Patents

Literature

33results about How to "Good anti-fooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

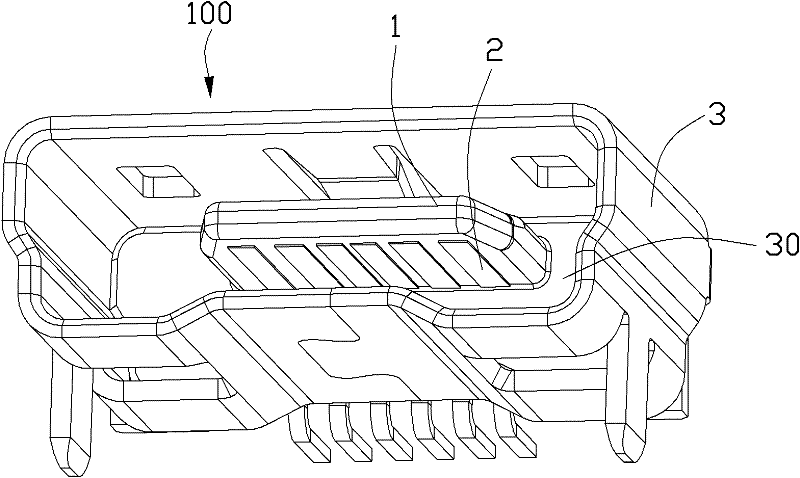

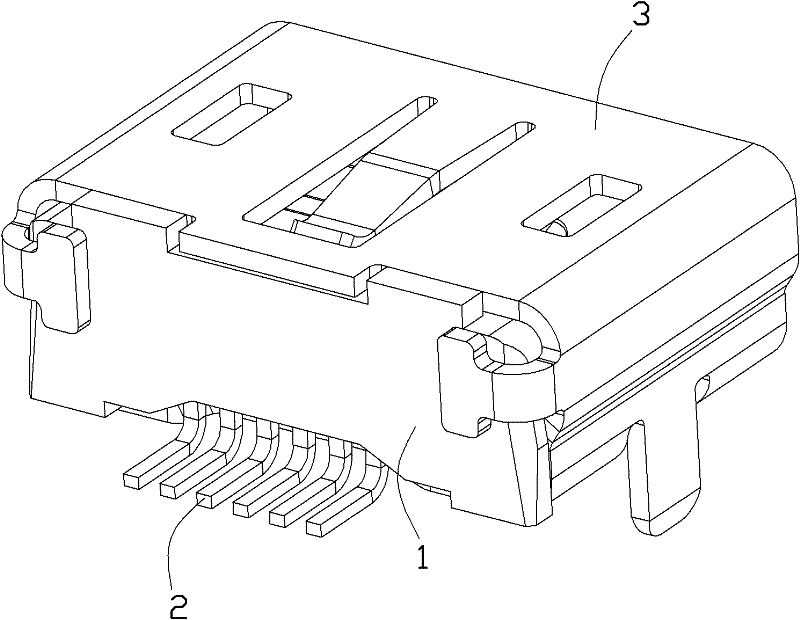

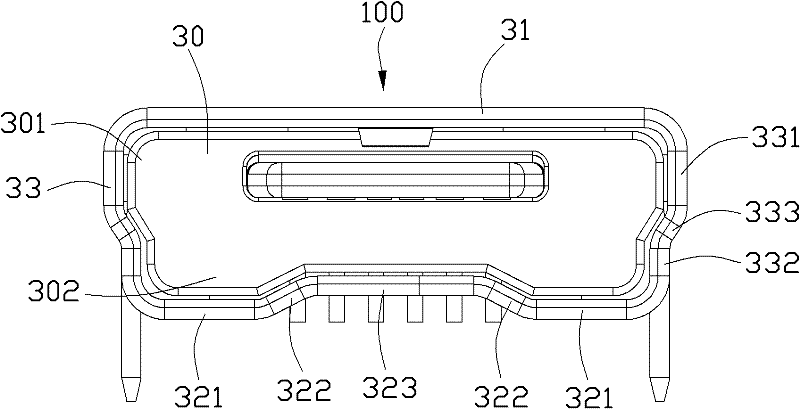

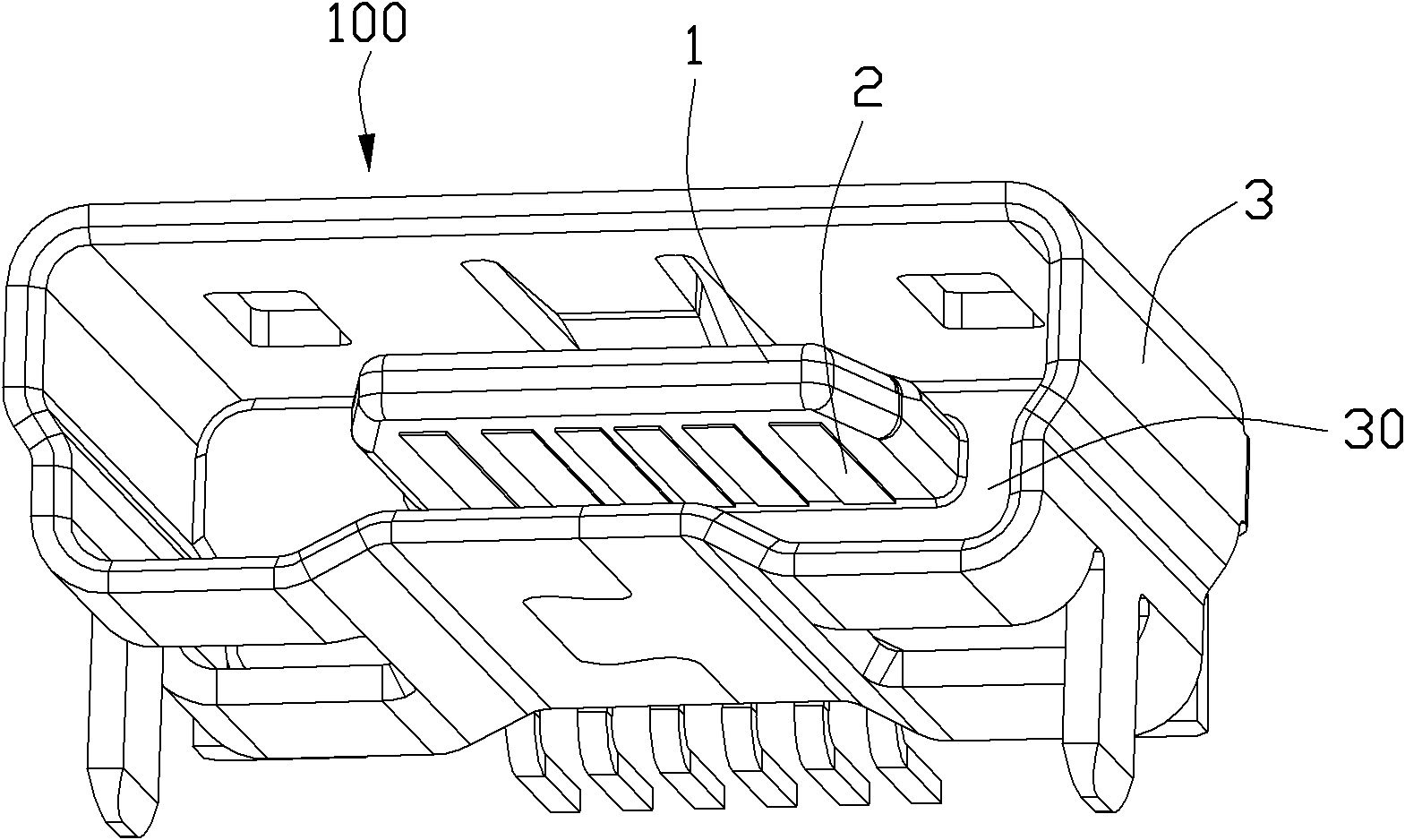

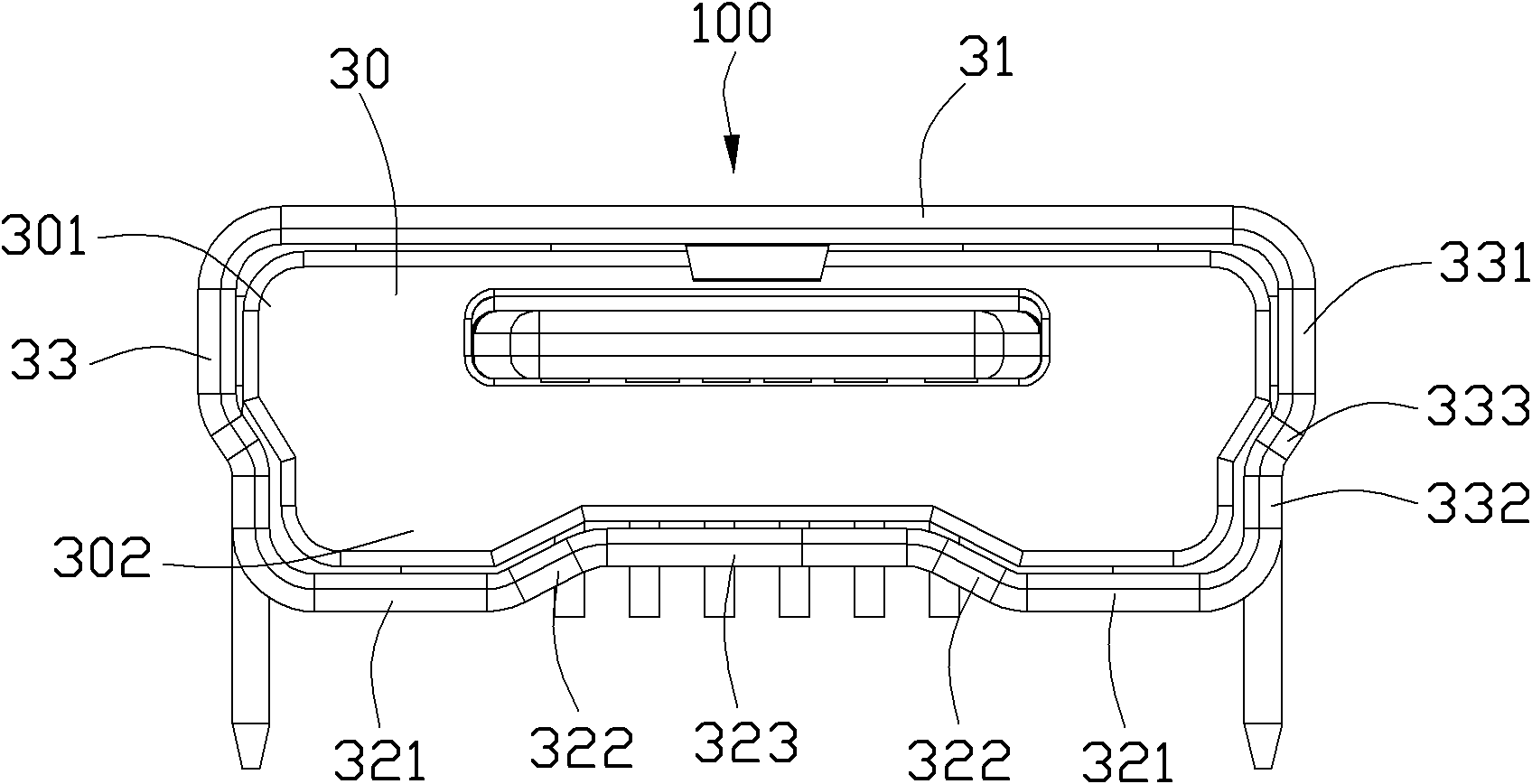

electrical connector

InactiveCN102290655AReduce volumePrecise positioningCouplings bases/casesCoupling protective earth/shielding arrangementsElectrical connectorFirst insertion

The invention provides an electric connector which is applicable to inserted connection of two different plug connectors. The electric connector comprises an insulating body, a plurality of conductive terminals fixedly clamped in the insulating body and a shielding shell covering the insulating body, wherein the insulating body is provided with a base part and a clapper extending forwards from the base part; the conductive terminals are provided with contact parts extending onto the clapper; the shielding shell is provided with a top wall and a bottom wall which are oppositely arranged as well as two side walls connected between the top wall and the bottom wall; the two side walls of the shielding shell have step-like outlines so as to form a first insertion hole corresponding to the outer outline of one plug connector and a second insertion hole corresponding to the outer outline of the other plug connector together with the top wall and the bottom wall; and the first insertion hole and the second insertion hole are partially shared.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

