Patents

Literature

389 results about "Bedding Material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

That which comprises the place where a subject sleeps. (NCI)

Pigpen fermentation bed and use thereof

The present invention relates to a fermentation bed for pigsty, comprising a groove for storing bedding materials, wherein the bedding materials formed by fermenting organic materials are laid in the groove. Using the fermenting bed to raise pigs can digest and decompose excrement such as feces and urine quickly, such that no flushing and no smell for the pigsty are in result by proper management and maintenance. The influence to the environment and residents around farms are greatly eased and the economic benefit is raised obviously.

Owner:CHINA AGRI UNIV

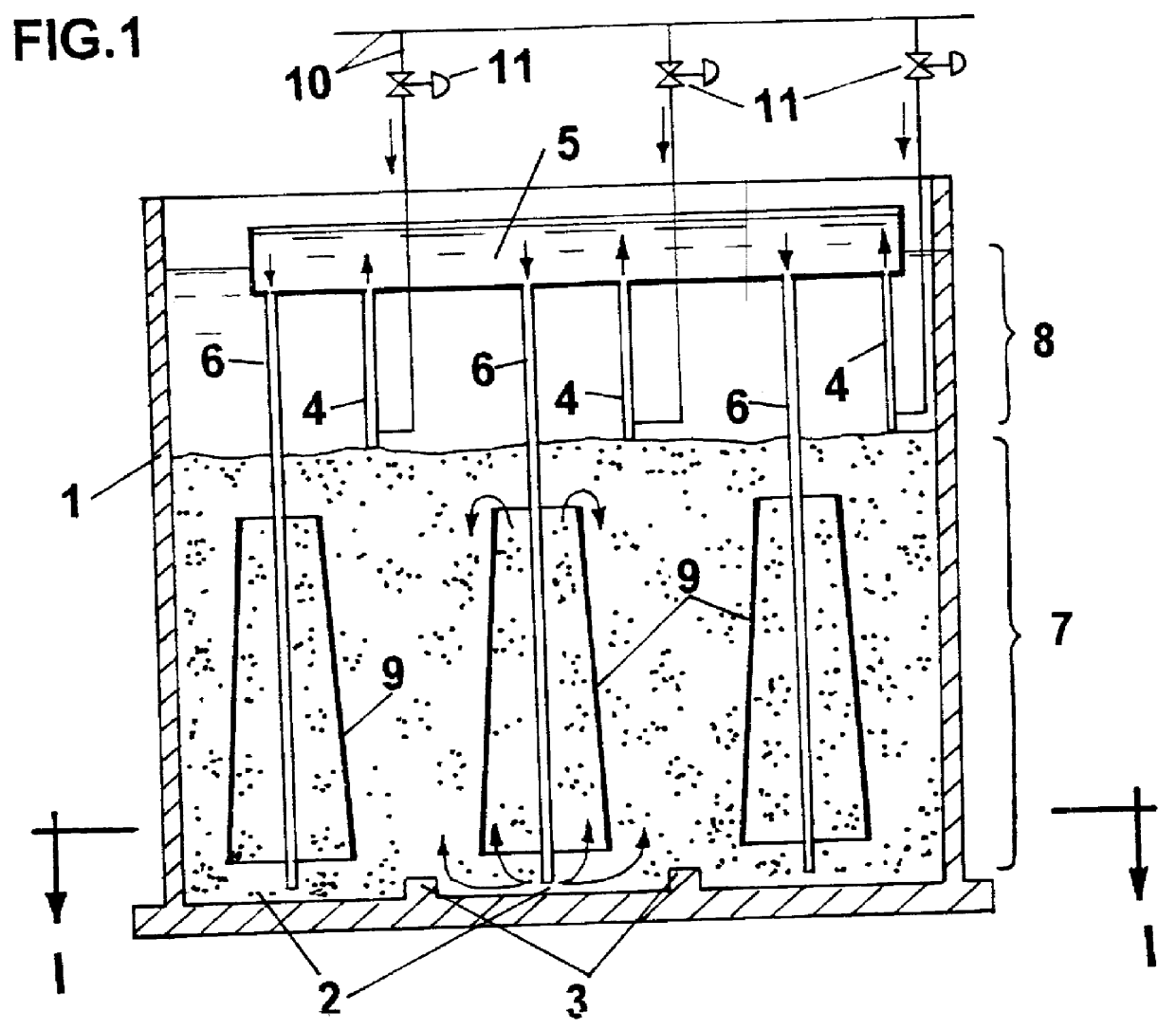

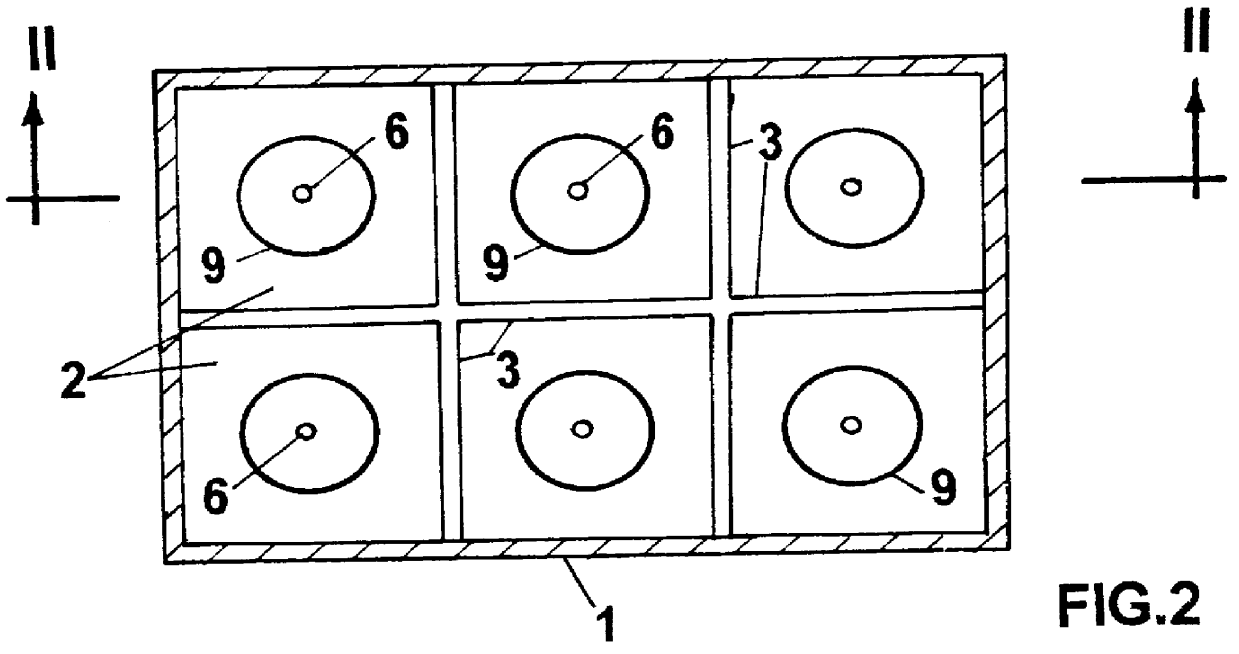

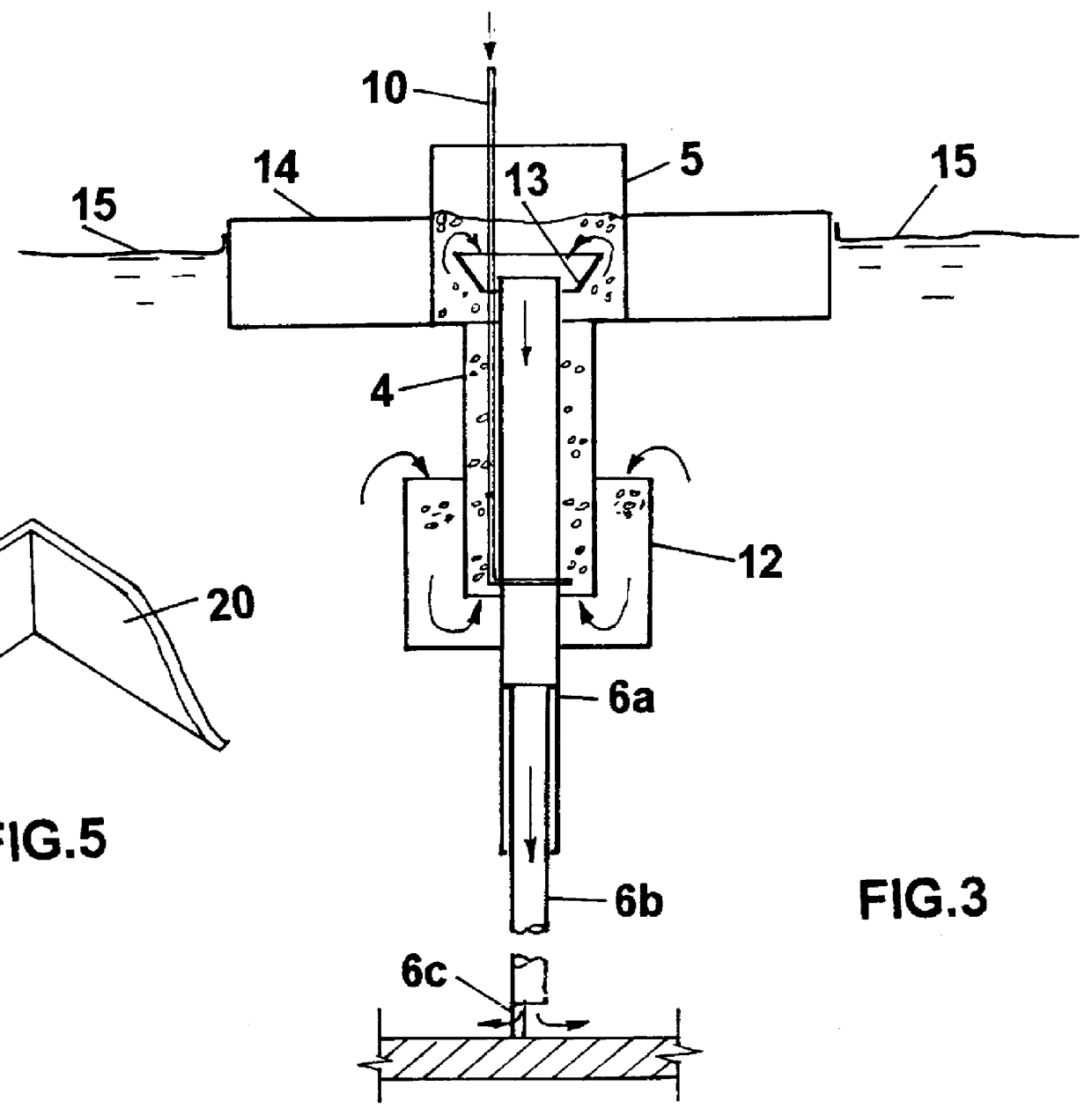

Method and apparatus for fluidization of particulate bed materials

InactiveUS6048459ATreatment using aerobic processesSolid sorbent liquid separationParticulatesOrganismal Process

A method for fluidization of a particulate bed material in a fluidized bed reactor with an upflow of fliud being treated, wherein a step of recycling said treated fluid is provided and further comprising the steps of (a) uniformly collecting at least a portion of the fluid above the fluidized bed and lifting this fluid by at least one gaslift having an intake above the bed, and (b) recycling the lifted fluid under the bed via at least one downcomer positioned within the bed. An generic apparatus for conducting the method steps in a variety of applications is also provided. The fluidized bed reactor can be used for chemical, physical chemical, biological processes, and combinations thereof in the chemical processing, food, environmental and other industries.

Owner:MOCKBA CORP

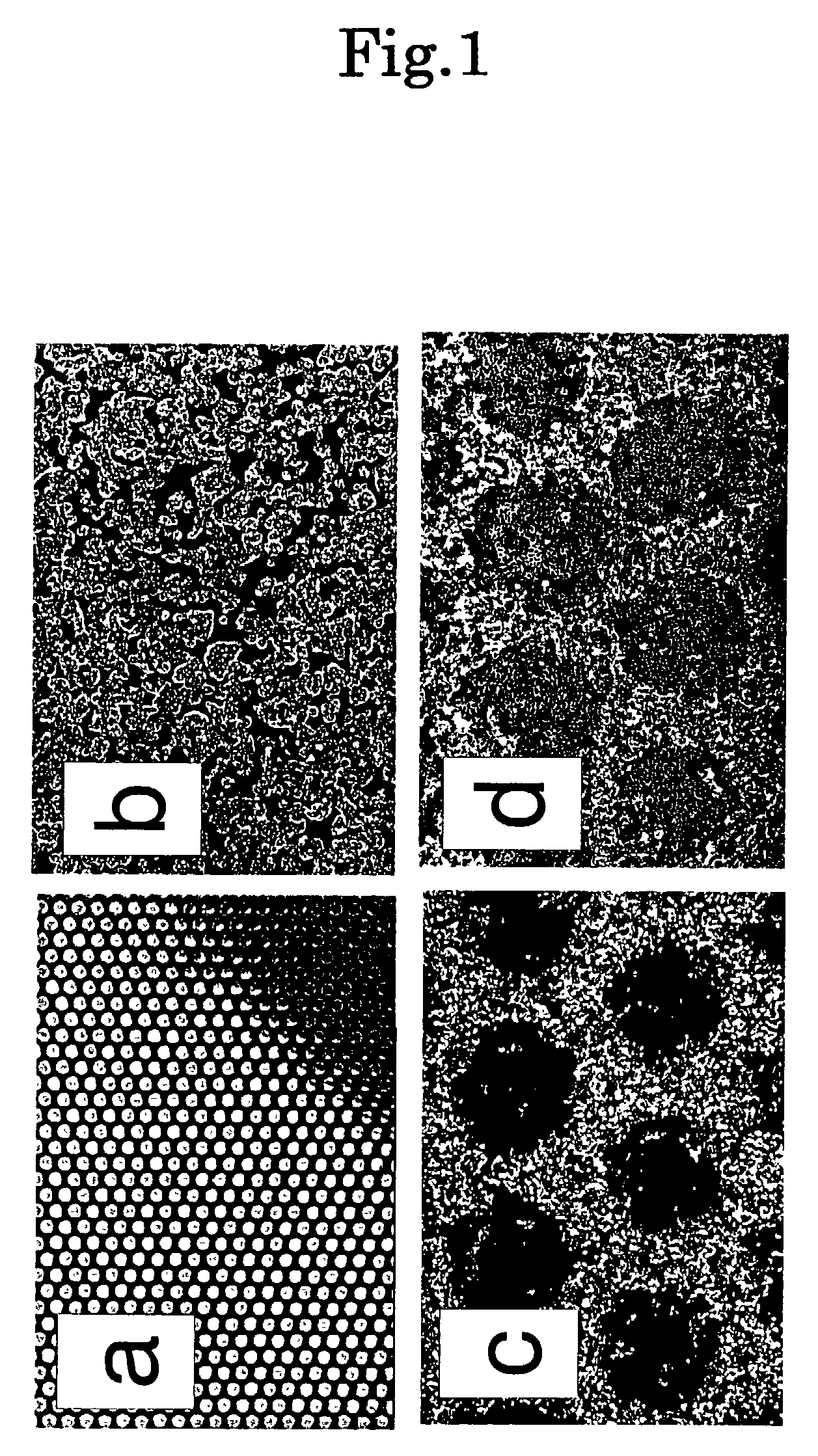

Cell cultivation-support material, method of cocultivation of cells and cocultivated cell sheet obtained therefrom

InactiveUS20030036196A1Rapid responseA large amountNervous system cellsArtificial cell constructsPolymer sciencePolymer chemistry

By using a bed material for cell culture having a surface composed of two domains of domain A coated with a temperature-responsive polymer and domain B composed of any one or a combination of a domain coated with a polymer having high affinity with cells, a domain coated with the temperature-responsive polymer in an amount different from the amount of the temperature-responsive polymer of domain A, and a domain coated with a polymer which responds to a temperature different from the temperature to which domain A responds, a method for the co-culture of a plurality of kinds of cells which has heretofore been difficult becomes possible.

Owner:CELLSEED

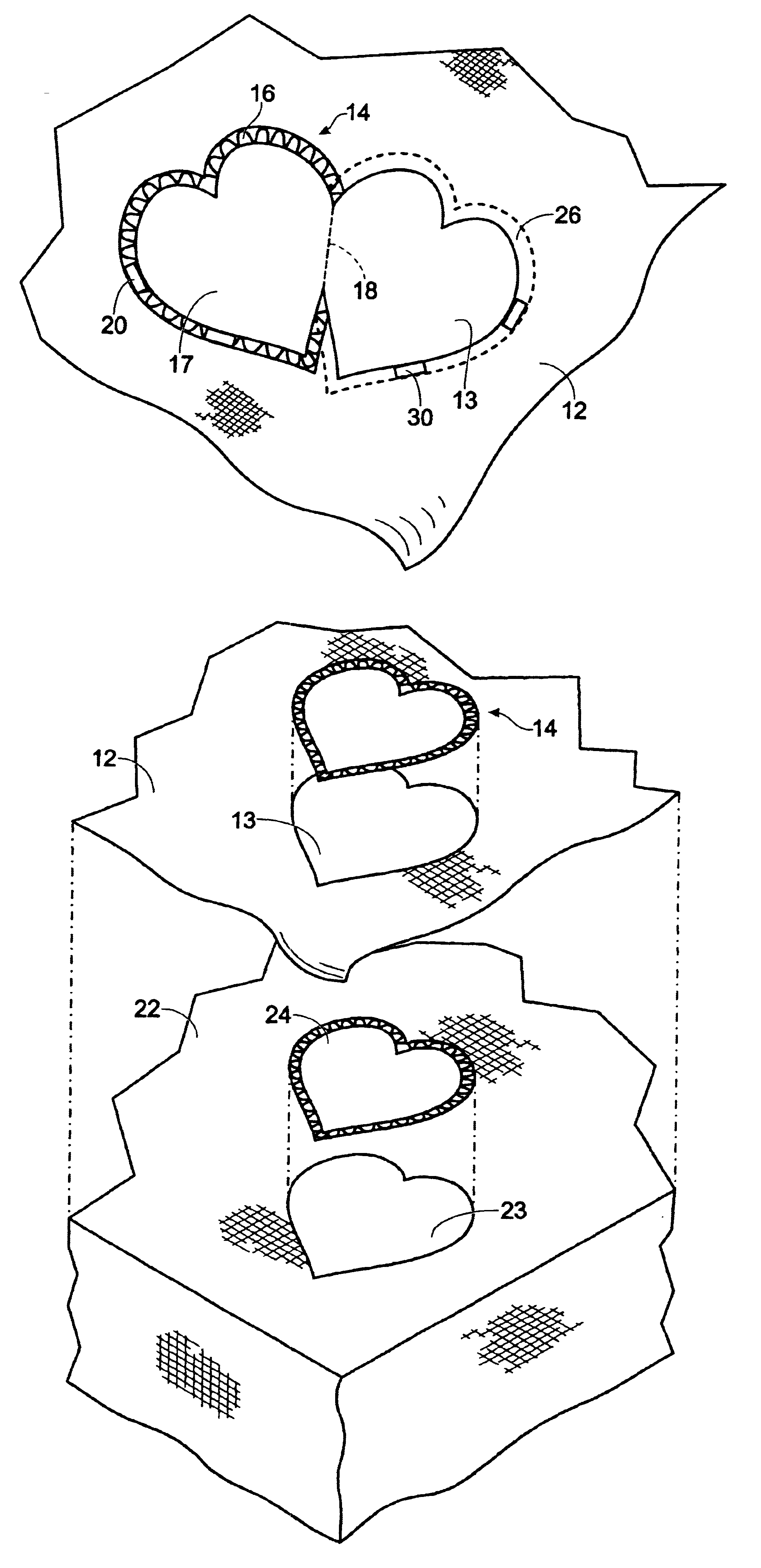

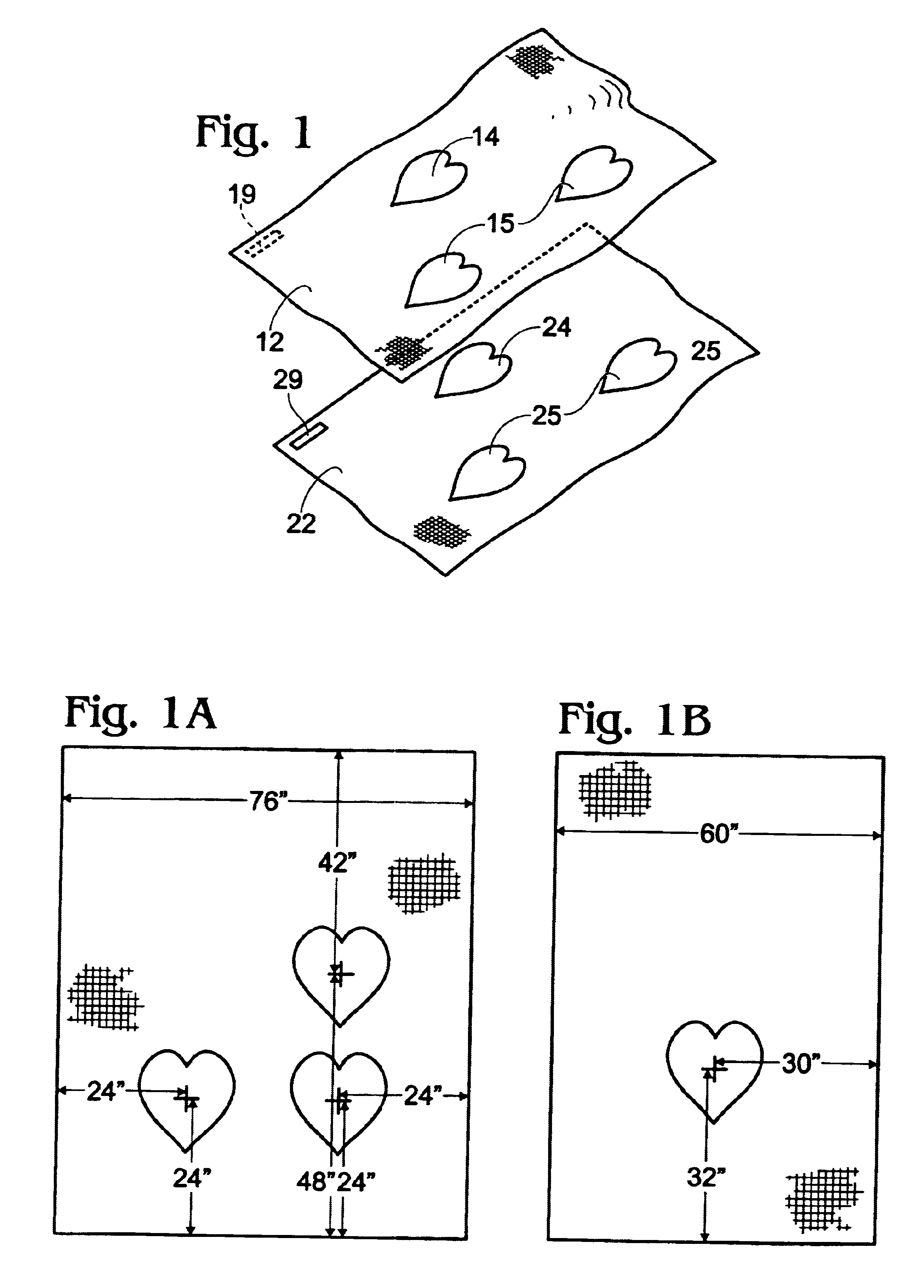

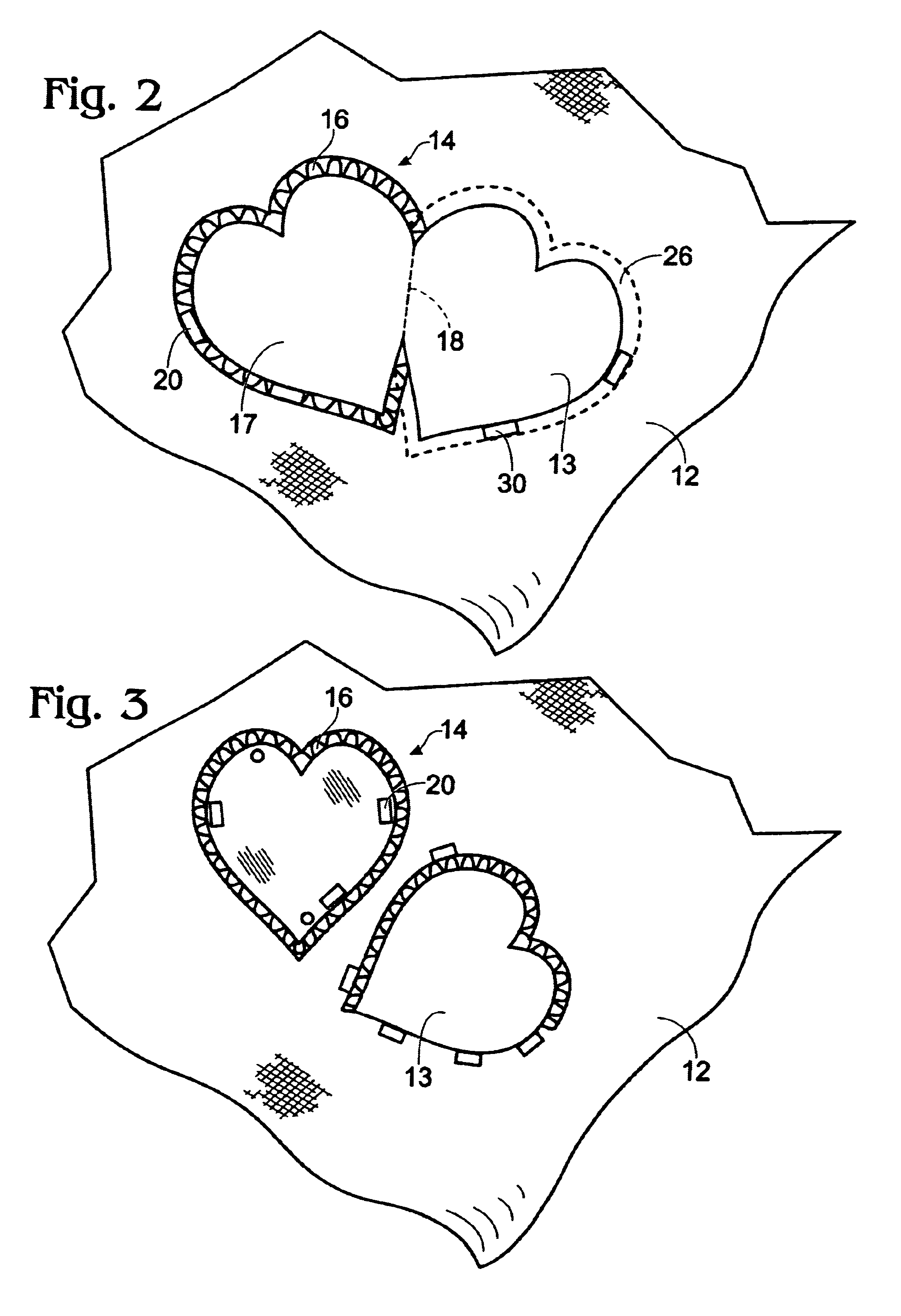

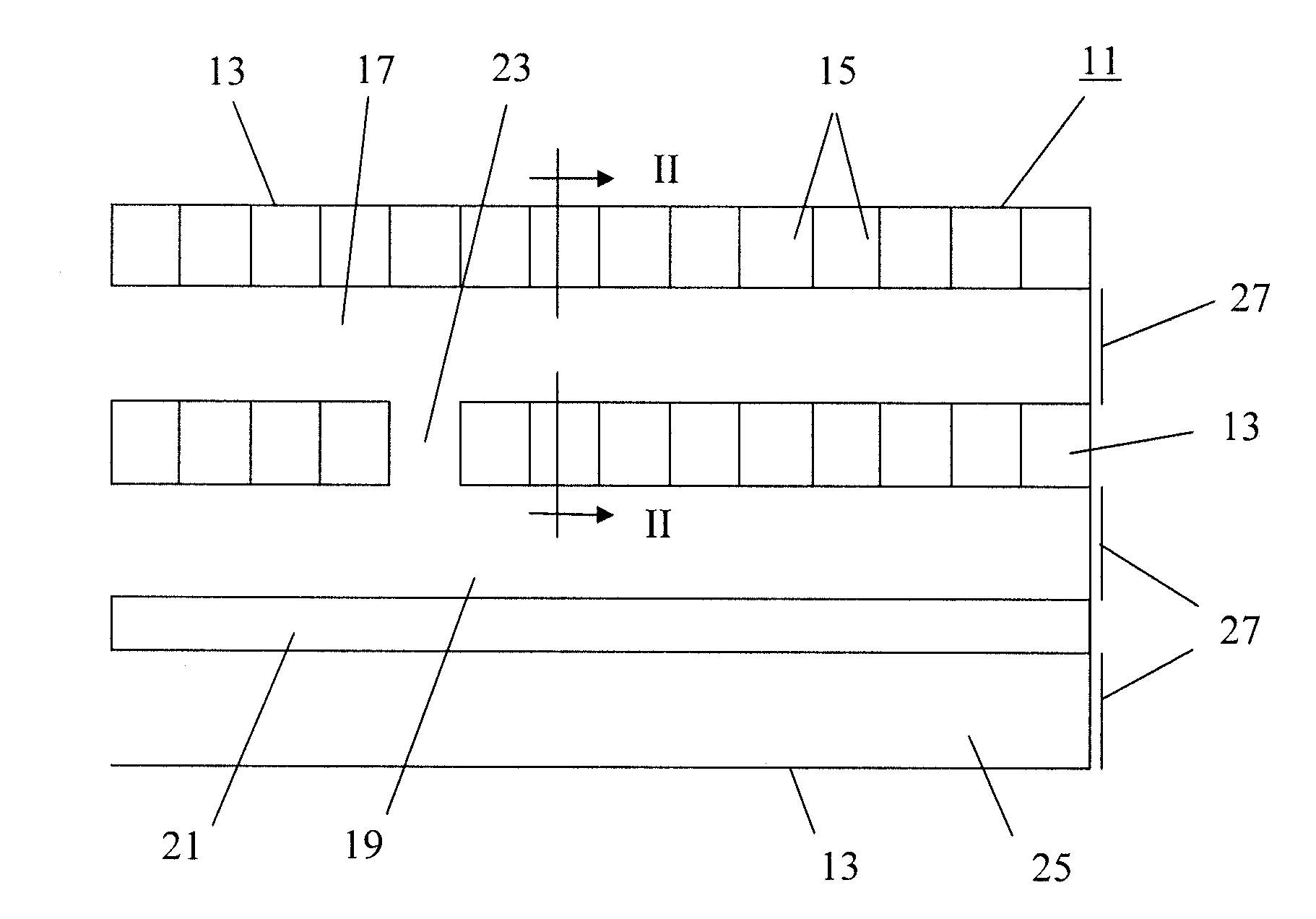

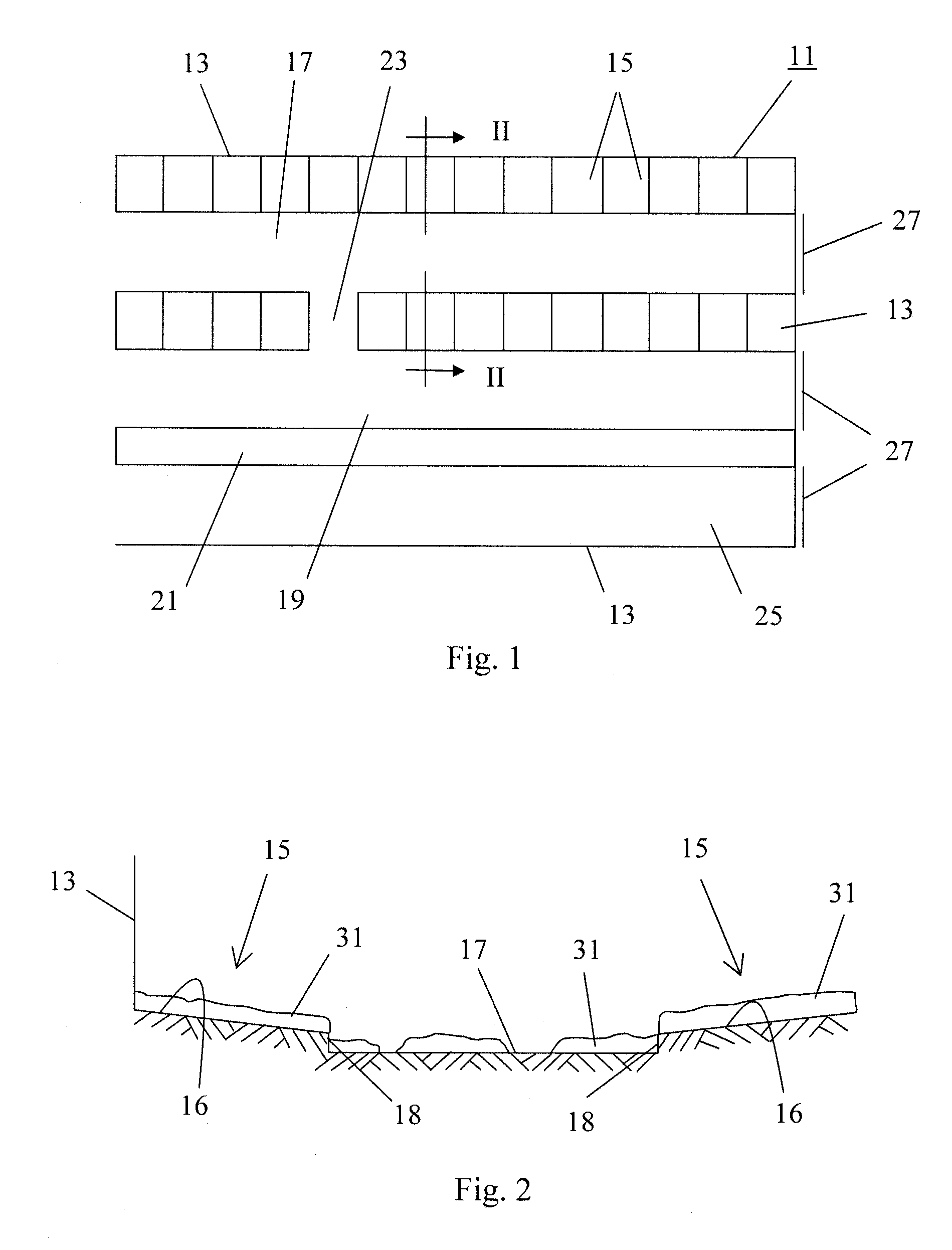

Bedding with multiple overlays and openings

Complimentary articles of bedding with cut-outs and removable or hinged opening overlays strategically located over the erogenous areas of bed occupants for purposes of enhancement of the sensual experience. Overlays are held in place over cut-outs or exposure openings with fasteners. Overlays attached to, or partly cloth hinged to blanket and / or sheet. Removable or partially openable at will by one or both partners as activities of an amorous nature may progress. Progressively smaller openings and overlays from top to bottom for a series of coaxially aligned openings and overlays in a mated sequence of bedding materials.

