Positioning assembling device for contact pin tinning process and contact pin tinning method

A technology for positioning tooling and pins, applied in the direction of assembling printed circuits with electrical components, etc., can solve the problems of inaccurate pin size, long production cycle, increased cost of tinning process, etc., to eliminate waiting for turnover and storage. The effect of saving equipment and space and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

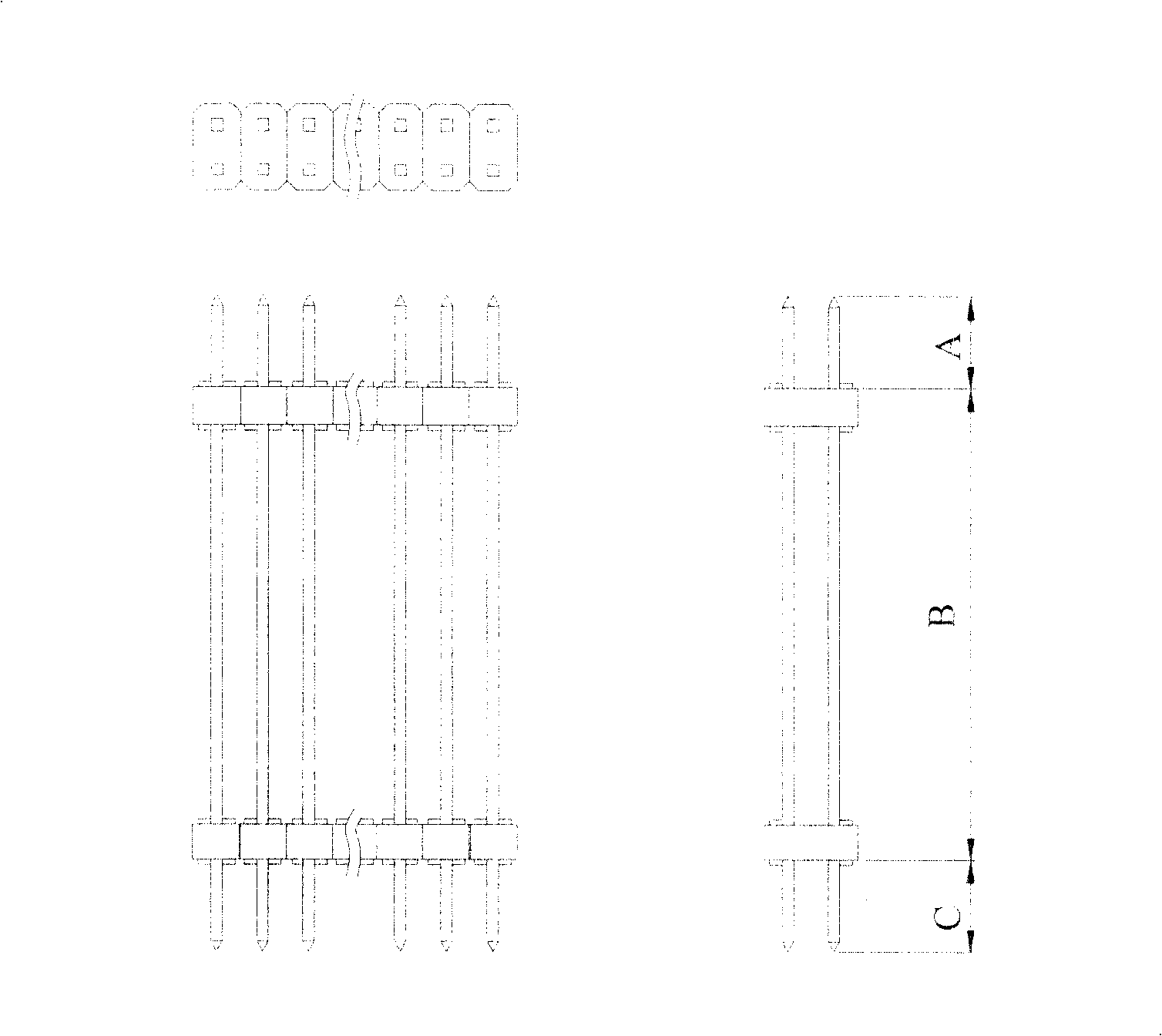

