Novel building wall material automatic production line and production process

An automated production line and building wall technology, which is applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of high labor intensity, low production capacity, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

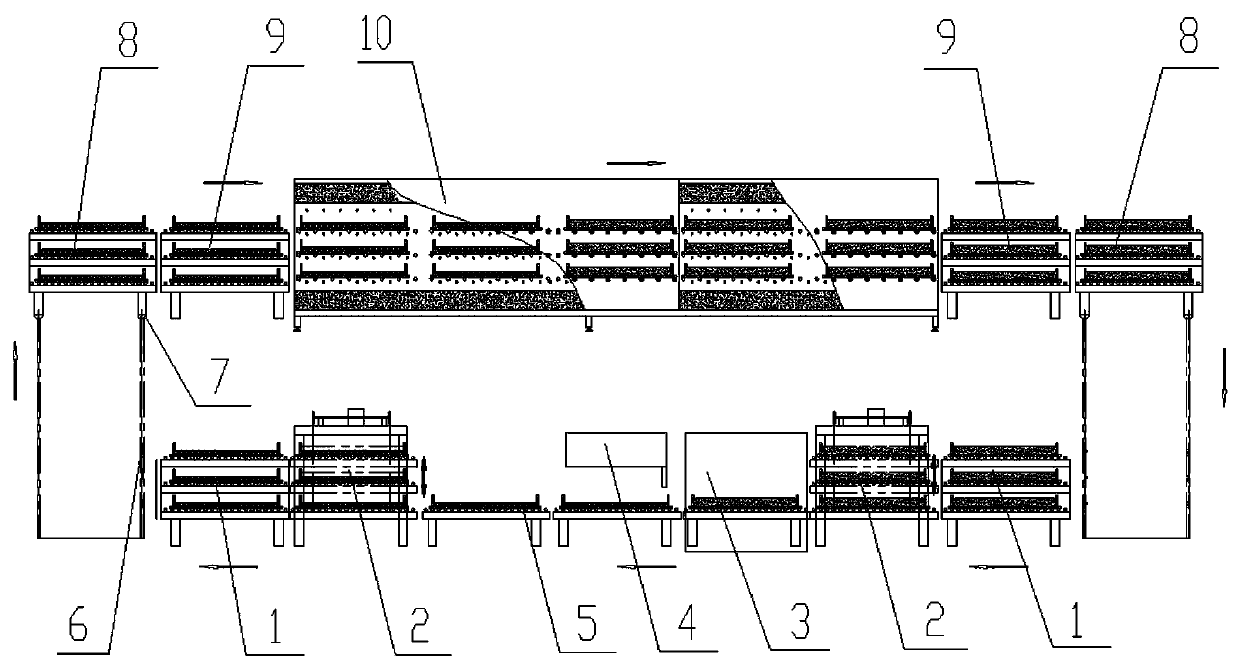

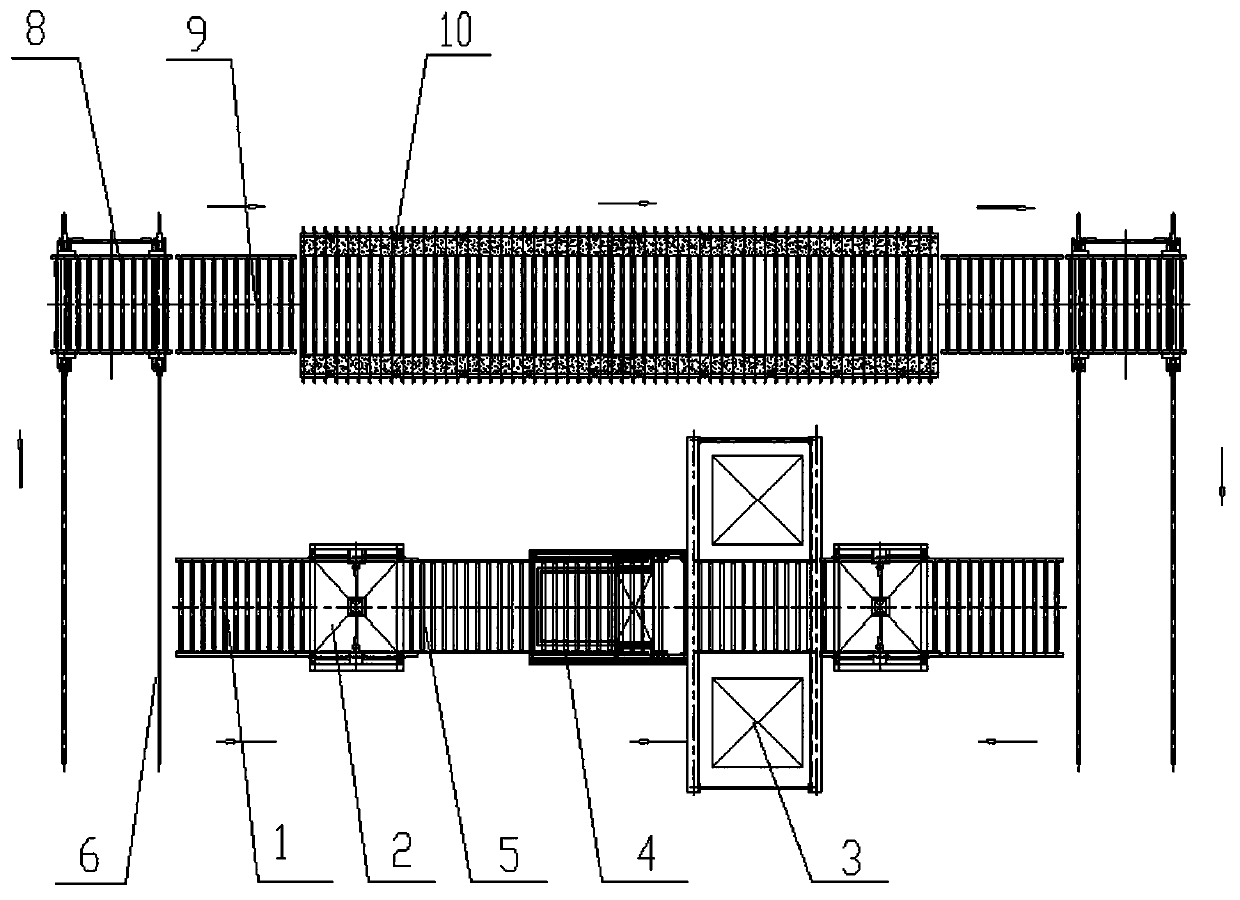

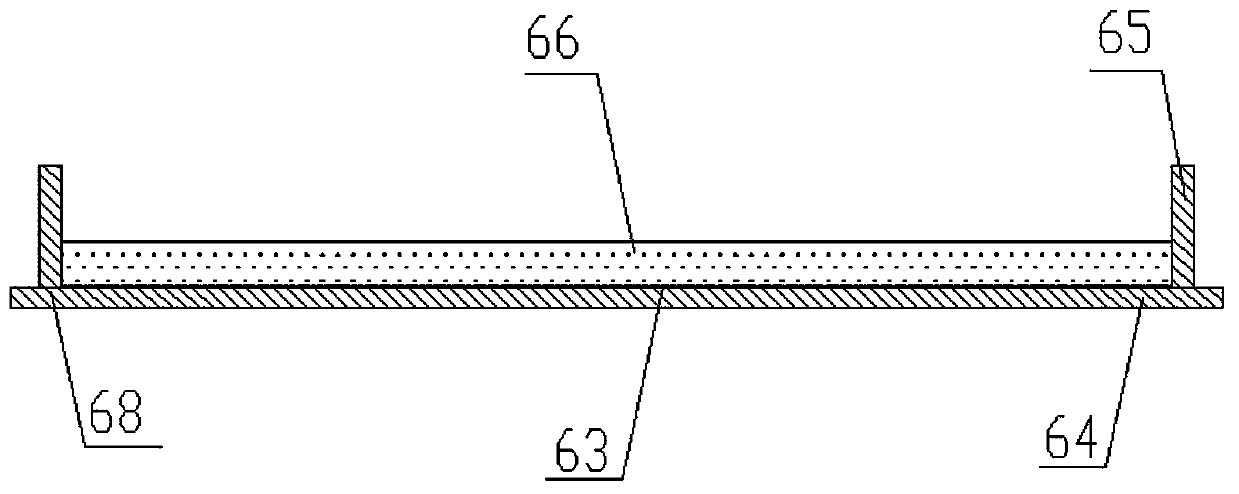

[0049] Such as figure 1 and figure 2 As shown, a new type of automatic production line for building wall materials of the present invention includes a crystallization forming furnace 10 with three layers of crystallization forming roller tables, a conveying device for carrying the forming mold 68 in and out of the crystallization forming furnace 10, and The distributing device 4 for injecting the raw material 66 into the forming mold 68 and the automatic operation device 3 for disassembling the forming mold 68 and taking out the forming material 67 from the forming mold 68 . The crystallization forming furnace 10 is similar to a slow cooling roller kiln CN207716845U for firing foamed ceramics in the disclosed patent, and no specific statement is made. Such as image 3 As shown, the structure of the forming mold 68 is a rectangular structure surrounded by a mold bottom plate 64 and four mold bottom plates 64 with an open top, through which the powdery raw material 66 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com