Owner:KIMBALL CARLTON H

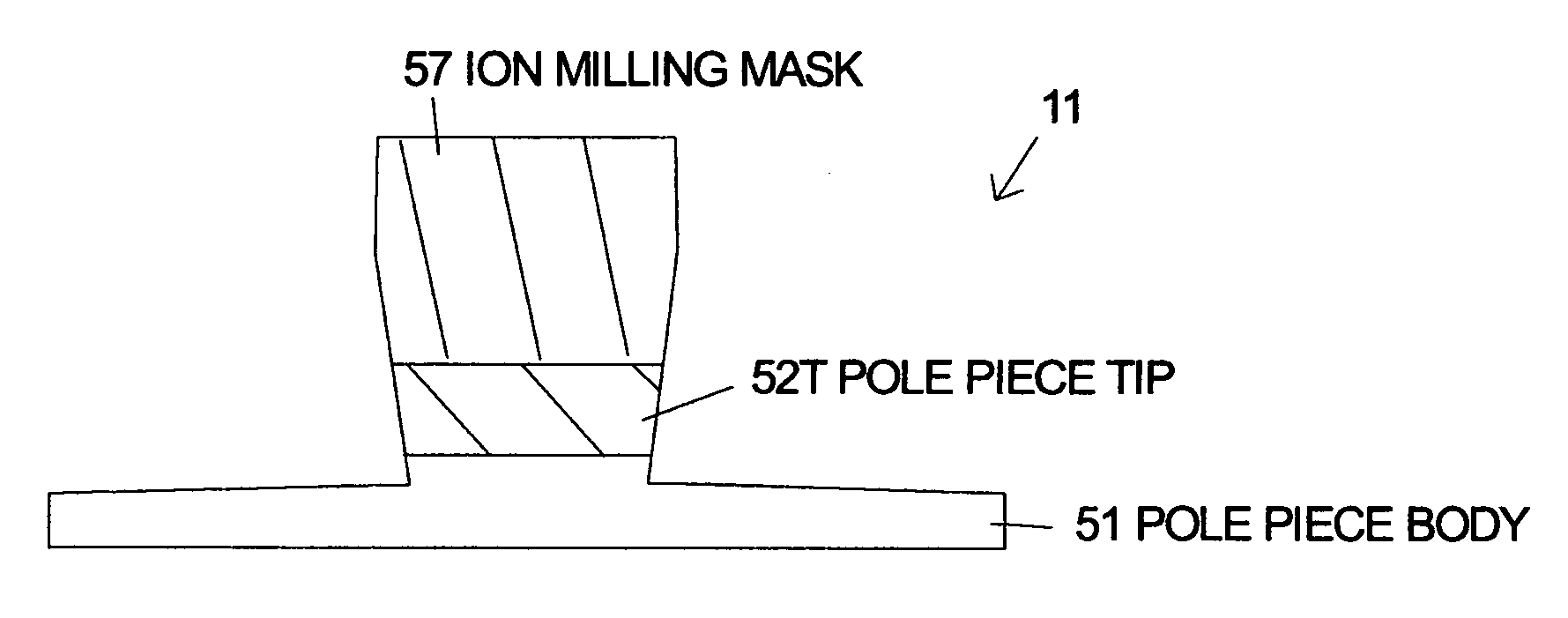

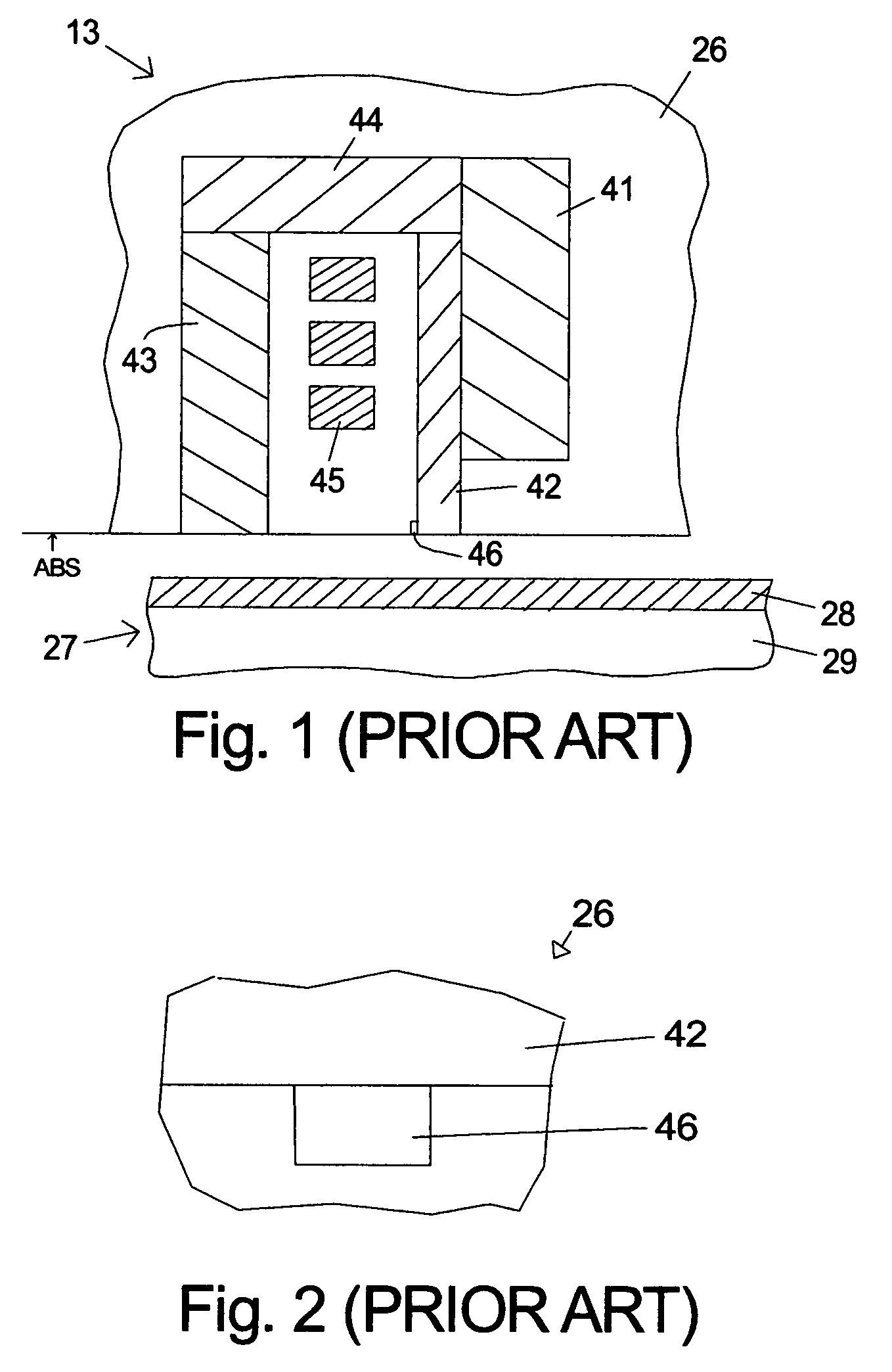

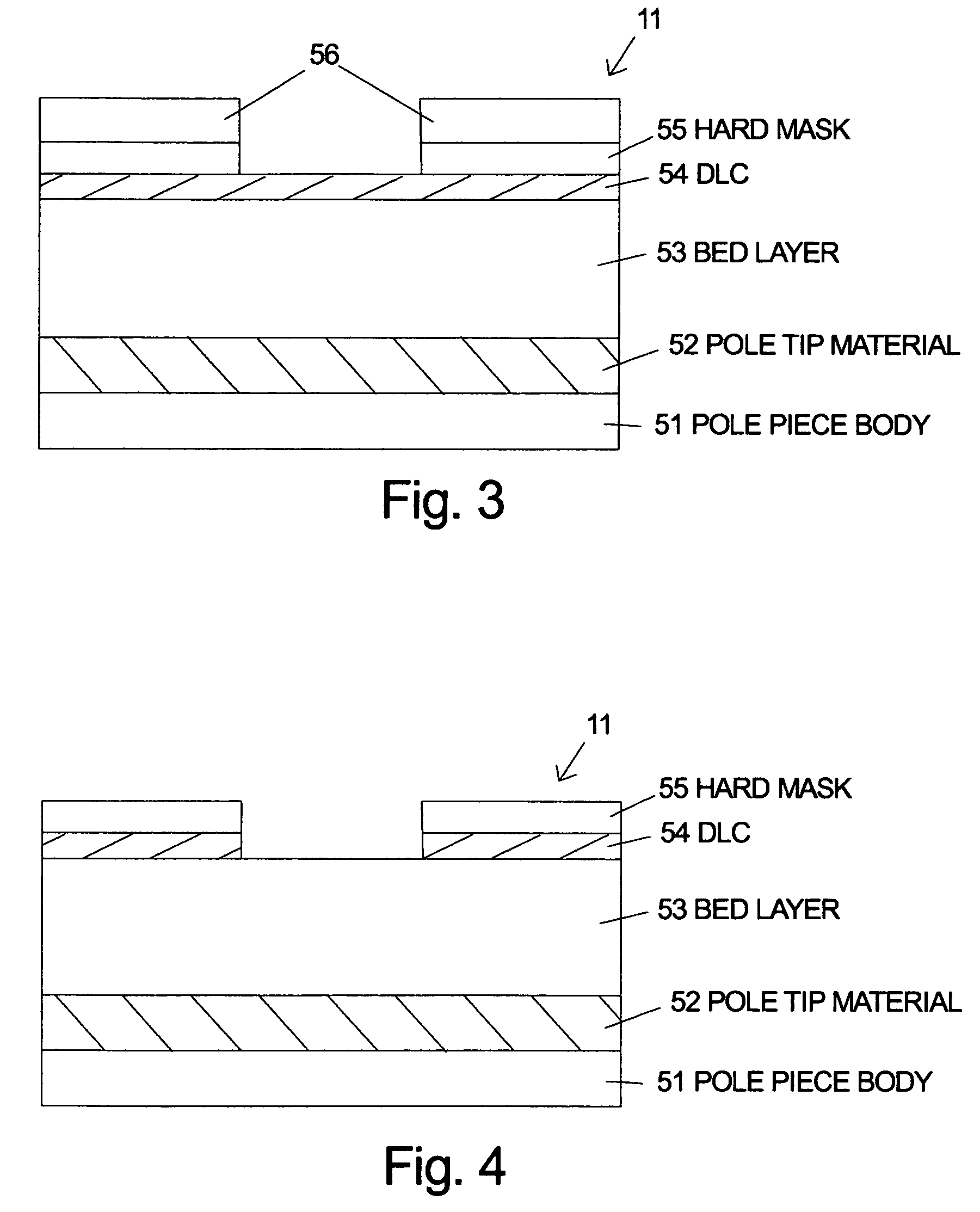

Method for fabricating a pole tip in a magnetic transducer

A method for fabricating a magnetic head with a trapezoidal shaped pole piece tip is described. The body of the main pole piece is deposited, then one or more layers for the pole piece tip are deposited. A bed material is deposited over the pole piece tip material. A void is formed in the bed material over the area for the pole piece tip. The void is filled with an ion-milling resistant material such as alumina preferably using atomic layer deposition or atomic layer chemical vapor deposition. The excess ion-milling resistant material and the bed material are removed. The result is an ion-milling mask formed over the area for the pole piece tip. Ion milling is then used to remove the unmasked material in the pole piece tip layer and to form a beveled pole piece tip and preferably a beveled face on the main pole piece.

Owner:WESTERN DIGITAL TECH INC

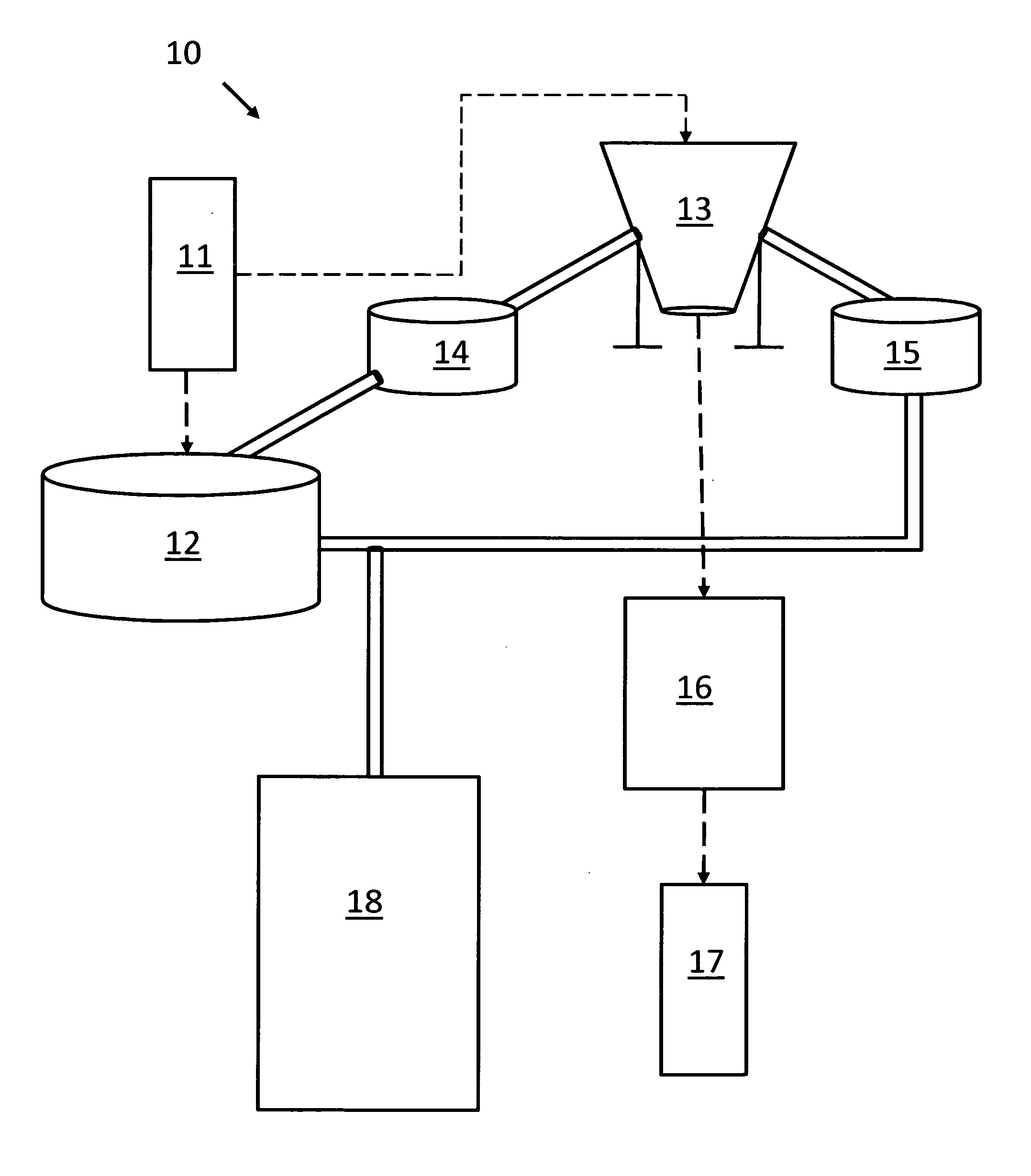

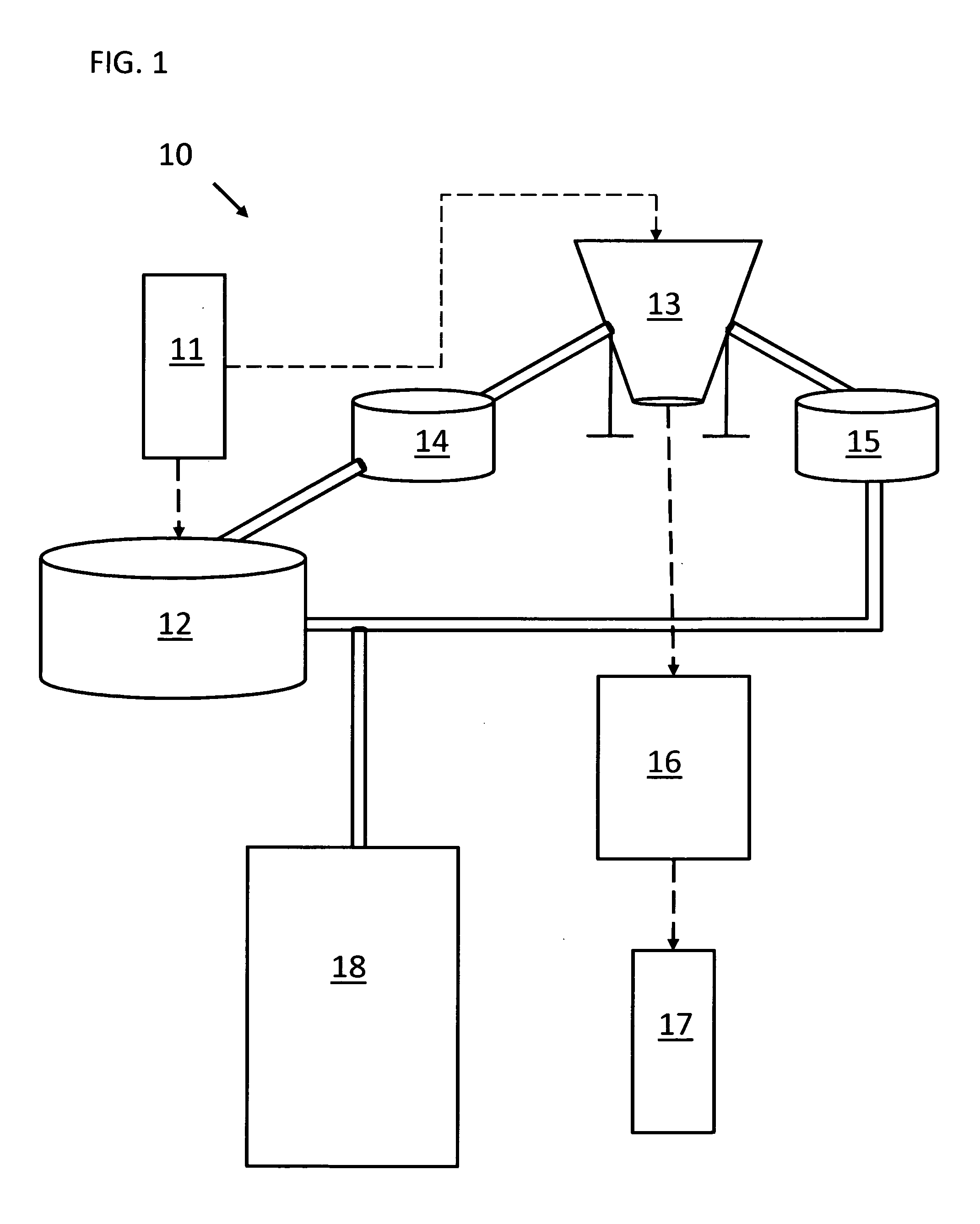

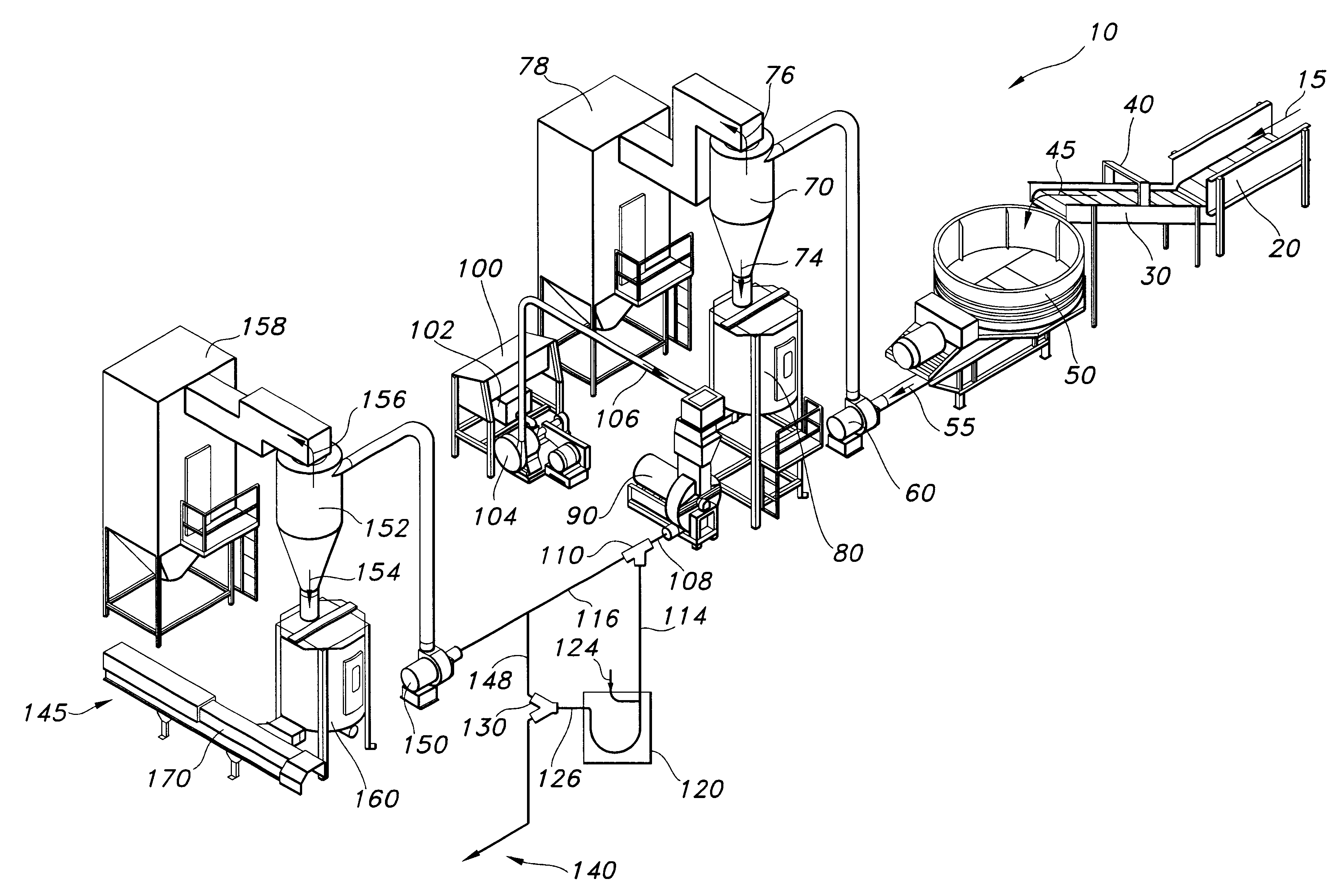

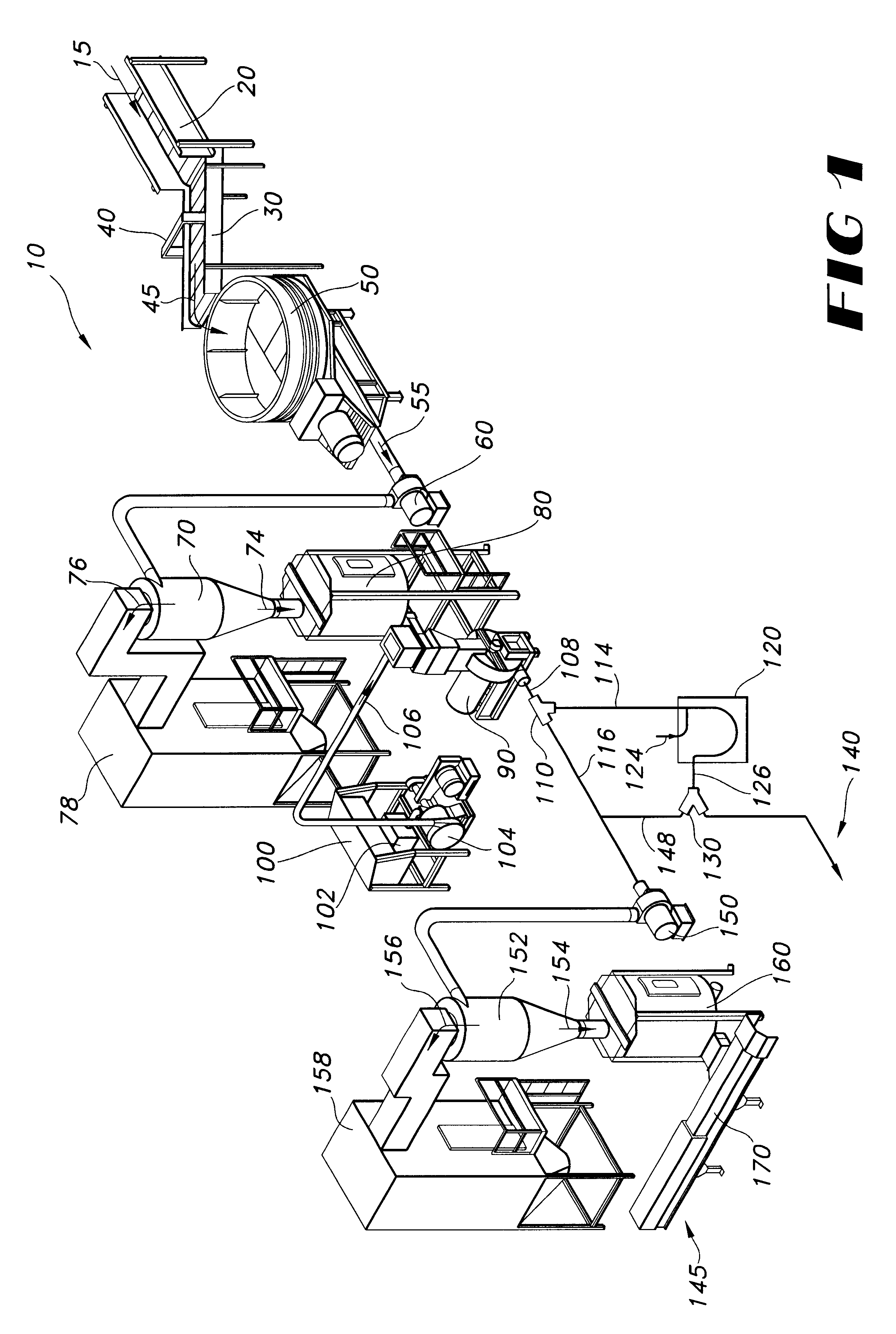

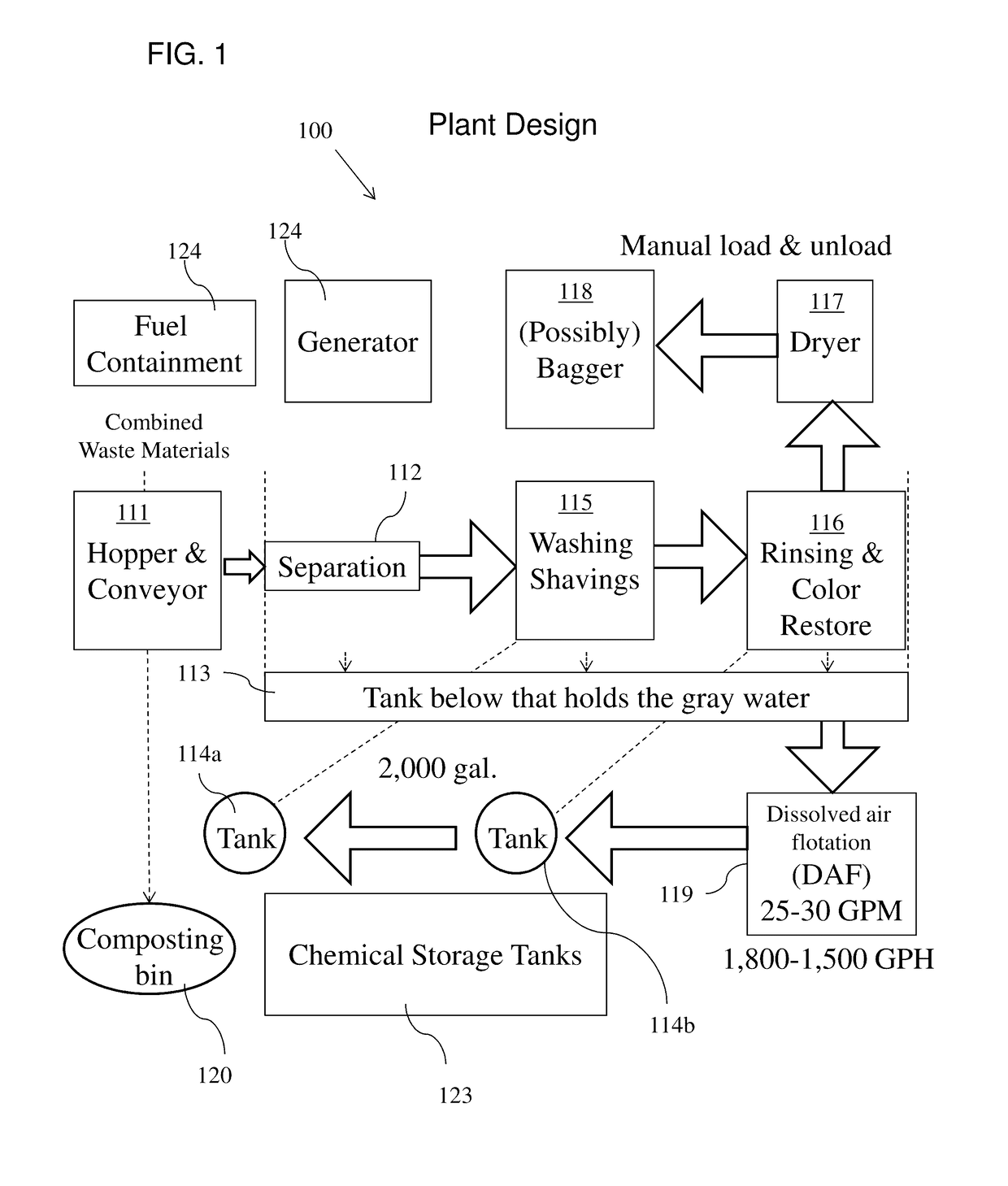

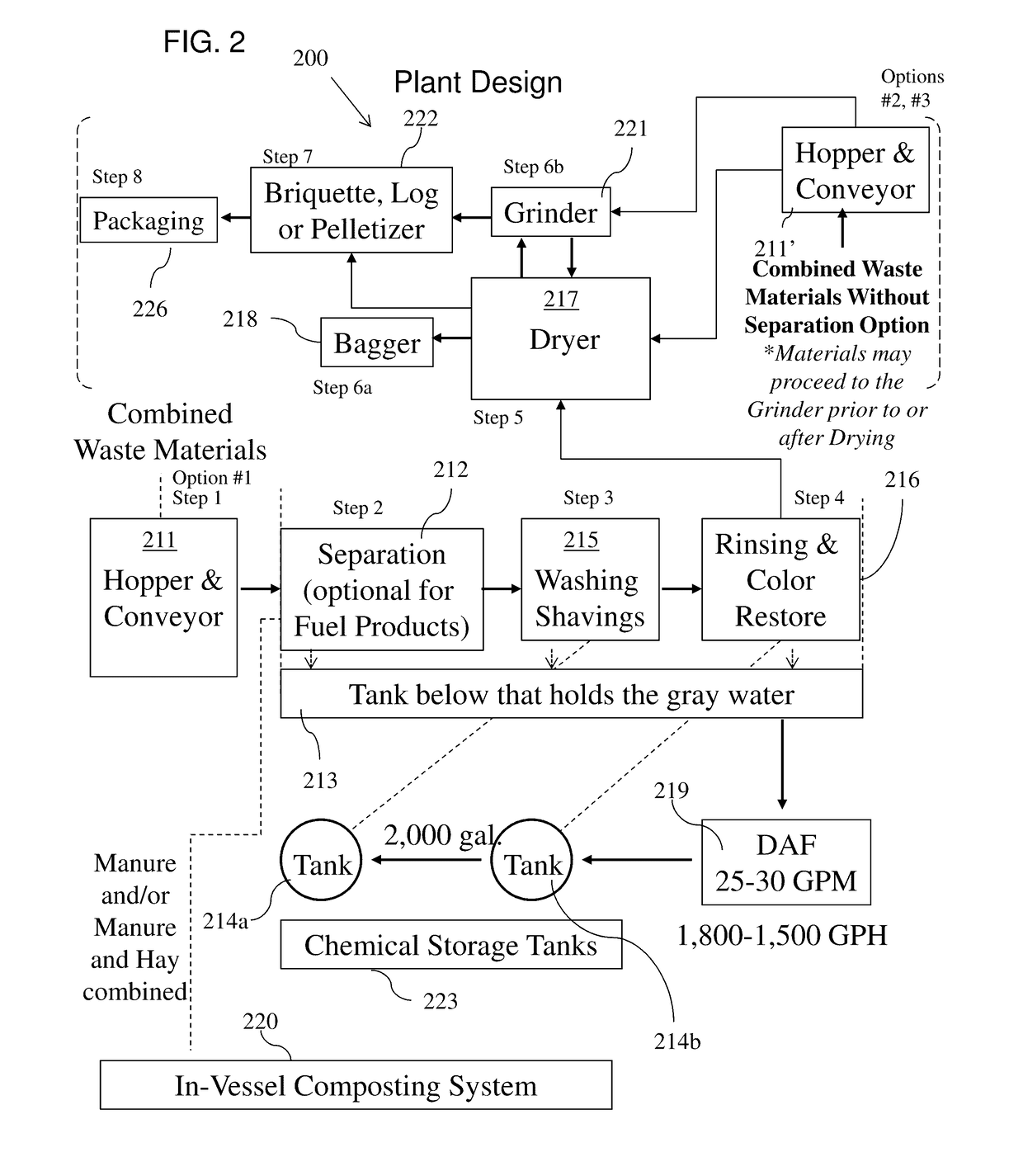

System and method for reprocessing animal bedding

ActiveUS20100212262A1Eliminate needBeneficially usedPackage sterilisationDough shapingFecesEngineering

A process and system reprocesses soiled animal bedding material commingled with animal manure. The material is to remove a preponderance of the manure. The remaining soiled bedding is washed in water and a cleaning agent, rinsed and, optionally, bleached to restore color and appearance. The resulting material is dewatered and dried to reduce its moisture content and kill any remaining pathogens. After being cleaned and sanitized, the material may be reused as bedding or further processed into pellets or other products, such as manufactured fire logs.

