Fully automatic hot pier head production system for railway spiral spikes

A technology of spiral spikes and production systems, applied in the direction of heating/cooling equipment, hooks, connecting components, etc., can solve problems such as difficult automation, poor working environment for workers, and affecting the health of operators, and achieve good product consistency , fast production cycle, and the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below according to the drawings and embodiments.

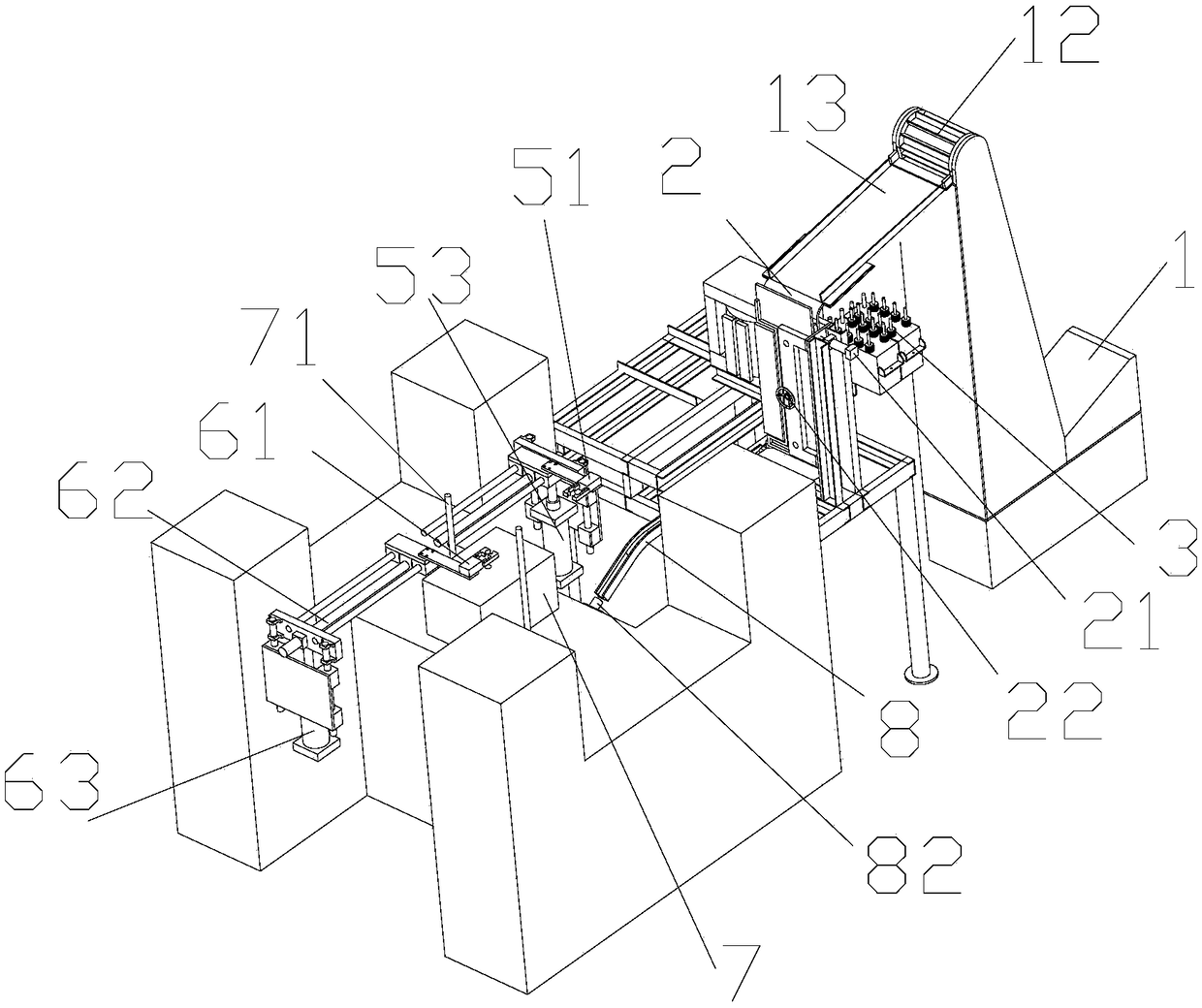

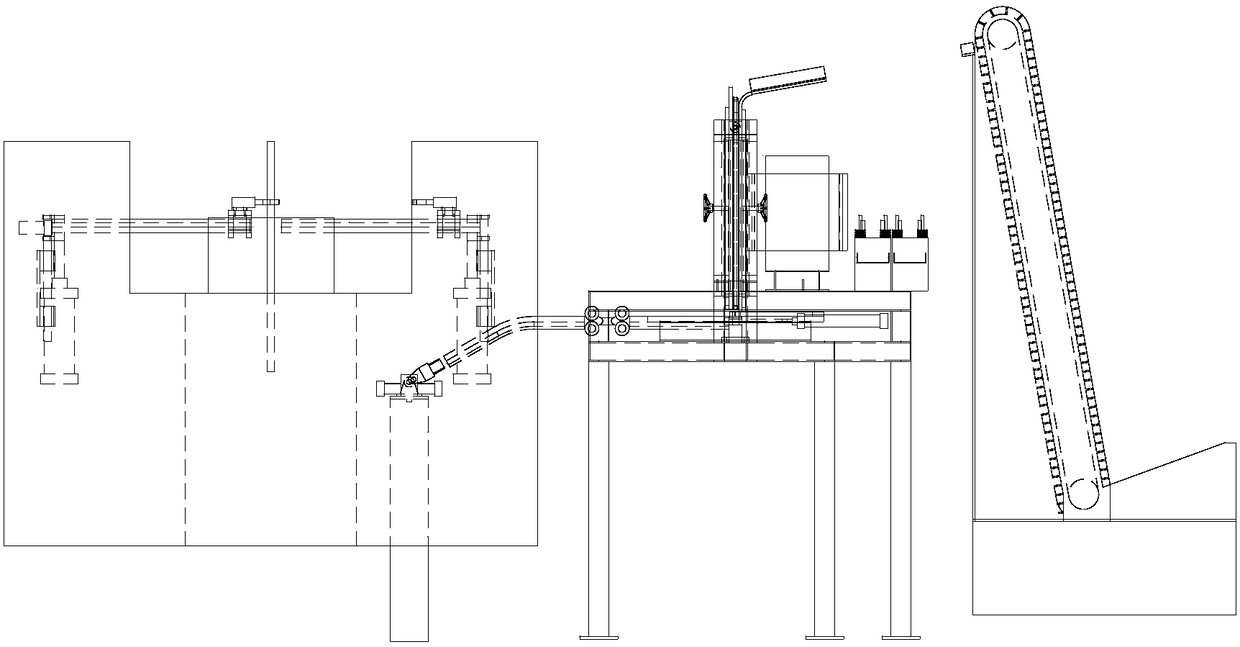

[0026] The present invention provides a fully automatic hot pier head production system for railway spiral spikes, comprising: a heating device and a grabbing device.

