Patents

Literature

49 results about "Pin distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

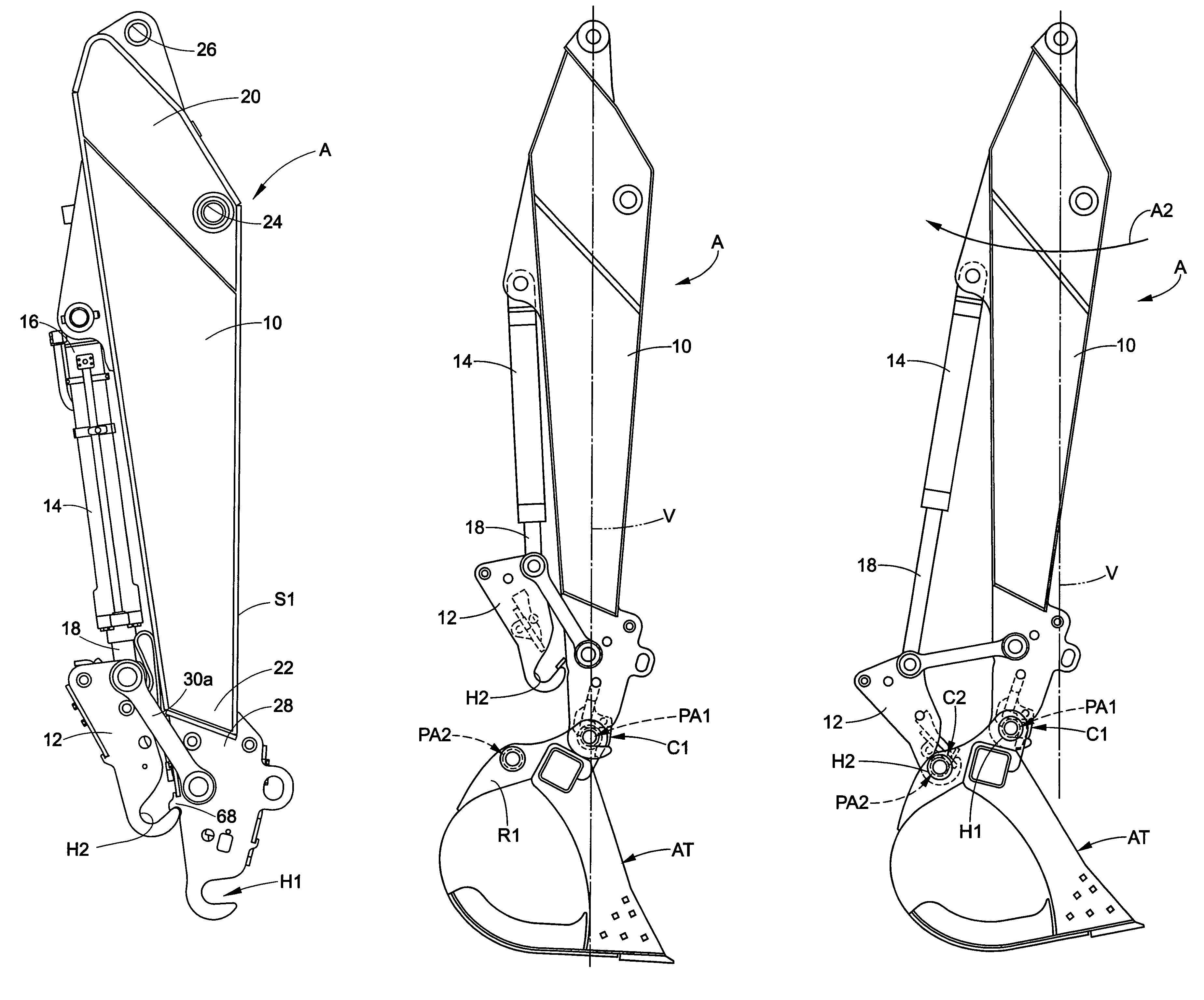

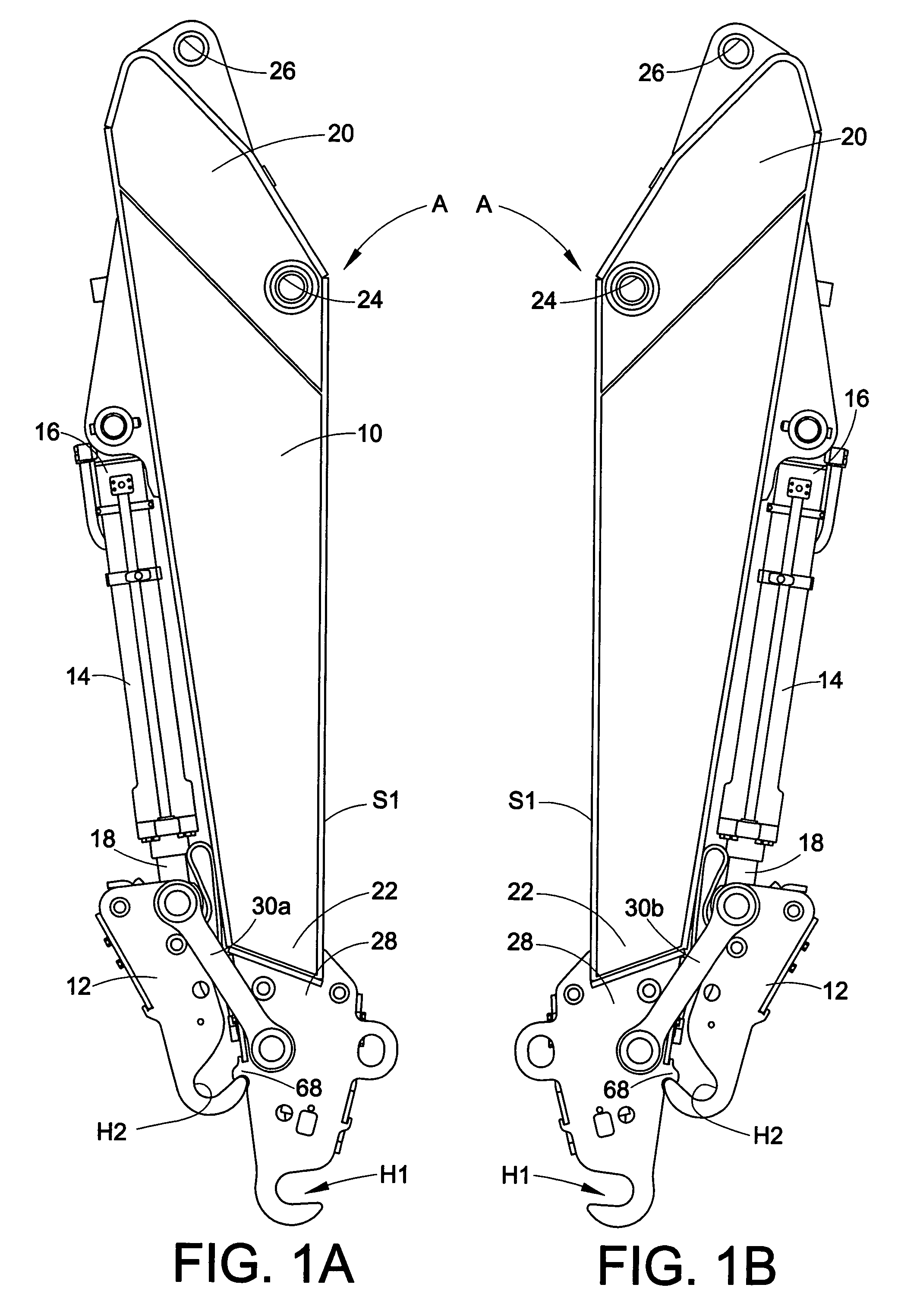

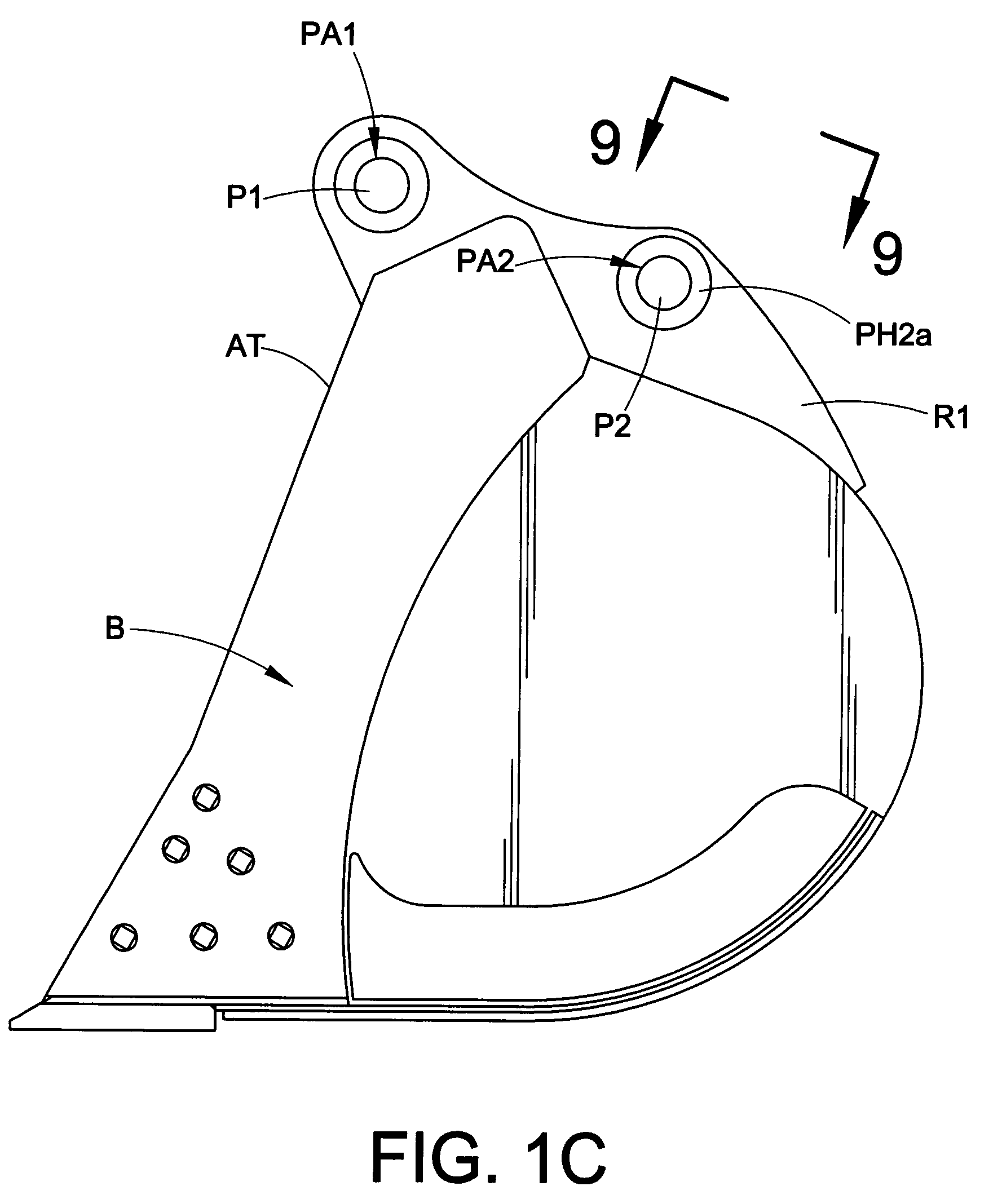

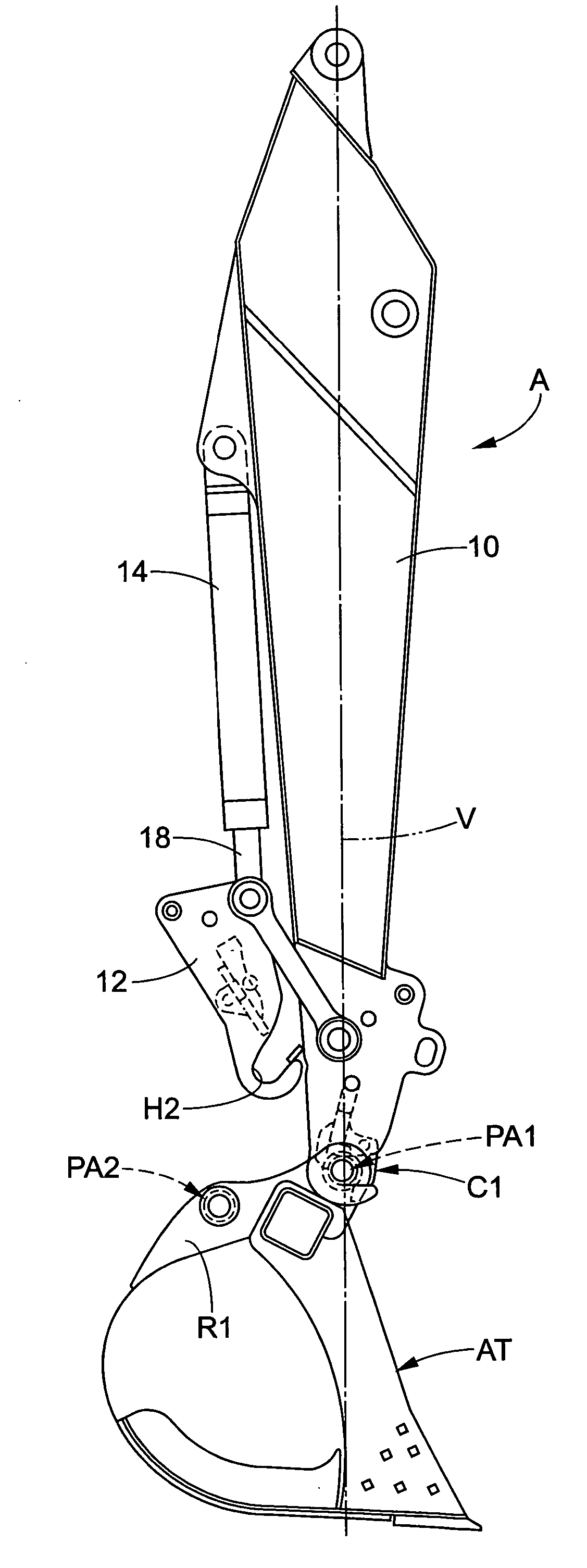

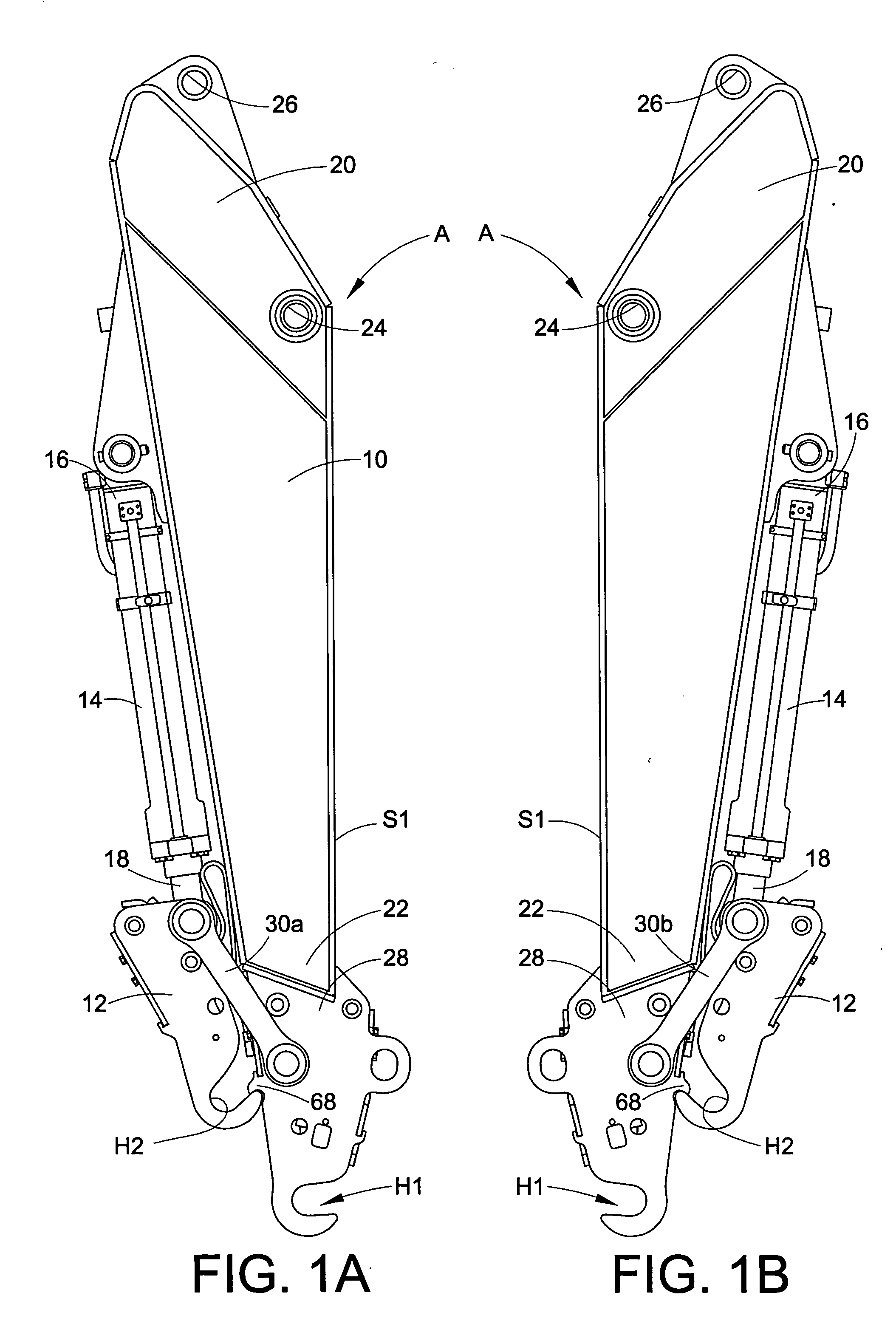

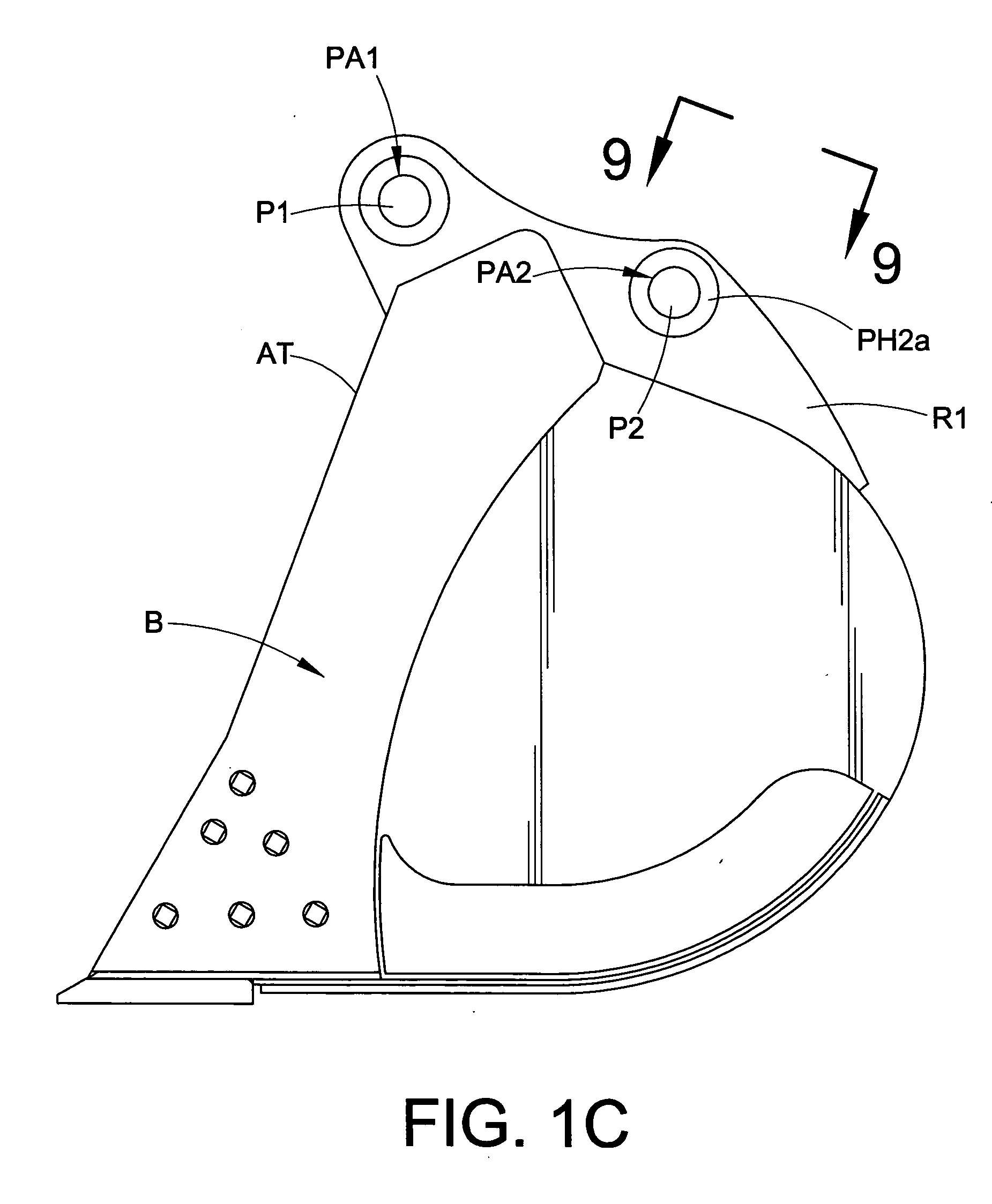

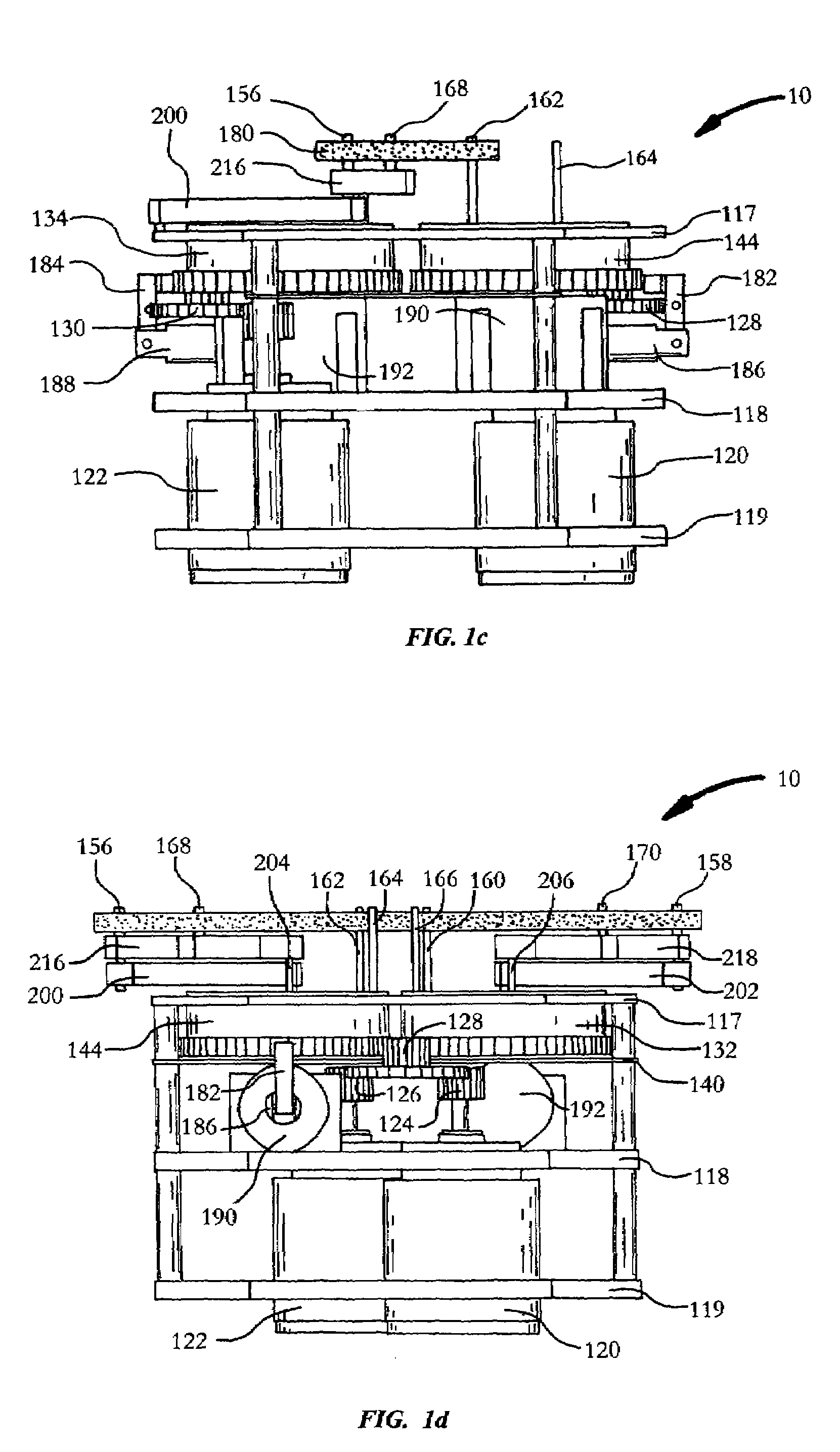

Arm assembly for excavation apparatus and method of using same

An arm assembly for an excavator includes an arm comprising a first hook including a first open mouth. The arm further includes a first pin capturing system that selectively obstructs the first open mouth. A link is movable relative to the arm and comprises a second hook including a second open mouth. The second open mouth is oriented toward the arm, and the link further comprises a second pin capturing system that selectively obstructs the second open mouth. The first and second pin assemblies of an attachment are selectively captured in the first and second hooks. The pin assemblies include a sleeve rotatably positioned on an attachment pin that extends between ribs of the attachment. The sleeve includes a bore that closely receives the attachment pin and the length of the sleeve is selected so that the sleeve fits closely between the attachment ribs, thereby allowing the arm assembly to pick-up various attachments with different pin diameters, ribs spacings and pin-to-pin distances. The arm assembly can be coupled to and decoupled from an associated attachment by an operator without assistance from a ground crew.