Owner:EQUINE ECO GREEN LLC

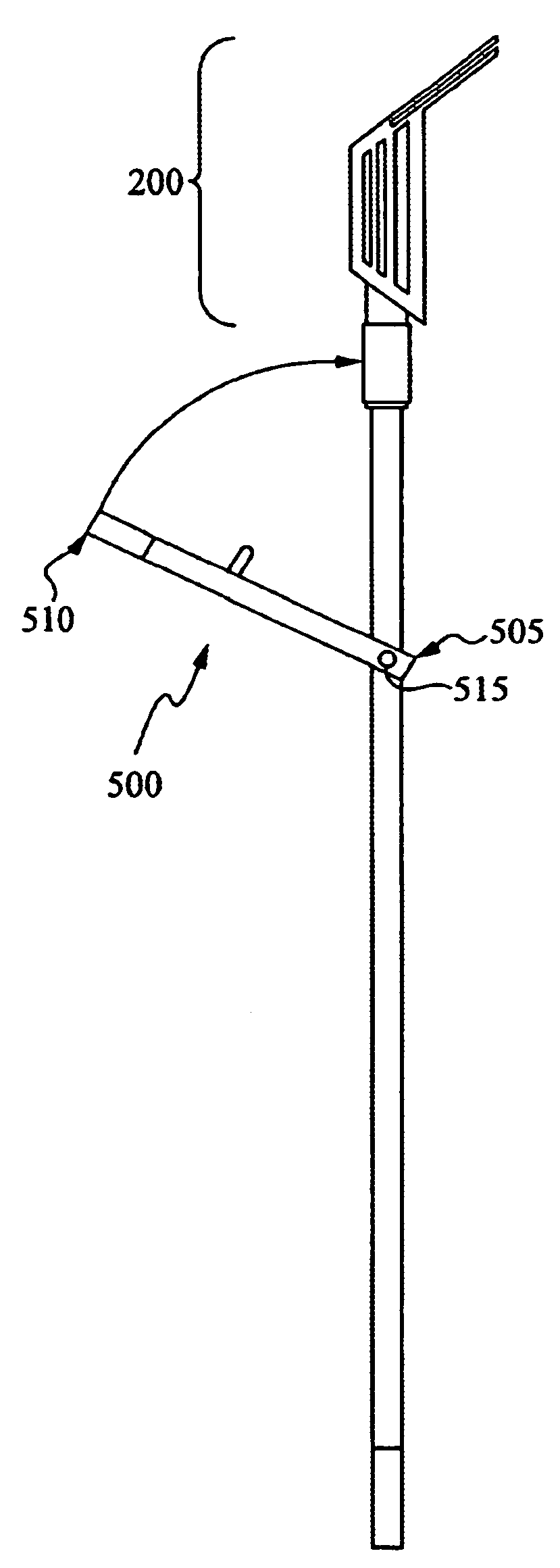

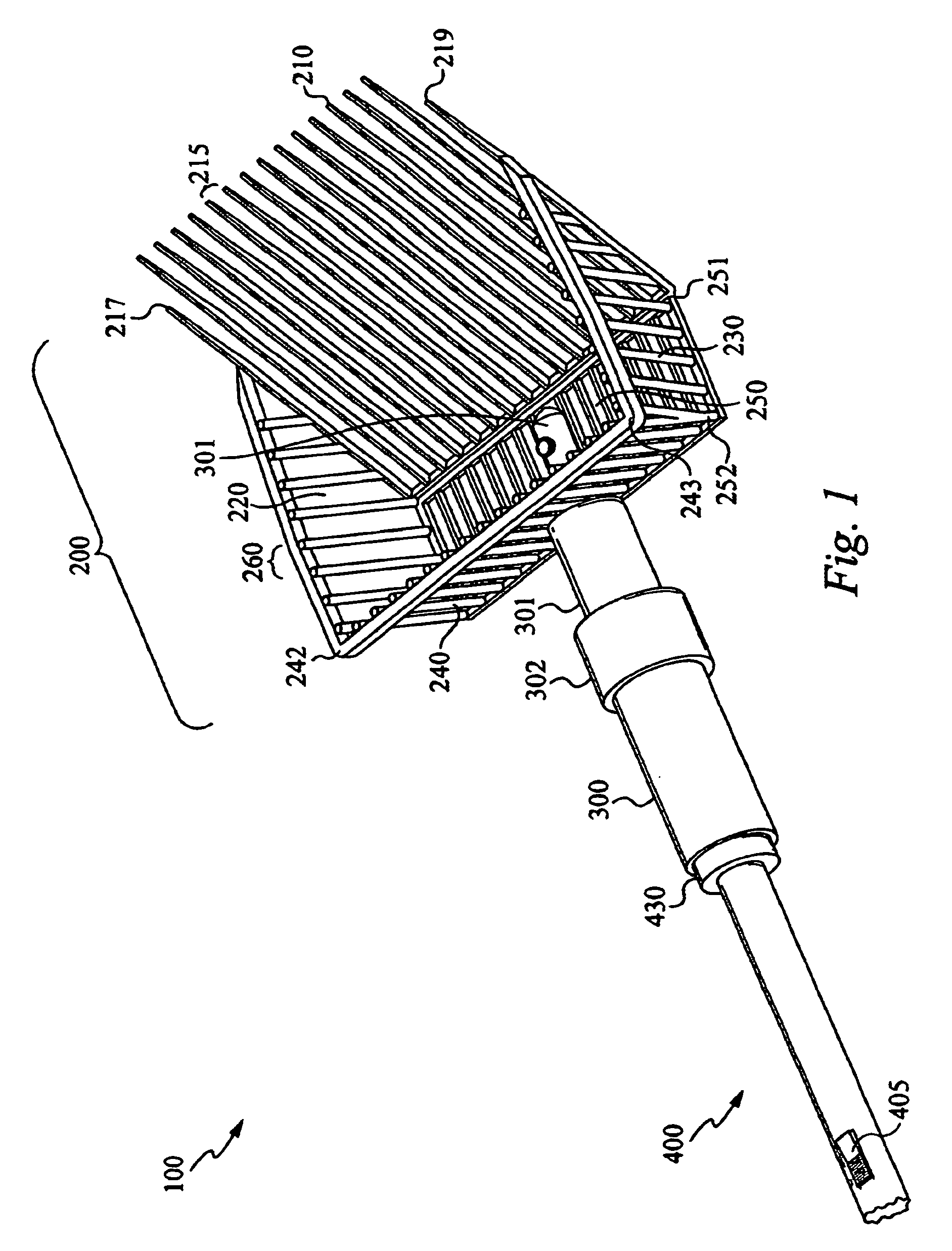

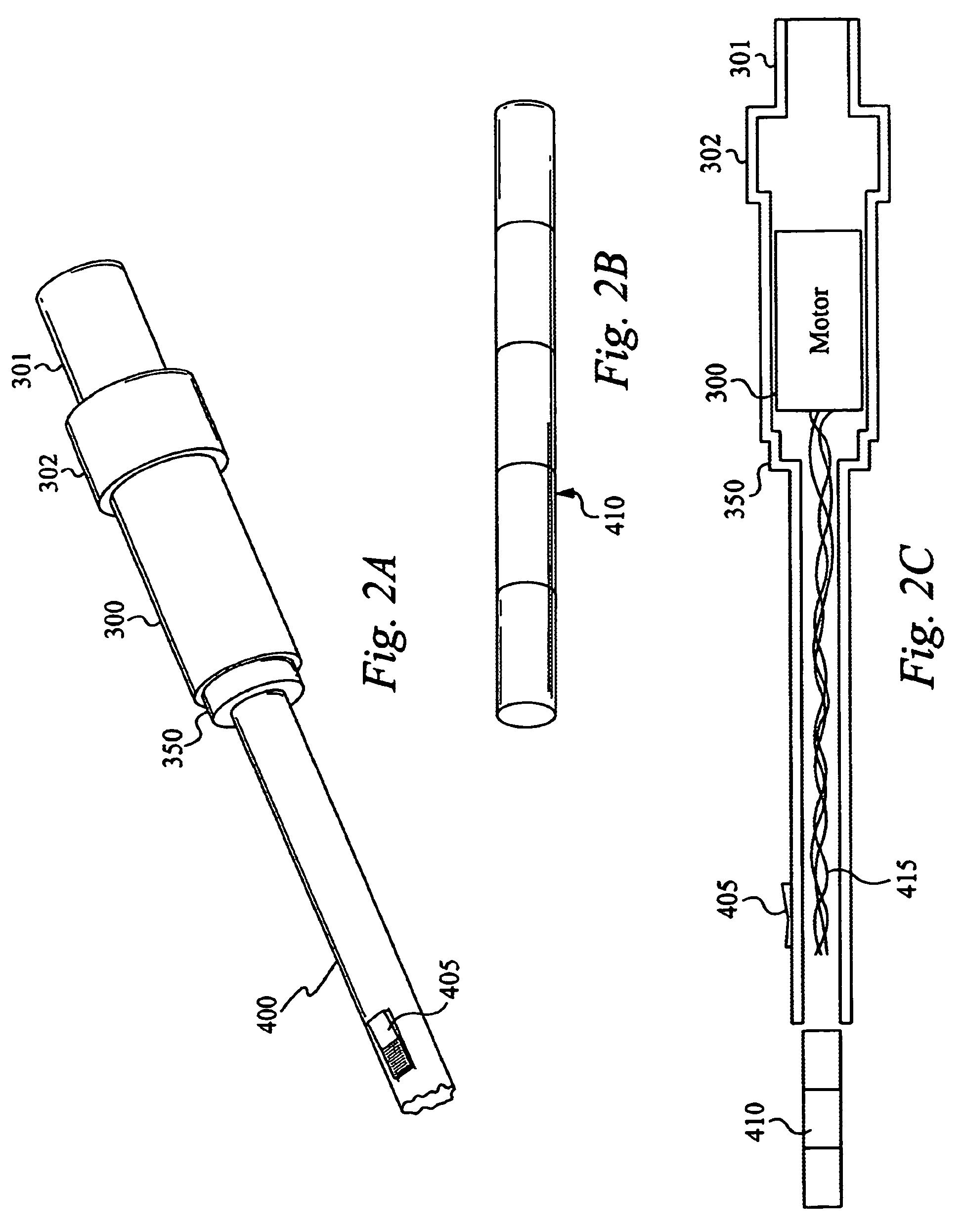

Vibrating scoop basket

A device is used to extract manure from bedding material in a manner that maximizes the amount of manure extracted from the bedding material. The device includes a detachable scoop head having a plurality of apertures, a detachable motor assembly coupled to the scoop head for vibrating the device, and a detachable handle coupled to the motor assembly via a connector. The handle can include a power pack for supplying electrical power to the motor assembly. The apertures are preferably formed between elongated elements. The power pack, which can be housed within the handle, forms a counterweight to the scoop head when the device is lifted. The device can further include a stand having a release mechanism coupled to the device, wherein the release mechanism releases the stand in a fully deployed position to facilitate raising the scoop head.

Owner:SHERIDAN CREEK ENTERPRISES

Alga control method for freshwater environment based on cultivation of barracudas and mullets

ActiveCN102040282ALow costEasy to operateClimate change adaptationPisciculture and aquariaEutrophicationFresh water organism

The invention discloses an alga control method for a freshwater environment based on cultivation of barracudas and mullets, relating to a water treatment method. Aiming at solving the problem that algae can not be stably and thoroughly controlled in a eutrophic fresh water body, the method comprises the following steps: at least introducing one species of estuarine / marine fishes, such as barracudas and mullets which can only be propagated in sea water, and carrying out desalination processing before cultivation to enable the barracudas and the mullets to be adapted to a freshwater living environment, wherein the mesh size in the large water body ensures whether the cultivated fishes can escape; dividing or mixing according to different ages, carrying out culture in enclosure in girds by meshes, and simultaneously cultivating and propagating silver carps, bighead carps, other local fishes and local shellfish; and propagating local common aquatic plants. Thus, the fishes can be fed on the algae in a filter-feeding mode and simultaneously swallow detritus substances, thereby achieving the purpose of thoroughly purifying the water environment. By harvesting the cultivated and propagated aquatic organisms to remove nitrogen / phosphorus nutrients in water and humus in bed material from the water body, the method disclosed by the invention greatly improves the water quality of the cultivation water body.

Owner:SHANGHAI NENGZHENG FISHING TECH DEV CO LTD

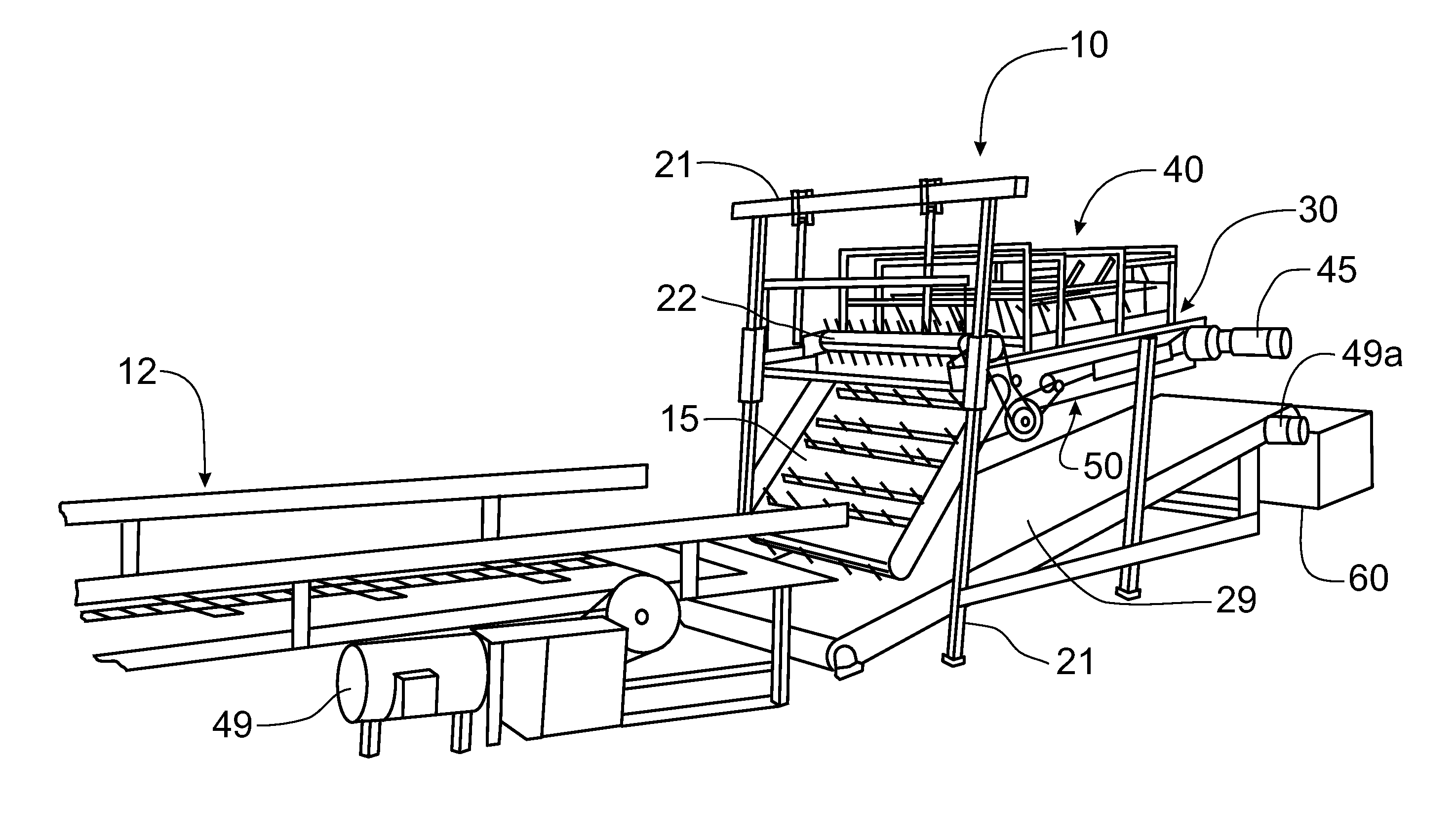

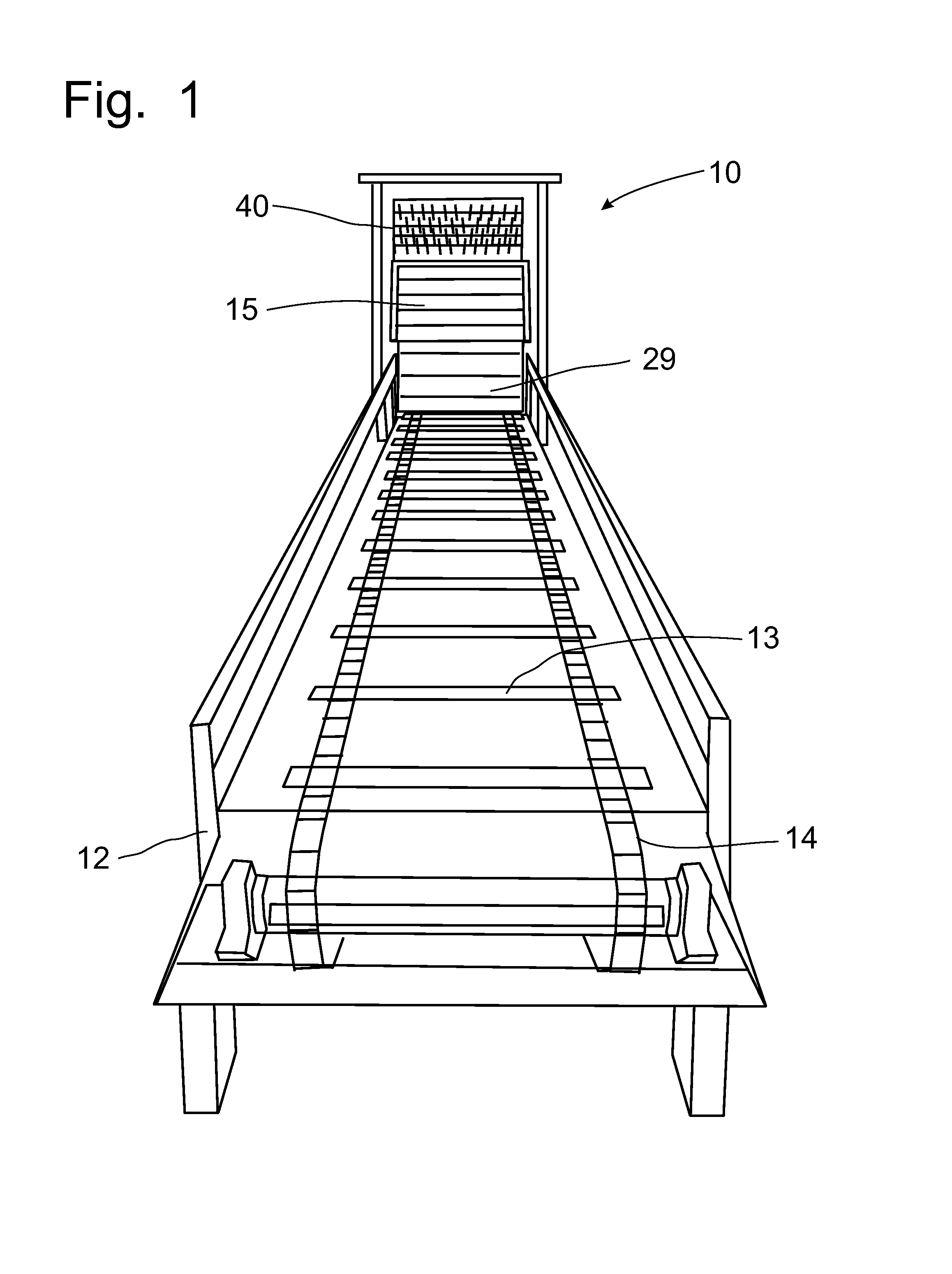

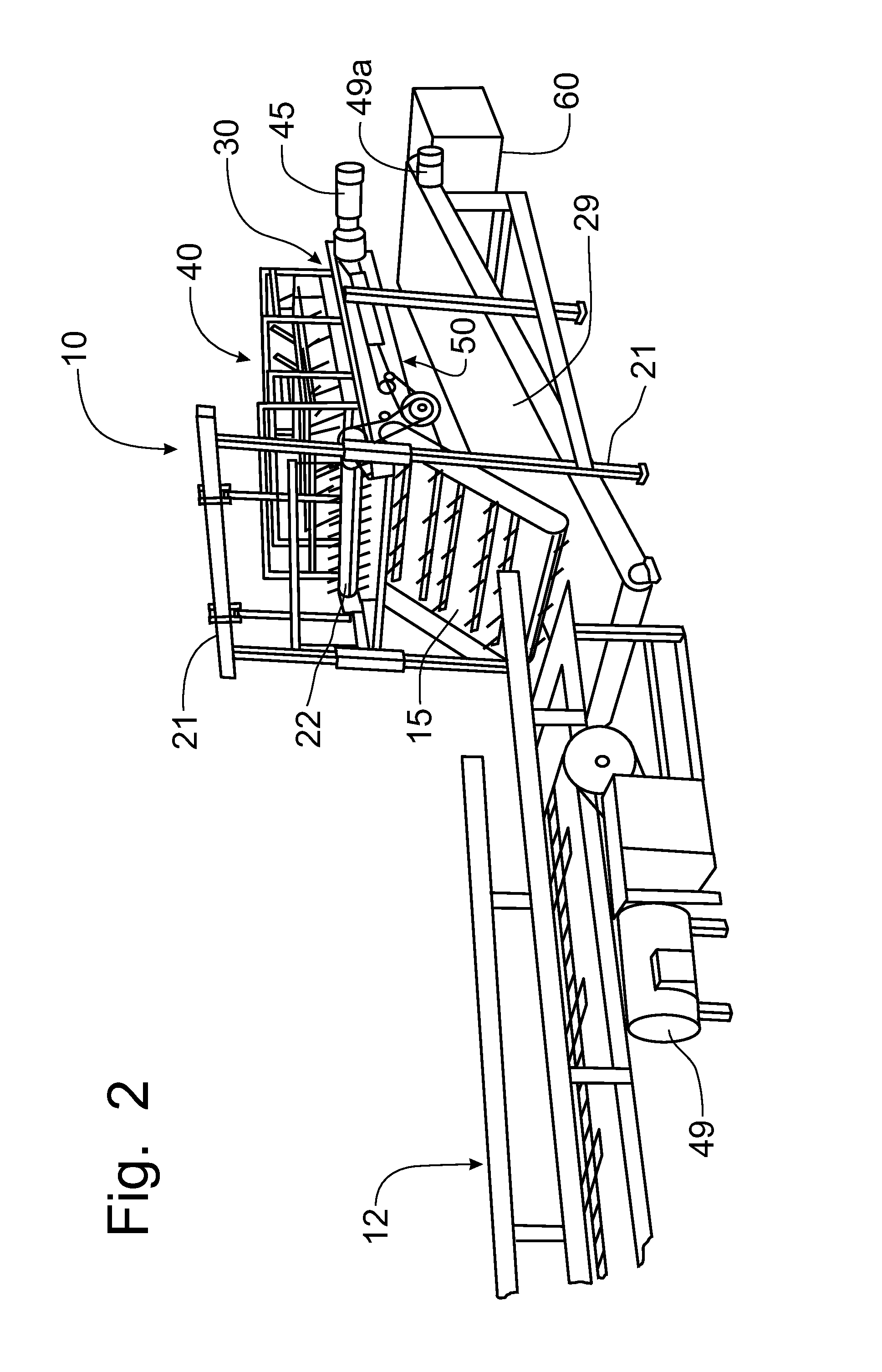

Apparatus for Converting Large Bales of Forage Material into Small Rectangular Bales of Forage Material

An apparatus for disintegrating large rectangular bales of forage or bedding material and reforming the disintegrated material into small rectangular bales includes an inclined conveyor having spikes projecting therefrom to remove slices of material from the large bale and a spiked roller to move the slice rearwardly onto a tumbler bed that receives the slice and affects disintegration thereof. The tumbler bed includes a plurality of transverse assemblies having disks interleaving with the disks on adjacent assemblies, each assembly rotating faster than the assembly immediately forwardly thereof. The disintegrated material falls through the tumbler bed as discrete components that land on a collecting conveyor that conveys the material rearwardly to a small rectangular baler for repackaging. The apparatus further includes a hold-down mechanism that presses the slices toward the tumbler bed to enhance disintegration. An approach conveyor feeds the large rectangular bales loaded thereon to the inclined conveyor for processing.

Owner:ROHRER GERALD A

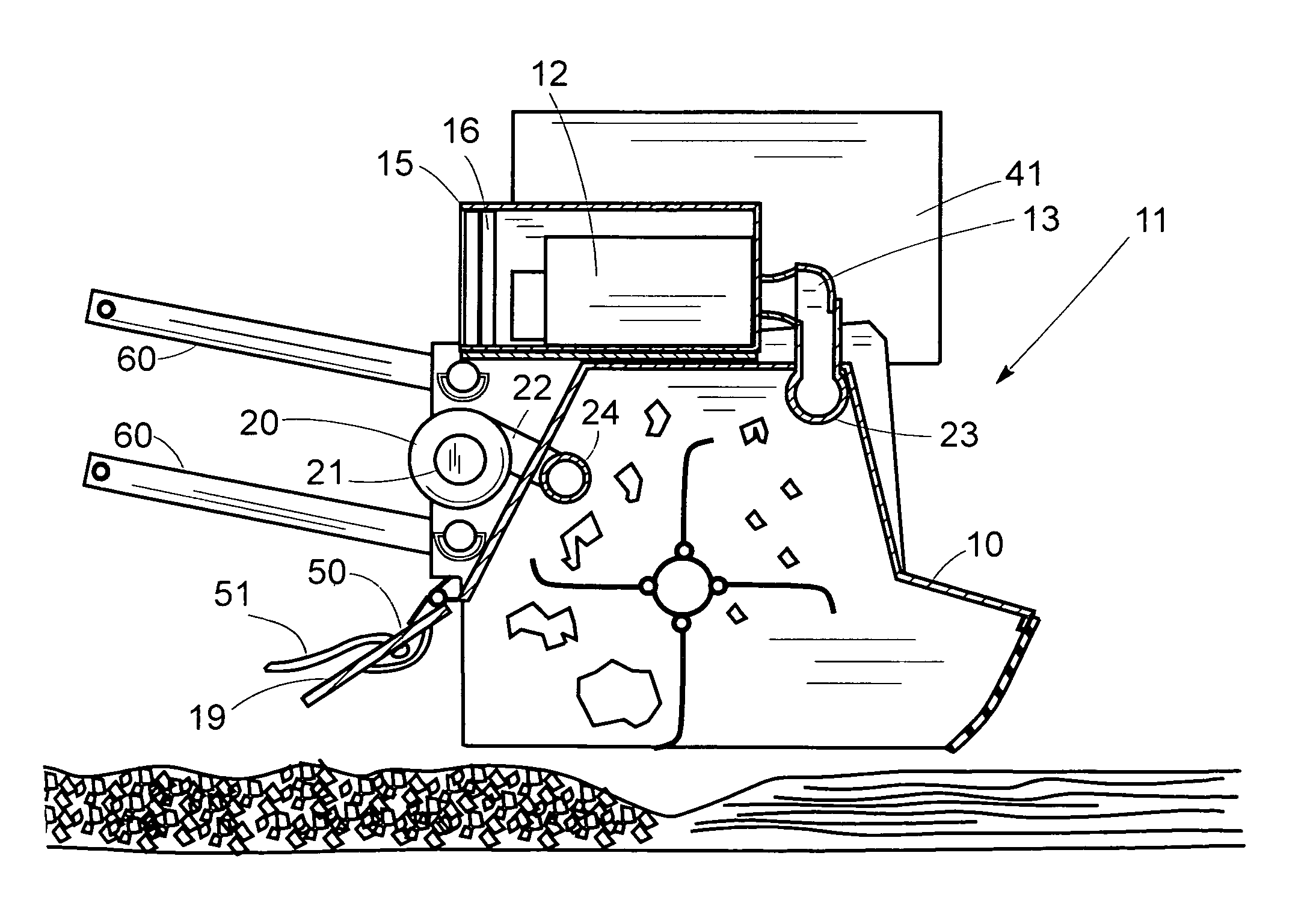

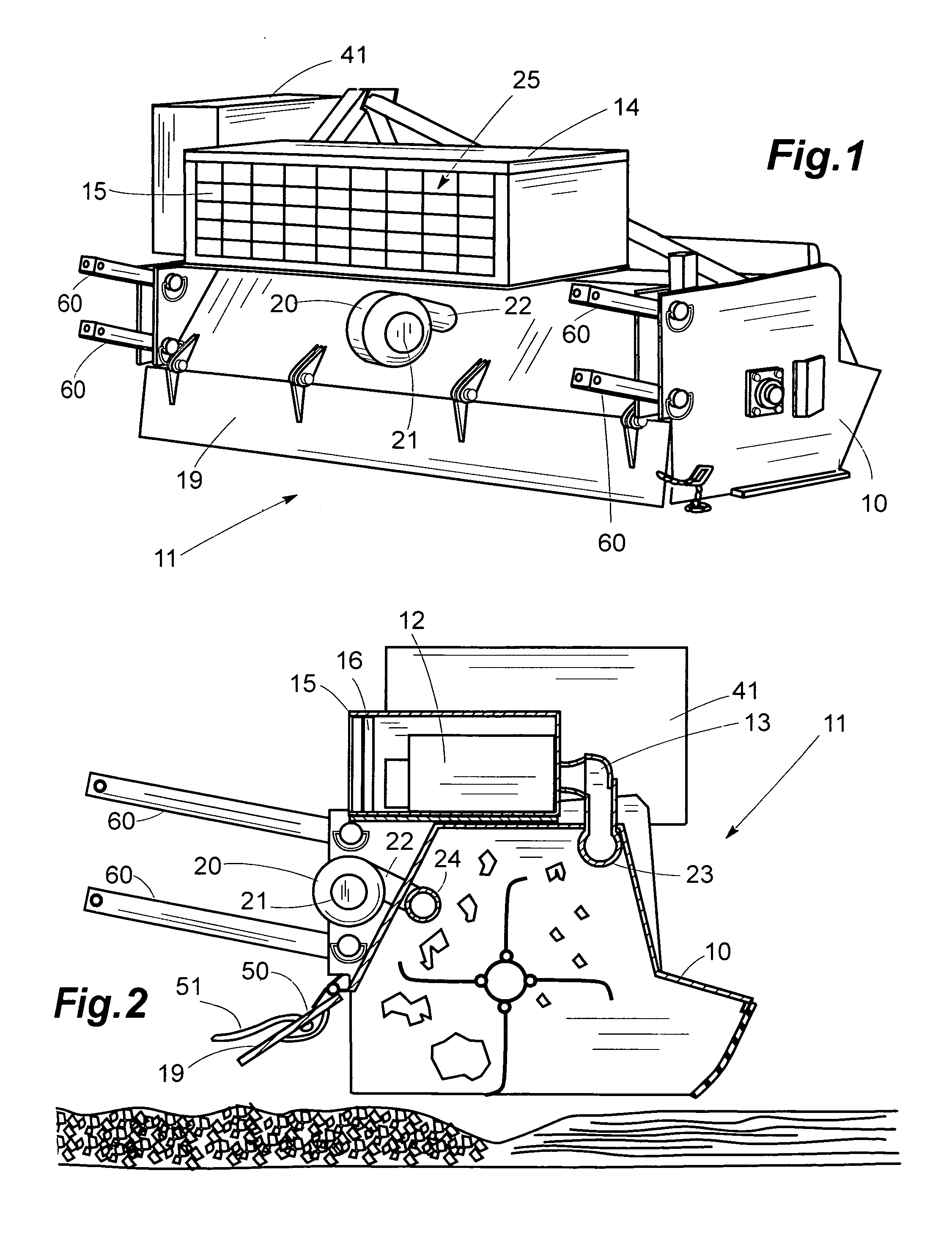

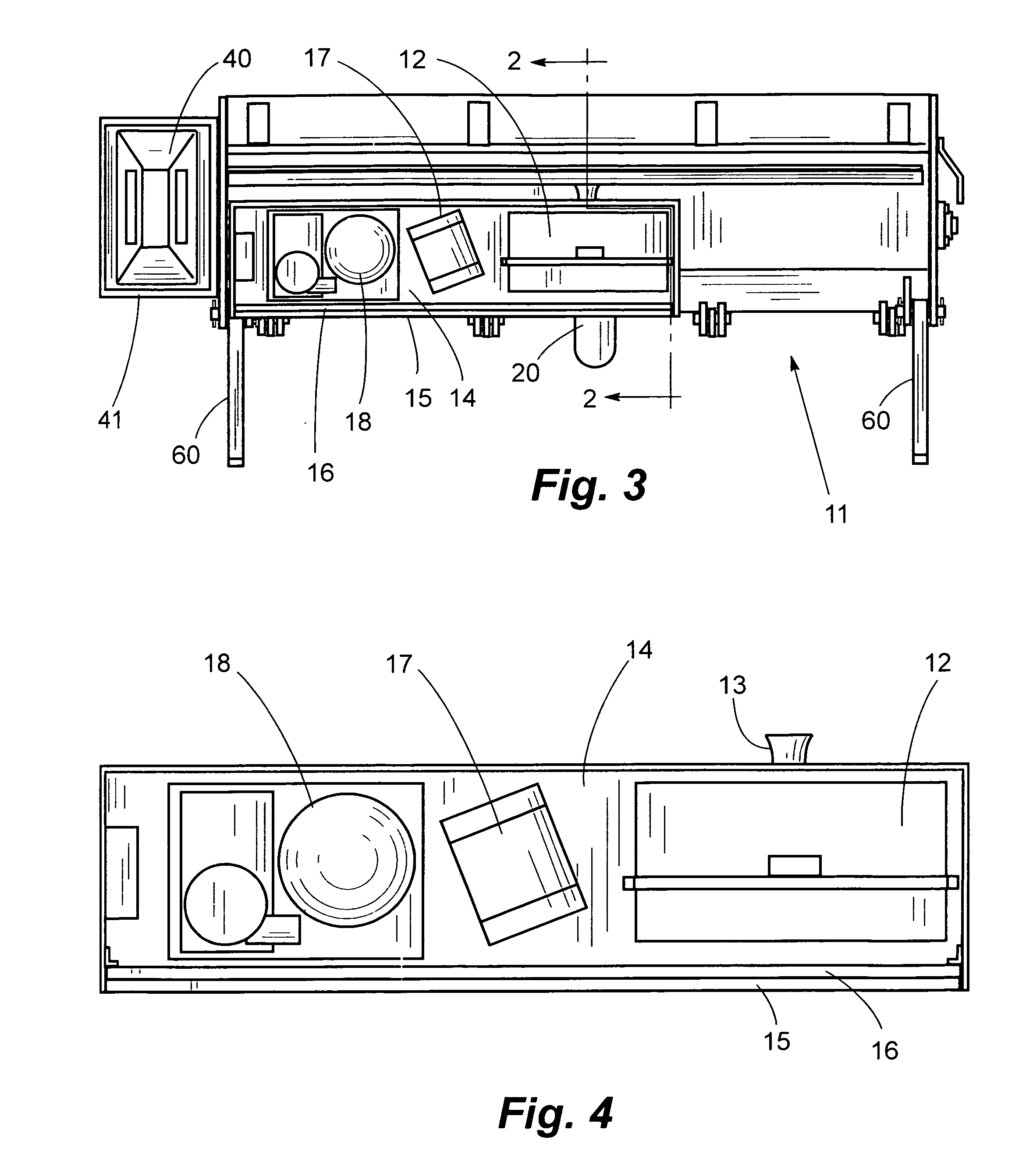

Animal bedding groomer

A grooming apparatus, for sloping, aerating and fluffing bedding material in livestock free stalls, is attached to a vehicle such as a skid steer. The grooming apparatus includes a rotary arm, having grooming members, and connected to the vehicle by a boom. The rotary arm, when viewed across the stalls, is angled at a slope. The grooming members contact the bedding material to fluff and aerate it, and arrange it according to the slope. The rotary arm, when viewed from the end of a stall, may be pitched forward or rearward. These pitches and angles permit the grooming members to more effectively move the bedding material within each stall to create the slope. Such a slope is beneficial for livestock that prefers a sloped bed. Using the boom, the rotary arm can be moved up and / or out of the way when the vehicle is moved through doorways and the like.