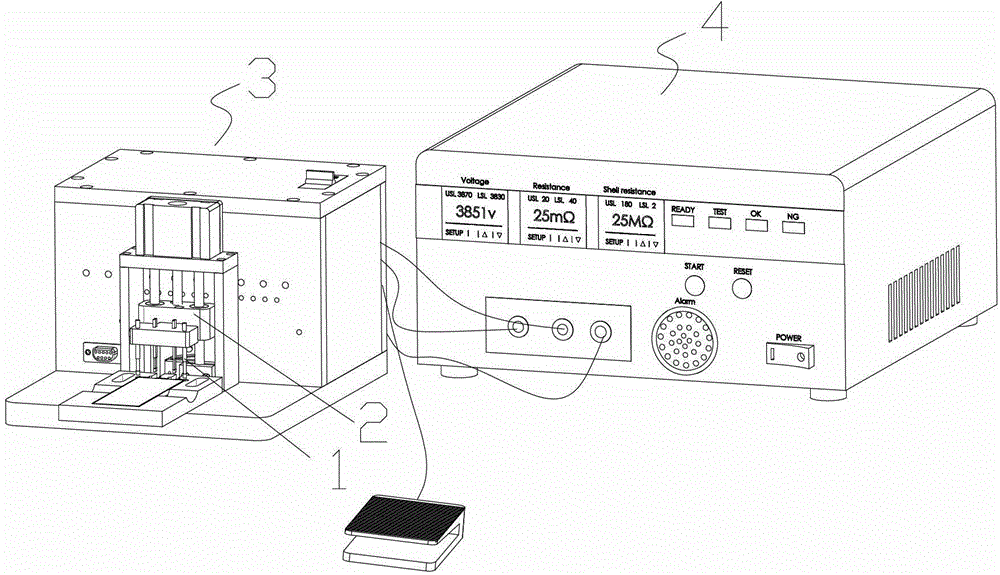

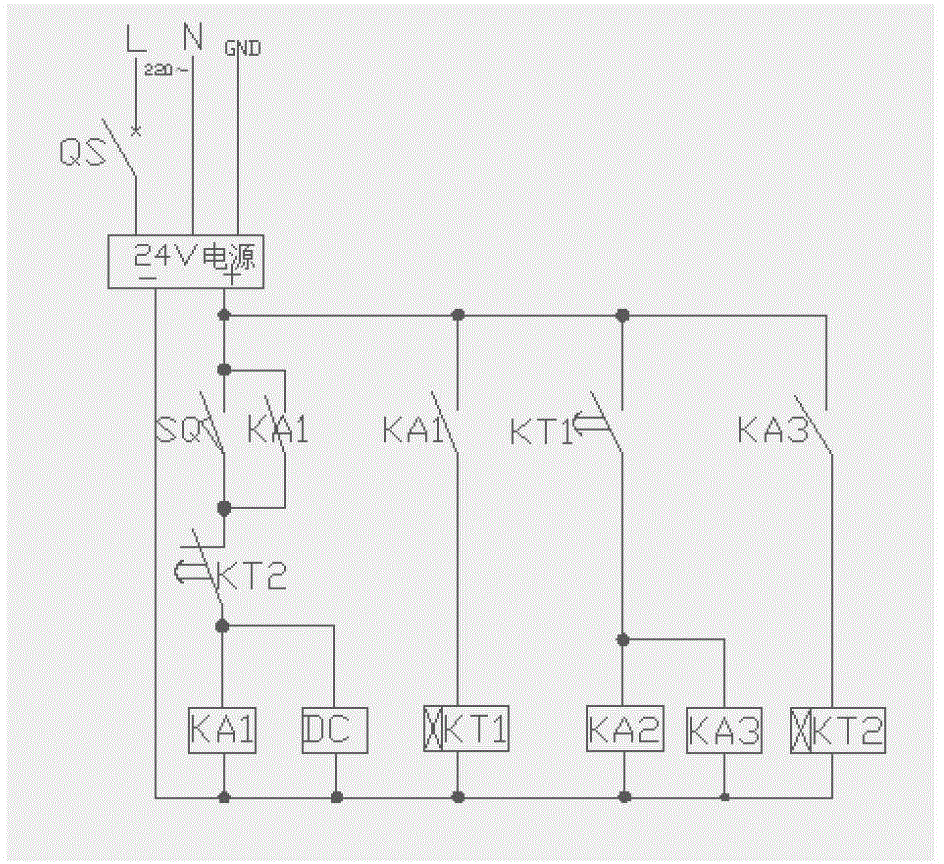

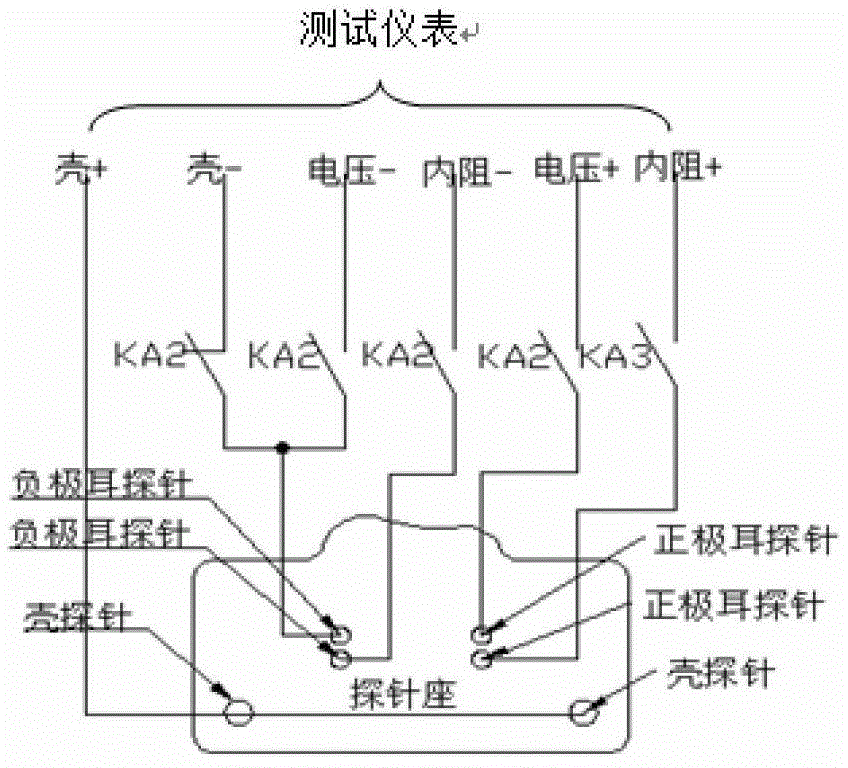

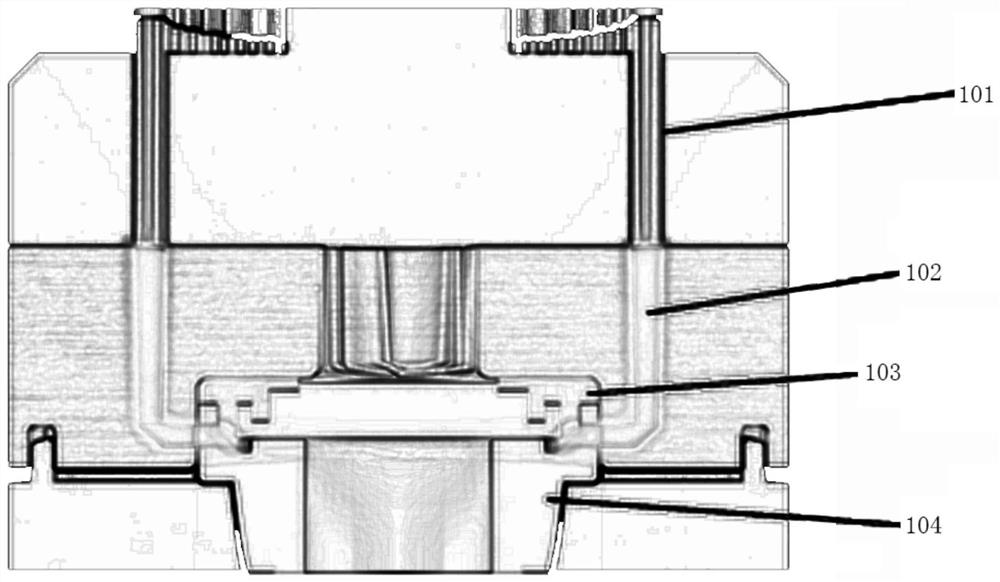

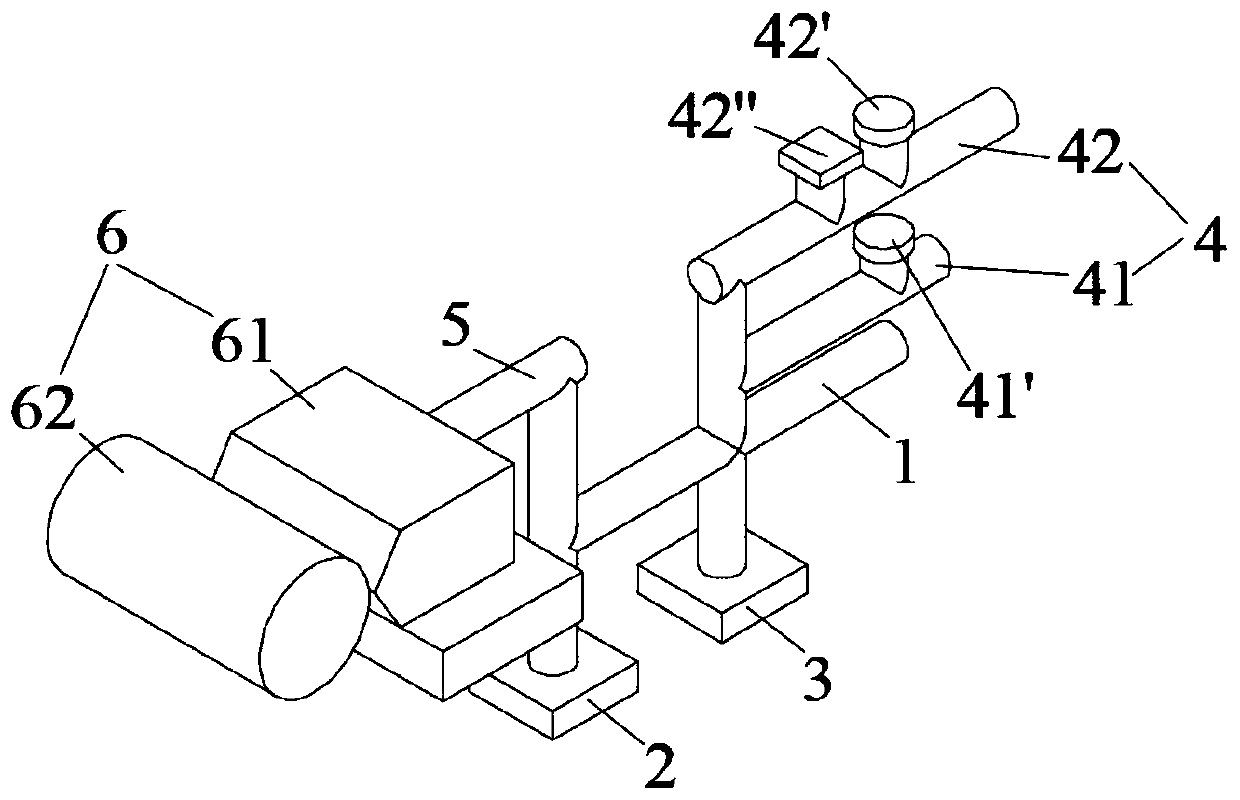

Lithium Ion battery voltage, internal resistance and shell resistance comprehensive test device

InactiveCN103336244APrevent leakageImprove test efficiencyResistance/reactance/impedenceElectrical testingElectrical resistance and conductanceInternal resistance

The invention relates to a lithium Ion battery voltage, internal resistance and shell resistance comprehensive test device which is characterized by comprising a probe testing mechanism and a testing digital display, the probe testing mechanism comprises a testing probe, a cylinder, a switch and a testing control circuit, the testing control circuit is composed of a testing main circuit and a control circuit; the testing main circuit realizes through / break switch through the opening of an intermediate relay normally open normally closed contact, and controls the switching of voltage inner resistance testing and shell resistance testing respectively; the control circuit realizes the switch between the testing main circuit and the control circuit through the self-locking through / break of the intermediate relay and the through / break function of a time relay. The device has the advantages of improving testing efficiency and badness detecting capacity, realizing combining operation of voltage inner resistance testing and shell resistance testing, and increasing unqualified battery alarming, so as to avoid unqualified battery leakage.

