Design principle for array needle type rolling drum printer

A design principle and needle printing technology, applied in printing and other directions, to achieve the effect of high success rate, easy adjustment, and cheap wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0178]Since the array needle cylinder printer is only a principle design, and the actual application design and prototype prototype production have not been carried out, only some research and development priorities that can be imagined in advance are listed here.

[0179] 1. Simulation design scheme:

[0180] A: design goals

[0181] ①Print mode: Four printing cylinders and four colors dynamic screen printing effect.

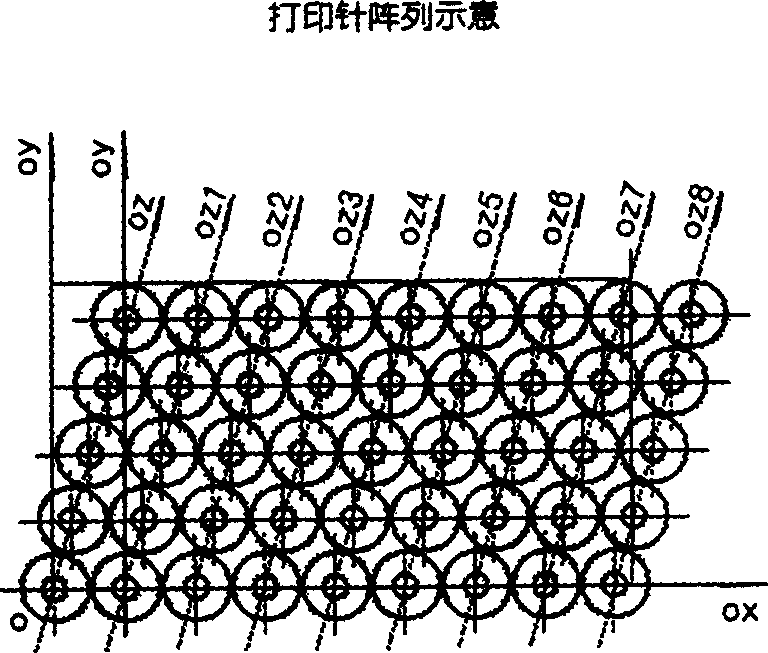

[0182] ②Print output resolution: 750DPI for a single print cylinder, achieving the equivalent of 175 lines of color printing quality.

[0183] B: Basic data:

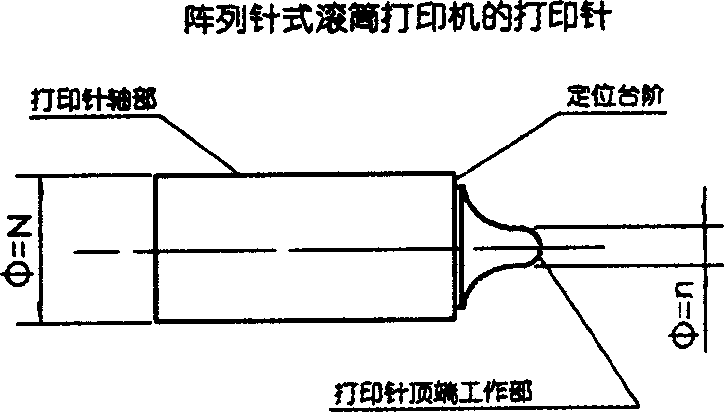

[0184] ①Printing needle shaft diameter: 2.5mm

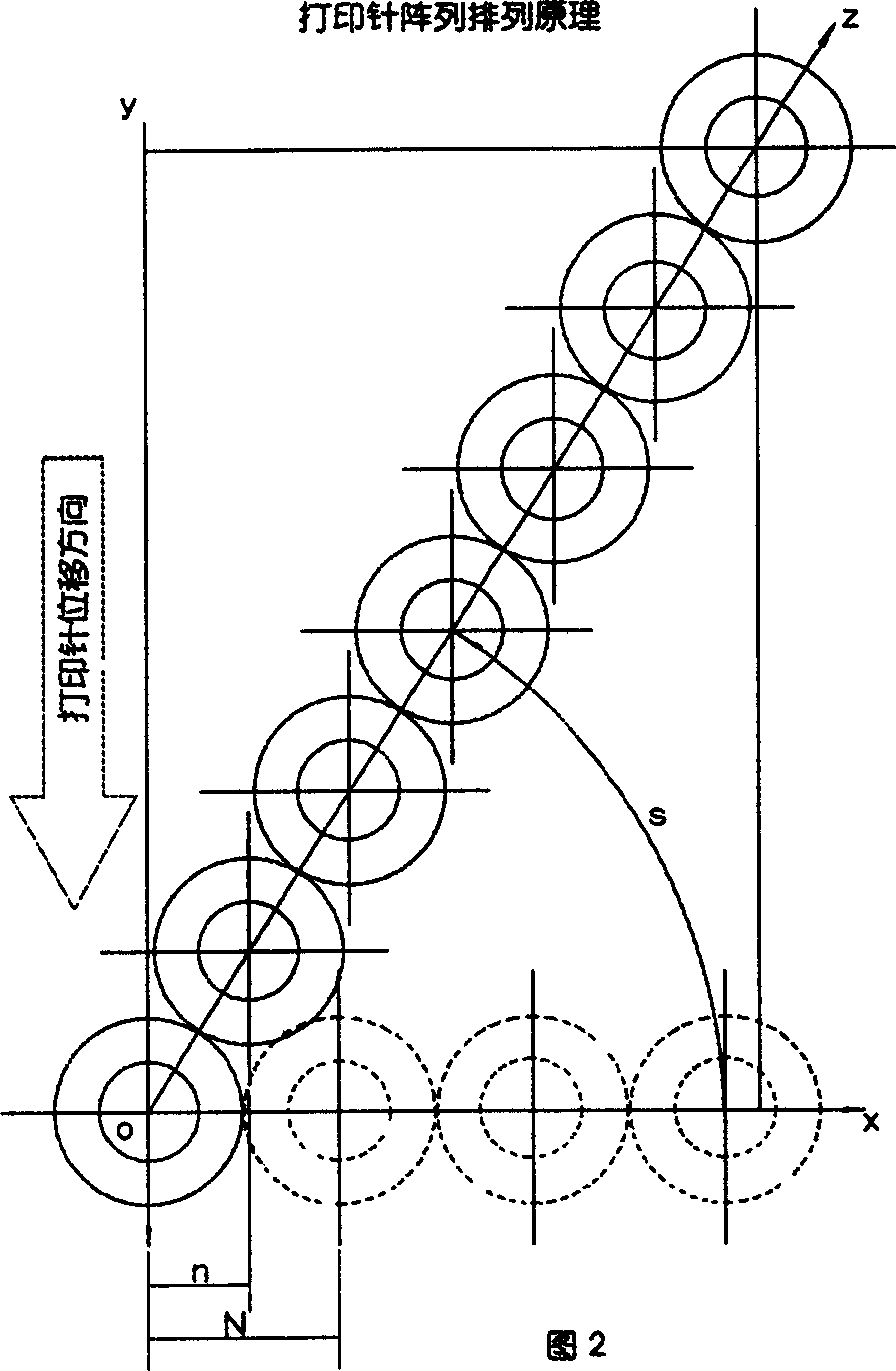

[0185] ②Axis center distance between adjacent printing pins: 3mm

[0186] ③Diameter of the working part at the tip of the printing needle: 0.03mm

[0187] ④ Effective printing width: 300mm (A3 printing paper)

[0188] ⑤Printing needle action mode: shrinking needle type

[0189] C: extrapolated data:

[0190] ①Number of stitches per row: 100 stitch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com