Automatic assembling machine for automobile starter switch screws

A technology for car starting and automatic assembly, applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of inability to guarantee assembly consistency, high labor intensity, and low assembly efficiency, and achieve compact structure and labor intensity. The effect of large and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

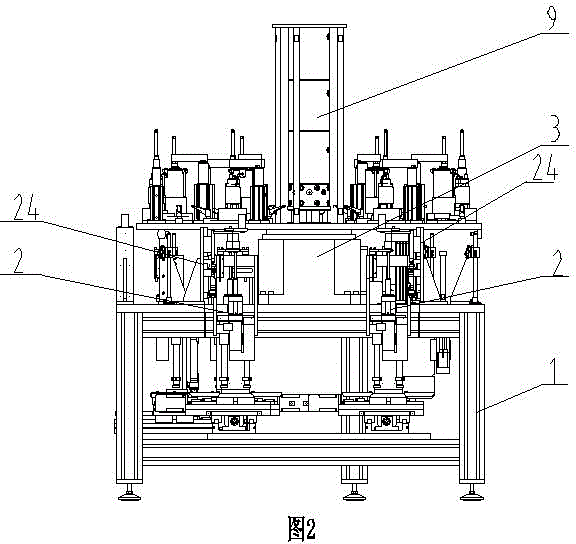

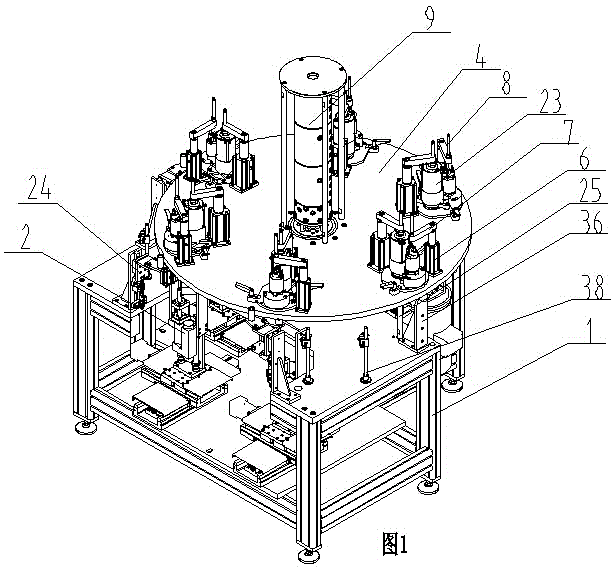

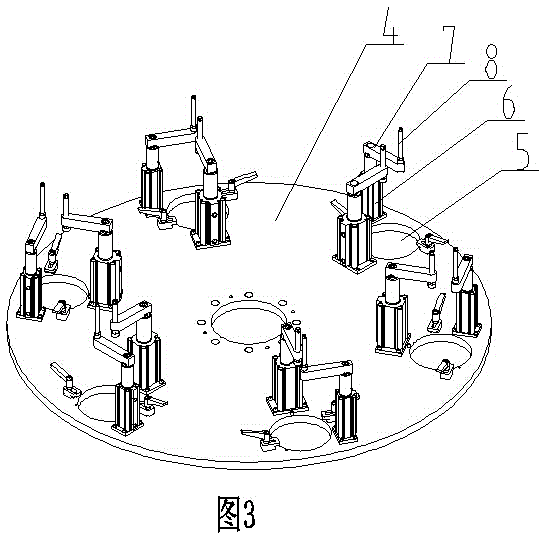

[0023] The automobile starter switch screw automatic assembly machine includes a frame 1, a tightening device 2, an indexer 3, a workpiece pressing device and an indexing plate 4. An indexing plate 4 is installed on the support panel of the frame 1 through an indexer 3, and a plurality of workpiece holes 5 are evenly distributed on the upper surface of the indexing plate 4, and workpiece pressing devices are symmetrically installed on both sides of each workpiece hole 5. . Work piece pressing device is made of rotary cylinder 6 and pressure handle 7, is equipped with pressure handle 7 on the piston rod of rotary cylinder 6, and compression screw rod 8 is installed in pressure handle 7 ends.

[0024] The central part of the indexing plate 4 is equipped with a gas distribution rotating cylinder 9, which is respectively connected with the rotary cylinder 6 of the workpiece pressing device through a communication hose. The function of the gas distribution rotary cylinder 9 is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com