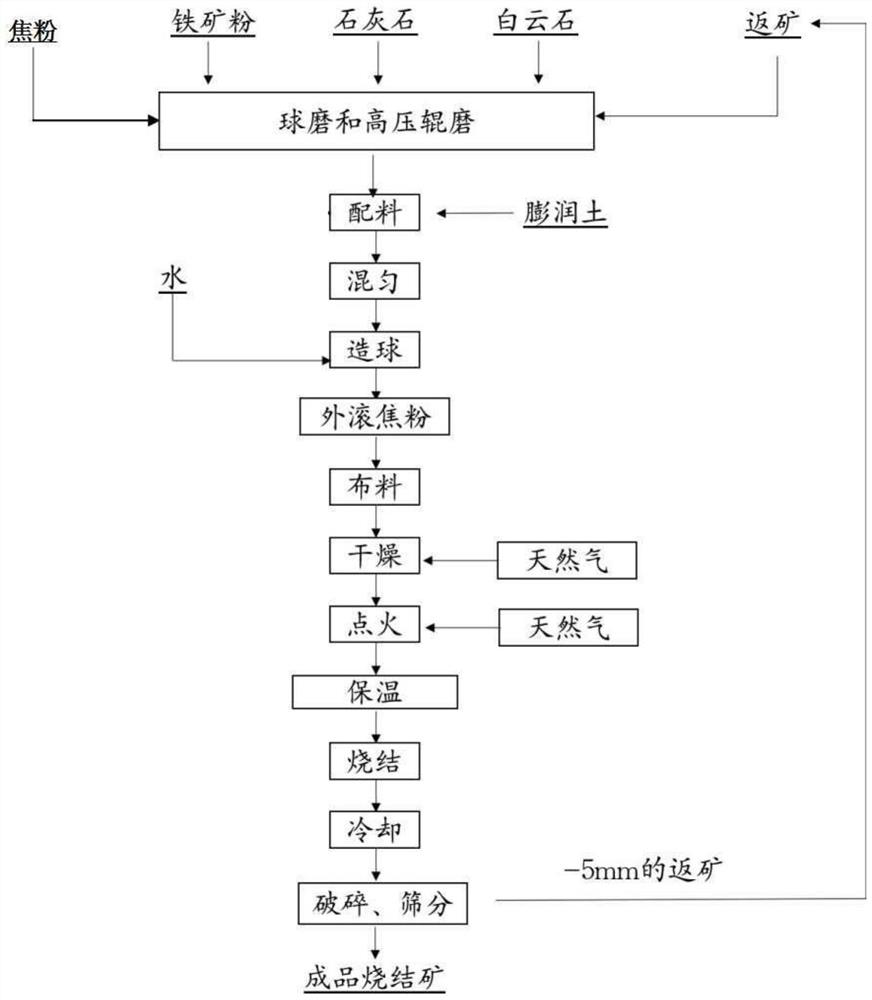

Sintering process of iron ore powder pellets

A technology for powder pellets and iron ore powder, which is applied in the field of sintering process of iron ore powder pellets, can solve the problems of unreasonable fuel distribution in the material layer, high energy consumption of sintered solids, poor sintered ore strength, etc., so as to improve the thermal state. Air permeability, improvement of consolidation effect, effect of improving sintered yield and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The coarse-grained iron ore powder, limestone, dolomite, coke powder and returned ore are pretreated by ball milling until the particle size is less than 0.074mm, accounting for about 65%, and the specific surface area is only 1098cm 2 / g, the finely ground material is further subjected to high pressure roller grinding, and the roller grinding to a specific surface area of 1710cm 2 / g; then add bentonite, the amount of bentonite is 1.0% for mixing, control the coke powder with 10%, control the binary basicity (CaO / SiO 2 mass ratio) is 1.85, MgO content is 1.80, SiO 2 The content is 5.20%; the mixed material is pelletized, the pelletizing moisture is controlled to 7.5%, and the pelletizing time is 12min. The obtained green pellets have a compressive strength of 13.9N / piece, a drop strength of 5.1 times / (0.5m), and a burst temperature of 340 ℃, the particle size of the raw meal is 10-16mm, and the raw ball index meets the industrial requirements; all the obtained raw b...

Embodiment 2

[0078] The coarse-grained iron ore powder, limestone, dolomite, coke powder and returned ore are pretreated by ball milling until the particle size is less than 0.074mm, accounting for about 65%, and the specific surface area is only 1098cm 2 / g, the finely ground material is further subjected to high pressure roller grinding, and the roller grinding to a specific surface area of 1710cm 2 / g; then add bentonite, the amount of bentonite is 1.0% for mixing, control the coke powder with 10%, control the binary basicity (CaO / SiO 2 mass ratio) is 1.85, MgO content is 1.80, SiO 2 The content is 5.20%; the mixed material is pelletized, the pelletizing moisture is controlled to 7.5%, and the pelletizing time is 12min. The obtained green pellets have a compressive strength of 13.9N / piece, a drop strength of 5.1 times / (0.5m), and a burst temperature of 340 ℃, the particle size of the raw meal is 10-16mm, and the green ball index meets the industrial requirements; all the obtained raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com