Owner:PALADIN BRANDS GROUP

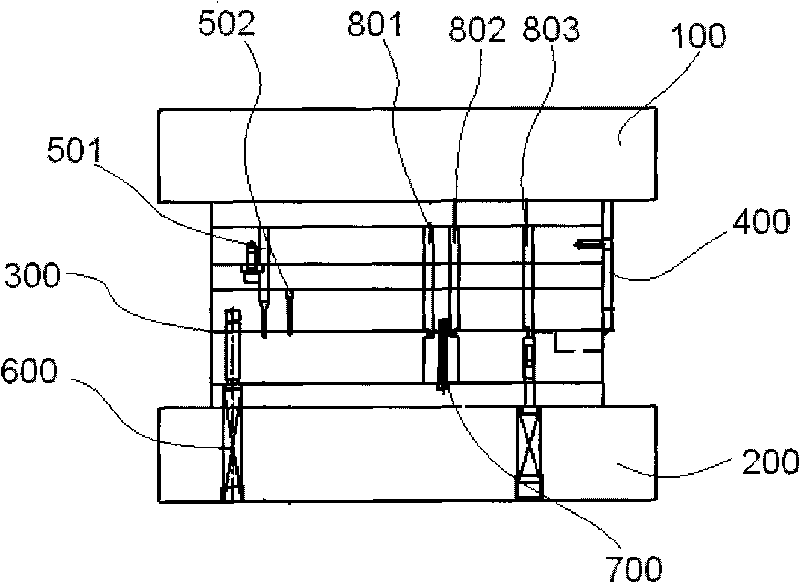

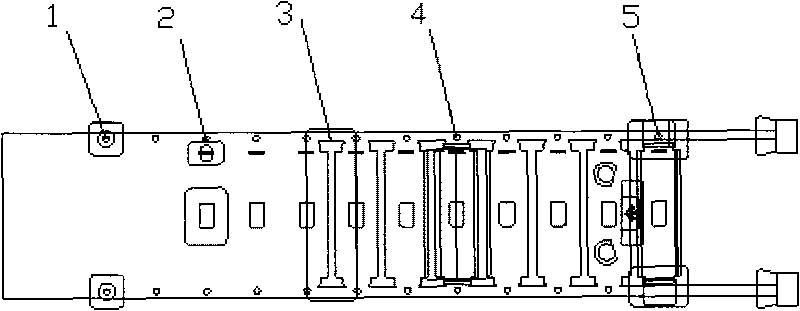

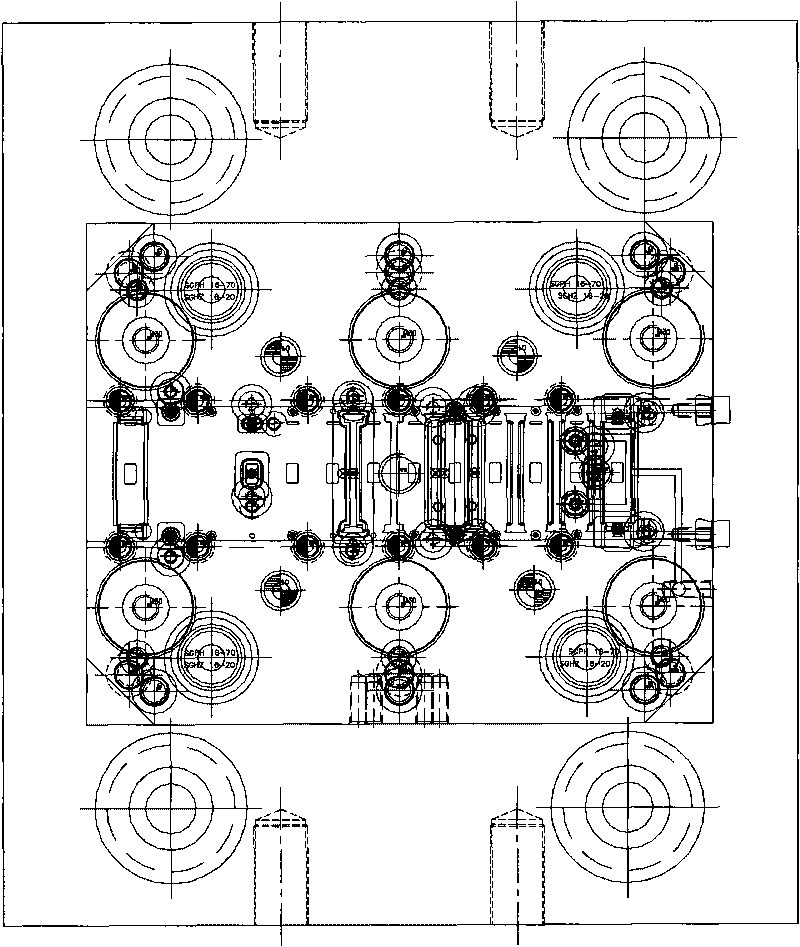

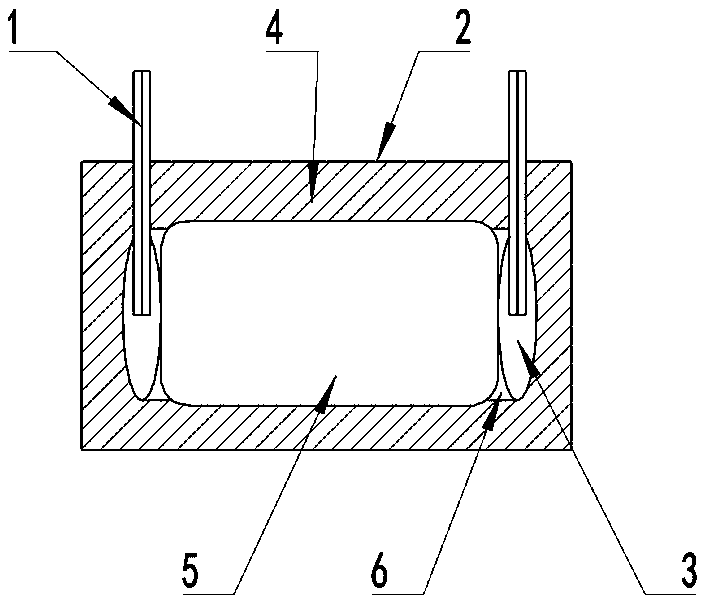

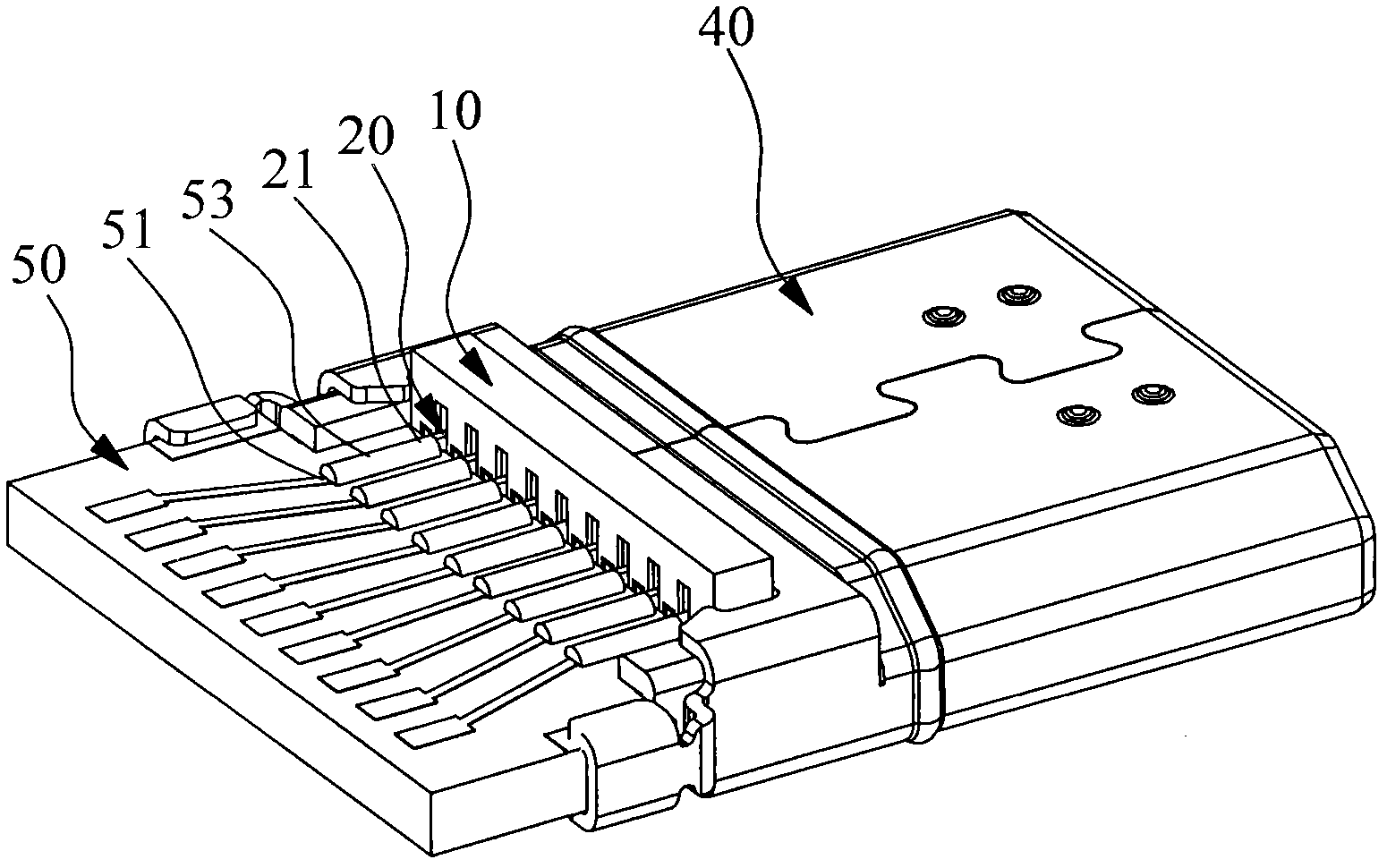

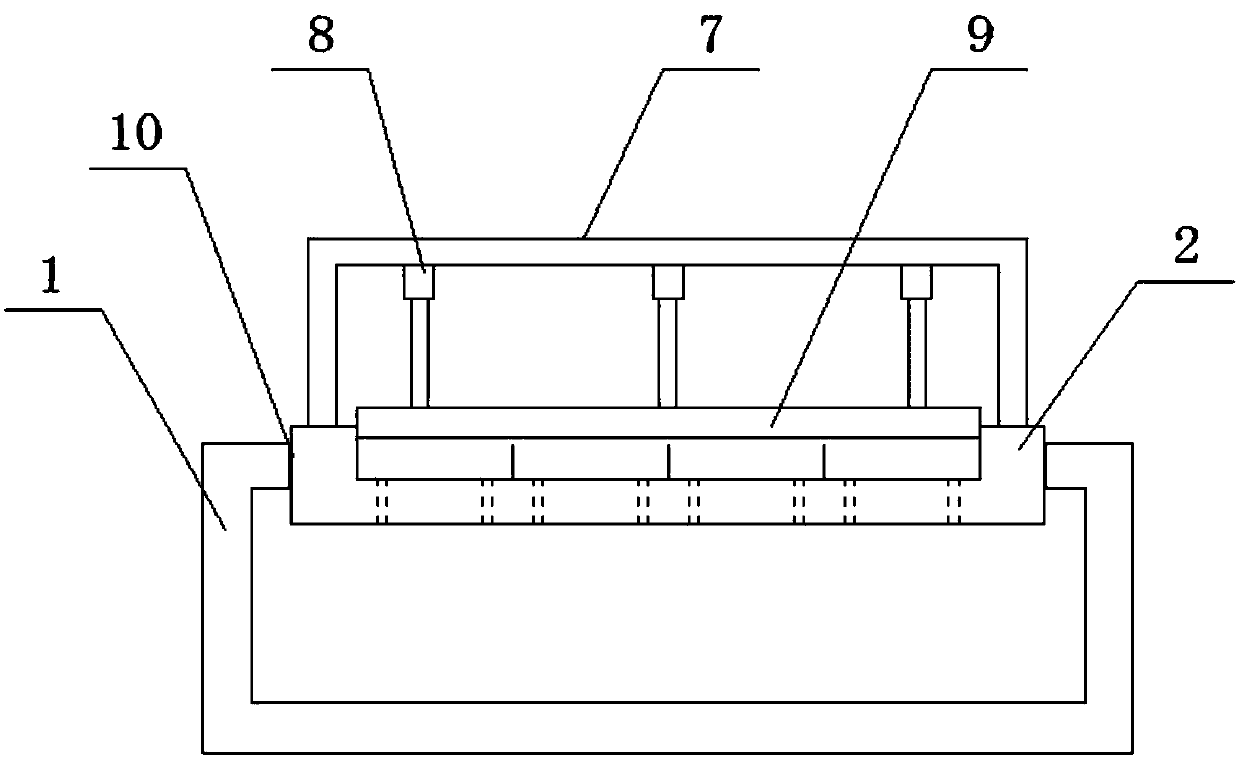

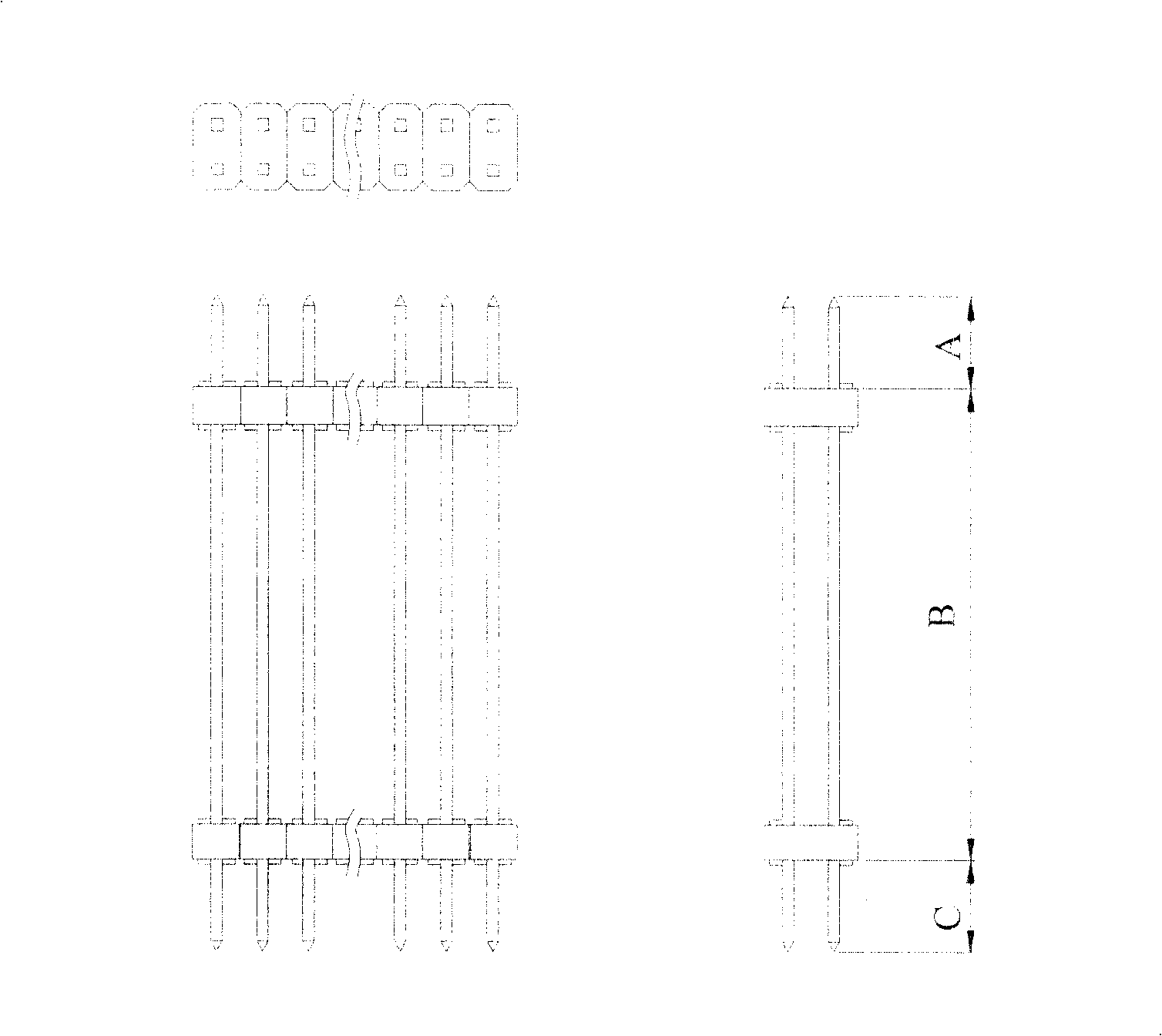

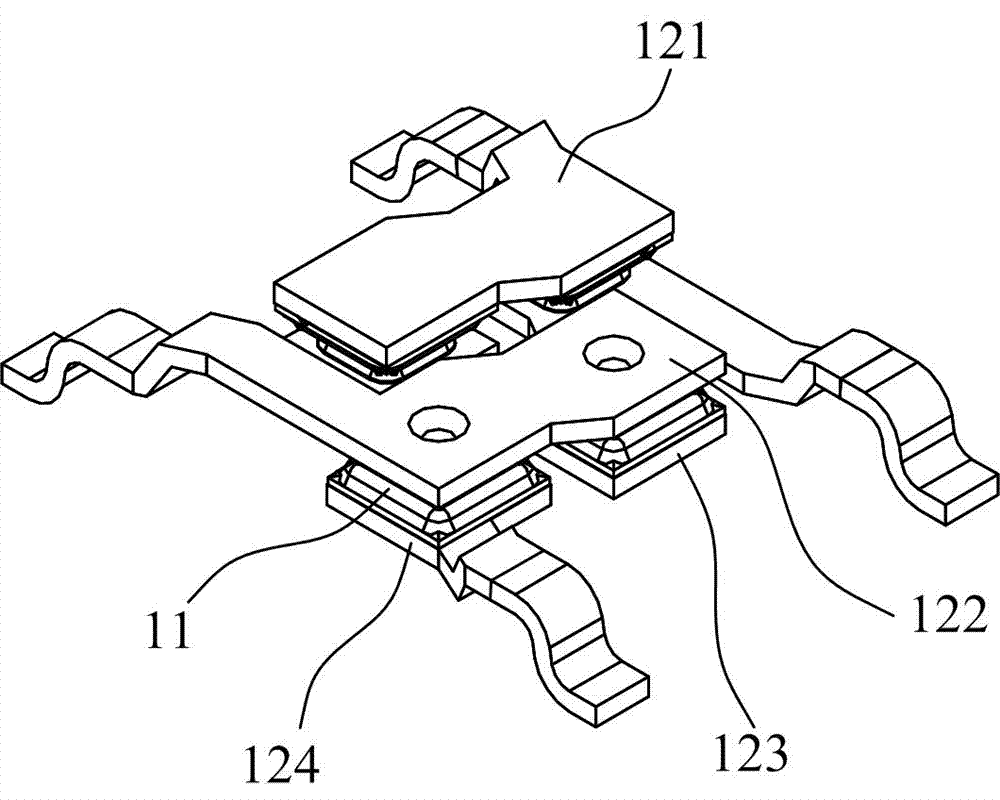

Die for progressive die of parts and components of electric appliance

The invention discloses a die for progressive die of parts and components of an electric appliance. The progressive die comprises a first guidance drift and a second guidance drift used for controlling PIN distance and guiding, a dual-purpose lifter pin, a belt, a forming insert, a cutter and punches, wherein the punches comprise a first punch, a second punch and a third punch; the dual-purpose lifter pin is arranged on a lower liner plate, and the forming insert is arranged on one side of the dual-purpose lifter pin; the belt is arranged above the lower liner plate; the first guidance drift and the second guidance drift are arranged on an upper die seat; the first punch, the second punch and the third punch are arranged on the upper die seat sequentially, and the cutter is arranged on one side of the upper die seat. The die has the advantages that the structure is simple, the manufacture is convenient, the cost is low, certain processing quality requirement can be satisfied, and compared with the common die, the on-production time is short, and the manufacturing cost is low, therefore, an economic and effective way is provided for the pilot production of new products and stamping production with less mass production requirement.

Owner:SUZHOU RISING CREATION PRECISION TOOLS

Arm assembly for excavation apparatus and method of using same

Owner:JRB ATTACHMENTS

High-moisture-resistance metallized polypropylene film capacitor and processing method thereof

InactiveCN110164691AImprove bindingImprove moisture resistanceFixed capacitor electrodesThin/thick film capacitorAdhesiveMoisture resistance

The invention discloses a processing method of a high-moisture-resistance metallized polypropylene film capacitor, and relates to the technical field of capacitors. The method comprises the followingsteps: S1, film coating: carrying out low-temperature plasma corona treatment on the surface of a polypropylene film so that a dangling bond can be formed on the surface of the polypropylene film, andthen plating a metal coating on the surface of the polypropylene film; S2, metal spraying: performing metal spraying treatment on the core (a metal spraying material is a zinc-aluminum wire), and coating the surface of the core with an aluminum foil adhesive tape after metal spraying is completed; S3, energizing: automatically testing the core on an energizing machine; S4, welding: automaticallyfeeding the core to a welding machine through a vibrating disc, and then performing the welding operation after the distance between the welding joints is adjusted to be equal to the pin distance of the capacitor. The invention has the beneficial effects that the capacitor manufactured through the method can meet the requirements of the service life test of 85 DEG C, 85% of RH, 1-time of rated voltage and 1000 hours, and the capacity attenuation of the capacitor is smaller than 10%.

Owner:艾华新动力电容(苏州)有限公司

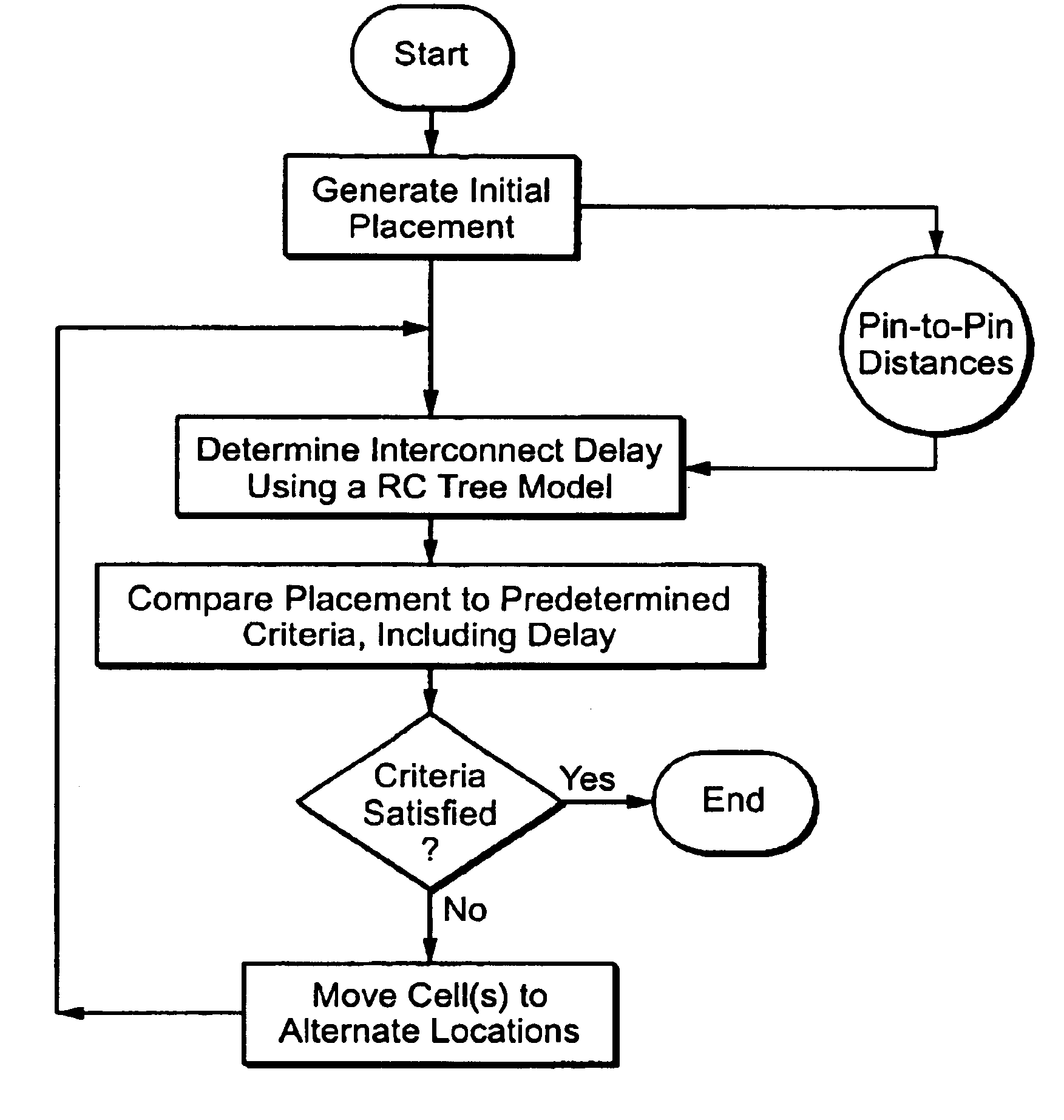

Timing-driven placement method utilizing novel interconnect delay model

InactiveUS6901571B1Computer aided designSoftware simulation/interpretation/emulationPin distanceEngineering

A method for optimal placement of cells on a surface of an integrated circuit, comprising the steps of comparing a placement of cells to predetermined cost criteria and moving cells to alternate locations on the surface if necessary to satisfy the cost criteria. The cost criteria include a timing criterion based upon interconnect delay, where interconnect delay is modeled as a RC tree expressed as a function of pin-to-pin distance. The method accounts for driver to sink interconnect delay at the placement level, a novel aspect resulting from use of the RC tree model, which maximally utilizes available net information to produce an optimal timing estimate. Preferred versions utilize a RC tree interconnect delay model that is consistent with timing models used at design levels above placement, such as synthesis, and below placement, such as routing. Additionally, preferred versions can utilize either a constructive placement or iterative improvement placement method.

Owner:BELL SEMICON LLC

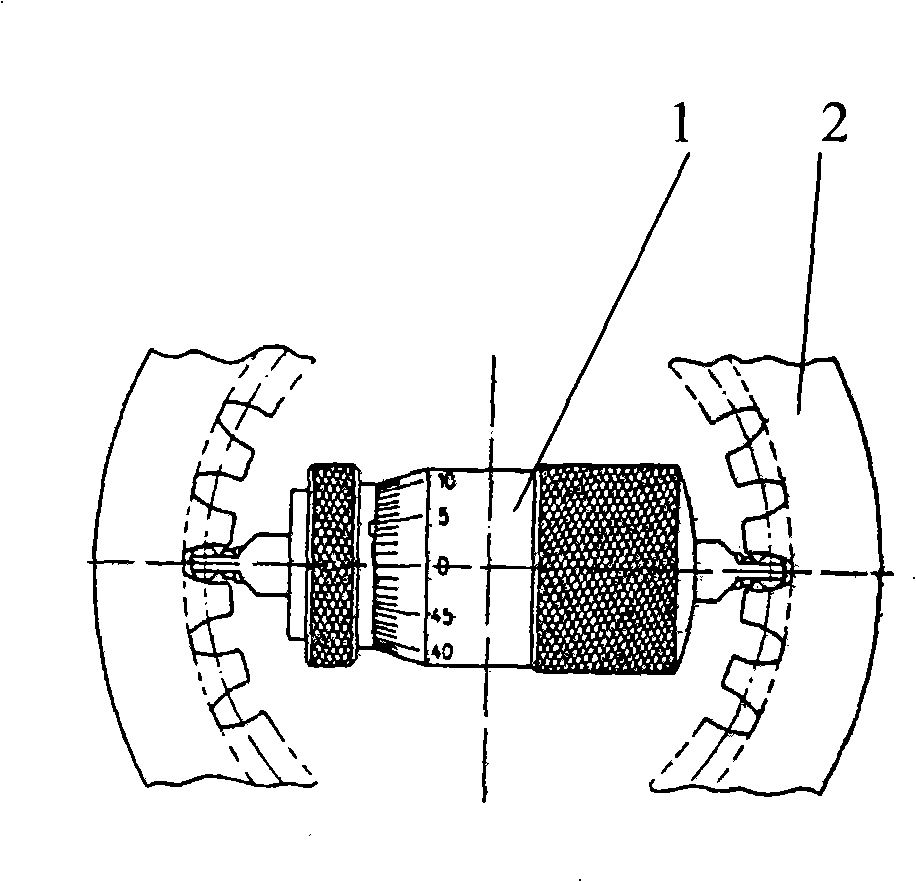

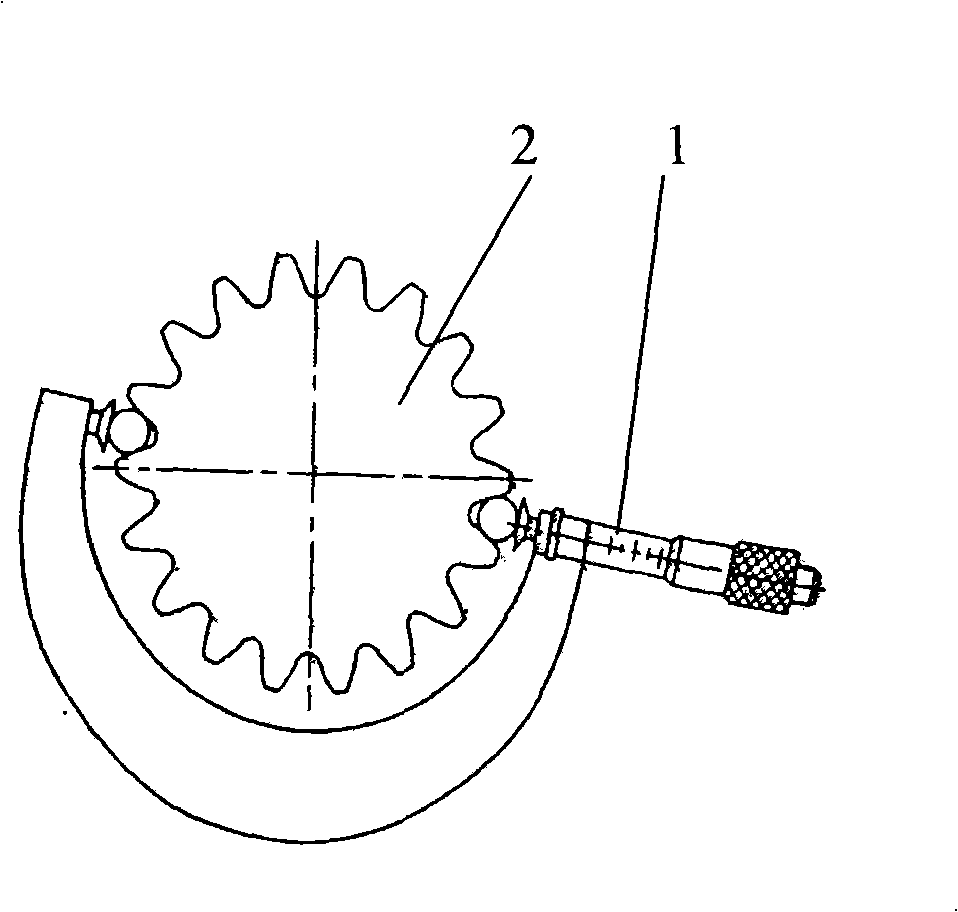

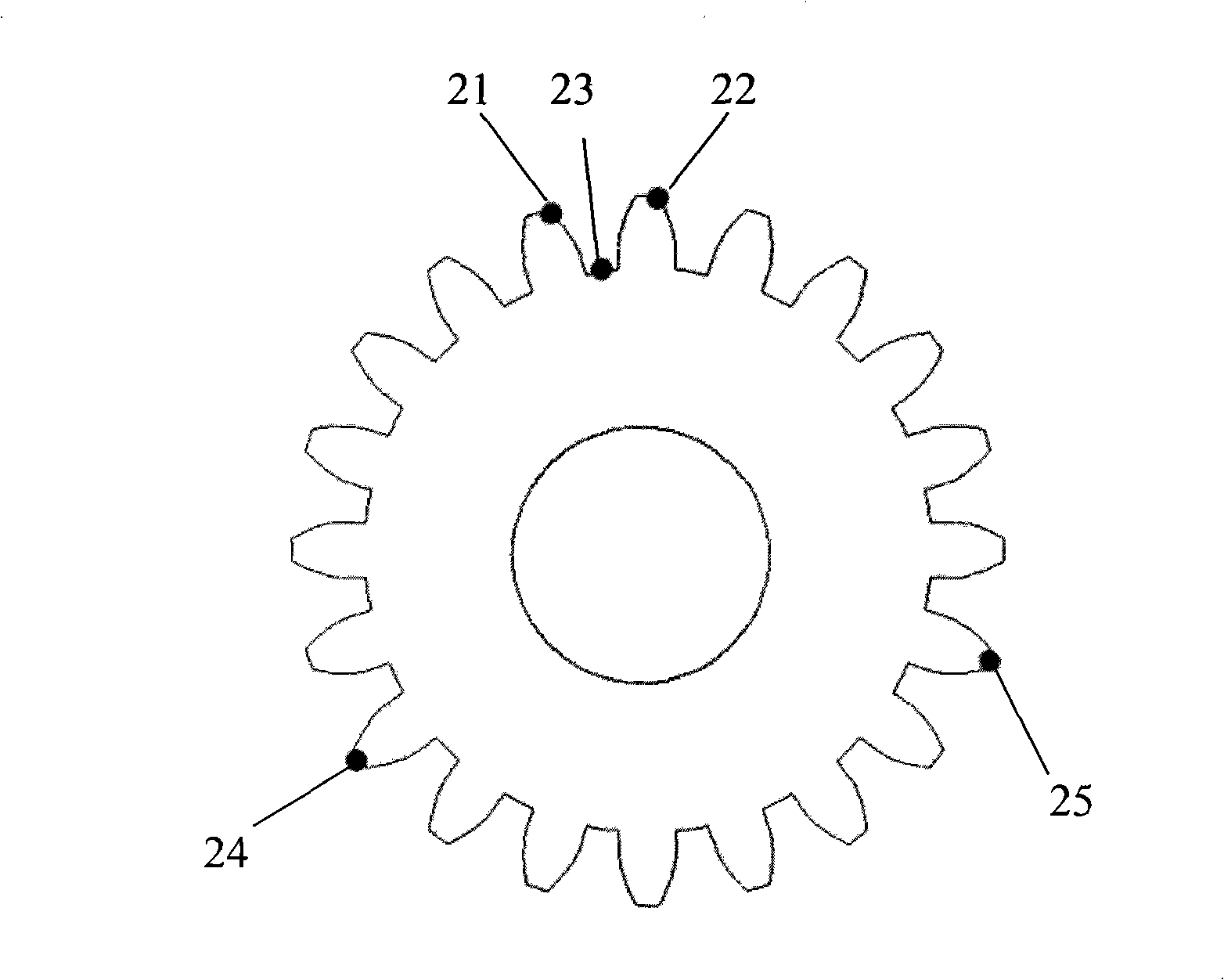

Gear cylinder or ball measurement method and system

InactiveCN101339009AAccurate spanAutomatic calculation of cross-pin distanceUsing optical meansTooth numberTeeth count

The invention provides a gear column or sphere measuring method and a system thereof. The method and the system are used for measuring an involute spur gear. The system initiates software achieving the method which comprises an image system and a data processing system. The data processing system comprises a CPU, an input device connected with the CPU by means of signal, a memory, a monitor, an output interface. The image system is connected with the CPU by means of signal. The method includes the following steps: the image system is used for inputting the outline of the gear to the coordinate system of the data processing system; two adjacent tooth top corresponding points, one tooth root point between the two points and another tooth top point are selected; the coordinates of the selected points are acquired; the coordinates of the center, the spanned tooth count and other gear parameters of the gear are computed; the outline of the gear is fitted; a base circle is drawn; the origin of a survey coordinate system coincides with the center of the gear; a spanned pin measurement sphere is supposed for measuring spanned pin distance; gear teeth are selected, and the measurement result is output. The method and the system provided by the invention significantly improve the accuracy of measurement of gears and measurement efficiency, which are used simply and conveniently.