Owner:TIANJIN LISHEN BATTERY

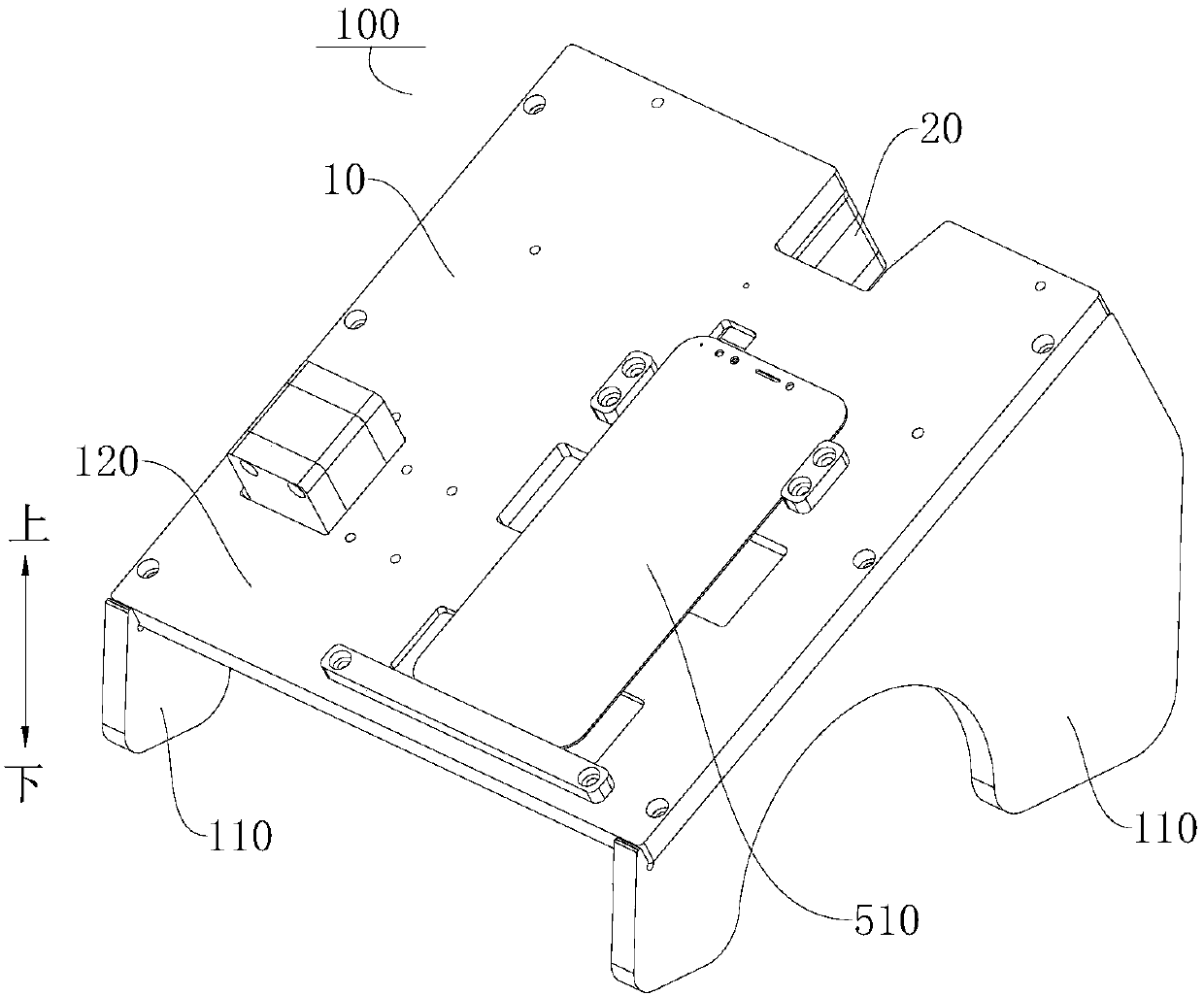