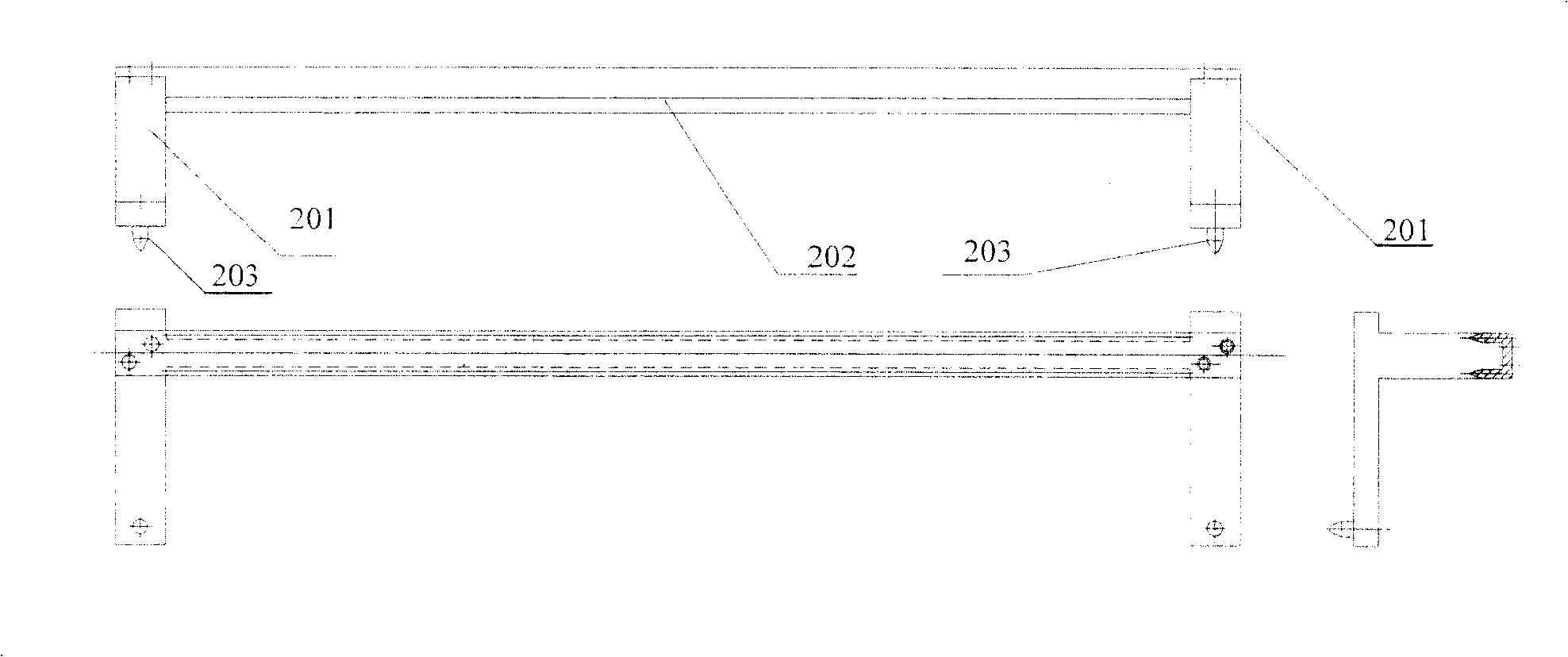

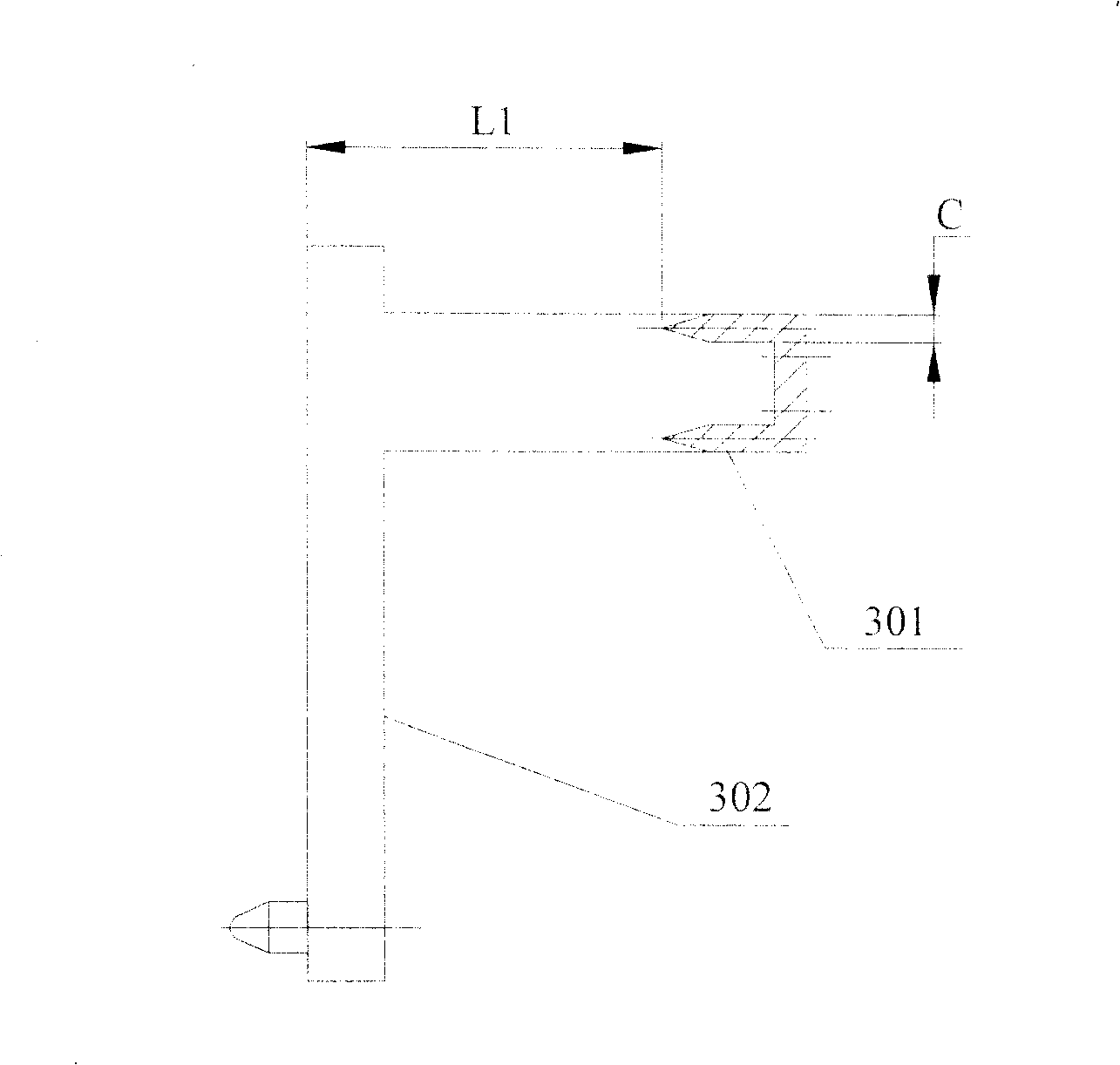

[0054] The present invention relates to a positioning tooling device in the tinning process of inserting pins and a tinning method using the device. The positioning tooling device is composed of a bracket, a positioning pin and a guiding rod, and the guiding part on the guiding rod Realize the positive guiding effect on the pins, so as to ensure the dimensional accuracy of the pins in the process of tin passing. When using this positioning tool to carry out soldering of pins, after inserting the pins into the circuit board, use the positioning tool to act on the pins to guide the pins so that the pins meet the positioning requirements in size, and then, in the Under the action of the positioning tool, the pins are tinned.

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0056] In order to realize the tin-passing process of pins on the circuit board, the present invention adopts figure 2 Tooling shown complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com