Owner:深圳智泰精密仪器有限公司

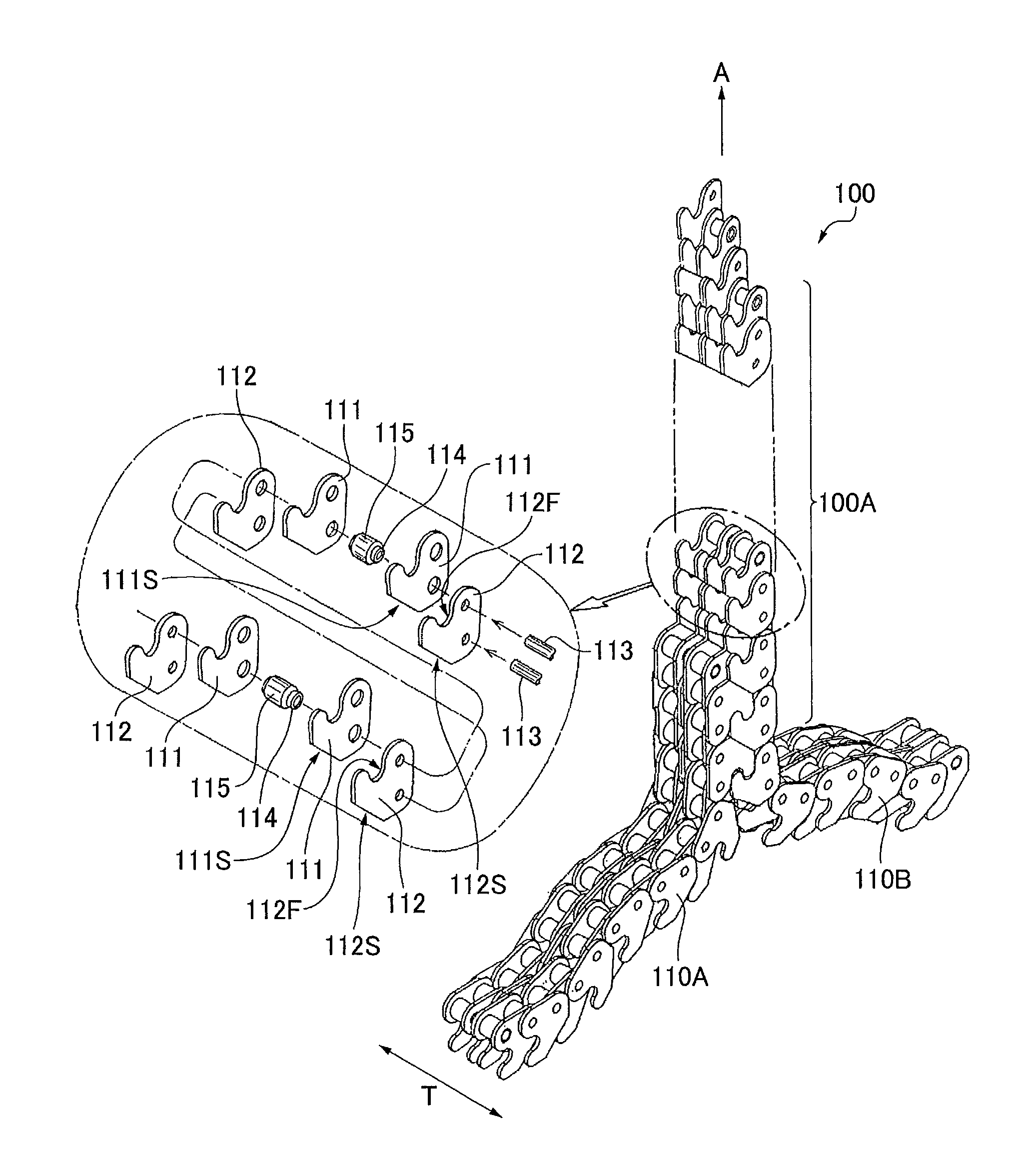

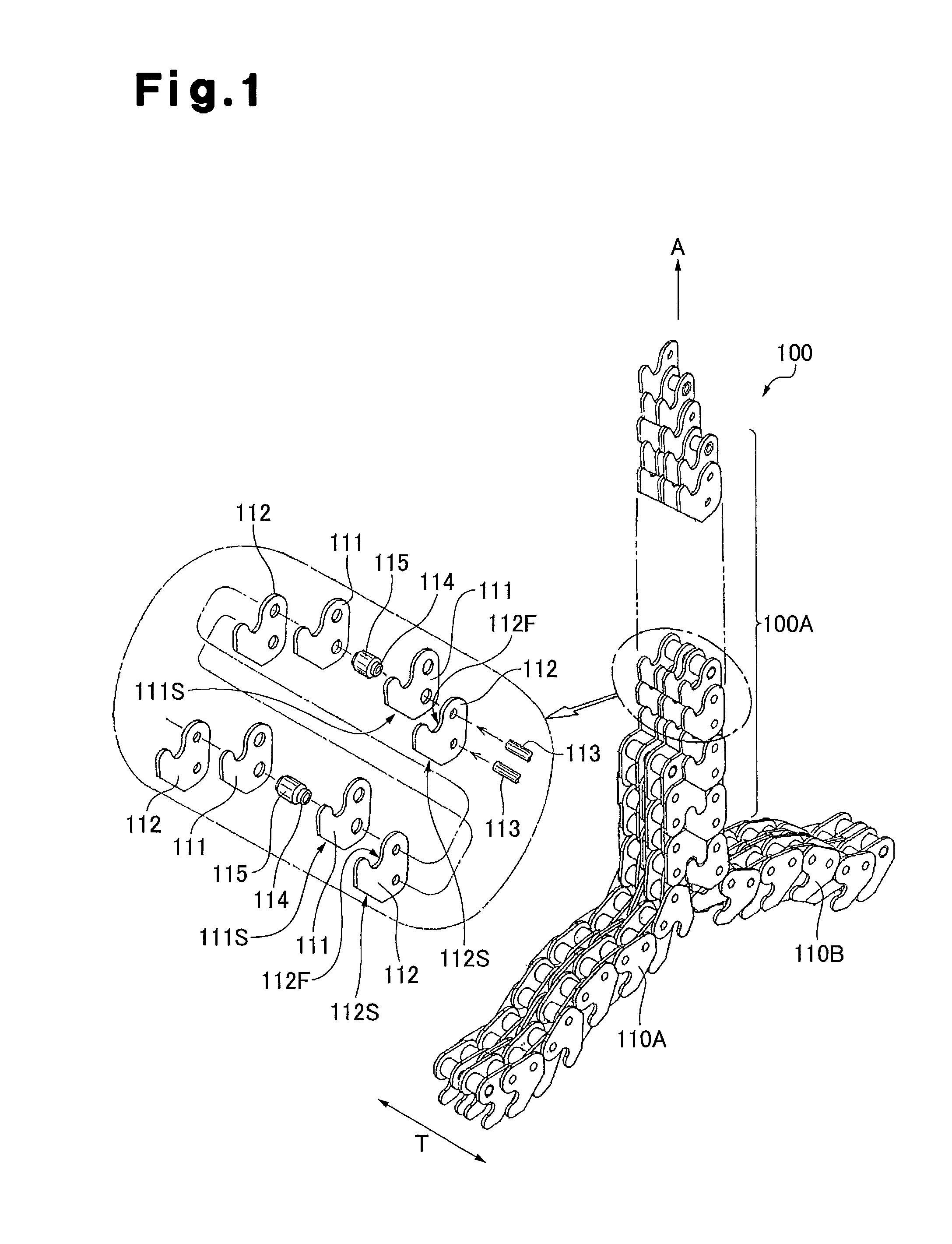

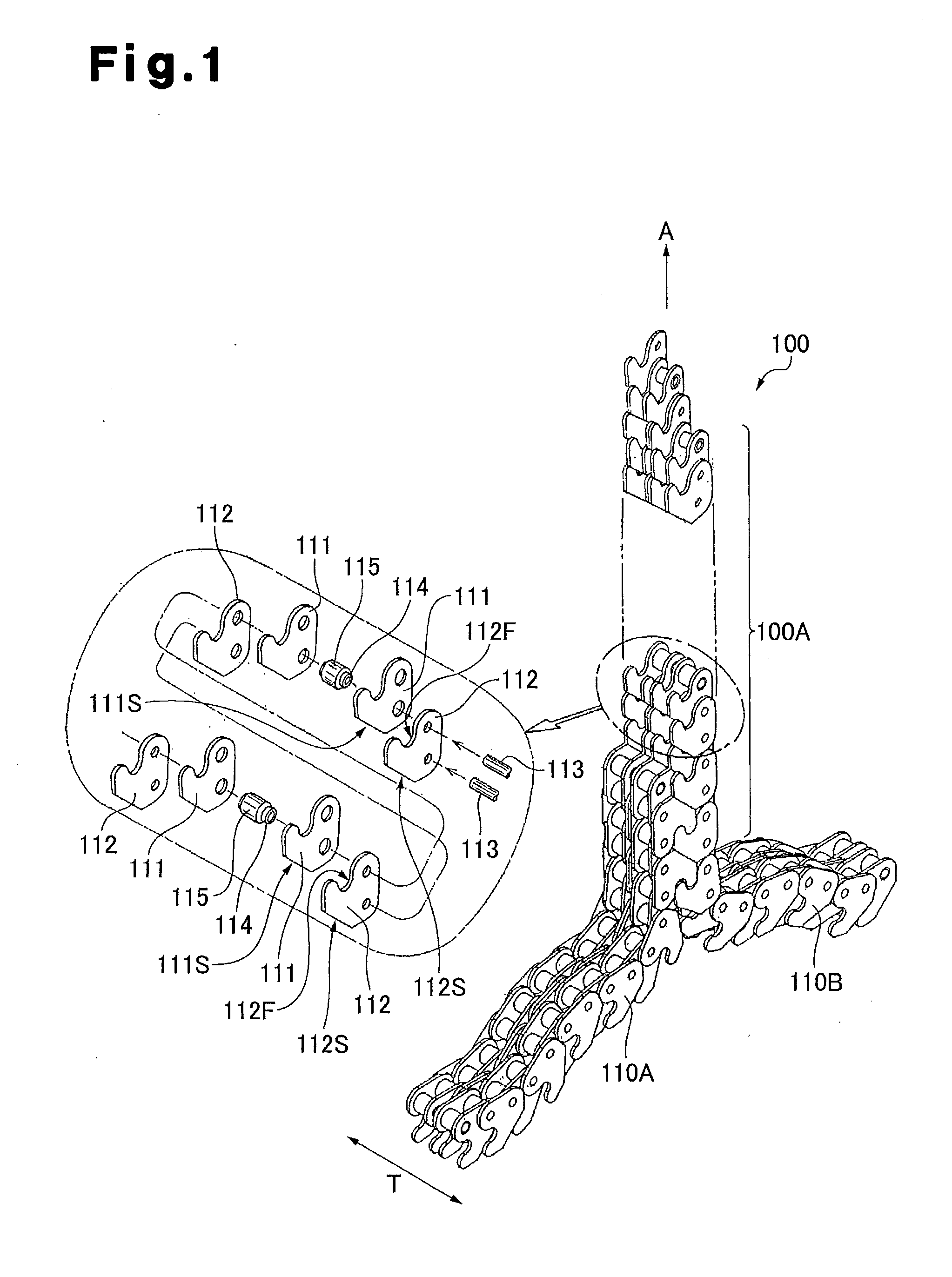

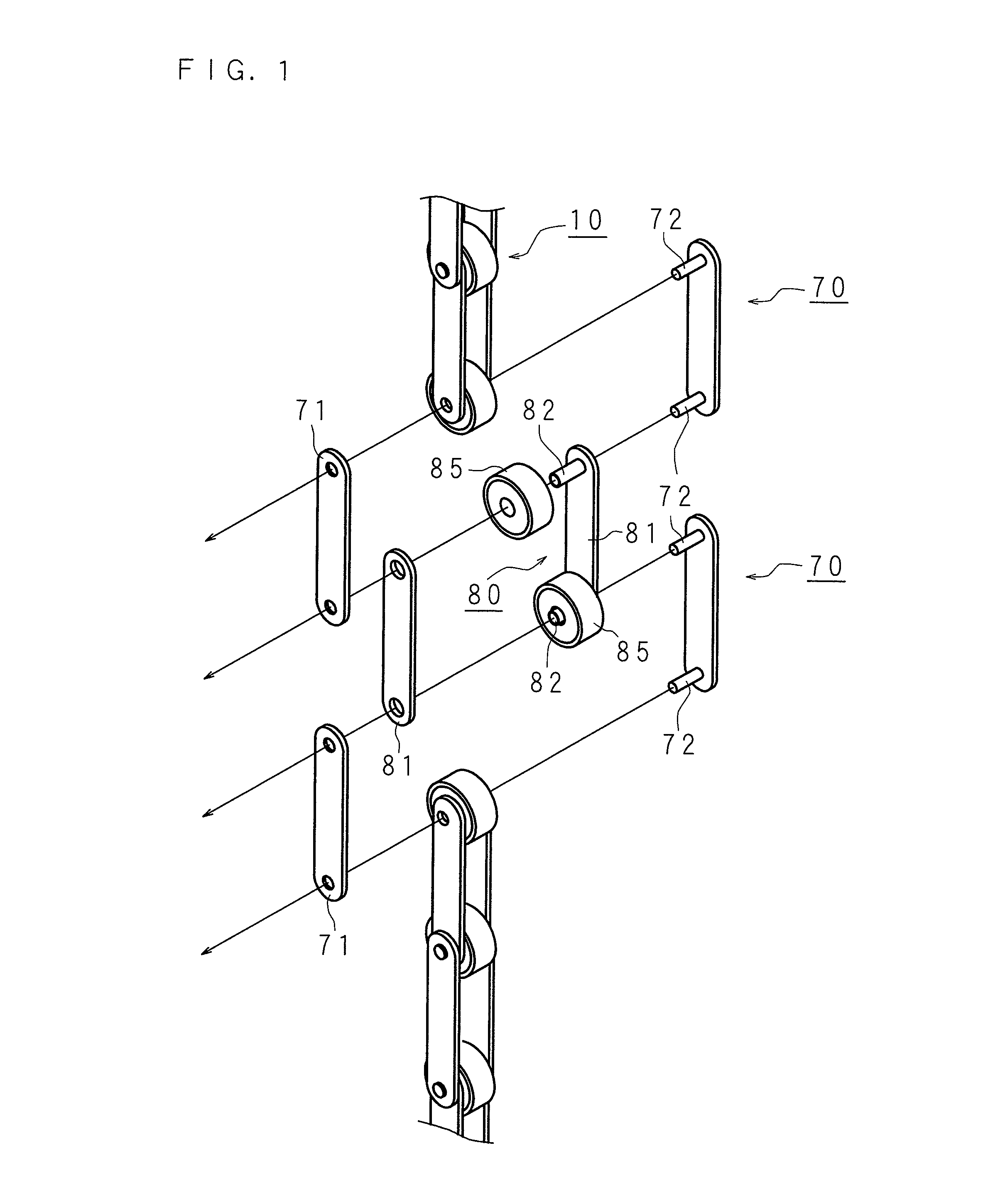

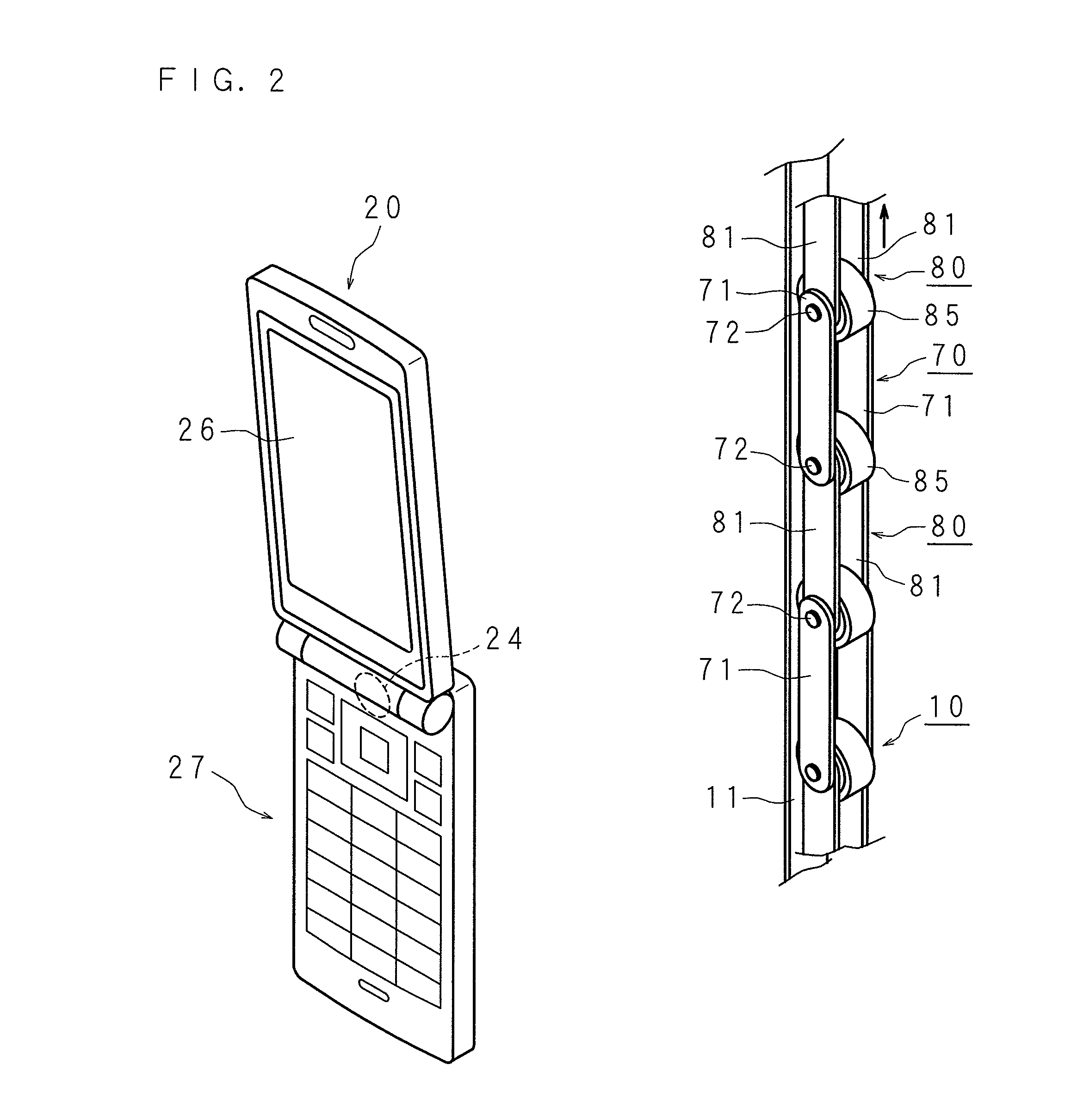

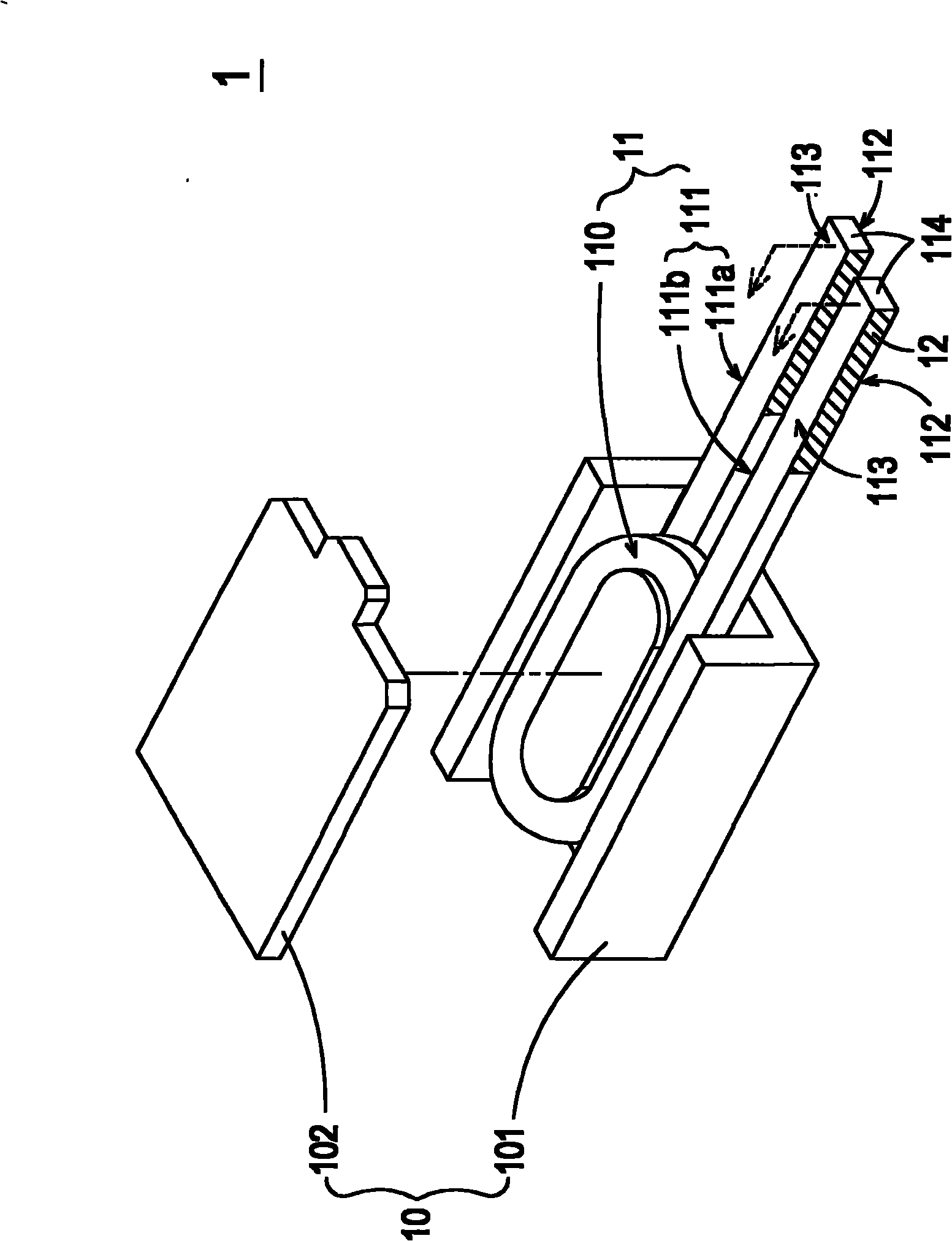

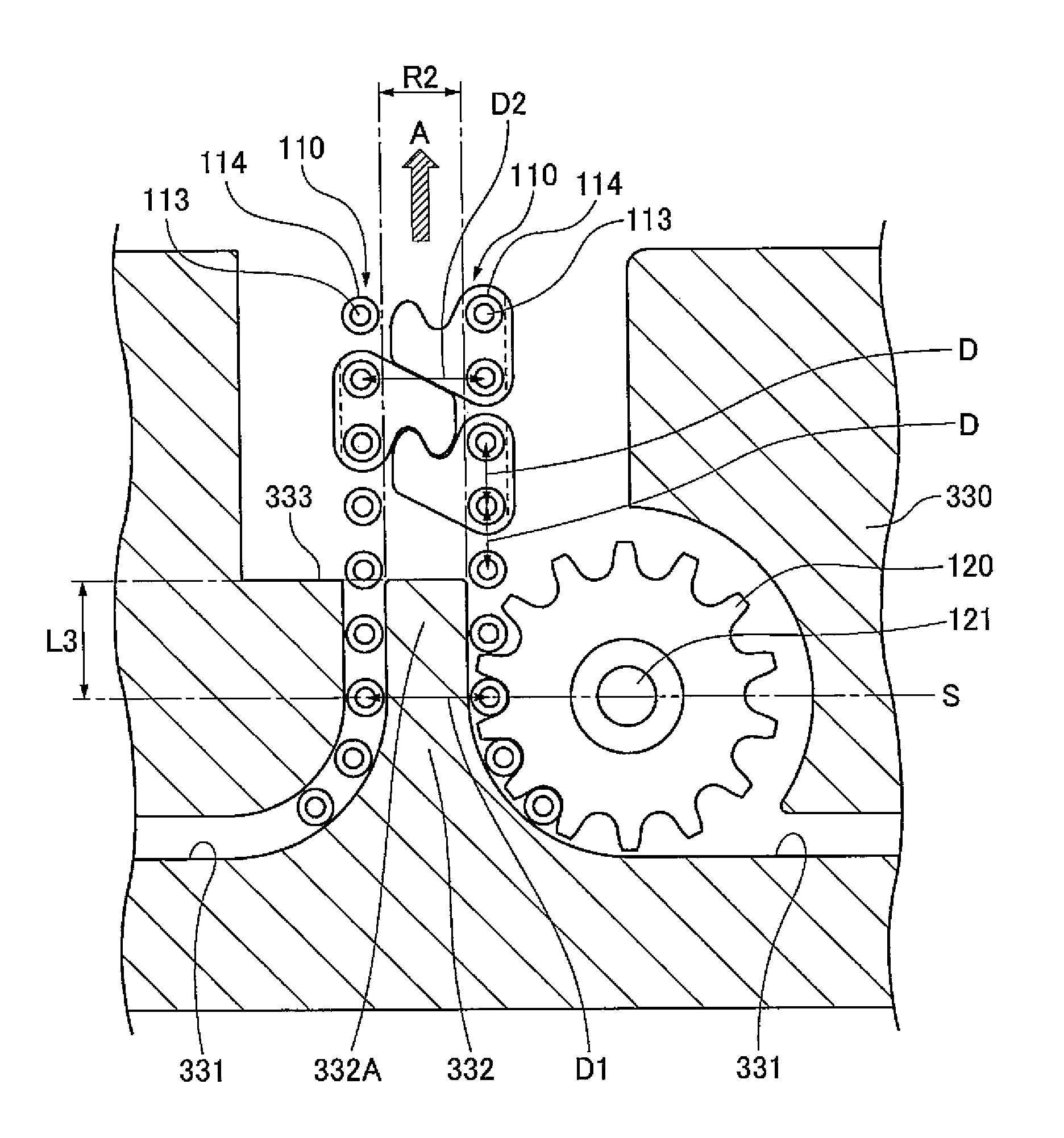

Engagement chain unit

ActiveUS8984975B2Difficult to avoid buckling, breaking, and bendingAccurate forward and backward movementLifting framesChain elementsPin distanceEngineering

Provided is an interlocking chain unit that has reliable and strong interlocking and avoids buckling, breaking, and bending of a rigidified chain portion. In the interlocking chain unit (100), the interlocking operation of an outer tooth link plate (112BZ) and an outer tooth link plate (112AY) that are just about to complete the interlocking operation is completed in a manner that causes a first inter-pin distance (d1) and a second inter-pin distance (d2) become substantially equal to each other, and causes a third inter-pin distance (d3) to approach the second inter-pin distance (d2).

Owner:TSUBAKIMOTO CHAIN CO

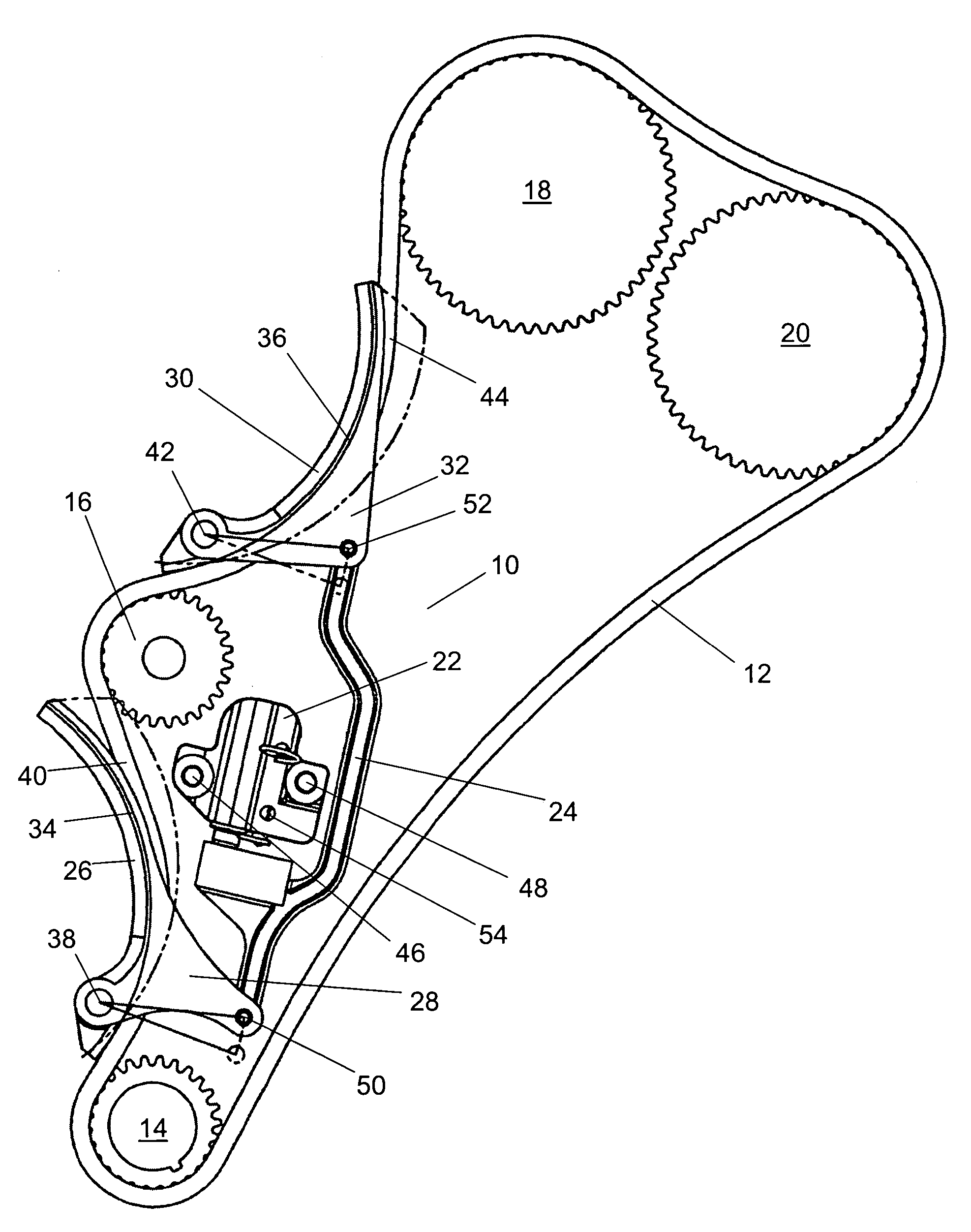

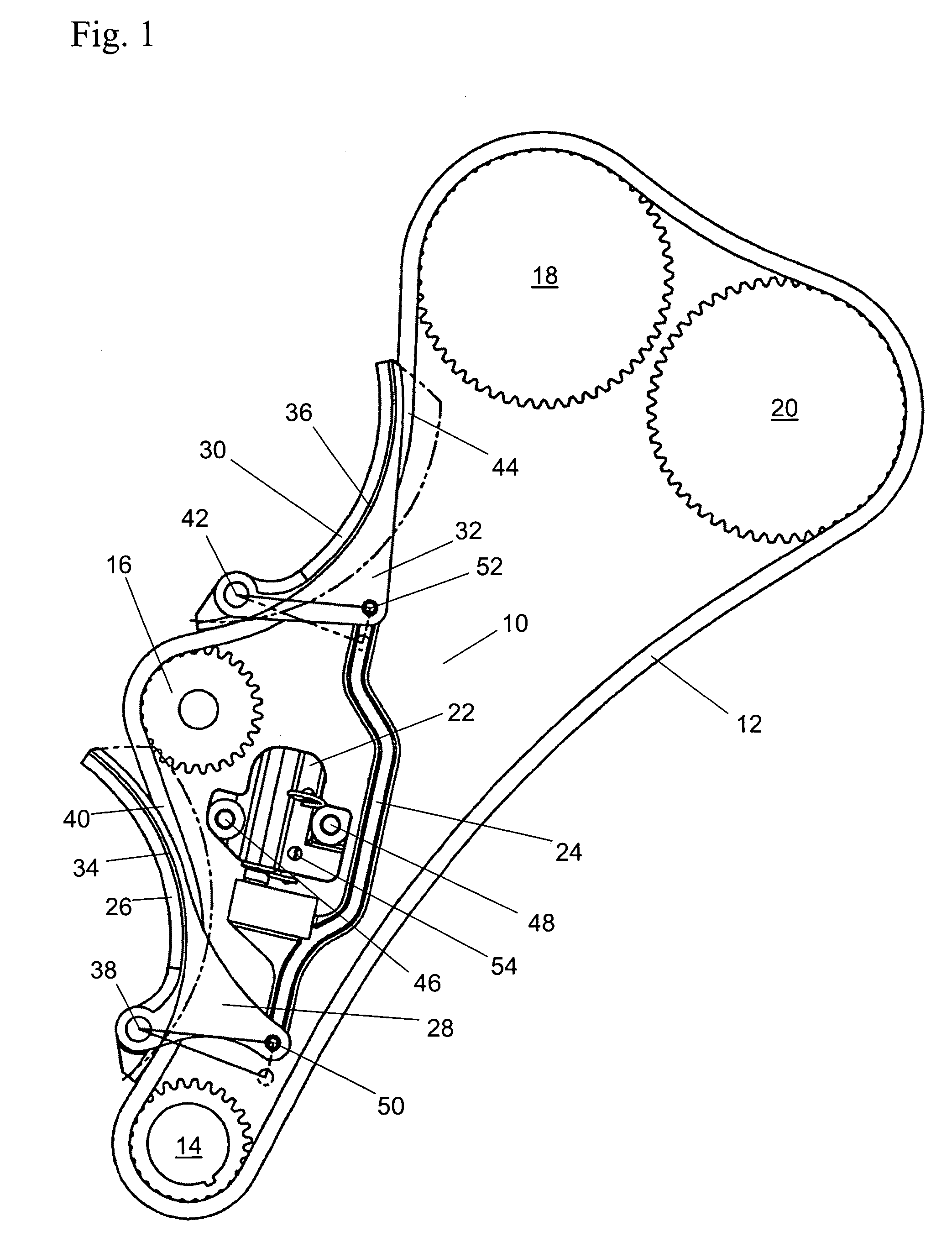

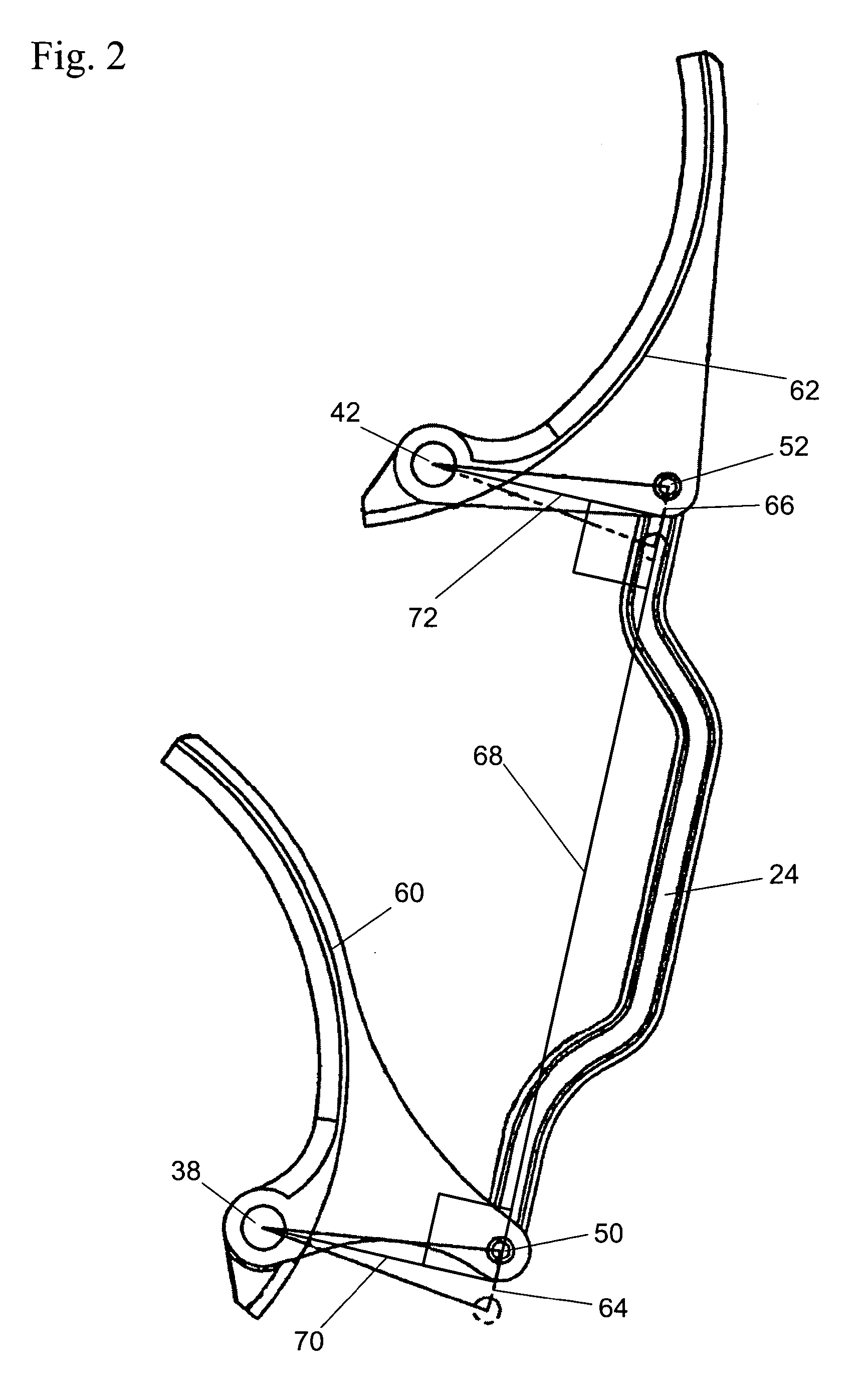

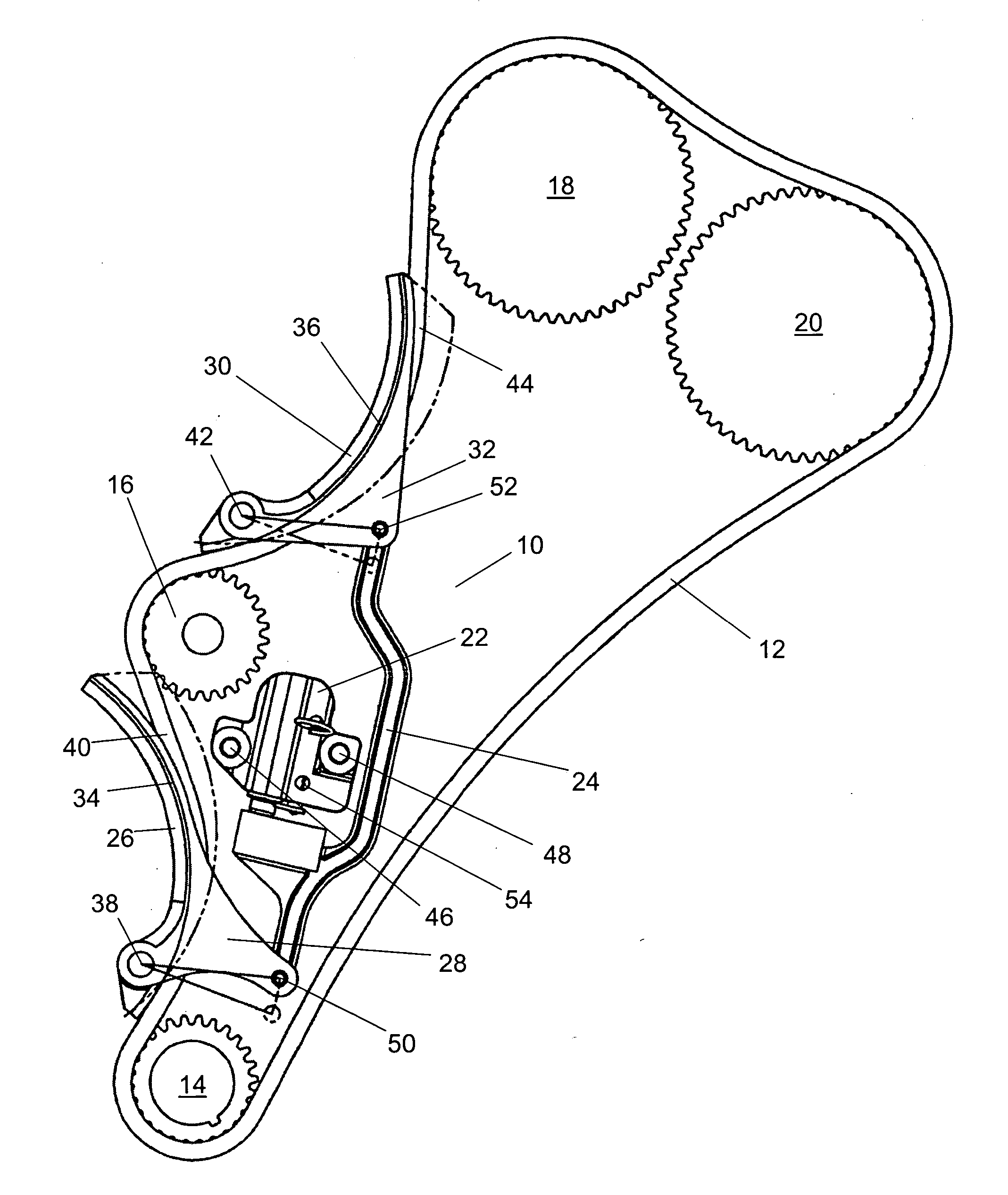

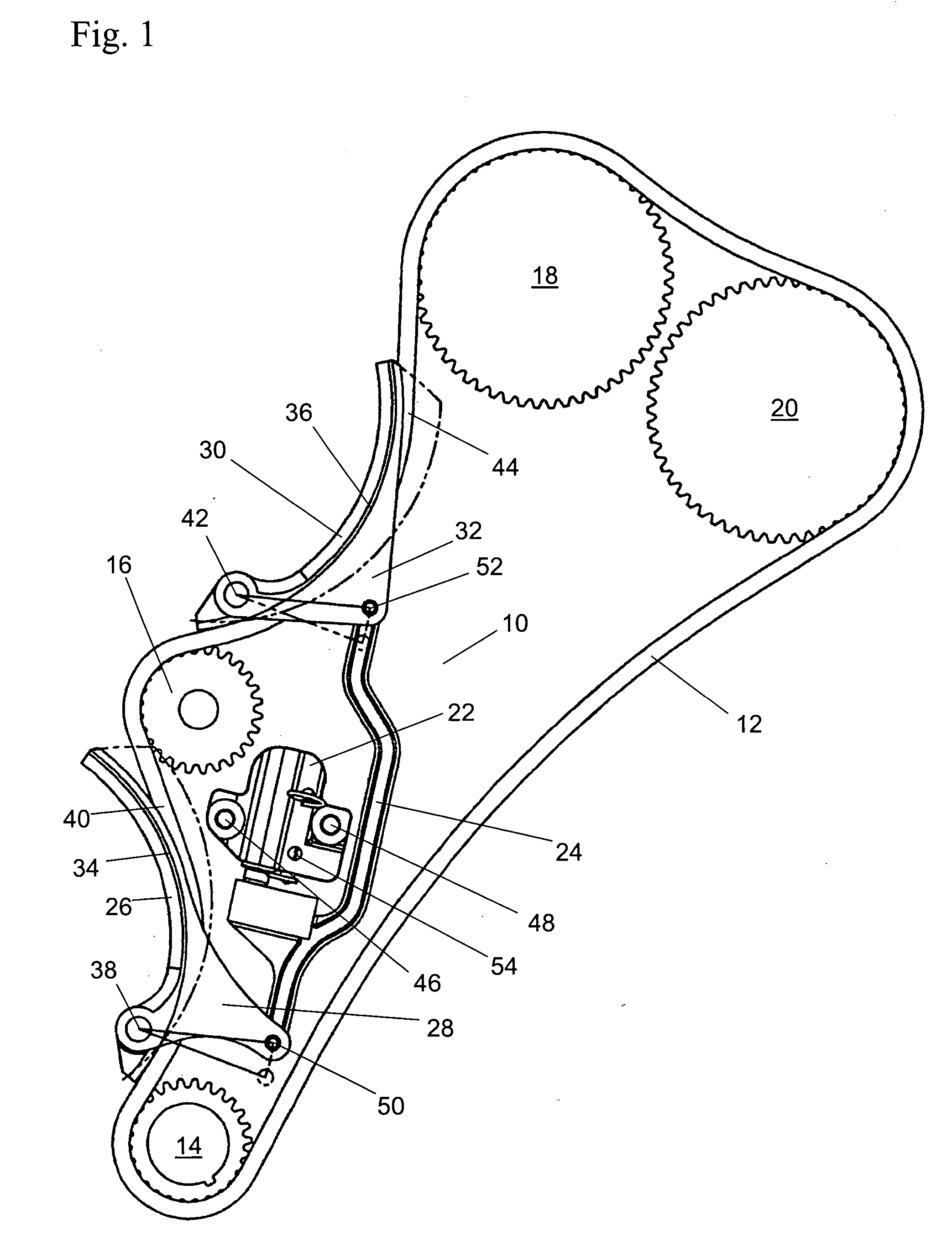

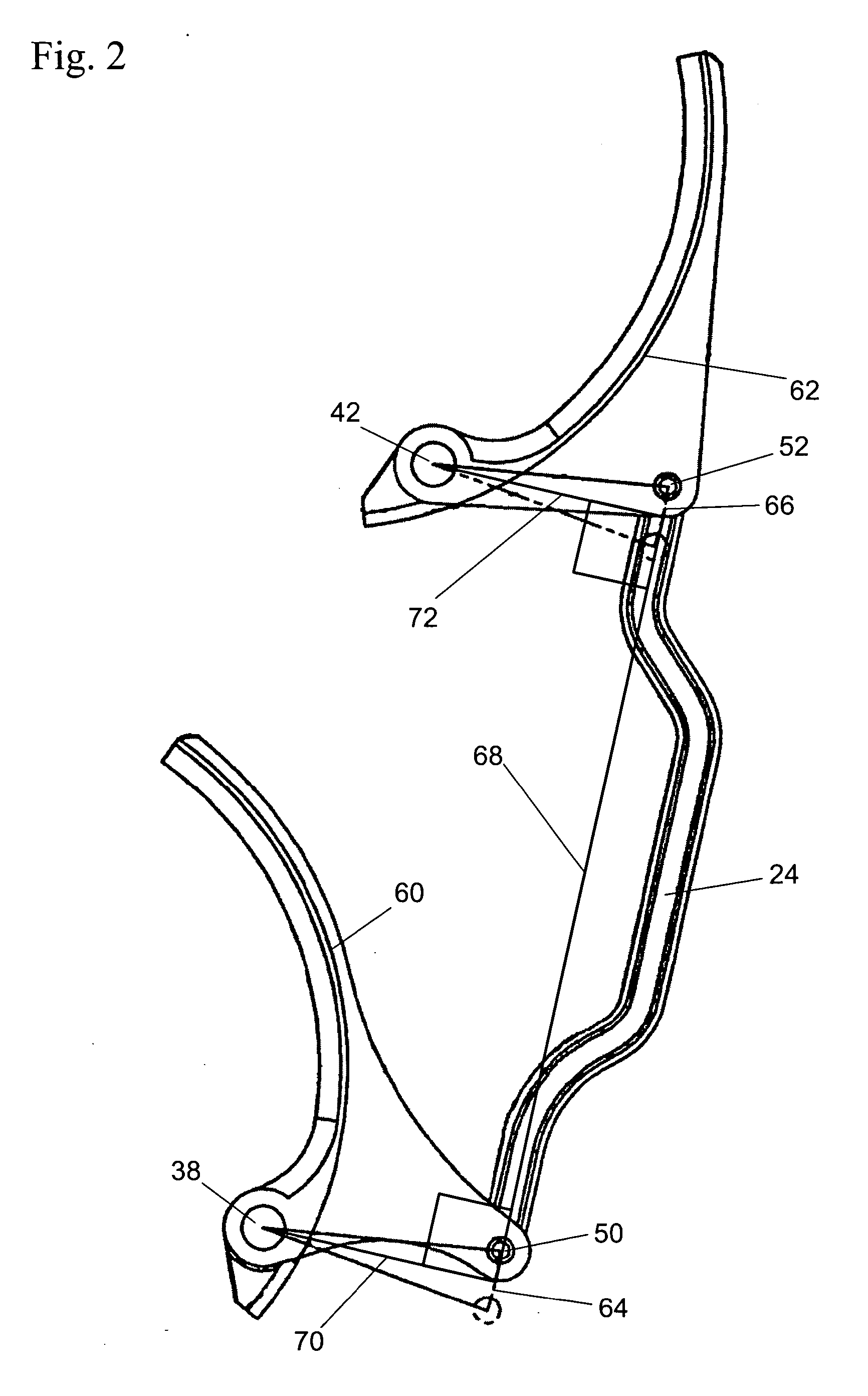

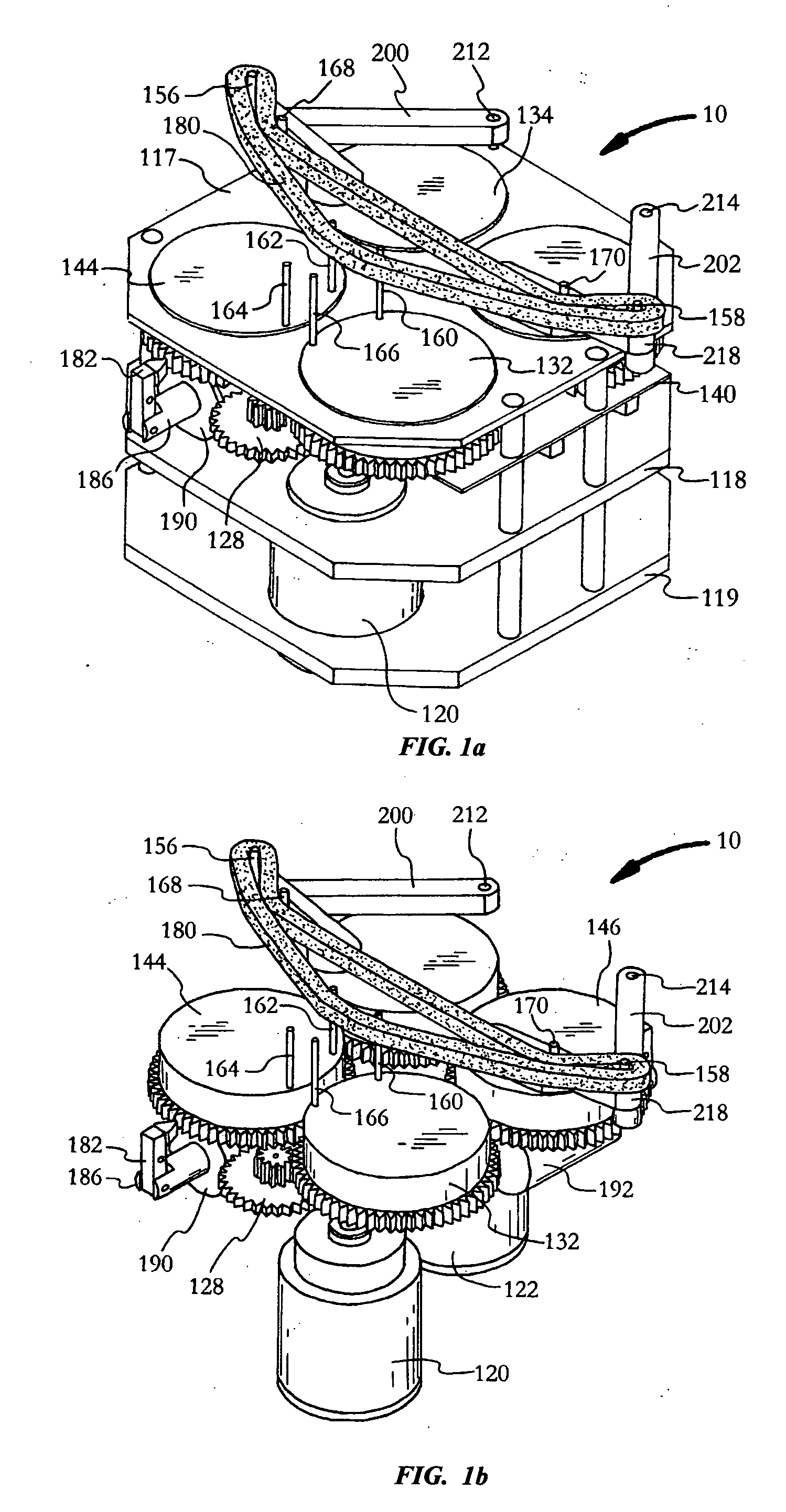

Common link dual arm tensioning device

A chain tensioning device links multiple tensioning arms to a common link, causing the tensioning arms to rotate into and displace chain strands with a single applied force and motion. The two tensioning arms rotate and tension proportionally, and when the pivot pin distances are equal, the two tensioning arms rotate and tension equally. The chain tensioner is preferably used to tension two slack chains flanking an auxiliary drive shaft. The chain tensioner is biased against the chain by a hydraulic tensioning assembly in one embodiment and by a spring tensioning assembly in another embodiment.