Owner:SUPERIOR ATTACHMENTS

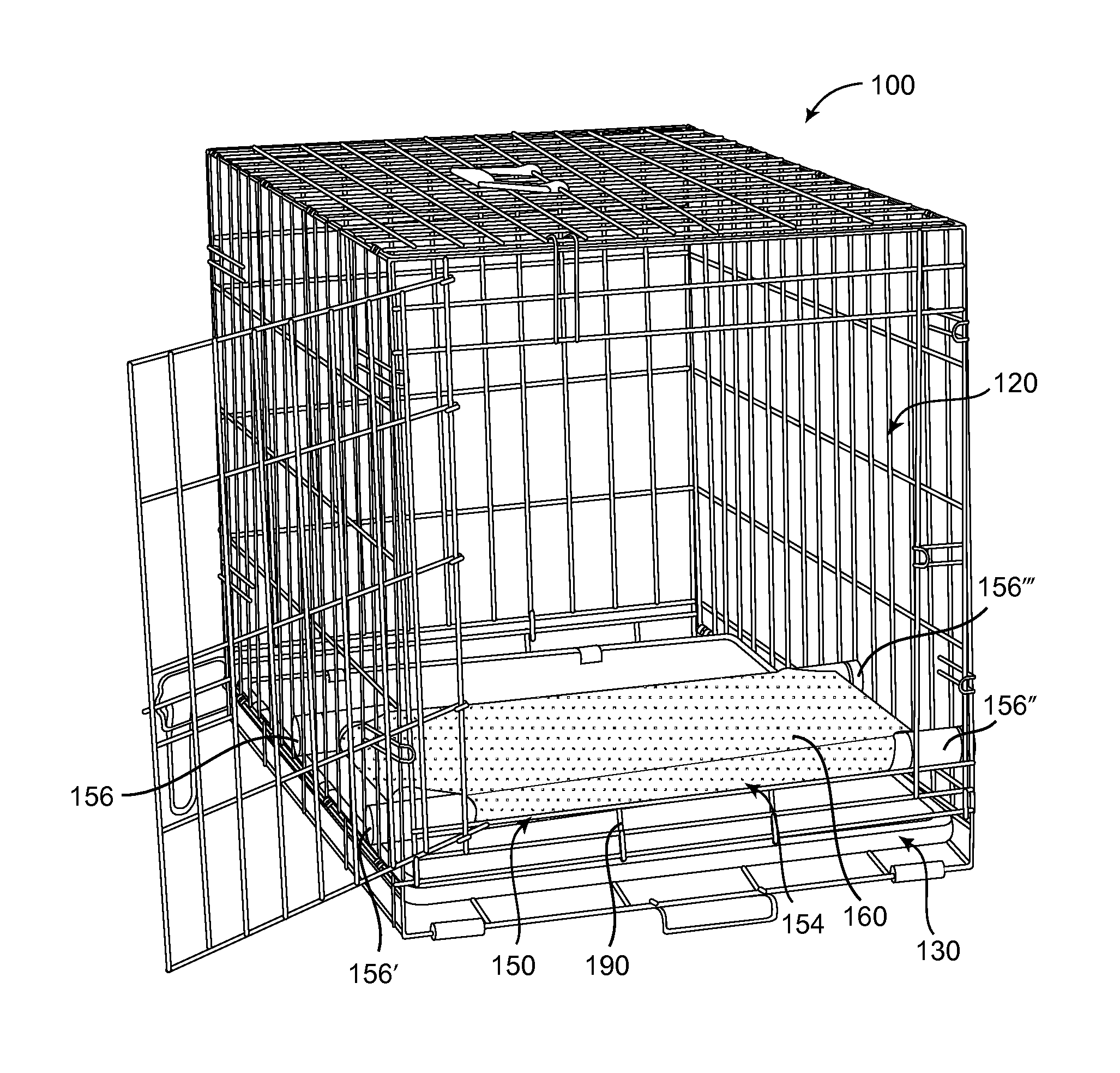

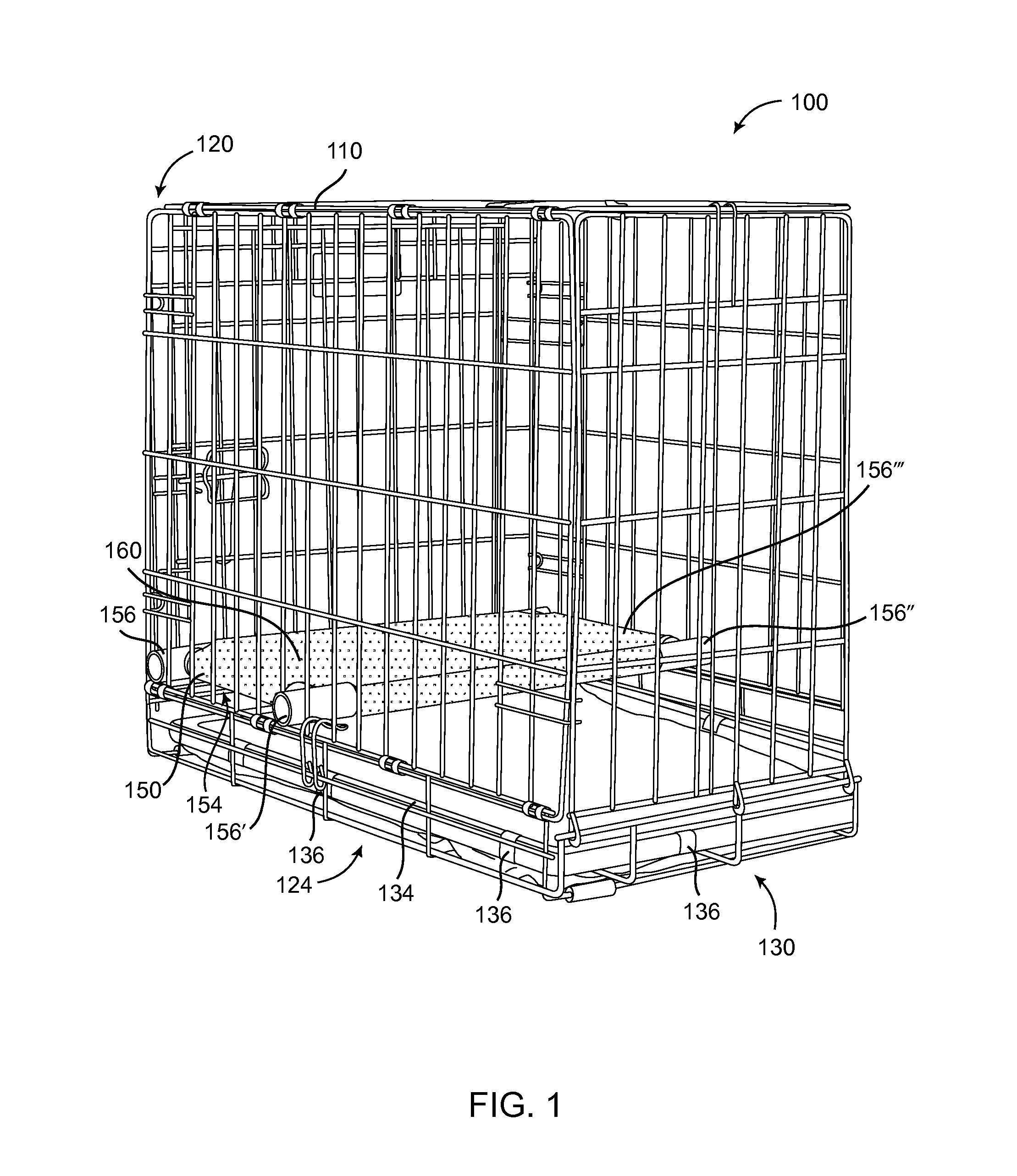

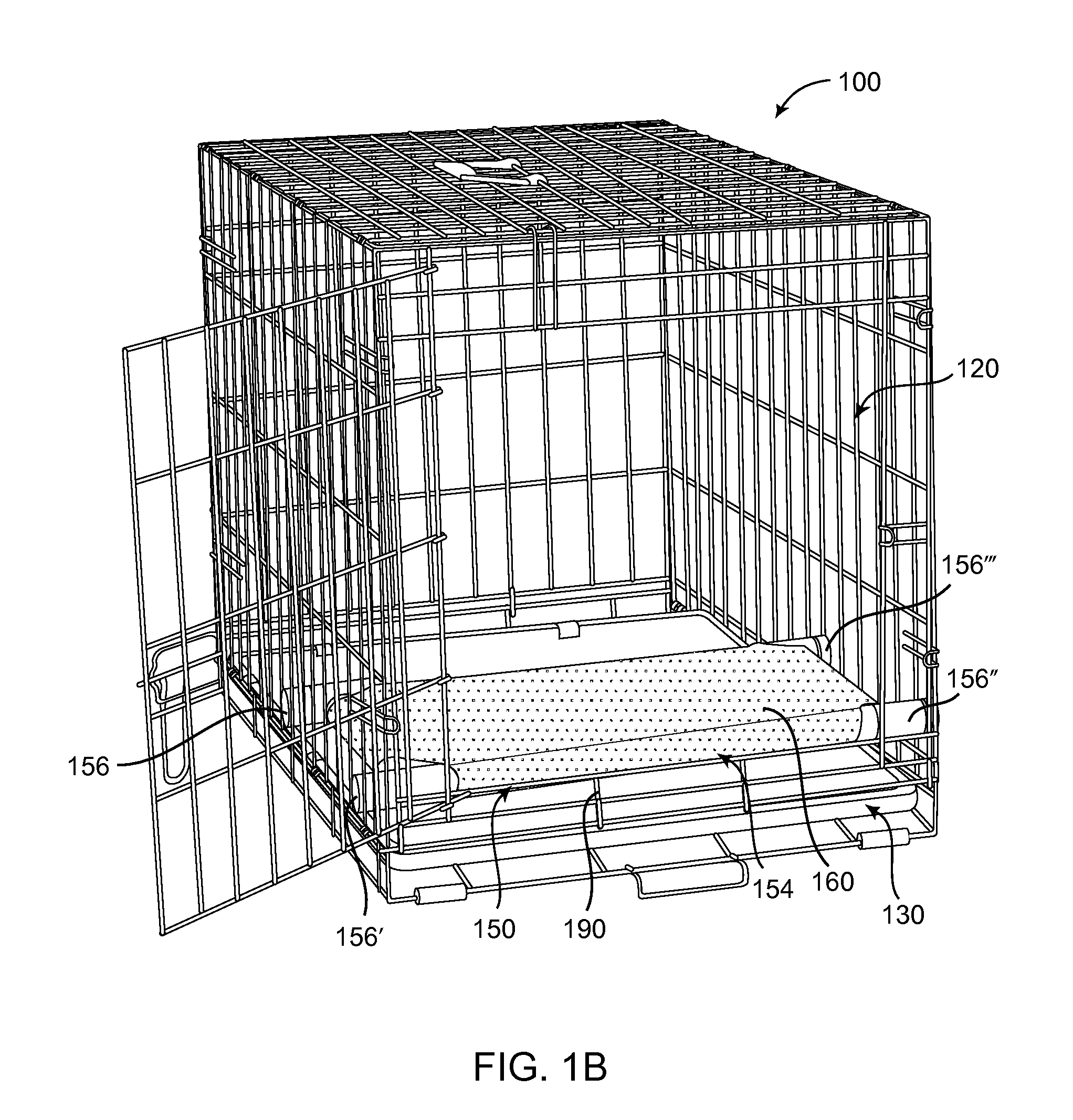

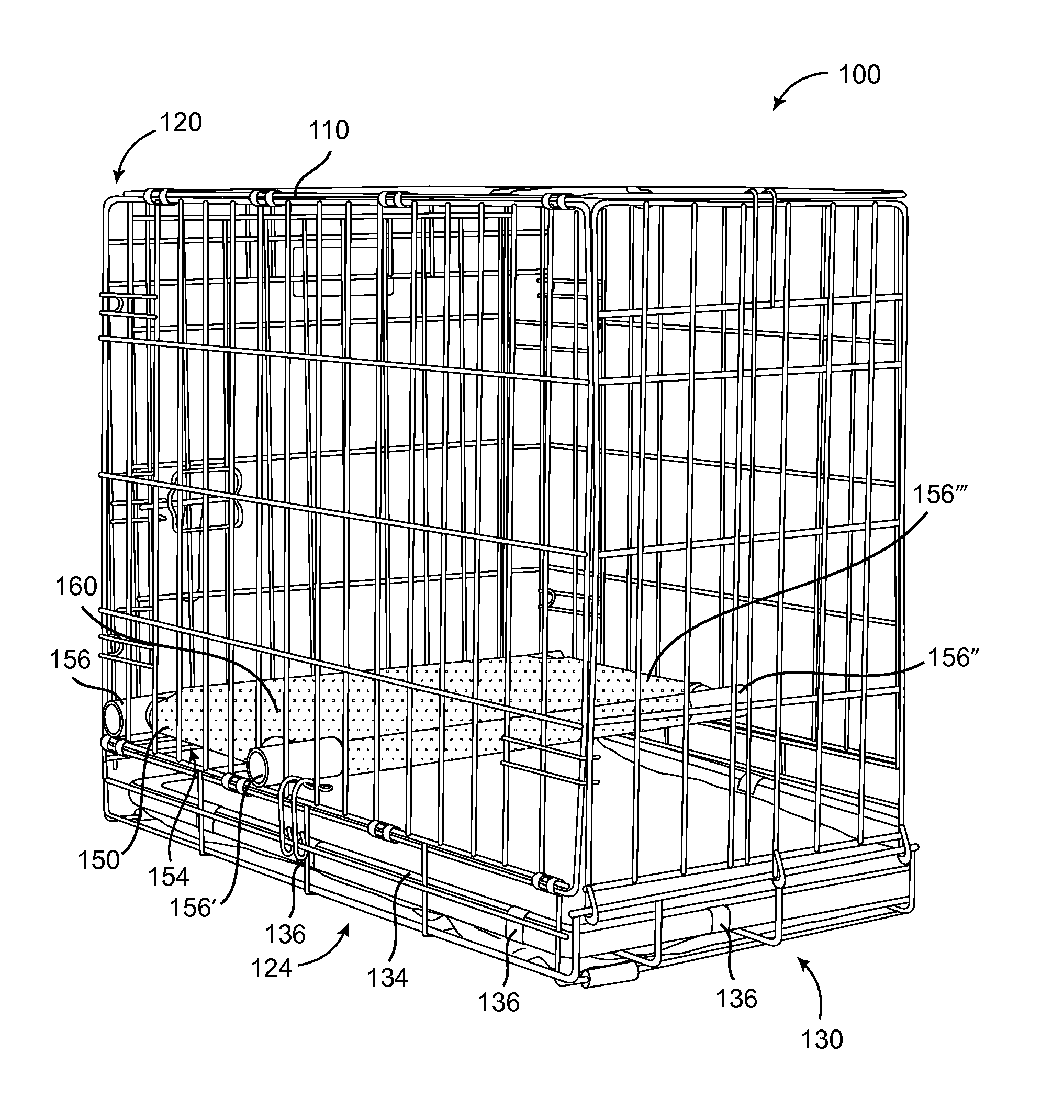

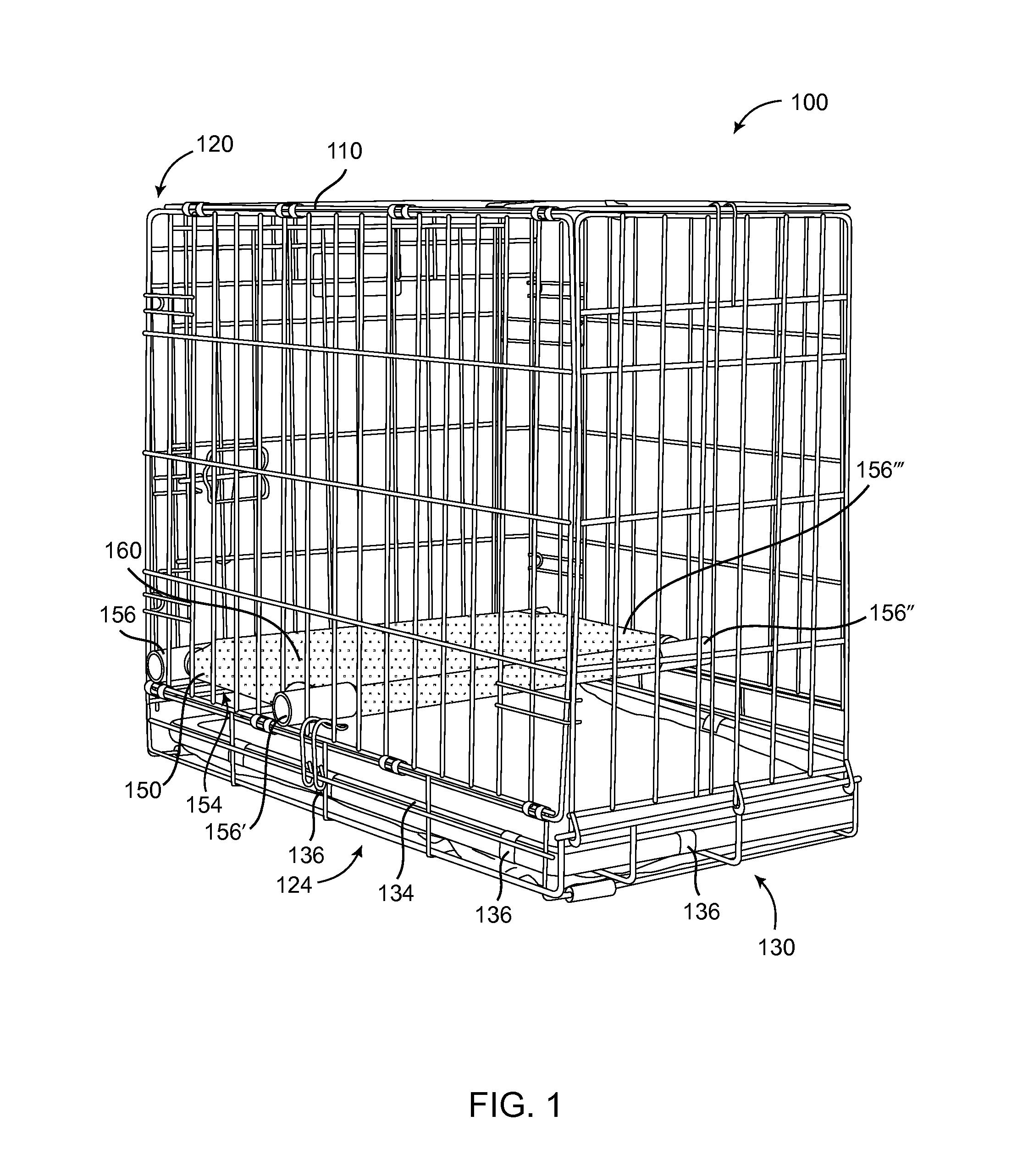

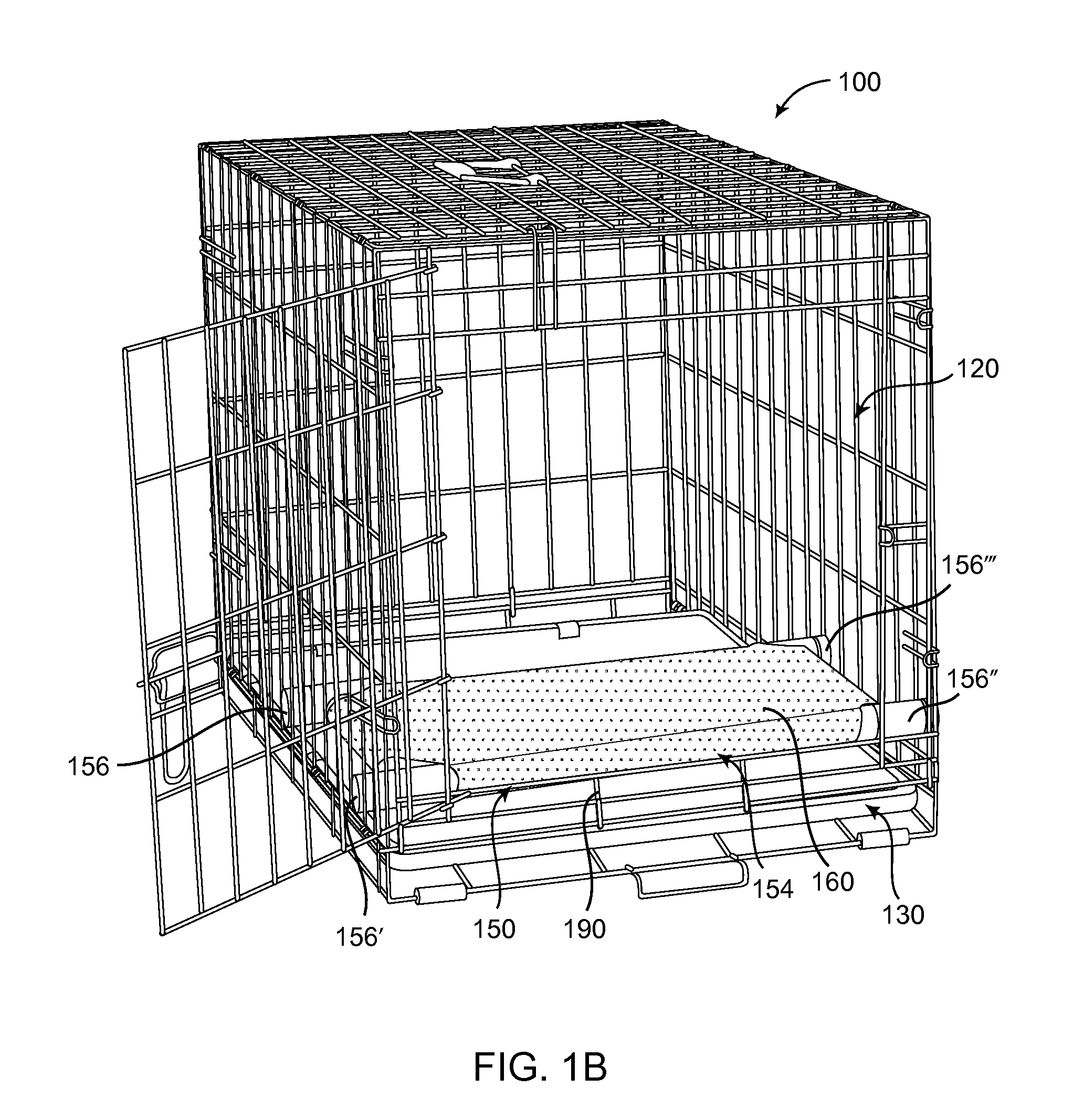

Pet Housetraining Crate System

A system for housetraining pets through the use of separated sleeping and waste areas contained within a pet cage. The cage encloses a waste tray section that runs along the floor of the cage, which holds an absorbent pad, secured by improved retention clips, for collecting pet waste that can be removed and replaced when soiled. A bedding area made of up a rectilinear frame covered in bedding material is raised above the floor of the cage by engaging frame extensions with perforations in the exterior of the cage. The system and associated method serve to aid in conditioning a pet for proper housetraining while the pet is confined to a cage.

Owner:RYBKA GARY +1

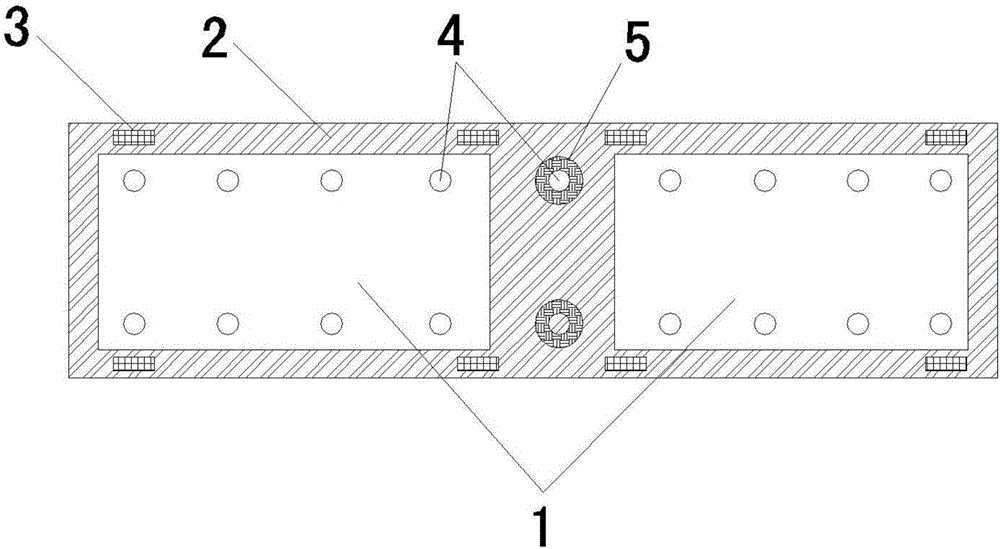

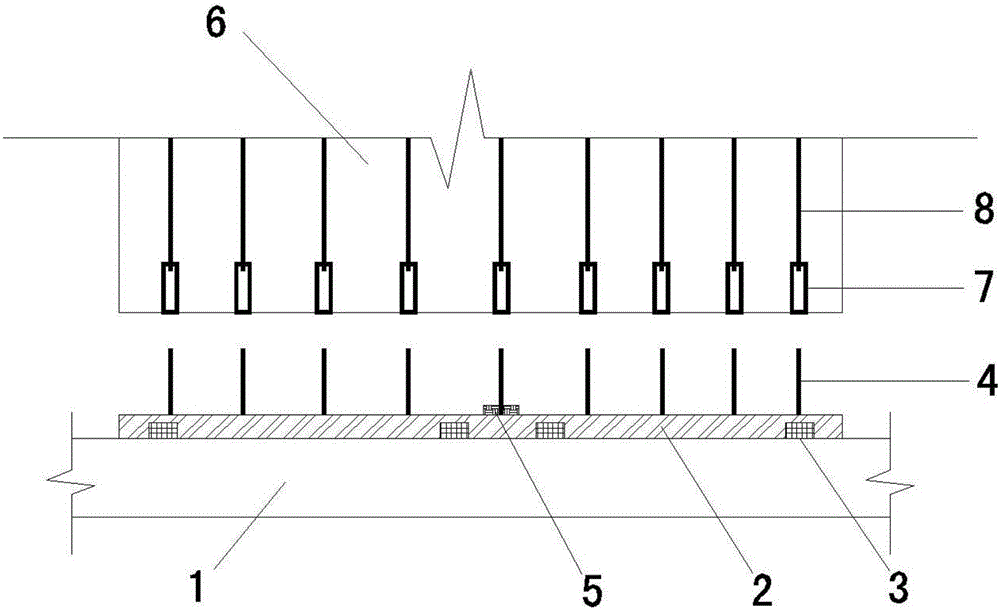

Semi-bedding and semi-grouting vertical connection construction method of prefabricated wall plate

InactiveCN105821978AGuaranteed elevation positionFully filledBuilding constructionsFloor slabEngineering

The invention discloses a construction method for vertical connection of prefabricated wall boards with semi-grouting and semi-grouting. At the same time, install the rubber pad in the sitting slurry; after the sitting slurry is wiped, put a rubber gasket thinner than the rubber pad on the vertical connection reinforcement of the floor at the sitting slurry; hoist the prefabricated wallboard, After aligning the grouting sleeve at the bottom of the prefabricated wall panel with the vertical steel bars of the floor, lower the prefabricated wall panel so that the vertical steel bars of the floor slab are inserted into the grouting sleeve at the bottom of the prefabricated wall panel one by one; when the prefabricated wall panel is completely put down Support on the rubber pad, then adjust the position of the prefabricated wall panel and fix it temporarily; after the prefabricated wall panel is fixed, perform grouting construction on the grouting sleeve so that the prefabricated wall panel is fixed on the floor through the curing connection of the grouting material and the sitting grout superior. This method can make the structure firm and stable.

