Patents

Literature

114results about How to "Fast production time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expression of heterologous multi-domain proteins in yeast

InactiveUS6358733B1Increase productionCost effective productionSugar derivativesAntibody mimetics/scaffoldsYeastSingle-Chain Antibodies

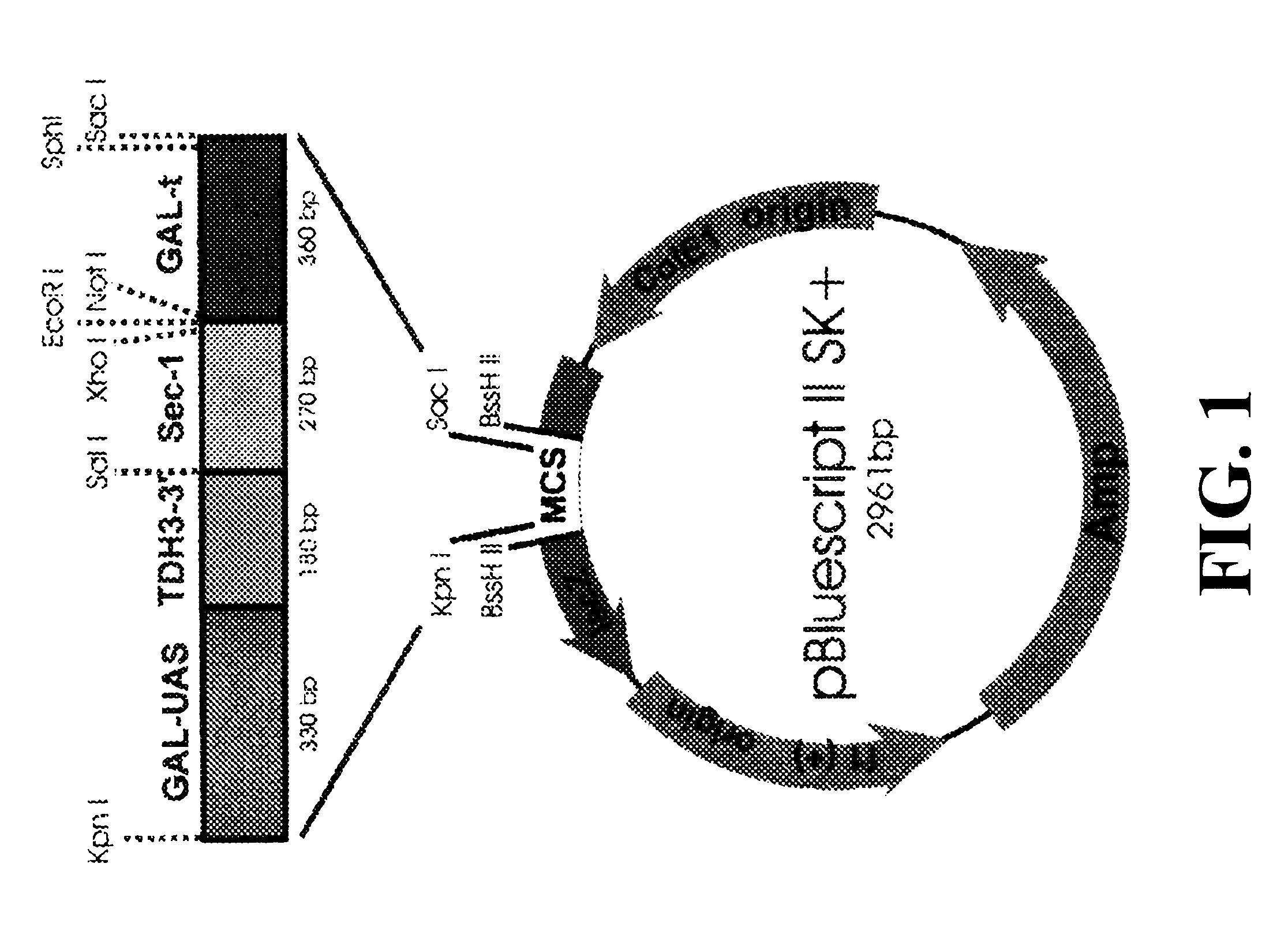

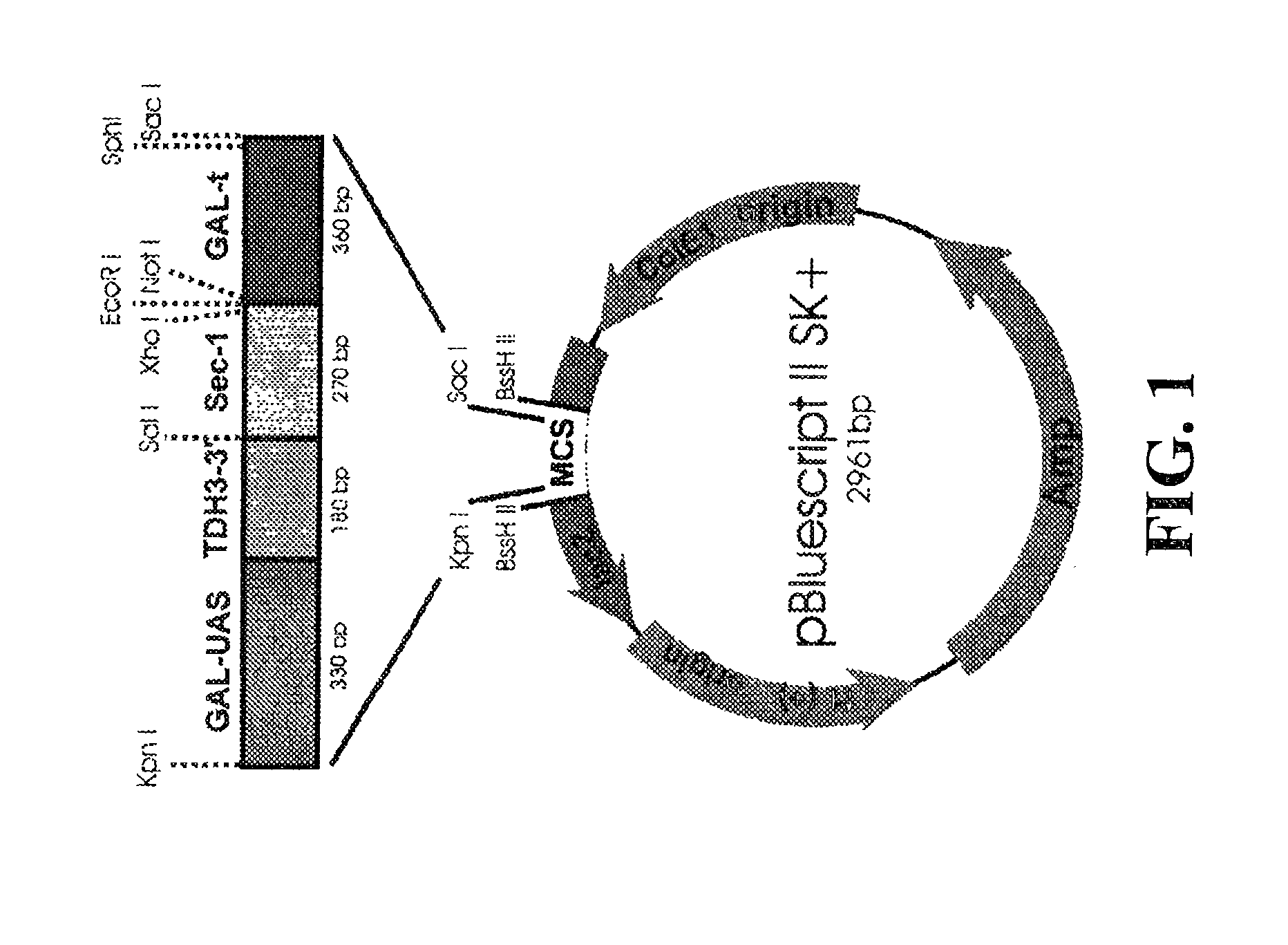

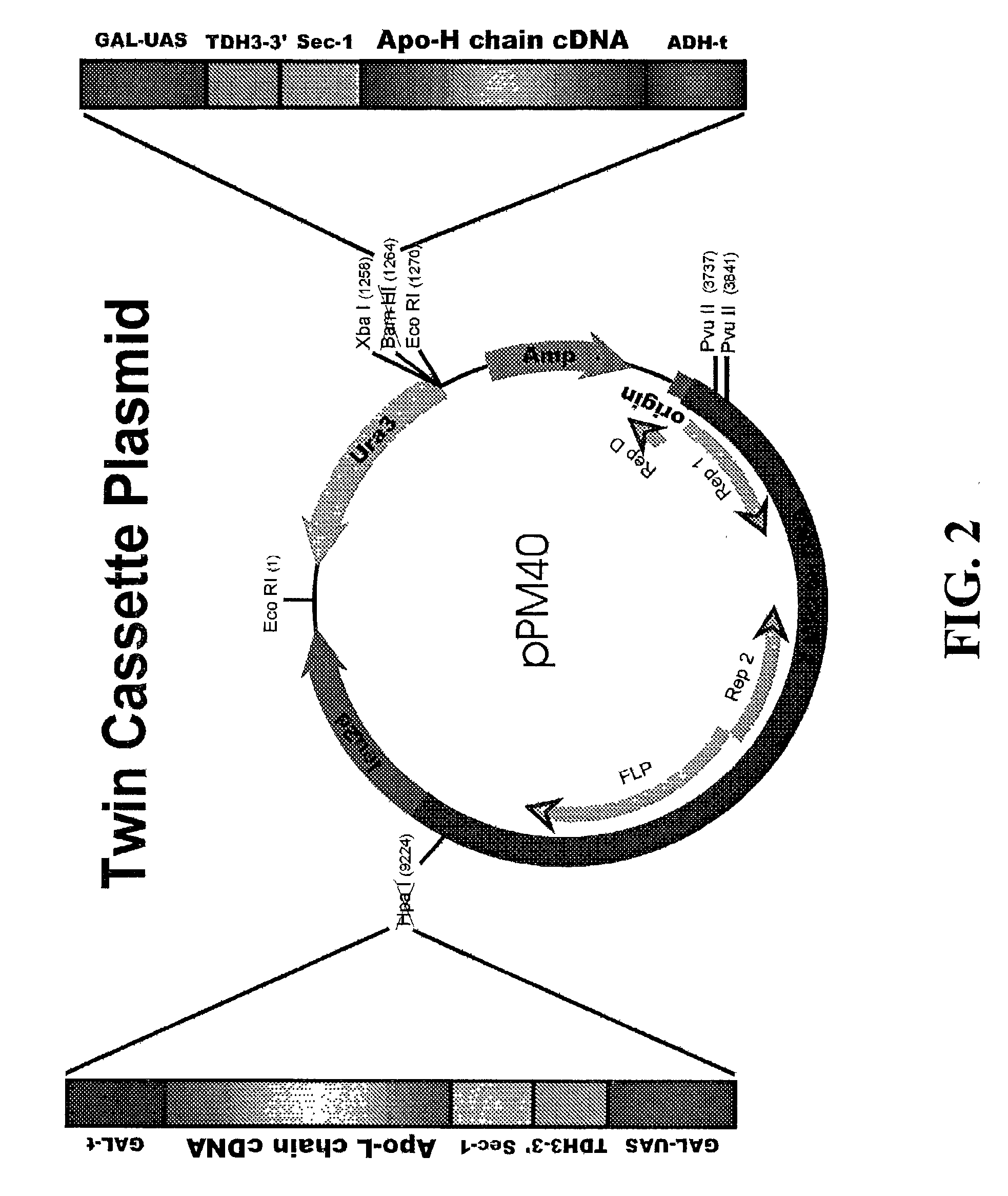

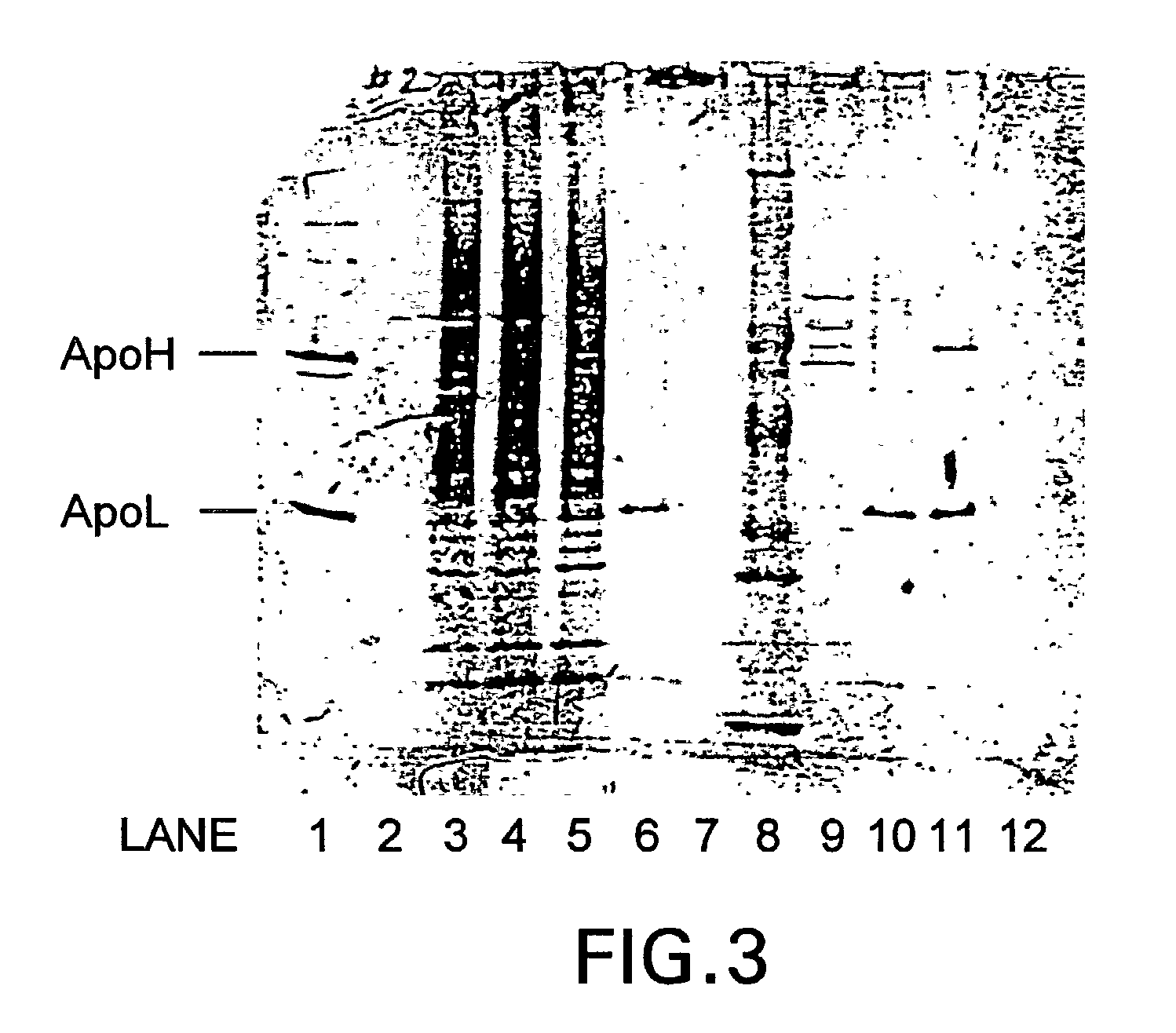

This invention demonstrates the utility of a yeast expression system for the expression of functional heterologous multi-domain proteins in yeast. The yeast expression system allows for the inclusion of a plurality of (up to three) modular expression cassettes which may encode multiple polypeptide chains of a heterologous multi-domain protein on a single plasmid (Twin Cassette). Because multiple polypeptide chains may be encoded for by the expression cassettes of the present invention in a single vector, the system can produce equivalent amounts of the multiple polypeptide chains, thereby enhancing the yield of a functional heterologous multi-domain protein. For example, functional monoclonal antibodies (MAbs) comprising a heavy chain and a light chain of an immunoglobulin (IgG), and functional immunotoxins comprising an antibody domain and an oxidase toxin may be produced using the Yeast expression system of the present invention. In addition, functional single chain antibodies, antibody fragments and chimeric antibodies may also be produced.