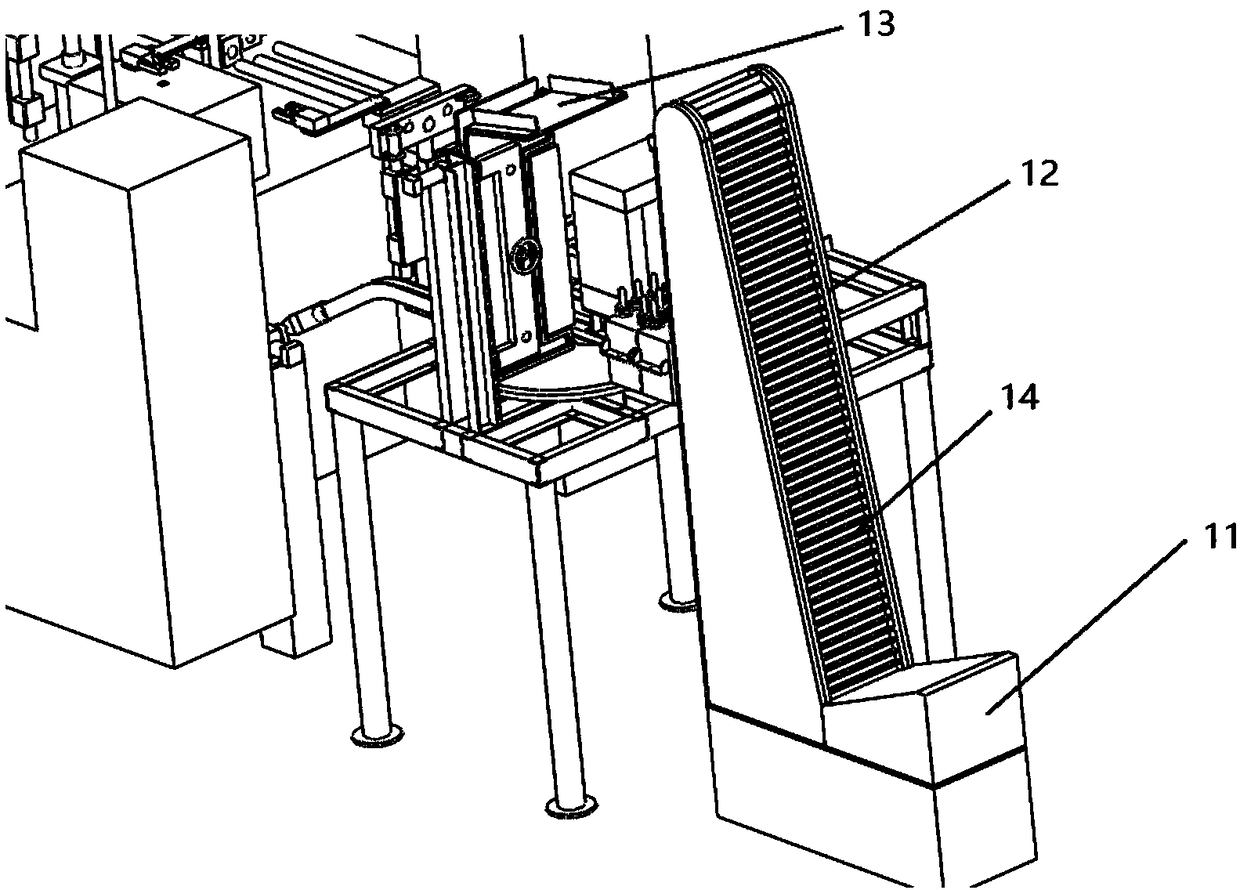

[0027] refer to image 3 , Figure 4 and combine figure 1 , figure 2 , a heating device, which includes an automatic feeder 1, an intermediate frequency heating tank 2, an intermediate frequency heating power supply 3, and a rotary pulsating feeding mechanism 4. The heating power supply 3 is connected to control the intermediate frequency heating tank 2 , and the rotating pulsating feeding mechanism 4 is disc-shaped and arranged at the notch at the bottom of the intermediate frequency heating tank 2 .

[0028] The automatic feeder 1 includes a feed bin 11, a lifting mechanism 12, and an intermediate frequency feeding slide 13. The inlet end of the lifting mechanism 12 is connected to the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com