Novel vehicle roof and production process thereof

A car roof and production process technology, applied in the field of car interiors, can solve problems such as increased product manufacturing costs, uneven product strength, damage, etc., and achieve the effect of improving NVH performance and reducing VOC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

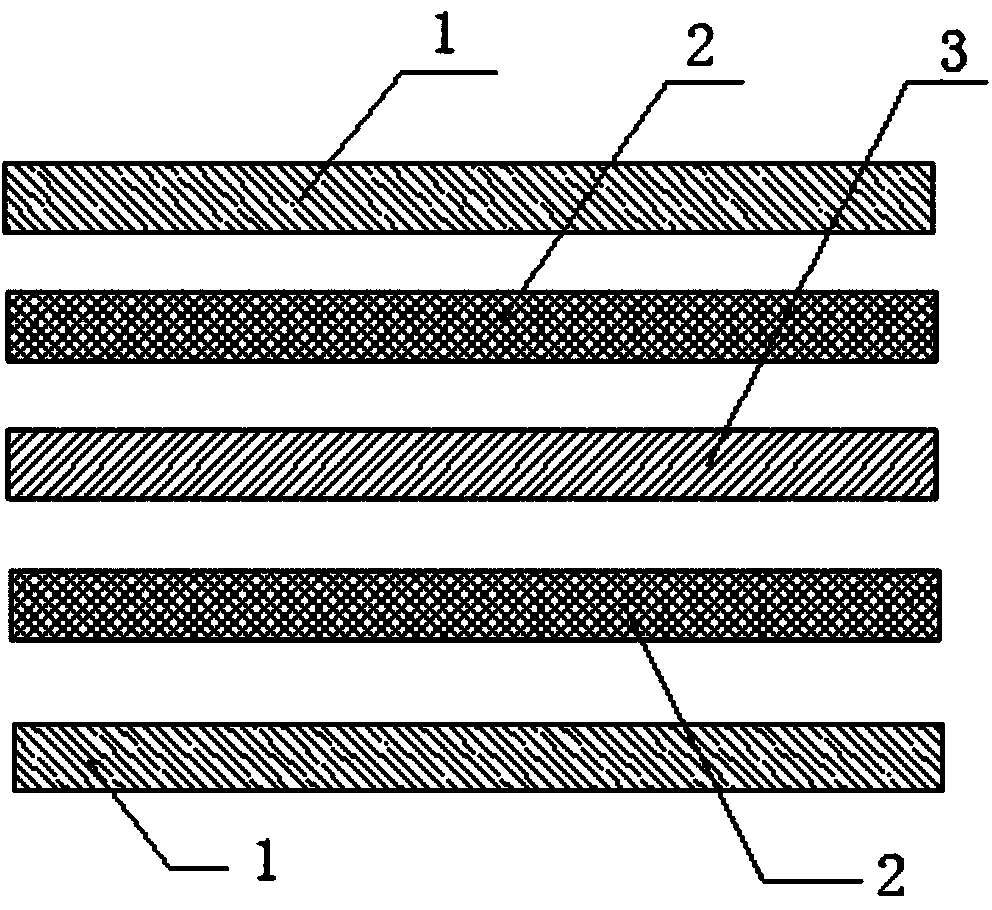

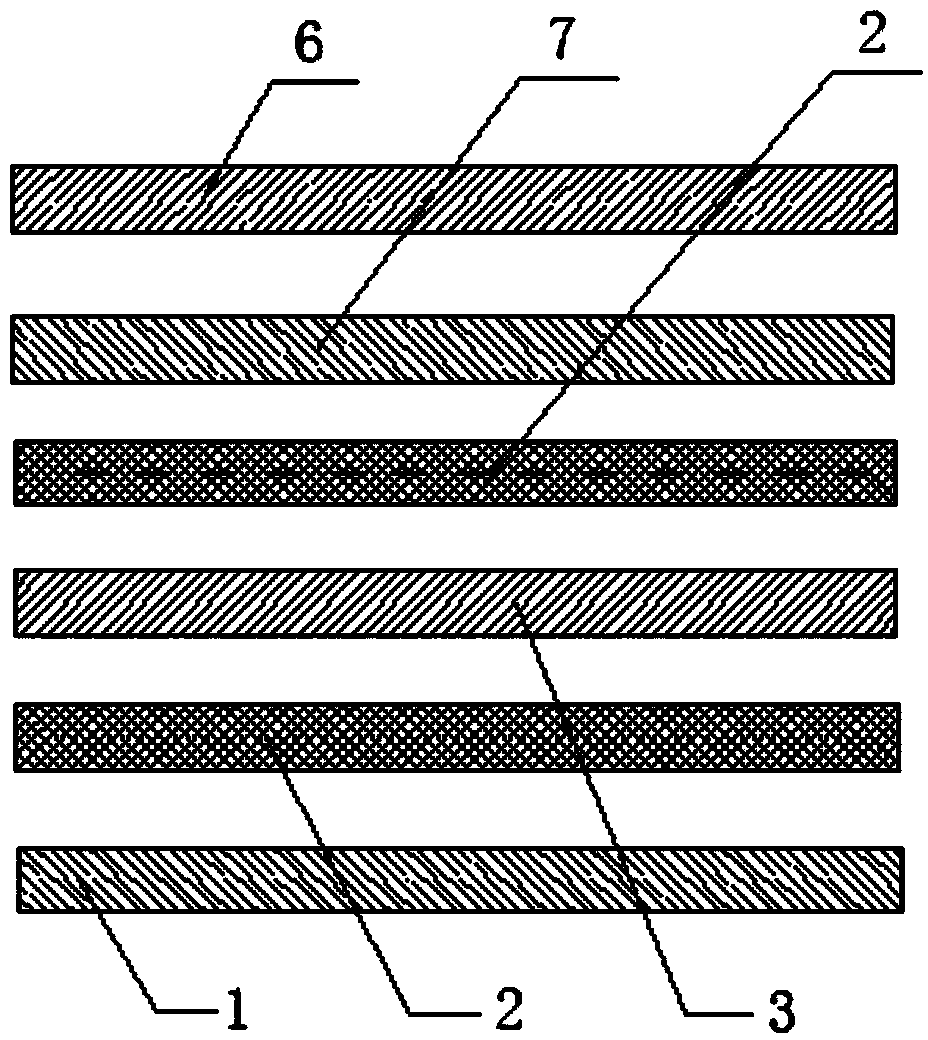

[0031] A new type of car roof, which is composed of composite knitted fabrics, glass fiber mats, foam boards, glass fiber mats, and bottom non-woven fabrics from top to bottom, and the layers are compounded by adhesive films.

[0032] The composite knitted fabric is composed of knitted fabric, polyester foam and bottom non-woven fabric, the bottom non-woven fabric plays the role of glue resistance, and the density of polyester foam is 29kg / m 3 .

[0033] The grammage of described glass fiber felt is 100g / m 2 ,; The film is mainly PE film with a weight of 60g / m 2 , the melting point is 120°C, the foam board is PU foam board, the density is 26kg / m 3 ; Among them, the PE film is polyethylene film, and the PU foam board is polyurethane foam board.

[0034] The present invention also provides a kind of technique of producing the above-mentioned novel automobile roof, comprises the steps:

[0035]1) Raw materials are superimposed, and the raw materials are superimposed in the or...

Embodiment 2

[0041] A new type of car roof, which is composed of composite knitted fabrics, glass fiber mats, foam boards, glass fiber mats, and bottom non-woven fabrics from top to bottom, and the layers are compounded by adhesive films.