Owner:APOLIFE

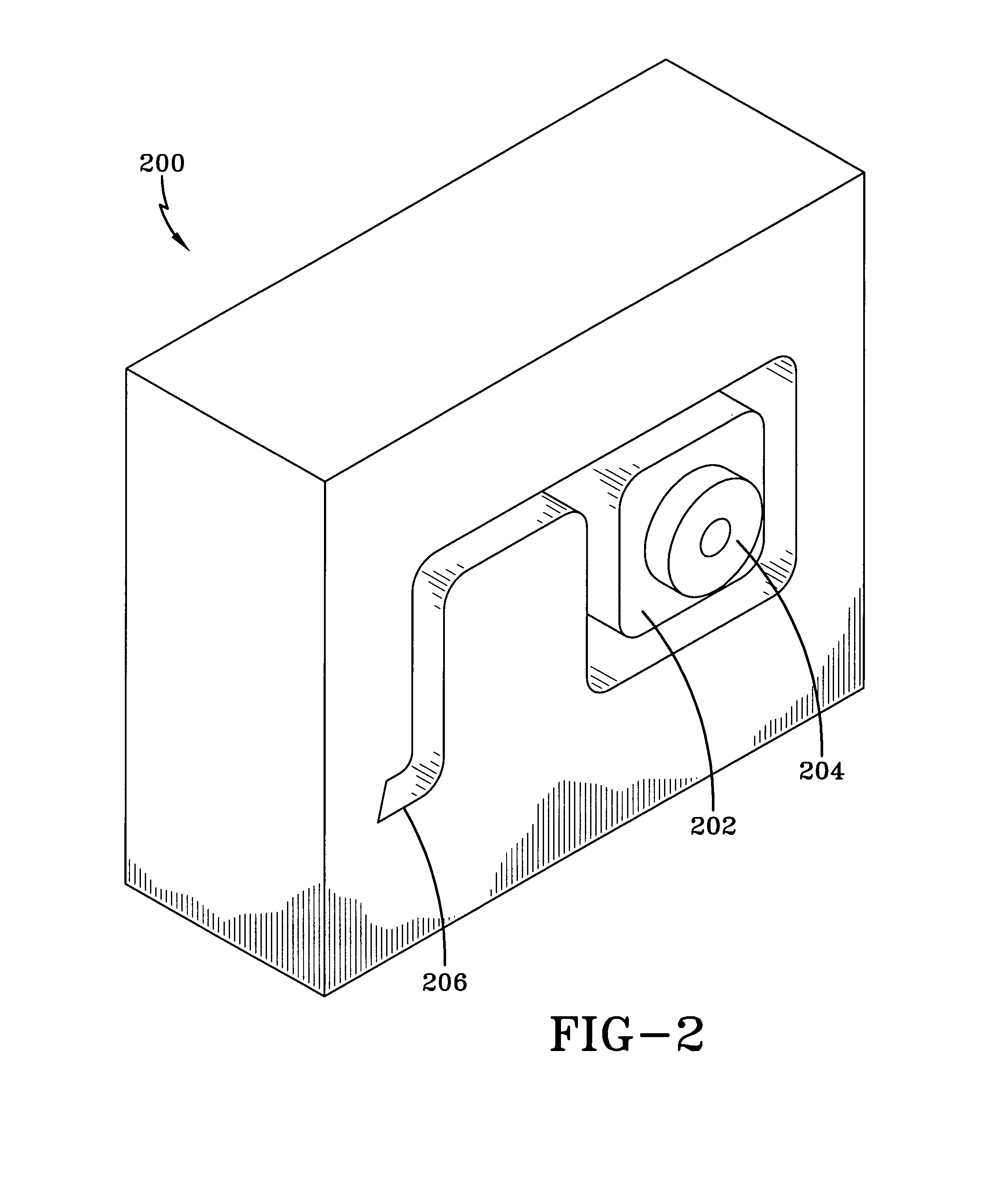

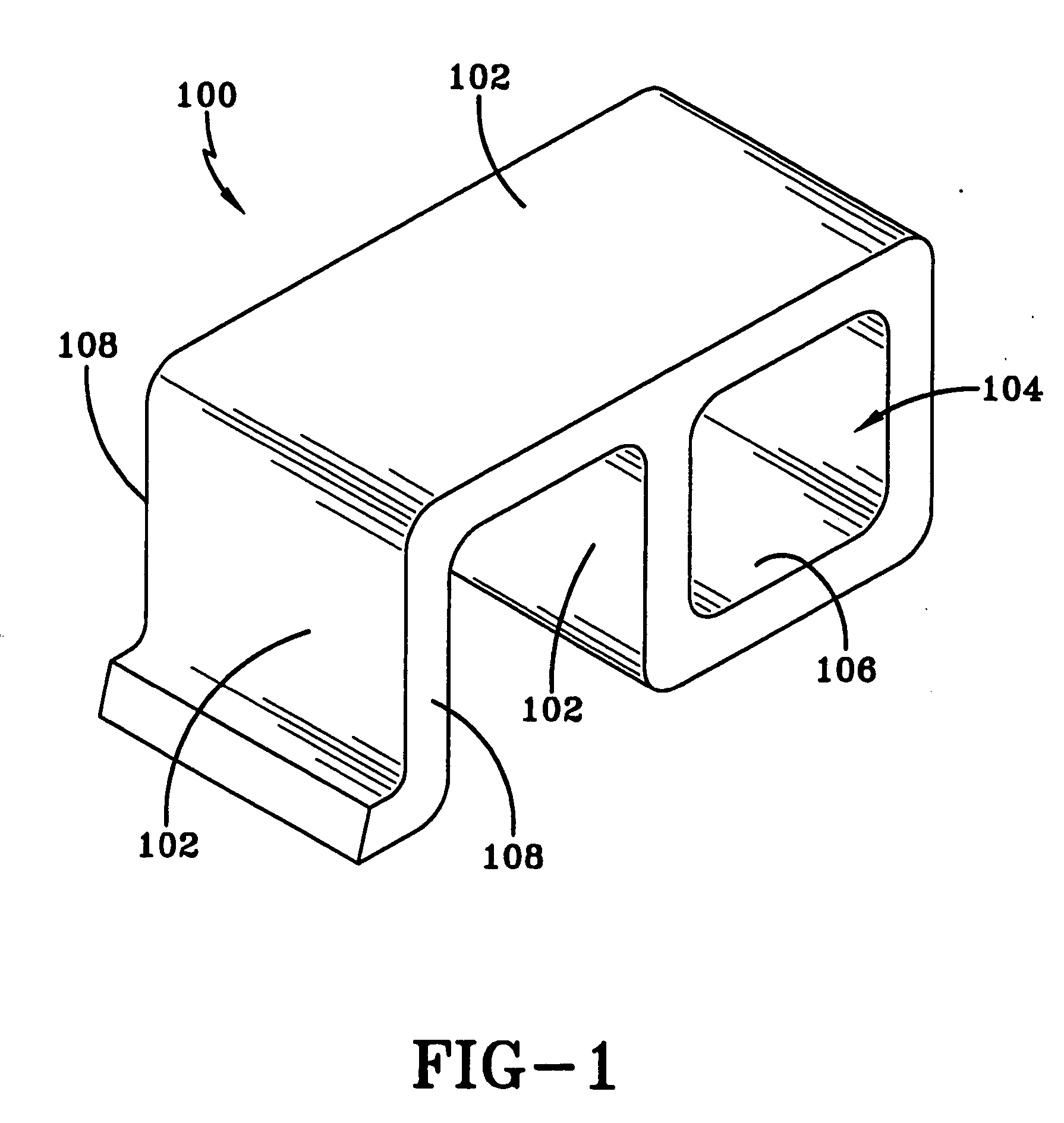

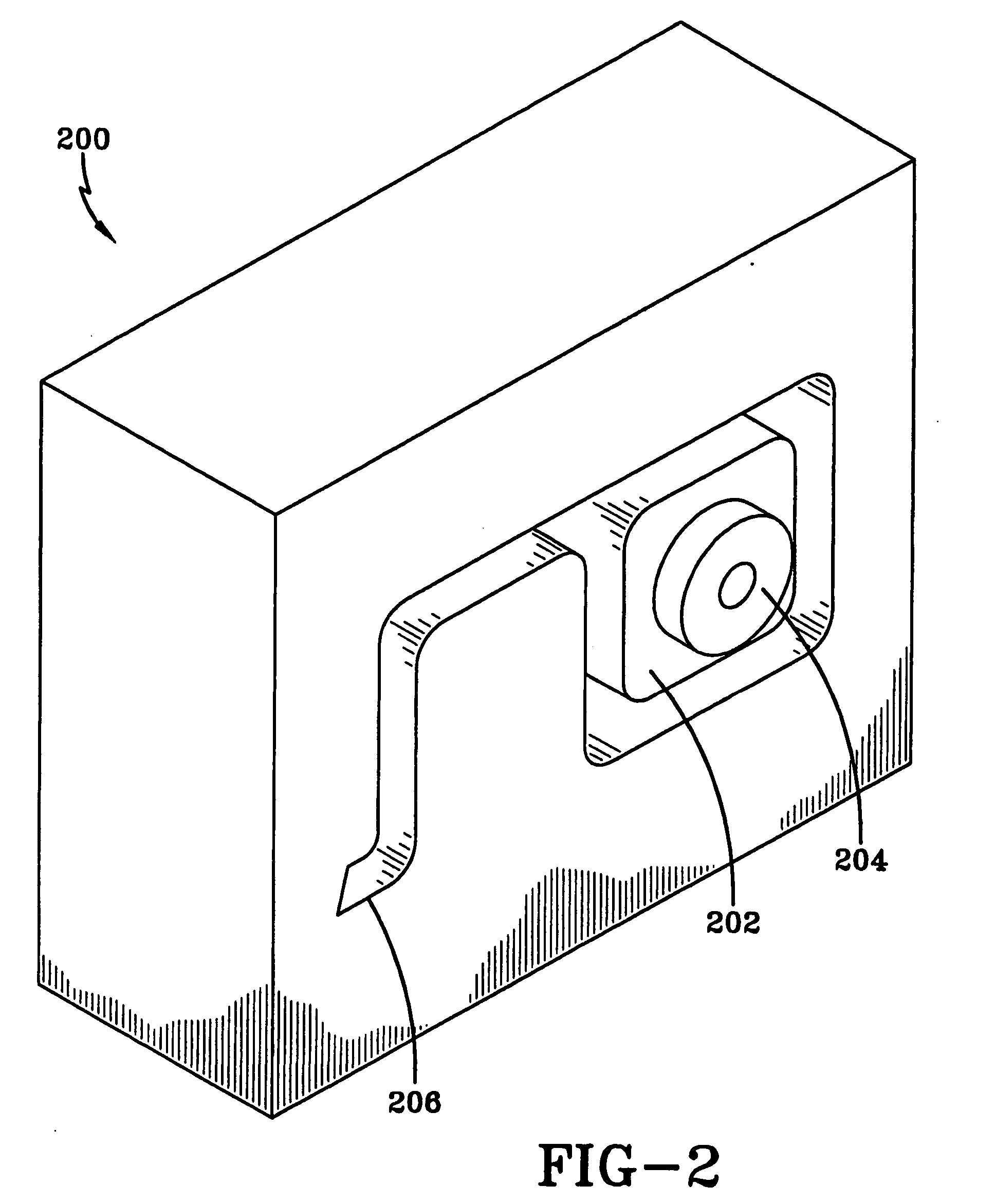

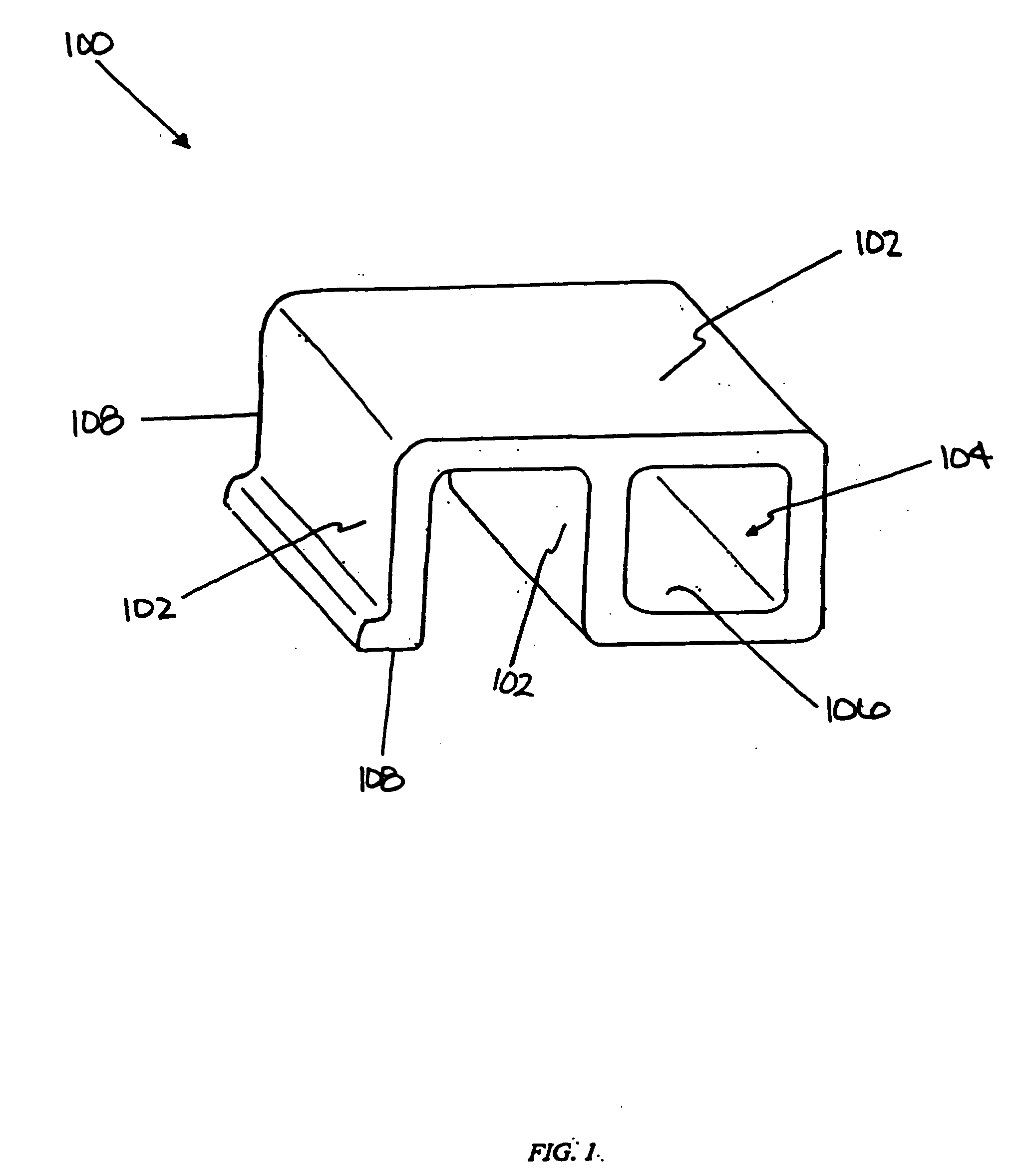

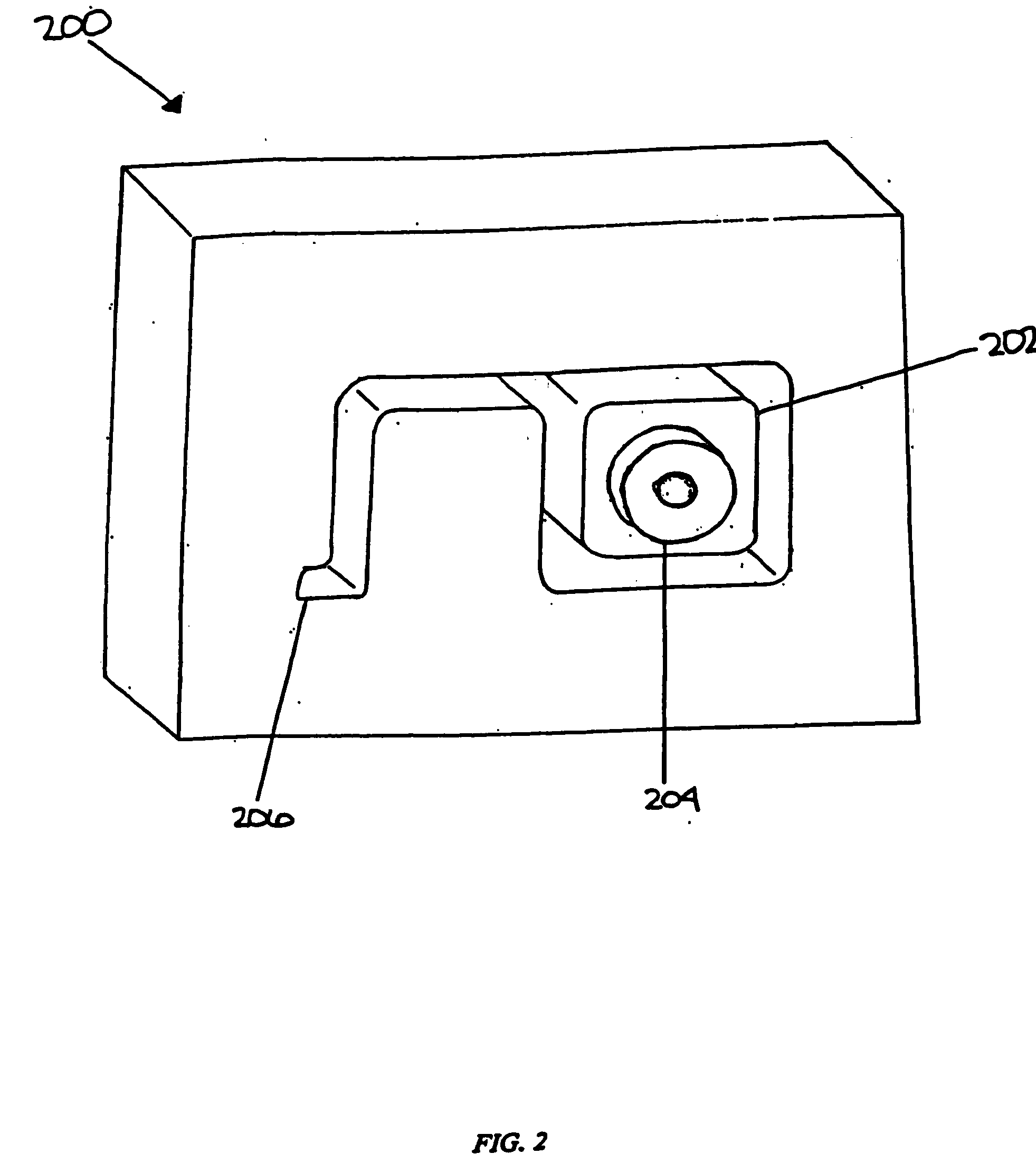

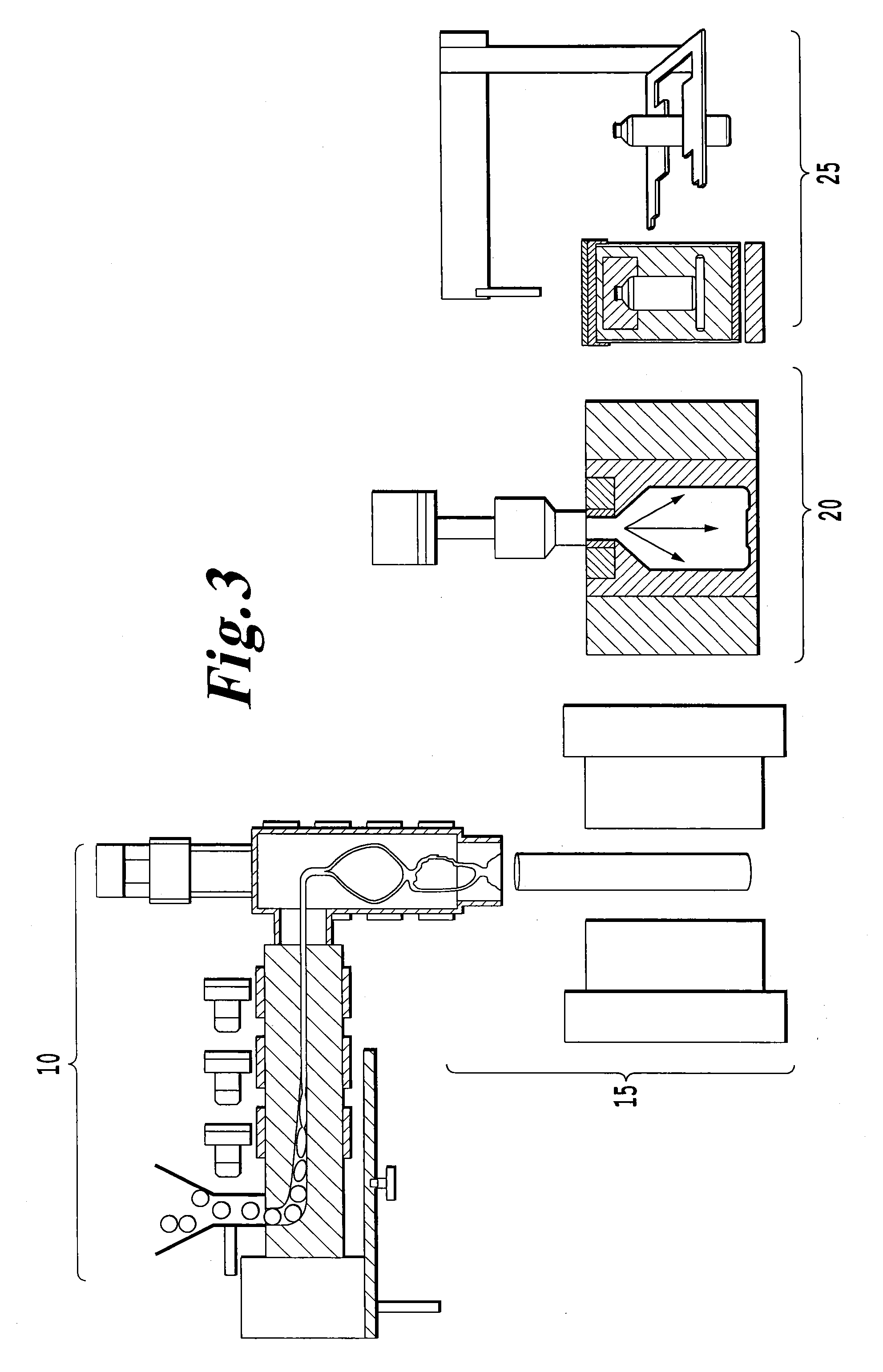

Cooling of extruded and compression molded materials

InactiveUS7017352B2Improved structural and physical and aesthetic characteristicEfficient preparationCompression machinesStationary refrigeration devicesCompression moldingProduction line

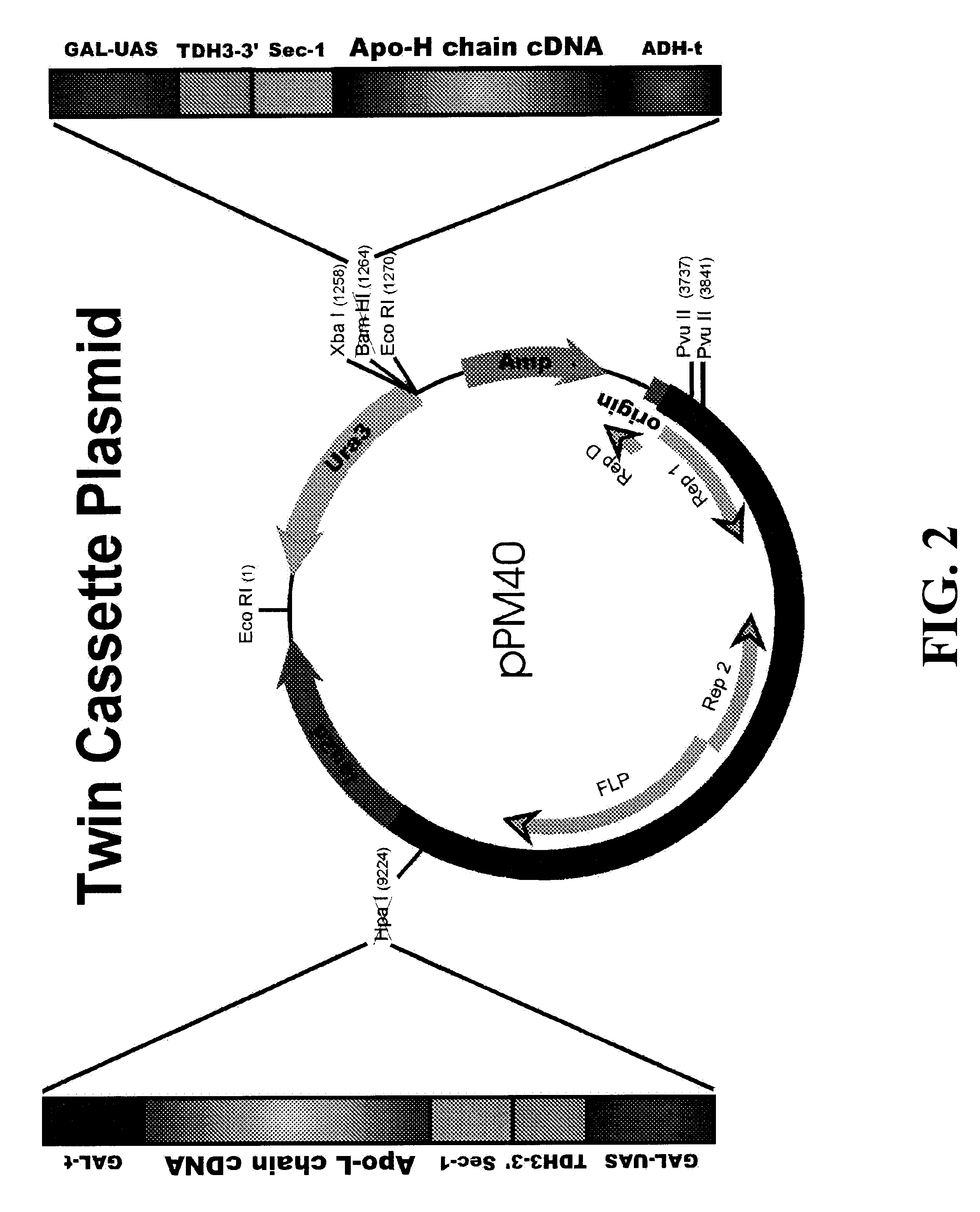

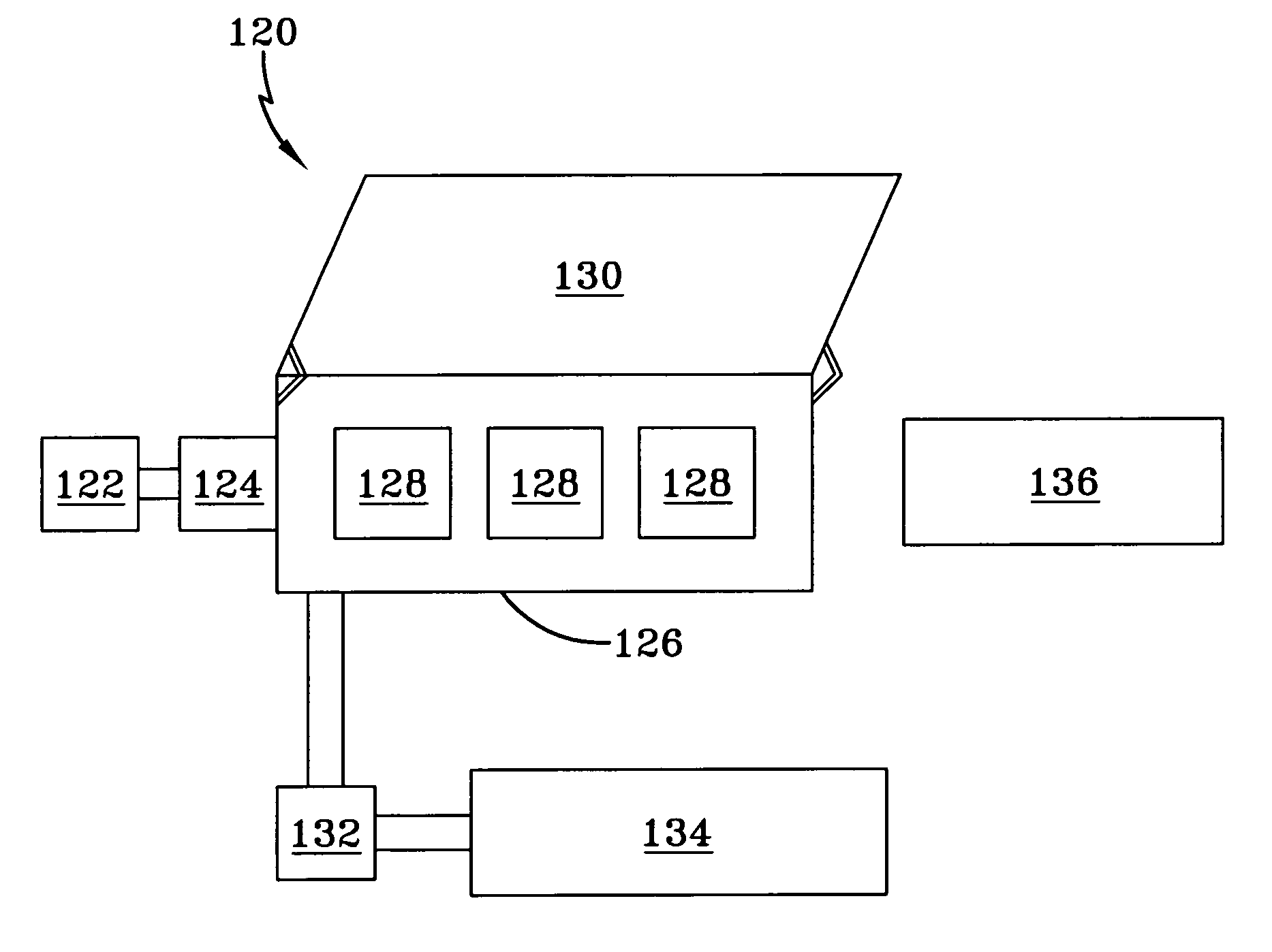

The present invention relates to a system and a method for cooling extruded and molded materials. The present invention is especially useful to thoroughly cool an extrudate by directing a cooling fluid toward a surface of the extrudate (e.g., an interior surface that defines a hollow portion of an extrudate). Hollows may be created in order to reduce material, weight, and / or processing time. A cooling fluid is diverted toward the surface of the extrudate so as to cool the material and assist in solidification. A baffle may serve to divert the cooling fluid in the desired direction. In another example, the extrudate may be partially or totally immersed in a liquid cryogenic fluid. Increases in production line throughput may result by rapidly cooling the molded material. In addition, the more efficient cooling may be achieved with a lesser amount of the cooling fluid, and the velocity and temperature of the cooling fluid may be reduced. Other uses for the present invention include injection molding, compression molding, gas assist molding, and co-extrusion.

Owner:CRANE BUILDING PRODS

Expression of heterologous multi-domain proteins in yeast

InactiveUS20030100112A1Increase productionCost effective productionAntibody mimetics/scaffoldsGenetic material ingredientsYeastSingle-Chain Antibodies

This invention demonstrates the utility of a yeast expression system for the expression of functional heterologous multi-domain proteins in yeast. The yeast expression system allows for the inclusion of a plurality of (up to three) modular expression cassettes which may encode multiple polypeptide chains of a heterologous multi-domain protein on a single plasmid (Twin Cassette). Because multiple polypeptide chains may be encoded for by the expression cassettes of the present invention in a single vector, the system can produce equivalent amounts of the multiple polypeptide chains, thereby enhancing the yield of a functional heterologous multi-domain protein. For example, functional monoclonal antibodies (MAbs) comprising a heavy chain and a light chain of an immunoglobulin (IgG), and functional immunotoxins comprising an antibody domain and an oxidase toxin may be produced using the Yeast expression system of the present invention. In addition, functional single chain antibodies, antibody fragments and chimeric antibodies may also be produced.

Owner:APOLIFE

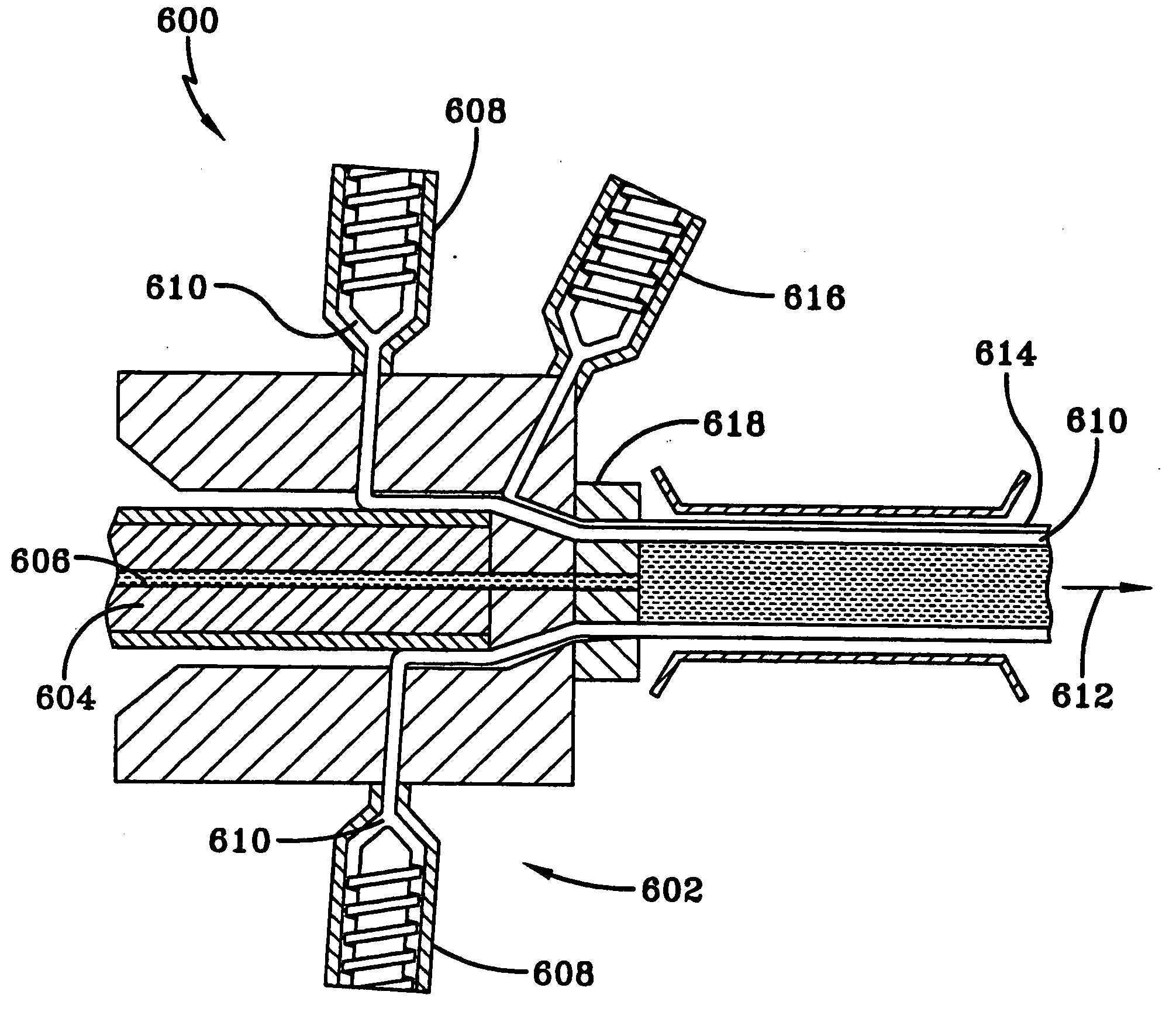

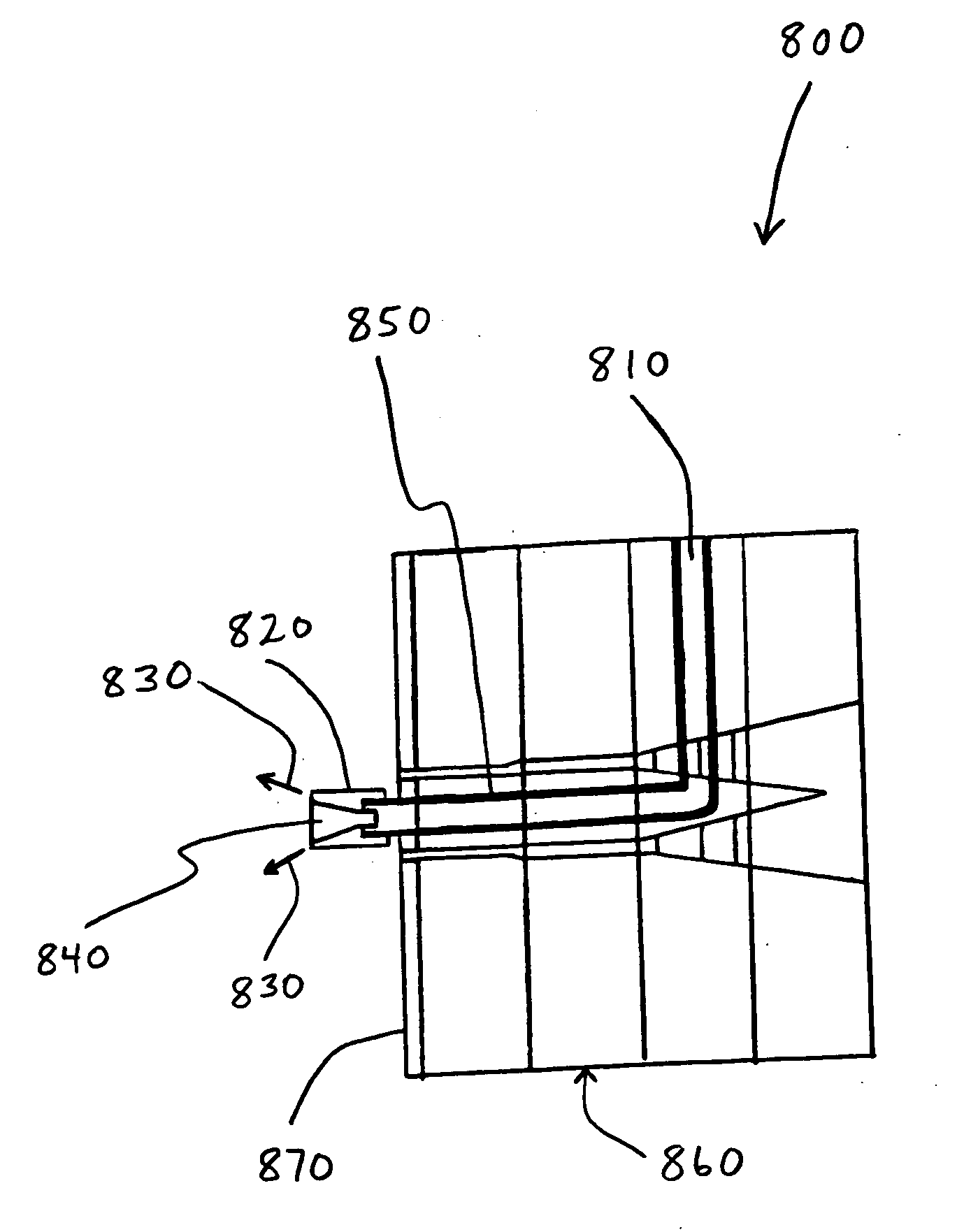

System and method for directing a fluid through a die

InactiveUS20060012066A1Fast production timeEfficiently manufactureDomestic articlesBiomedical engineeringCooling fluid

A system and method for directing a fluid through a die. A transfer device for a fluid (e.g., a cooling fluid or a material) may extend through an interior of the die. The transfer device may be situated such that undesired heat transfer with other portions of the die is limited.

Owner:CRANE BUILDING PRODS

Cooling of extruded and compression molded materials

InactiveUS20060010884A1Improved structural and physical and aesthetic characteristicEfficient preparationCompression machinesMovable spraying apparatusCompression moldingProduction line

The present invention relates to a system and a method for cooling extruded and molded materials. The present invention is especially useful to thoroughly cool an extrudate by directing a cooling fluid toward a surface of the extrudate (e.g., an interior surface that defines a hollow portion of an extrudate). Hollows may be created in order to reduce material, weight, and / or processing time. A cooling fluid is diverted toward the surface of the extrudate so as to cool the material and assist in solidification. A baffle may serve to divert the cooling fluid in the desired direction. In another example, the extrudate may be partially or totally immersed in a liquid cryogenic fluid. Increases in production line throughput may result by rapidly cooling the molded material. In addition, the more efficient cooling may be achieved with a lesser amount of the cooling fluid, and the velocity and temperature of the cooling fluid may be reduced. Other uses for the present invention include injection molding, compression molding, gas assist molding, and co-extrusion.