Owner:BORGWARNER INC

Common link dual arm tensioning device

A chain tensioning device links multiple tensioning arms to a common link, causing the tensioning arms to rotate into and displace chain strands with a single applied force and motion. The two tensioning arms rotate and tension proportionally, and when the pivot pin distances are equal, the two tensioning arms rotate and tension equally. The chain tensioner is preferably used to tension two slack chains flanking an auxiliary drive shaft. The chain tensioner is biased against the chain by a hydraulic tensioning assembly in one embodiment and by a spring tensioning assembly in another embodiment.

Owner:BORGWARNER INC

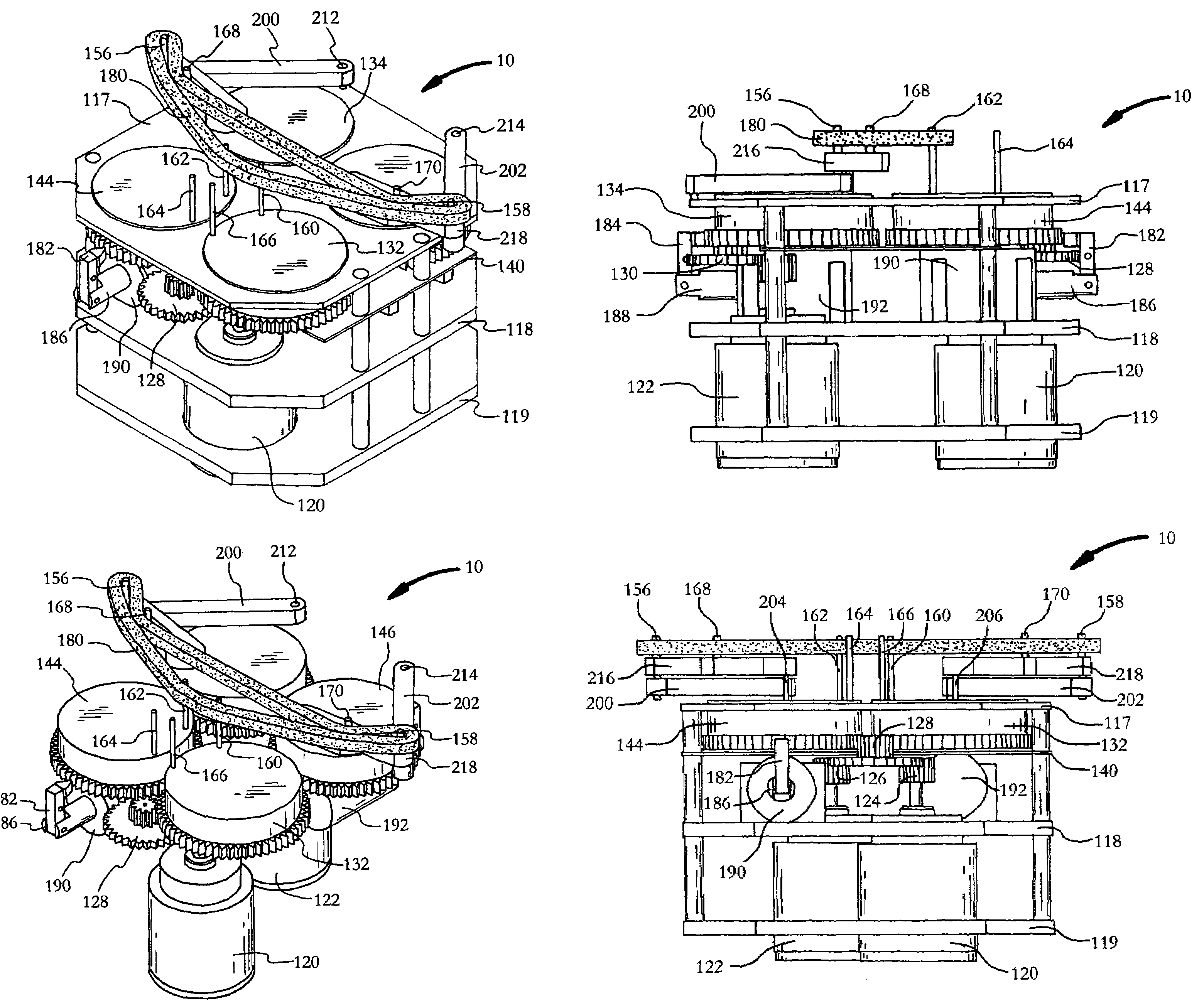

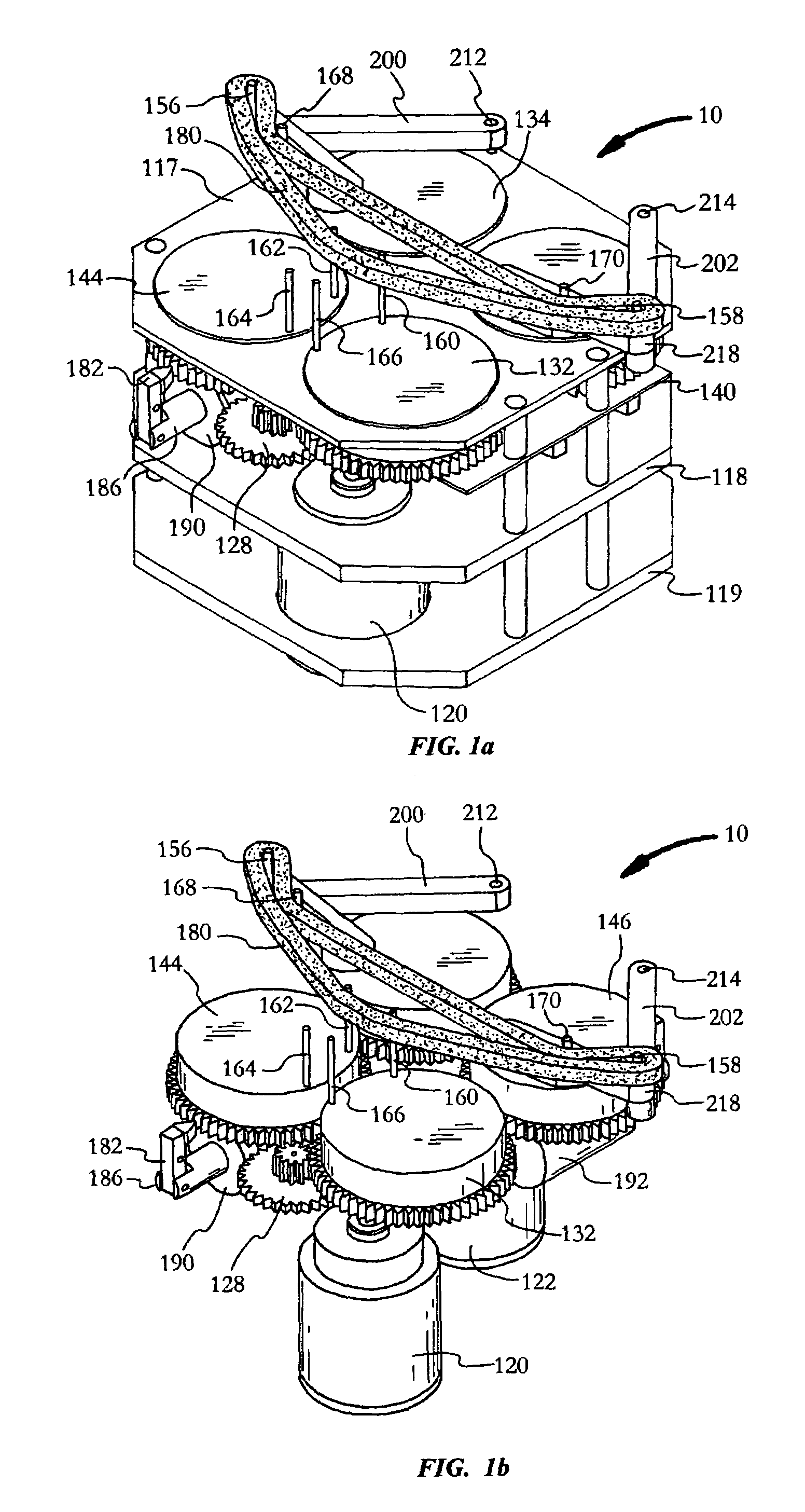

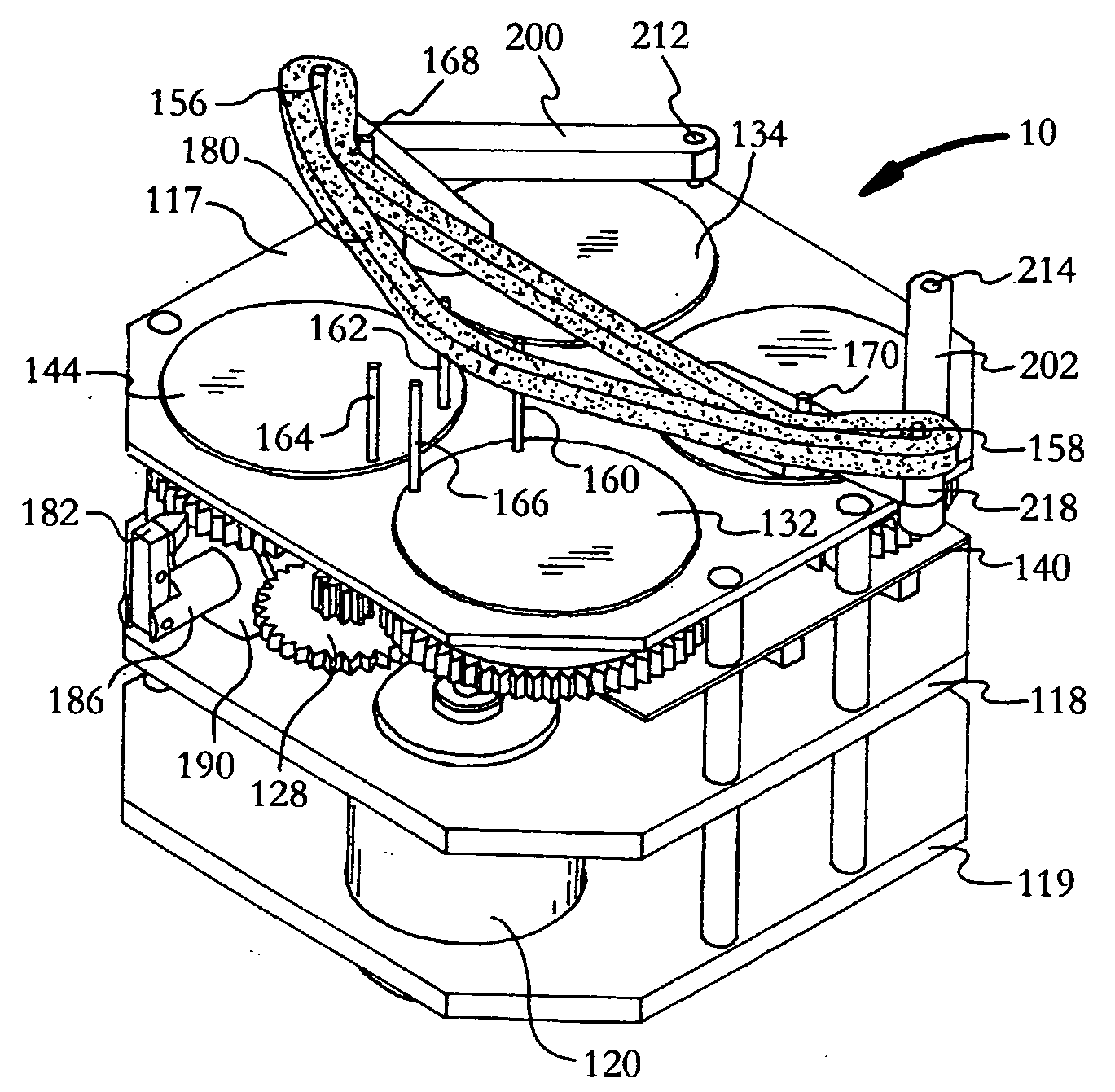

Enhanced expressive feature mechanism for animated characters and devices

InactiveUS7234988B2Efficient constructionEfficient designDollsSelf-moving toy figuresPin distanceGear wheel

A mechanism effectively mimics human facial expressions for use in animated characters. On the front surface of the mechanism, four gears, meshed in pairs, provide rotational surfaces for a series of cranks and pins. As the gears rotate, the cranks and pins engage a loop of elastomeric material. As pin distance from each other, the loop stretches. As pins approach each other, the loop contracts. Other pins located on the cranks or gears cause an inflection or deflection of the loop as the gears rotate. The resulting stretch or bending of the loop more accurately and efficiently mimics facial expressions.

Owner:THIN AIR CREATIONS

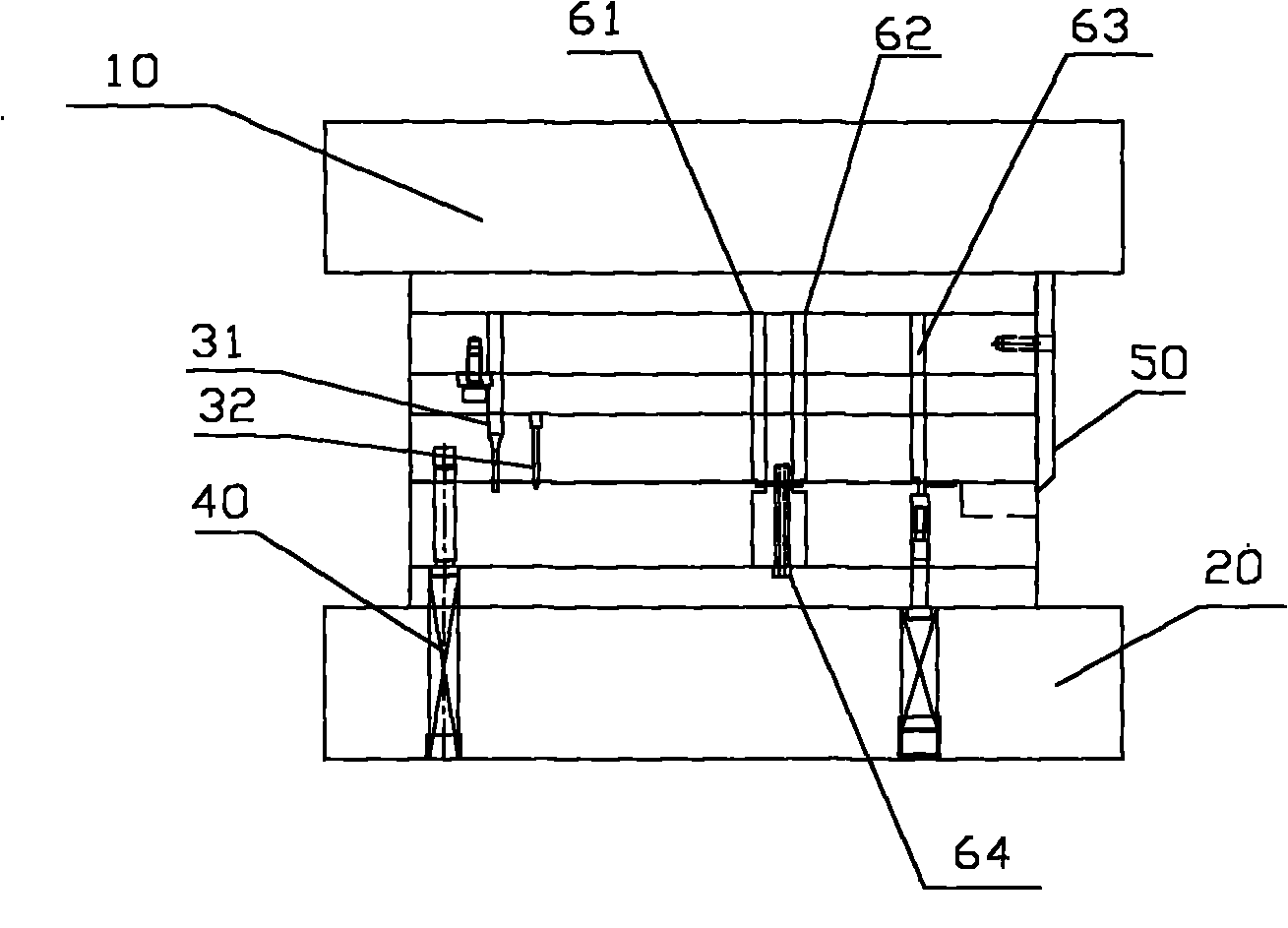

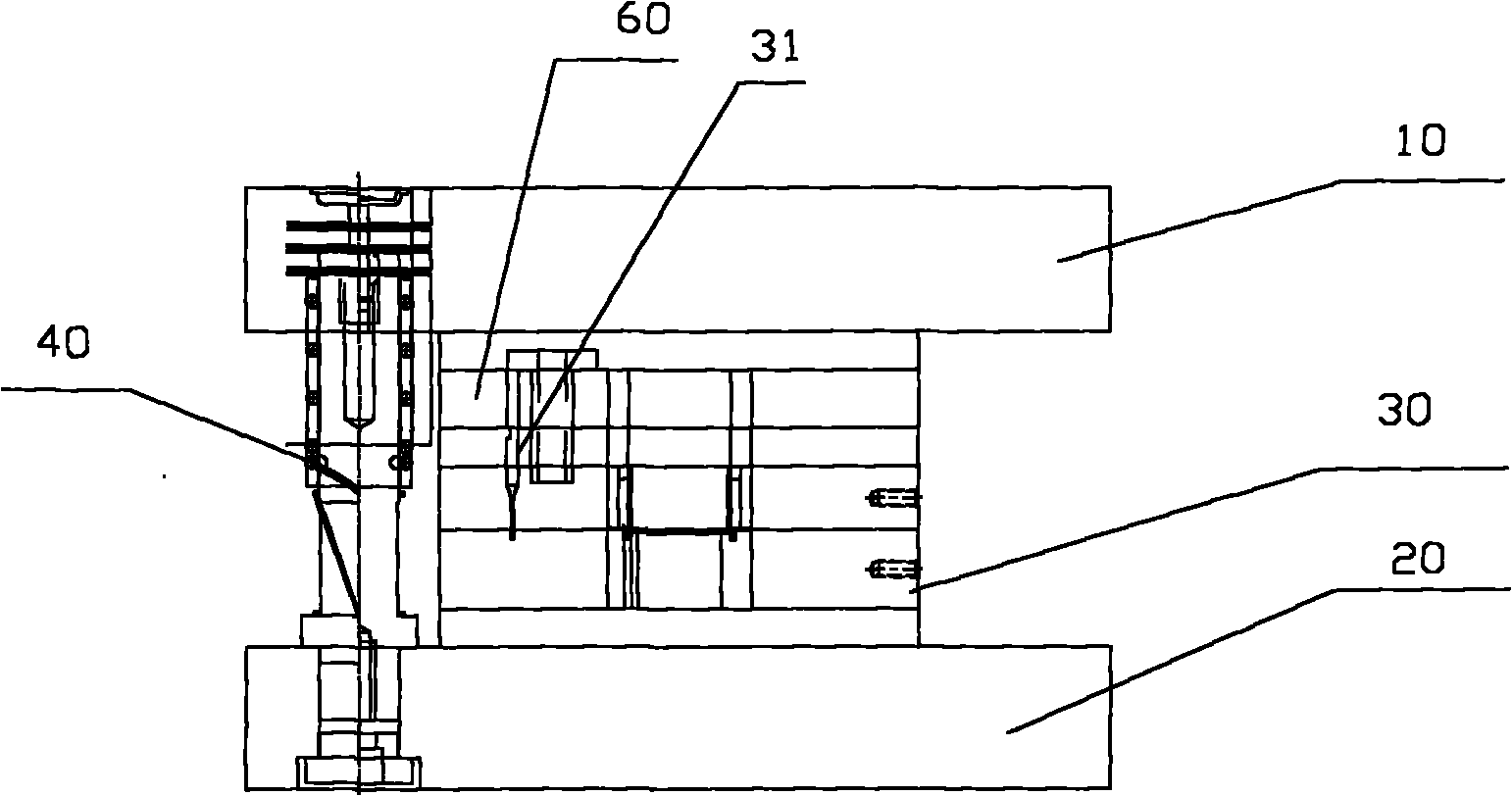

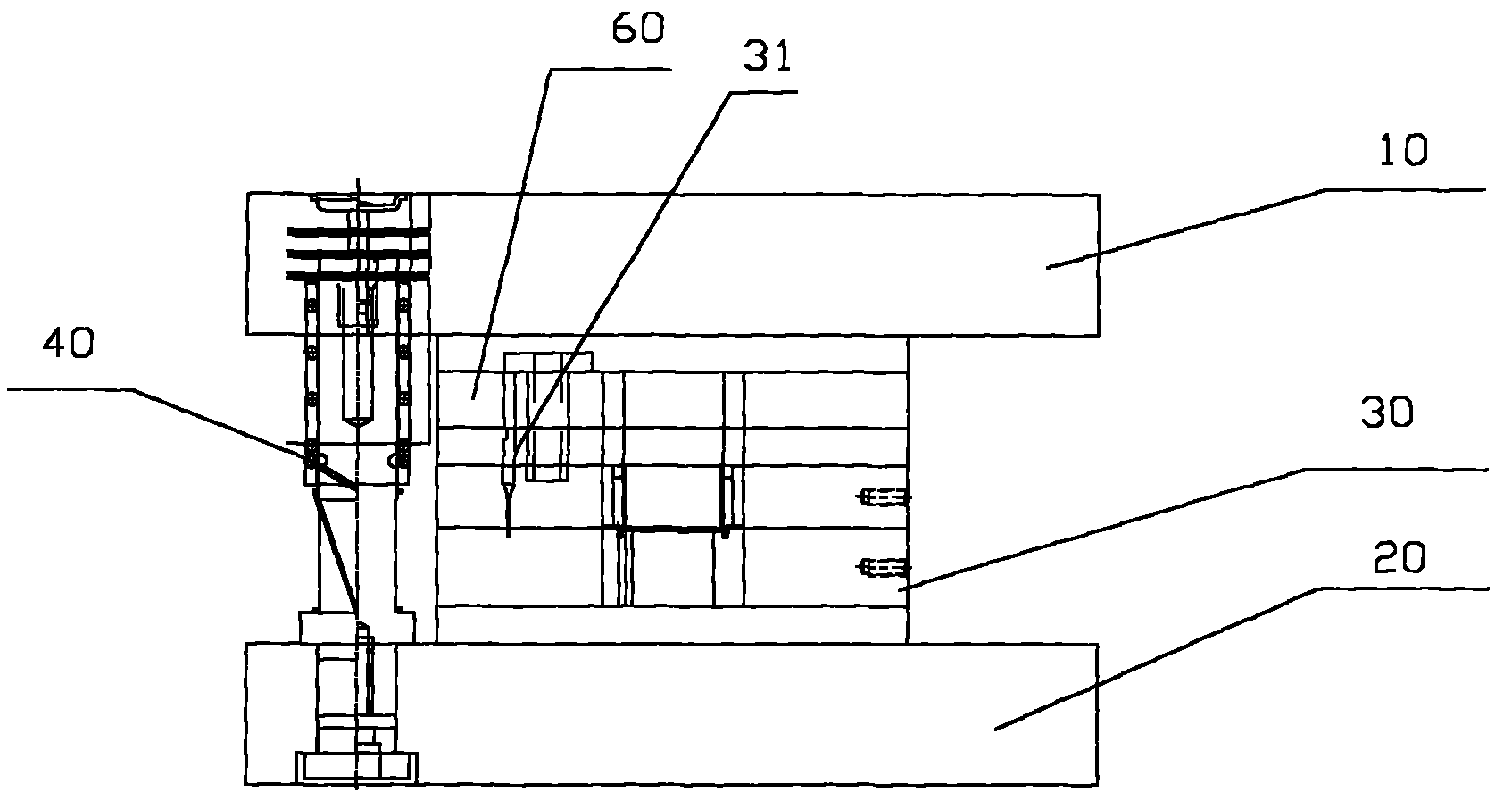

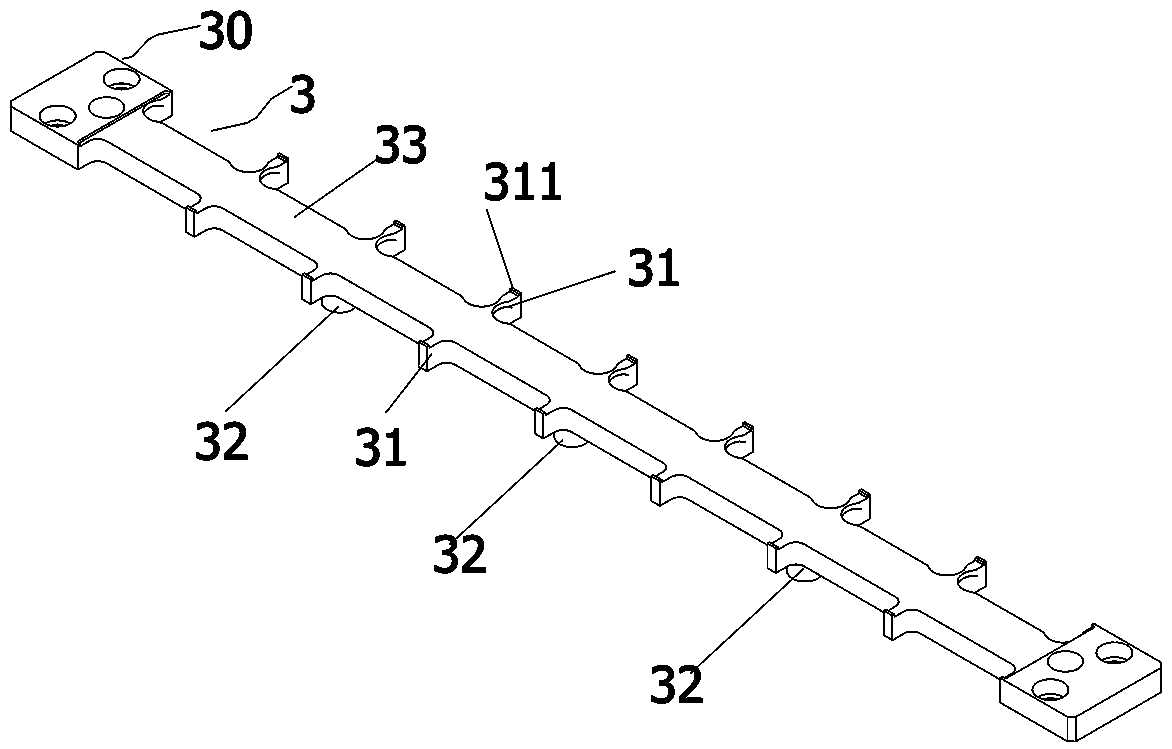

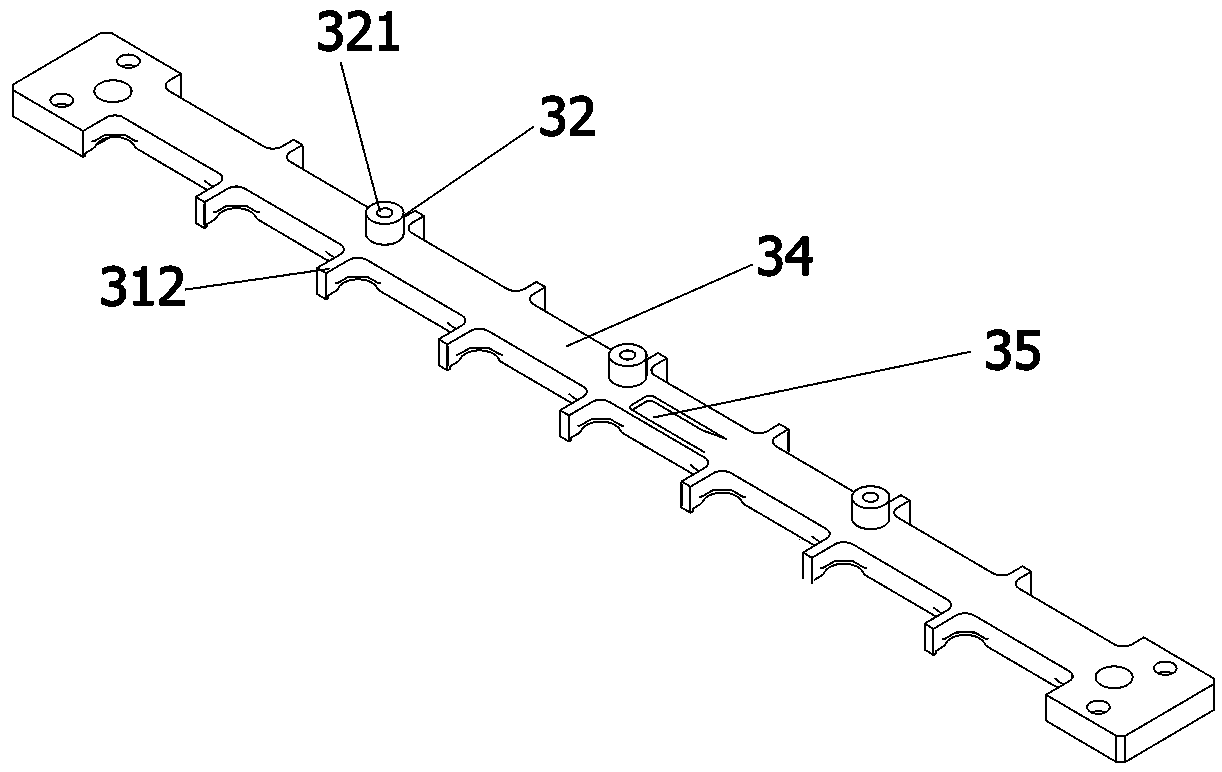

Continuous die mould of part

The invention discloses a continuous die mould of a part, comprising an upper die holder, a lower die holder, a terrace die, a die, a punch fixed plate, an upper base plate, a material belt and a cutter. a terrace die and a die in each station are sequentially arranged on the terrace die and the die of the mould in the punch process order of the electrical parts; a guide pin for controlling the PIN distance and for guiding is further fixed on the central position of the upper base plate; the guide pin comprises a first guide punch and a second guide punch; both the first and second guide punches are fixedly arranged on the upper die holder; the mould is further provided with a pin with double purposes of floatation and opening, a molded insert core and a punch. The invention is featured by convenient manufacturing, low cost, safety, stability, rapid lead time and low manufacturing cost, can satisfy a certain processing quality requirement, ensures that the punching operation of mould in multiple steps is finished continuously, and obviously improving the working efficiency, thereby providing an economic and effective way for trail production of new products and production of stamping parts without high batch requirement.