Owner:天津住宅集团建设工程总承包有限公司

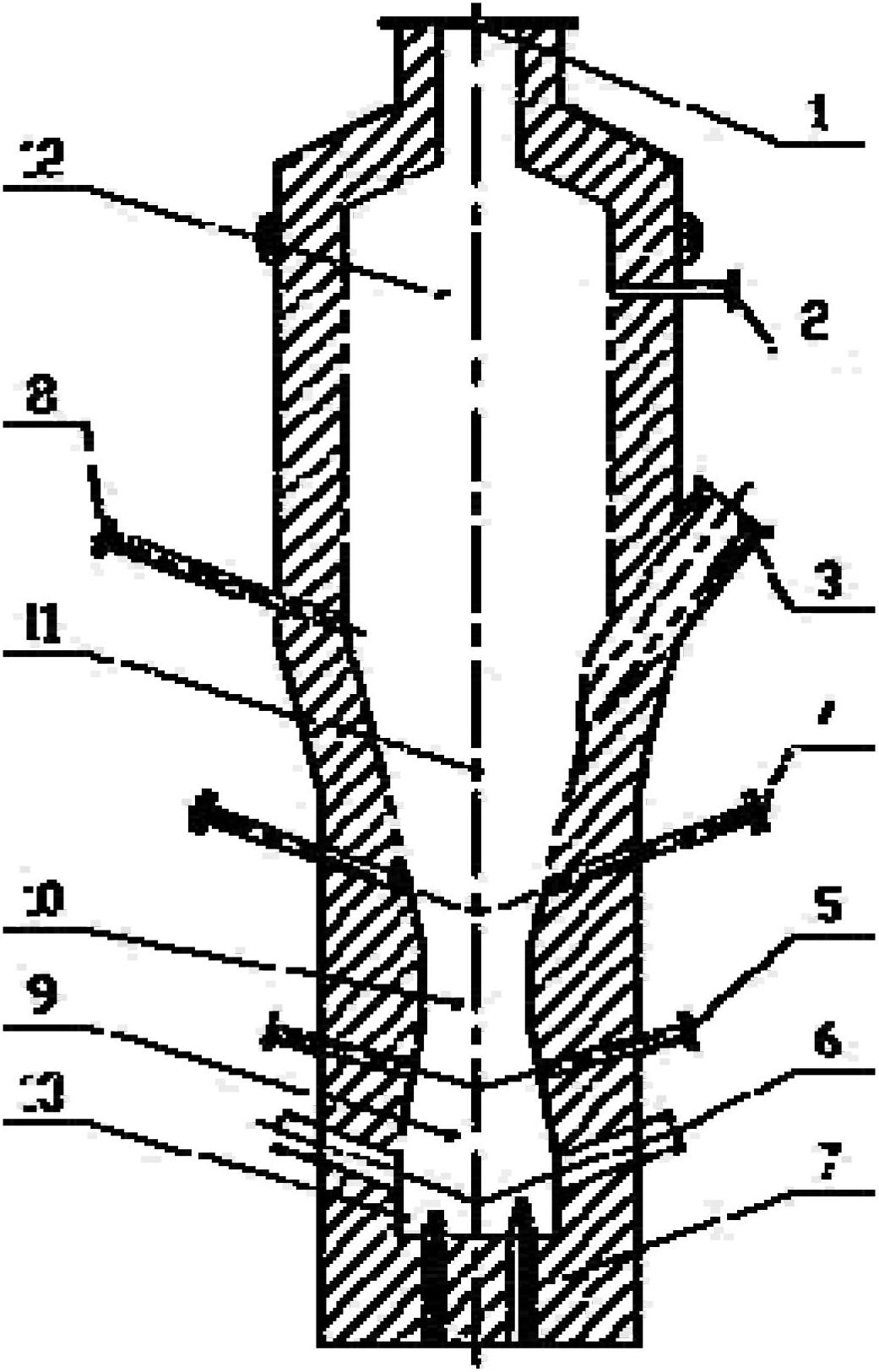

Household garbage and burning fly ash joint-disposal method and equipment

The invention relates to household garbage and burning fly ash joint-disposal method and equipment. The equipment comprises a plasma torch system and a gasification smelting furnace, wherein the smelting furnace comprises a slag discharge port, a gas lead-out port, a slag bin, a smelting burning chamber, a gasification chamber, a drying chamber, a fuel gas negative-pressure bin, a feed bin, a plasma torch interface, an air inlet and a thermocouple interface. The method comprises the following steps of: adding the bed material into the smelting furnace, and starting the plasma torch system; when the furnace temperature reaches the rated value, feeding the mixture of the household garbage and the burning fly ash into the feed bin; after drying and smelting burning, discharging the generated synthesis gas out of the smelting furnace through the fuel gas negative-pressure bin and the gas lead-out port; and discharging the generated slag through the slag bin and the slag discharge port. Through the invention, the toxic and harmful wastes in the mixture of the household garbage and the burning fly ash can be completely eliminated, the synthesis gas generated by the gas smelting can be used for the power generation of an internal combustion engine, and continuous feed / discharge of the material can be realized at the same time; and moreover, the structure is relatively simple and reliable, and the economic benefits are very obvious.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD

Treatment method for metallurgy sintering of abandoned SCR flue gas denitrification catalyst

ActiveCN105907950ARealize green comprehensive utilizationNo secondary pollutionFlue gasBlast furnace smelting

The invention discloses a treatment method for metallurgy sintering of an abandoned SCR flue gas denitrification catalyst. The method is characterized by comprising the following steps that the catalyst is broken, wherein the abandoned SCR flue gas denitrification catalyst is broken and ground, and catalyst powder being 100 meshes to 200 meshes is obtained; granulating is conducted, wherein the catalyst powder with the weight percent being 1% to 20% is mixed with iron ore powder, a fluxing agent, fuel, return fines and water, and a sintering mixture is obtained through granulating; and sintering is conducted, wherein the sintering mixture is laid on a bedding material of a sintering machine trolley to be sintered, and sintered ores are formed. By means of the method, the abandoned denitrification catalyst can be treated, the leaching amount of heavy metal of a formed sintered body is relatively low, the environment-friendly requirement is met, and meanwhile parts of the sintered ores can meet the performance requirement and used for blast furnace smelting.

Owner:ZHEJIANG UNIV

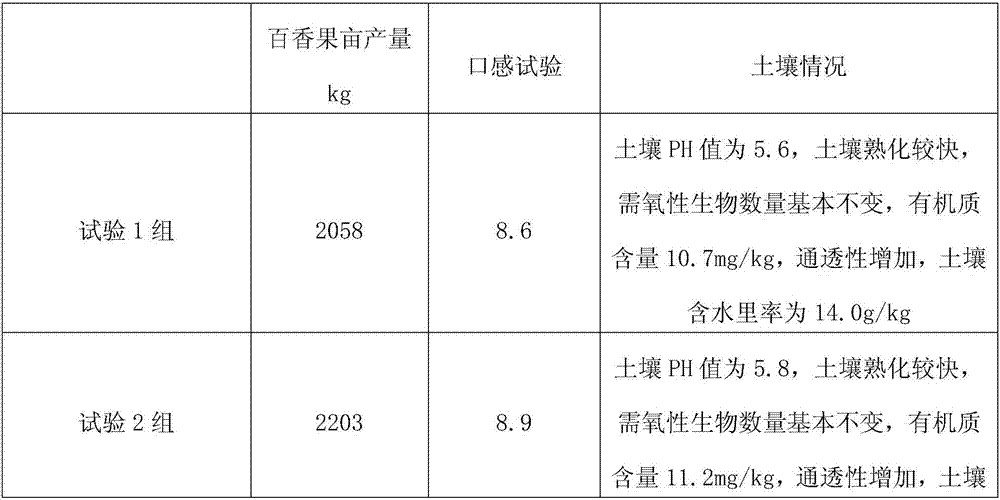

Method for planting passion fruits

InactiveCN106941897ANot volatileNot easy to loseBioloigcal waste fertilisersPlant cultivationFruit treeSoil properties

The invention relates to the technical field of fruit tree planting and particularly relates to a method for planting passion fruits. The method provided by the invention comprises the following steps: a. carrying out land preparation and seed preparation: deeply plowing land after Beginning of Spring, applying lime and carbendazim during deep plowing, sunning soil for 4 to 8 days, then, carrying out leveling, and digging passion fruit planting pits; b. shelving passion fruit planting shelves; c. planting the passion fruits: firstly, applying a bedding material to the bottom of each planting pit, planting passion fruit seedlings, covering the planting pits with soil, irrigating field planting water, and digging a round of dressing furrow in a manner of taking each passion fruit seedling as a center; d. carrying out field management: 3 years after planting, pulling out 1 / 4 to 1 / 3 of old vines in turn every year in a spaced manner; and e. carrying out harvesting: carrying out picking in a non-scheduled manner when the passion fruits are mature. According to the method provided by the invention, soil properties are improved, the problem, i.e., soil hardening is effectively solved, and the soil is high in permeability and plays roles in preserving moisture and heat; and by rational application of fertilizer, the utilization rate of the fertilizer is increased, yield and income are increased, and thus, a reference is provided for sustained development of the passion fruits.

Owner:陆川县一品养殖专业合作社

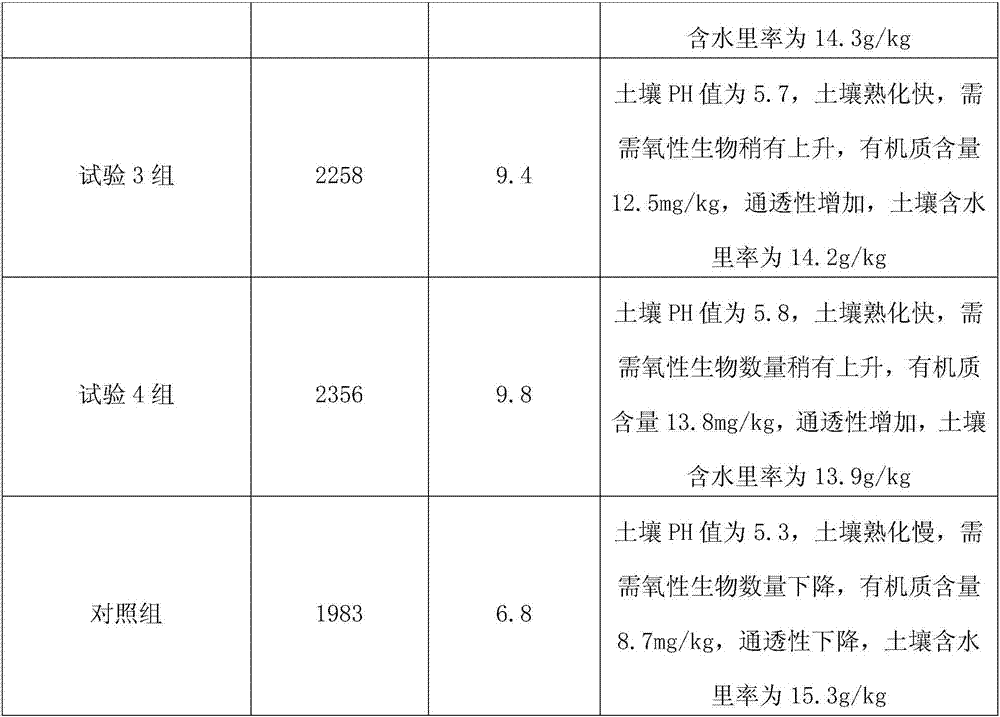

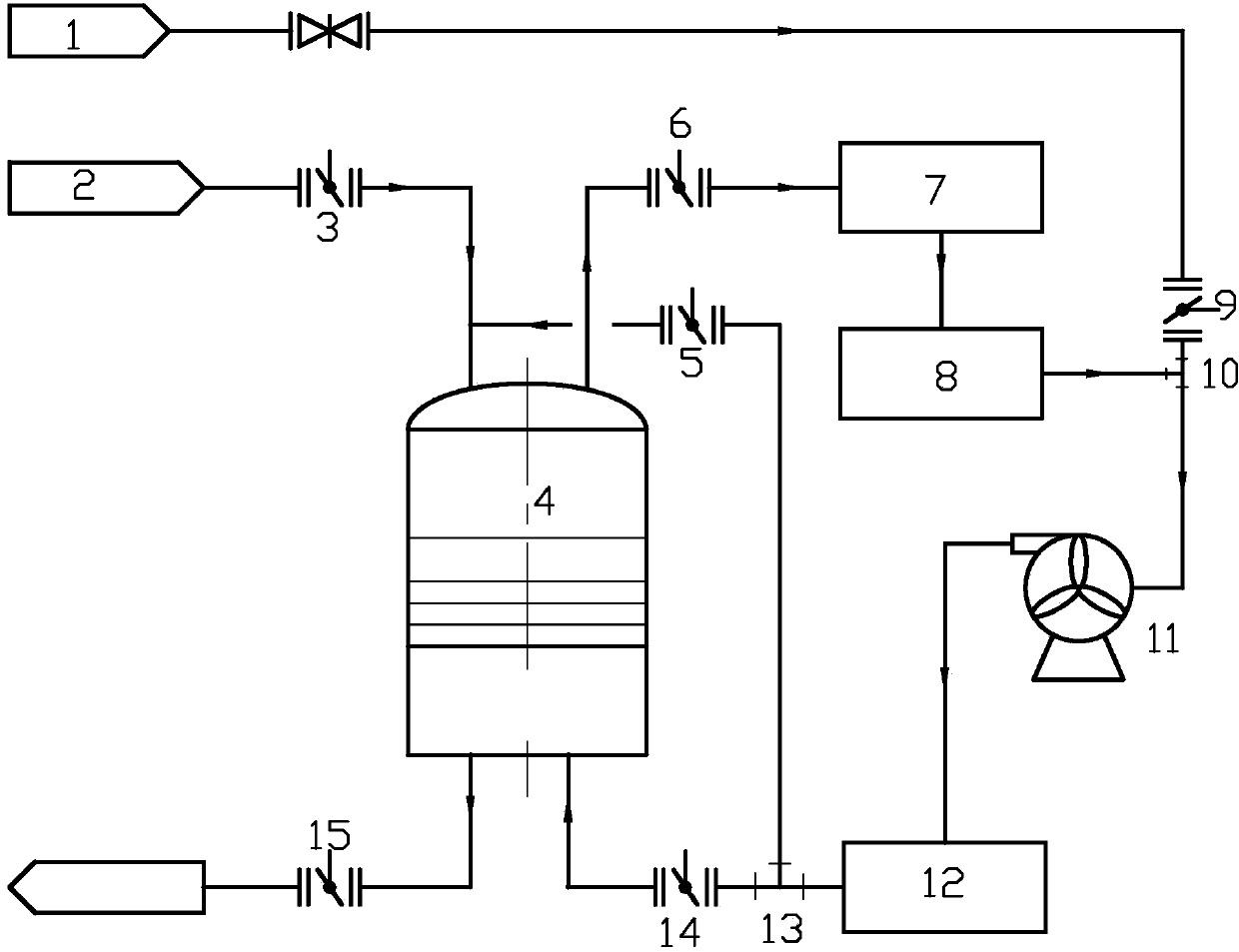

Raw coke oven gas dedusting device and raw coke oven gas dedusting method

ActiveCN103468323AAvoid breakingIncrease dust contentGas purification by non-gaseous materials condensationGas dust removalGas heaterBaghouse

The invention relates to a raw coke oven gas dedusting device and a raw coke oven gas dedusting method. The device consists of at least one dedusting unit; each dedusting unit comprises a filter; the filter is respectively communicated with a raw coal oven gas pipeline, a coal oven gas cooler as well as a gas replacement pipeline; the coal gas cooler is communicated with a bag-type deduster; the bag-type deduster and an oil-free gas pipeline are communicated with a circulation fan; the circulation fan is communicated with a coal oven gas heater; a purified gas outlet in the bottom of each filter is communicated with a purified gas emission pipeline; a blowback gas inlet is communicated with a blowback gas pipeline; the blowback gas pipeline and a gas replacement pipeline are communicated with a coal gas heater. The whole device is simple in structure, runs stably, is low in energy consumption, and is high in filtering efficiency; a circulation ash blowing regeneration system is not arranged, bed materials are not required to be circulated, filter materials are prevented from being crushed during the filtering process and the abrasion to equipment is prevented; multiple dedusting devices can be in parallel combination for filtering. According to the method provided by the invention, the operation is simple and convenient, the dedusting efficiency is high, pressure difference is low, energy consumption is low, and the cost is low.

Owner:SHENMUFUYOU ENERGY TECH

Method and system for producing prescription animal bedding from recycled paper waste products

A method and system for producing an animal bedding material from recycled waste paper, and including one or more chemical additives. The base material is fiberized, and the chemical additives may include: pesticides, disease immune additives (medicines), ammonia inhibitors, fire retardants, or other additives, depending on the characteristics desired of the final product. At least one of the additives is applied as a liquid.

Owner:CELLULOSE TECH GROUP

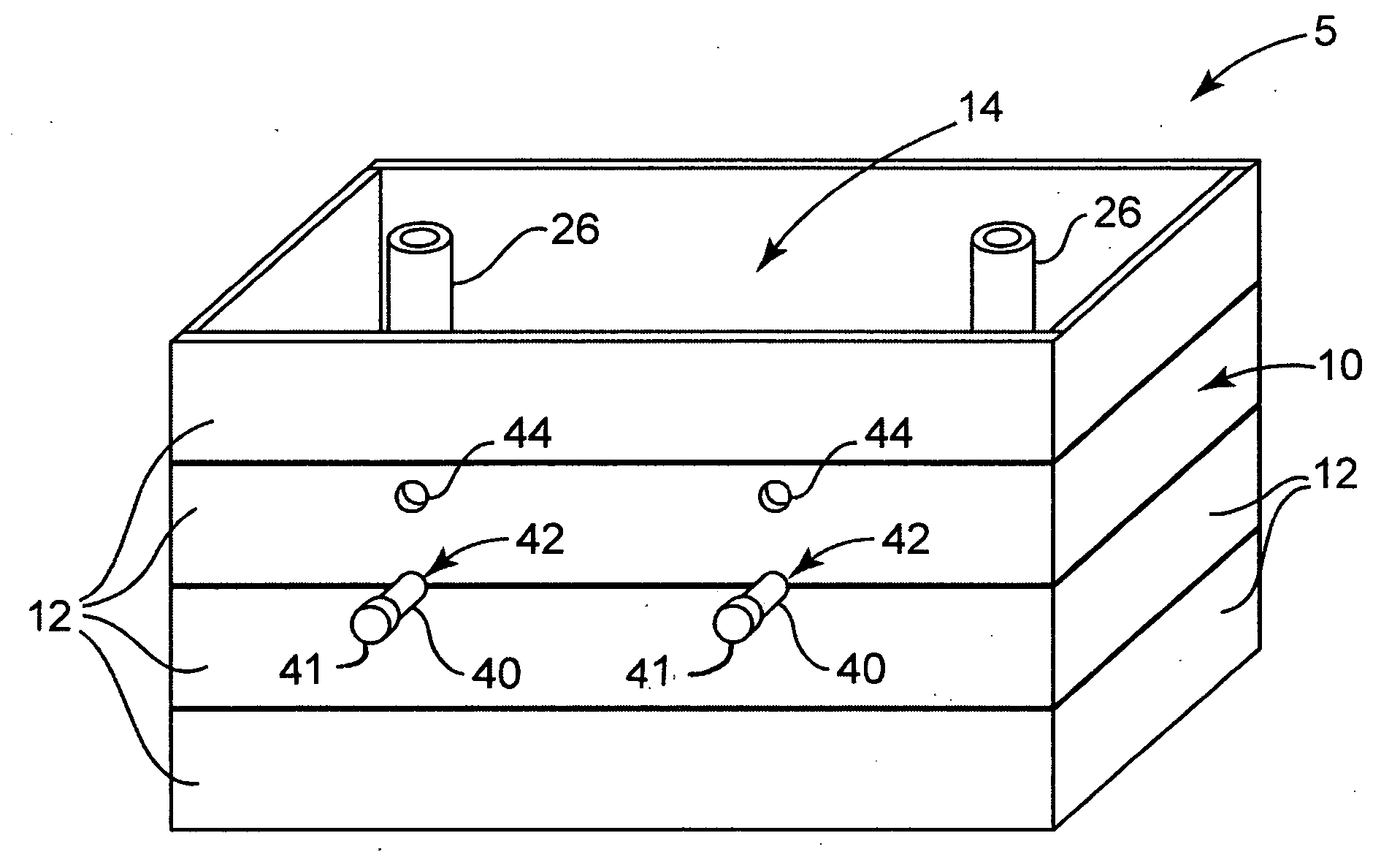

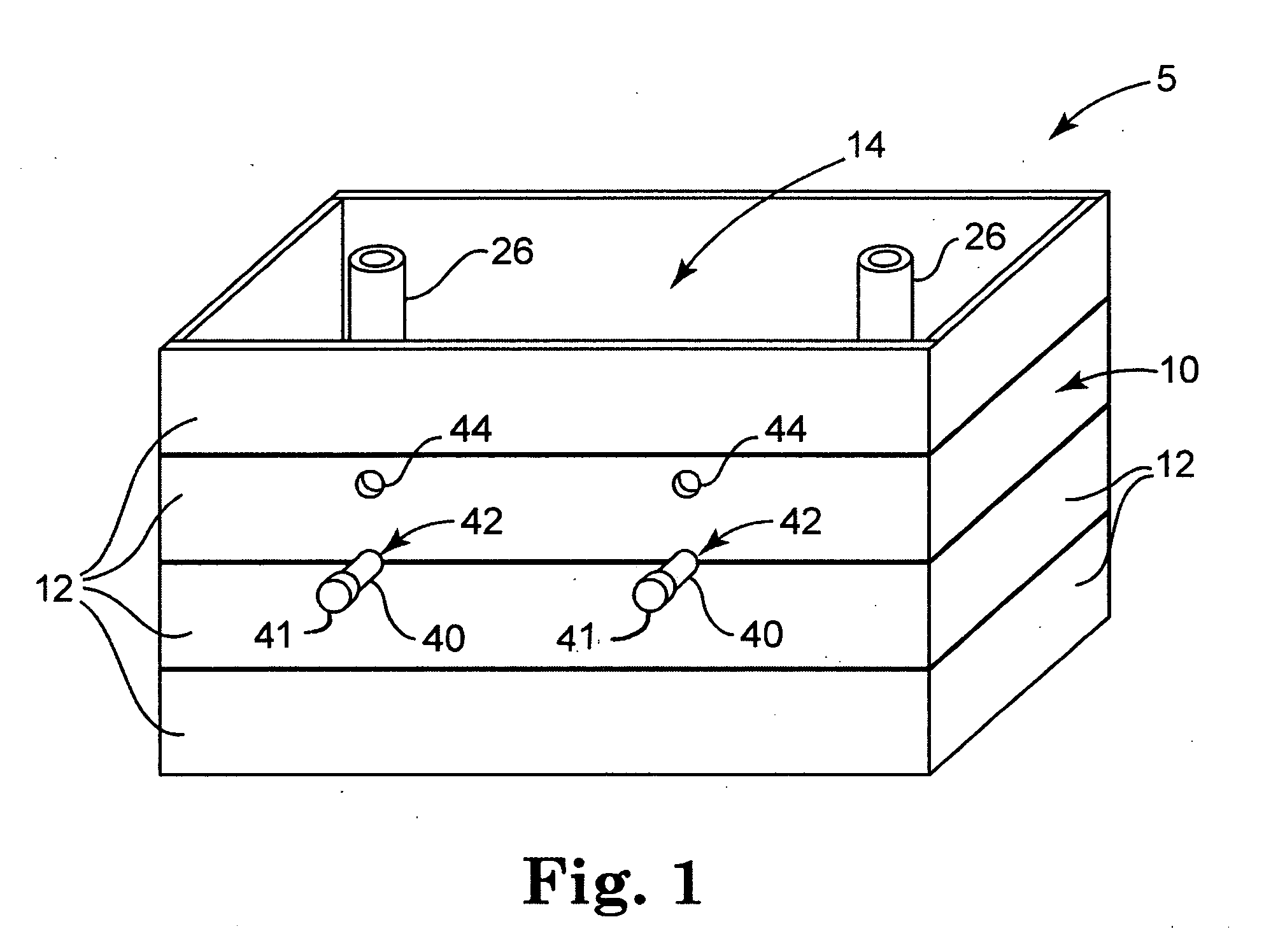

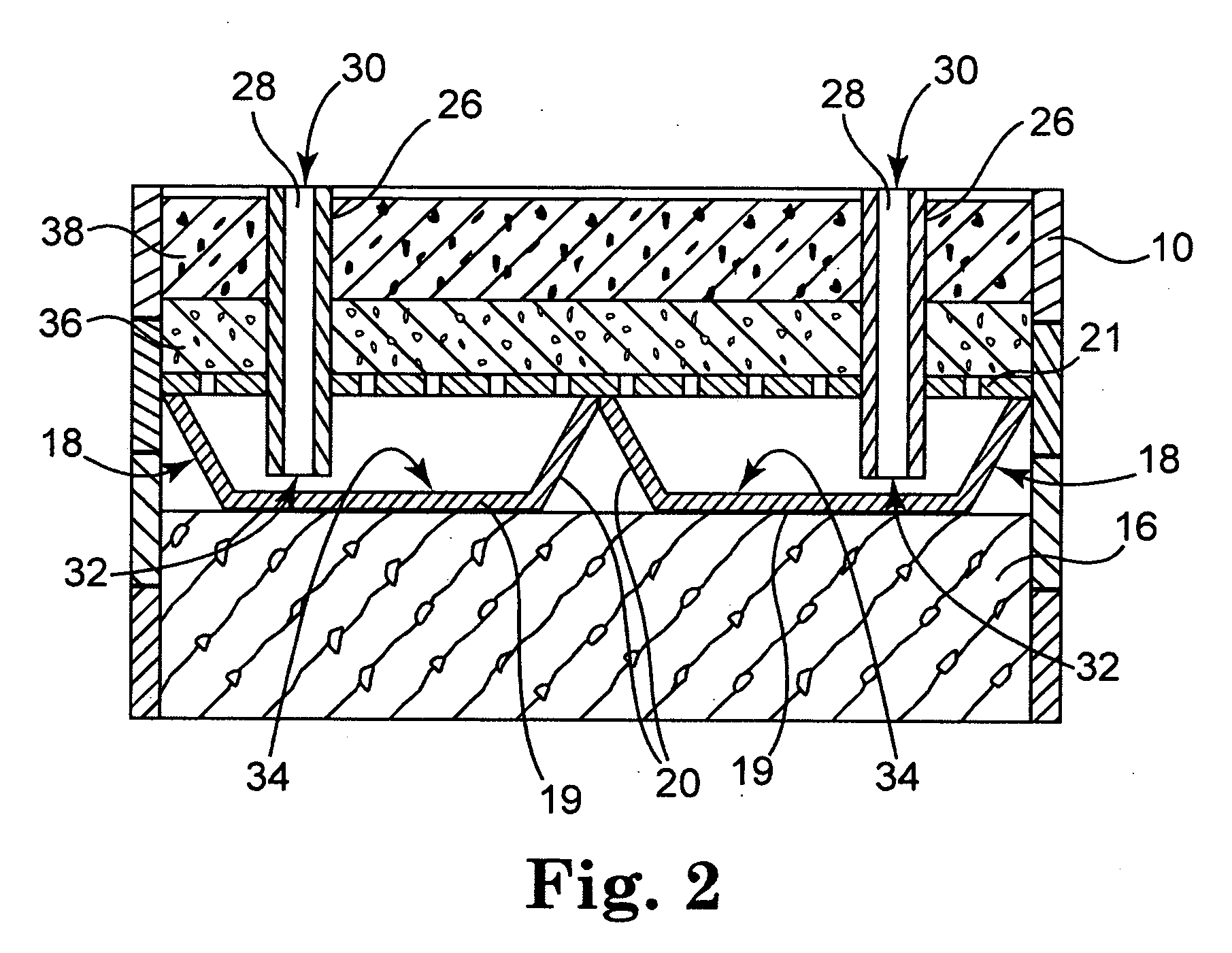

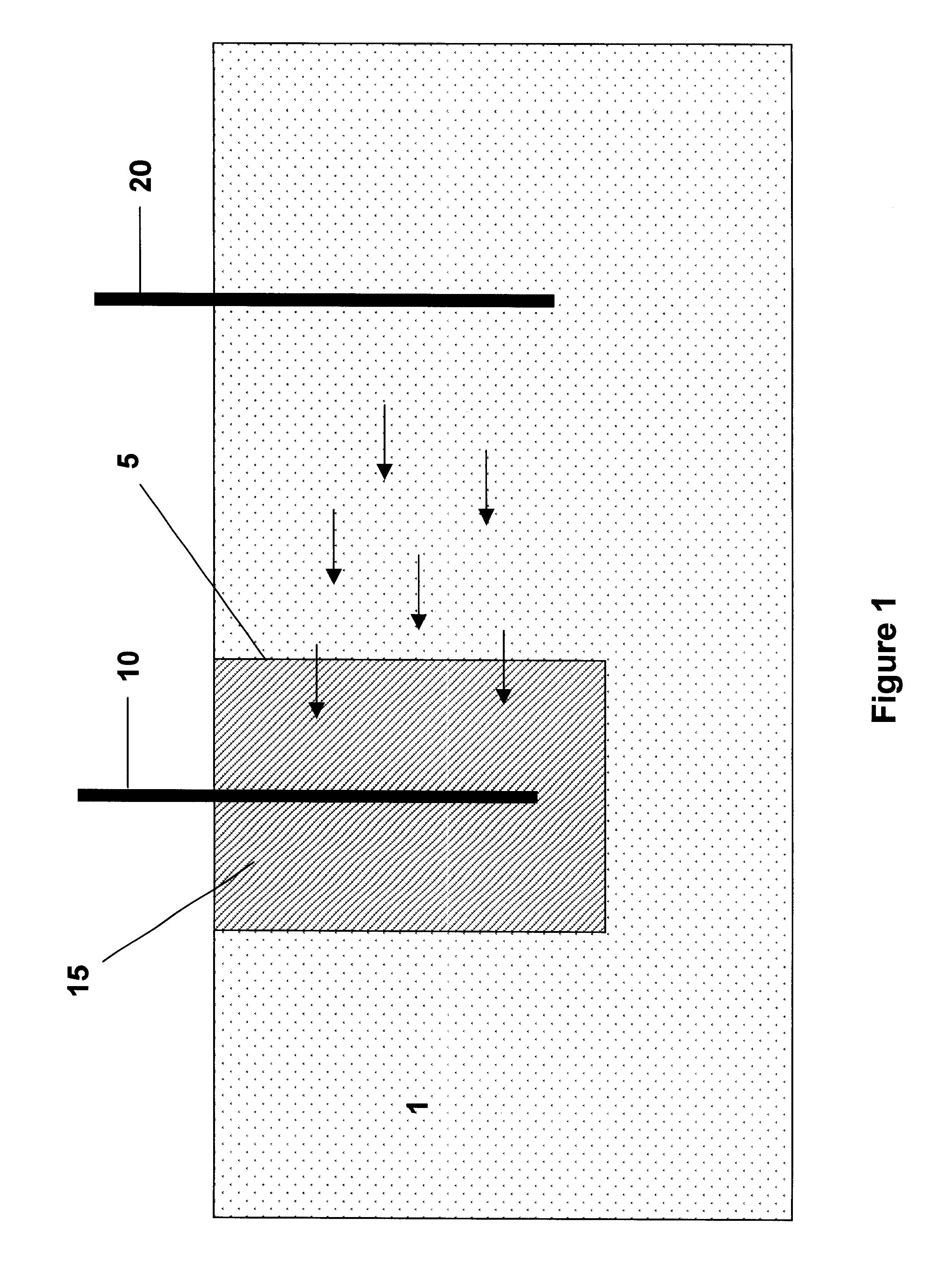

Garden or planter system with elevated bed and water reservoir

InactiveUS20090031629A1Avoid enteringEasy to fillWatering devicesCultivating equipmentsEngineeringMechanical engineering

Described is a planter system, comprising: at least one water retaining vessel; a bedding material layer disposed above the at least one water retaining vessel; a structure surrounding the at least one water retaining vessel and the bedding material layer; and at least one fill tube extending from above the bedding material layer, through the bedding material layer, and into the at least one water retaining vessel, through which water is supplied to the at least one water retaining vessel to a predetermined level. Also, a method of making such a planter system having an elevated bedding material layer.