Owner:CRANE PLASTICS PARTNERSHIP

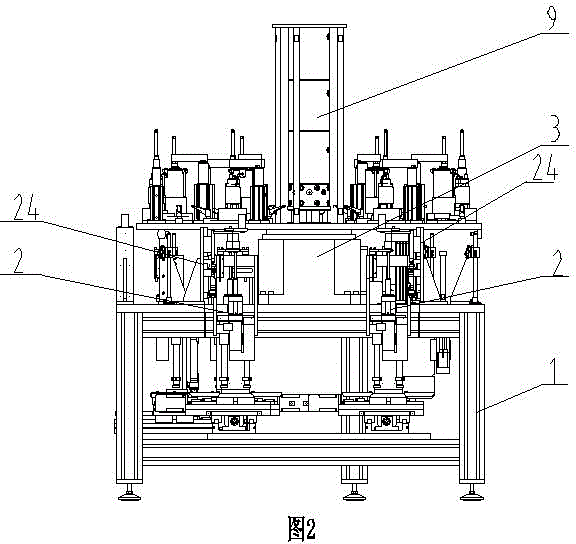

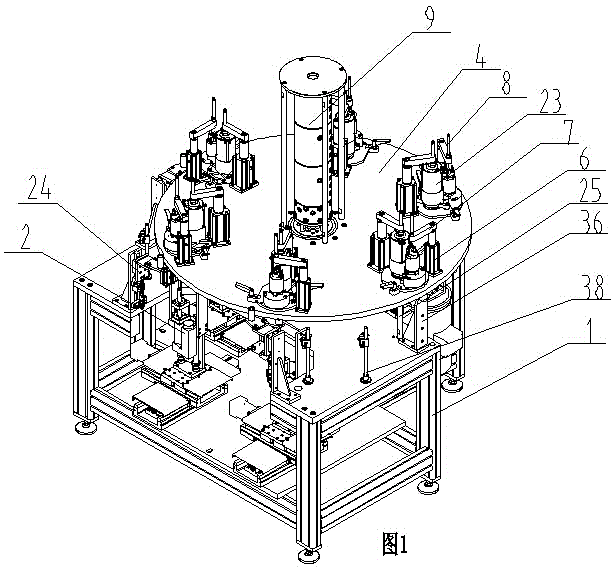

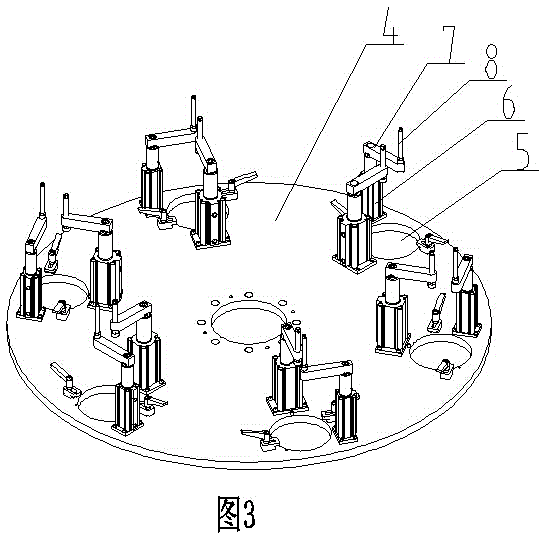

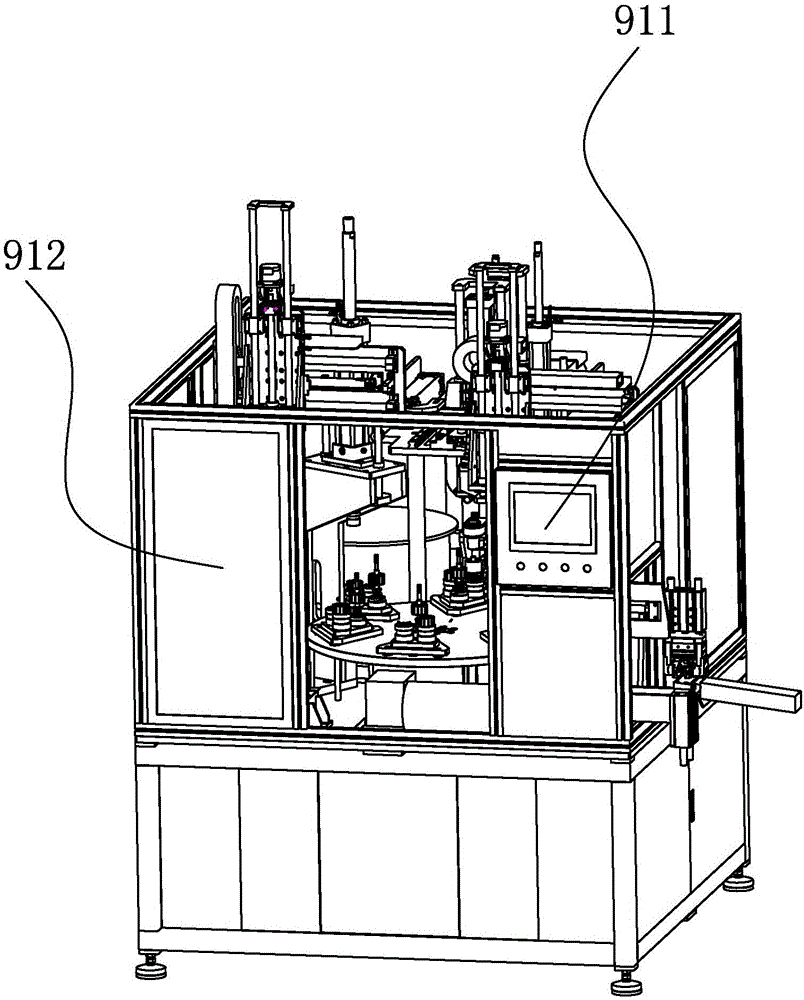

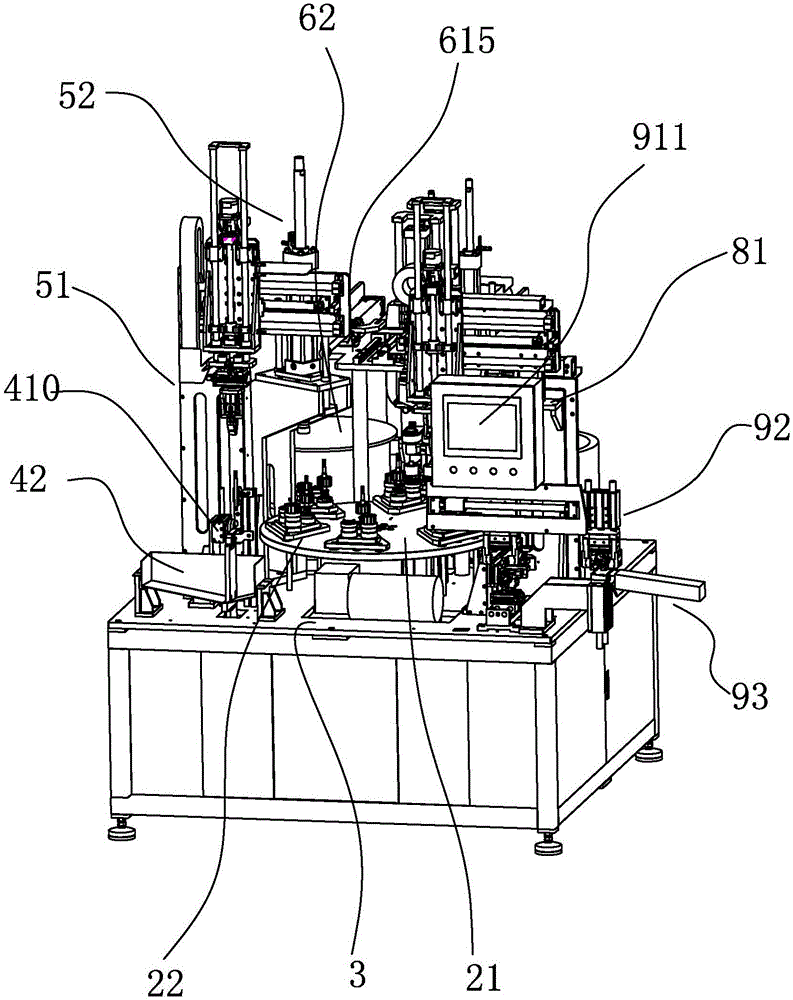

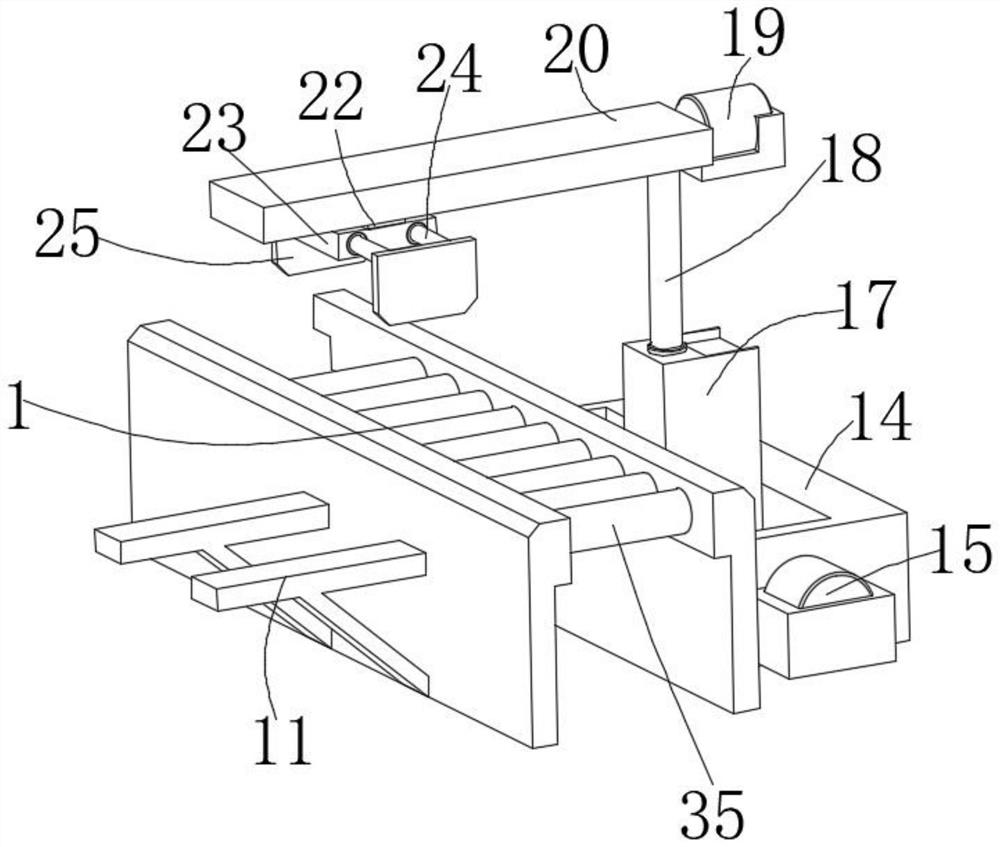

Automatic assembling machine for automobile starter switch screws

ActiveCN104786053ACompact structureHigh degree of automationWork holdersMetal working apparatusConsistency problemUltimate tensile strength

The invention relates to an automatic assembling machine for automobile starter switch screws, and belongs to the technical field of automobile starter motor assembly assembling equipment. The automatic assembling machine comprises a rack, multiple tightening devices, a graduator, a workpiece fixture and an index plate; the index plate is installed on the rack, an air distributing rotation barrel is installed in the center of the index plate, the tightening devices are installed on the rack, and a vibration loader is arranged on one side of the rack; a switch screw feeding device is arranged at one side of each tightening device and connected with the vibration loader through a communication pipe. According to the automatic assembling machine for the automobile starter switch screws, the structure is compact, the automation degree is high, and the problems that in an existing manual starter switch screw assembling mode, time and labor are wasted, the assembly efficiency is low, the labor intensity is high, and the assembly consistency cannot be guaranteed are solved. The automatic assembling machine for the automobile starter switch screws is particularly suitable for being used in automatic assembling of the automobile starter motor switch screws.

Owner:HUBEI JINGCHUAN INTELLIGENT EQUIP

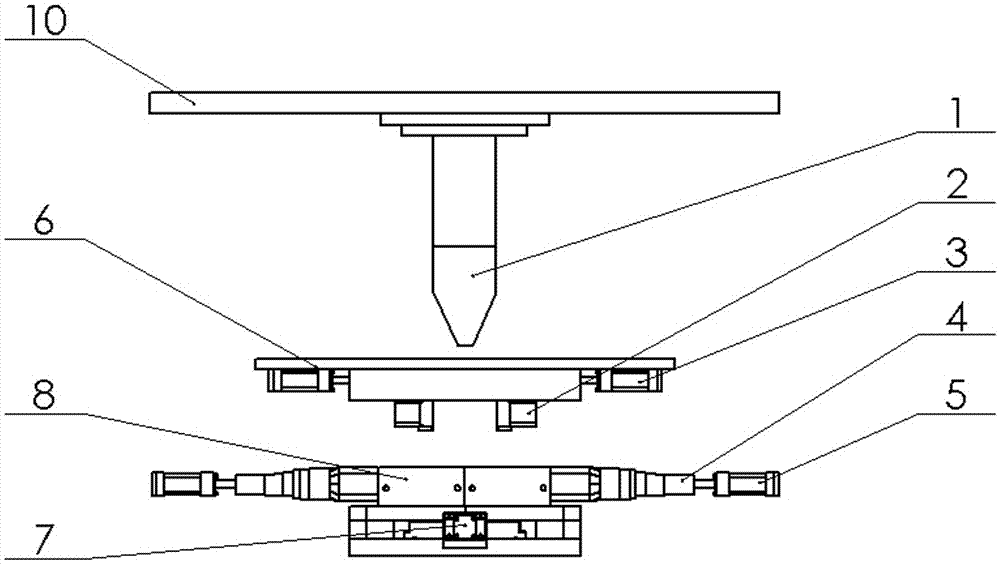

Forming method for banjo axle housing

ActiveCN105436350AEliminate product defectsImprove product qualityShaping toolsEngine componentsHydraulic cylinderEngineering

The invention discloses a forming method for a banjo axle housing. The forming method includes the following steps of (S1) blanking, (S2) extrusion of a shaft head, (S3) square pushing, (S4) manufacturing of a process groove, (S5) heating of a workpiece, (S6) radial expansion, (S7) shaping and (S8) upward resetting of a lower press sliding block and taking-out of the workpiece. According to the (S6), a wedge punch penetrates through a central hole of the lower press sliding block, pushes two radial expansion core molds to expand the radial direction of a workpiece central hole and axially squeezes the workpiece synchronously. According to the (S7), two axial shaping core molds are attached, the lower press sliding block moves downwards to enable the axial shaping core molds to be inserted into the position between two radial shaping core molds, an upper press sliding block moves downwards, and the wedge punch is inserted into the position between the two axial shaping core molds to shape the workpiece central hole and axially squeeze a hydraulic cylinder for axial limitation. The forming method integrates heat expansion and shaping, work procedures are reduced, a process chain is shortened, and the outline size accuracy is obviously improved.

Owner:吴志强 +1

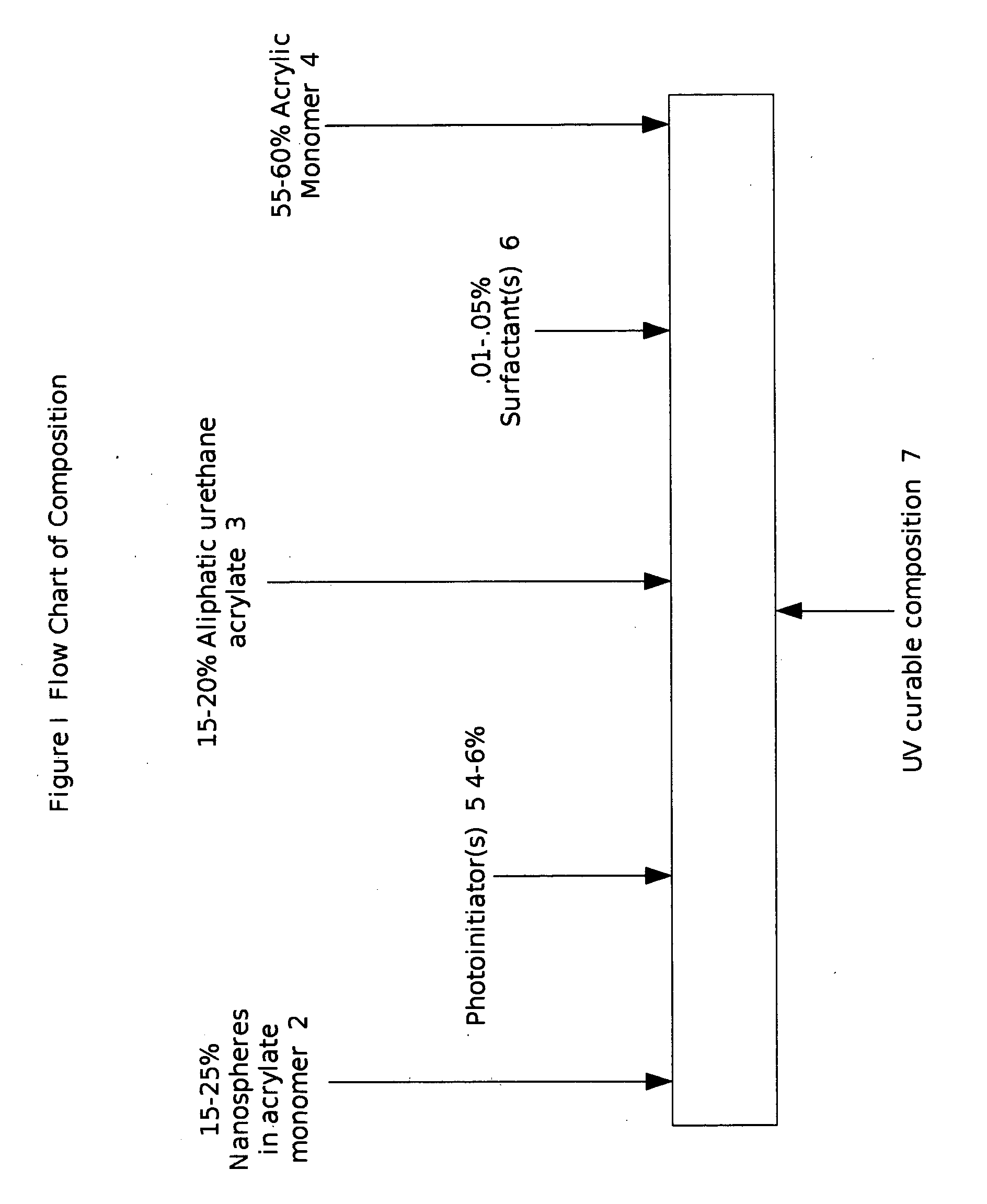

Composition of matter comprising UV curable materials incorporating nanotechnology for the coating of fiberglass

InactiveUS20050203205A1Eliminate emissionsFast production timeOptical articlesGlass fiberSolvent free

A composition of matter incorporating nanotechnology with UV curable materials for the coating of fiberglass. A one-part, substantially solvent-free coating composition for applying to fiberglass substrates, consisting essentially of: a polymerizable compound which comprises a mixture of acrylates, photoinitiator or a photoinitiator mix, silicon dioxide monospheres, and surfactant or mixture of surfactants.

Owner:ECOLOGY COATING

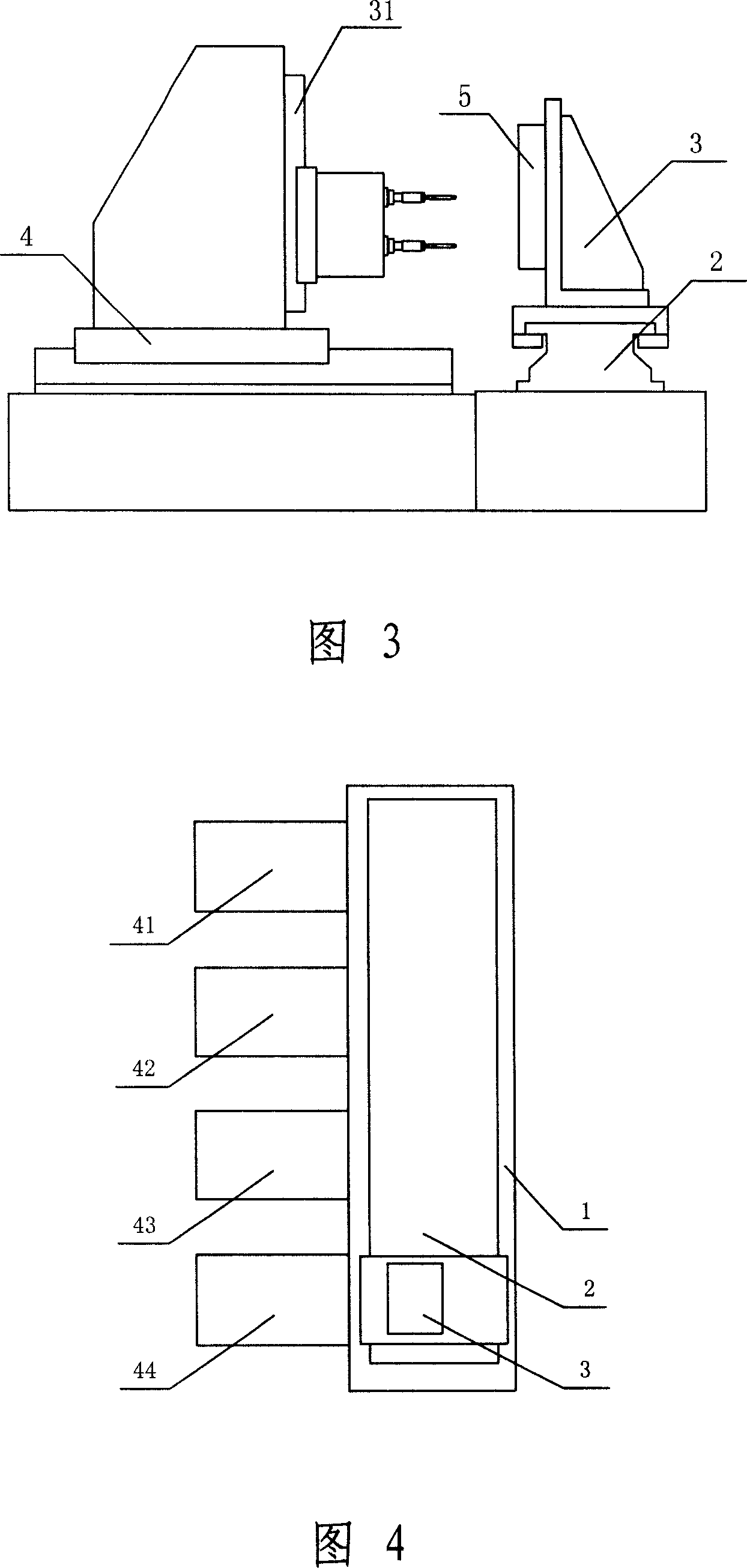

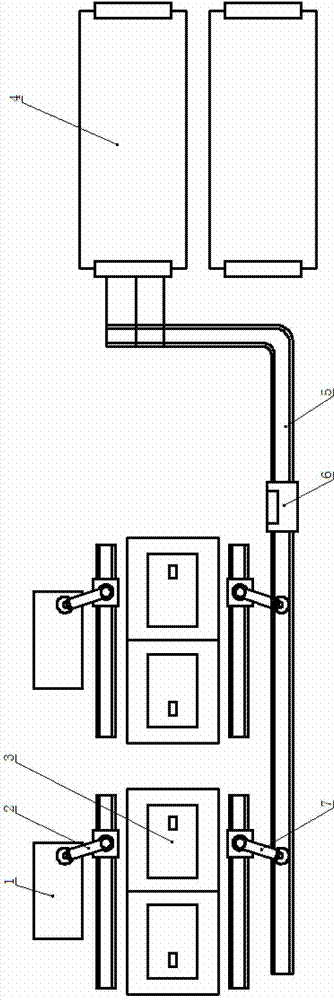

Coarctation hole series multi-operation part process technique and special equipment thereof

InactiveCN101152690AEfficient use ofExtended processing timeElectric programme controlOther manufacturing equipments/toolsMachine controlControl system

A hole-intensive multi-processing components manufacturing technique and specialized equipment, the technique comprises up material, under material and a plurality of multi-modules processing units which are serially processed between the up material and the under material. The specialized equipment comprises a machine base, a displacement slipway provided with at least two processing modules, a shift slipway, a clamp which is fixed on the shift slipway, a supplying slipway, a power box, a spindle box, a knife auxiliary equipment and a machine control system. The inner of the spindle box is provided with a transmission system and at least two sets of spindles; and each set of the spindle is provided with a spindle output which corresponds to the processing module of the two-position slipway. A location-fixed clamp device is arranged on the clamp and corresponds to the spindle; a feeding mechanism is arranged between the location-fixed clamp devices, so that the processing module can change place among the location-fixed clamp devices. The processing of the multi-modules processing units is processed serially and simultaneously; work pieces are processed through each processing unit by order and a plurality of work pieces can be processed simultaneously, which highly overlaps the processing time. The technique is capable of efficiently using of resources and improving the production efficiency.

Owner:南京东华车享智驾科技有限公司

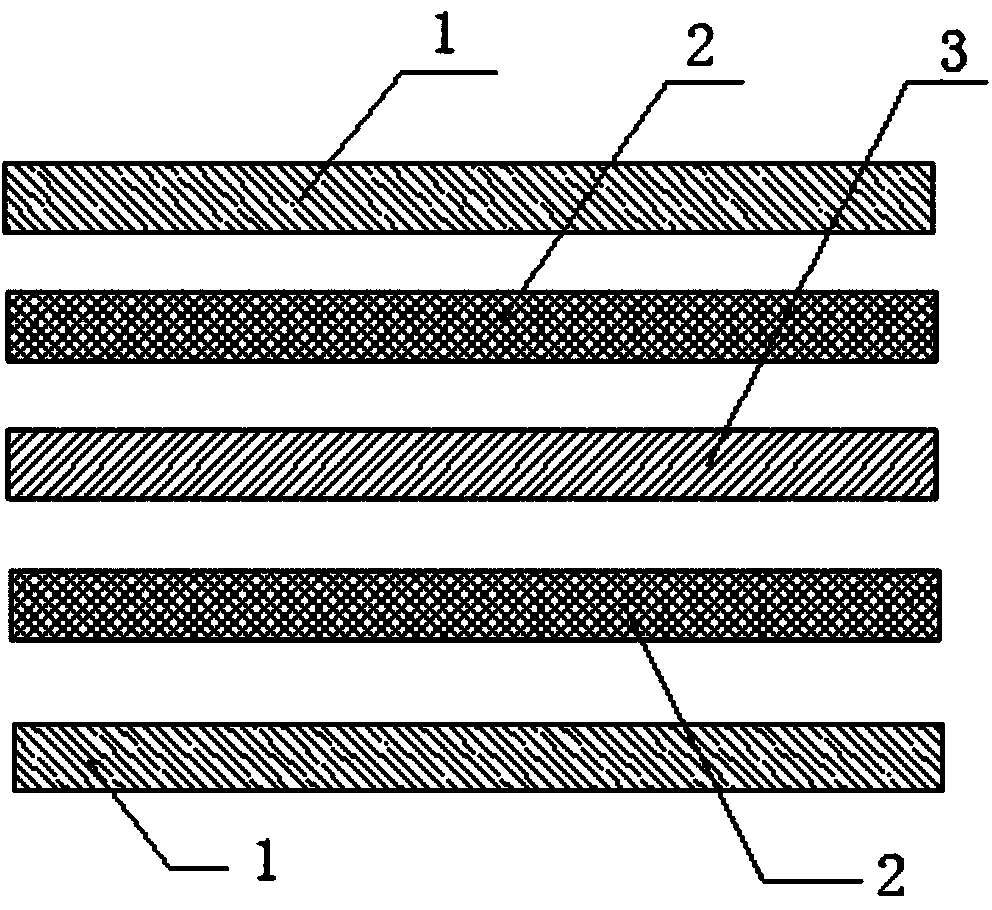

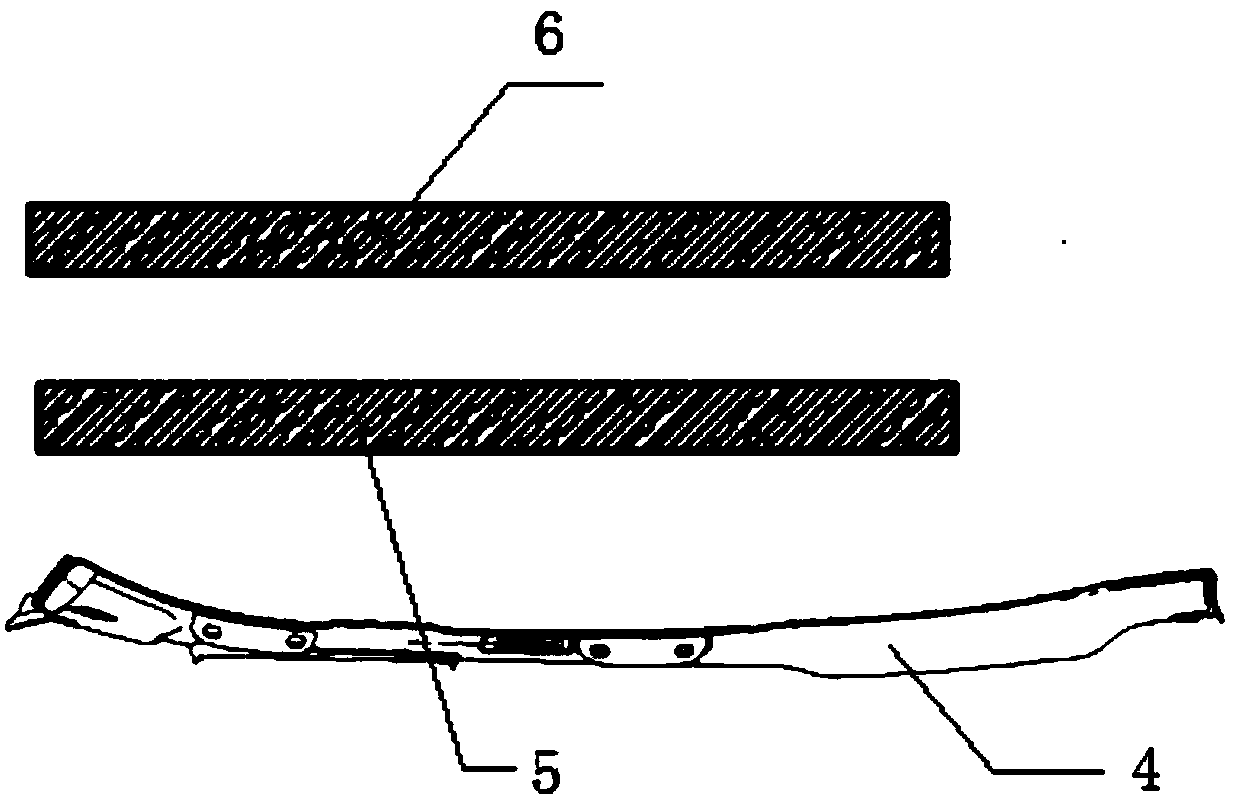

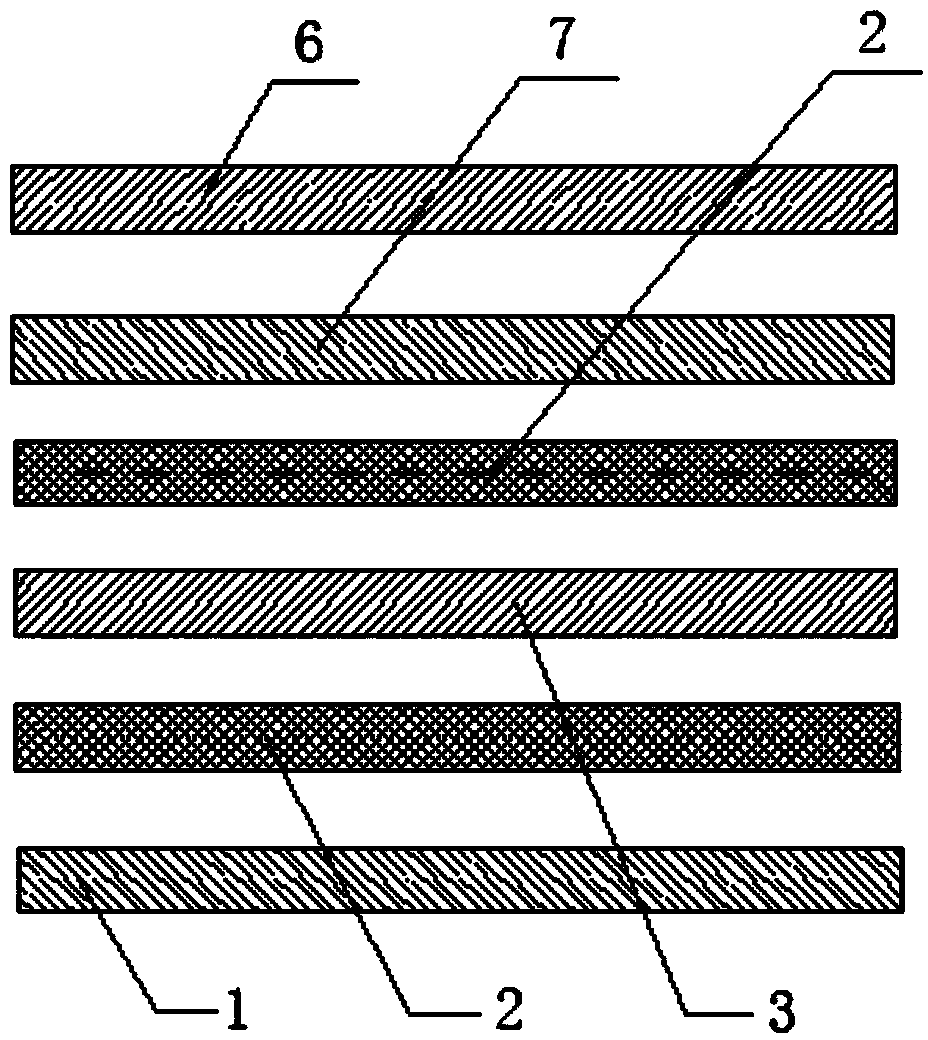

Novel vehicle roof and production process thereof

InactiveCN103921504AReduce a lot of volatilizationReduce VOC performanceLaminationLamination apparatusGlass fiberProduction rate

The invention provides a novel vehicle roof, which is formed by sequentially combining a composite knitted fabric, a fiberglass mat, a foam plate, another fiberglass mat and a bottom-layer non-woven fabric from top to bottom by adhesive films. The invention also provides a process for producing the novel vehicle roof. According to the production process, the advantages of simple procedure, high production rate and the like of a dry forming process and the advantages of roof forming performance higher than that of the dry forming process, lightweight roof and the like of a wet forming process are combined, namely the production process is used for forming the novel vehicle roof under a dry condition in a wet forming way (namely a cold material and a hot die). The VOC (volatile organic compound) performance of the roof is weakened, and the NVH (noise vibration and harshness) performance of the roof is improved; the novel vehicle roof and the production process have the advantages of high product forming performance, lightweight product, capability of improving the production rate of the product, less environmental pollution and the like.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