Owner:昆山凯意工模具配套有限公司

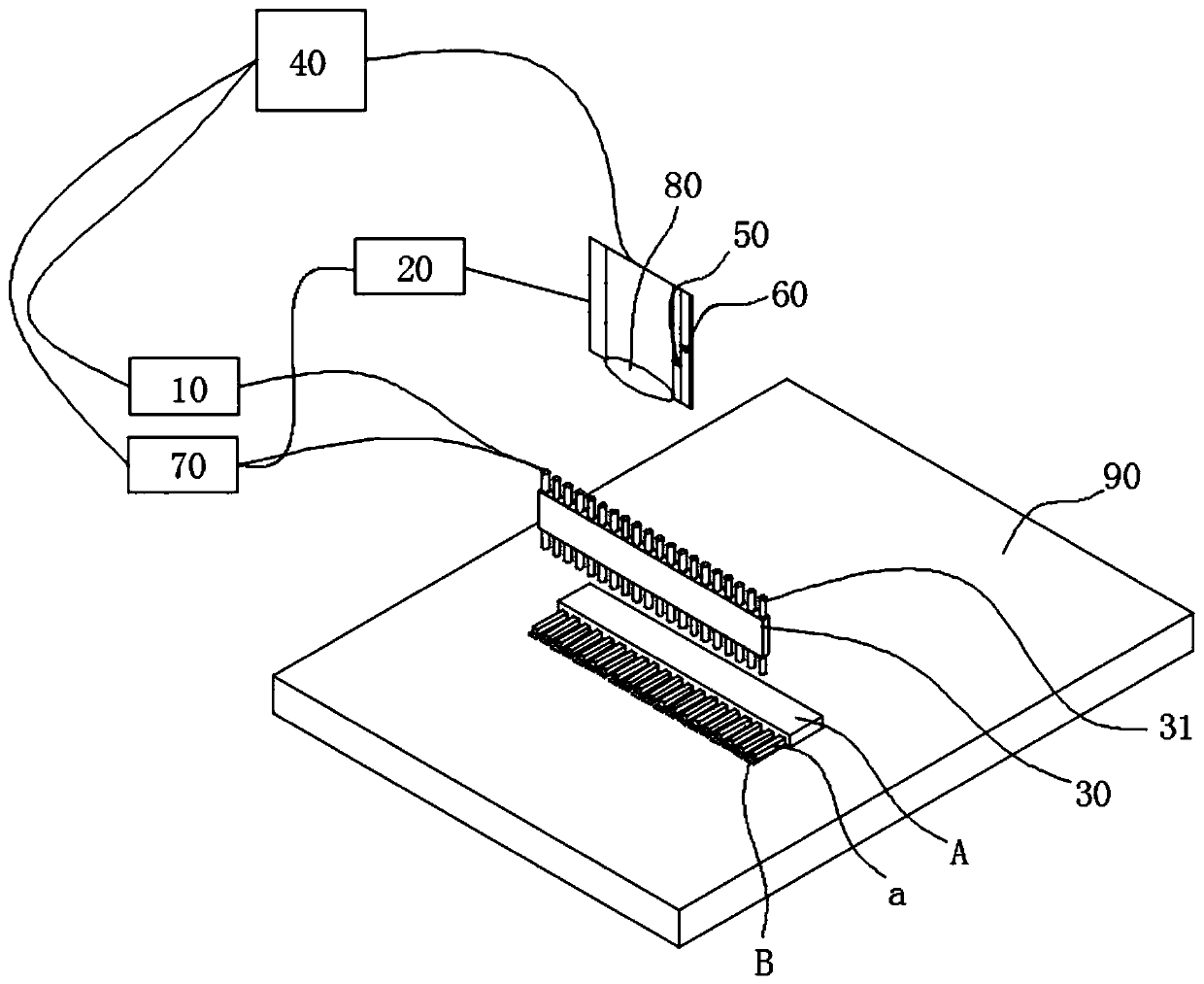

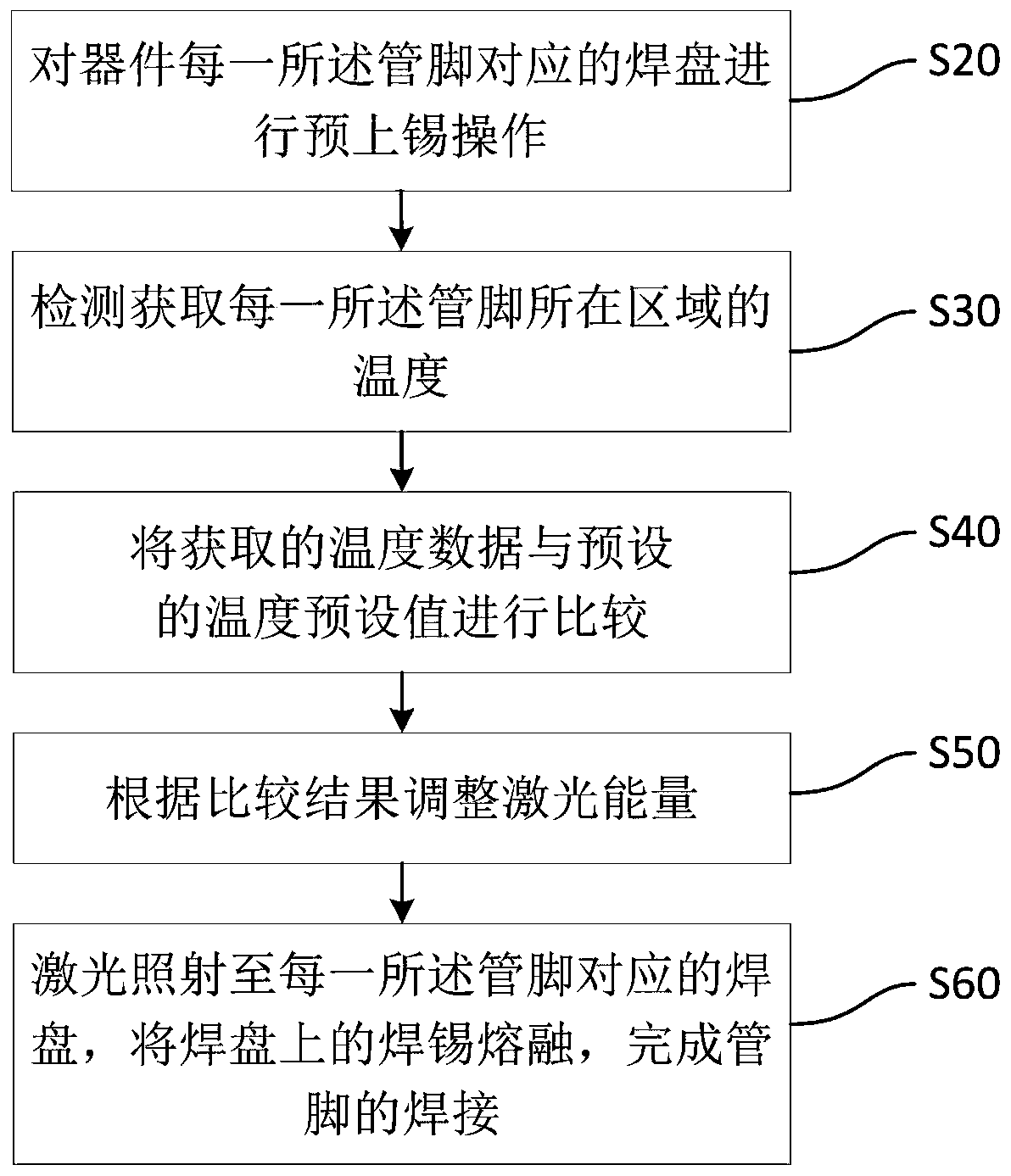

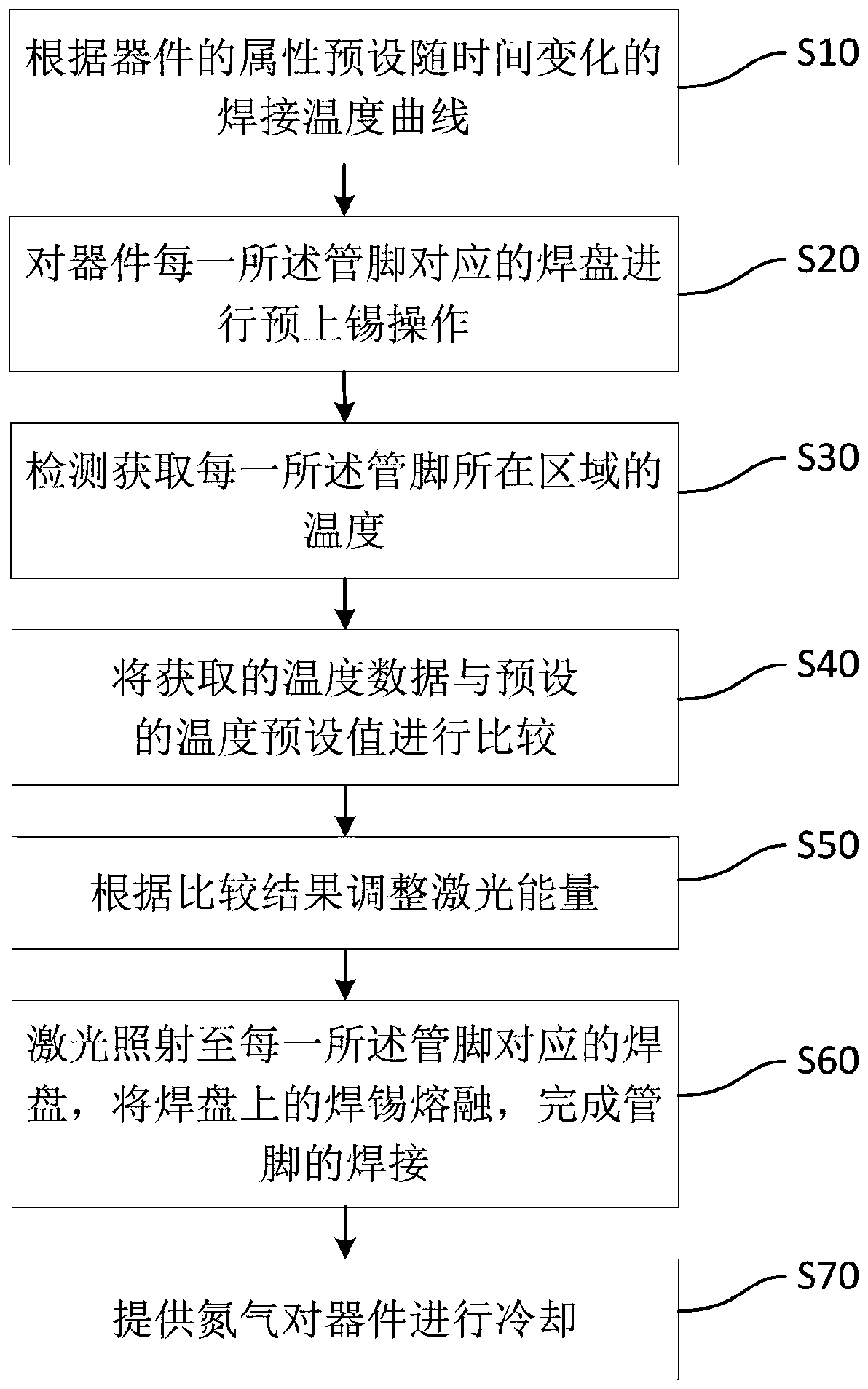

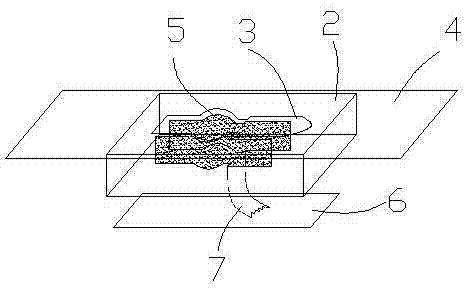

Welding system and method of device pins

PendingCN110280862AFast solderingAccurateWelding/soldering/cutting articlesMetal working apparatusPin distanceEngineering

The invention relates to the field of optical communication, in particular to a welding system and a method of device pins. The welding system comprises a laser emission device for generating laser light, a temperature detection module for detecting a temperature of an area where each pin is located, a lens module provided with a plurality of lens structures corresponding to the pins respectively, and a master control module connected with the laser emission device and the temperature detection module, wherein temperature preset values of the areas where the pins are located are set in the master control module; the master control module acquires temperature data detected by the temperature detection module, compares the temperature data with the temperature preset values, and controls and adjusts laser energy of the laser emission device according to comparison results; and the laser light is irradiated to welding discs corresponding to the pins for welding through the lens module. Precise contraposition of a device with a small pin distance, quick welding and controllable temperature can be achieved; the welding quality of the device is ensured; an occupied space is small; mass production is available; and the production efficiency is improved.

Owner:O NET COMM (SHENZHEN) LTD

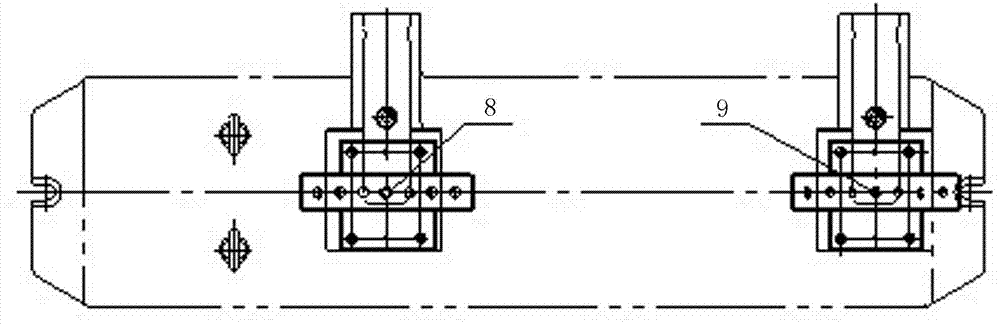

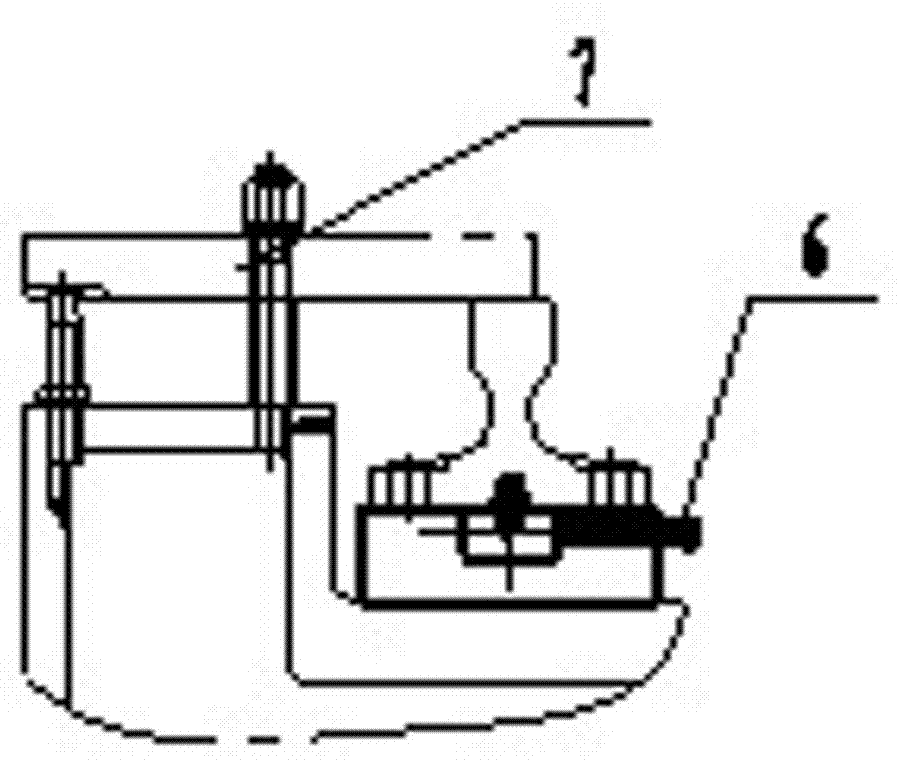

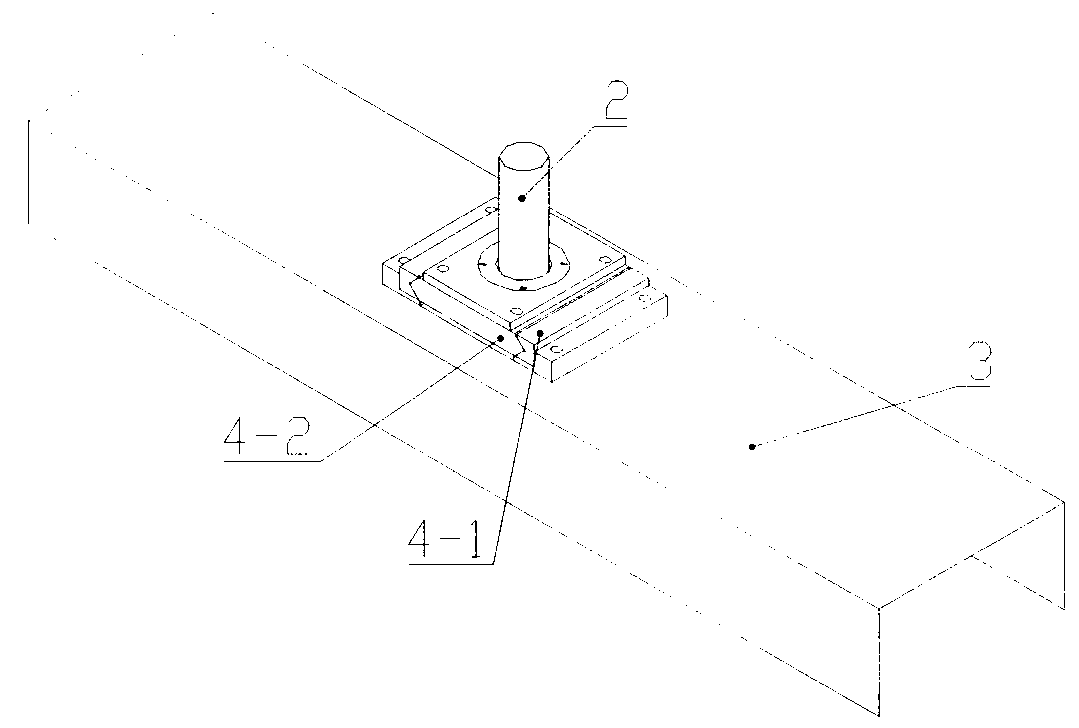

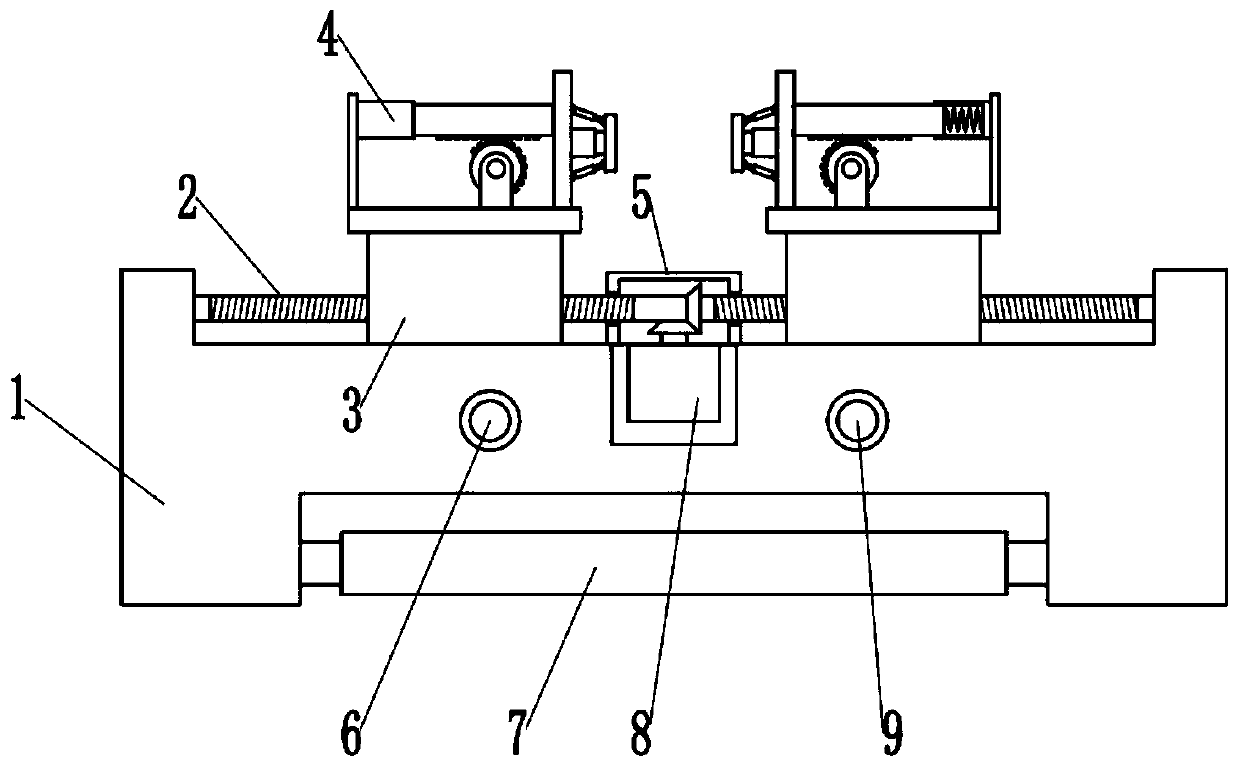

Device of drill front shaft master pin hole

InactiveCN102773728AAccurate and fast sizeReduce labor intensityPositioning apparatusMetal-working holdersPin distanceSlide plate

The invention relates to a device of a drill front shaft master pin hole. The device comprises a fixture body (1), a rear backing board (2), a rear sliding plate (3), a front backing board (4), a front sliding plate (5), compression screws (6), a chucking device (7), a cylindrical pin (8) and a rhombus pin (9), the rear backing board (2), the front backing board (4) and the chucking device (7) are arranged on the fixture body (1), the rear sliding plate (3) is disposed on the rear backing board (2), the rhombus pin (9) is arranged on the rear sliding plate (3), the front sliding plate (5) is mounted on the front backing board (4), the cylindrical pin (8) is disposed on the front sliding plate (5), and the compression screws (6) are arranged on the rear backing board (2) and the front backing board (4) respectively. The device has the advantages that a plate spring distance and a master pin distance can be accurately and rapidly adjusted, the device is multipurpose, the labor intensity of workers can be effectively reduced, time and effort are saved, and the work efficiency is increased.

Owner:王庆

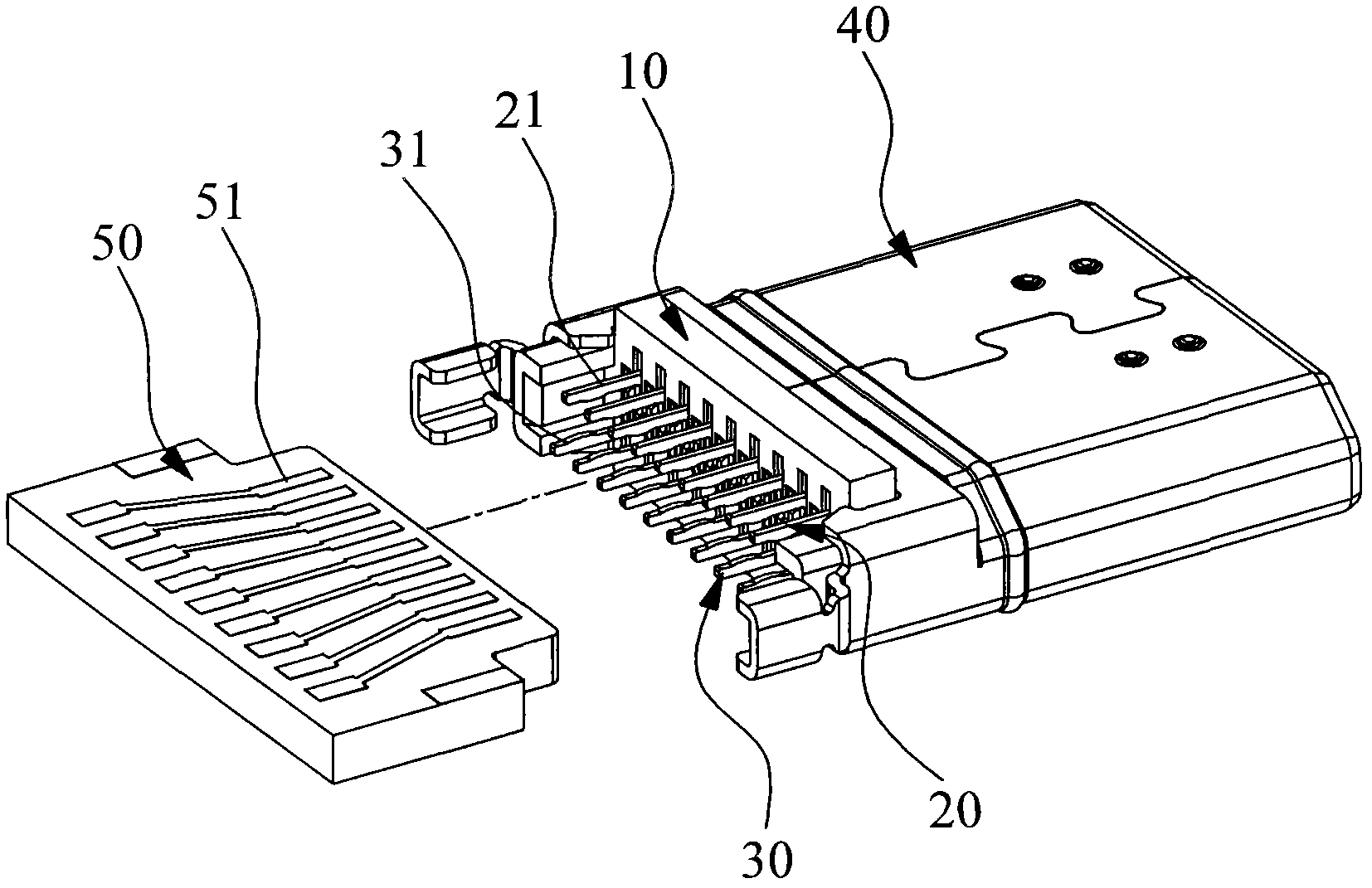

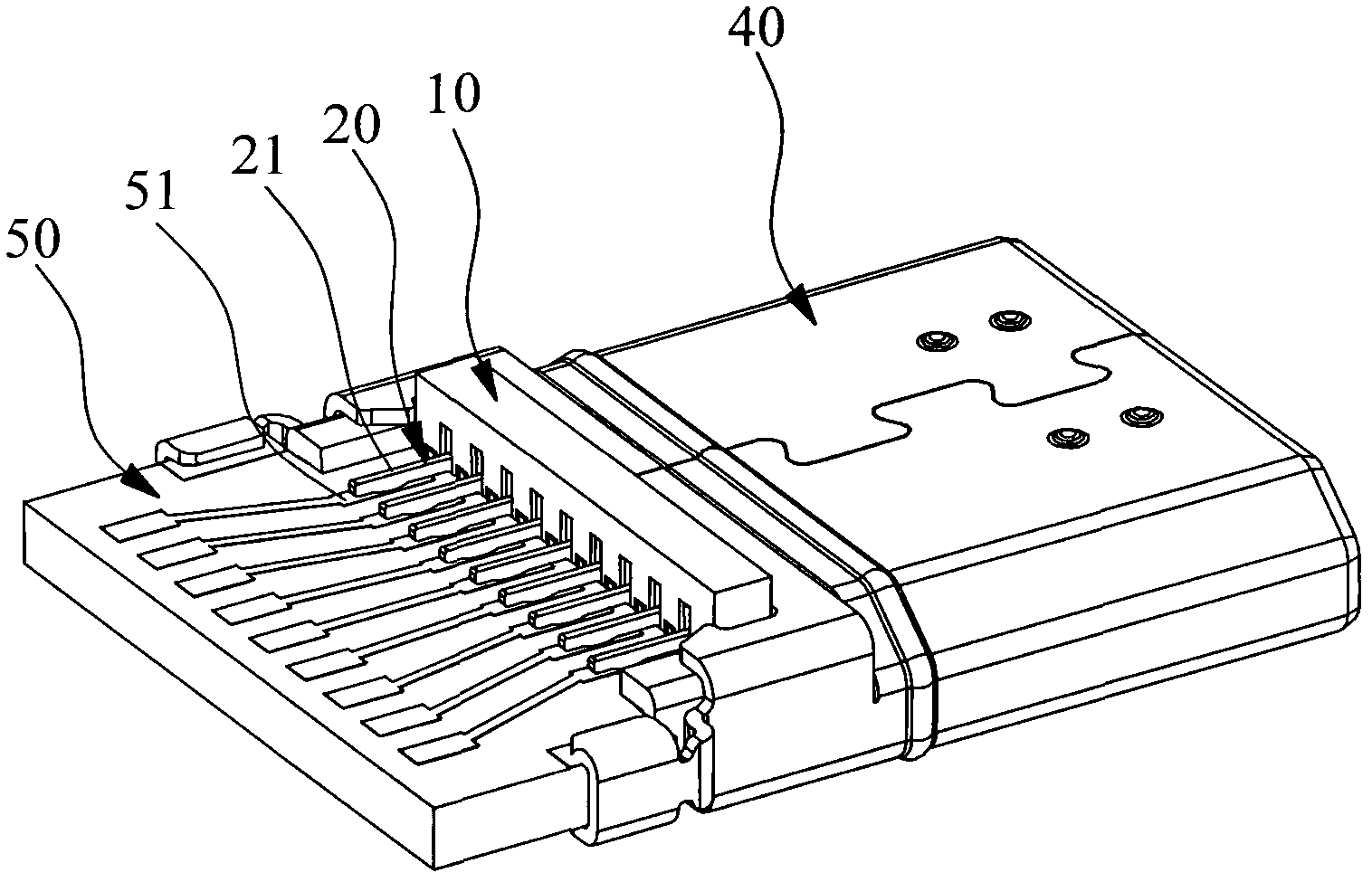

Soldering and mounting method of electric connector

InactiveCN102122786AReduce manufacturing costAvoid welding short circuit phenomenonLine/current collector detailsElectricityDip soldering

The invention discloses a soldering and mounting method of an electric connector, and the method comprises the following steps: (1) assembling an insulating body, conductive terminals and a metal housing into the electric connector; (2) butting the electric connector with a PCB (printed circuit board), and enabling the soldering parts of the conductive terminals to prop against the corresponding tin soldering region of the PCB, thus forming a semi-finished product; (3) soaking the board end of the semi-finished PCB product into a liquid soldering flux; (4) taking out, then placing the board end of the PCB into a tin furnace, and enabling the part which needs to perform tin soldering to be completely soaked in the tin furnace, wherein the temperature of the tin furnace is 270 DEG C-290 DEG C; and (5) taking the semi-finished product out of the tin furnace, and further cleaning the board end of the PCB with alcohol. Therefore, the soldering parts and the tin soldering region are soldered together by heating through the tin furnace, the phenomenon of easy emergence of soldering short-circuit due to manual soldering can be avoided, the qualification rate of products can be improved, the method is applicable to soldering the electric connectors with small PIN distance, the operation is further simple and high-efficient, and the method is conductive to reducing the production cost of an enterprise.

Owner:SUYING ELECTRCNICS (DONG GUAN) CO LTD

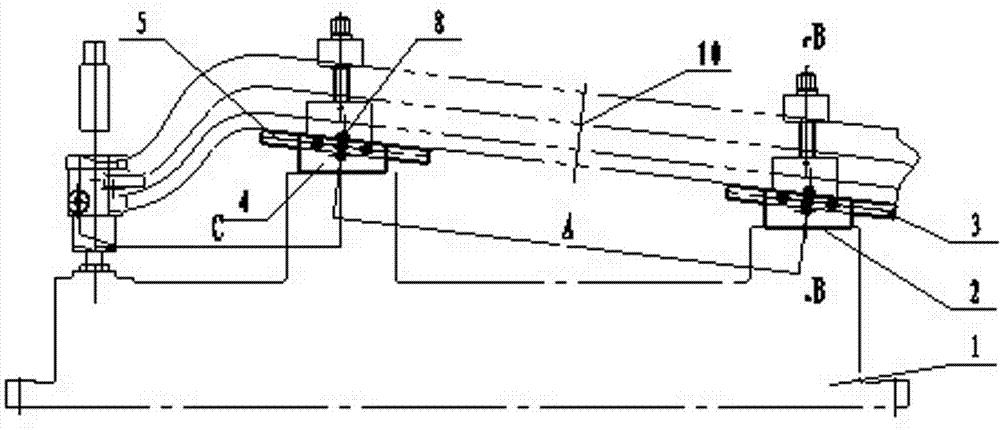

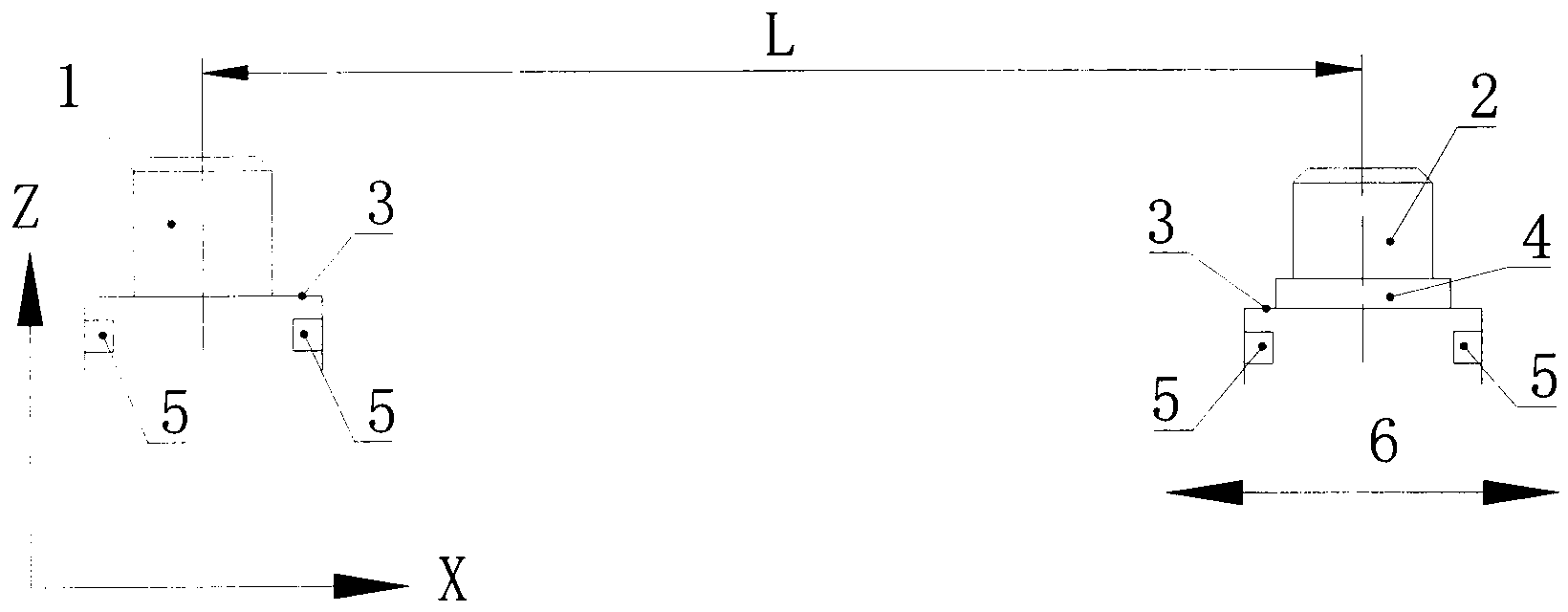

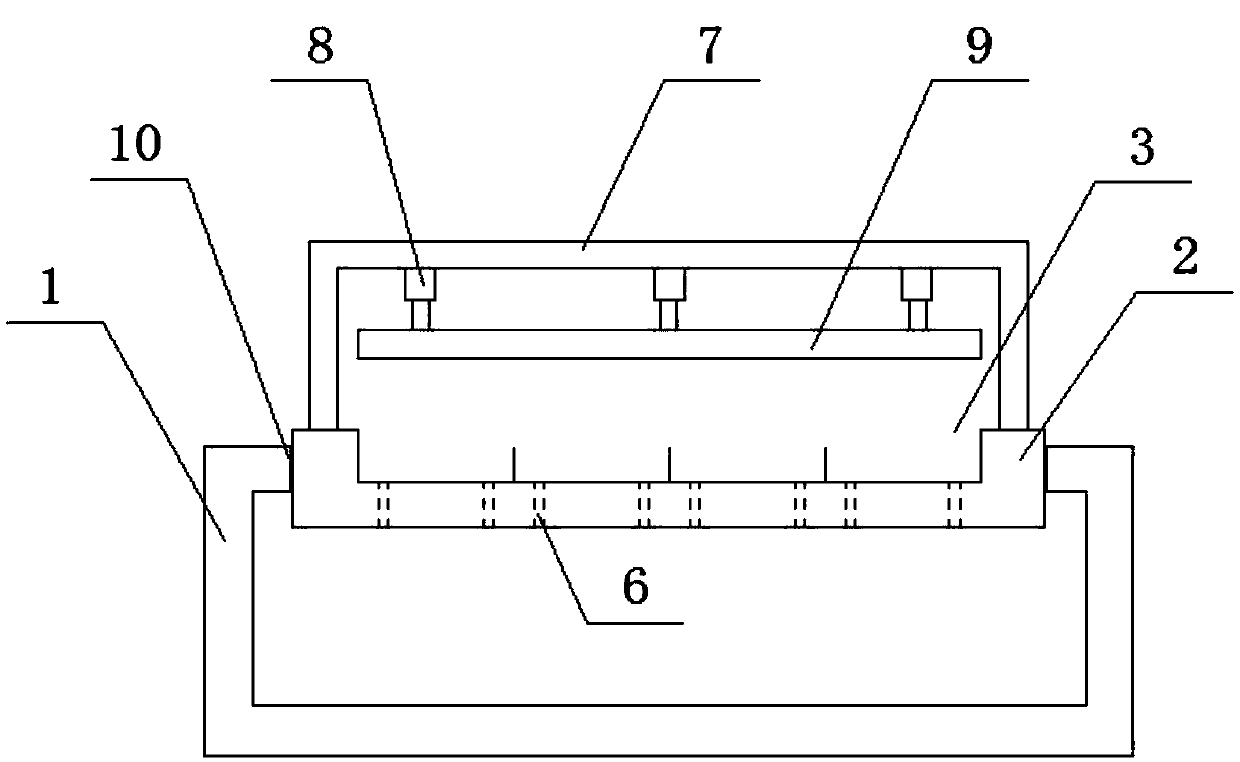

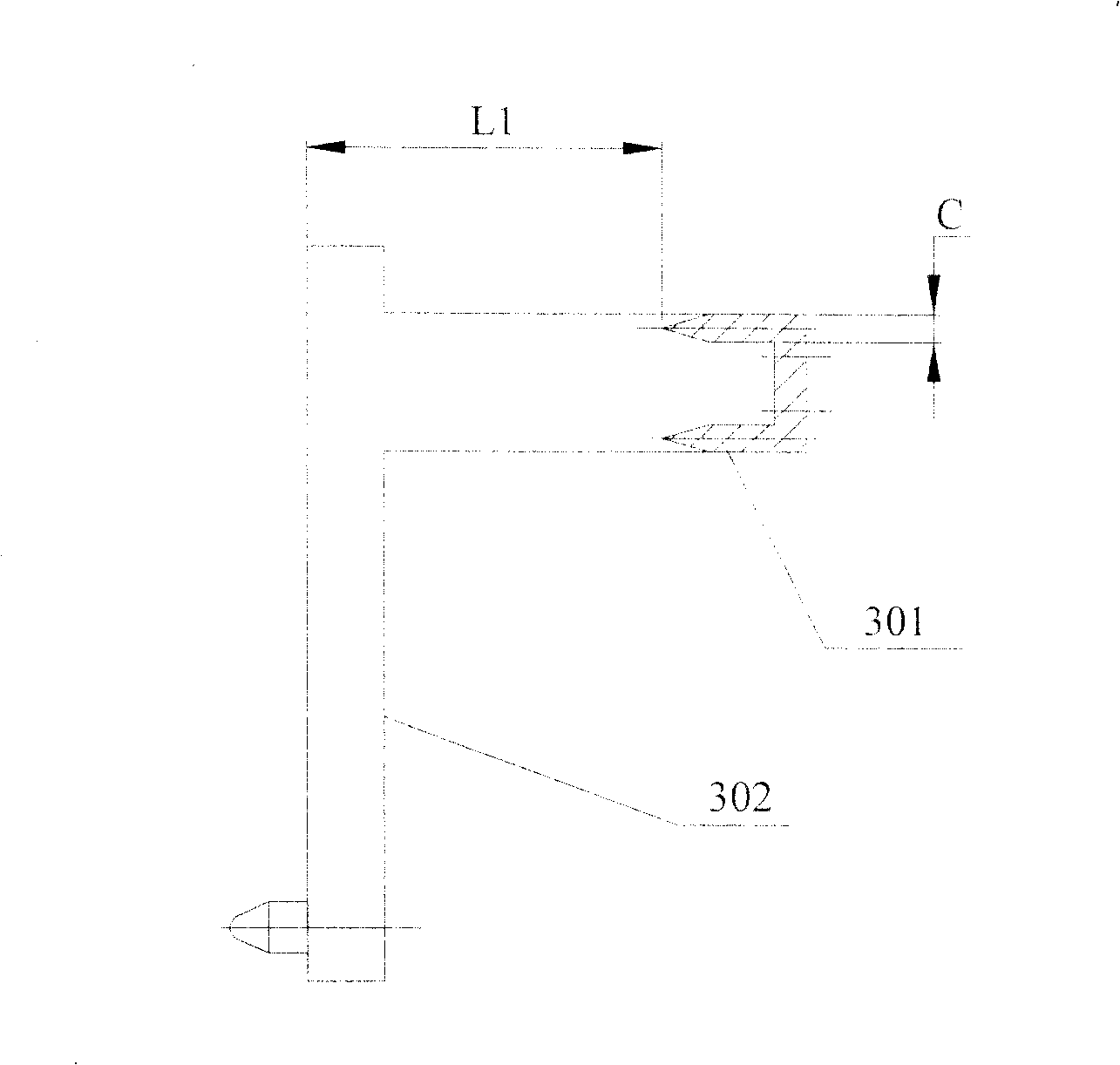

Adjustable pin distance large-size locating device with two pins on one side

InactiveCN103213083ASolve the positioning problemMeet job requirementsWork holdersPin distanceMechanical equipment

The invention discloses an adjustable pin distance large-size locating device with two pins on one side and belongs to the technical field of mechanical equipment. The adjustable pin distance large-size locating device with the two pins on one side is composed of a fixing locating pin, a movable locating pin, a locating block, a sliding pair and at least eight guide wheels. The large-size locating device is installed in a guide rail guiding groove of large machinery through the at least eight guide wheels, and the needed motion is achieved along with a transmission mechanism. The adjustable pin distance large-size locating device with the two pins on one side is characterized in that at least two guide wheels are fixedly connected at each edge of the inner side of a side plate of the locating block, the fixing locating pin is installed on a locating face of the locating block in a floating mode, the sliding pair is fixedly connected with the locating face of the locating block, the movable locating pin is installed on the sliding pair in a floating mode, and the movable locating pin can be driven to move through the sliding pair to achieve adjusting the center distance between the two locating pins. Edges of the locating pins in the adjustable pin distance large-size locating device do not need to be cut, and the adjustable pin distance large-size locating device with the two pins on one side is high in intensity, capable of solving the locating problems of large-size stressed parts, capable of changing along with poses of center lines of two locating holes in the working process of the large-size stressed parts and meeting work requirements of the large-size stressed parts.