Owner:ECO GARDEN SYST LLC

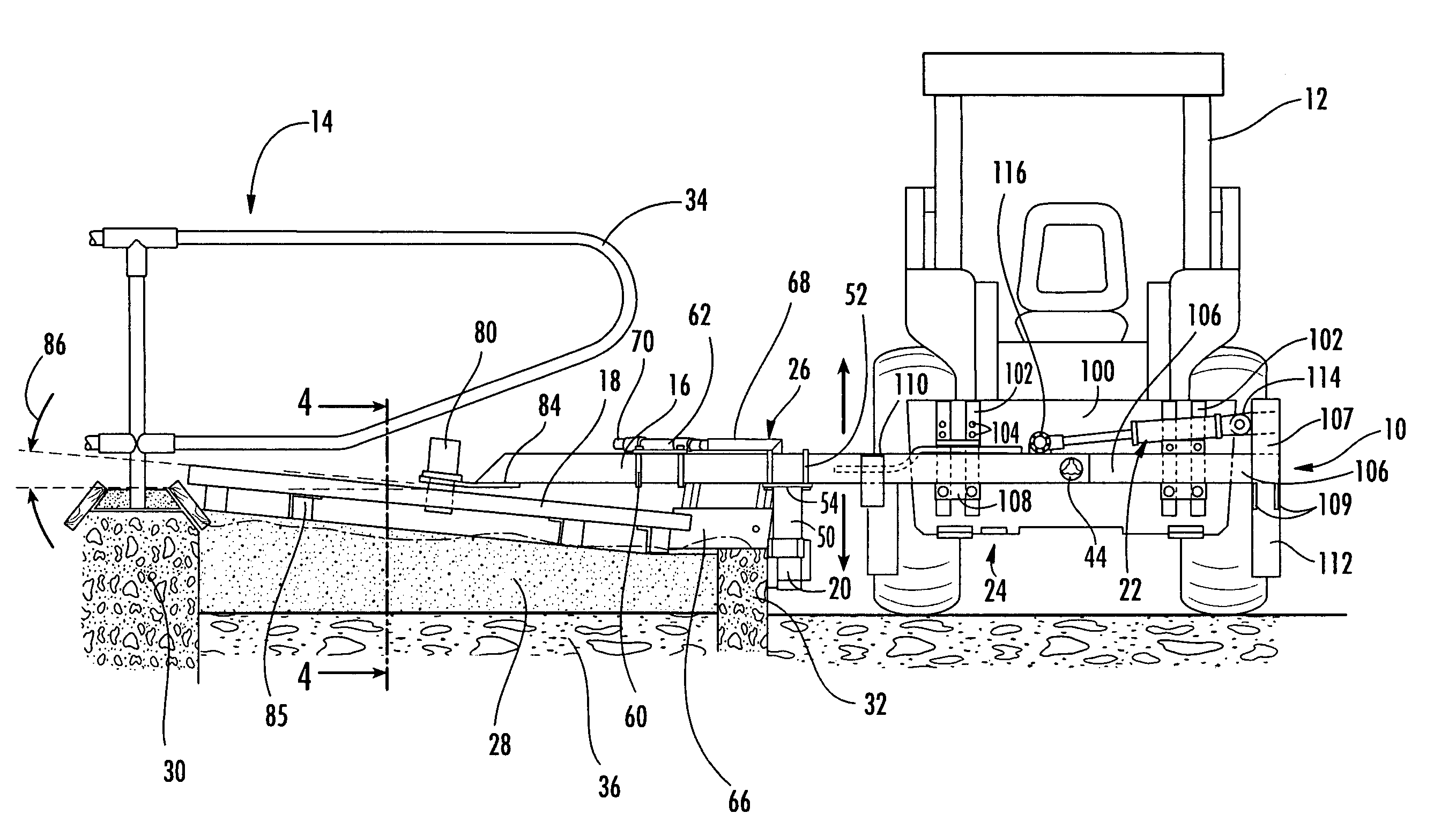

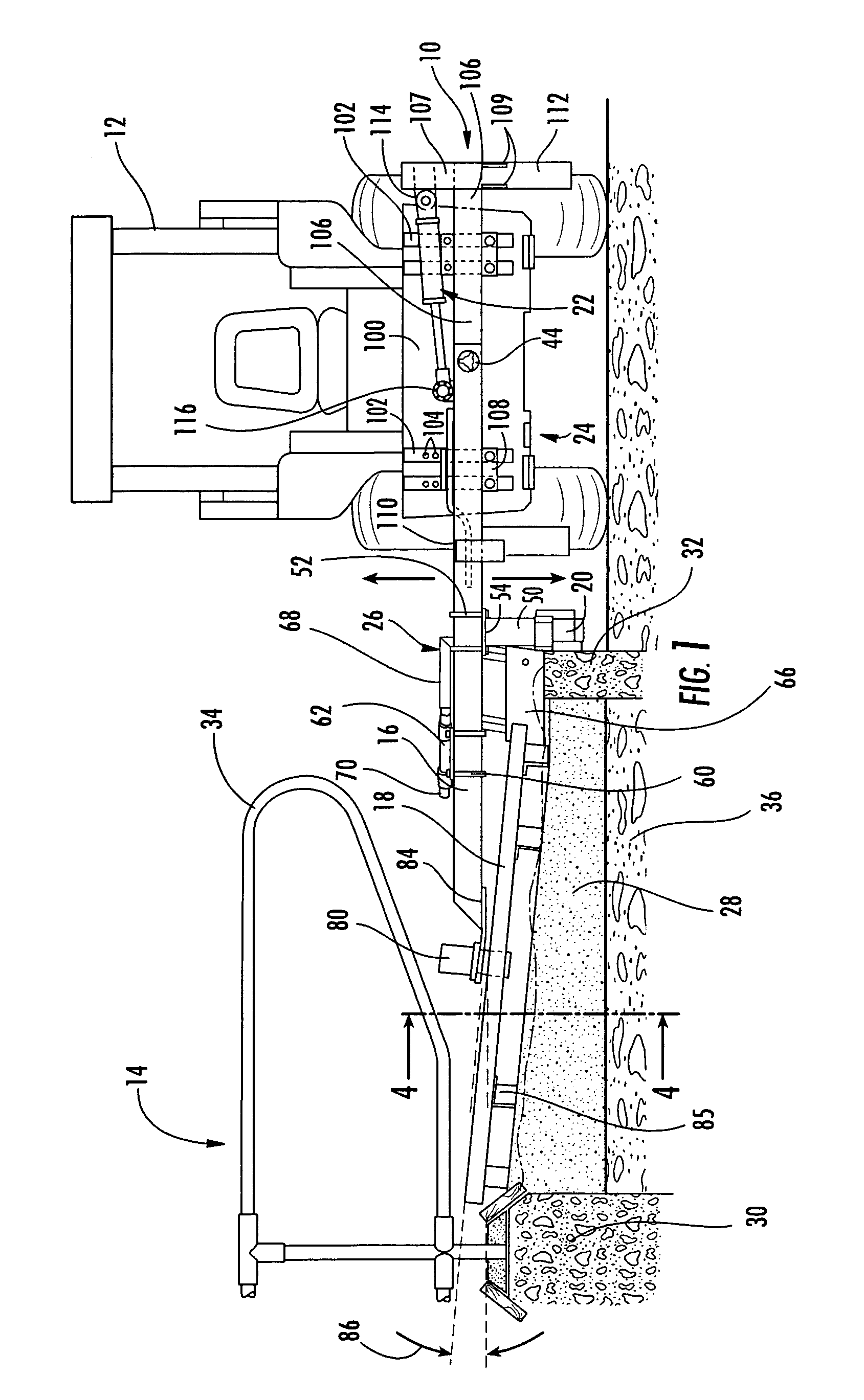

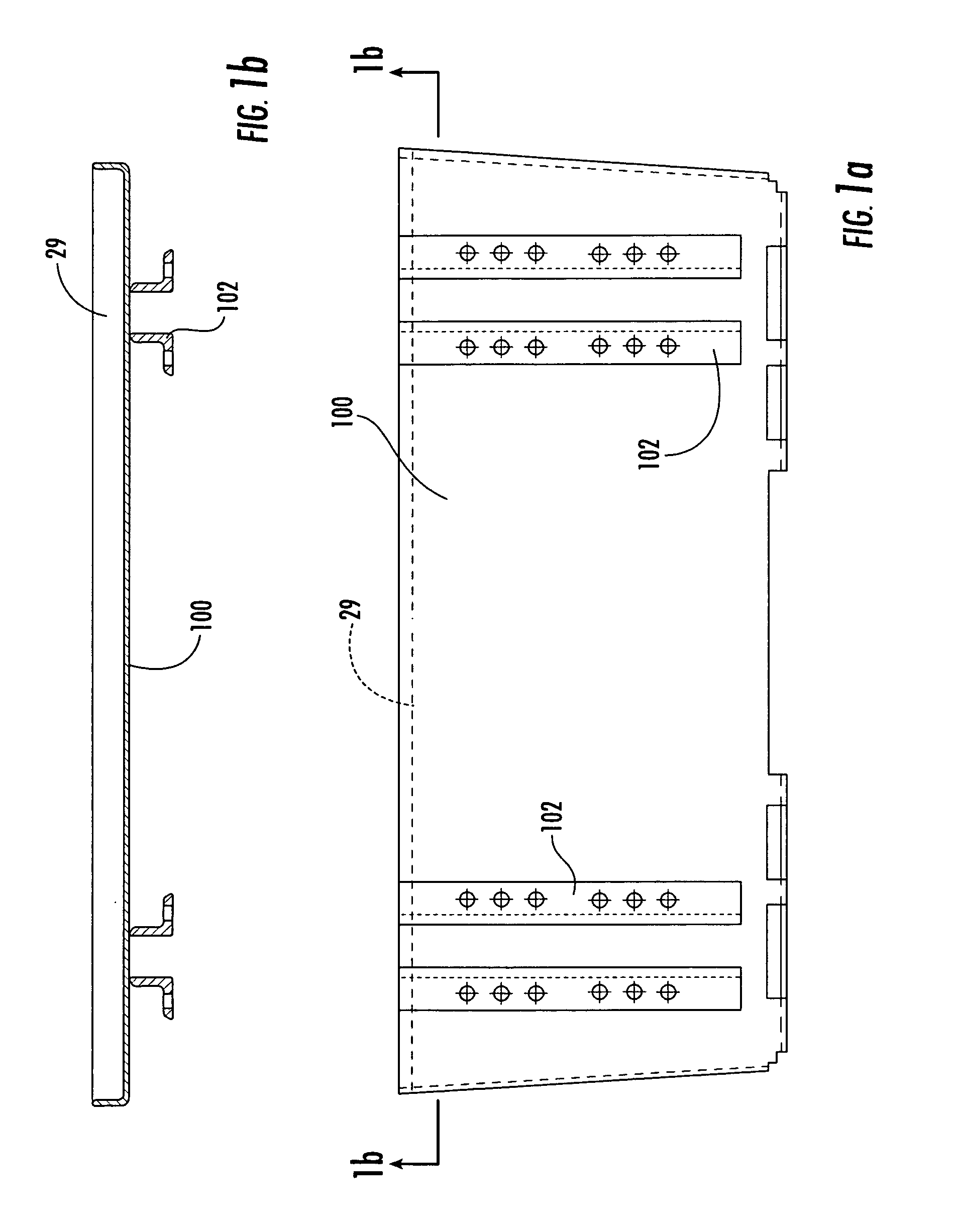

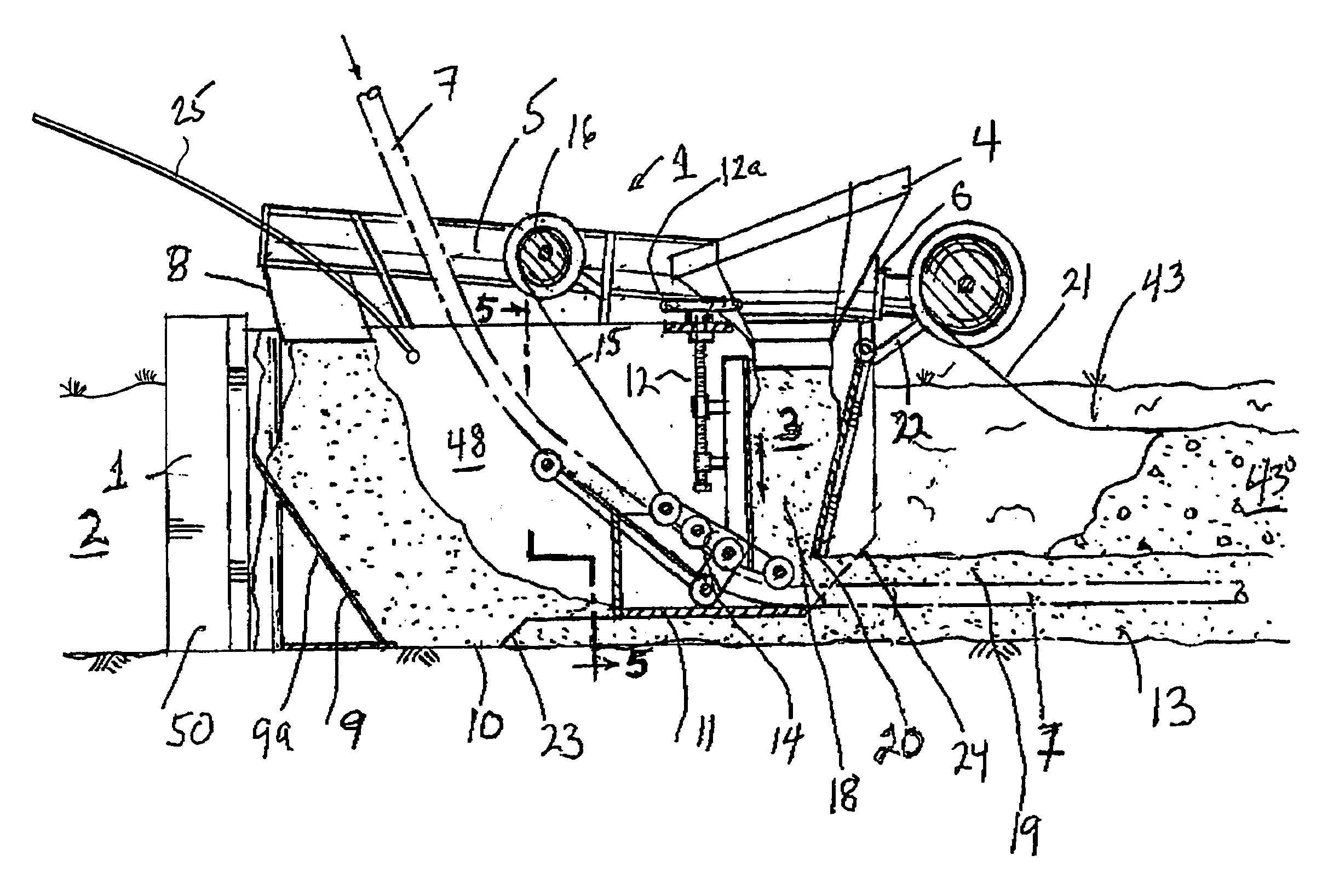

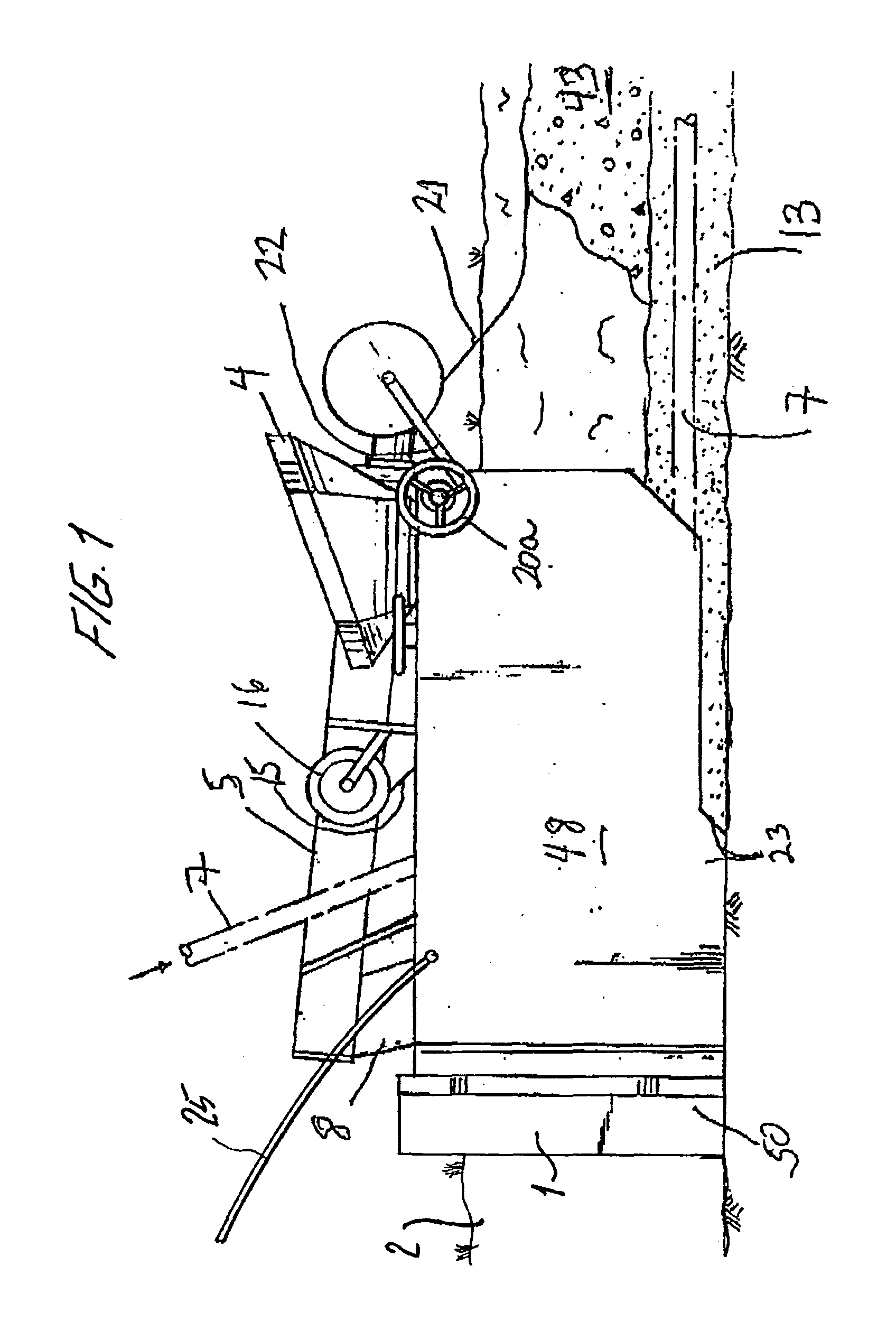

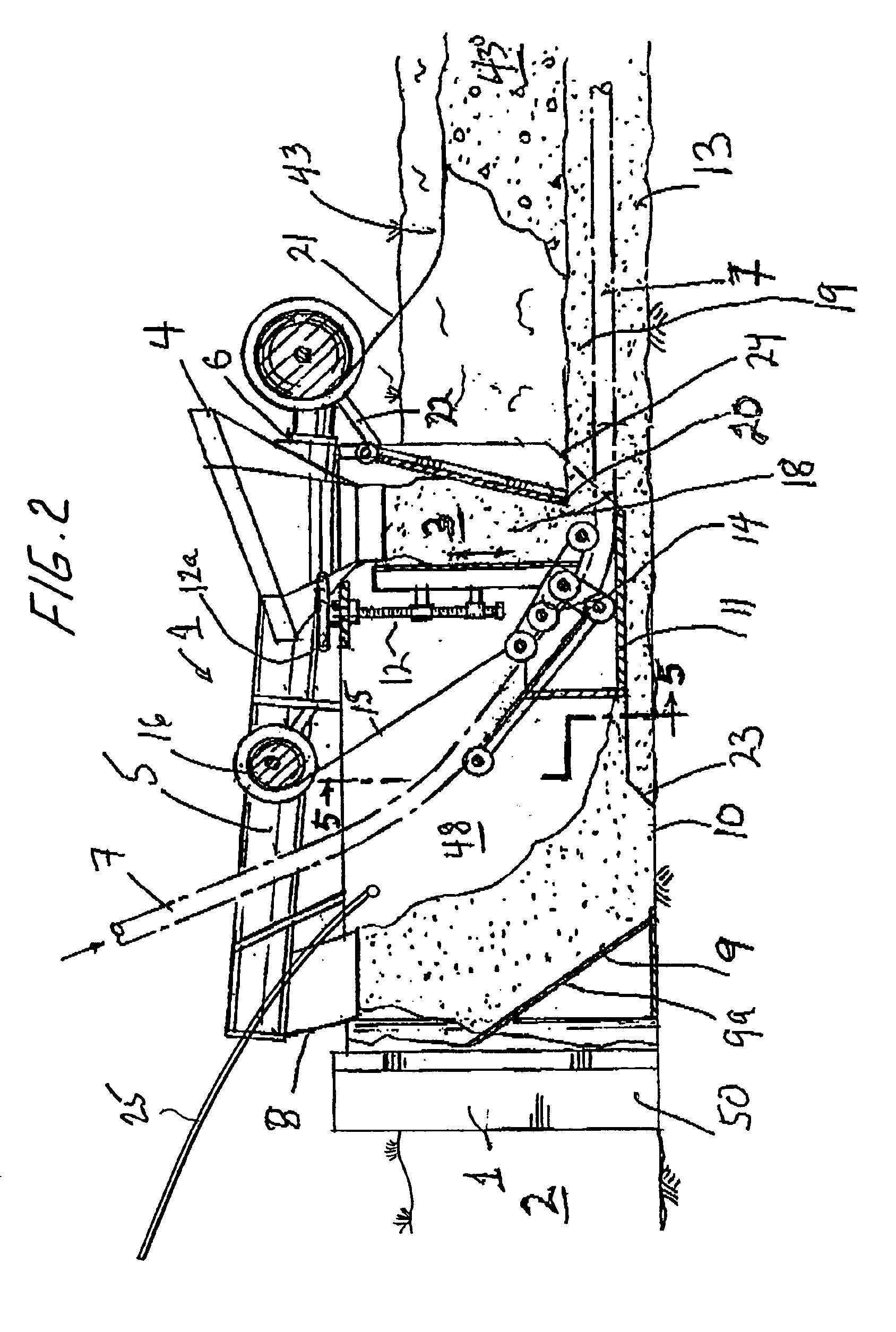

Apparatus for establishing adjustable depth bed in trenches for utility lines and encasing the lines

ActiveUS6854931B1Highly versatileSimple taskPipe supportsPipe laying and repairEngineeringContinuous operation

A mechanized unit that places a predetermined and adjustable depth of a selected bedding material on the bottom of a trench in the ground, then places on the bed a continuous length of a utility or utilities having a predetermined spatial relationship with each other and then encases the utility or utilities with additional select material to a predetermined and adjustable depth of cover in a continuous operation. The unit has a single hopper that receives and contains the material that is used both to form the bed and also to encase the one or more utilities laid on the bed. The hopper conveys material in the direction of movement of the unit and the material is dispensed from the conveyor into the trench to form the bed. An adjustable height blade is provided which both sets the bed height and also smoothes the bed upper surface. As the unit moves, the utility or utilities are laid on the bed upper surface. Thereafter, material is dispensed from the bottom of the hopper on top of and around the utility or utilities to encase them. An adjustable height blade is also provided to set the height of the encasement and also to smooth out its upper surface.

Owner:TRENCHING

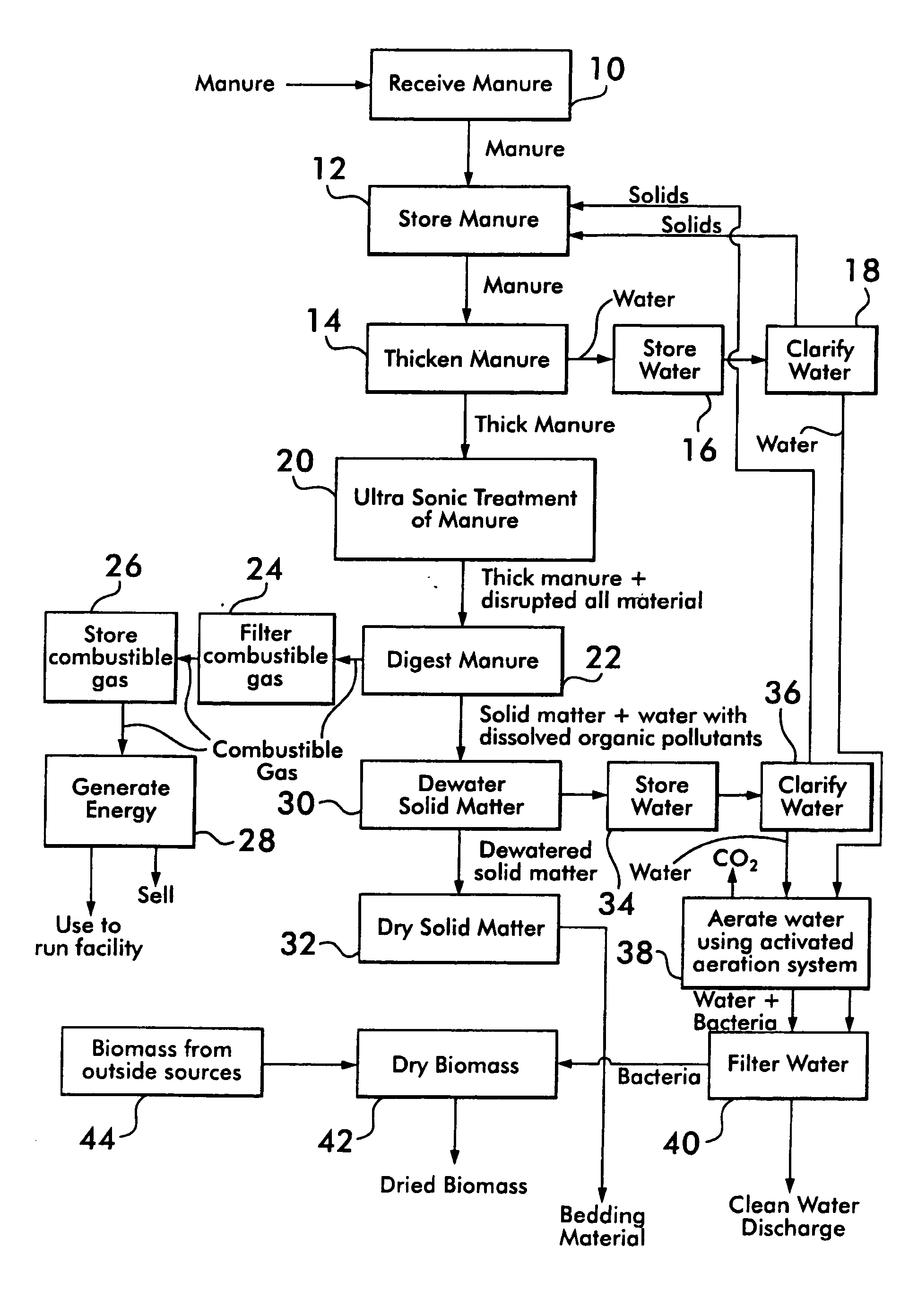

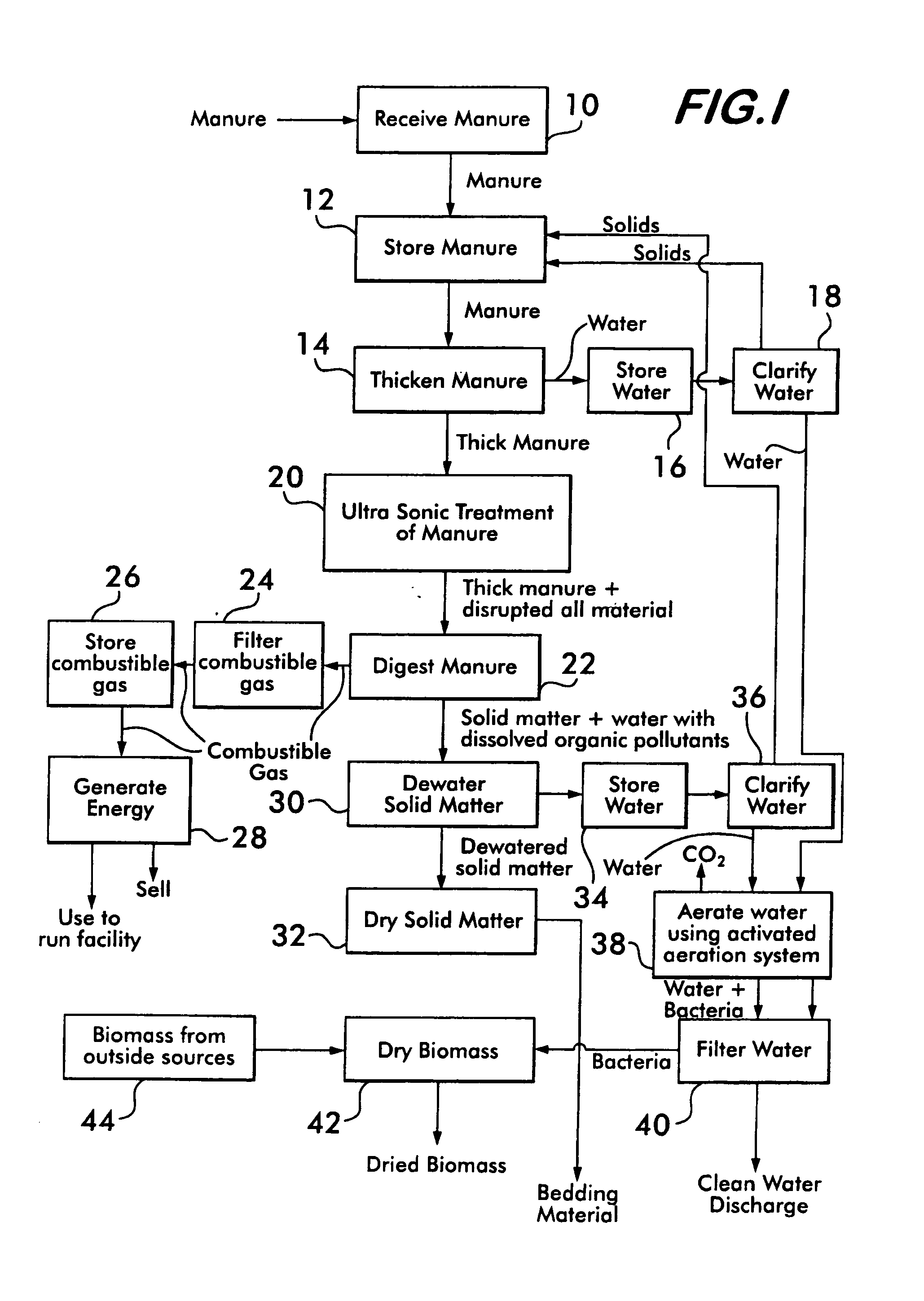

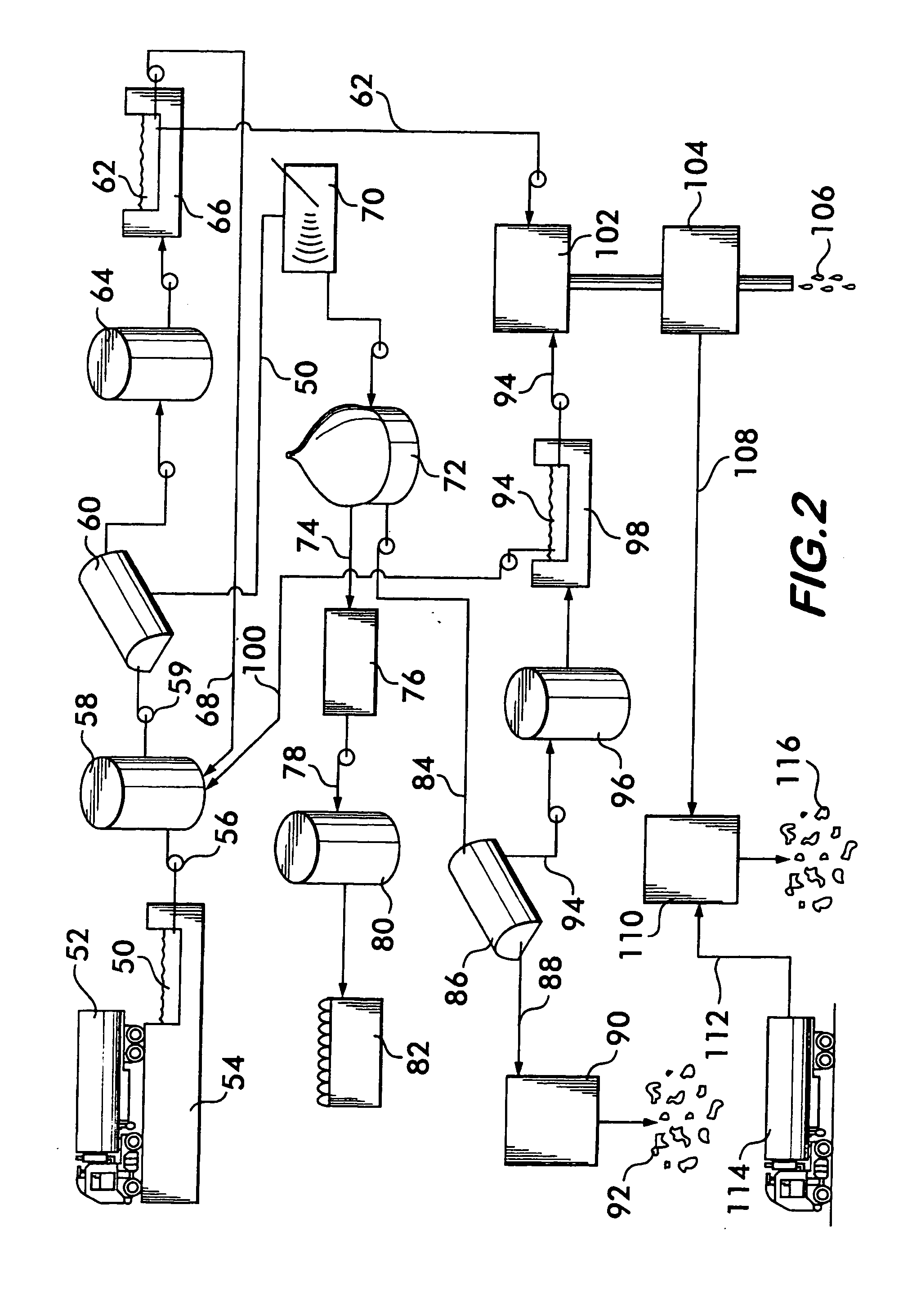

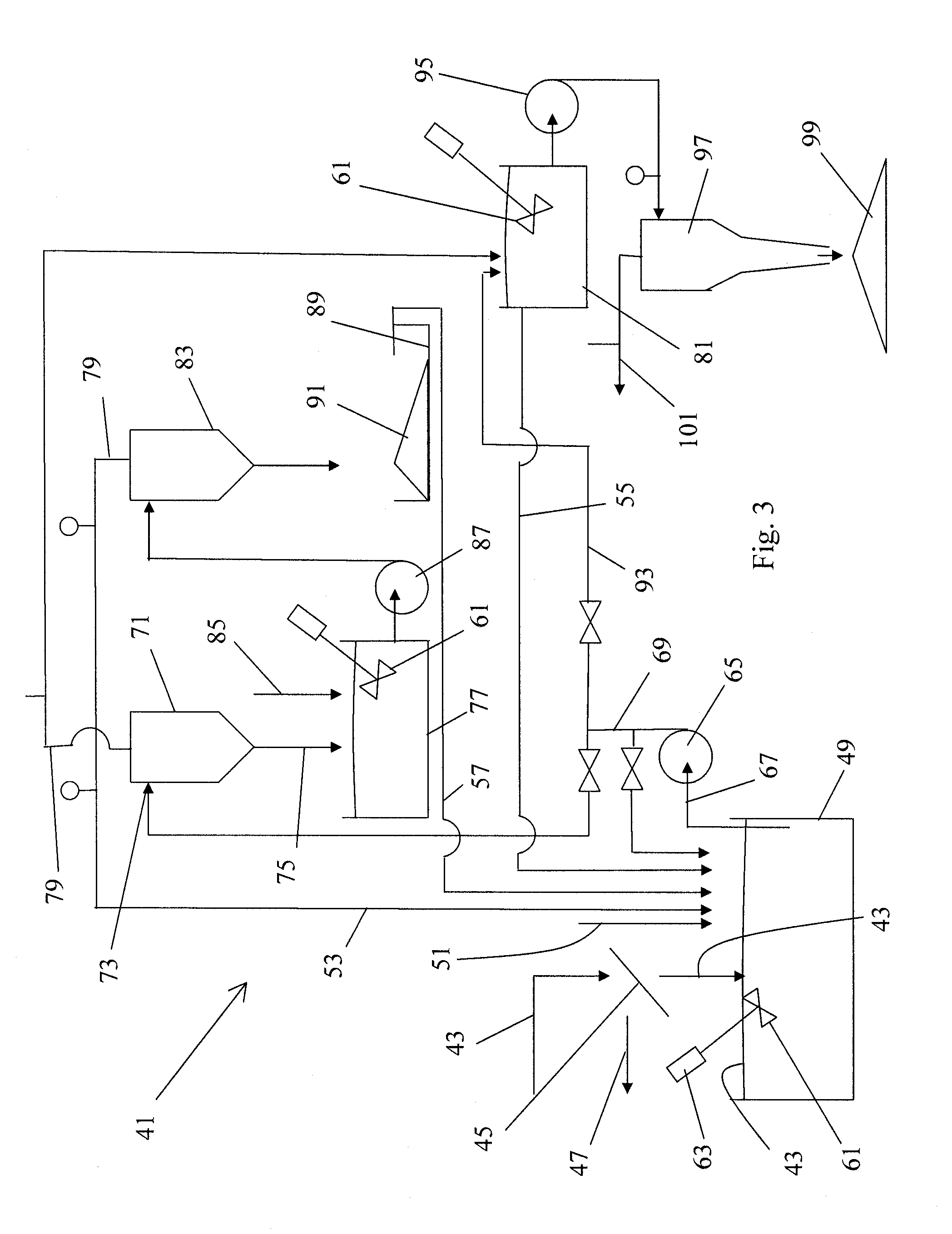

Method and facility for treatment of animal waste

ActiveUS20080093292A1Increase gas productionWater/sewage treatment by centrifugal separationWater/sewage treatment with mechanical oscillationsActivated sludgeCell wall

A method and a facility for the treatment of waste from concentrated animal feed operations are disclosed. The method includes receiving manure at a central location, digesting the manure and producing therefrom combustible gases, solid matter and water containing dissolved organic pollutants. The combustible gases are used to provide energy and the water is separated from the solid matter. The solid matter is dried to produce a useful bedding material and the water is treated using an activated sludge aeration system to reduce the dissolved organic pollutants to carbon dioxide, bacteria and water. The facility includes various means for executing the method and includes an ultrasonic treatment station for disrupting bacteria cell walls to improve digestion efficiency.