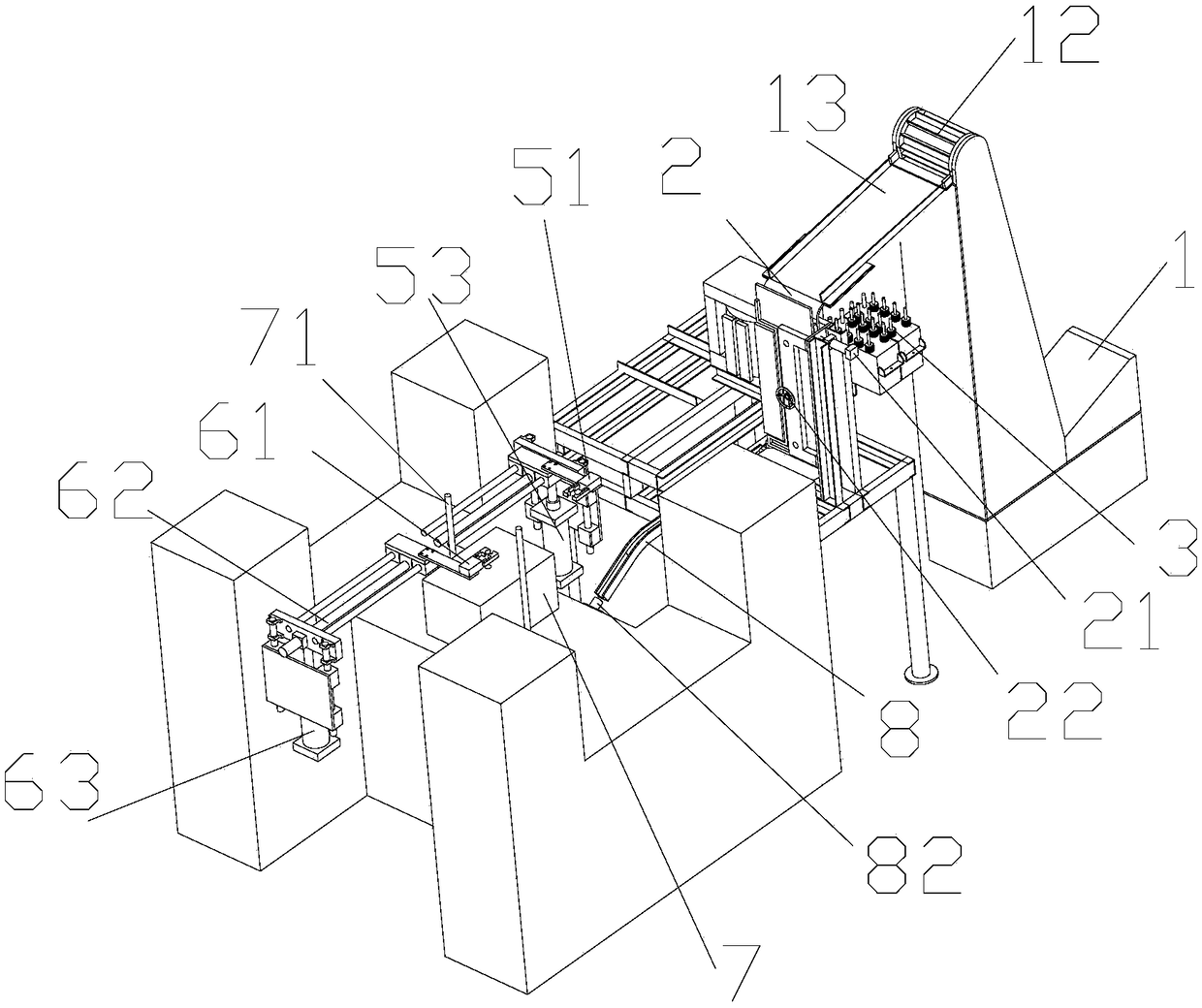

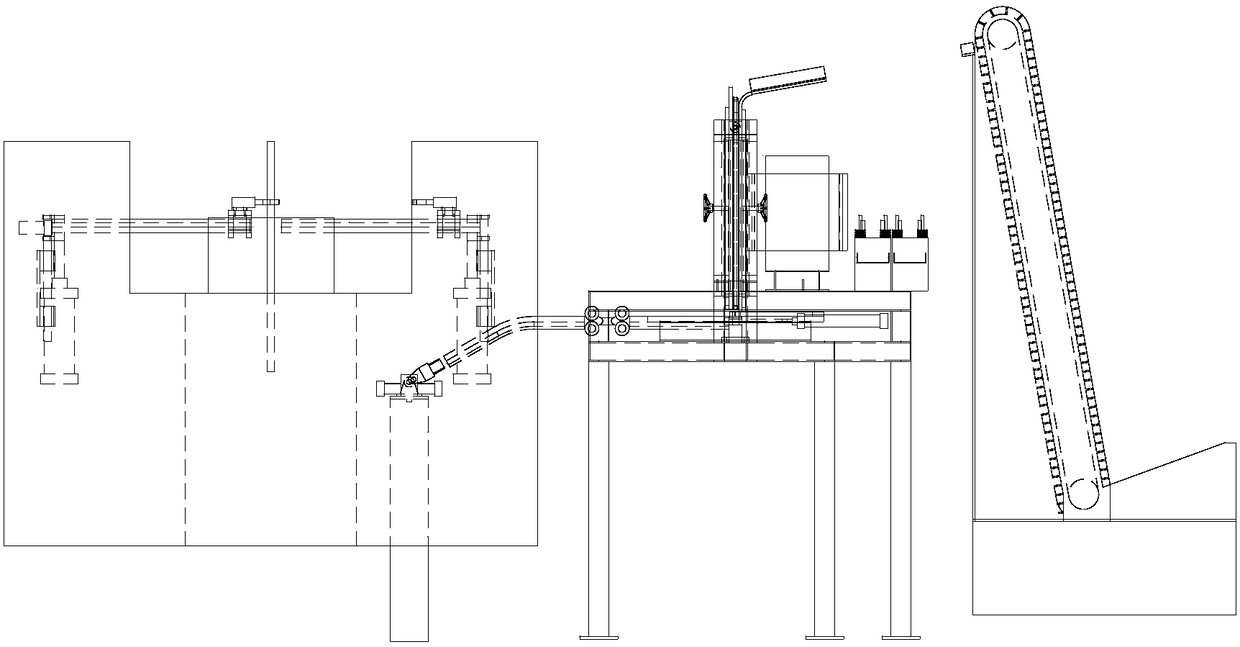

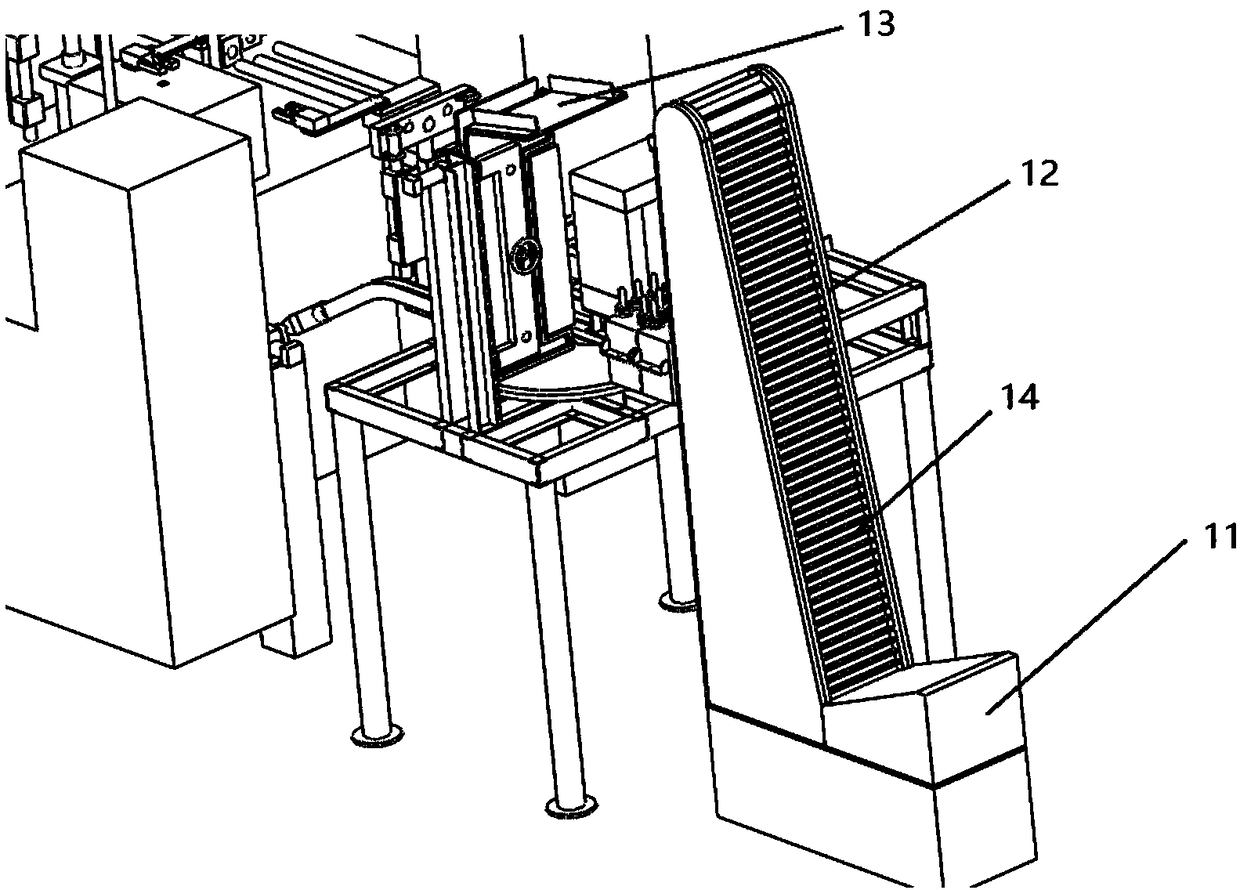

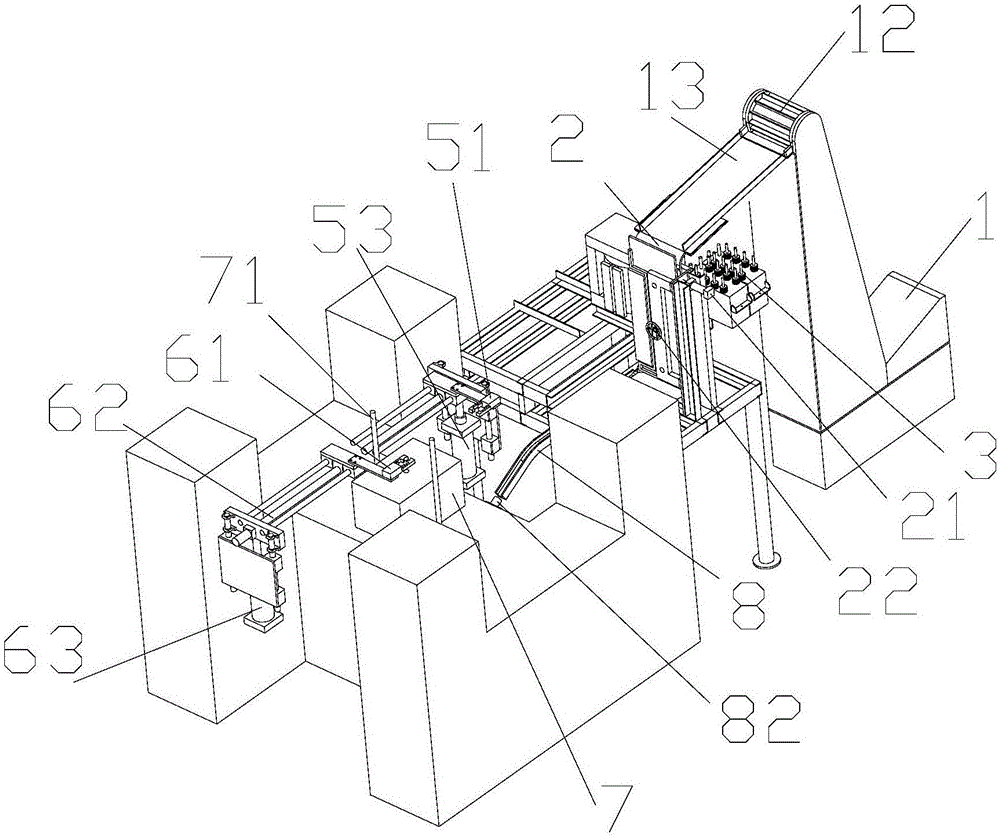

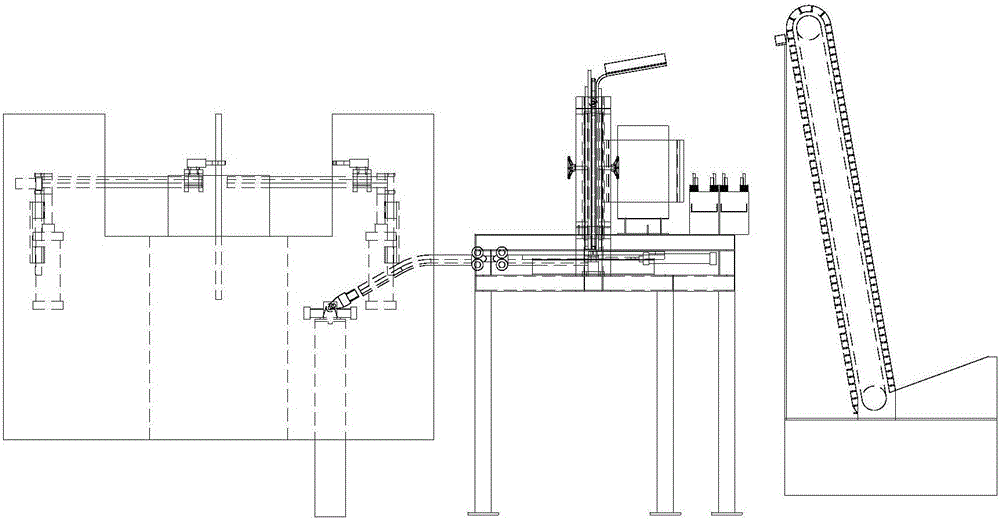

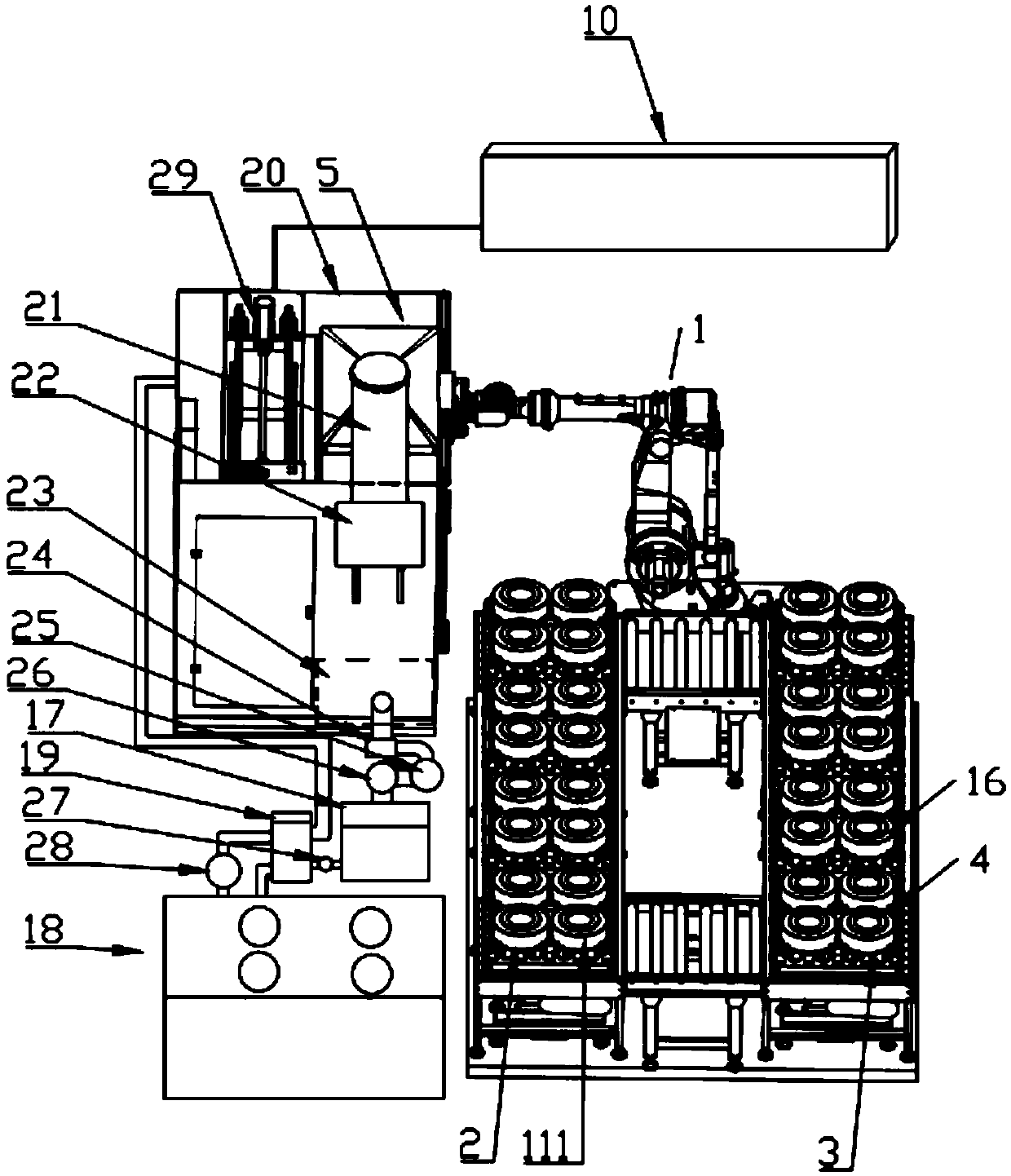

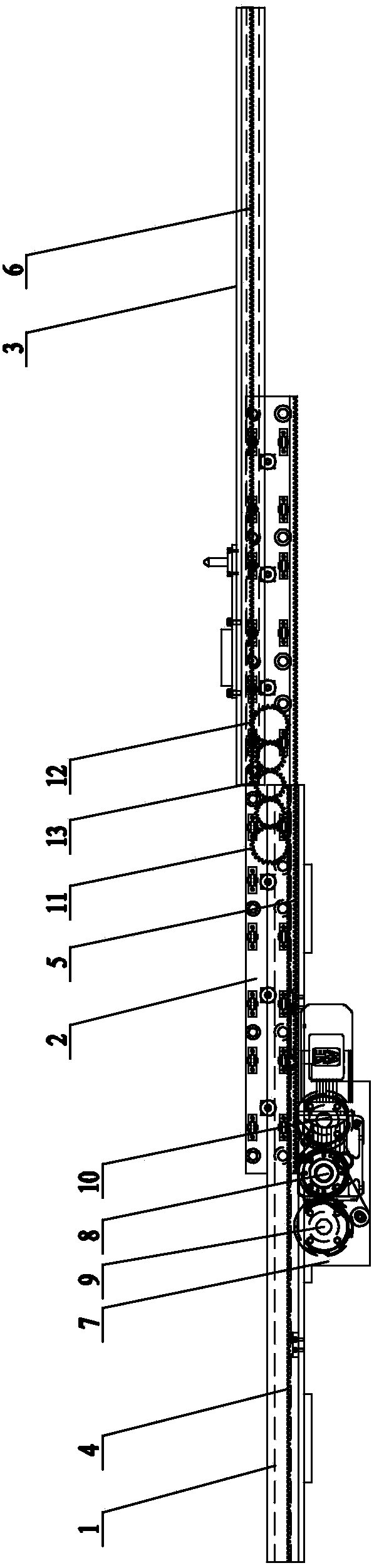

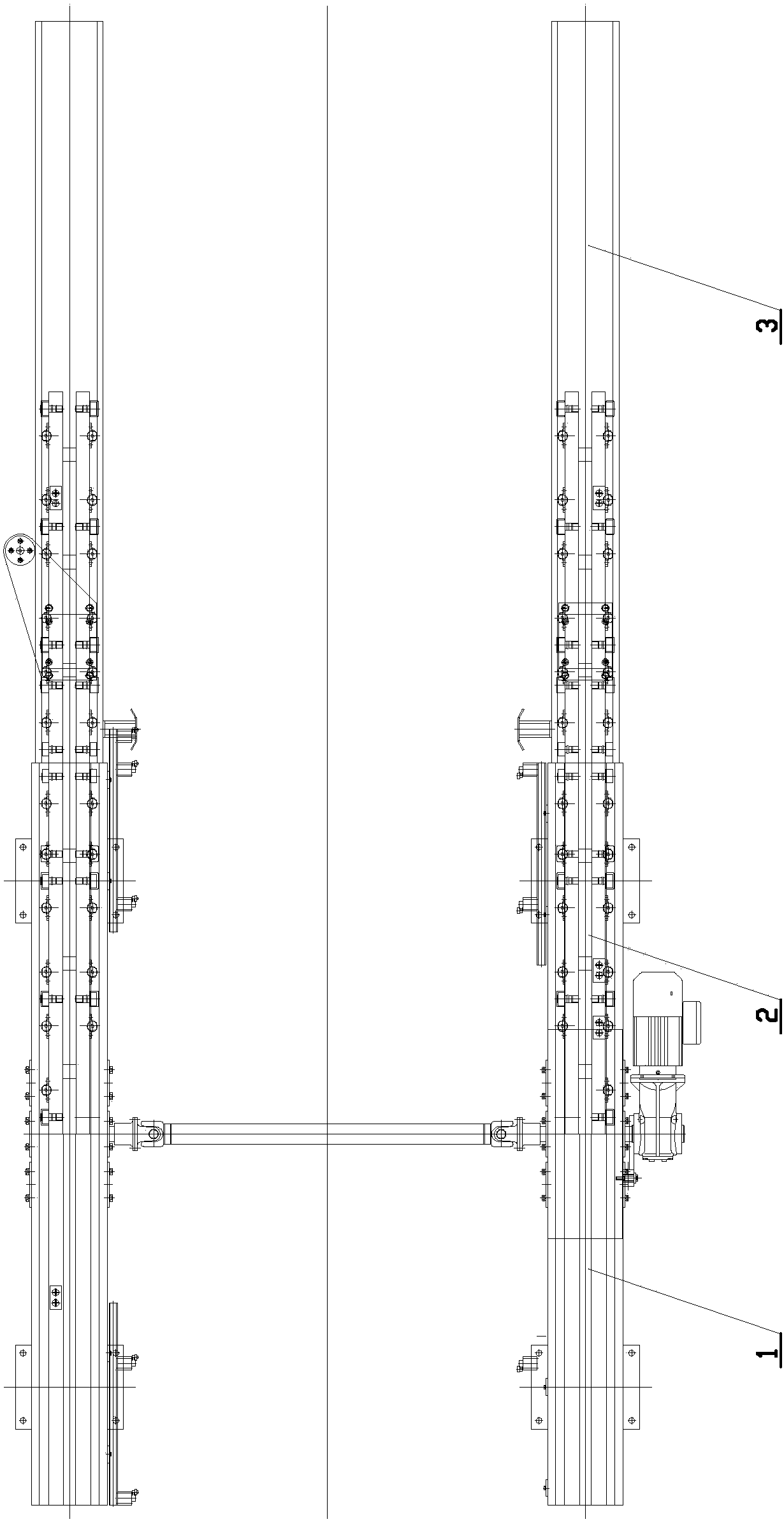

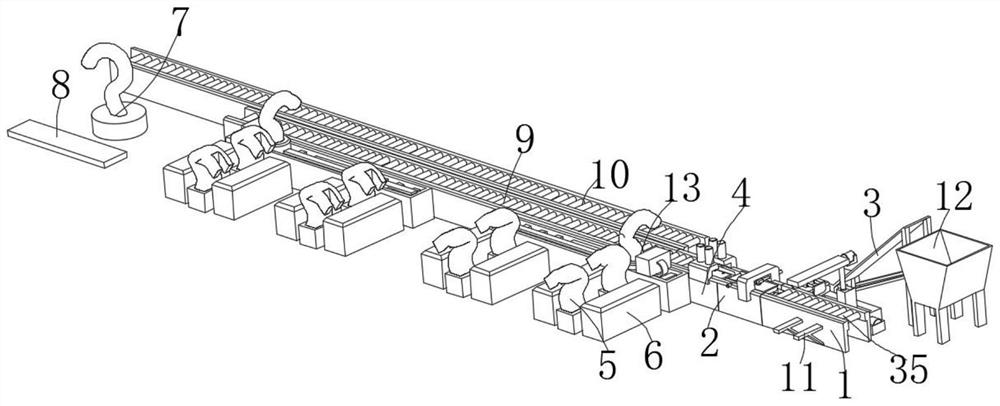

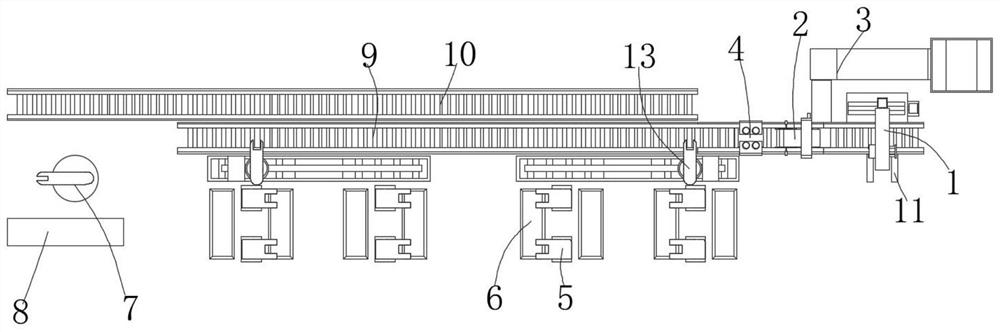

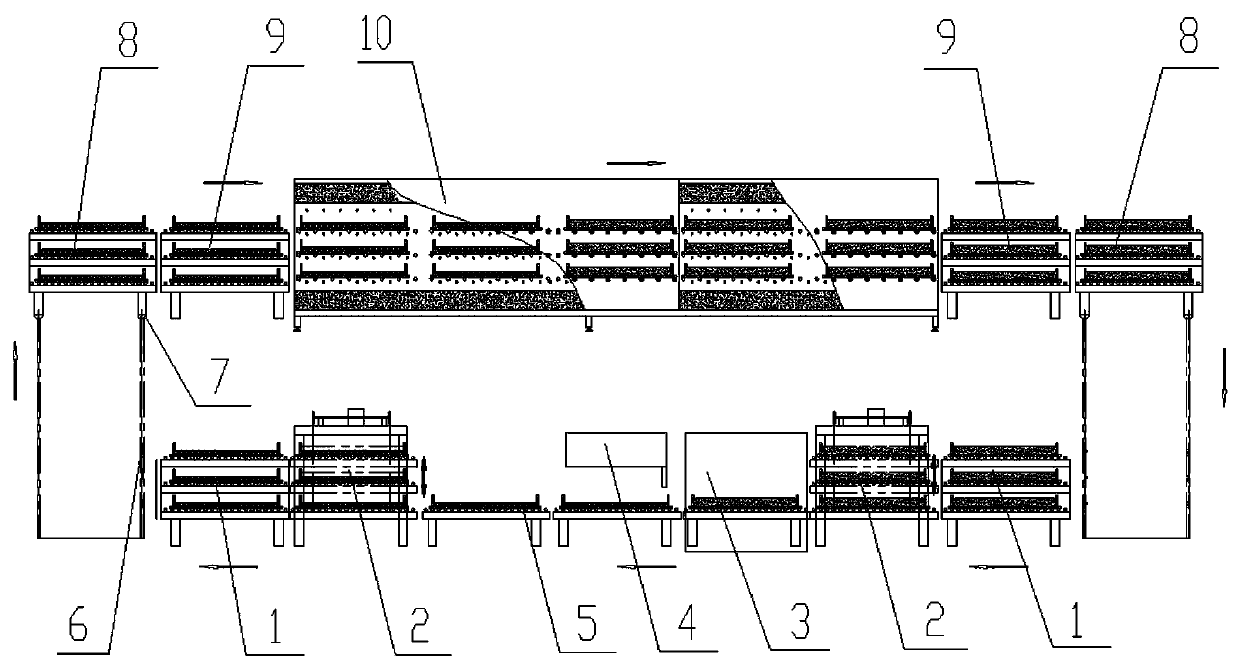

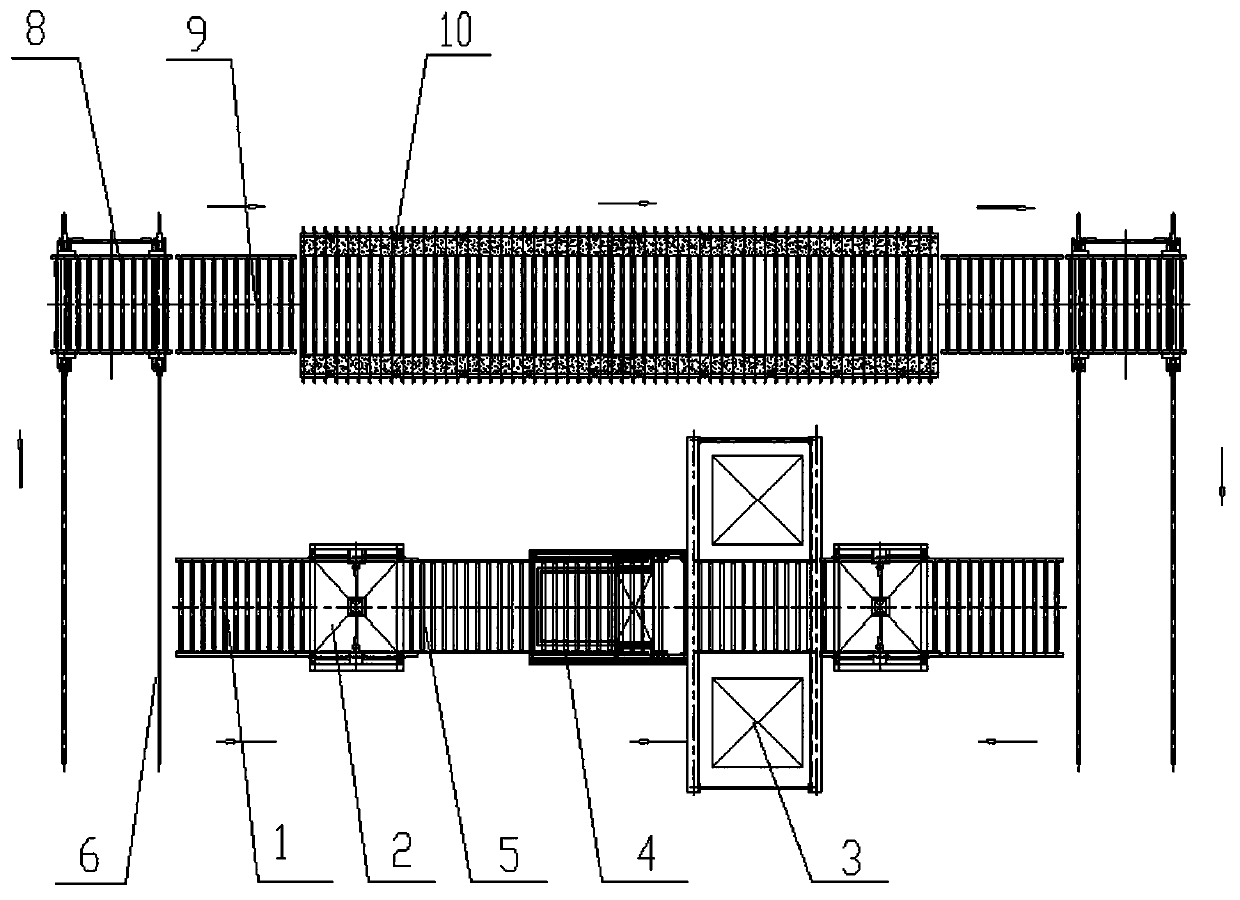

Fully automatic hot pier head production system for railway spiral spikes

ActiveCN106238663BReduce pollutionReduce in quantityForging/hammering/pressing machinesHandling devicesCircular discPunch press

The invention discloses a fully automatic hot upset head production system for railway screw spikes. The fully automatic hot upset head production system comprises a heating device and a grasping device, wherein the heating device comprises an automatic feeding machine, a medium-frequency heating groove, a medium frequency heating power supply and a rotation pulsation feeding mechanism; the discharging end of the automatic feeding machine is arranged at a notch formed in the top of the medium-frequency heating groove; the medium frequency heating power supply is connected with and controls the medium frequency heating groove; the rotation pulsation feeding mechanism is in a circular disc shape and is arranged at a notch formed in the bottom of the medium frequency heating groove; the grasping device comprises a first mechanical hand, a first guide rail, a second mechanical hand, a second guide rail, an upset head mold and a feeding slide groove; the inlet of the feeding slide groove is formed in the rotation pulsation feeding mechanism; the first guide rail and the second guide rail are arranged in the same line; in addition, the upset head mold is arranged between the first guide rail and the second guide rail, and is provided with a punching bed material jacking mechanism. The fully automatic hot upset head production system has the beneficial effect that the fully automatic production is realized.

