Injection-molded thermoplastic composite vehicle wheel

A composite material and injection molding technology, which is applied in the direction of wheels, wheels, and vehicle parts made of non-metallic materials, can solve the problems that civilian vehicles are not used, and achieve the effects of fast production cycle, guaranteed dimensional accuracy, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following description, the present invention will be described in detail based on exemplary embodiments.

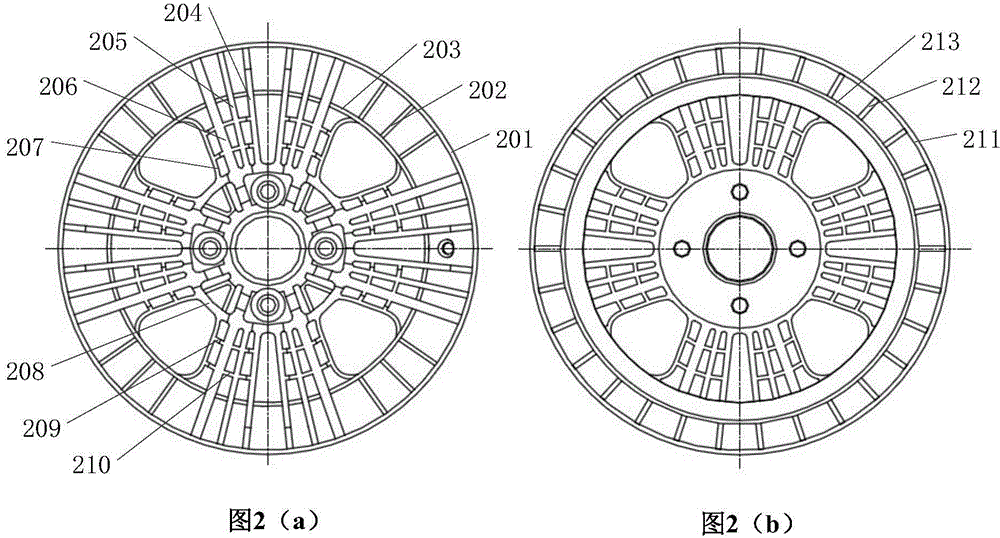

[0046] The example of the present invention is based on a certain model of aluminum alloy wheel with a rim size of 14 x 5.5 inches and four bolt holes.

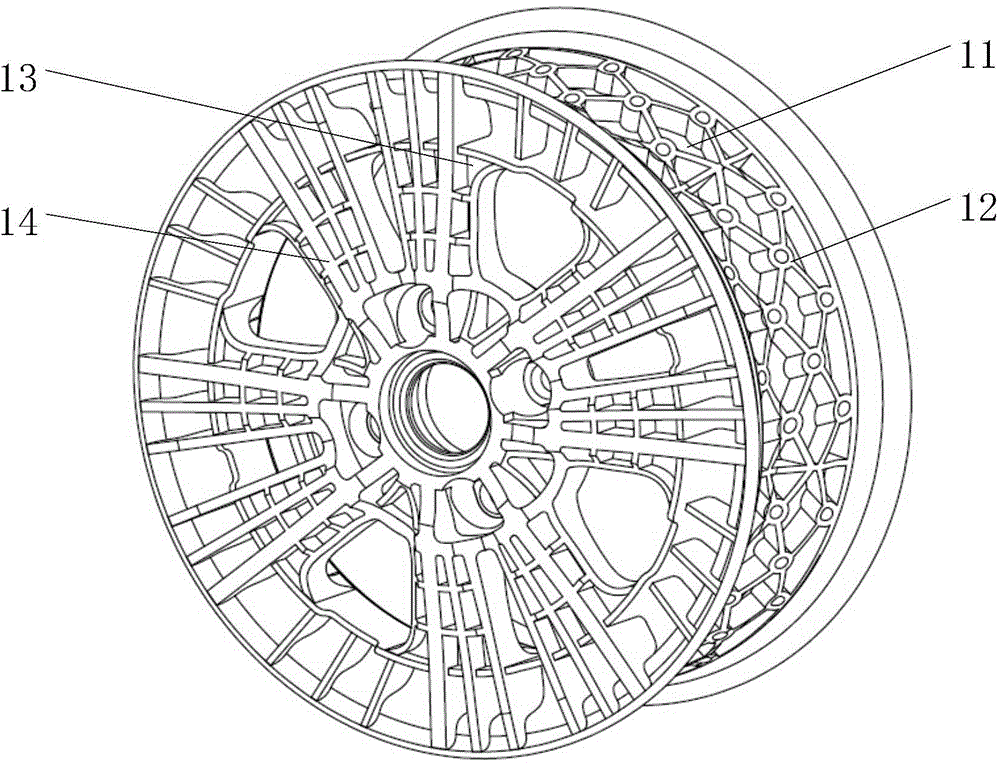

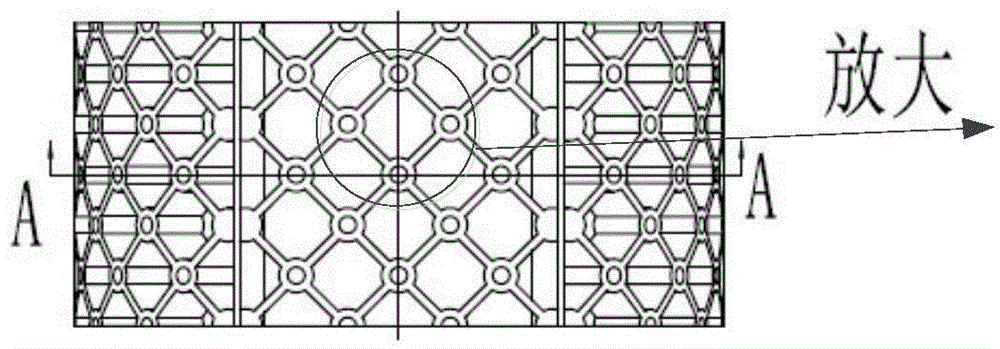

[0047] The present invention is a thermoplastic composite material wheel suitable for injection molding, the rim of which can be regarded as the composition of the rim base and the rim reinforcement structure, such as figure 1, the rim base 11 is similar to the rim of an aluminum alloy wheel, and the rim reinforcement structure 12 is attached to the rim base 11, and the outer profile formed by the two together meets the rim profile required by the national standard. To preserve the interior space of the rim, increase the rim diameter to 15 inches. The bead seats on both sides of the rim are in contact with the tire, which requires tightness, so the rim reinforcement structure 12 is designed in the middle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com