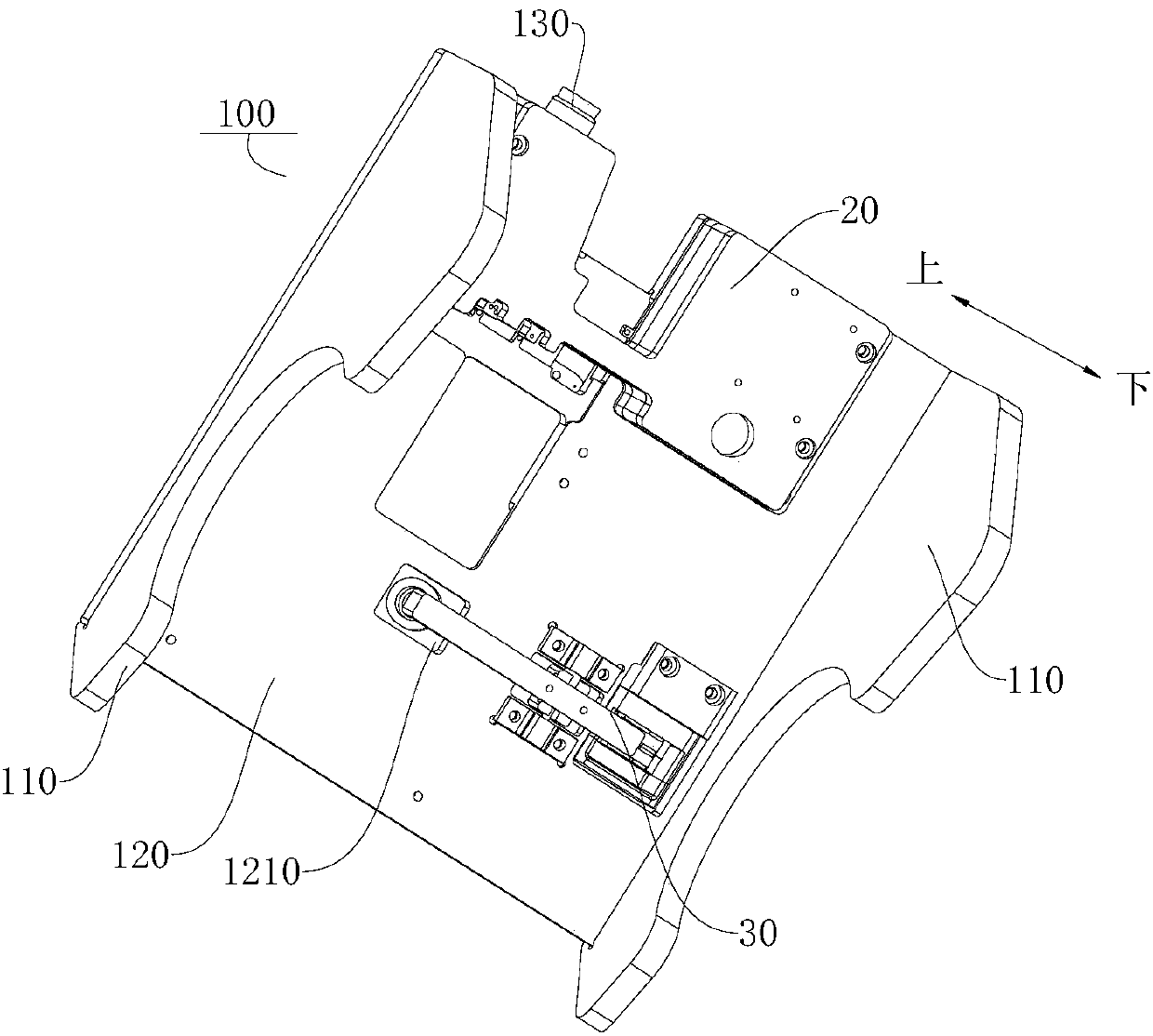

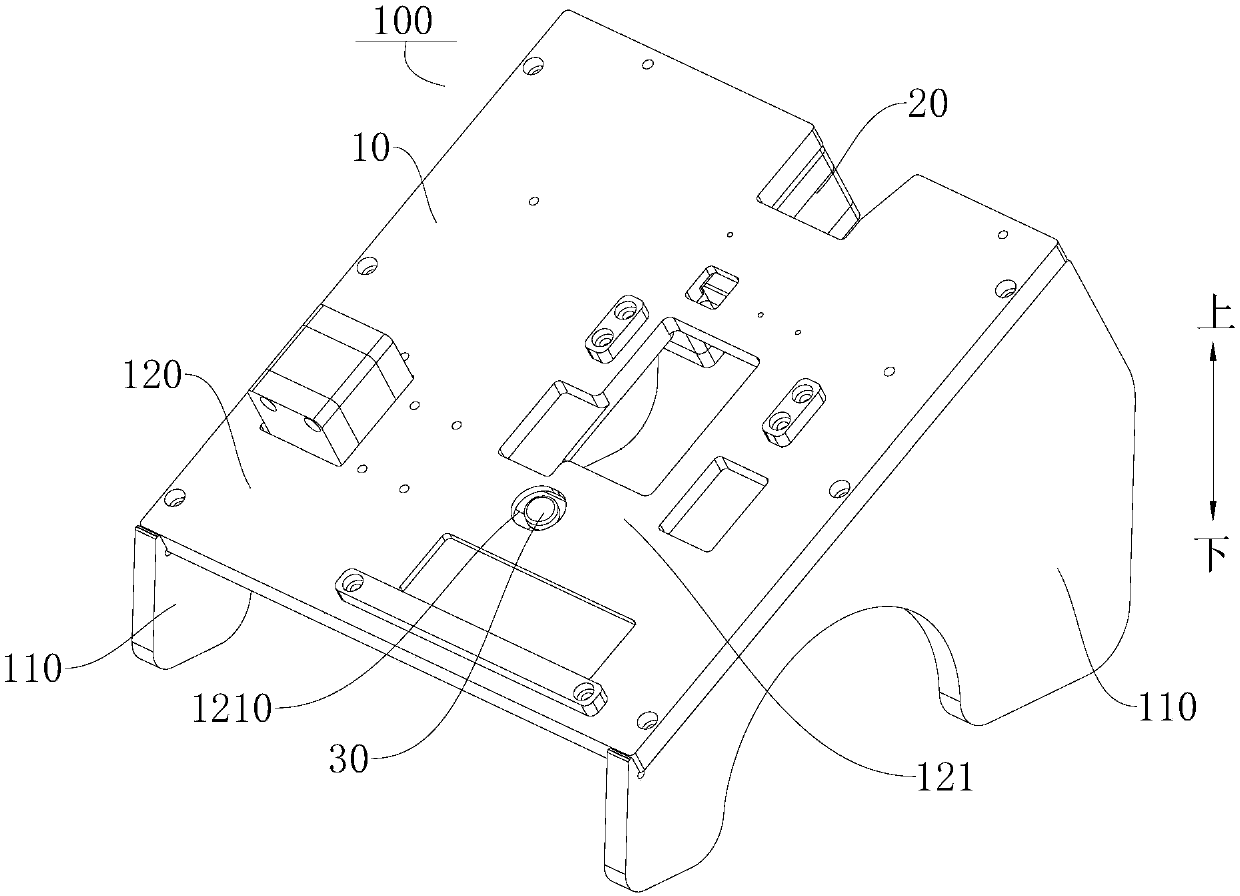

