Series excited motor rotor assembly machine

A technology of series excitation motor and assembly machine, which is applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of low production efficiency, slow production rhythm and high production cost, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

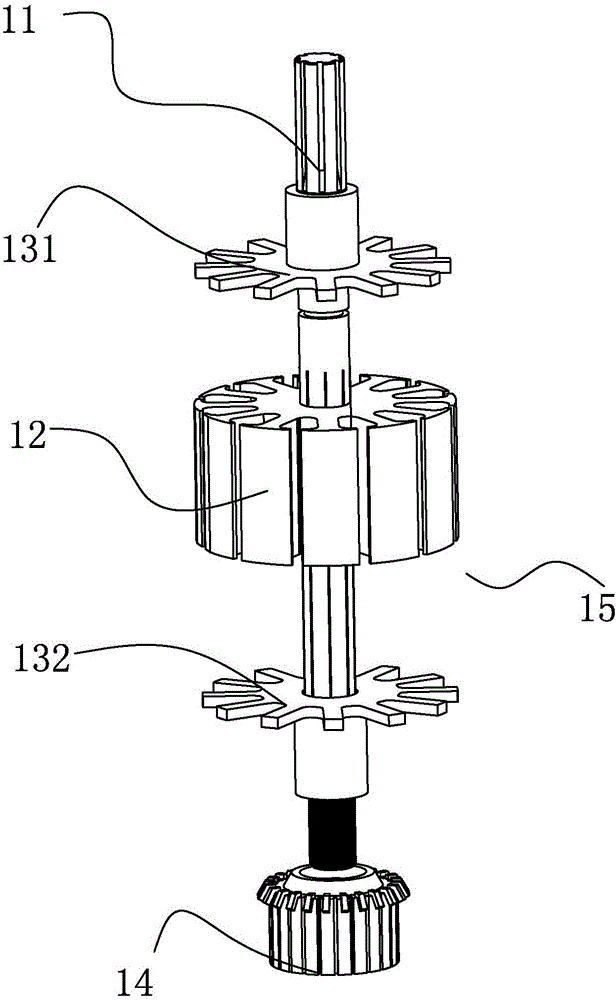

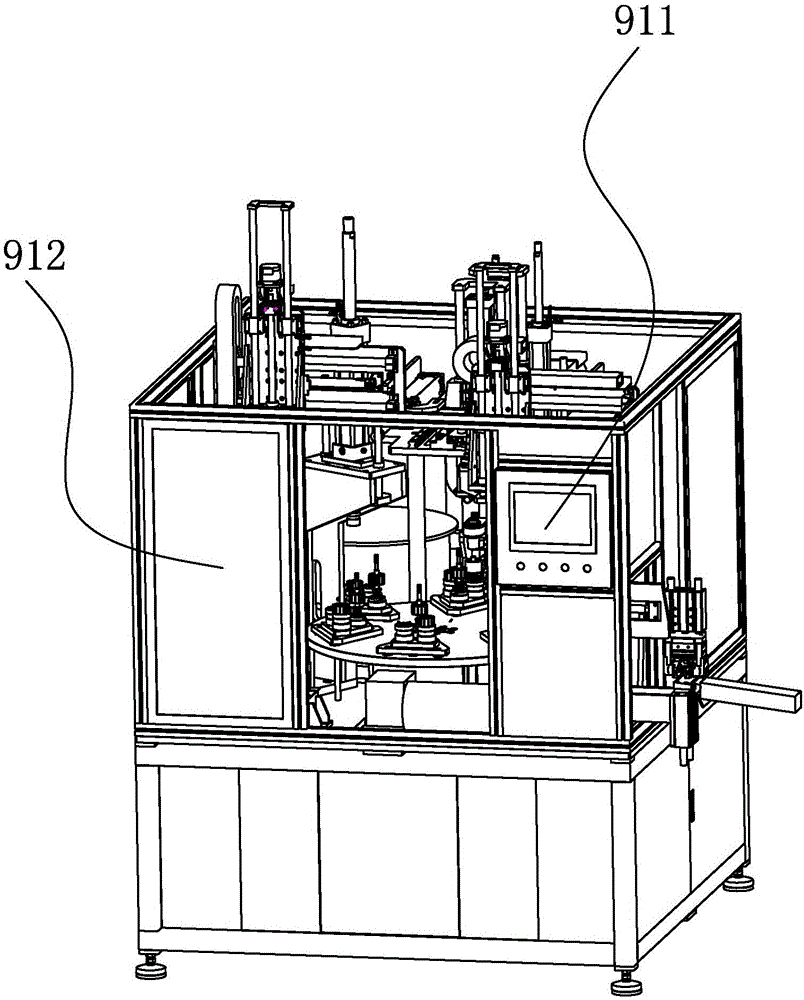

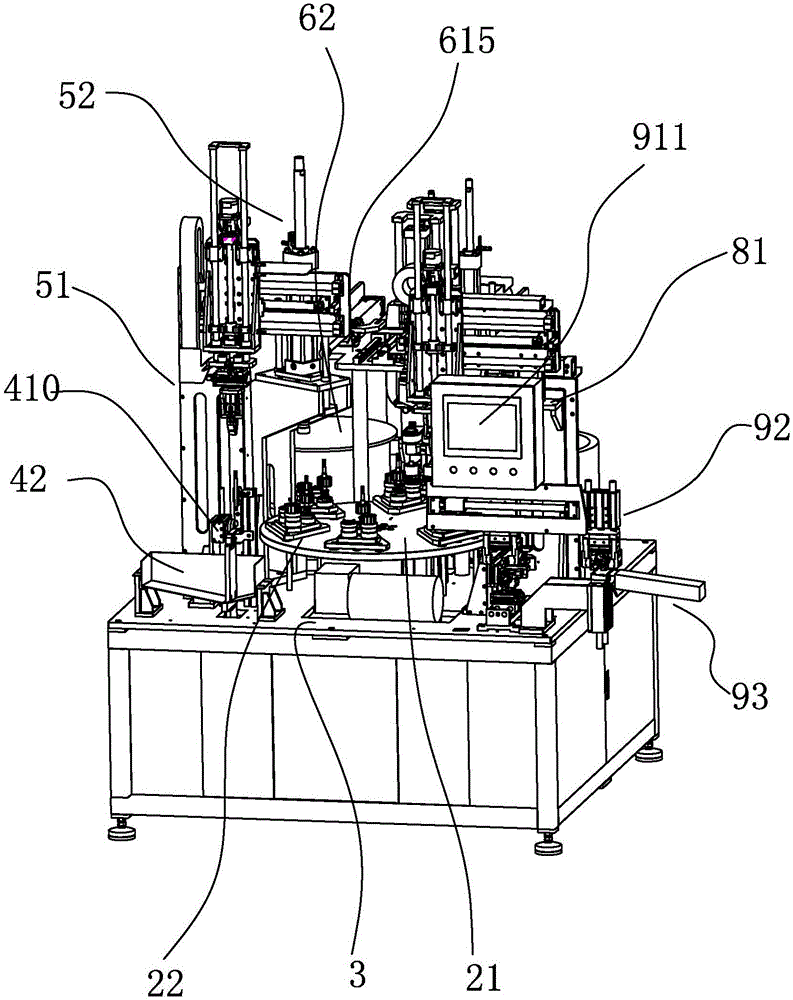

[0072] refer to Figure 1~14 , a series motor rotor assembly machine, including an organic board 3, an indexing device installed on the machine board 3 to control the rotation, a shaft storage device arranged circumferentially along the indexing device and installed on the machine board 3, an upper Shaft and finale device, baffle feeding device, baffle pressing device, direction guide pressing device, discharging device, the shaft storage device stores the shaft 11, the upper shaft and finale device takes out the middle shaft 11 of the shaft storage device and Pressed into the iron core 12, the baffle plate feeding device carries out supply and assembly on the upper baffle plate 131 and the lower baffle plate 132, and the baffle plate pressing device installs the upper baffle plate 131 and the lower baffle plate 132 on the iron core with the shaft 11 On the core 12, the direction guider press-in device installs the guider 14 on the iron core 12 equipped with the shaft 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com