Owner:ANHUI CHAOHU CASTING FACTORY

Forging method and forging device of twice forcing molten soup forging wheel

ActiveCN103084559AAvoid damageMeet mechanical performance requirementsRefined grainsMechanical property

The invention relates to a forging method and a forging device of a twice forcing molten forging wheel. The forging method of the twice forcing molten forging wheel is conducted circularly by the following steps: (1) materials smelting; (2) heat preservation deposit; (3) molten soup degassing; (4) the molten soup being injected into a lower die; (5) main piston forcing and pressure maintaining; (6) auxiliary piston forcing and pressure maintaining; (7) die sinking; (8) product transfer and deposit; (9) die cooling. Product quality is improved and molten soup dosage is reduced, and twice forcing is conducted to further improve inner structure refined grain of metals, and therefore the forging method and the forging device of the twice forcing molten forging wheel has the advantages of improving product mechanical property, tensile property and other overall properties, shortening product production time, increasing output, improving production efficiency and ex-factory percent of pass of products.

Owner:TIANJIN NANUO MACHINERY MFG

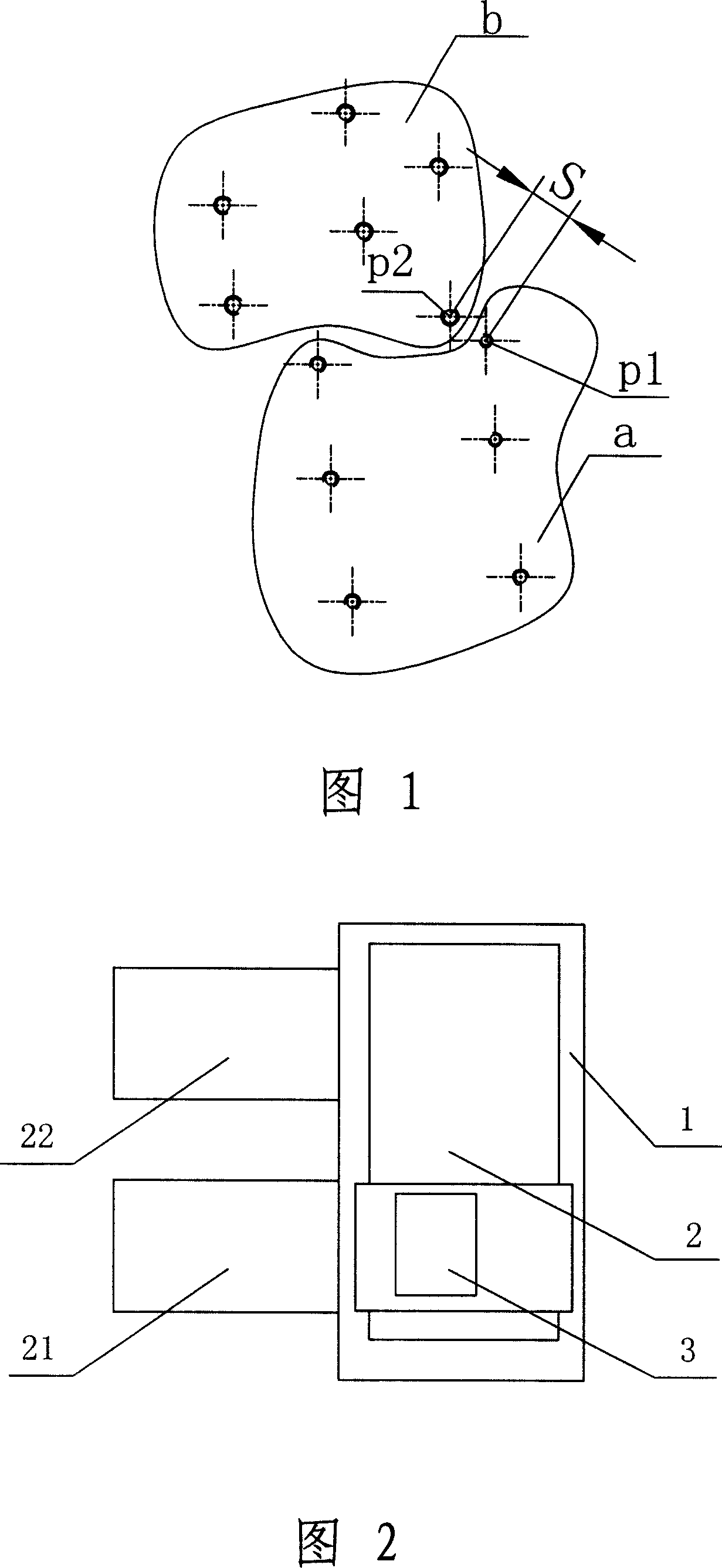

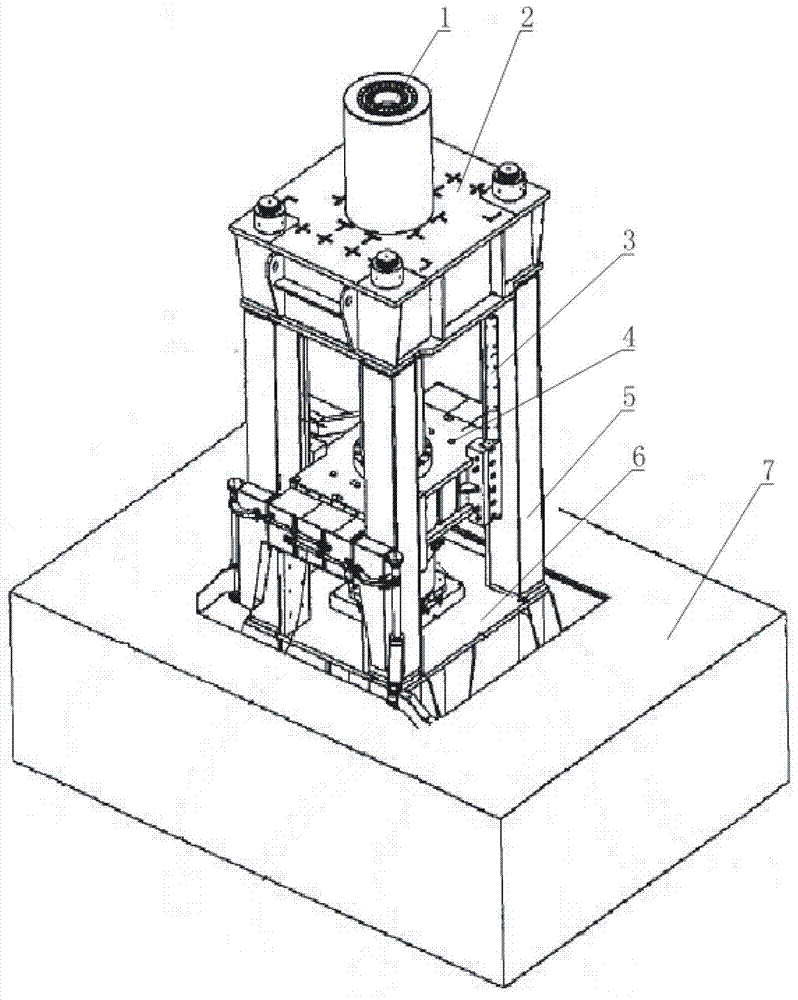

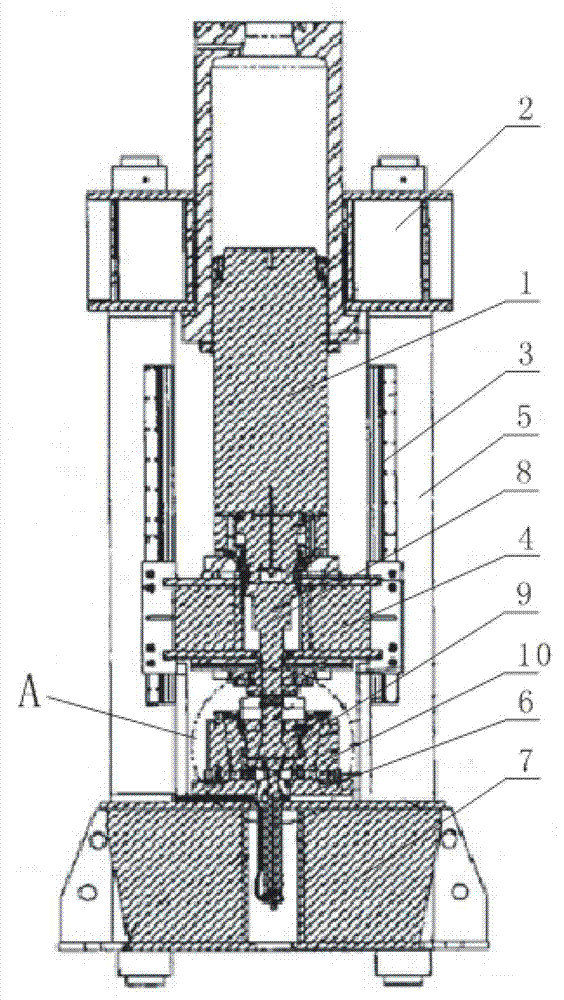

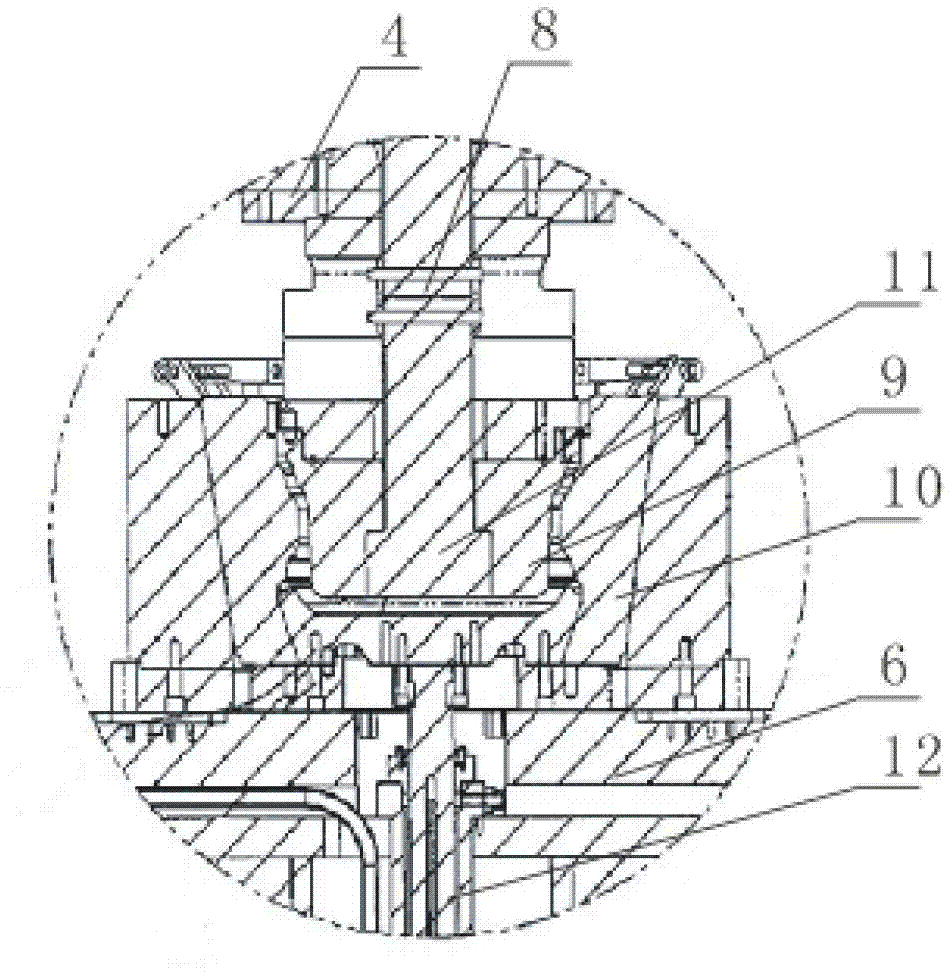

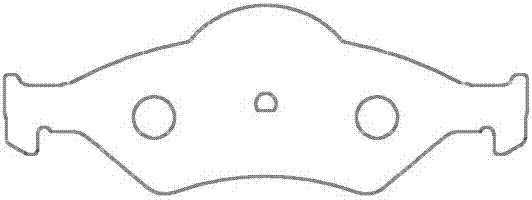

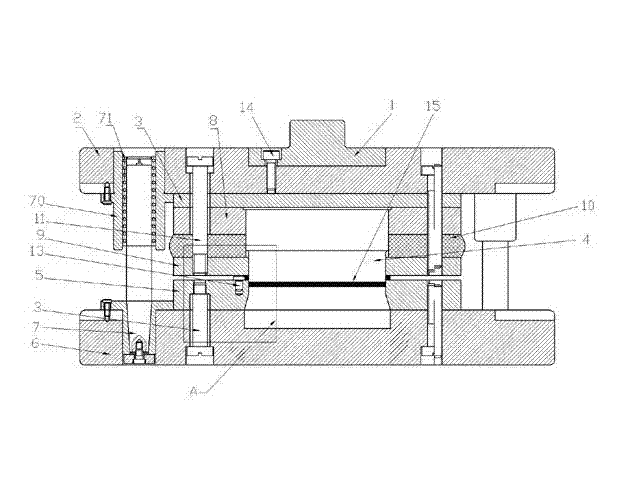

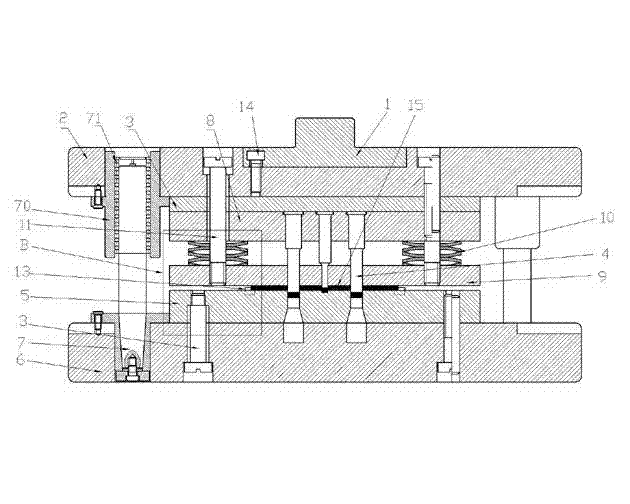

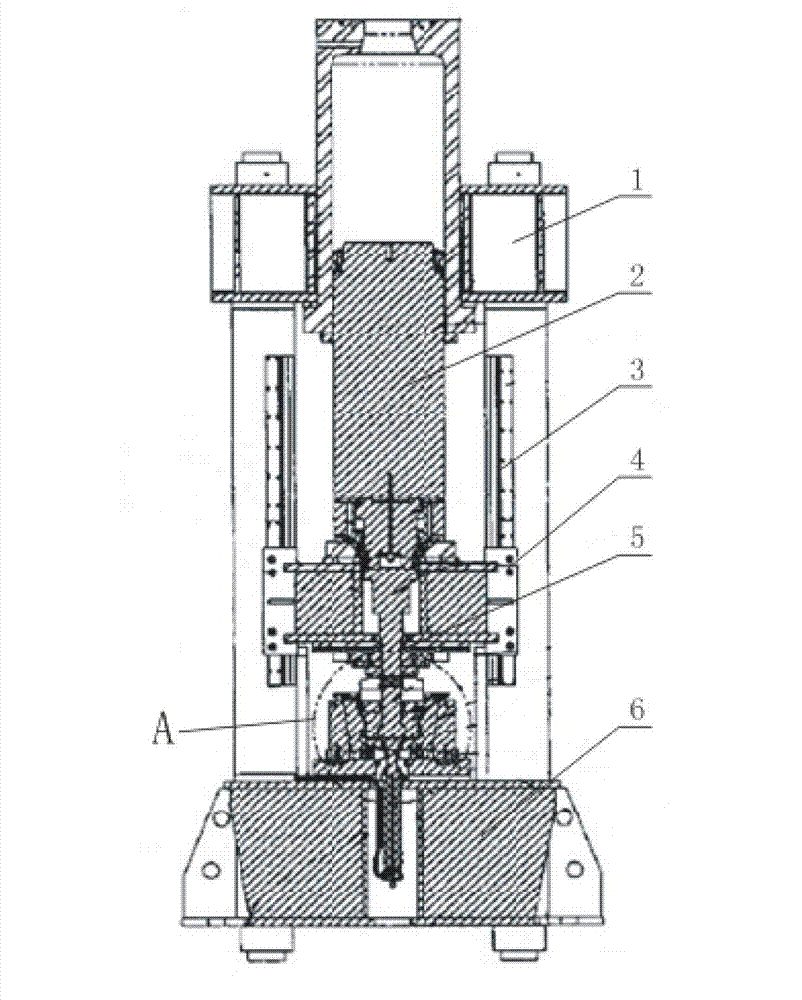

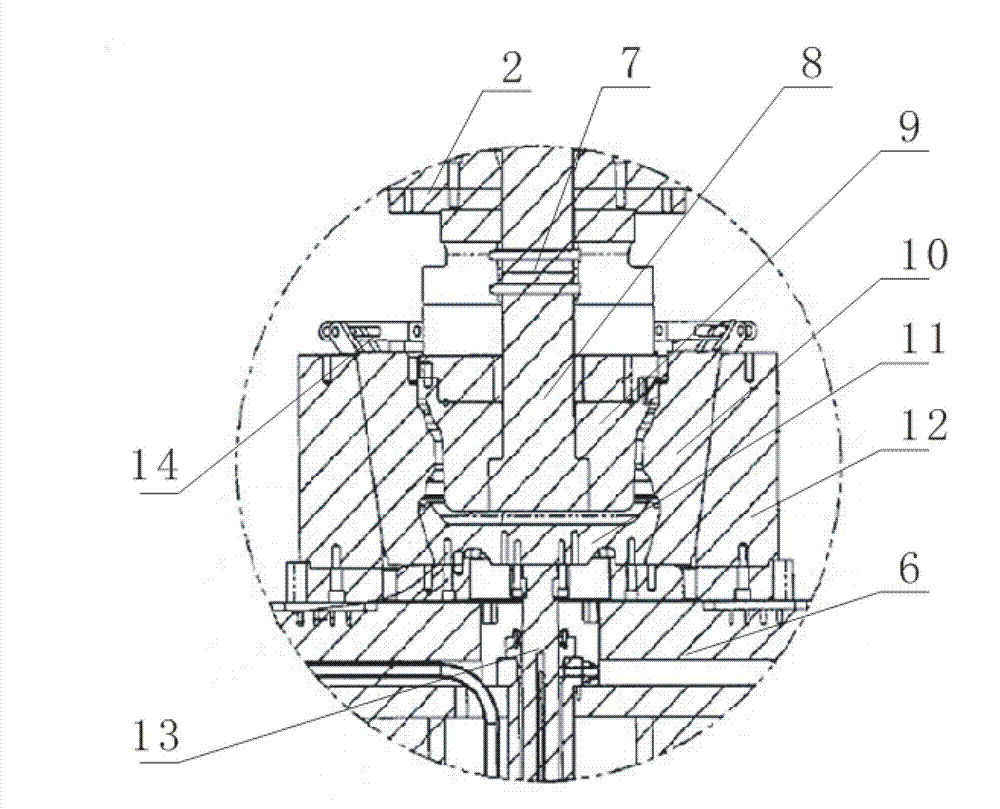

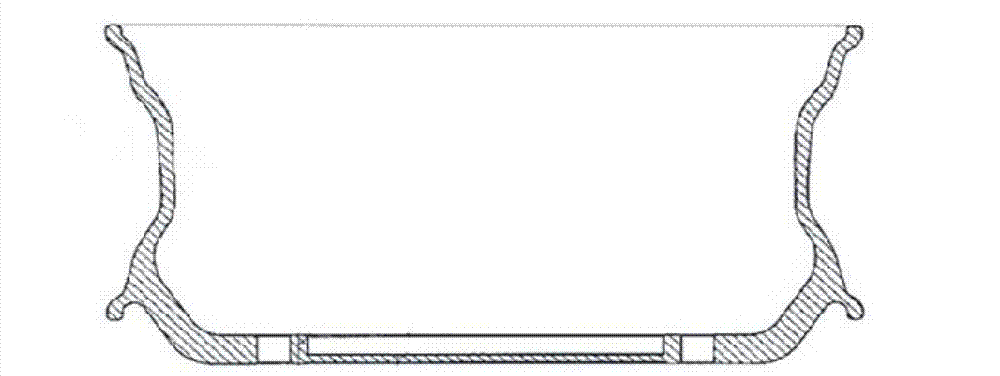

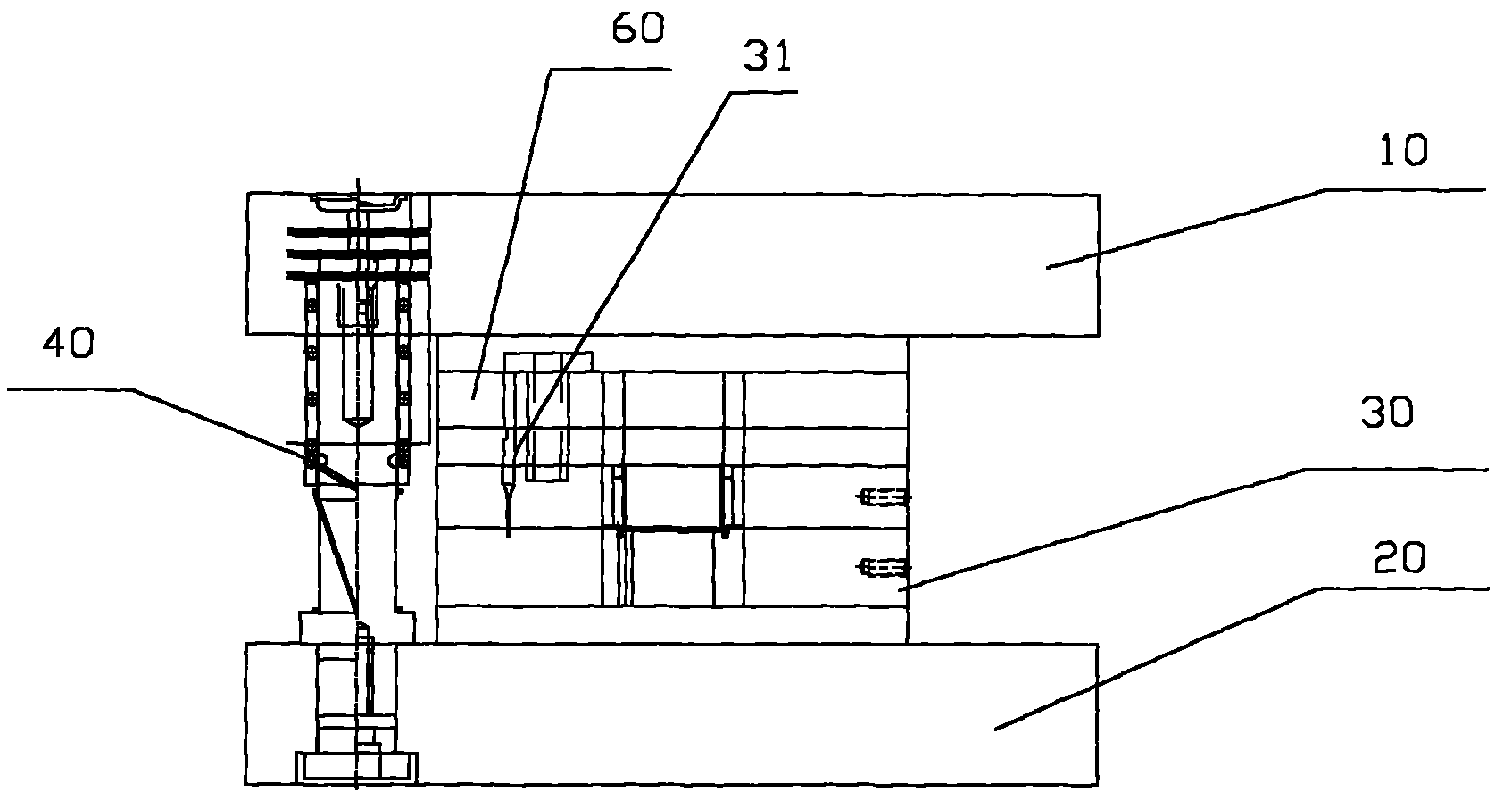

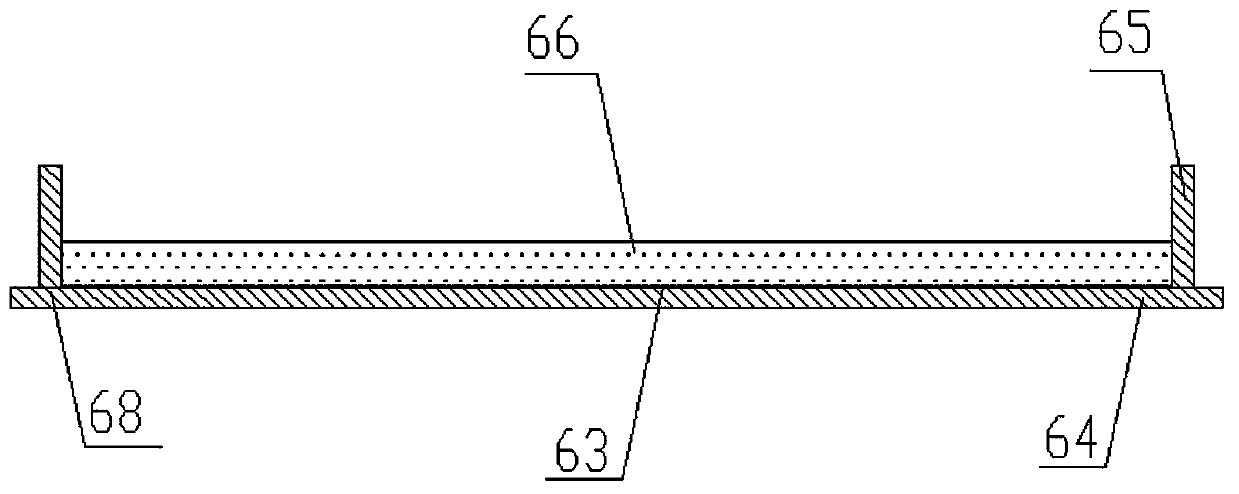

Fine stamping die and fine stamping method of automobile disc brake pad steel back

The invention discloses and provides a fine stamping die and a fine stamping method of an automobile disc brake pad steel back. The fine stamping die of the automobile disc brake pad steel back comprises a die handle (1), a punch set (2), an upper base plate (3), a core die (4), a cavity die (5) and a die set(6), wherein the die handle (1) is arranged on the punch set (2) and the cavity die (5) is arranged on the die set(6); the fine stamping die of the automobile disc brake pad steel back comprises an elastic discharging device as well; the punch set (2), the upper base plate (3) and the elastic discharging device are sequentially connected through a screw (11), the core die (4) penetrates and is connected inside the elastic discharging device in a sliding mode, and the core die (4) and the elastic discharging device are both located above the cavity die (5). Based on the fine stamping die, the fine stamping method of the automobile disc brake pad steel back has the advantages of being high in efficiency, low in energy consumption, capable of effectively improving the quality of the product and low in production cost and being capable of effectively removing the defect caused by the normal stamping method.

Owner:ZHUHAI HUALI FRICTION MATERIAL

Fully automatic hot upset head production system for railway screw spikes

ActiveCN106238663AReduce pollutionReduce in quantityForging/hammering/pressing machinesHandling devicesCircular discPunch press

The invention discloses a fully automatic hot upset head production system for railway screw spikes. The fully automatic hot upset head production system comprises a heating device and a grasping device, wherein the heating device comprises an automatic feeding machine, a medium-frequency heating groove, a medium frequency heating power supply and a rotation pulsation feeding mechanism; the discharging end of the automatic feeding machine is arranged at a notch formed in the top of the medium-frequency heating groove; the medium frequency heating power supply is connected with and controls the medium frequency heating groove; the rotation pulsation feeding mechanism is in a circular disc shape and is arranged at a notch formed in the bottom of the medium frequency heating groove; the grasping device comprises a first mechanical hand, a first guide rail, a second mechanical hand, a second guide rail, an upset head mold and a feeding slide groove; the inlet of the feeding slide groove is formed in the rotation pulsation feeding mechanism; the first guide rail and the second guide rail are arranged in the same line; in addition, the upset head mold is arranged between the first guide rail and the second guide rail, and is provided with a punching bed material jacking mechanism. The fully automatic hot upset head production system has the beneficial effect that the fully automatic production is realized.

Owner:ANHUI CHAOHU CASTING FACTORY

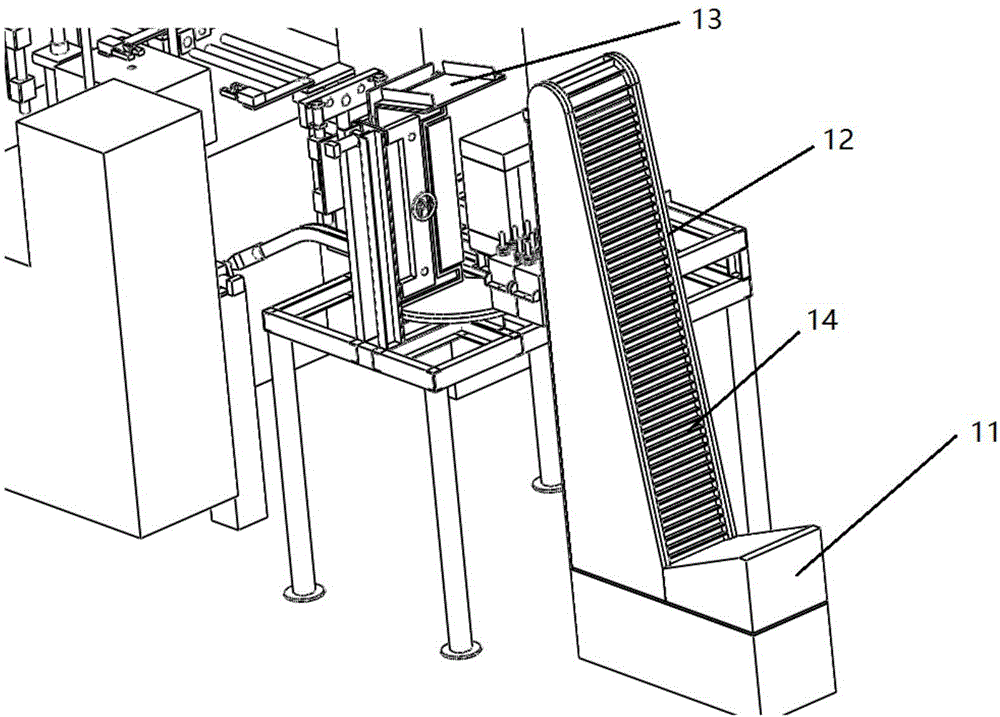

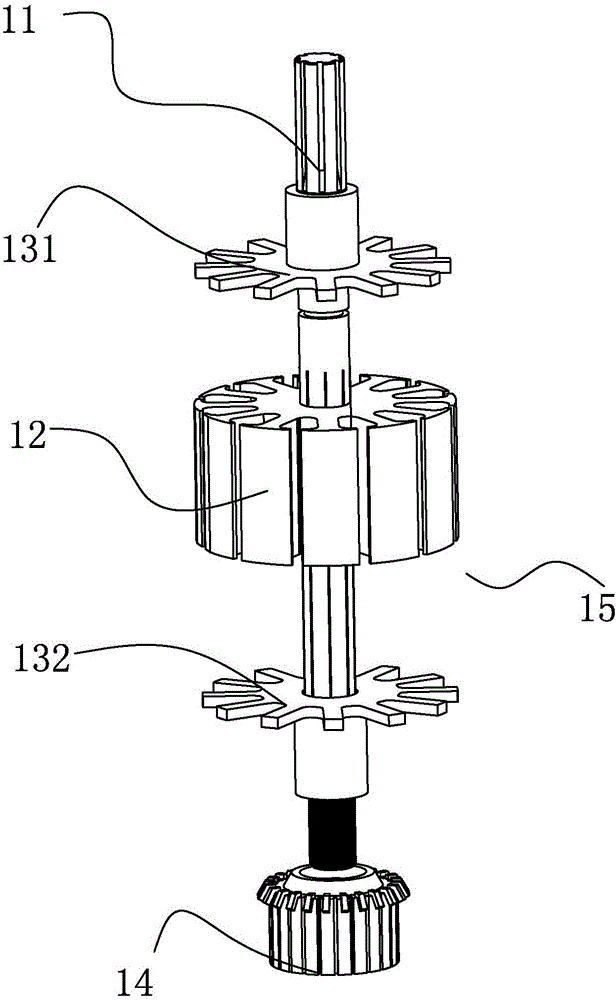

Series excited motor rotor assembly machine

InactiveCN106100252AEasy to take outSimple structureManufacturing stator/rotor bodiesEngineeringAssembly machine

The invention relates to the series excited motor rotor assembly field, and discloses a series excited motor rotor assembly machine. A shaft storage device stores a shaft. A shafting-mounting and shaft-pressing device takes a shaft out from the shaft storage device out and presses the shaft into an iron core. A baffle feeding device conveys an upper baffle and a lower baffle and provides for the rotor assembly. A baffle pressing device installs the upper baffle and the lower baffle on the iron core with the shaft. A direction device pressing device installs a direction device on the iron core provided with the shaft, the upper baffle, and the lower baffle. A discharging device discharges the assembled rotor and conveys the rotor to the next process. The manual assembly is omitted, and the production beat is fast. The production efficiency is high and the production cost is low.