[0042] The composite knitted fabric is composed of knitted fabric, polyester foam and bottom non-woven fabric, the bottom non-woven fabric plays the role of glue resistance, and the density of polyester foam is 35kg / m 3 .

[0043] The grammage of described fiberglass mat is 150g / m 2 ;The film is mainly PE film with a weight of 80g / m 2 , the melting point is 130°C, the foam board is PU foam board, the density is 28kg / m 3 ; Among them, the PE film is polyethylene film, and the PU foam board is polyurethane foam board.

[0044] The present invention also provides a kind of technique of producing the above-mentioned novel automobile roof, comprises the steps:

[0045] 1) Raw materials are superimposed, and the raw materials are superimposed in the order...

Embodiment 3

[0051] A new type of car roof, which is composed of composite knitted fabrics, glass fiber mats, foam boards, glass fiber mats, and bottom non-woven fabrics from top to bottom, and the layers are compounded by adhesive films.

[0052] The composite knitted fabric is composed of knitted fabric, polyester foam and bottom non-woven fabric, and the bottom non-woven fabric plays the role of glue resistance. Preferably, the density of polyester foam is 35kg / m 3 .

[0053] The weight of the glass fiber mat is 200g / ㎡; the film is mainly PE film, the weight is 100g / ㎡, the melting point is 135°C, the foam board is PU foam board, and the density is 29kg / m 3 ; Among them, the PE film is polyethylene film, and the PU foam board is polyurethane foam board.

[0054] The present invention also provides a kind of technique of producing the above-mentioned novel automobile roof, comprises the steps:

[0055] 1) The raw materials are superimposed, and the raw materials are superimposed in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com