Owner:NANJING AGRICULTURAL UNIVERSITY

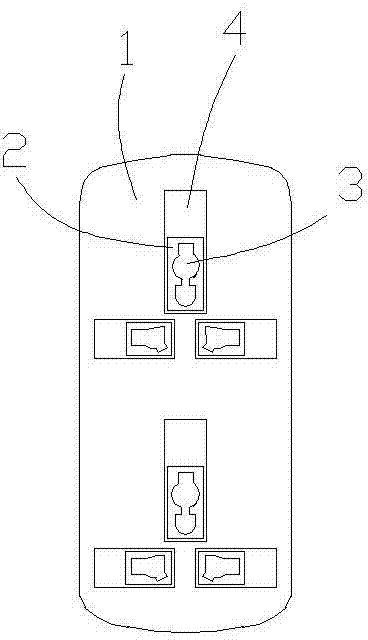

Modular socket

ActiveCN103050850AImprove universal applicabilityReduce electric shockCoupling contact membersPin distanceModularity

The invention discloses a modular socket which comprises a socket body, pin contact spring pieces and jacks, wherein any jack can be separately moved on the socket body; sliding grooves are formed in the socket body, modules are embedded into the sliding grooves, the jacks are formed in the modules, and the pin contact spring pieces are arranged in the modules; connecting piece contact plates are arranged on the bottom surface in the socket body and electrically connected with the pin contact spring pieces through connecting pieces; and the modules are made of synthetic resin. The modular socket can be matched with plugs with multiple pin distances and pin shapes and is suitable for standards of various countries, and the general applicability of the socket can be effectively improved.

Owner:LUMI LEGEND ELECTRICAL

Common-mode inductor production process

InactiveCN109545533AReduce spendingImprove pass rateInductances/transformers/magnets manufactureFixed signal inductancesPin distanceCopper wire

The invention discloses a common-mode inductor production process which comprises the following steps of copper wire cutting, winding, gluing, pin cutting, soldering, and inspection. The gluing step is executed after the winding step and before the soldering step. The soldering step is executed after the pin cutting step. The gluing step comprises gluing an inner ring to fix two inner pins. The pin cutting step comprises fixing a pin distance by a manual pin cutting device, and then cutting the extended length of the pin. The common-mode inductor production process reduces four steps by simplification and improvement, achieves a qualified rate of the finished products to 99%, simplifies the operations, reduces manpower expenditure, greatly improves production efficiency, and has a certaineconomic value.

Owner:安徽众恒复合材料科技有限公司

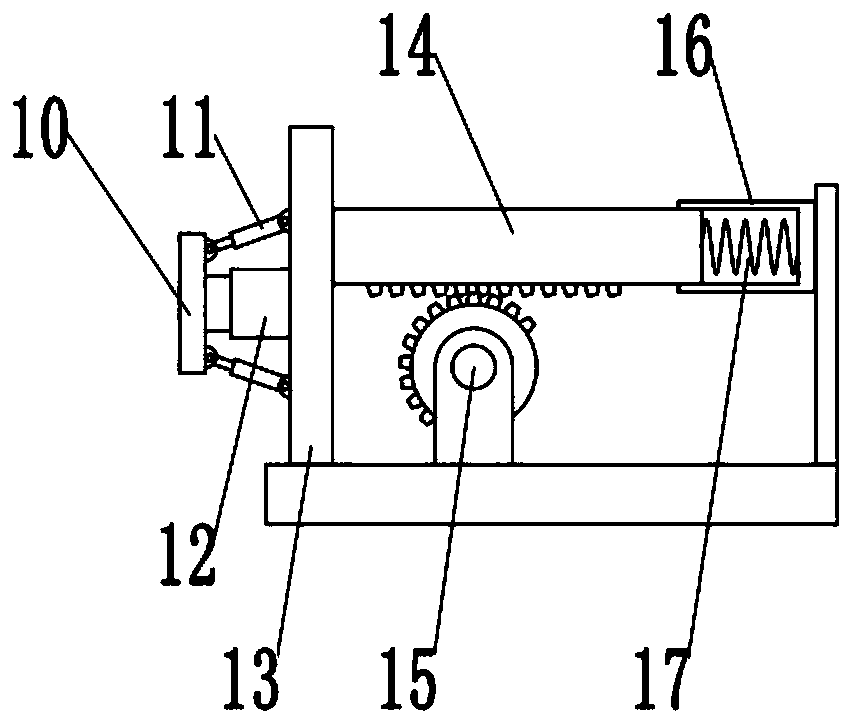

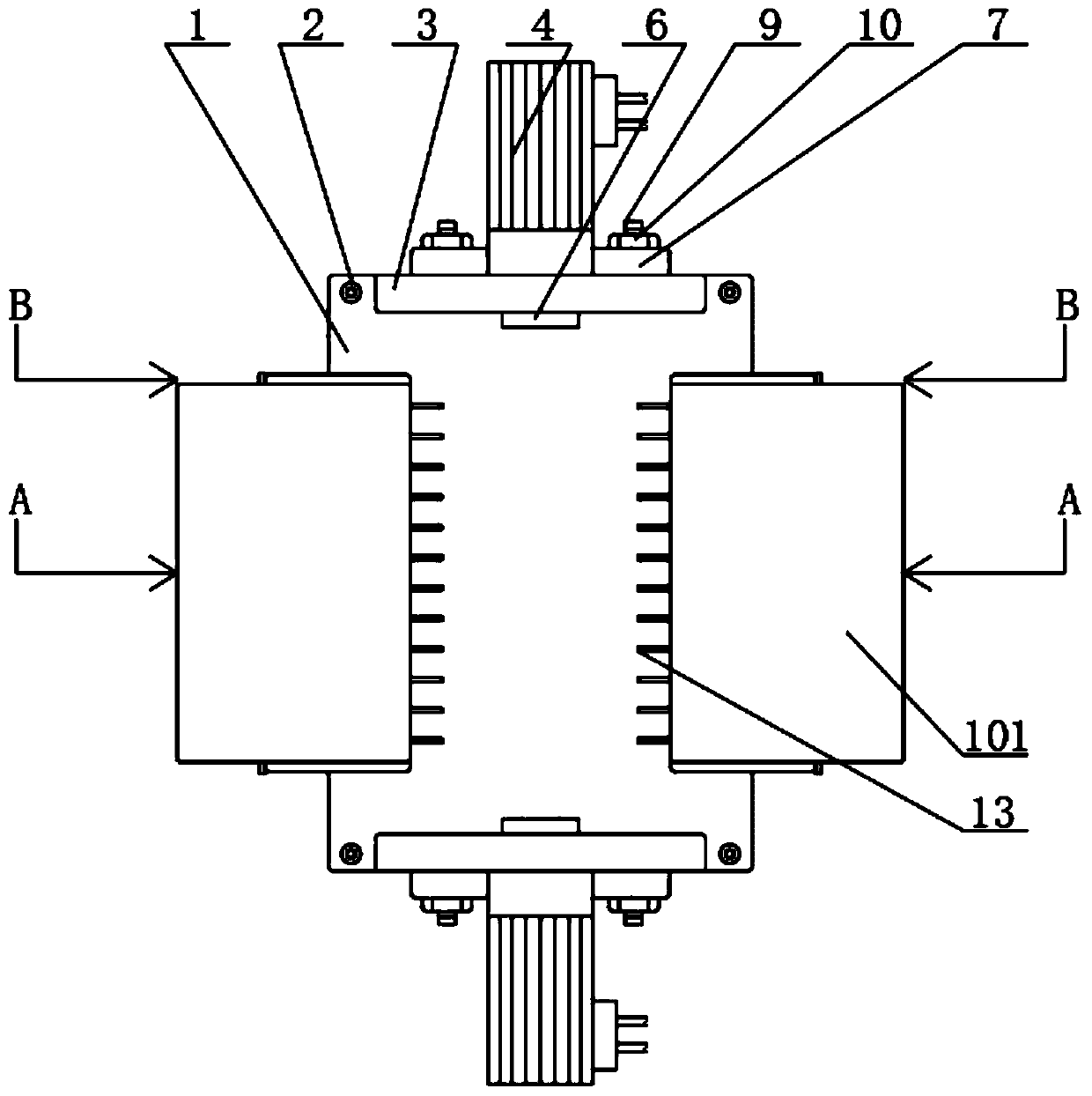

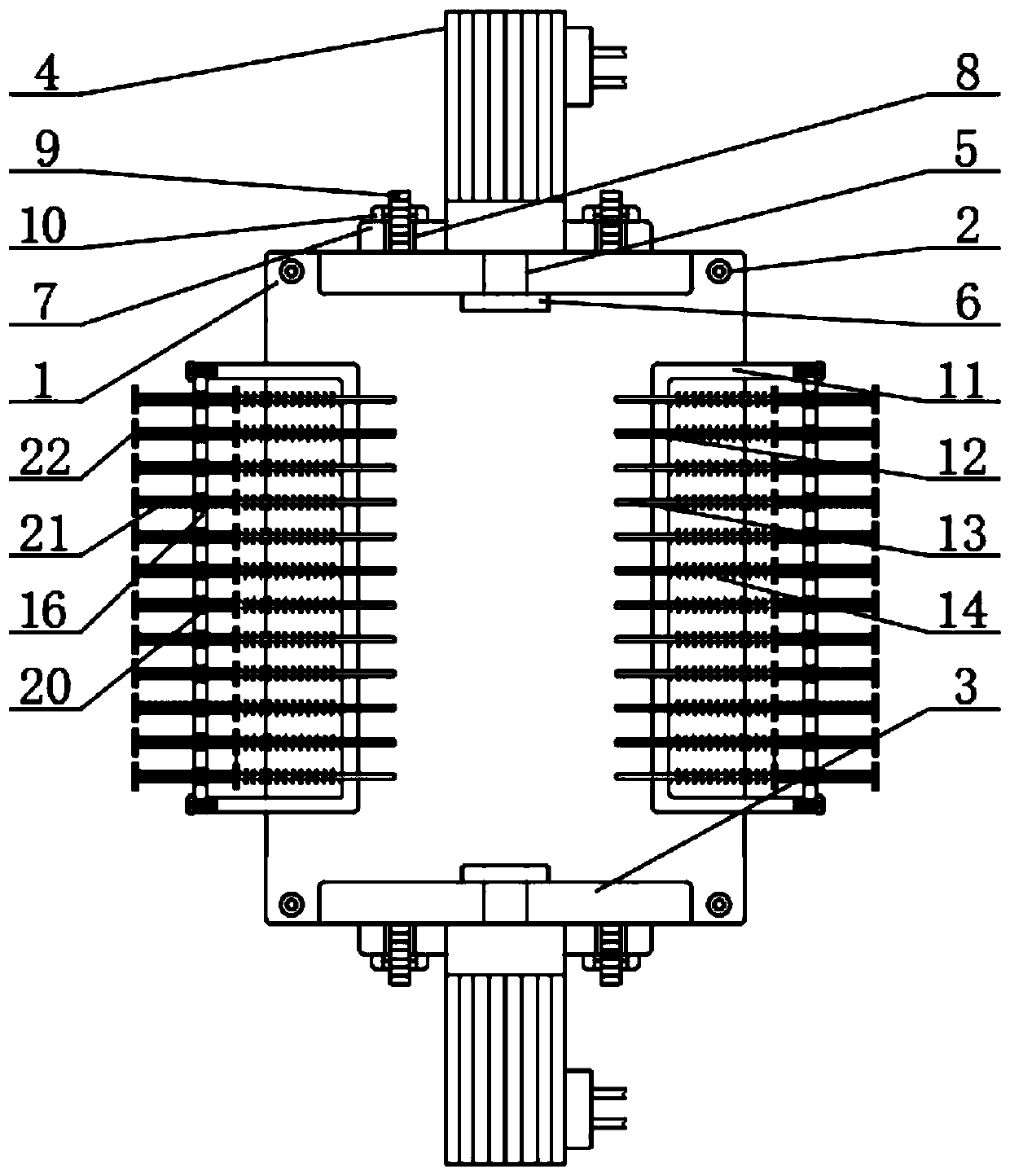

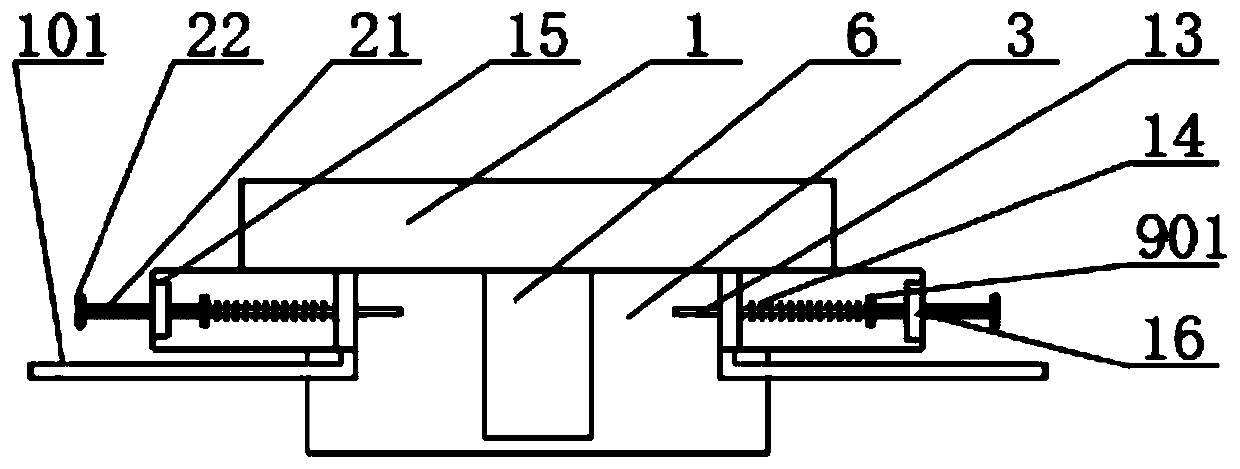

Pin distance adjusting mechanism of network transformer

ActiveCN110918827AImprove leveling efficiencyInductances/transformers/magnets manufacturePin distanceTransformer

The invention relates to the technical field of pin distance adjusting, in particular to a pin distance adjusting mechanism of a network transformer. The pin distance adjusting mechanism comprises a body and adjusting mechanisms, wherein the front side of the body is rotatably provided with a first adjusting screw rod, the left side and the right side of the first adjusting screw rod are symmetrically provided with two opposite external threads, the left side and the right side of the first adjusting screw rod are further symmetrically in threaded connection with two screw sleeves, and the other sides of the screw sleeves are fixedly connected with the corresponding adjusting mechanisms; and each adjusting mechanism comprises a mounting plate horizontally mounted on each screw sleeve and acollision plate, a push plate is vertically mounted at the end, facing the middle of the first adjusting screw rod, of each mounting plate, a main telescopic rod is fixedly installed on the outer side of each push plate, and the telescopic end of each main telescopic rod is fixedly connected with the corresponding collision plate. According to the pin distance adjusting mechanism, when pins are adjusted, a screw rod is driven to slide by rotating the first adjusting screw rod, and the adjusting mechanisms are moved to the proper positions; and then the lengths of the main telescopic rods areadjusted, the pins are squeezed by the collision plates, and the pins are forced to reset.

Owner:LEIYANG YAXIANG ELECTRONICS TECH

Engagement chain unit

ActiveUS20140076082A1Accurate forwardingAccurate backward movementToothed gearingsLifting framesPin distanceEngineering

Provided is an interlocking chain unit that has reliable and strong interlocking and avoids buckling, breaking, and bending of a rigidified chain portion. In the interlocking chain unit (100), the interlocking operation of an outer tooth link plate (112BZ) and an outer tooth link plate (112AY) that are just about to complete the interlocking operation is completed in a manner that causes a first inter-pin distance (d1) and a second inter-pin distance (d2) become substantially equal to each other, and causes a third inter-pin distance (d3) to approach the second inter-pin distance (d2).

Owner:TSUBAKIMOTO CHAIN CO

Enhanced expressive feature mechanism for animated characters and devices

InactiveUS20050059319A1Efficient constructionEfficient designDollsSelf-moving toy figuresPin distanceAnimation

A mechanism effectively mimics human facial expressions for use in animated characters. On the front surface of the mechanism, four gears, meshed in pairs, provide rotational surfaces for a series of cranks and pins. As the gears rotate, the cranks and pins engage a loop of elastomeric material. As pin distance from each other, the loop stretches. As pins approach each other, the loop contracts. Other pins located on the cranks or gears cause an inflection or deflection of the loop as the gears rotate. The resulting stretch or bending of the loop more accurately and efficiently mimics facial expressions.

Owner:THIN AIR CREATIONS

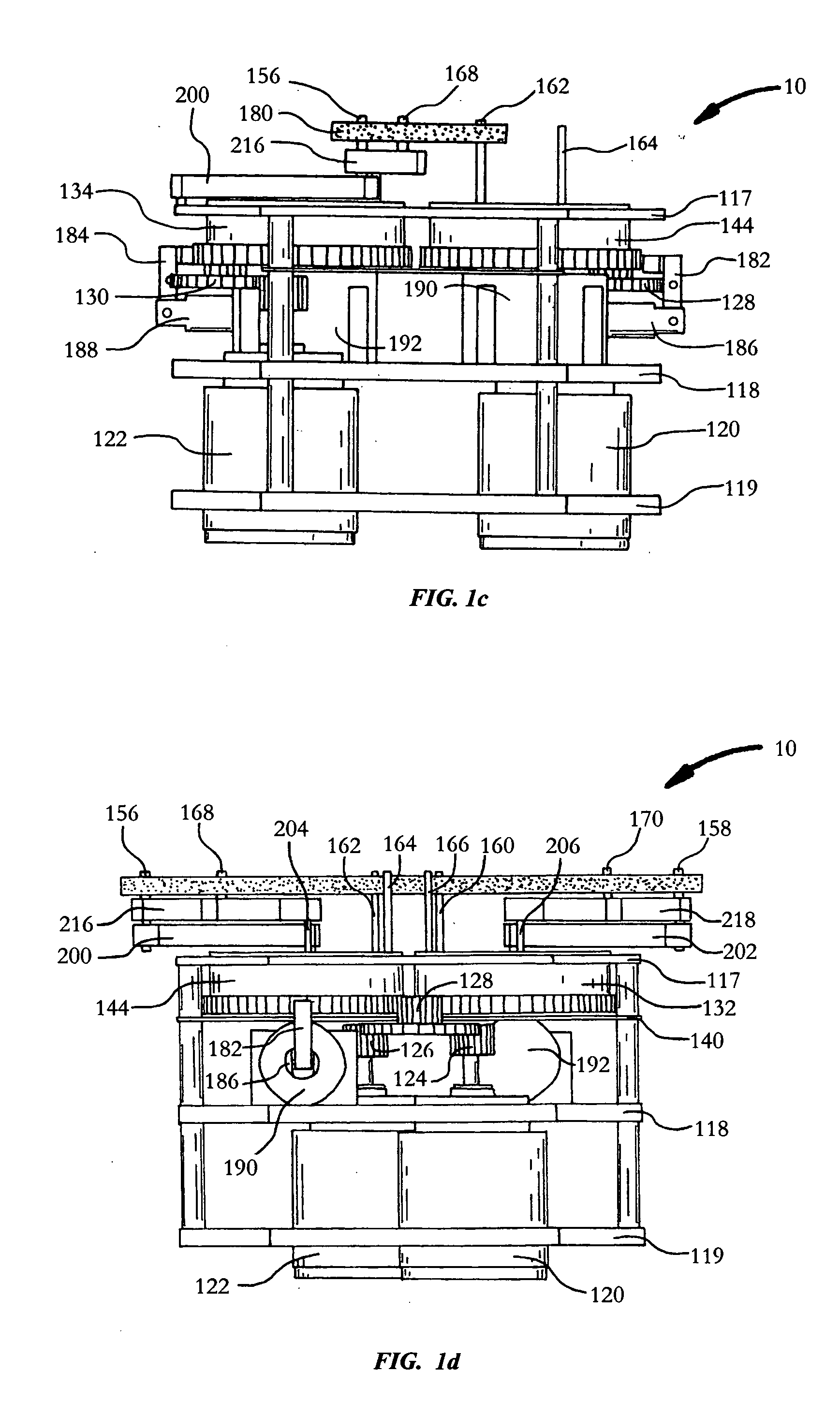

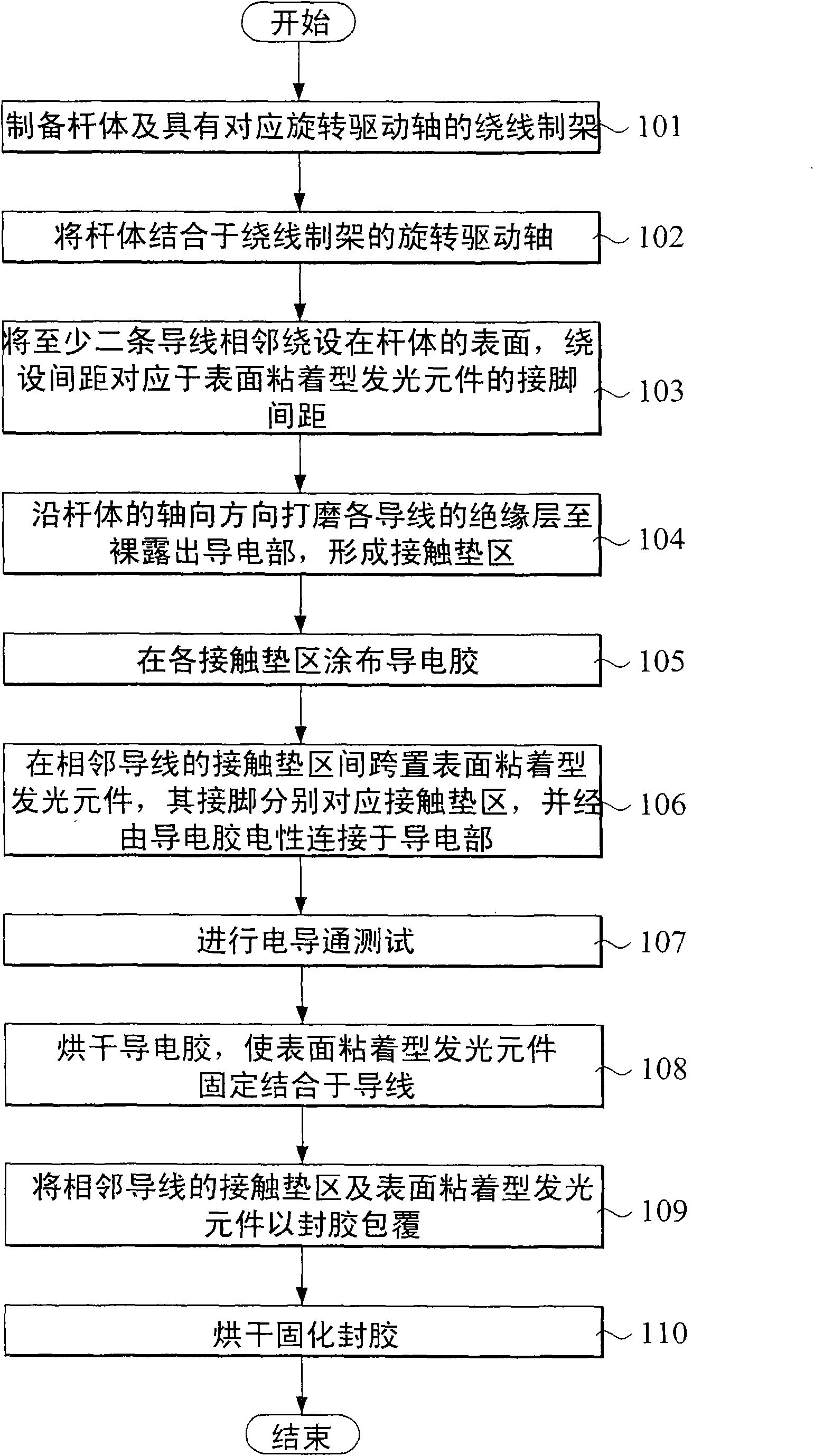

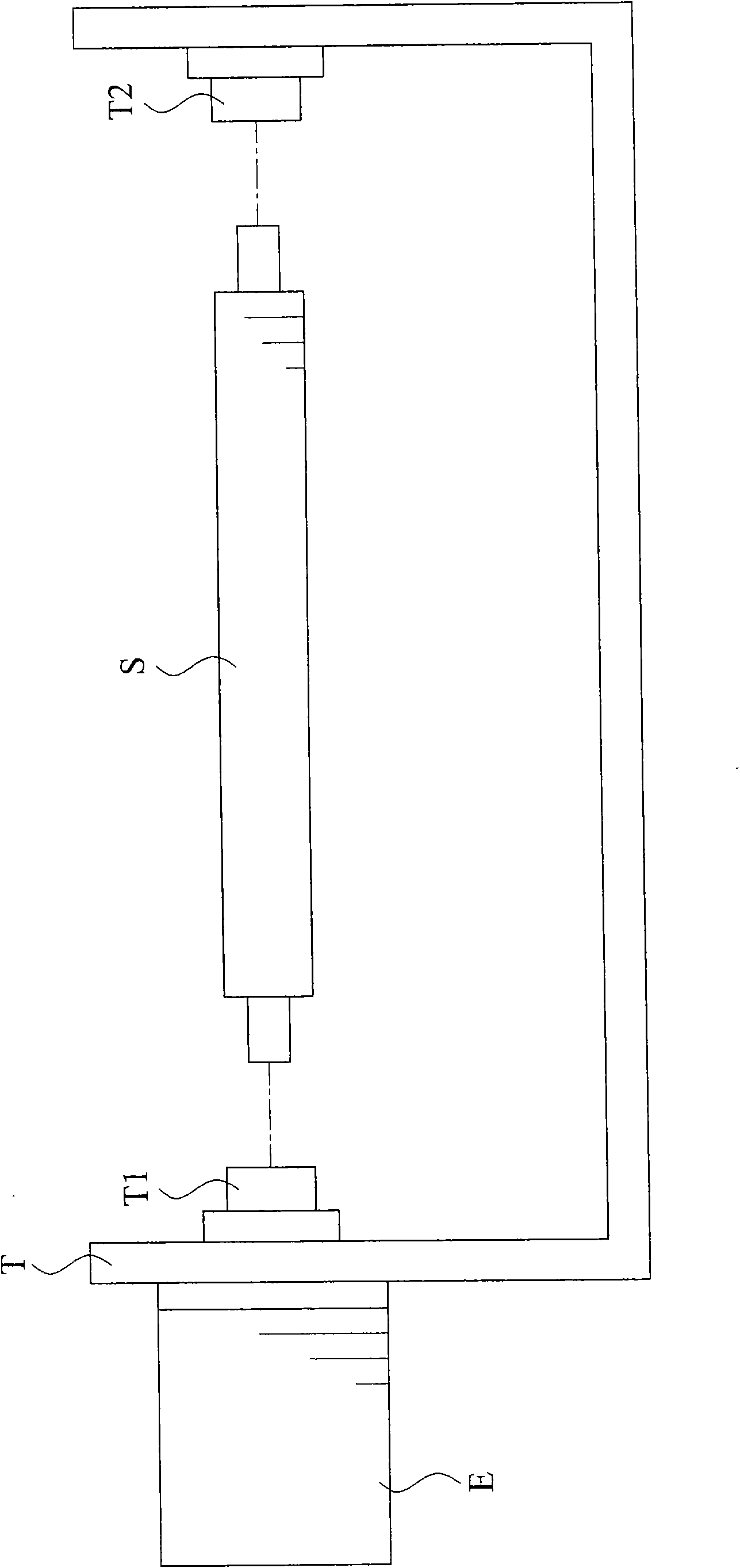

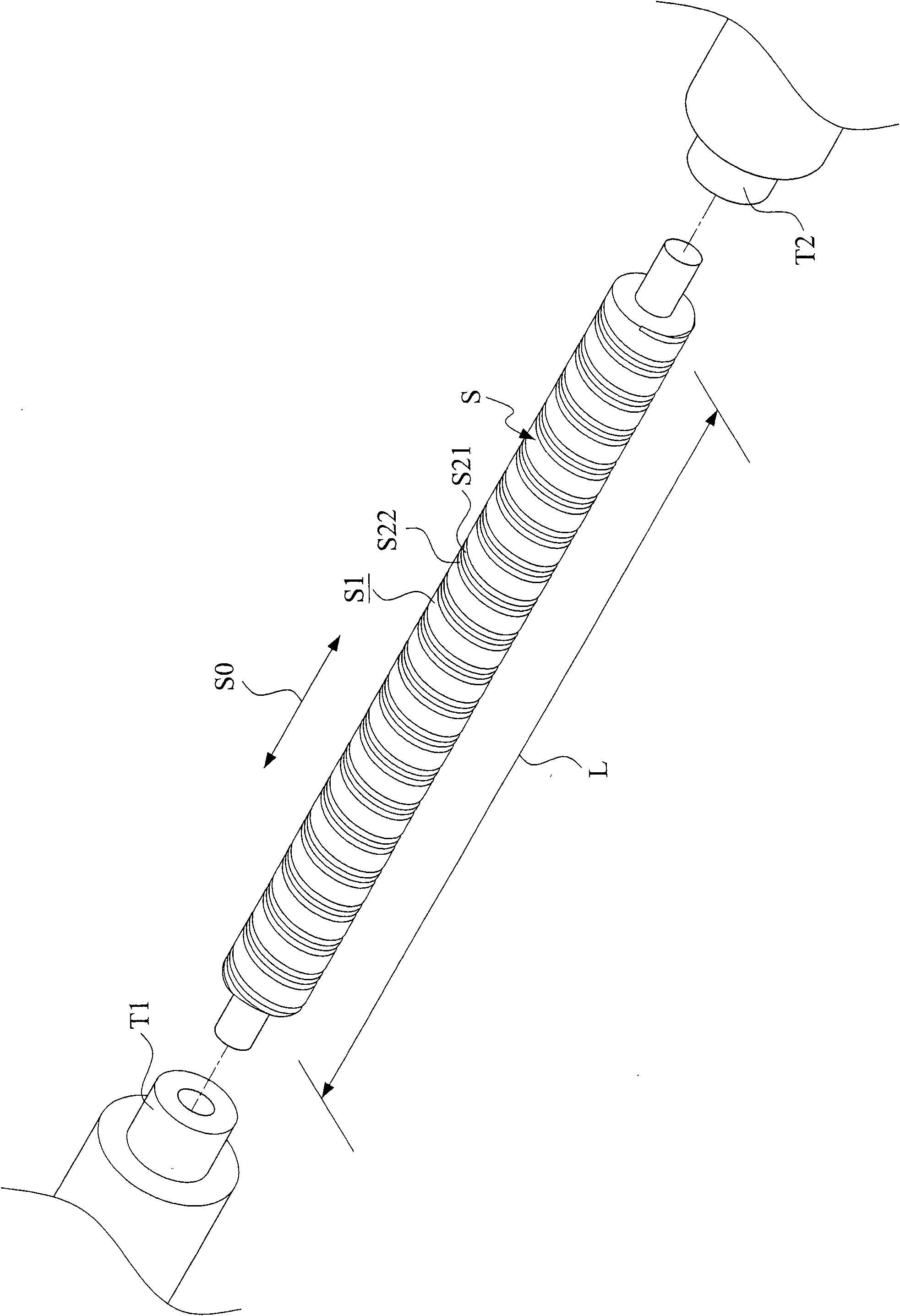

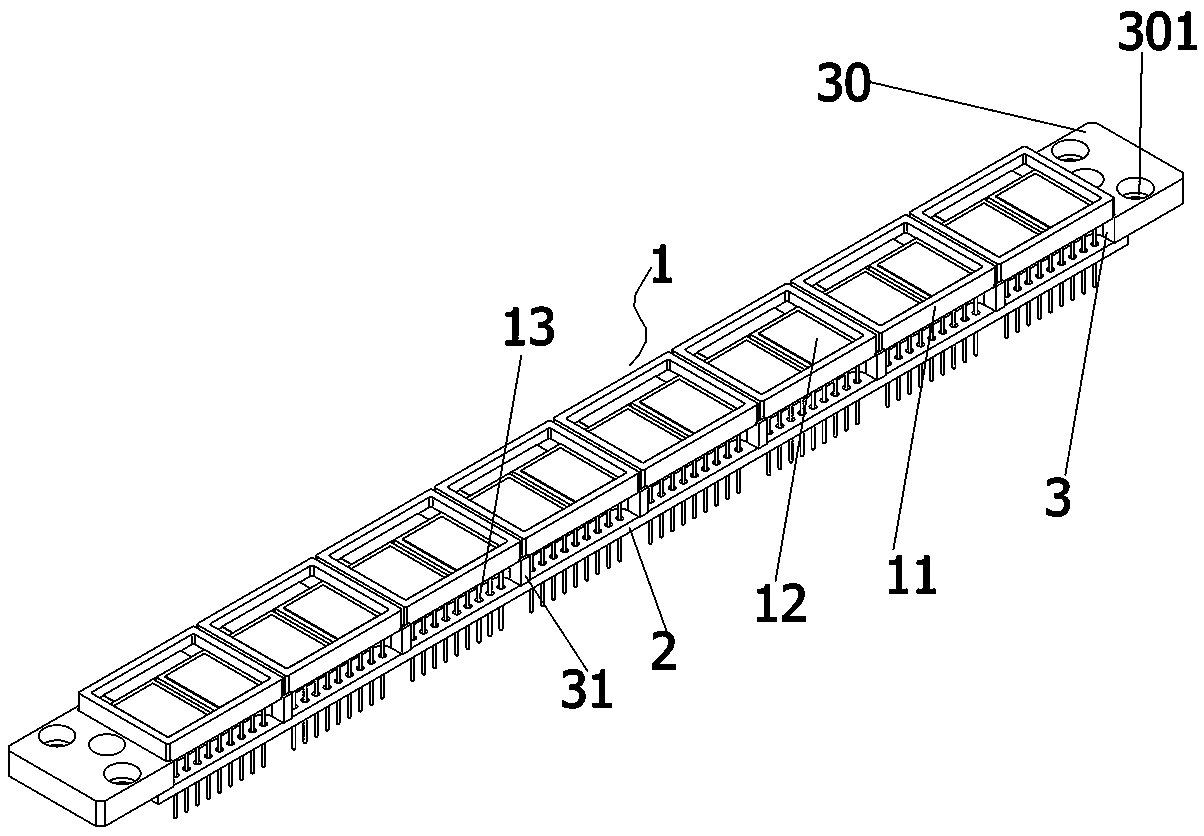

Manufacturing method of surface adhered light-emitting element lamp group

InactiveCN101963303ASave man hoursImprove efficiencyLighting support devicesPoint-like light sourceContact padPin distance

The invention discloses a manufacturing method of a surface adhered light-emitting element lamp group, which comprises the following steps of: firstly, manufacturing a rod with a predetermined length and a winding frame with a corresponding rotary drive shaft; driving the rod to rotate by using a winding device after integrating the rod with the rotary drive shaft so as to wind conducting wires around the surface of the rod adjacently in a predetermined winding distance, wherein the winding distance is corresponding to the pin distance of a selected surface adhered light-emitting element; polishing an insulating layer of each conducting wire along the axial direction of the rod until the conducting part of each conducting wire is exposed, forming contact pad regions, coating a conducting adhesive to each contact pad region, bridging the surface adhered light-emitting element so that all pins of the surface adhered light-emitting element are respectively corresponding to the contact pad regions of the adjacent conducting wires; and electrically connecting the pins with the conducting parts of the conducting wires through the conducting adhesive, and coating with a sealing adhesive.