Owner:江门市维凯智能装备有限公司

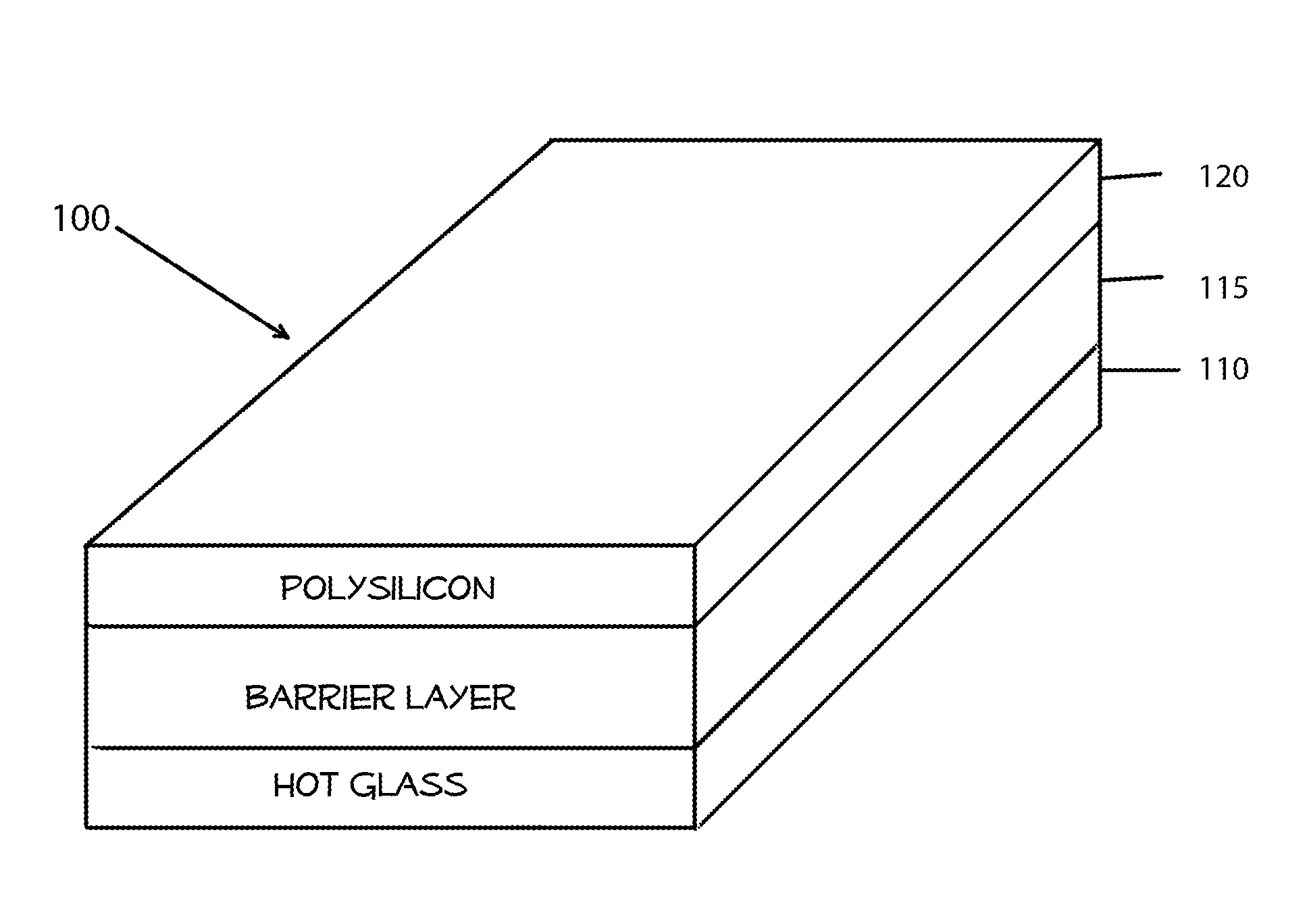

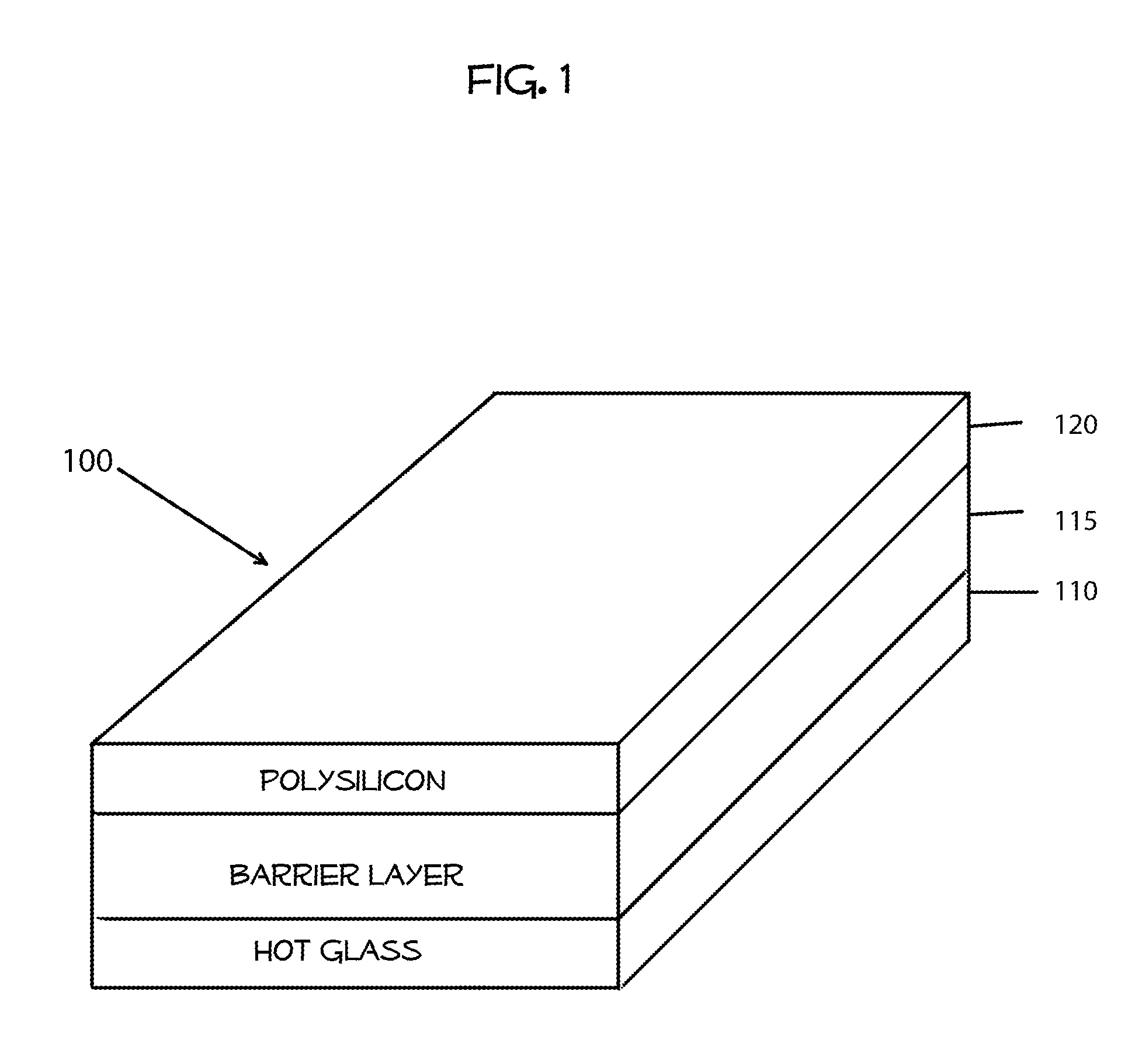

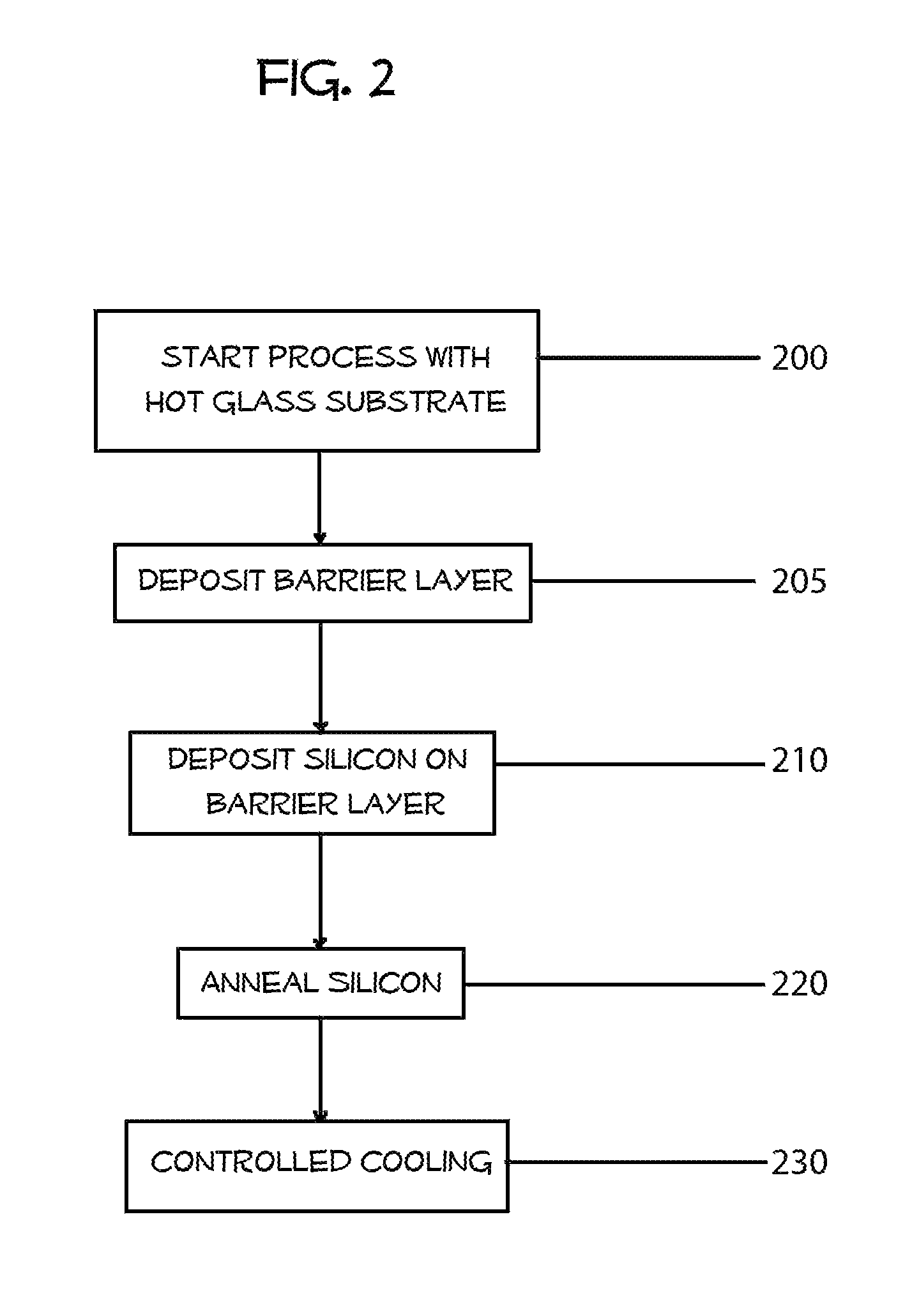

Method for producing high temperature thin film silicon layer on glass

InactiveUS8129215B1Faster transistor speedLow costSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayImage resolution

A method for producing a High Temperature Thin Film Layer On Glass (HTTFLOG) of silicon, which is a precursor component of thin film transistors (TFTs). The invention described here is a superior method of fabricating HTTFLOG precursor structures or components for liquid crystal displays (LCDs) with quicker production time and lower cost of manufacture while enabling a groundbreaking increase in small and large screen resolution. This invention is a new sub-assembly intended for original equipment manufacturer (OEM) consumption and inclusion in display products.

Owner:CAMPBELL JAMES P +3

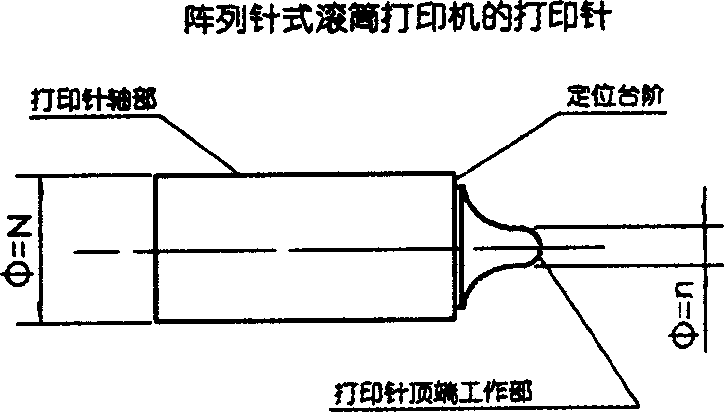

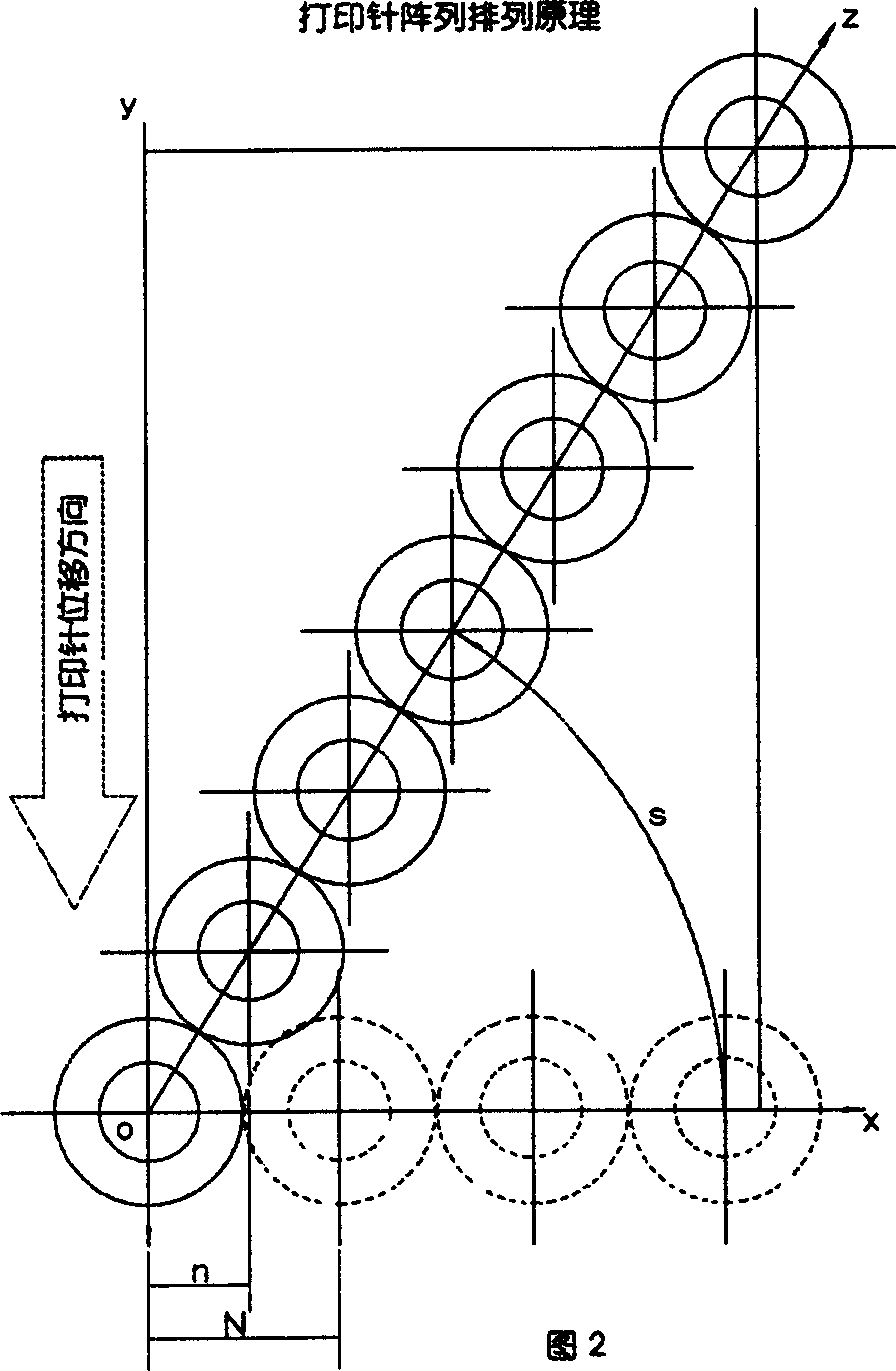

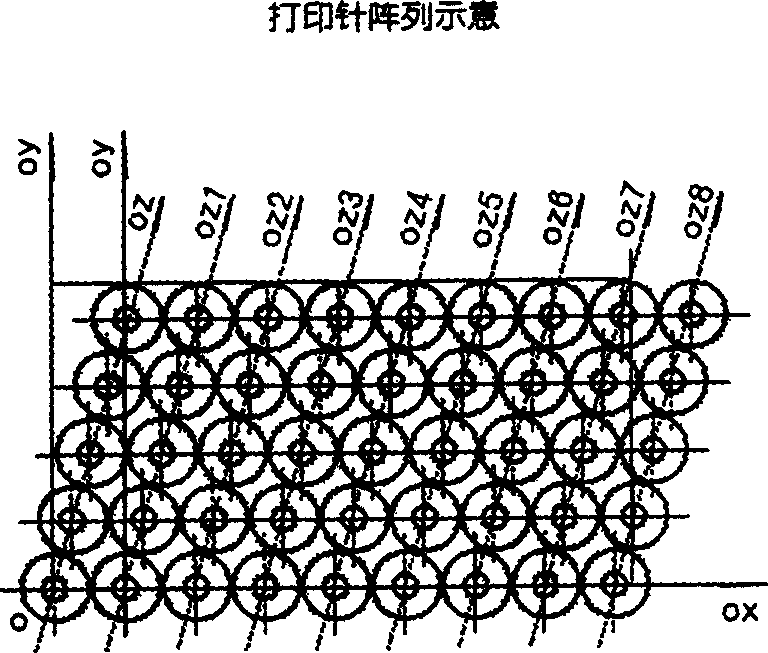

Design principle for array needle type rolling drum printer

The present invention relates to the design principle of one printer capable of performing high resolution monochromic and color print in common paper with convertional offset printing ink. It has a basic structure comprising five core parts including array needle type printing roll and electromagnetic driving assembly, ink painting mechanism, transferring rubber roll, paper feeding mechanism, and frame and motor drawing mechanism; and it is operated by means of printing management software. The printer may suit different printing requirement. Printers with different stylus arrangement and corresponding electromagnetic driving assembly may be designed. The printer has no theoretic upper limit of resolution and may reach the four-colour printing effect similar to a offset press.

Owner:和近建

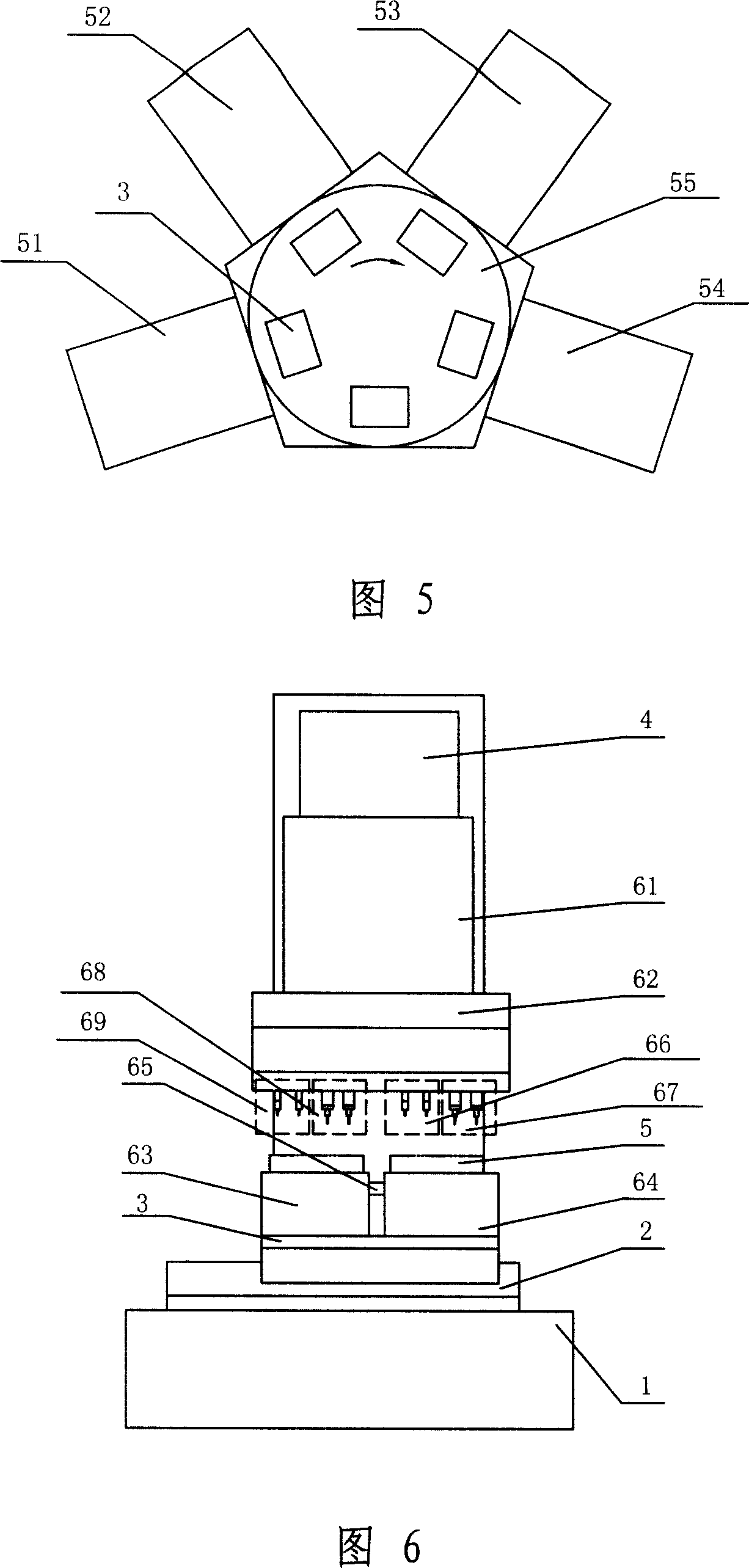

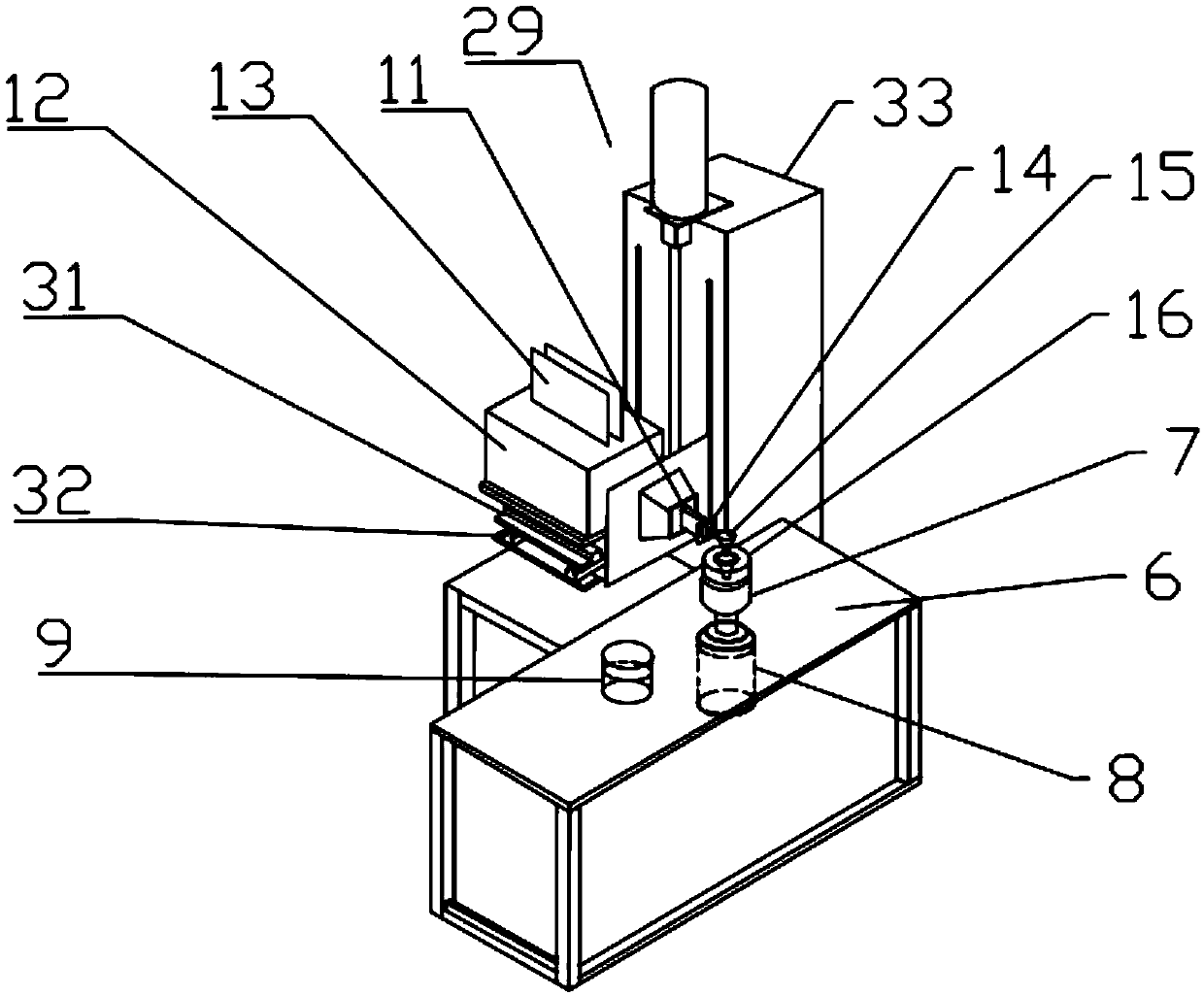

Full-automatic induction quenching machine tool for conical face of front machine cylinder of molding machine and circuit protecting method

PendingCN109652634AImprove machine adaptabilityFast production timeElectronic switchingFurnace typesMachine toolTransformer

The invention provides a full-automatic induction quenching machine tool for the conical face of a front machine cylinder of a molding machine. The machine tool comprises an automatic feeding and conveying roller way, an industrial robot, an automatic induction quenching chamber, a loading platform, an IGBT transistor power source and a quenching liquid circular cooling system. The automatic induction quenching chamber is formed by combining a molding machine front machine cylinder loading lathe bed, an automatic lifting induction heating, spraying and quenching device, a quenching transformer, and an inductor installed on a transition bar of the quenching transformer. The lathe bed is formed by a molding machine front machine cylinder loading platform and a rotating tool clamp. The automatic lifting induction heating, spraying and quenching device is formed by a quenching transformer, a compensation capacitor, a power switching device, an accessory circuit and a water and electricityintegration quick-changing induction device. The inductor and the water and electricity integration quick-changing induction device are arranged in the conical face of the front machine cylinder of the molding machine in a suspending manner to carry out rotary induction heating or liquid spraying quenching on the conical face of the front machine cylinder of the molding machine, the industrial automatic robot takes the front machine cylinder from a pre-locating part and places the front machine cylinder to a rotary drive part, and the front machine cylinder of the molding machine is taken fromthe rotary drive part, and transferred and placed on the automatic feeding and conveying roller way.