Owner:AIR PROD & CHEM INC +1

Deodorizing, sterilizing and moisture reduction system for chicken litter

ActiveUS20130298842A1Clean upReduce moisture contentAnimal housingBird housingsParticulatesAnimal science

A portable system for recycling used chicken litter in place which one can use to accommodate a succession of flocks, in the same commercial chicken house, with the same bedding material. The system comprises a litter pulverizer mounted within a hood-like housing, a high output ozone generator, fluidly connected thereto, which, in use, discharges ozone into a flux of pulverized chicken litter and pathogen-laden dust particulates, killing pathogens and neutralizing ammonia odors in the process, and an ultraviolet light source for further sterilizing pulverized litter and for destroying excess ozone discharged with it from the hood-like housing's base. Enhancing the system's pathogen-killing capacity are at least one hot air blower also fluidly connected to the hood-like housing and a moisture detector. The latter measures, in real time, the dryness of ozone-treated litter being discharged from the hood-like housing onto the chicken house floor.

Owner:UNDERWOOD ROY E

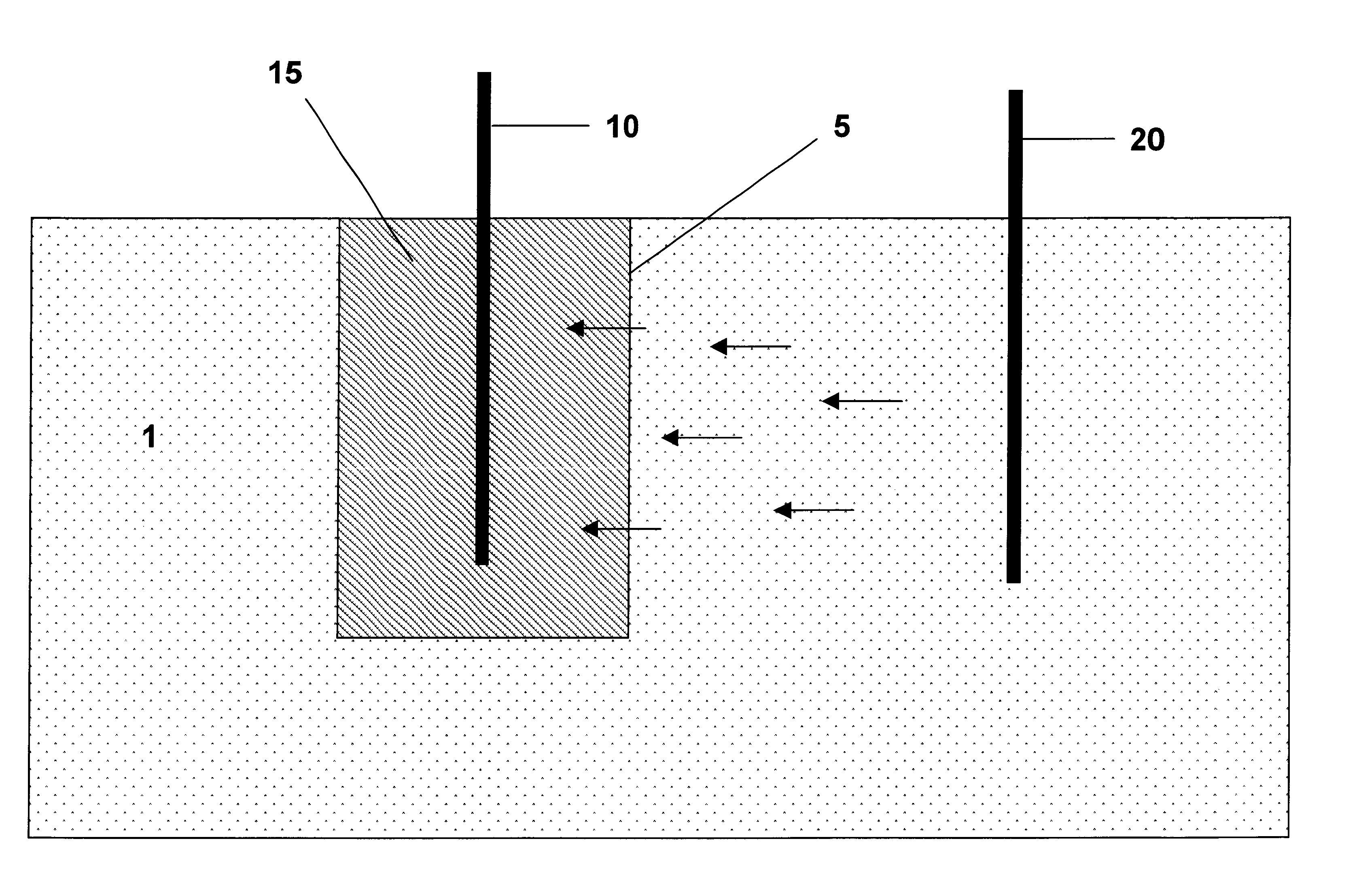

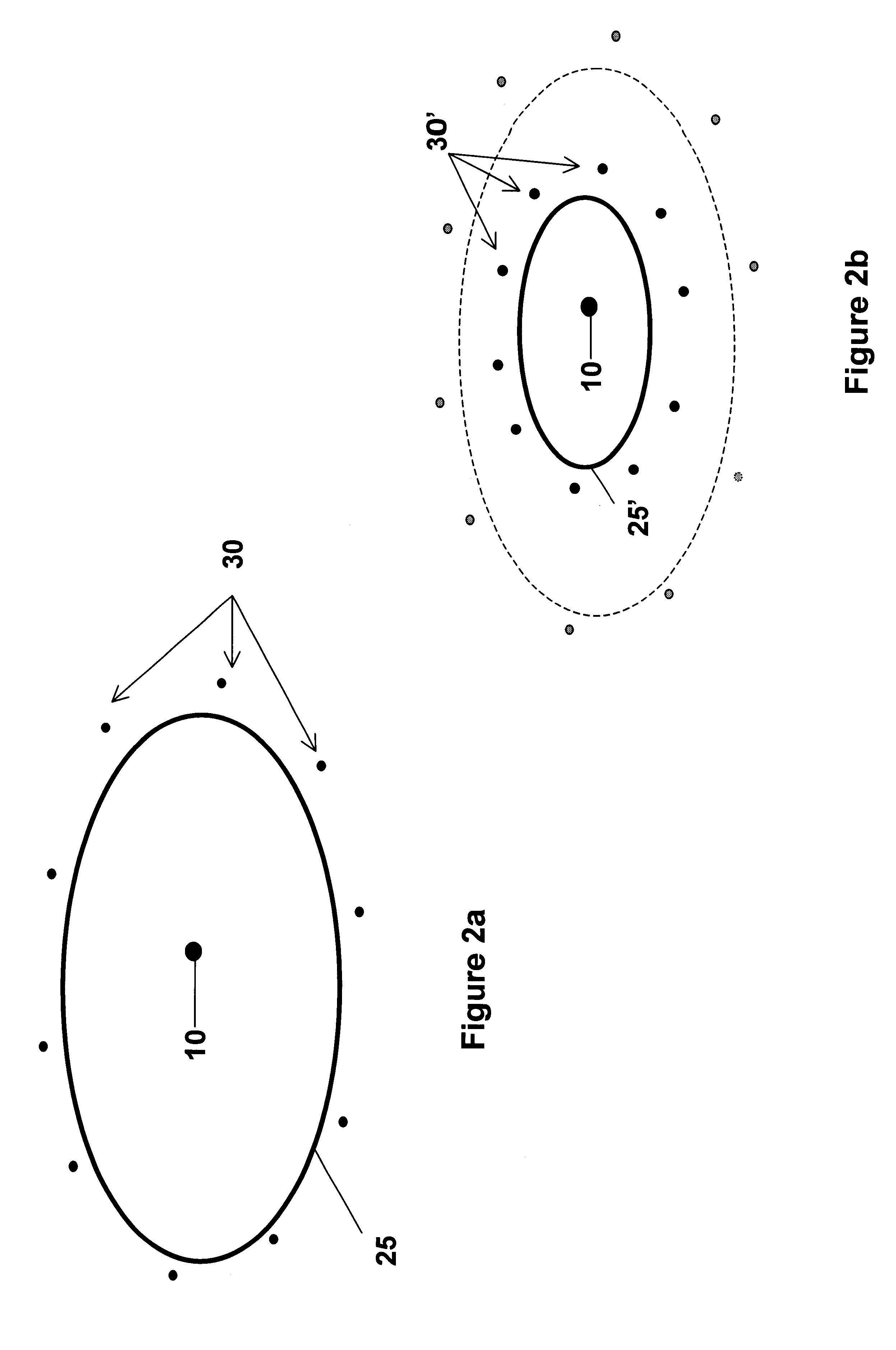

Electrokinetic removal of charged contaminant species from soil and other media using moderately conductive adsorptive materials

InactiveUS6221237B1Easy to collectConvenient removalFrom normal temperature solutionsElectrolysis componentsActivated carbonPower flow

Method for collecting and concentrating charged species, specifically, contaminant species in a medium, preferably soil. The method utilizes electrokinesis to drive contaminant species into and through a bed adjacent to a drive electrode. The bed comprises a moderately electrically conductive adsorbent material which is porous and is infused with water or other solvent capable of conducting electrical current. The bed material, preferably activated carbon, is easily removed and disposed of. Preferably, where activated carbon is used, after contaminant species are collected and concentrated, the mixture of activated carbon and contaminant species is removed and burned to form a stable and easily disposable waste product.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Pet housetraining crate system

A system for housetraining pets through the use of separated sleeping and waste areas contained within a pet cage. The cage encloses a waste tray section that runs along the floor of the cage, which holds an absorbent pad, secured by improved retention clips, for collecting pet waste that can be removed and replaced when soiled. A bedding area made of up a rectilinear frame covered in bedding material is raised above the floor of the cage by engaging frame extensions with perforations in the exterior of the cage. The system and associated method serve to aid in conditioning a pet for proper housetraining while the pet is confined to a cage.

Owner:RYBKA GARY +1

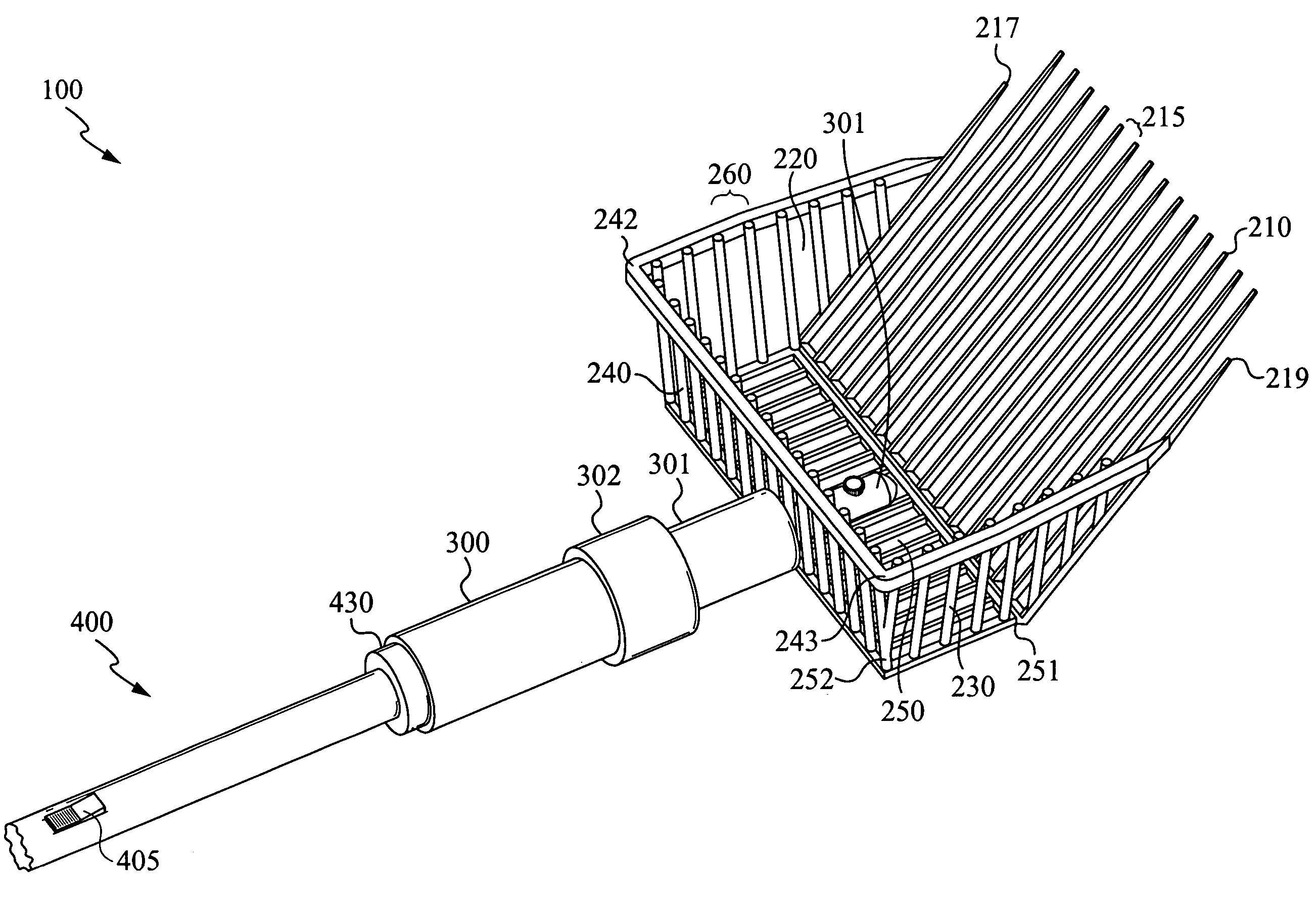

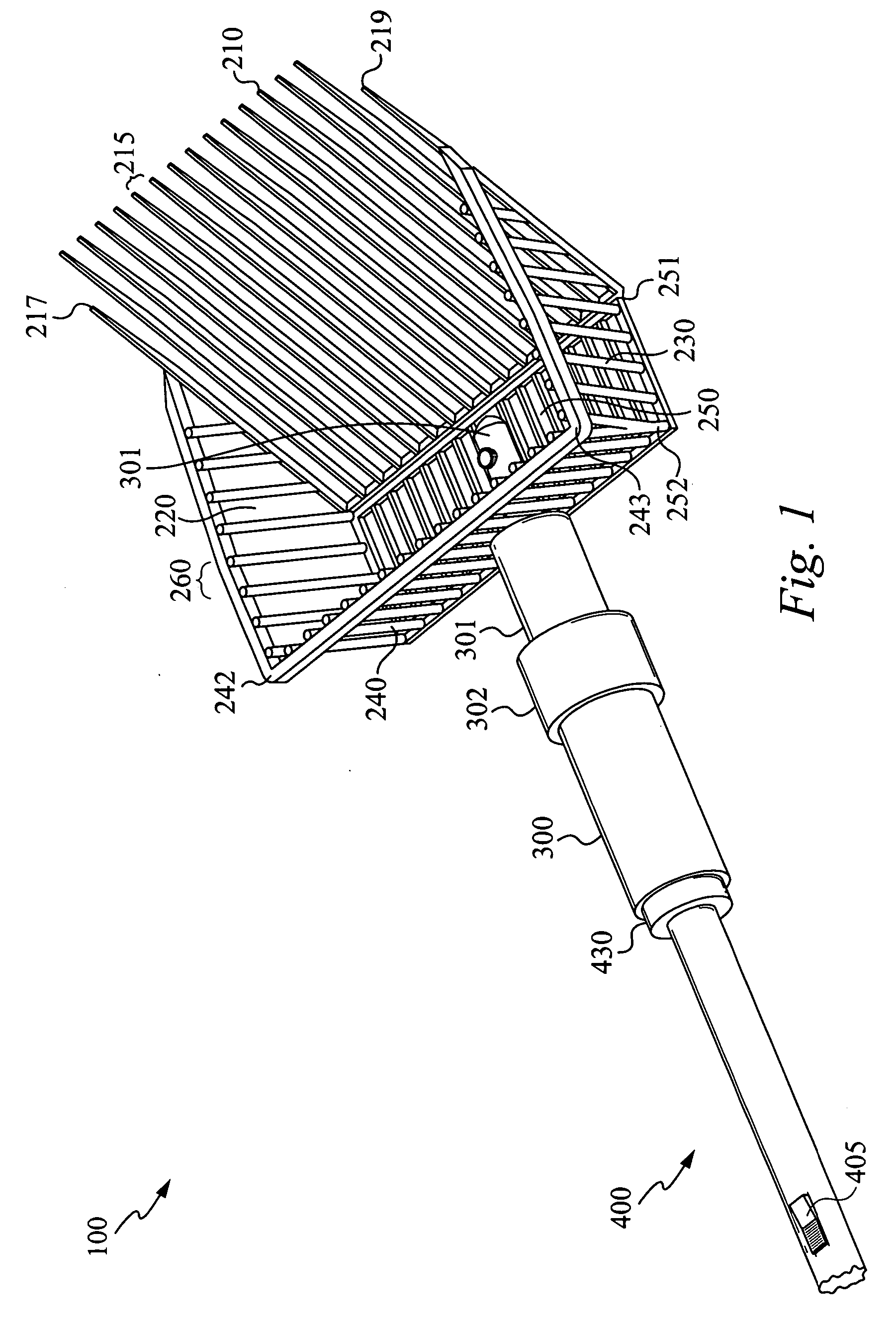

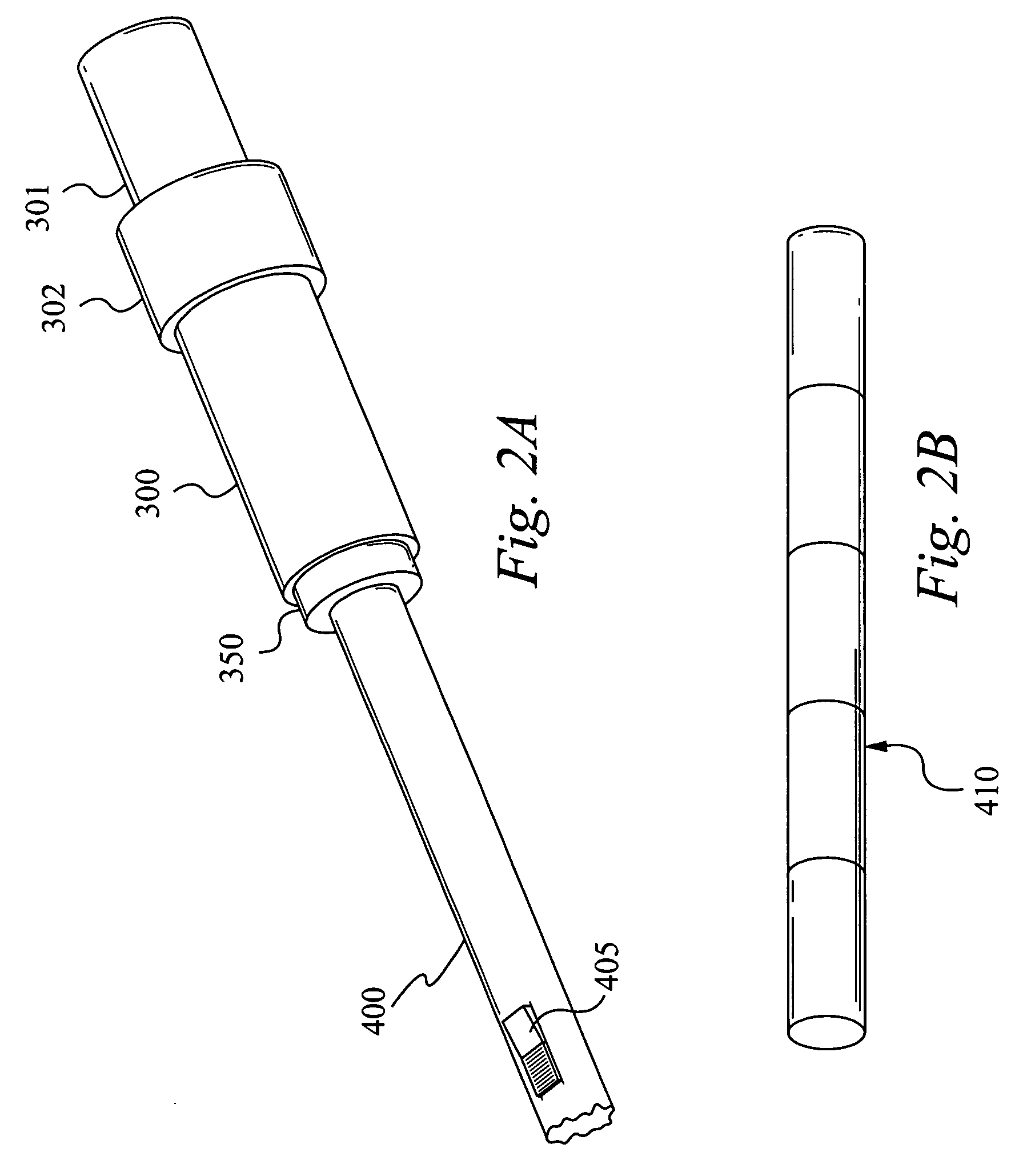

Vibrating scoop basket

A device is used to extract manure from bedding material in a manner that maximizes the amount of manure extracted from the bedding material. The device includes a detachable scoop head having a plurality of apertures, a detachable motor assembly coupled to the scoop head for vibrating the device, and a detachable handle coupled to the motor assembly via a connector. The handle can include a power pack for supplying electrical power to the motor assembly. The apertures are preferably formed between elongated elements. The power pack, which can be housed within the handle, forms a counterweight to the scoop head when the device is lifted. The device can further include a stand having a release mechanism coupled to the device, wherein the release mechanism releases the stand in a fully deployed position to facilitate raising the scoop head.

Owner:SHERIDAN CREEK ENTERPRISES

Method of cleaning soiled bedding material in barns

A method of cleaning bedding sand soiled with animal manure removes the bedding sand from an animal bedding area. An aqueous slurry of the bedding sand is made. The slurry is subjected to cyclonic action so as to separate the sand from the manure. The separated sand is then respread back into the animal bedding area for reuse. The clean bedding sand is free of organic contaminants such as manure, urine and milk. In addition, the bedding sand may contain inorganic contaminants such as clay and silt particles as well as fine particles which are undesirable in a bedding material. Processing the sand removes these inorganic contaminants and fine particles to produce a superior bedding sand for animals.

Owner:FAGAN PAUL J

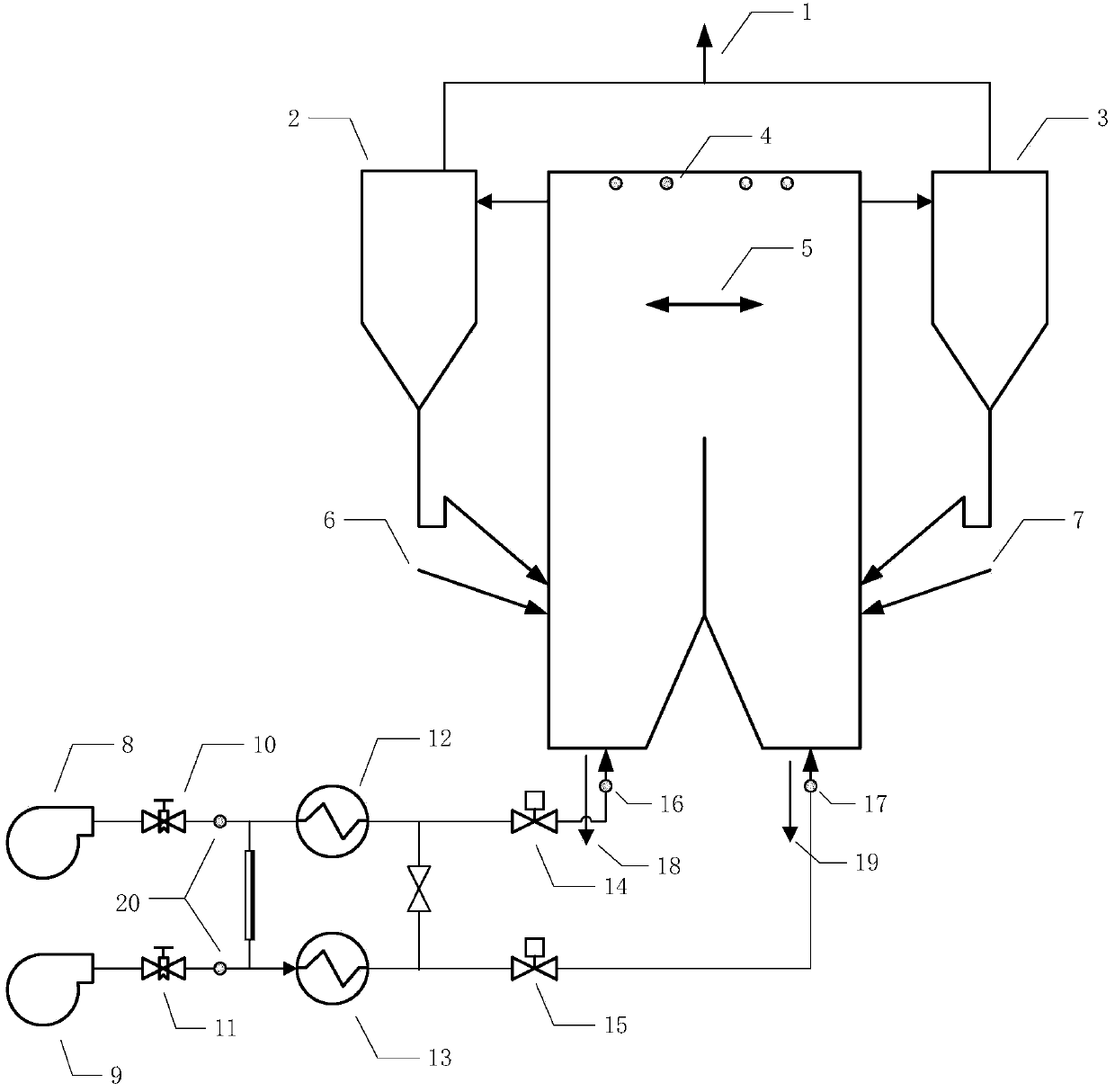

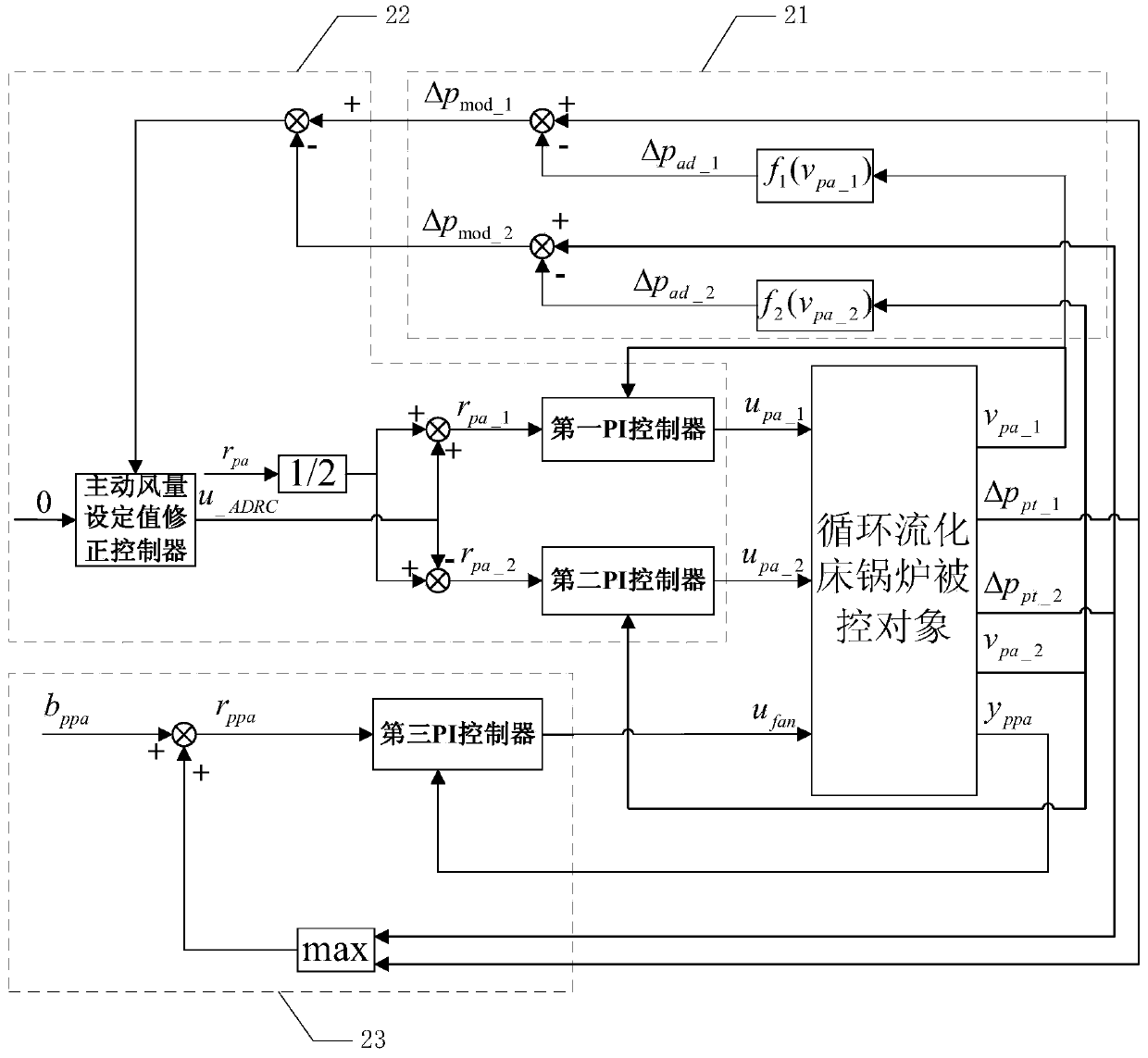

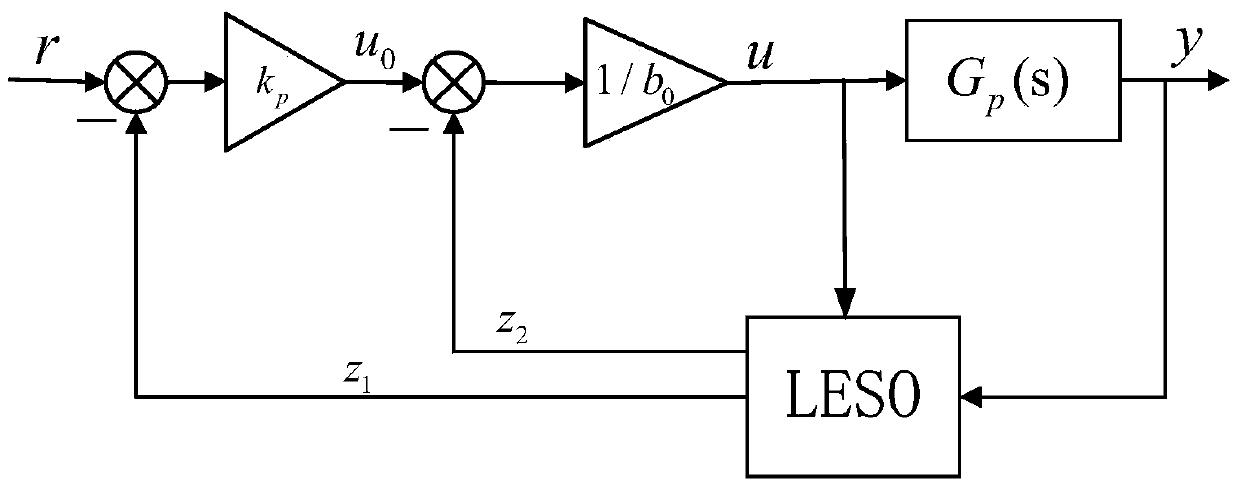

Method for controlling bed material balance of breeches-leg shaped CFBC (circulating fluidized bed boiler)

ActiveCN103727531AReduce fluctuation timeReduce the possibilityFluidized bed combustionApparatus for fluidised bed combustionAir volumeMaterial balance

The invention discloses a method for controlling the bed material balance of a breeches-leg shaped CFBC (circulating fluidized bed boiler). The method is implemented through calculating the pressure drop of an air-distribution plate according to the characteristic data fitting function and actual primary air volume of the air-distribution plate, and then further obtaining the pressure drops of corrected beds for balancing the bed material quantity more accurately; by taking the difference between the pressure drops of the corrected beds on both sides as feedback quantities, and through using an auto-disturbance rejection control algorithm, calculating the correction quantity of an active primary air set value; respectively adding and subtracting the correction quantity into and from 1 / 2 of a total primary air volume set value, taking the obtained values as set values of two controllers for regulating the air volumes of two sides, and controlling the openings of primary air adjusting doors on both sides through the two controllers; taking a value obtained by adding the total pressure drop of the inlet and outlet of a hearth into a positive offset as a set value of a controller for regulating the air pressure, comparing the set value with the pressure feedback of a primary air mother-tube, controlling the guide vane opening of a primary air fan through a regulator, providing a sufficient air pressure, and normally operating in cooperation with primary air volume control. A primary air control system designed in the invention can automatically adjust the bed material balance, and effectively shorten the duration time that bed material unbalance causes adverse impact on the system.