Owner:RUBERNOS

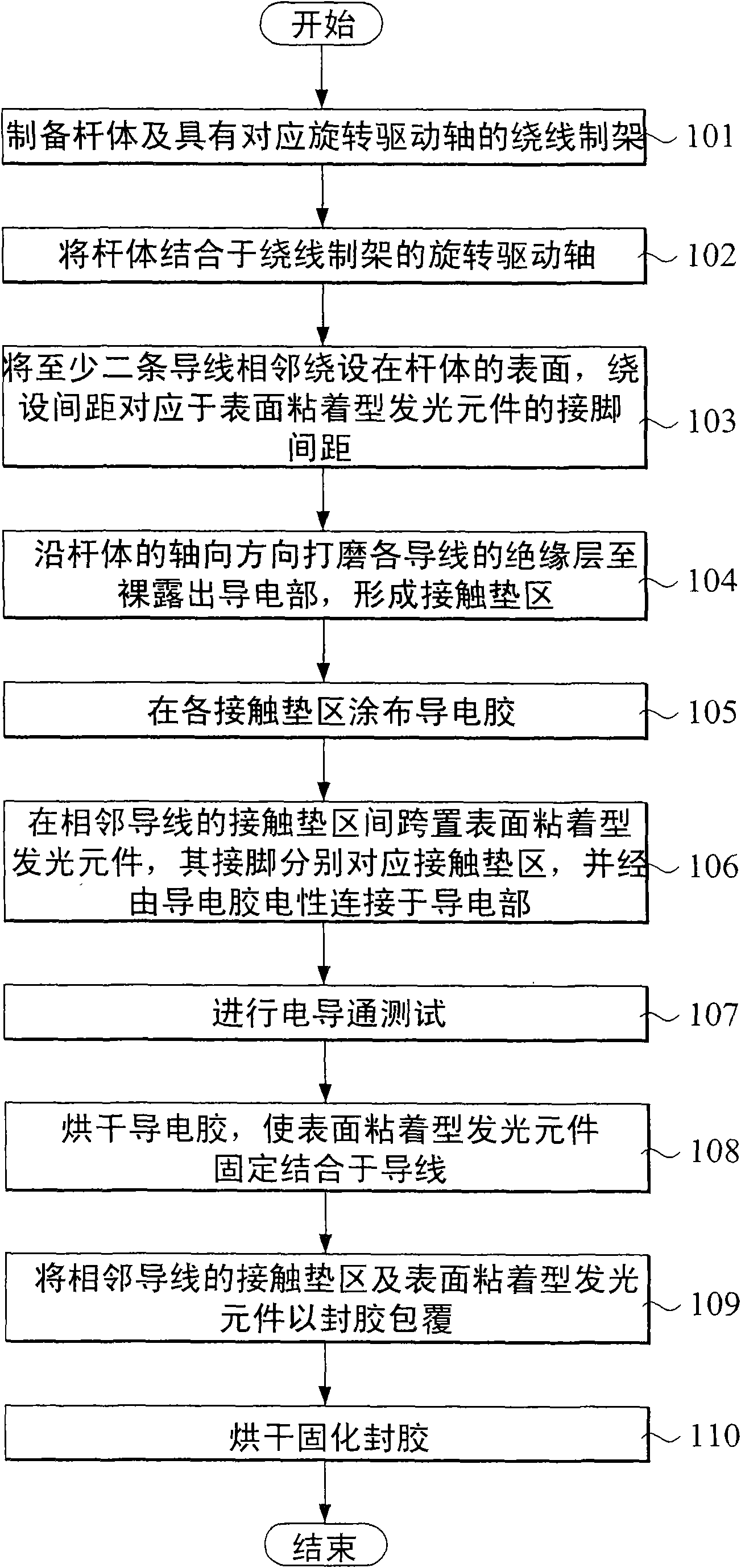

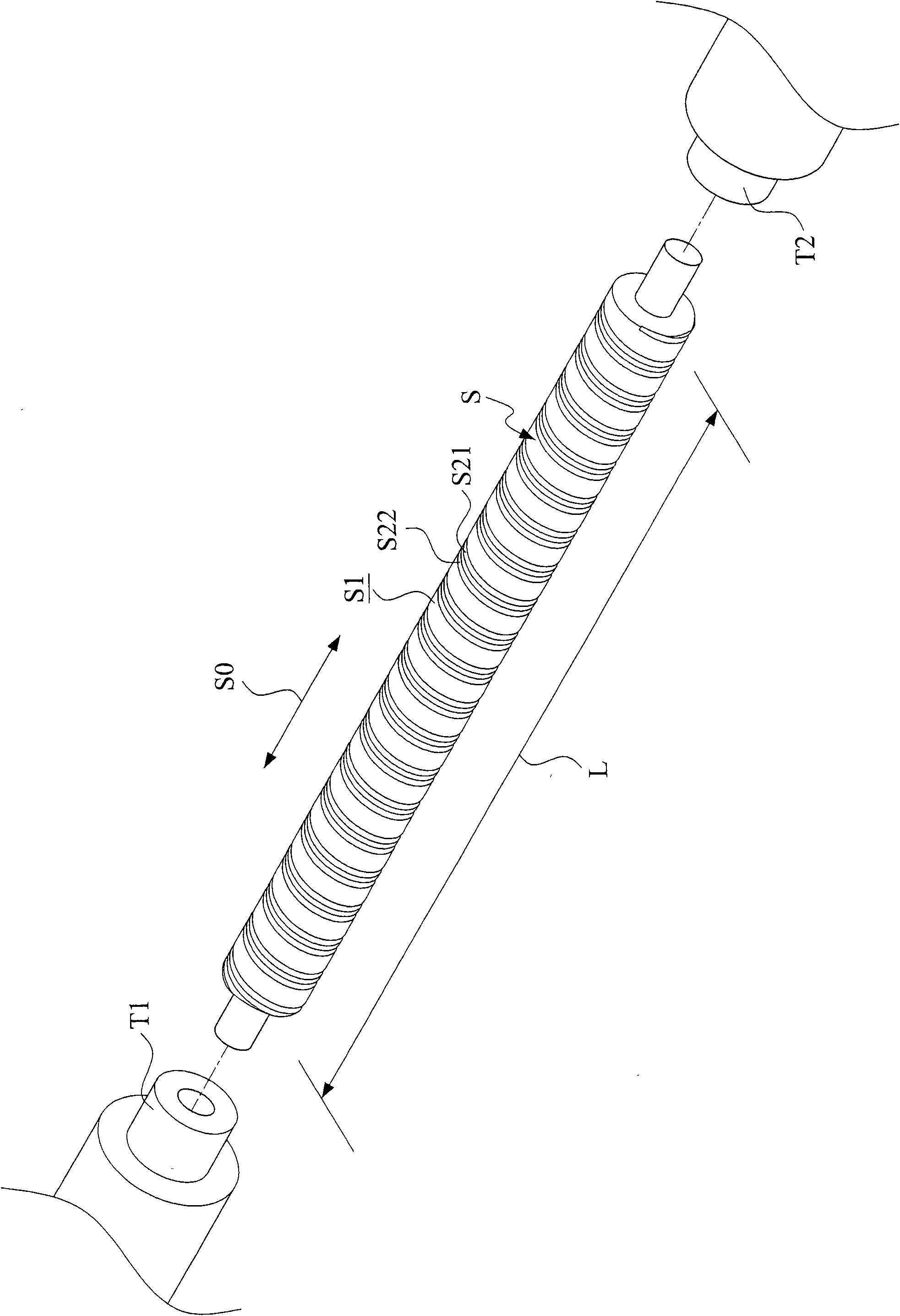

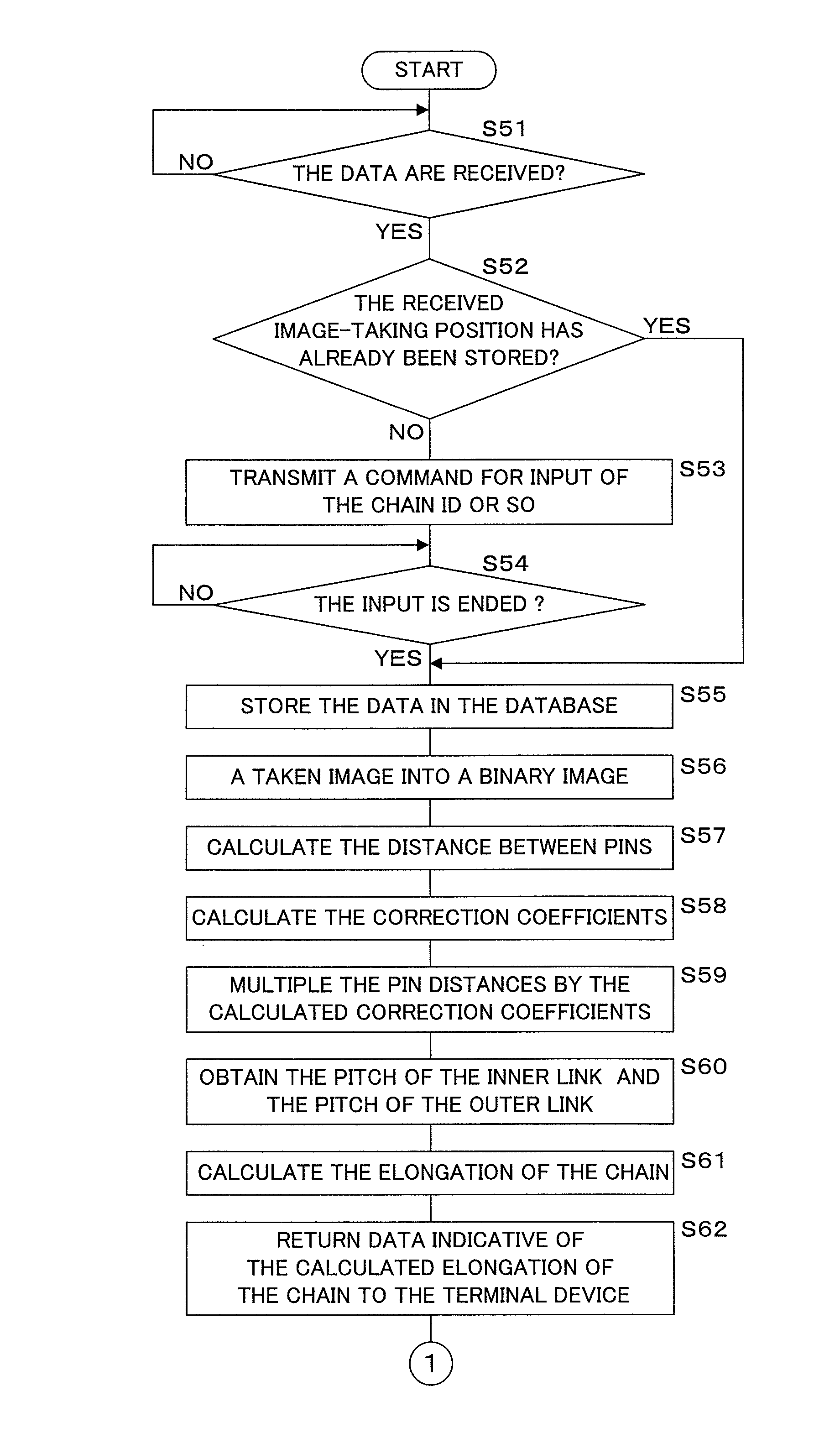

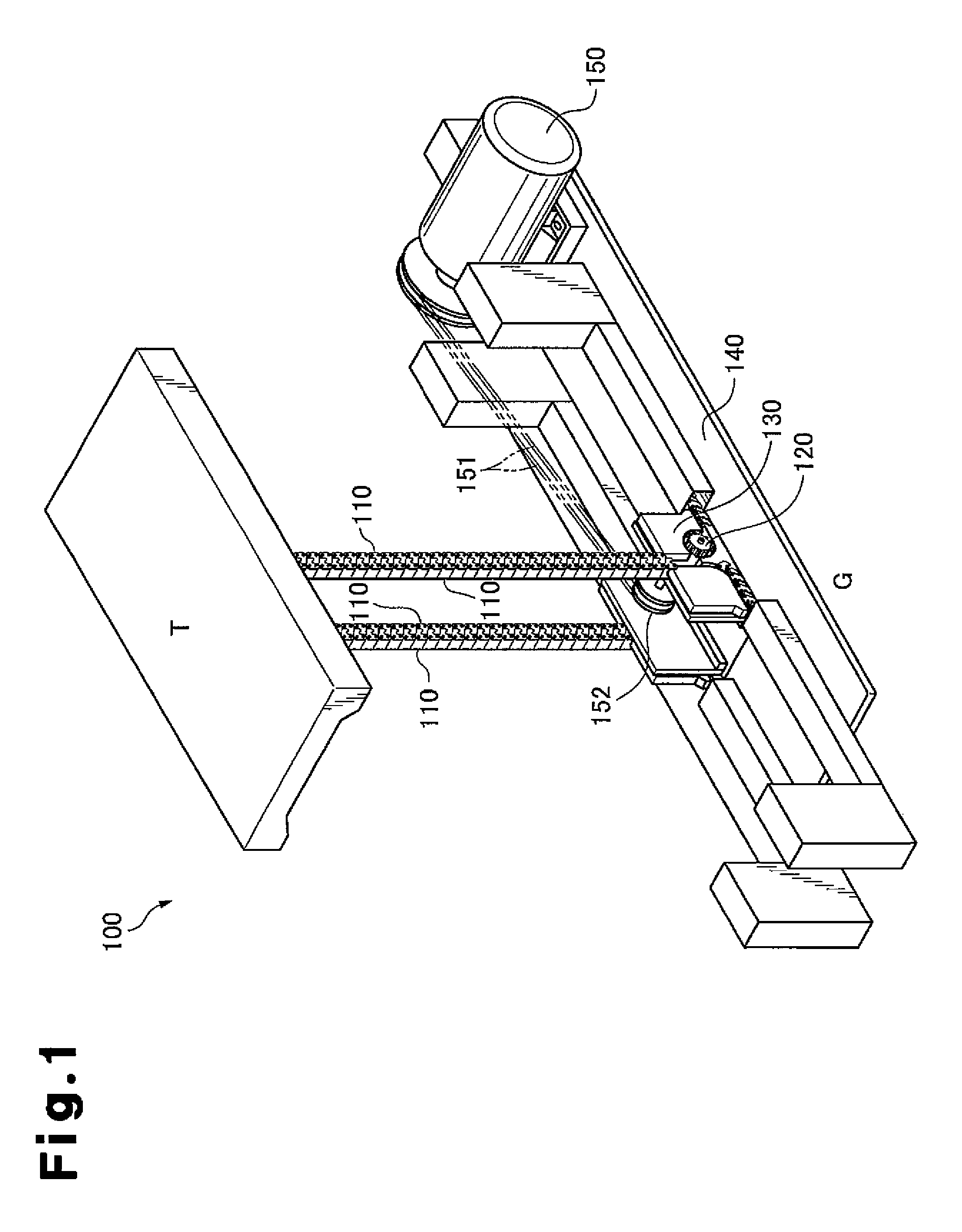

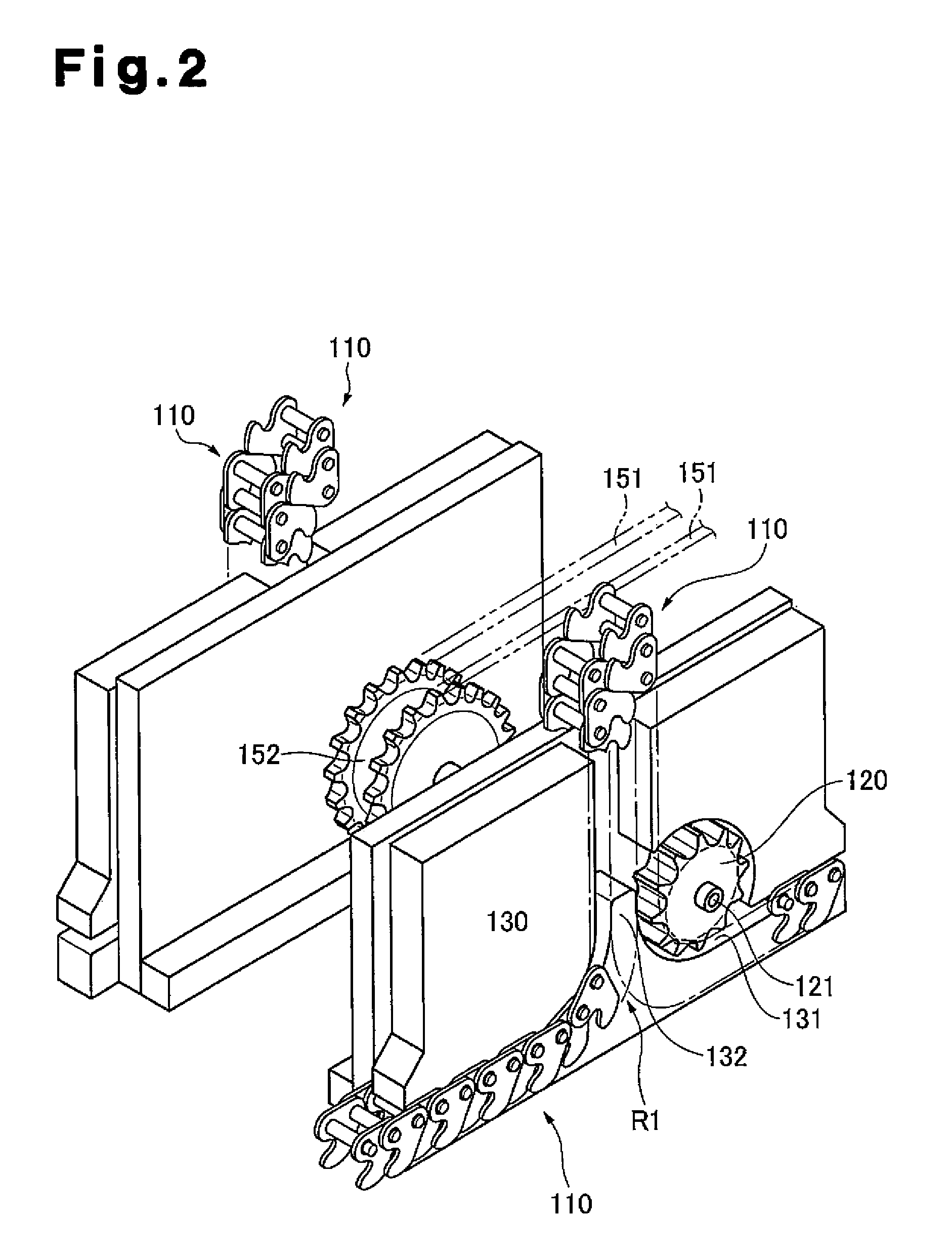

Elongation measuring apparatus, elongation measurement system, and non-transitory medium

InactiveUS9014482B2Control devices for conveyorsCharacter and pattern recognitionPin distanceShortest distance

The present invention provides an elongation measuring apparatus, an elongation measurement system and a non-transitory medium recording a computer program, which enable measurement of an elongation of a chain without presetting a distance between rollers before use. Based on an image of three or more pins, two adjacent inter-pin distances are each calculated. As a result of a comparison between the two calculated inter-pin distances, the longer distance is determined as a pitch of an inner link and the shorter distance is determined as a pitch of an outer link. The outer link is not elongated while only the inner link is elongated, and therefore, a ratio of a difference between both of the pitches to the pitch of the outer link is determined as an elongation of a chain.

Owner:TSUBAKIMOTO CHAIN CO

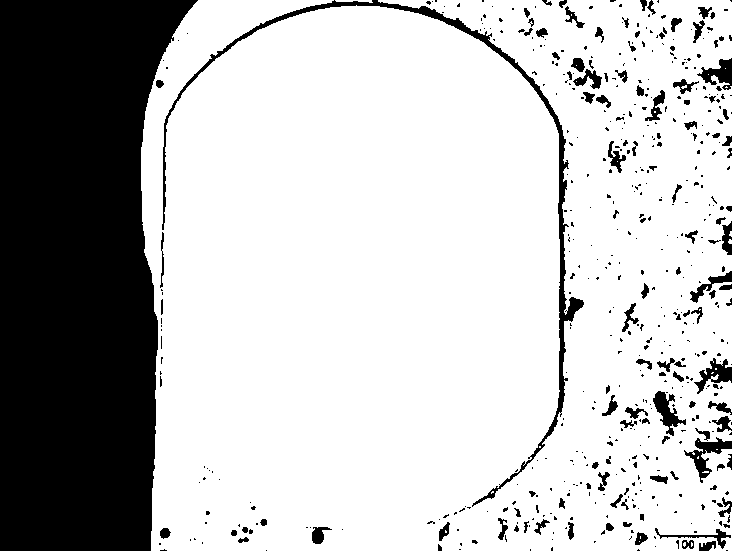

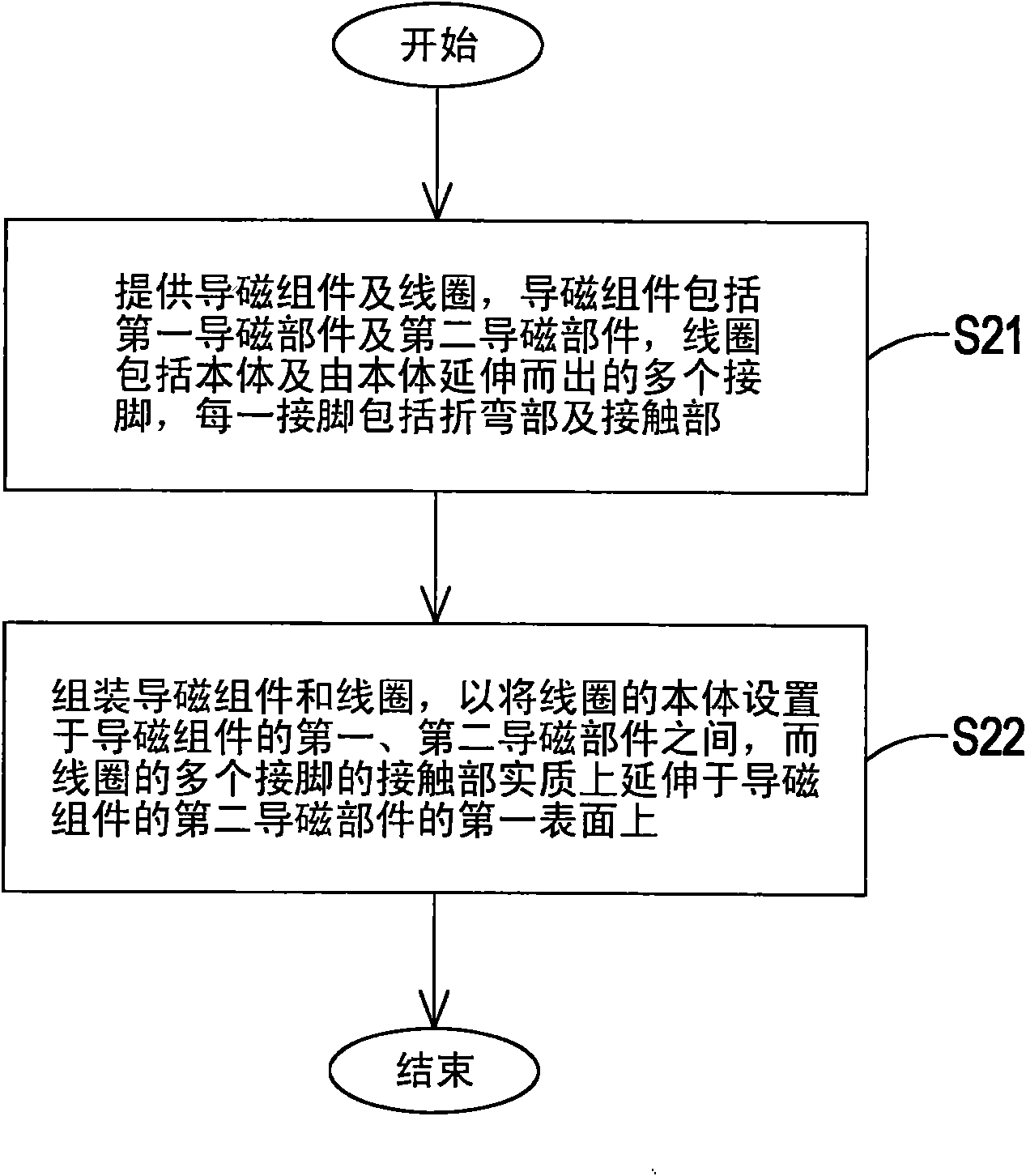

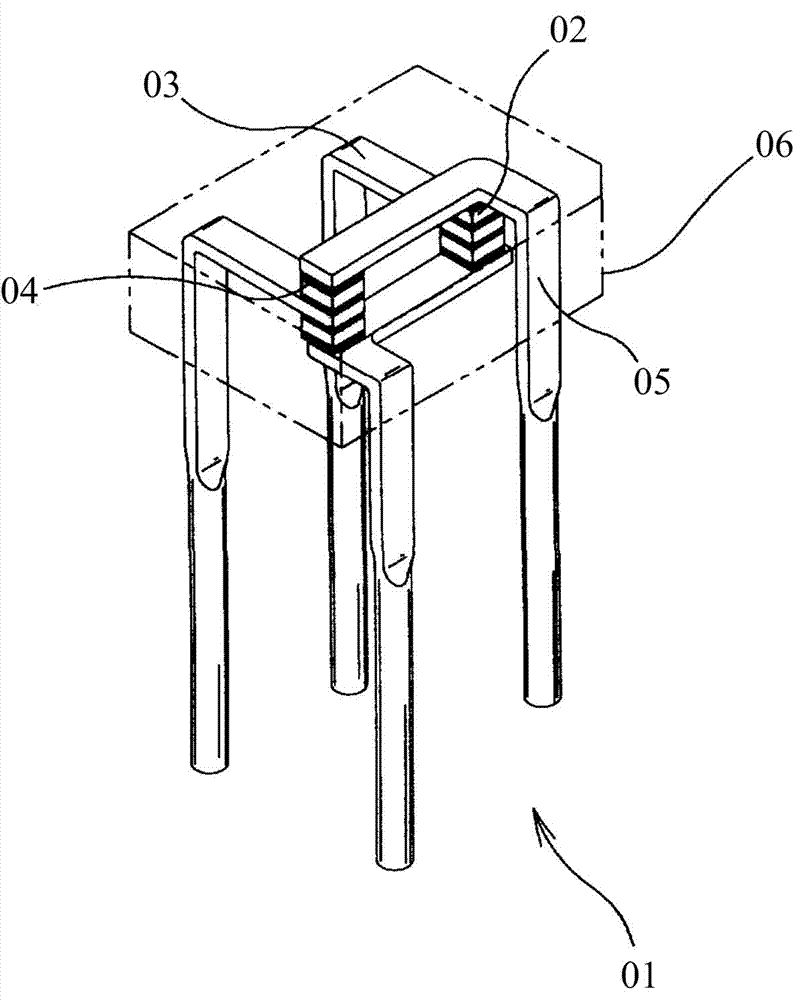

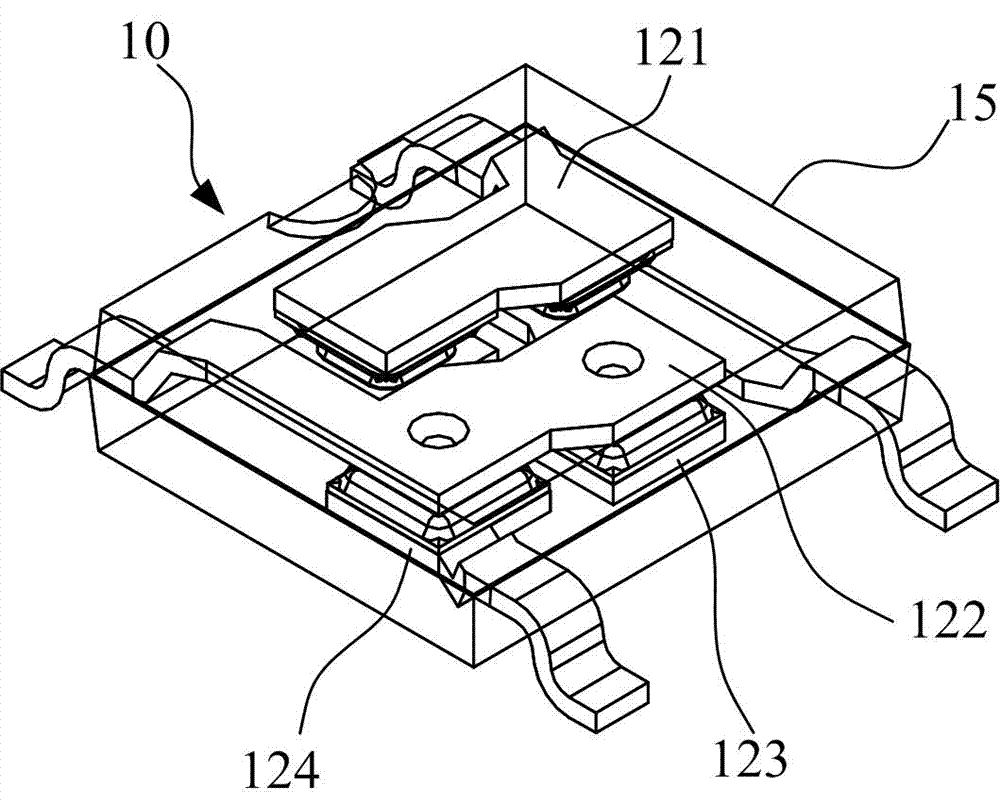

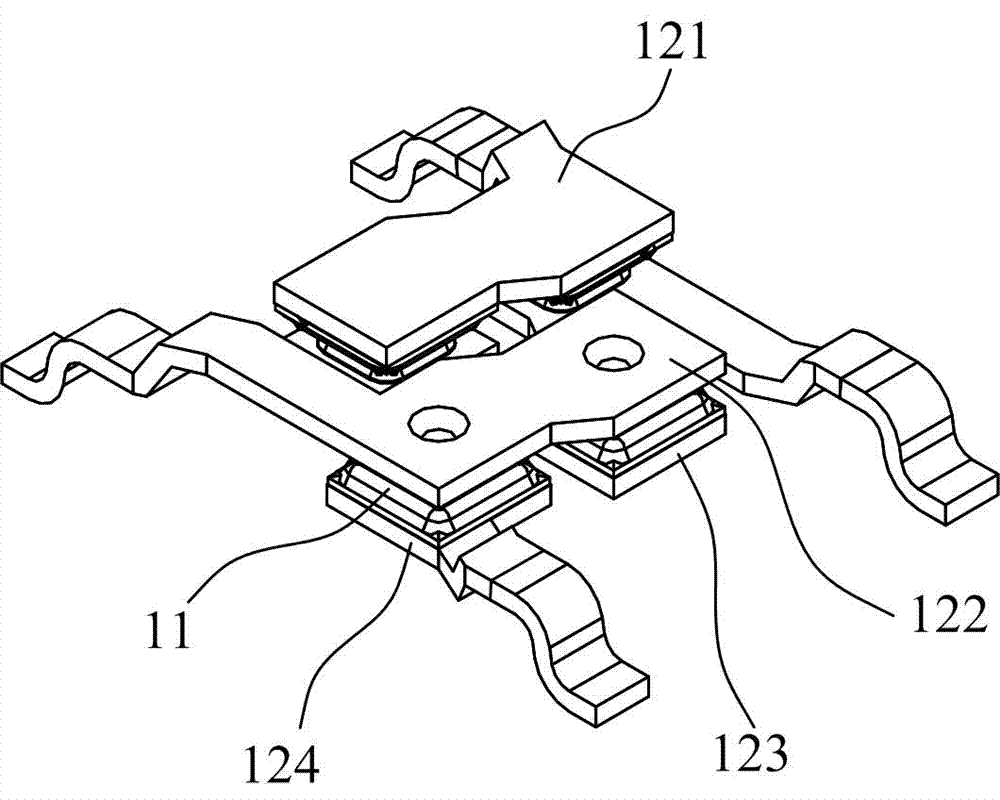

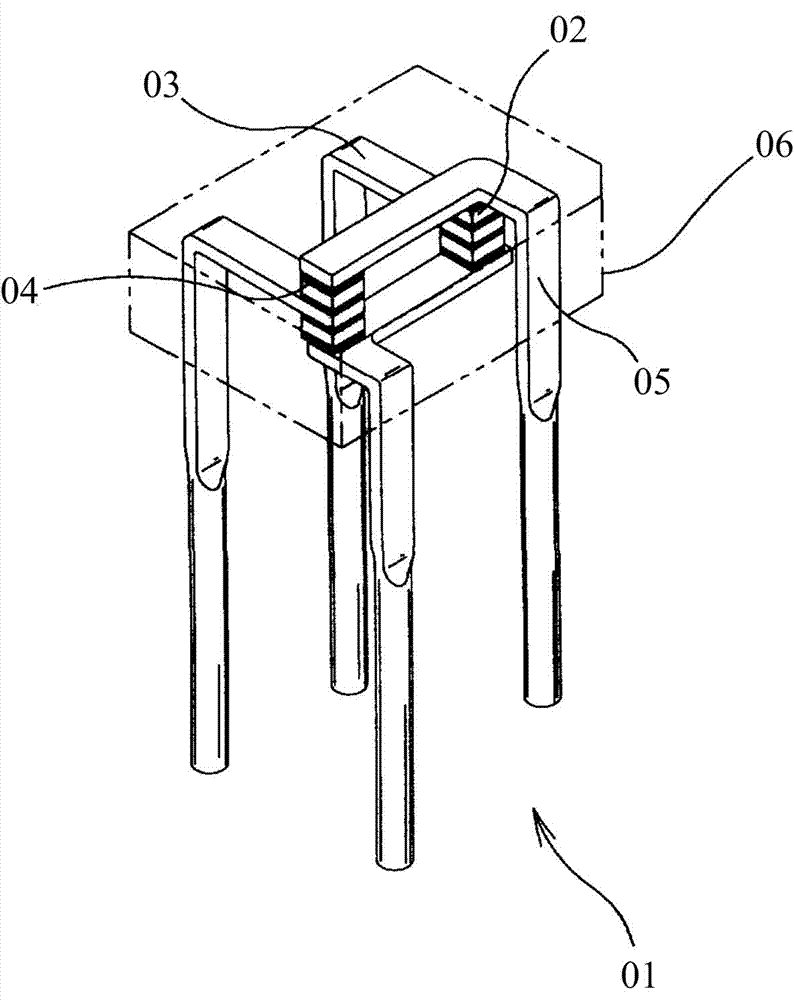

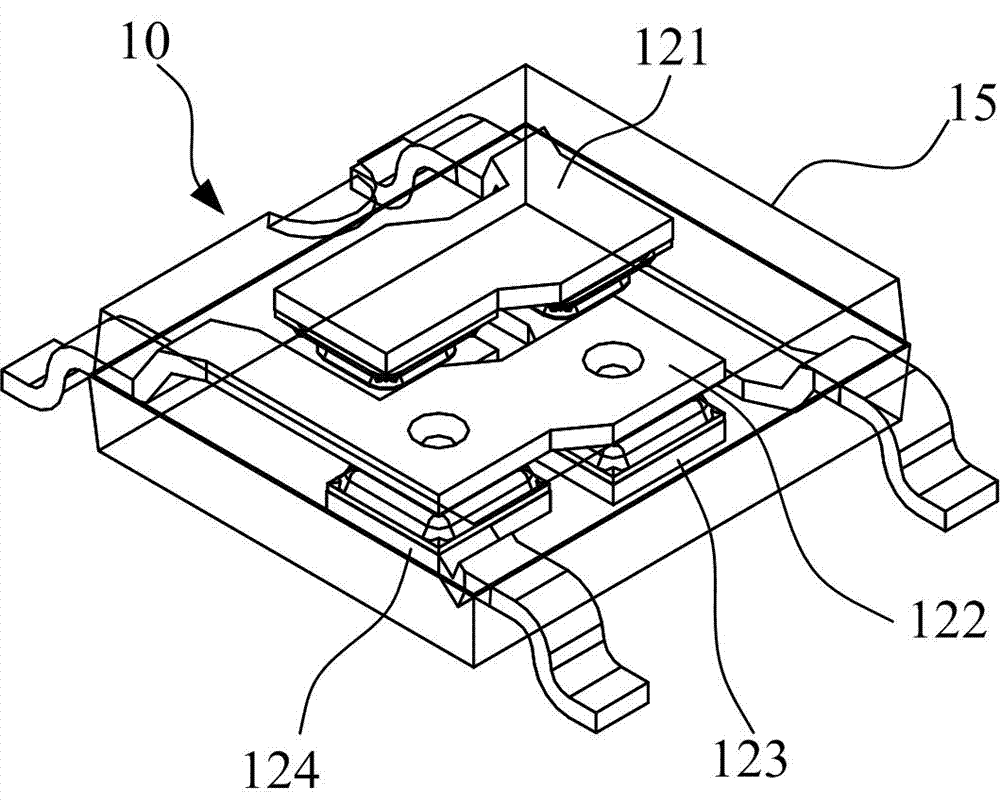

Surface-stuck type magnetic element as well as manufacturing method and coil thereof

The invention relates to a surface-stuck type magnetic element as well as a manufacturing method and a coil thereof, wherein the manufacturing method comprises the following steps of: (a) providing a magnetic conducting assembly and a coil, wherein the magnetic conducting assembly comprises a first magnetic conducting component and a second magnetic conducting component, the coil comprises a body and a plurality of pins formed by extending from the body, and each pin comprises a bent part and a contact part; and (b) assembling the magnetic conducting assembly and the coil, wherein the body of the coil is arranged between the first magnetic conducting component and the second magnetic conducting component of the magnetic conducting assembly, and the contact parts of the pins of the coil substantially substantially extend on the first magnetic conducting component and the second magnetic conducting component of the magnetic conducting assembly. The manufacturing method can avoid various known inconveniences caused by artificially bending the pins of the coil after the assembly of the magnetic conducting assembly and the coil and many problems of unfairness of the bent pins, uneven length and pin distance of the pins, overlarge bending amplitude and the like.