Owner:十堰高周波科工贸有限公司

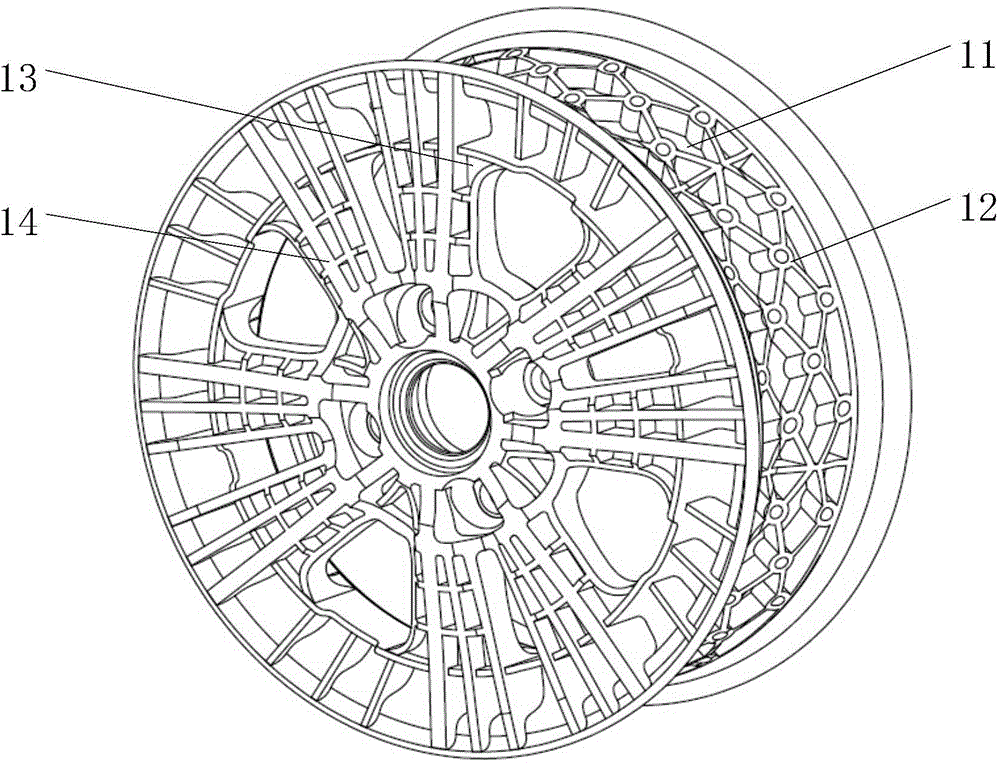

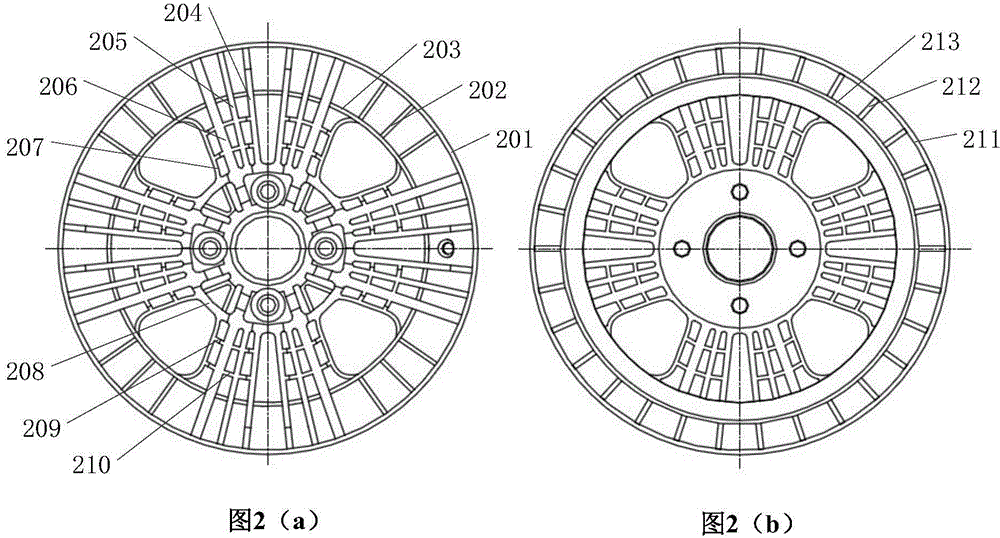

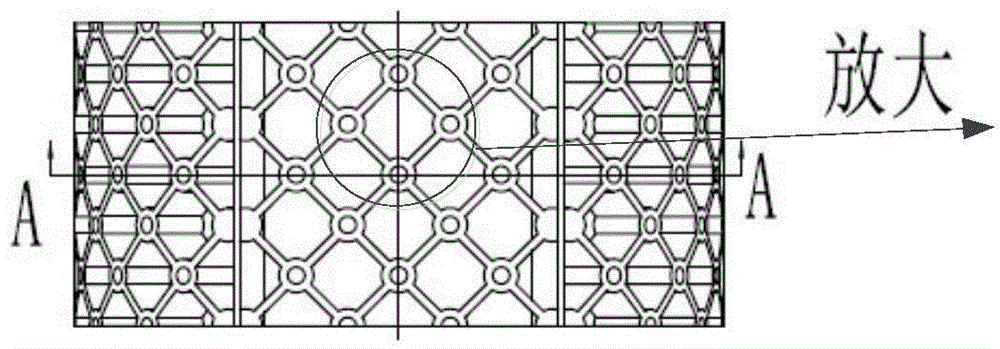

Injection-molded thermoplastic composite vehicle wheel

InactiveCN104085250AOvercome the disadvantage of less rigidityMeet the use requirementsNon-metallic wheel bodyContour formInjection moulding

The invention provides an injection-molded thermoplastic composite vehicle wheel. A rim of the vehicle wheel is composed of a rim base and a rim reinforcing structure. The rim base is similar to an aluminum alloy wheel rim. The rim reinforcing structure is attached to the rim base. An outer contour formed by the rim base and the rim reinforcing structure jointly can meet requirements. Bead seats on the two sides of the rim make contact with a tire. The rim reinforcing structure is designed to be located in the middle area between the two bead seats. The circumference of the rim reinforcing structure is divided into a plurality of areas. The included angle of each area is theta and corresponds to one draft direction passing through the center of the vehicle wheel, and the number of rim moulds can be changed by changing theta. The rim reinforcing structure is formed by a predetermined number of reinforcing units in a composite manufacturing mode. Each reinforcing unit is composed of two rib plates in a crossed X shape, and the intersection between the two rib plates is provided with a hollow cylinder for transition. The structure of the injection-molded thermoplastic composite vehicle wheel has a large rigidity mass ratio, so the thermoplastic composite vehicle wheel is designed to be a hollowed-out structural style, and the defect that thermoplastic composites are low in elasticity modulus is overcome.

Owner:BEIHANG UNIV

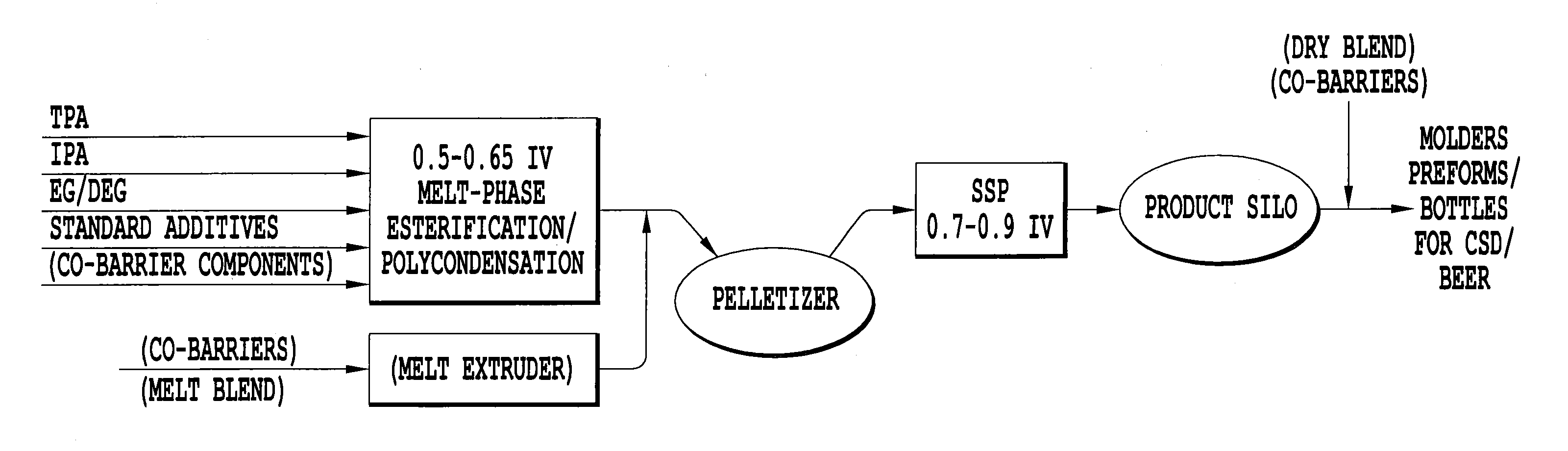

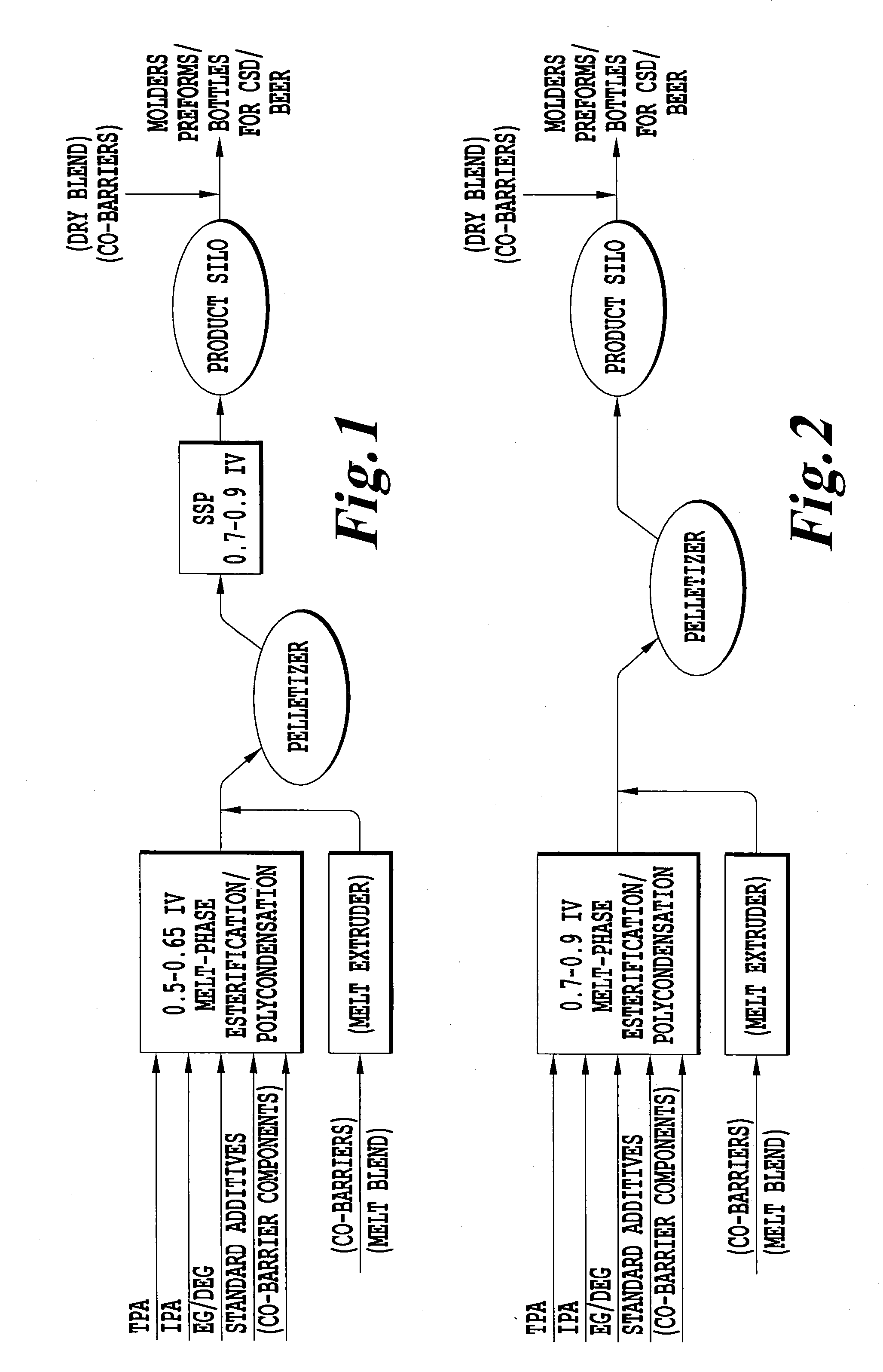

Ultra-high iv polyester for extrusion blow molding and method for its production

ActiveUS20130183470A1Reduce crystallinityUltra-high IV polyesterLayered productsBottlesPolyesterBlow molding

Owner:DAK AMERICAS LLC

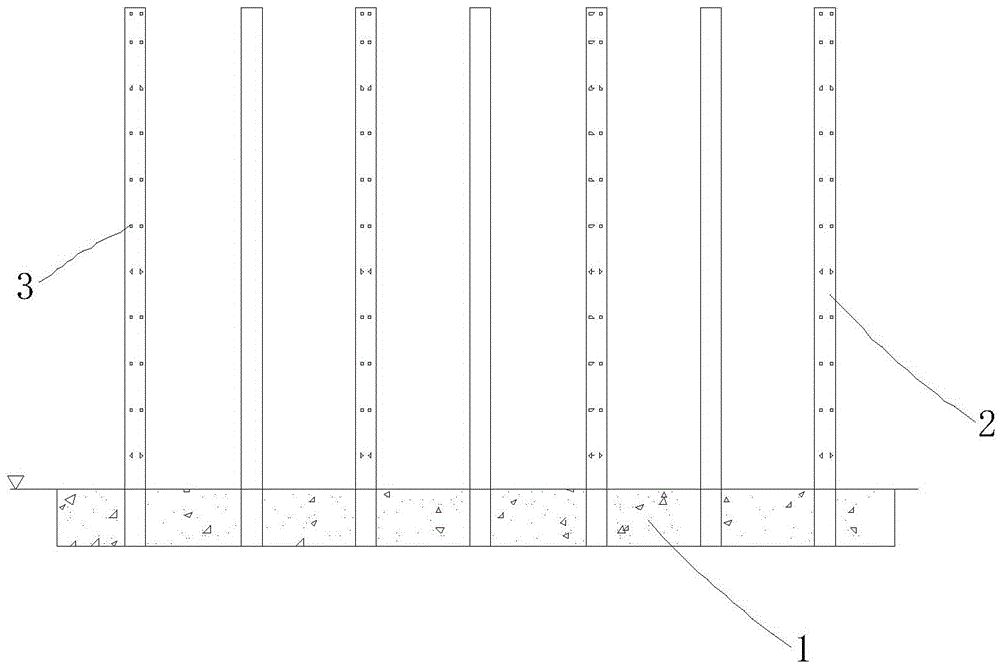

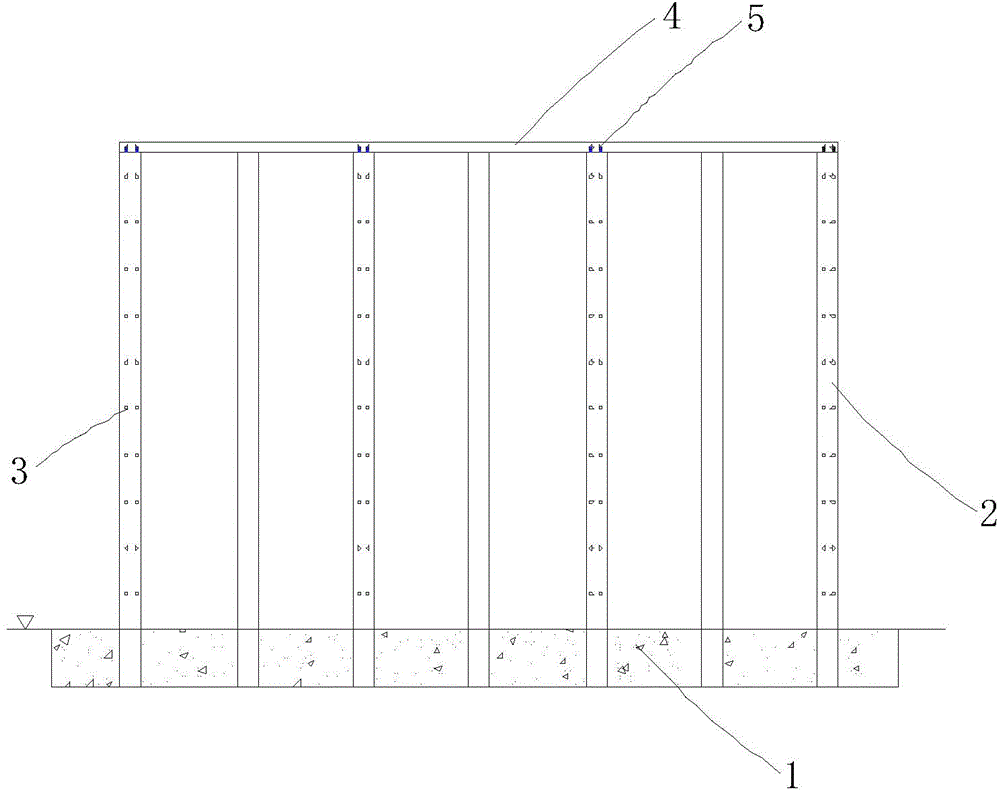

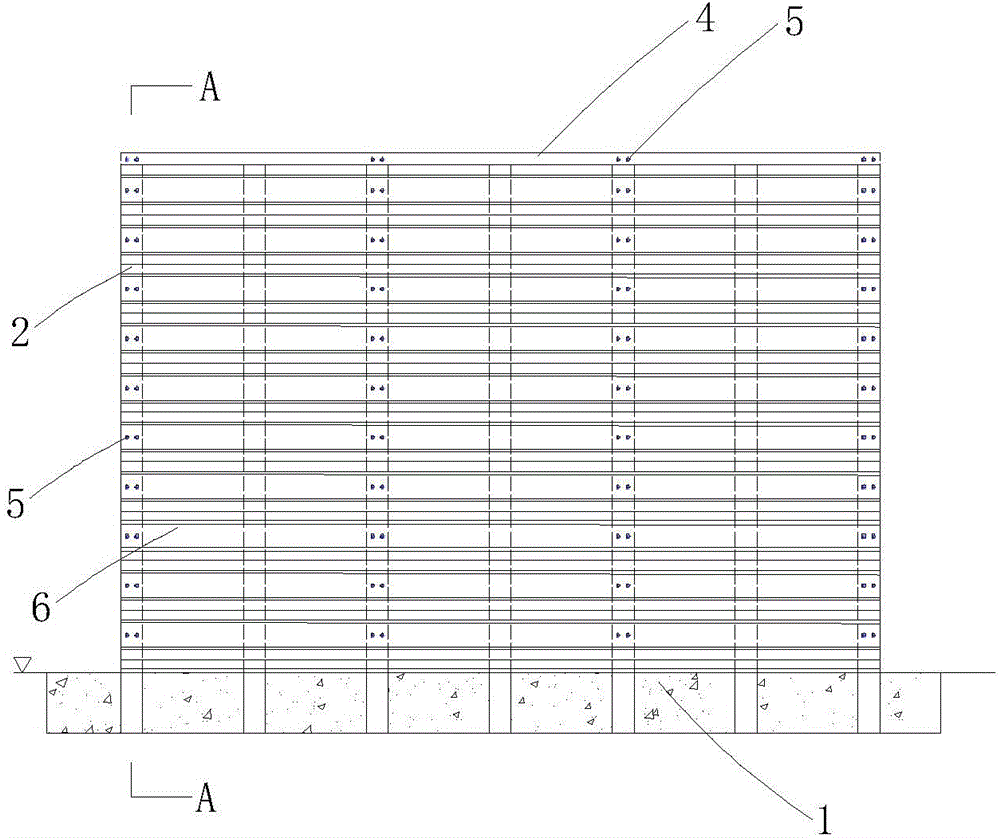

Reusable assembled mixing station storage silo partition wall and construction method thereof

ActiveCN104405165AQuality improvementEasy to operateBulk storage containerWave shapeStructural engineering

The invention discloses a reusable assembled mixing station storage silo partition wall. The reusable assembled mixing station storage silo partition wall comprises the concrete base of the partition wall and a plurality of H-shaped steel upright columns embedded in the concrete base; the H-shaped steel upright columns are arranged on the partition wall in the length direction at intervals; inverted U-shaped steel plate caps are locked to the top ends of the H-shaped steel upright columns; corrugated steel sheets are fixedly arranged on the two side surfaces of the plurality of H-shaped steel upright columns to form the inner and outer side surfaces of the partition wall. The reusable assembled mixing station storage silo partition wall can be reused after being manufactured once, and has the characteristics of safety, high efficiency, easy operation, low cost, high quality, going green and environmental protection and the like.

Owner:ANHUI ROAD & BRIDGE GRP

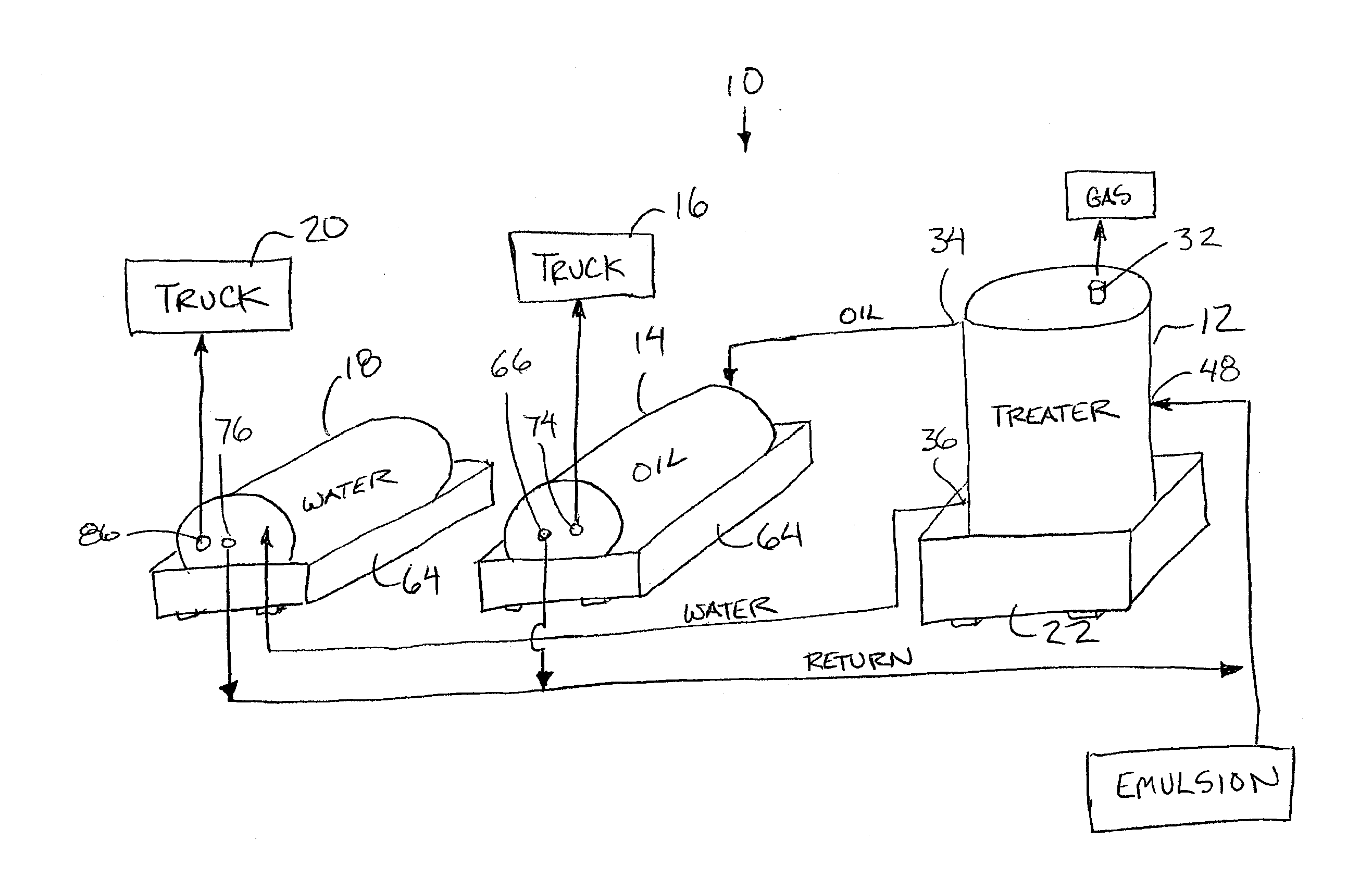

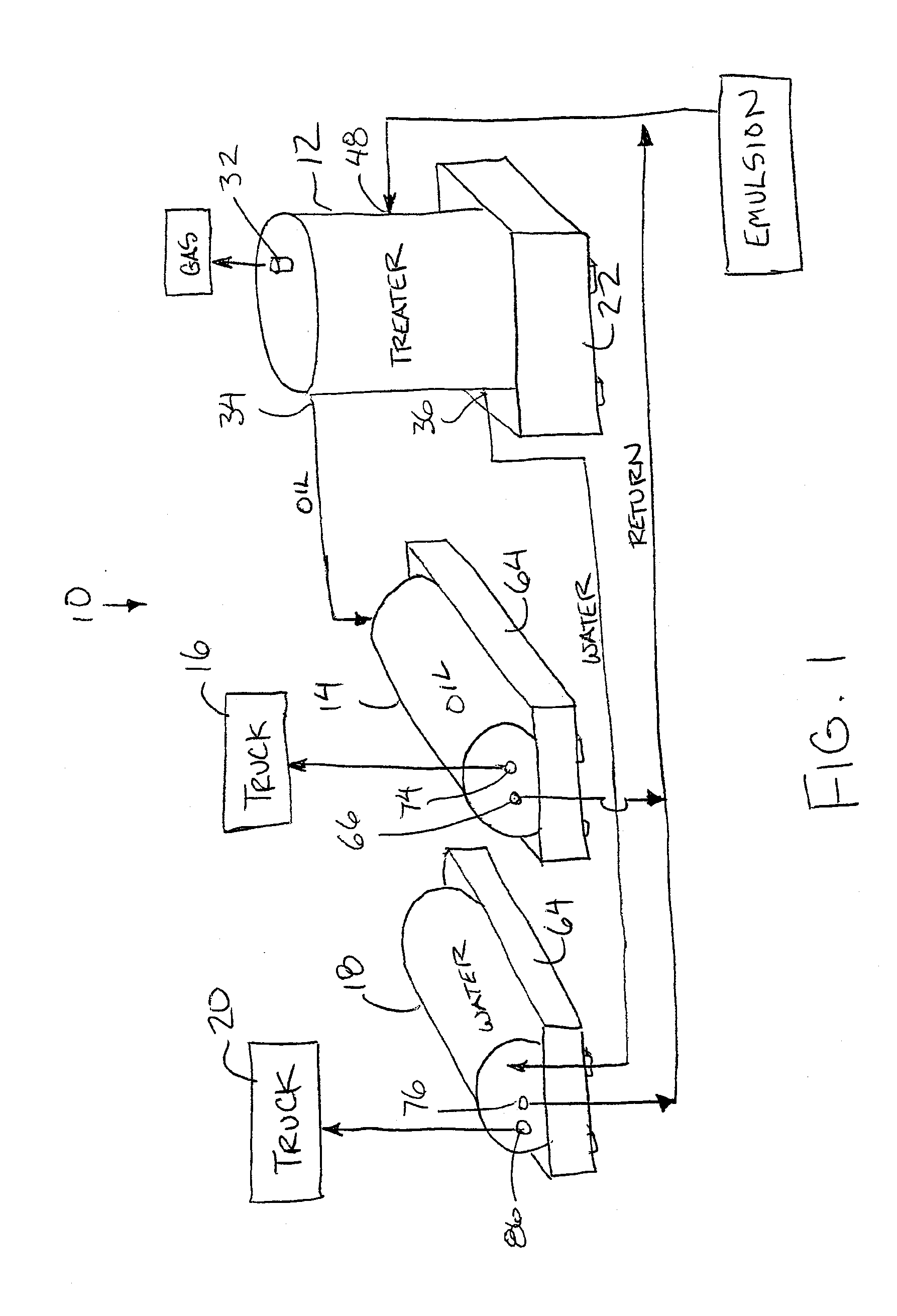

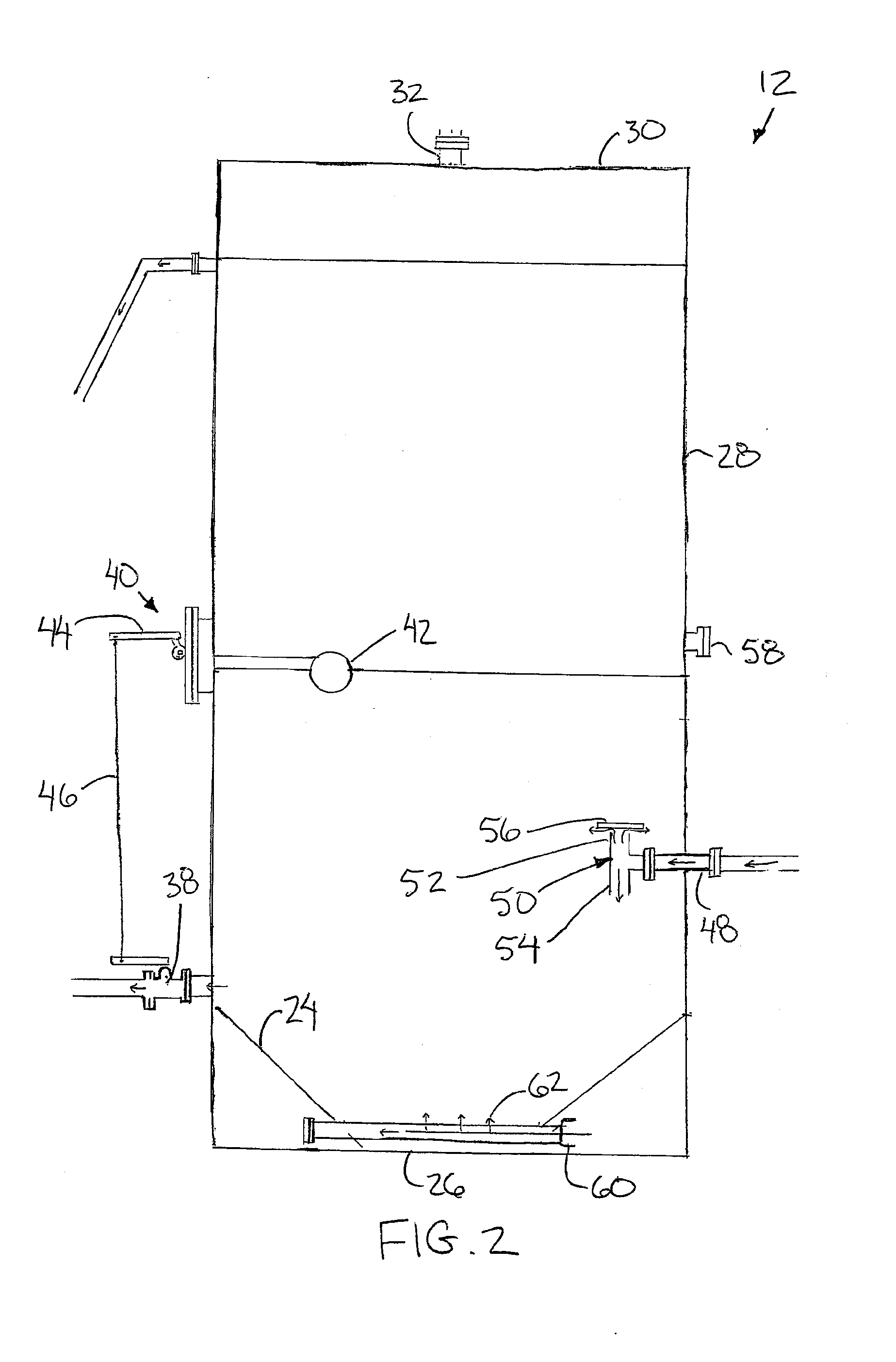

Hydrostatic Oil Treatment System

ActiveUS20150375140A1Easy to transportEasy to operateWaste water treatment from quariesLiquid separation auxillary apparatusEmulsionFuel tank

A hydrocarbon emulsion treatment system includes a treatment tank having a gas vent for operating the treatment tank near atmospheric pressure. The treatment tank separates water and oil in the emulsion for discharge to separate water and oil tanks respectively. According to a preferred embodiment, the treatment tank and the oil tank are supported on a common frame including an integral secondary containment structure providing secondary containment to both the treatment tank and the oil tank. The treatment tank is supported at greater elevation than the oil tank to allow the flow of oil from the treatment tank to the oil tank primarily under force of gravity.