Owner:TSINGHUA UNIV

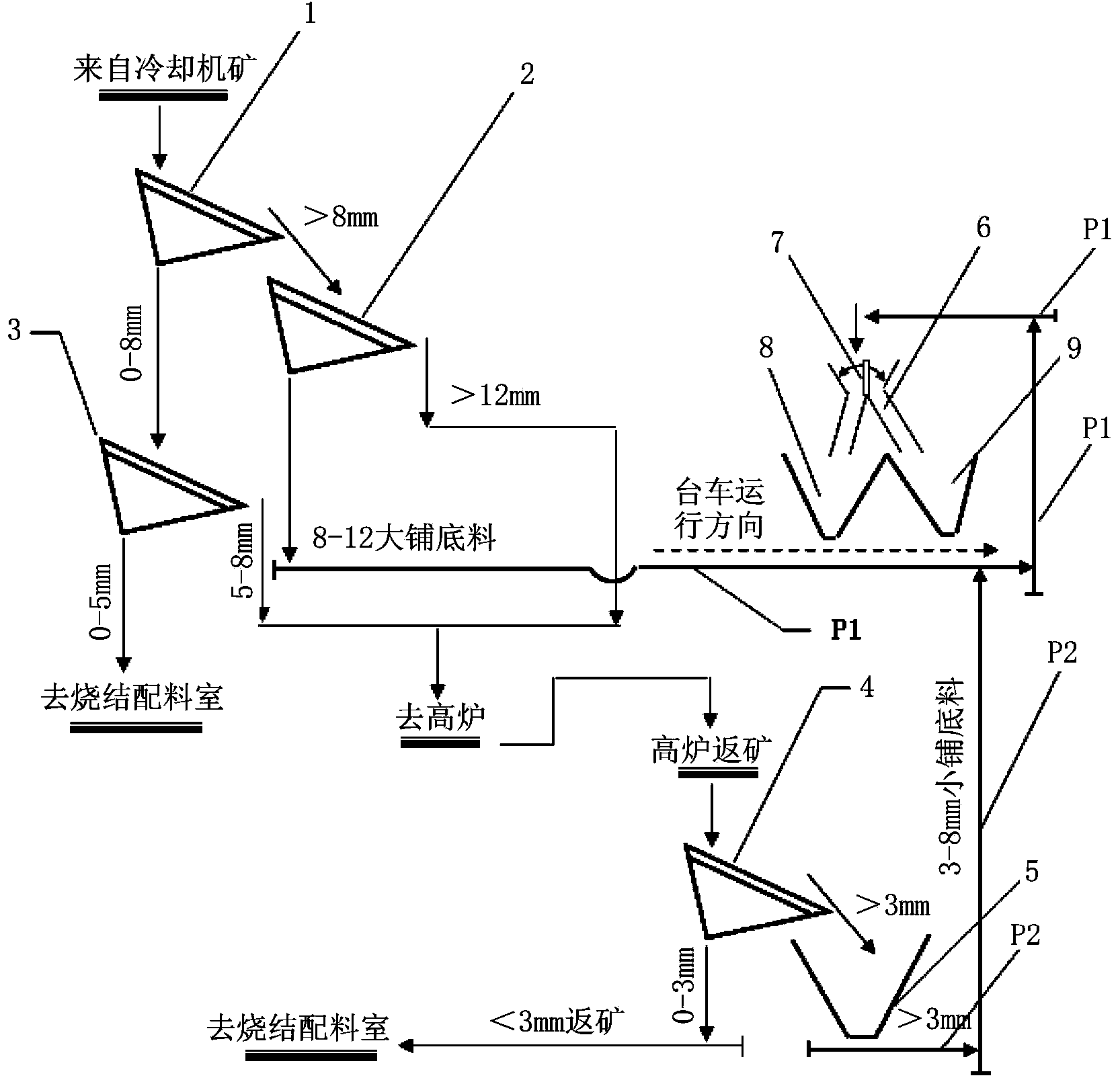

Paving method for sintering machine's bilayer bedding materials

ActiveCN103643038AIncrease sinter productionImprove the utilization rate of return oreGranularityMixed materials

The invention discloses a method for paving bedding materials on a sintering machine before paving a mixed material into the sintering machine. The method includes the steps of: (1) paving a first layer of large bedding material on sintering machine trolley grate bars, with the large bedding material being sintered ore with a particle size of 8-12mm and thickness of 10-20mm; and (2) paving a second layer of small bedding material on the first layer of large bedding material, with the small bedding material being sintered ore with a particle size of 3-8mm and thickness of 10-15mm. The paving method for sintering machine's bilayer bedding materials provided by the invention can reduce consumption of large particle grade sintered ore without changing grate bar interval, improving the output of sintered ore and enhancing the utilization rate of blast furnace ditch return mine.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Cold start method for circulating fluidized bed boiler

InactiveCN102818263AReduce air volumeSmall fuel consumptionFluidized bed combustionApparatus for fluidised bed combustionCombustionAir volume

The invention discloses a cold start method for a circulating fluidized bed boiler, sequentially comprising the following steps of: filling the main bed of a hearth with an inert bed material; carrying out a material level test for the bed material on the main bed; carrying out a fluidization test for the bed material on the main bed; lighting an oil gun at a critical fluidized air volume, and starting to heat the bed material; regulating the output of a primary air fan, heating the bed material at a solid bubble air volume, regulating the output of the oil gun, and heating the bed material up; when the temperature of the bed material reaches a coal feeding temperature, regulating the output of the primary air fan, and ensuring a primary air volume that is not lower than the critical fluidized air volume; and feeding coal into the hearth through a coal feeding port, and stopping the oil gun, thus finishing cold start for the combustion side of the boiler. The bed material is heated up in a static bed state through primary air with the solid bubble air volume; the air volume is low, so the cold start consumes low power and low fuel oil, and costs short time, and reasonable particle size distribution of the bed material can be realized; and the cold start method for the circulating fluidized bed boiler disclosed by the invention can ensure the safety of the boiler, reduce cold start time and obviously reduce energy consumption.

Owner:LIAONING DIAOBINGSHAN COAL GANGUE POWER GENERATION CO LTD

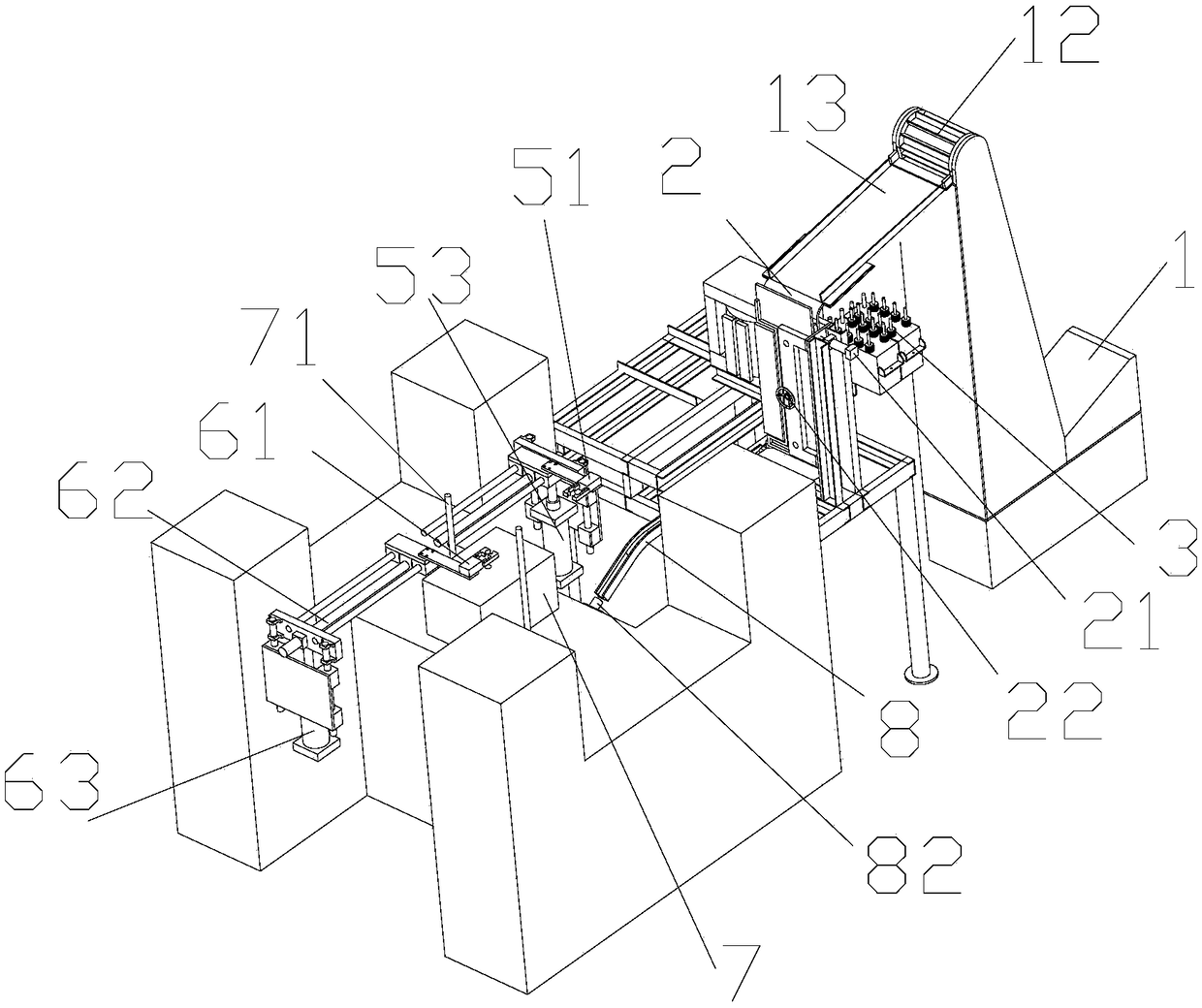

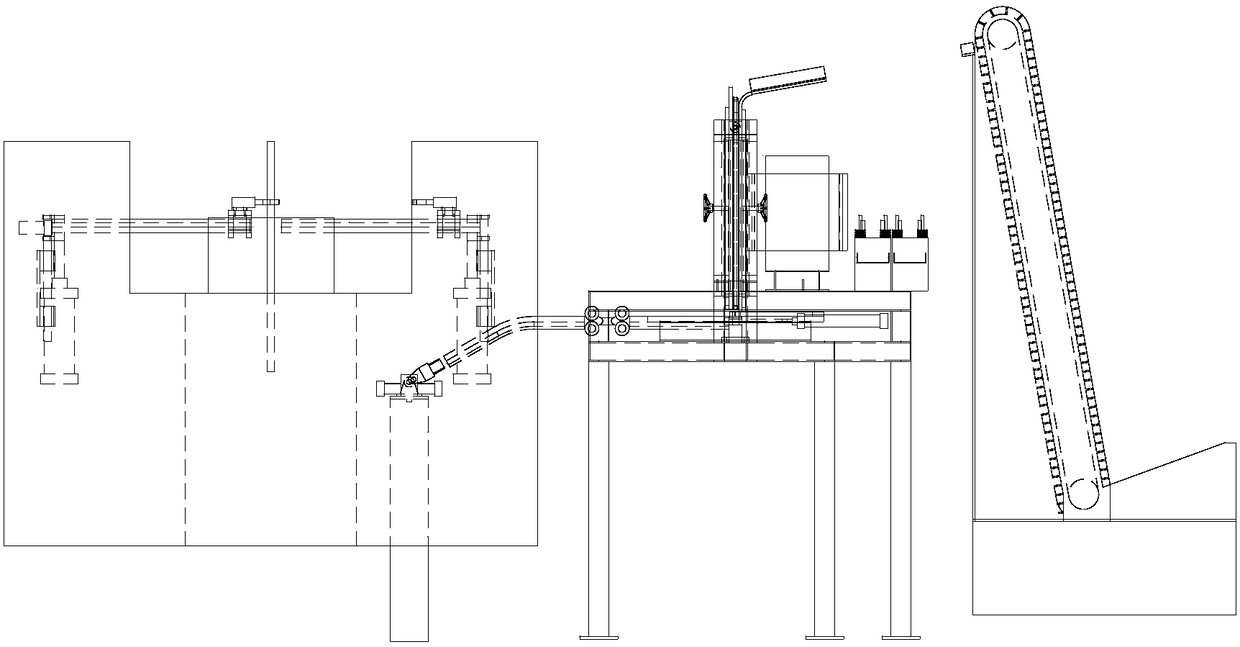

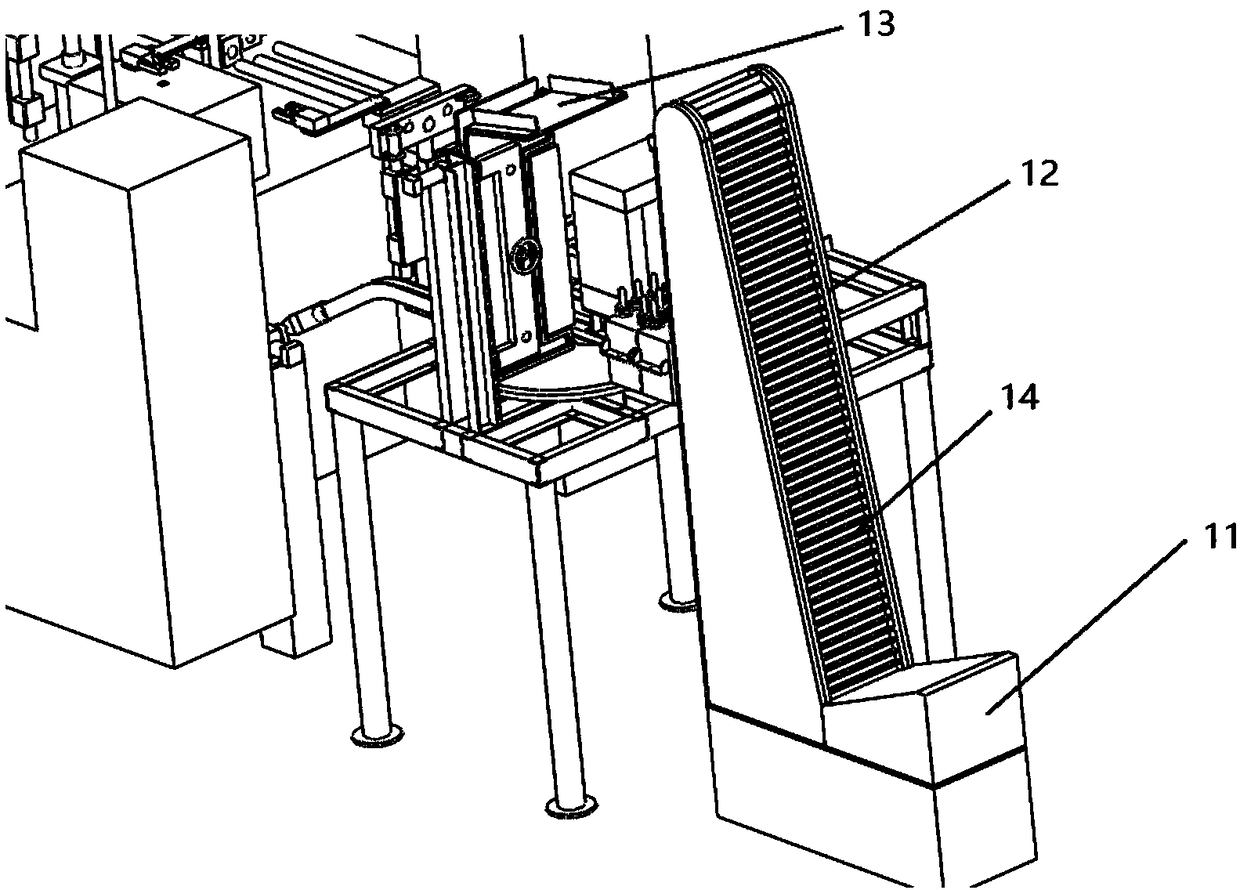

Fully automatic hot pier head production system for railway spiral spikes

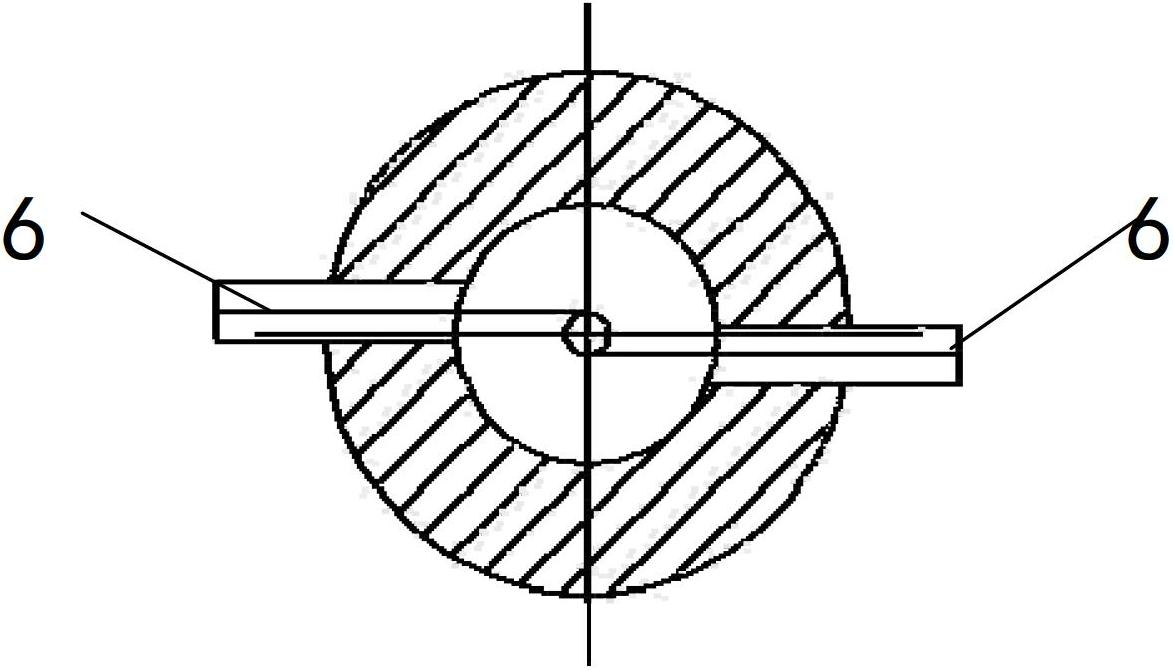

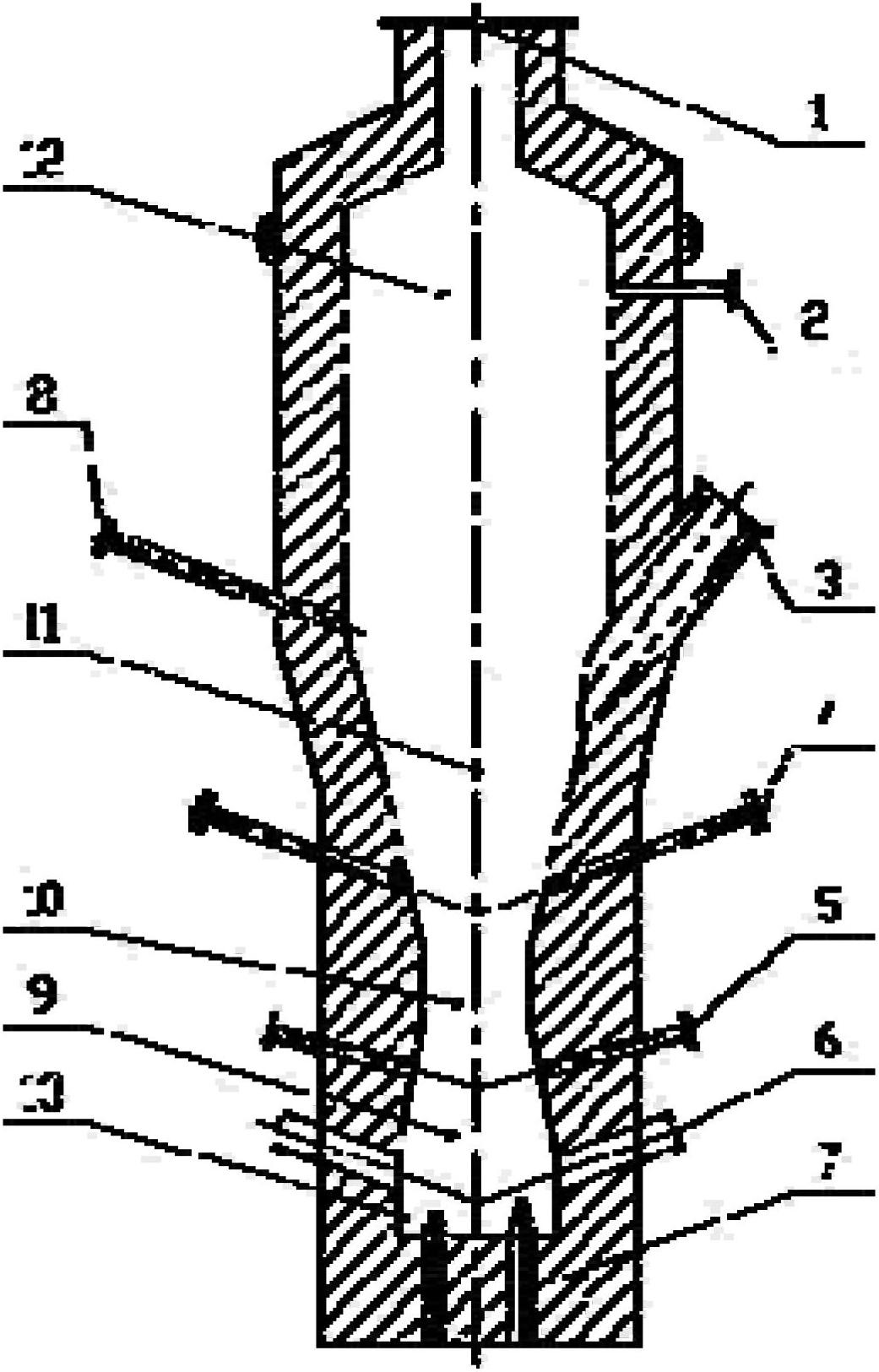

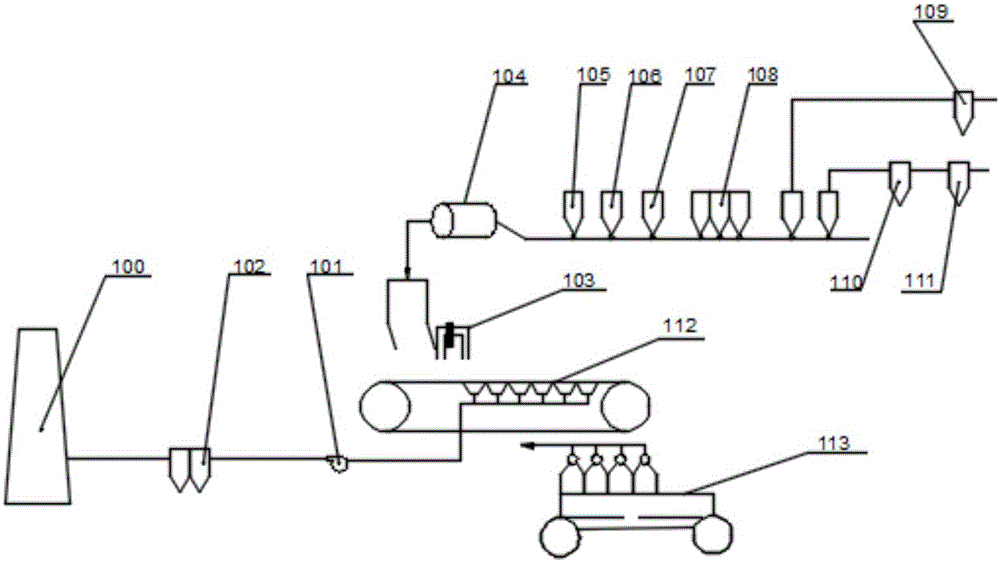

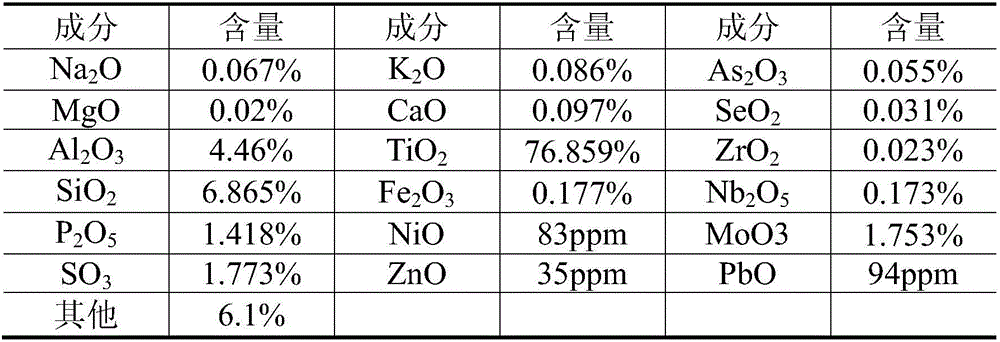

ActiveCN106238663BReduce pollutionReduce in quantityForging/hammering/pressing machinesHandling devicesCircular discPunch press

The invention discloses a fully automatic hot upset head production system for railway screw spikes. The fully automatic hot upset head production system comprises a heating device and a grasping device, wherein the heating device comprises an automatic feeding machine, a medium-frequency heating groove, a medium frequency heating power supply and a rotation pulsation feeding mechanism; the discharging end of the automatic feeding machine is arranged at a notch formed in the top of the medium-frequency heating groove; the medium frequency heating power supply is connected with and controls the medium frequency heating groove; the rotation pulsation feeding mechanism is in a circular disc shape and is arranged at a notch formed in the bottom of the medium frequency heating groove; the grasping device comprises a first mechanical hand, a first guide rail, a second mechanical hand, a second guide rail, an upset head mold and a feeding slide groove; the inlet of the feeding slide groove is formed in the rotation pulsation feeding mechanism; the first guide rail and the second guide rail are arranged in the same line; in addition, the upset head mold is arranged between the first guide rail and the second guide rail, and is provided with a punching bed material jacking mechanism. The fully automatic hot upset head production system has the beneficial effect that the fully automatic production is realized.

Owner:ANHUI CHAOHU CASTING FACTORY

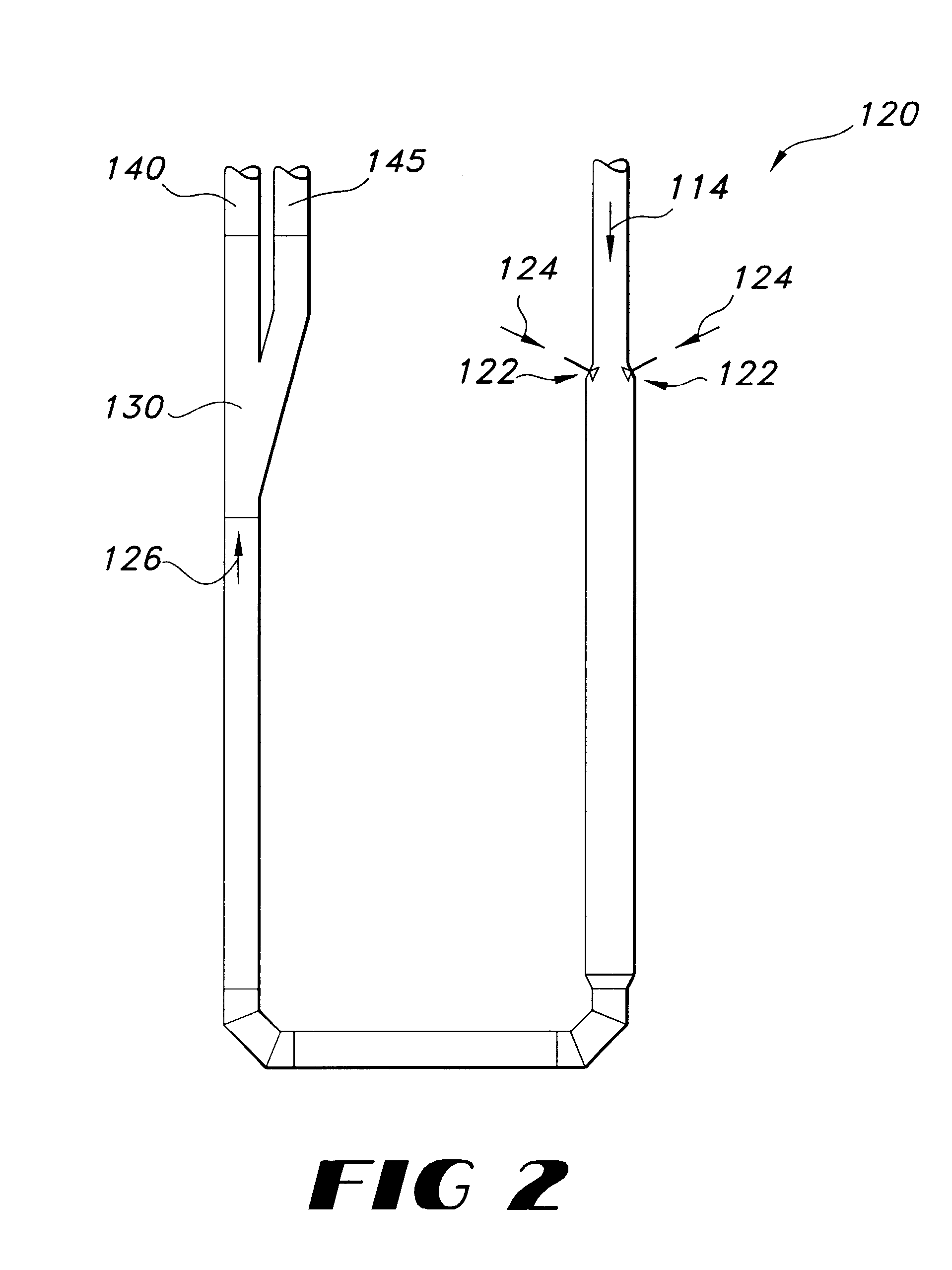

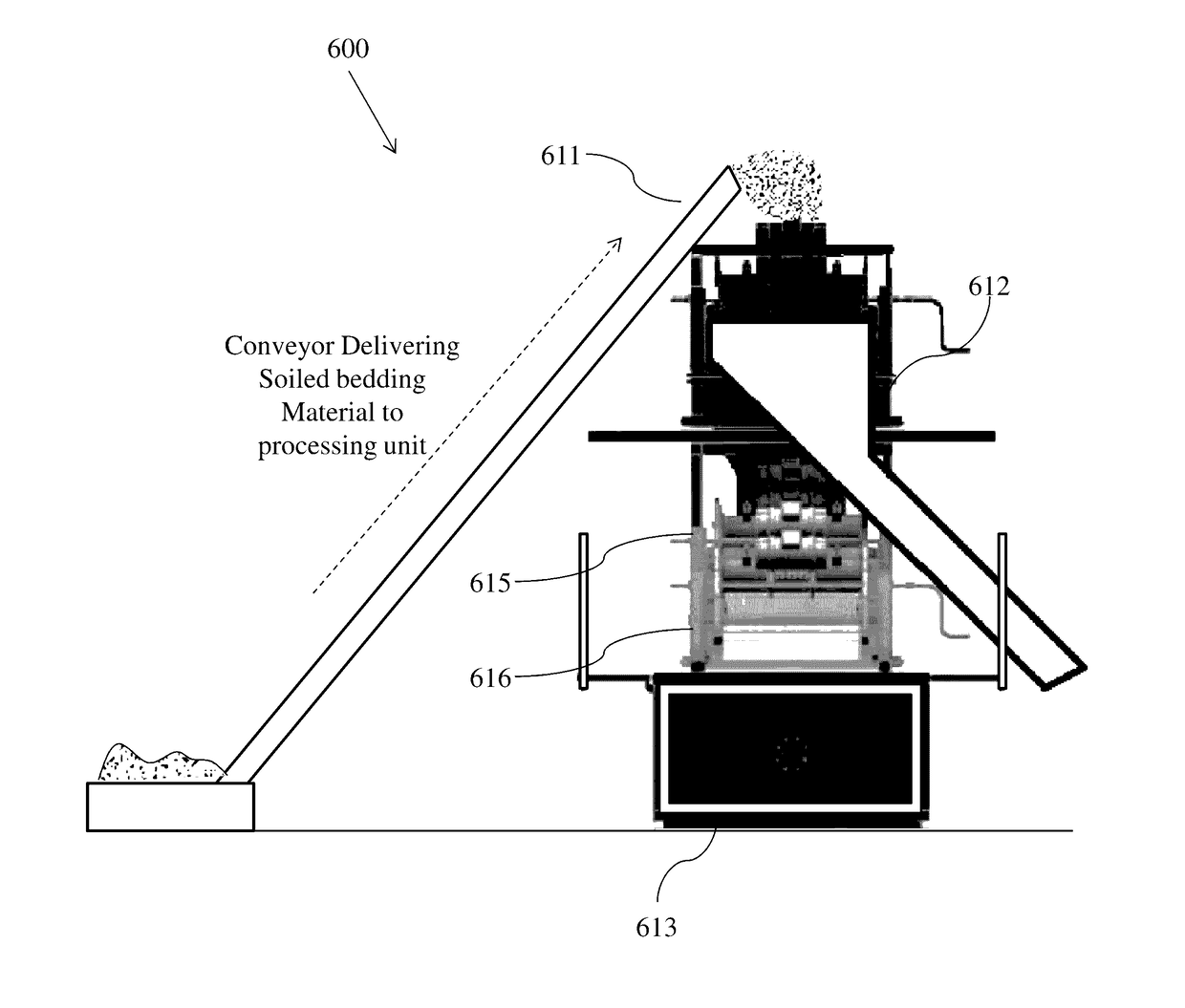

System And Method For Reprocessing Animal Bedding

ActiveUS20170081251A1Eliminate needBeneficially usedBio-organic fraction processingBiofuelsEngineeringHandling system

A method and system reprocess soiled animal bedding material commingled with animal manure. In one aspect the soiled animal bedding material is separated in a shaker to send at least a preponderance of said manure to a holding tank. In another aspect the bedding is cleaned, rinsed and color is restored. Said bedding material is subsequently dried and a bedding product, fertilizer product, and / or compacted product is formed. Alternatively, said bedding material is dried (without a compacting step) to form a product. In another aspect, the steps of separation, cleaning, rinsing and / or color restoration may be omitted.

Owner:EQUINE ECO GREEN LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com