Owner:DELTA ELECTRONICS INC

Ultrathin full-wave rectifier

InactiveCN102790044ACompact structureImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesElectricityPin distance

The embodiment of the invention discloses an ultrathin full-wave rectifier which comprises four wafers, four pole contacts and a package glue body, wherein the four wafers are arranged in a quadrilateral shape in a same plane, and polarities of the wafers on adjacent peripheries are in alternating arrangement of different-same in sequence; the pole contacts are divided into an upper-layer group of pole contacts and a lower-layer group of pole contacts; the two pole contacts at the upper layer are respectively used for electrically connecting two wafers with a same polarity on the upper surfaces of the four wafers; the two pole contacts at the lower layer are respectively used for electrically connecting two wafers with different polarities in a same direction on the lower surfaces of the four wafers; and the package glue body is used for packing the wafers and the pole contacts. By adopting the ultrathin full-wave rectifier, a rectifier which is thinner than the conventional rectifier can be produced, and the pin distance between two pins and types of the wafers can be selected according to the actual requirements, so that the ultrathin full-wave rectifier can be applied flexibly, the four wafers are in a plane placing structure, a product can be tightly attached on a radiating surface of a PC (printed circuit) board, relatively good radiating performance can be obtained, the temperature of a PN node can be controlled within a reasonable range, and the working efficiency is improved.

Owner:广东良得光电科技有限公司

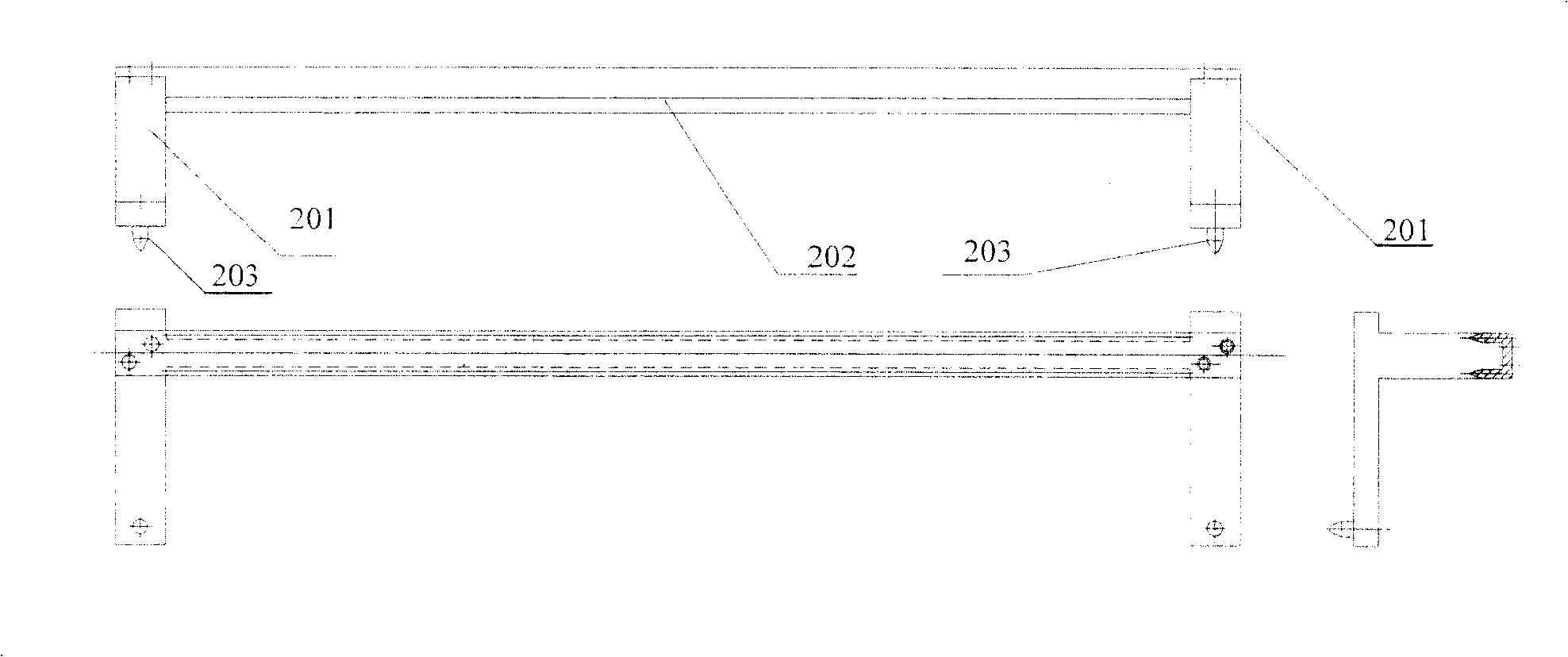

Positioning assembling device for contact pin tinning process and contact pin tinning method

InactiveCN100455166CLow efficiencyReduce multiple processesPrinted circuit assemblingTinningPin distance

The invention discloses a locating industrial mounting device in a pin soldering process, and the device includes: straight leader, brackets and locating pin, where two ends of the straight leader are connected vertically with the brackets, respectively, the distance tolerance between the acting height of a straight leading part in the straight leader and a pin plastic pad is between 0 and a preset tolerance, and the difference value between the pin-pin distance and the width of the straight leading part is between o and a corresponding preset tolerance. The invention also discloses a pin soldering method using the locating industrial mounting device, including the following steps: firstly, inserting pins in a circuit board, inserting the locating industrial mounting device on the circuit board by the locating pin to make the leading part of the straight leader act on the pins; and then making pin soldering.

Owner:广州博士科技交流中心有限公司

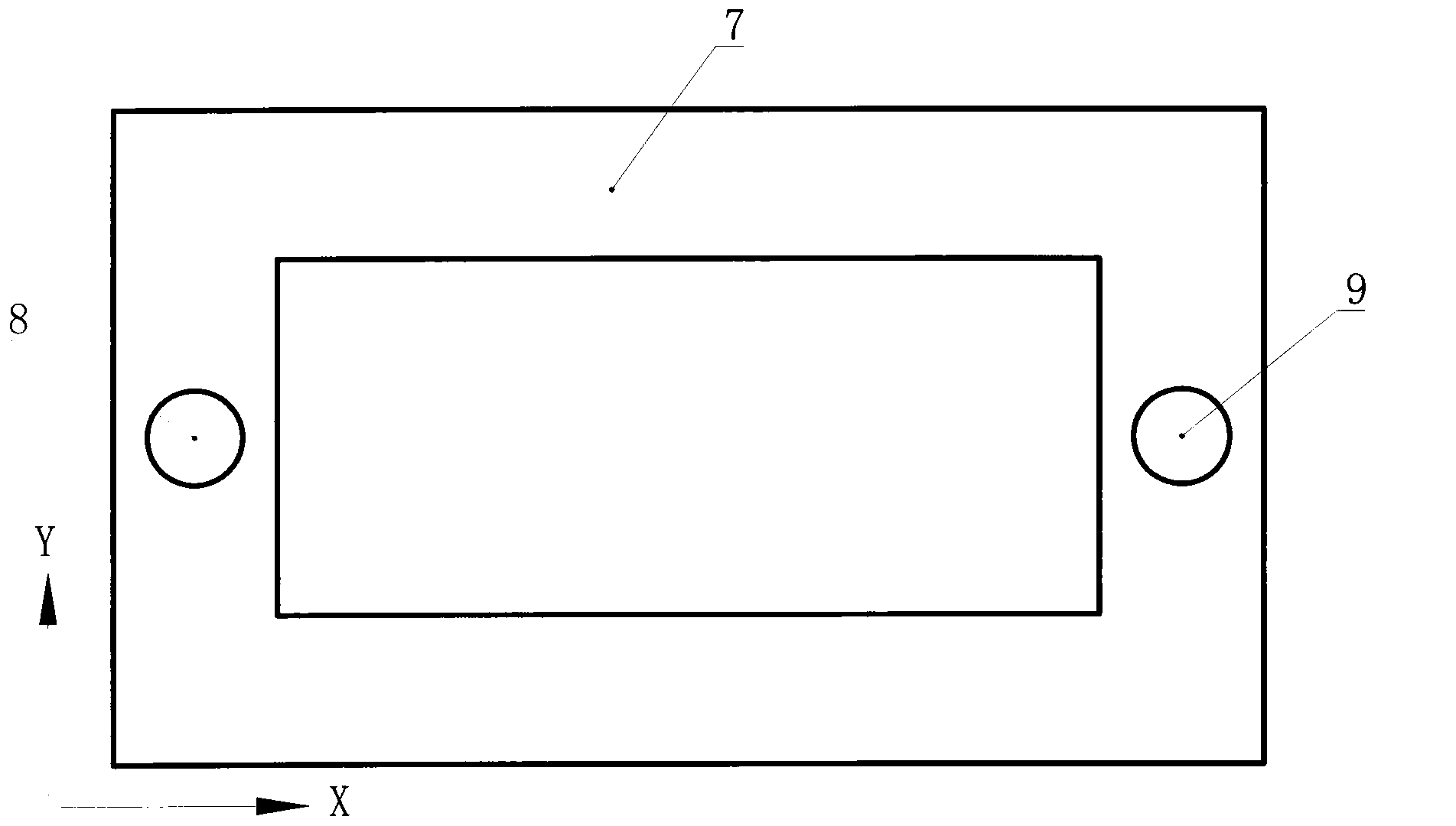

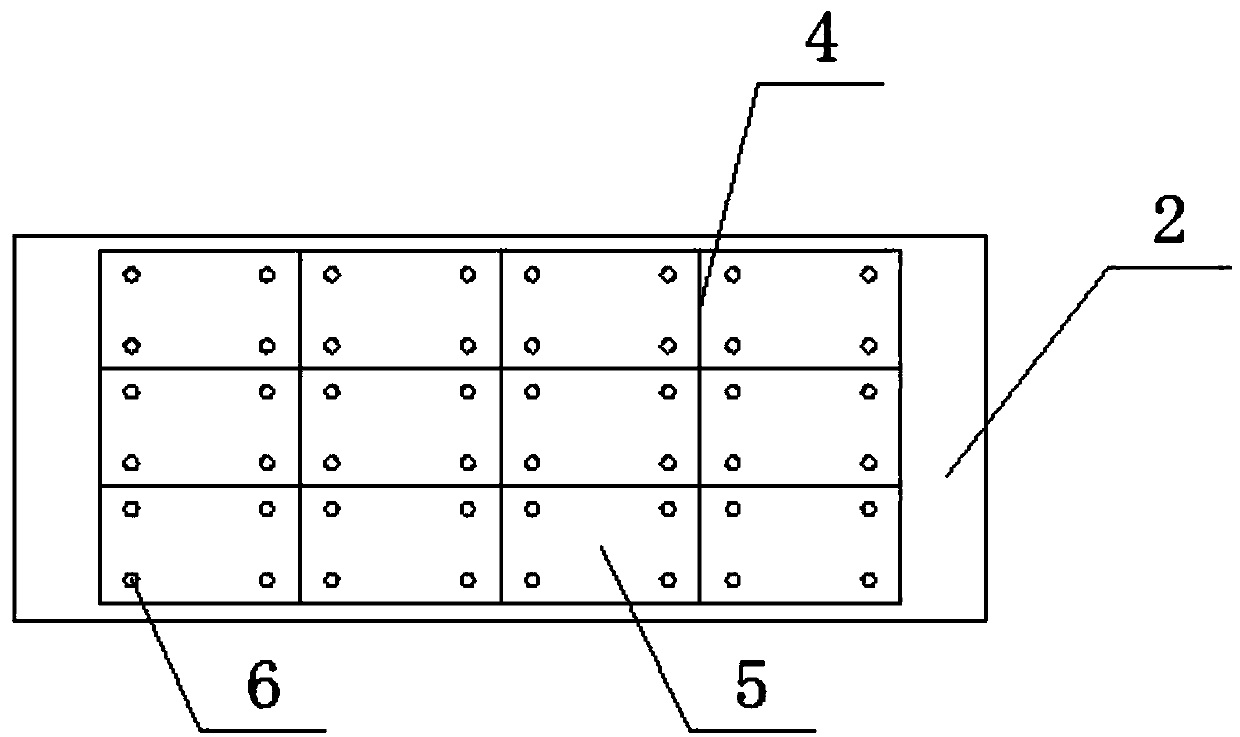

Workpiece processing safety fool-proof device of numerical control machine tool

ActiveCN111360564AGood anti-fooling effectSolve the problem that there is no fool-proof effect for clamping plate-shaped workpiecesPositioning apparatusMetal-working holdersNumerical controlPin distance

The invention discloses a workpiece processing safety fool-proof device of a numerical control machine tool. The workpiece processing safety fool-proof device of the numerical control machine tool comprises a mounting plate and mounting holes arranged on four sides of the mounting plate, wherein support frames are symmetrically arranged on the other two sides of the mounting plate, sliding holes are uniformly formed in one sides of the support frames, limiting pins are inserted into the sliding holes in a penetrating mode, an abutting plate is arranged at one end of each limiting pin, a fixingplate is arranged on the other side of each support frame, screw holes are formed in the fixing plates and correspond to the positions of the sliding holes and are in threaded connection with lead screws, and one end of each lead screw is provided with a rotating plate. By disassembling and assembling the fixing plates, springs can be conveniently replaced. Through the fool-proof limiting of thelimiting pins, a plate-shaped workpiece can only be placed corresponding to the fixed limiting pin distances on the left side and the right side, so that the plate-shaped workpiece can stably contactwith the mounting plate, only one time of adjustment is needed, tool resetting is not needed, safety and high efficiency are achieved, the fool-proof effect is good, and the problem that the fool-proof effect of clamping the plate-shaped workpiece does not exist in the prior art is solved.

Owner:杭州联德精密机械股份有限公司

Manufacturing method of surface adhered light-emitting element lamp group

InactiveCN101963303BSave man hoursImprove efficiencyPoint-like light sourceLighting support devicesContact padPin distance

The invention discloses a manufacturing method of a surface adhered light-emitting element lamp group, which comprises the following steps of: firstly, manufacturing a rod with a predetermined length and a winding frame with a corresponding rotary drive shaft; driving the rod to rotate by using a winding device after integrating the rod with the rotary drive shaft so as to wind conducting wires around the surface of the rod adjacently in a predetermined winding distance, wherein the winding distance is corresponding to the pin distance of a selected surface adhered light-emitting element; polishing an insulating layer of each conducting wire along the axial direction of the rod until the conducting part of each conducting wire is exposed, forming contact pad regions, coating a conducting adhesive to each contact pad region, bridging the surface adhered light-emitting element so that all pins of the surface adhered light-emitting element are respectively corresponding to the contact pad regions of the adjacent conducting wires; and electrically connecting the pins with the conducting parts of the conducting wires through the conducting adhesive, and coating with a sealing adhesive.

Owner:RUBERNOS

A detection module and its installation method

ActiveCN108307603BGuaranteed positioning accuracyFirmly connectedStackable modulesMultiple connection subassembliesPin distanceEngineering

The invention discloses a detection module and an installation method thereof. The detection module comprises a detector and a detector welded PCB, wherein the detector and the detector welded PCB arerespectively installed and fixed on two surfaces of an elongated metal plugboard, multiple groups of opposite protruding ribs are formed at two sides of the metal plugboard in a length direction andhorizontally protrude outwards, the intervals among the protruding ribs at each side are same, a plurality of positioning bosses are formed at a connection side of the detector welded PCB and the metal plugboard, threaded screw holes are formed in centers of the positioning bosses, the metal plugboard is glued with a contact surface of the detector, and the detector welded PCB is glued with the metal plugboard after positioning of the positioning bosses. By the detection module, the positioning accuracy and the pin distance of the detector are ensured.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

Ultrathin full-wave rectifier

InactiveCN102790044BCompact structureImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesElectricityPin distance

The embodiment of the invention discloses an ultrathin full-wave rectifier which comprises four wafers, four pole contacts and a package glue body, wherein the four wafers are arranged in a quadrilateral shape in a same plane, and polarities of the wafers on adjacent peripheries are in alternating arrangement of different-same in sequence; the pole contacts are divided into an upper-layer group of pole contacts and a lower-layer group of pole contacts; the two pole contacts at the upper layer are respectively used for electrically connecting two wafers with a same polarity on the upper surfaces of the four wafers; the two pole contacts at the lower layer are respectively used for electrically connecting two wafers with different polarities in a same direction on the lower surfaces of the four wafers; and the package glue body is used for packing the wafers and the pole contacts. By adopting the ultrathin full-wave rectifier, a rectifier which is thinner than the conventional rectifier can be produced, and the pin distance between two pins and types of the wafers can be selected according to the actual requirements, so that the ultrathin full-wave rectifier can be applied flexibly, the four wafers are in a plane placing structure, a product can be tightly attached on a radiating surface of a PC (printed circuit) board, relatively good radiating performance can be obtained, the temperature of a PN node can be controlled within a reasonable range, and the working efficiency is improved.

Owner:广东良得光电科技有限公司

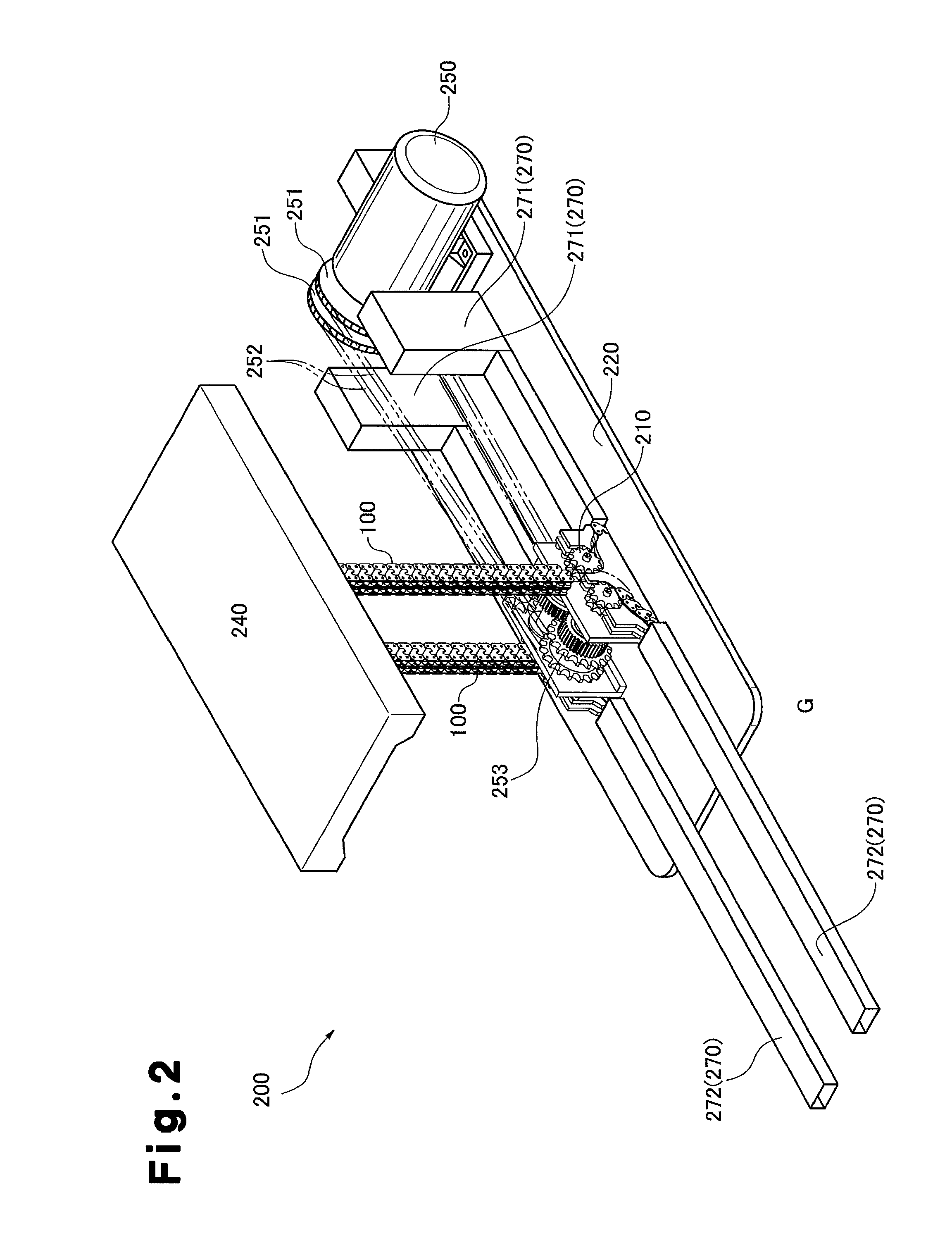

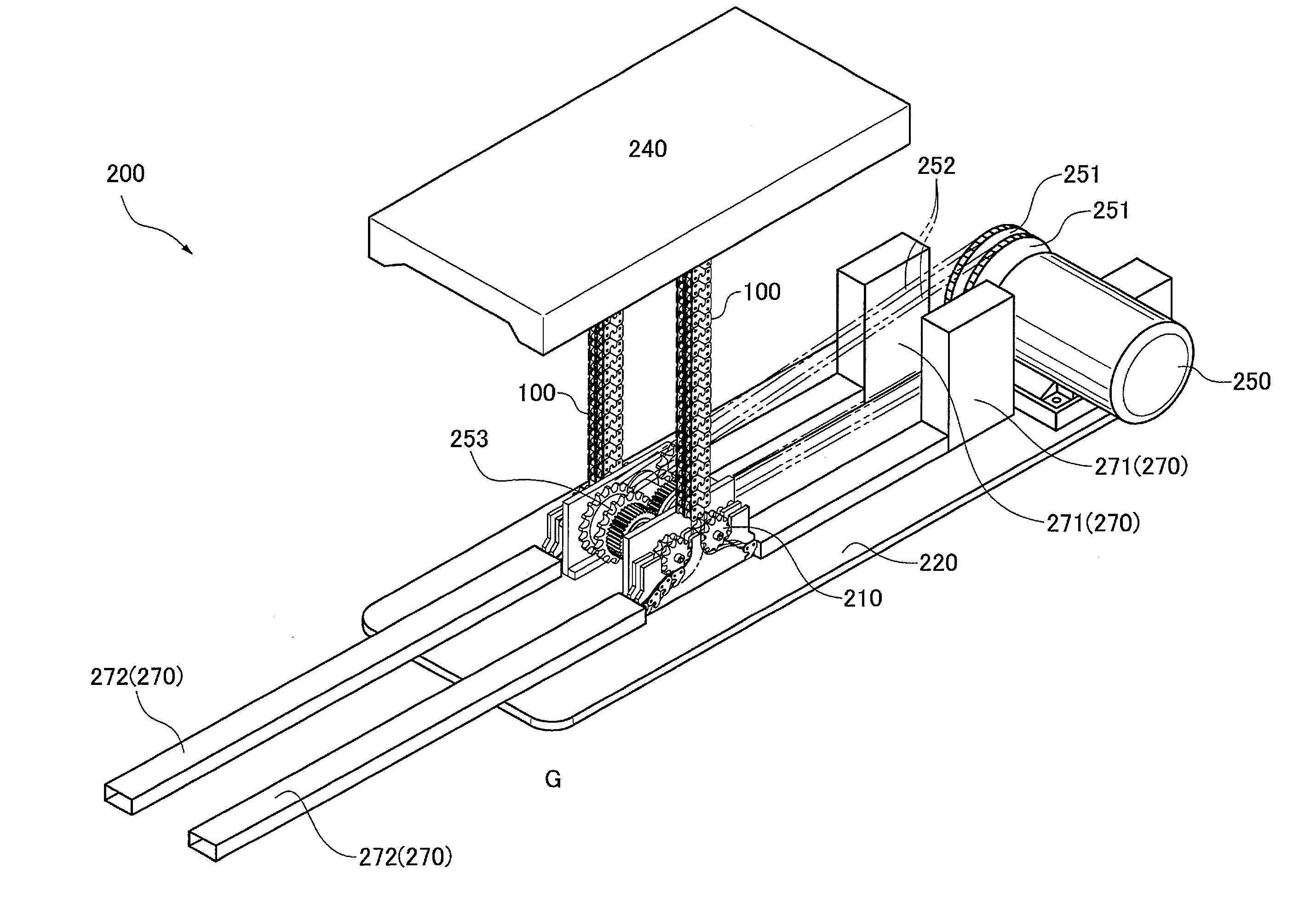

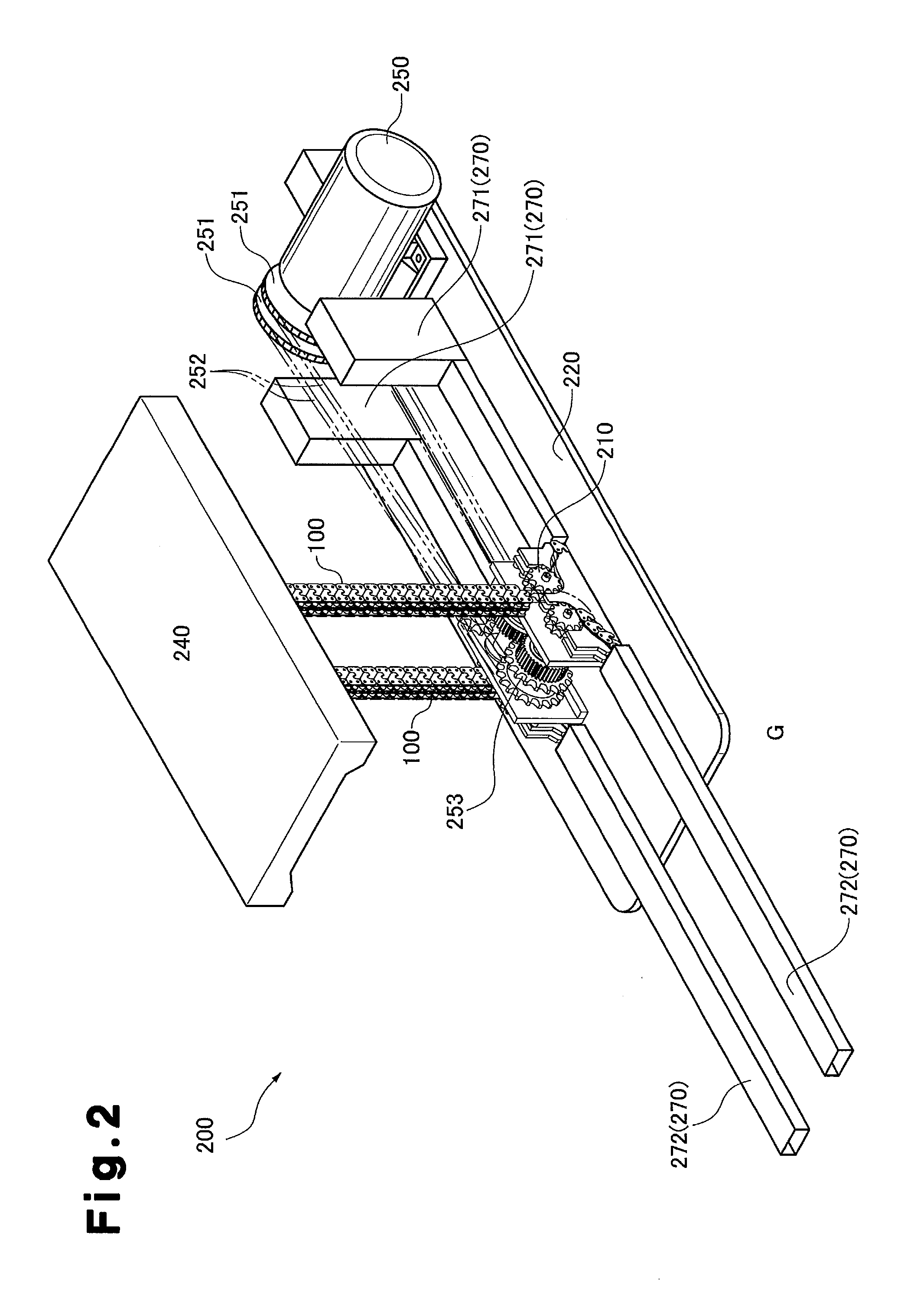

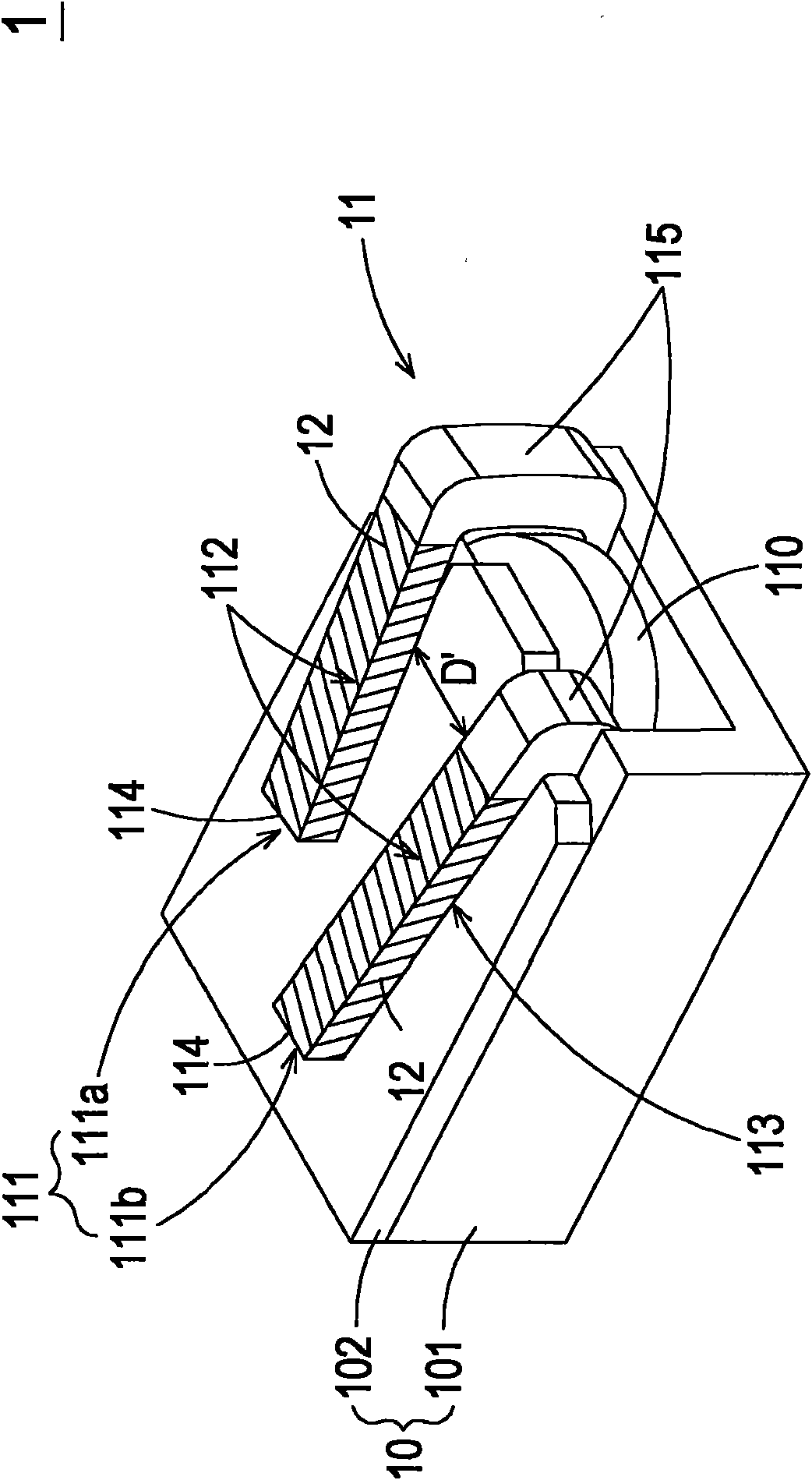

Advancing/retracting actuation device with meshing chain

ActiveUS9255630B2Guaranteed smooth completionSmoothly advanceLifting devicesChain elementsPin distanceChain type

An interlocking chain type forward and backward actuating device is provided that does not increase workload involved in assembling the device, adjusting the rotation phase, and servicing and maintaining the device. The device is capable of smoothly actuating a driven body by advancing and retracting the body, and of preventing any pulsation or the like of the meshing chain. The interlocking chain type forward and backward actuating device includes chain-guide grooves formed so as to equalize an interlocked-state pin-to-pin distance (D1) between a pair of connecting pins that face each other in a chain interlocking imaginary plane (S) and a rigid-state pin-to-pin distance (D2) between a pair of connecting pins.

Owner:TSUBAKIMOTO CHAIN CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com