Owner:BLACK SUEDE HYDRO CARBON PROCESSING

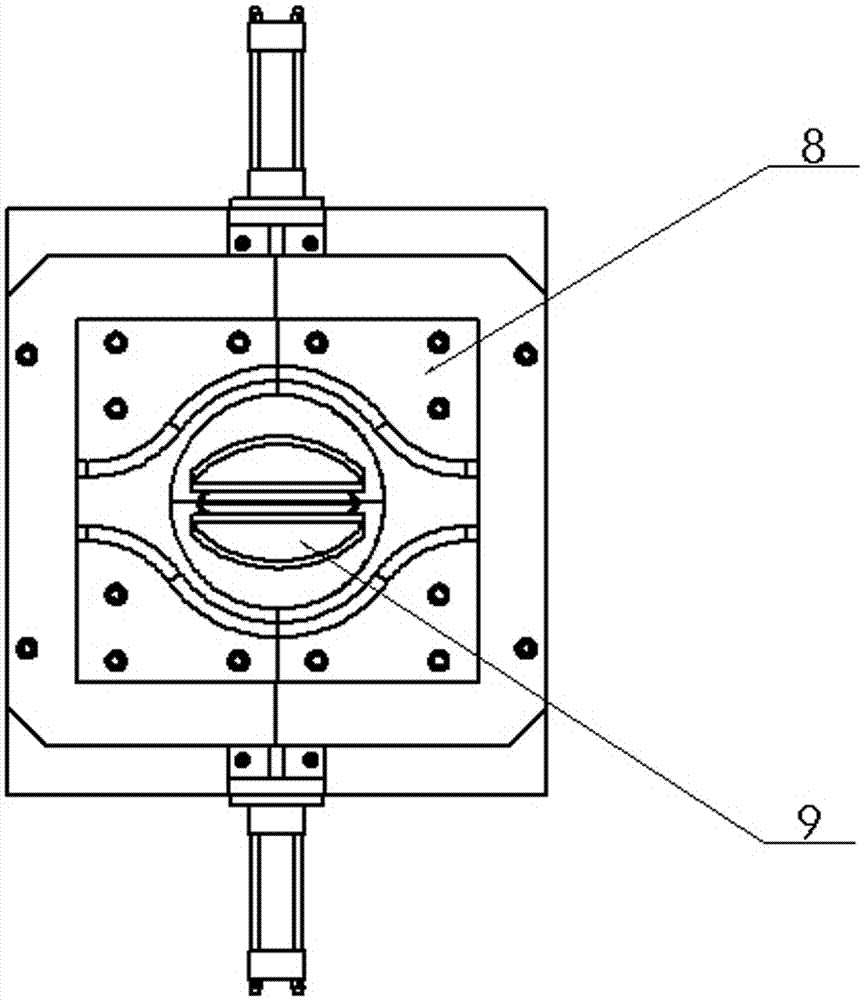

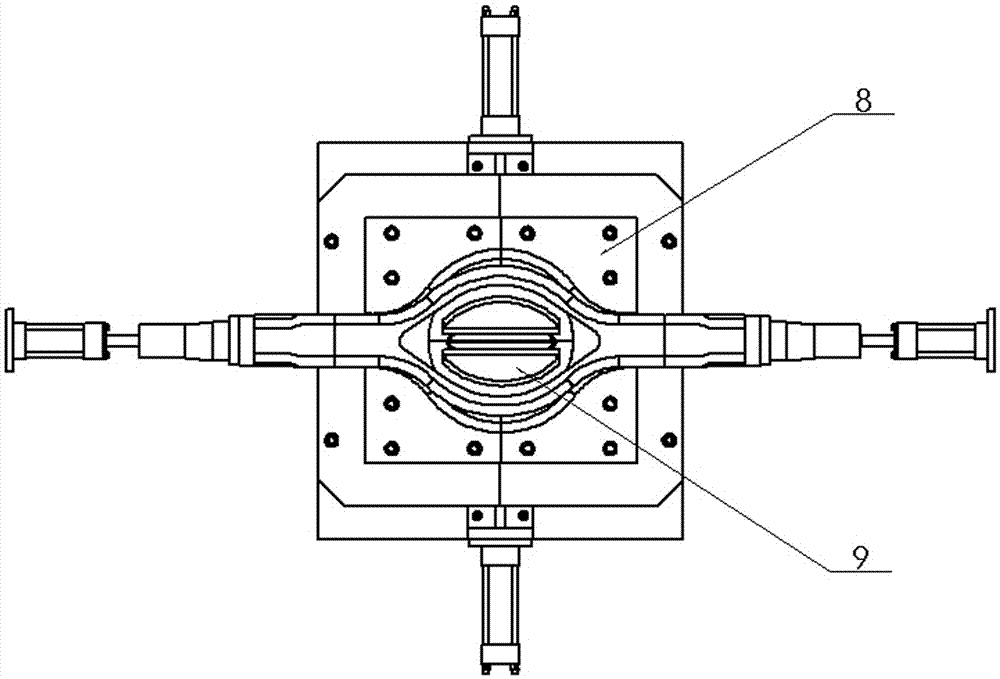

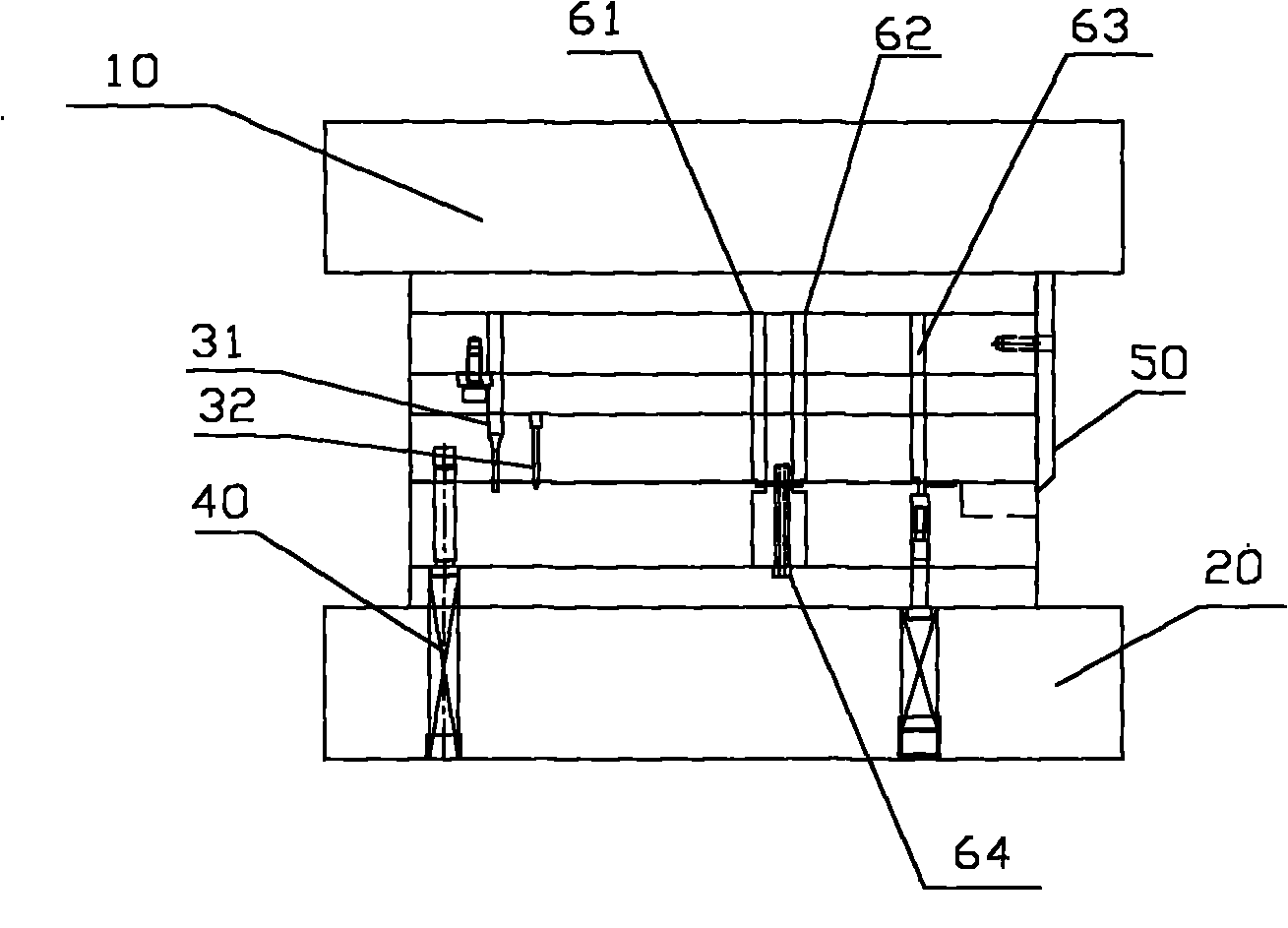

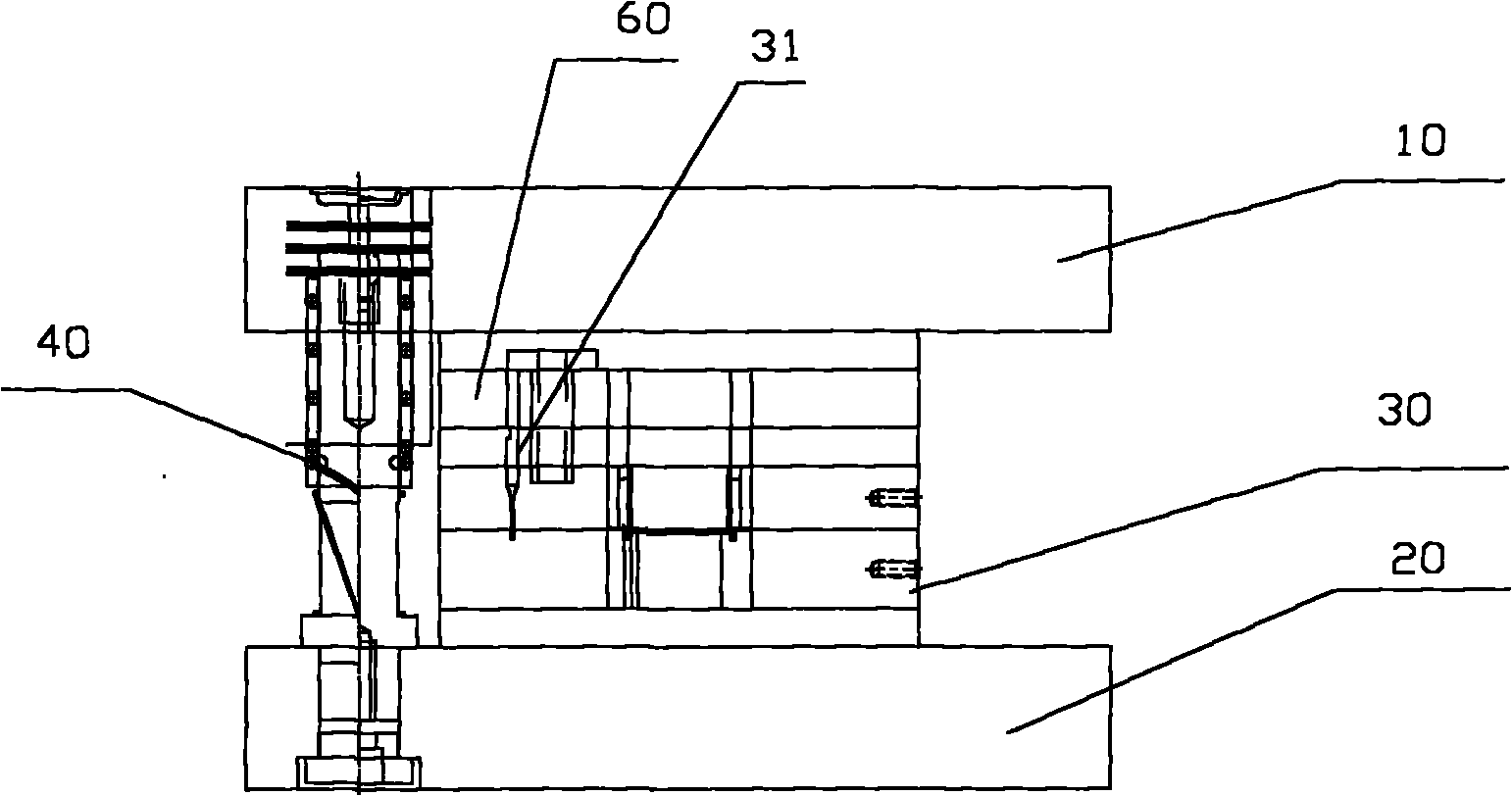

Molten soup forging method and die thereof

ActiveCN103084560AAvoid damageMeet mechanical performance requirementsMechanical propertyRefined grains

The invention relates to a molten soup forging method and a molten soup forging die. The molten soup forging method and the molten soup forging die comprise an upper die, a lower die and side dies, to-be-produced wheel-shaped die cavity is formed among the upper die, the lower die and the side dies, wherein the molten soup forging method and the molten soup forging die are characterized in that a lower die assembly formed by coaxially enclosing the plurality of side dies and the lower die is coaxially embedded in a pressure bearing die sleeve, and a hydraulic pressure lifting mechanism which is vertically upward and used for lifting products is coaxially arranged at the lower end of the lower die. The molten soup forging method and the molten soup forging die have the advantages of improving product quality, reducing molten soup dosage, improving inner structure refined grain of metals, improving product mechanical property, tensile property and other overall properties, shortening product production time, reducing equipment maintenance cost, increasing output, improving production efficiency and prolonging die service life.

Owner:TIANJIN NANUO MACHINERY MFG

Continuous die mould of part

The invention discloses a continuous die mould of a part, comprising an upper die holder, a lower die holder, a terrace die, a die, a punch fixed plate, an upper base plate, a material belt and a cutter. a terrace die and a die in each station are sequentially arranged on the terrace die and the die of the mould in the punch process order of the electrical parts; a guide pin for controlling the PIN distance and for guiding is further fixed on the central position of the upper base plate; the guide pin comprises a first guide punch and a second guide punch; both the first and second guide punches are fixedly arranged on the upper die holder; the mould is further provided with a pin with double purposes of floatation and opening, a molded insert core and a punch. The invention is featured by convenient manufacturing, low cost, safety, stability, rapid lead time and low manufacturing cost, can satisfy a certain processing quality requirement, ensures that the punching operation of mould in multiple steps is finished continuously, and obviously improving the working efficiency, thereby providing an economic and effective way for trail production of new products and production of stamping parts without high batch requirement.

Owner:昆山凯意工模具配套有限公司

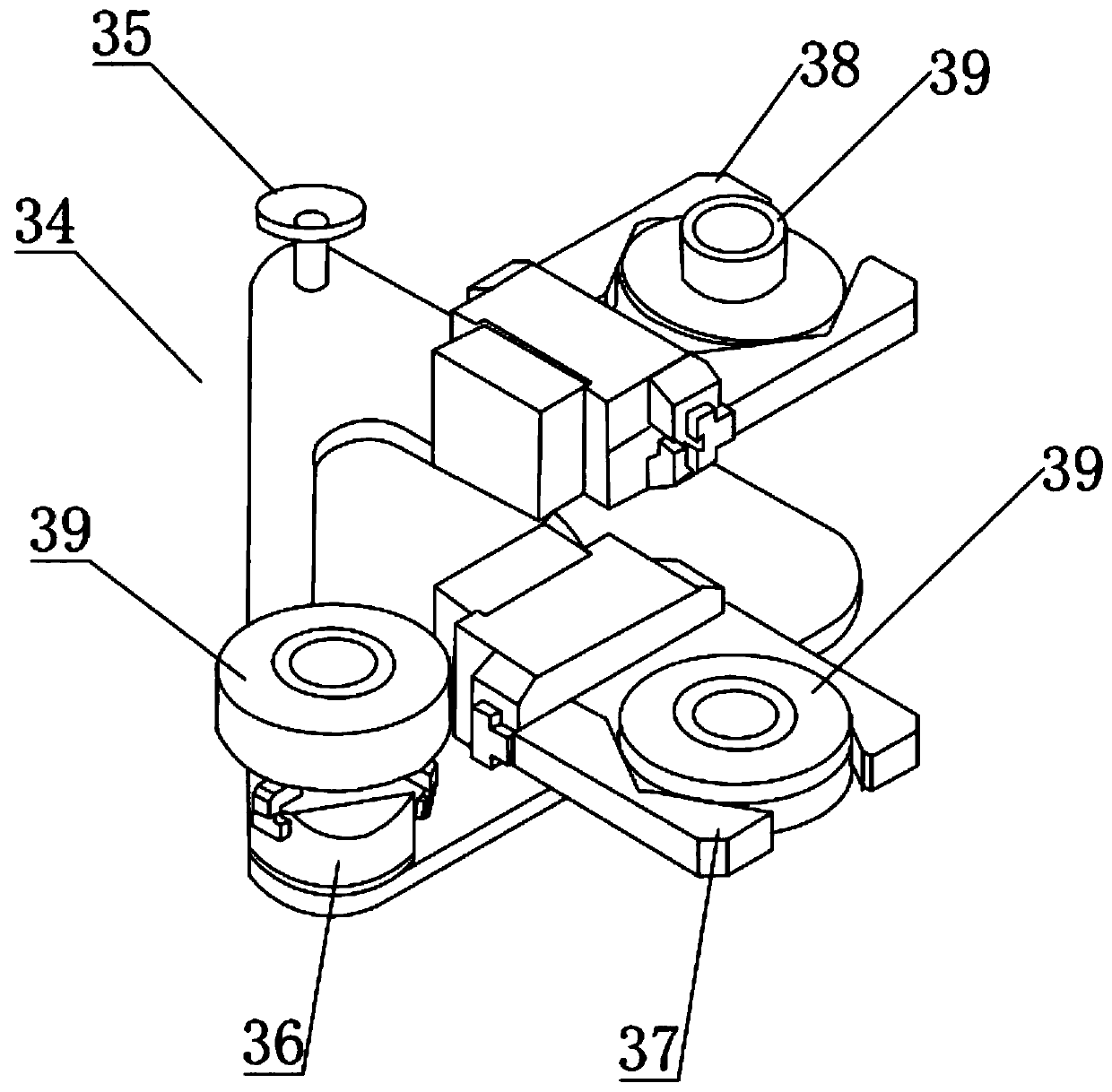

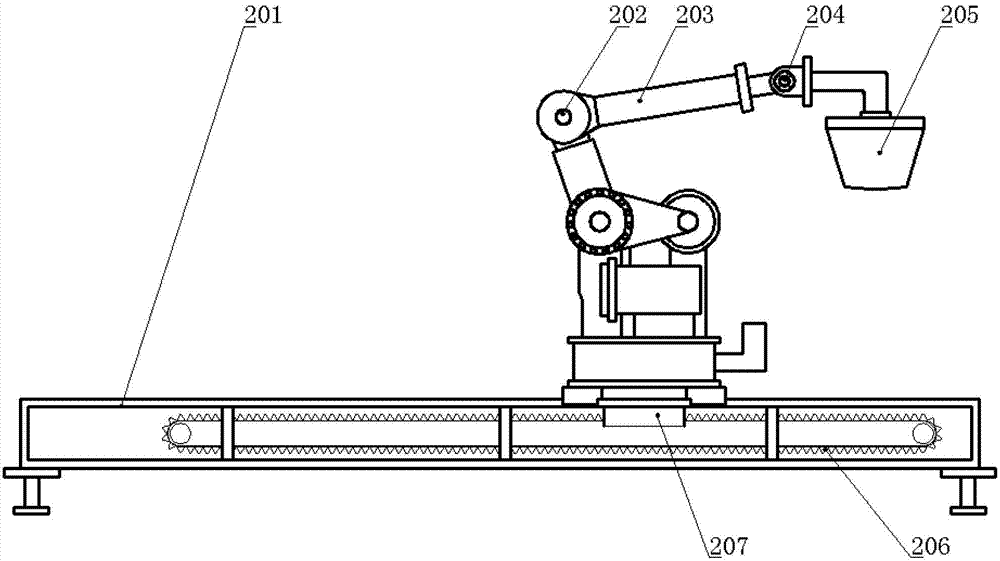

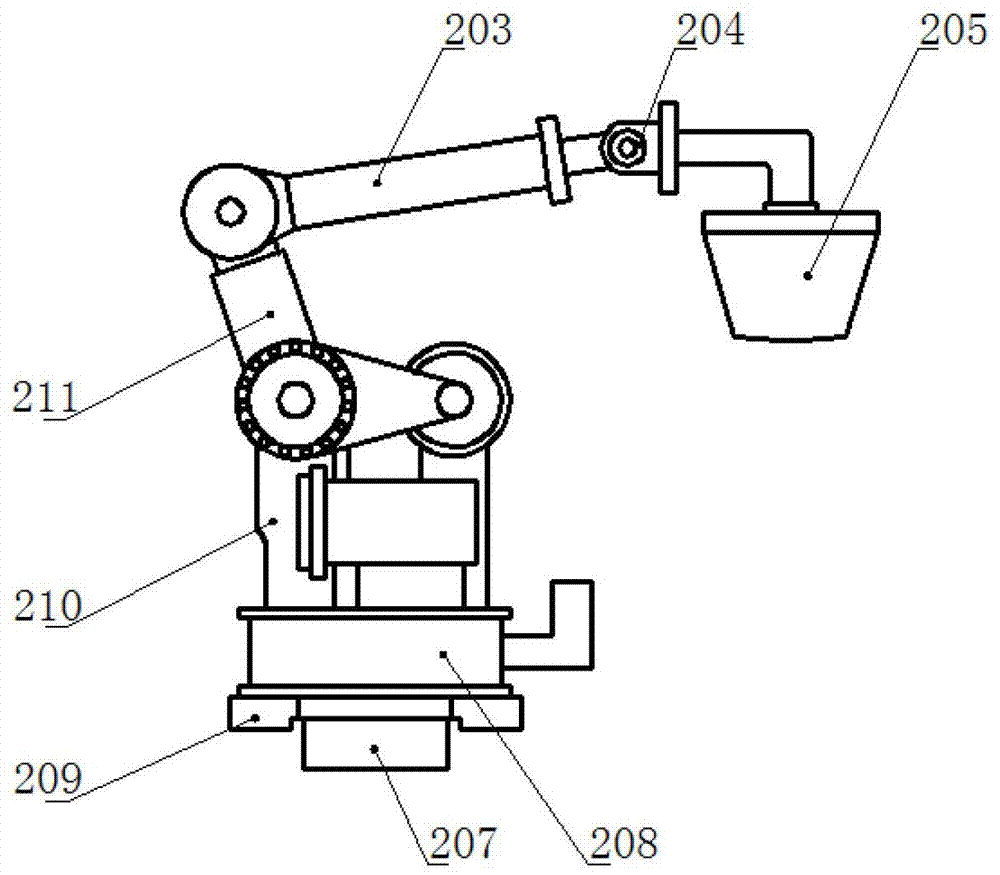

Double-station hydraulic die forging machining system and machining process

ActiveCN103111571AAvoid damageMeet the mechanical performance requirementsForging/hammering/pressing machinesForging press detailsRobot handMachine

The invention relates to a dual-station hydraulic die forging machining system and a machining process. The machining system comprises a heat preservation furnace, a forging machine, a melt feed manipulator, a product grabbing manipulator, a transferring rail and a storage frame. The heat preservation furnace is arranged at one side of the forging machine, and the melt feed manipulator installed between the forging machine and the heat preservation furnace scoops melt from the heat preservation furnace and conveys to the forging machine for machining. The other side of the forging machine is provided with the transferring rail, and the product grabbing manipulator is installed between the forging machine and the transferring rail. The machining system can achieve multi-station full-automatic production, and is simple in layout, easy and convenient to operate, capable of qualifying work of two forging machines when only one operator is needed, capable of making use of resources in the greatest degree and saving labor cost, meanwhile capable of obviously improving production efficiency, stable in operation, and reliable in quality.

Owner:TIANJIN NANUO MACHINERY MFG

Fork type transfer loading mechanism in vehicle body transfer loading system

InactiveCN105947663AReduce labor intensityFast stretchingConveyorsConveyor partsIn vehicleGear wheel

The invention relates to a fork type transfer loading mechanism in a vehicle body transfer loading system. A middle-layer fork is slidingly inserted in a bottom-layer fork; an upper-layer fork is slidingly inserted in the middle-layer fork; a bottom-layer rack is fixed on the bottom-layer fork; a middle-layer rack is fixed on the middle-layer fork; an upper-layer rack is fixed on the upper-layer fork; a main gear box is fixed on the bottom-layer fork; a main gear is mounted in the main gear box; a first driving gear is mounted in the main gear box on the left side of the main gear; a second driving gear is mounted in the main gear box on the right side of the main gear; and a front-end driven gear, a back-end driven gear and odd transition gears are rotationally mounted on the middle-layer fork. The fork type transfer loading mechanism is fast in extension speed, high in travel, simple in structure and reliable in use, can reduce the labor intensity of workers, and can improve the production efficiency.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

U-plate full-automatic production line

InactiveCN111633383AHigh degree of automationImprove efficiencyPositioning apparatusMetal working apparatusProduction linePunching

The invention discloses a U-plate full-automatic production line, and relates to the technical field of mechanical equipment. The U-plate full-automatic production line comprises a feeding mechanism,a transporting belt is arranged at the bottom end of the inner side of the feeding mechanism, an aluminum template is placed at the top of the transporting belt, the feeding mechanism comprises a first motor, a first screw rod, a first sliding block, a lifting air cylinder, a second motor, a supporting frame, a second screw rod, a second sliding block, a supporting plate, a clamping air cylinder and a clamping plate, and a material sawing mechanism is arranged on one side of the feeding mechanism. According to the U-plate full-automatic production line, the functions of automatic feeding, automatic sawing, automatic tailing collection, automatic punching, automatic welding, automatic discharging and the like are integrated, the degree of automation is high and covers the overall process procedures from raw materials to finished product discharging, the truly intelligent and unmanned automatic production of the whole line is achieved, the compatibility is good, the U-plate full-automatic production line can be suitable for the production of aluminum templates with various specifications, the efficiency is improved, and the problems of efficiency lowering caused by large labor intensity, operation fatigue and the like can be avoided by using machines.

Owner:YUNNAN KEBAO FORMWORK & SCAFFOLD +1

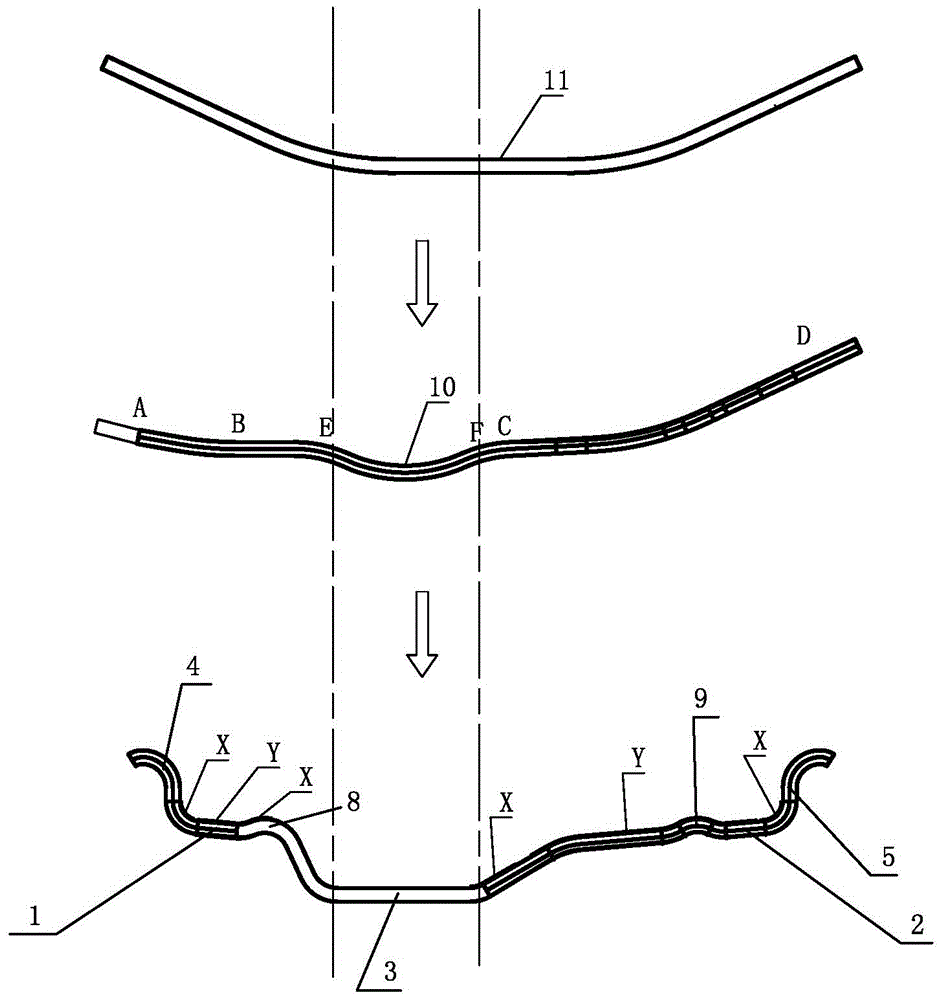

Machining method for rim blank for spinning rim

The invention relates to a machining method for a rim blank for spinning rim. The machining method is used for conducting segmented spinning machining on the flaring rim blank, wherein the middle of the rim blank is a flat bottom, and the two sides of the rim blank extend obliquely. The method includes the steps that firstly, the EF segment is rolled to form positioning protrusions, and the positioning protrusions are used for positioning a workpiece; secondly, the AB segment is spun to be thinned; and thirdly, the CD segment is spun to be thinned, the width of the workpiece is widened while spinning is conducted, and the increased maximum width is 40 mm. By means of the manner, spinning force is smaller, energy is greatly reduced, and abrasion on a die is smaller; the molding quality can be effectively improved, and stability after forming is further enhanced; and in addition, the quality qualification rate is also increased, the production takt is faster, and the production efficiency is higher.

Owner:ZHEJIANG JINGU CO LTD

Microorganism growth promoter

InactiveCN102911870AQuality assuranceFast production timeFungiBacteriaSulphur reducing bacteriaPhylum Cyanobacteria

The invention relates to a microorganism growth promoter. The microorganism growth promoter mainly comprises more than 560 types of microorganisms, the effective viable count per milliliter is larger than 1010, the pH value is 3.5-5.5, and the microorganism growth promoter comprises a lactic acid bacterium group, a photosynthetic bacterium group, a saccharomycete group, an actinomycete group, a linear bacterium group, a decomposing bacterium group, deoxidizing bacteria, Shanyu bacteria, spore bacteria, nitrobacteria and a ZERO bacterium group; and the ZERO bacterium group mainly comprises one or more of lactic acid bacteria, photosynthetic bacteria, saccharomycete and fermentation system filamentous fungi, as well as cyanobacteria, nitrogen fixing bacteria, bacillus subtilis, acetic acid bacteria, sulfur reducing bacteria and bacteroides.

Owner:刘跃魁 +2

Novel building wall material automatic production line and production process

PendingCN111231096AIncrease productivityMeet the needs of automated production processesCeramic shaping plantsProcess engineeringManufacturing line

The invention relates to the field of novel building wall materials, in particular to a novel building wall material automatic production line and a production process. The production line comprises acrystallization forming furnace with multiple layers of crystallization forming roller ways, a conveying device for bearing forming dies to come in and go out of the crystallization forming furnace,a distributing device for injecting raw materials into the forming dies and an automatic operation device for dismounting and mounting the forming dies and taking forming materials out of the formingdies. The mechanization and automation degree of novel building wall materials can be improved, so that the labor intensity is reduced, and the production efficiency is improved.

Owner:洛阳北玻轻晶石技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com