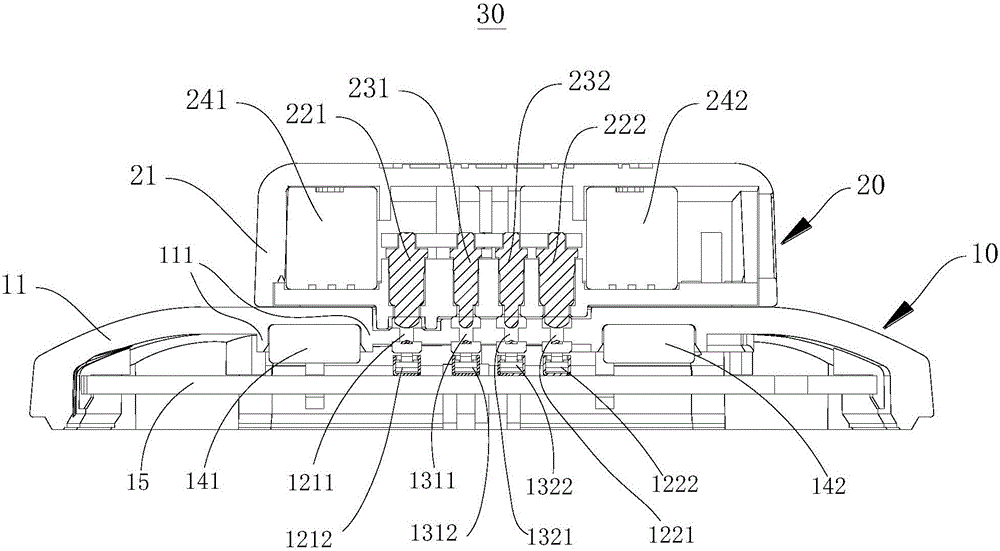

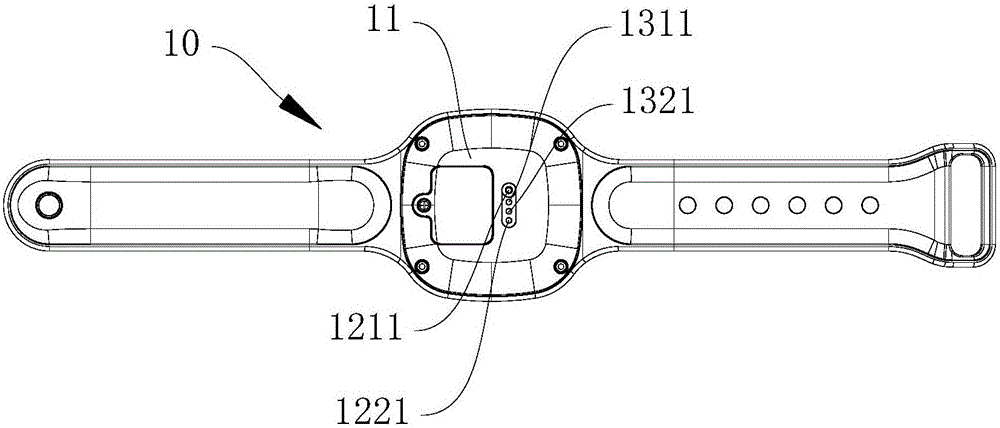

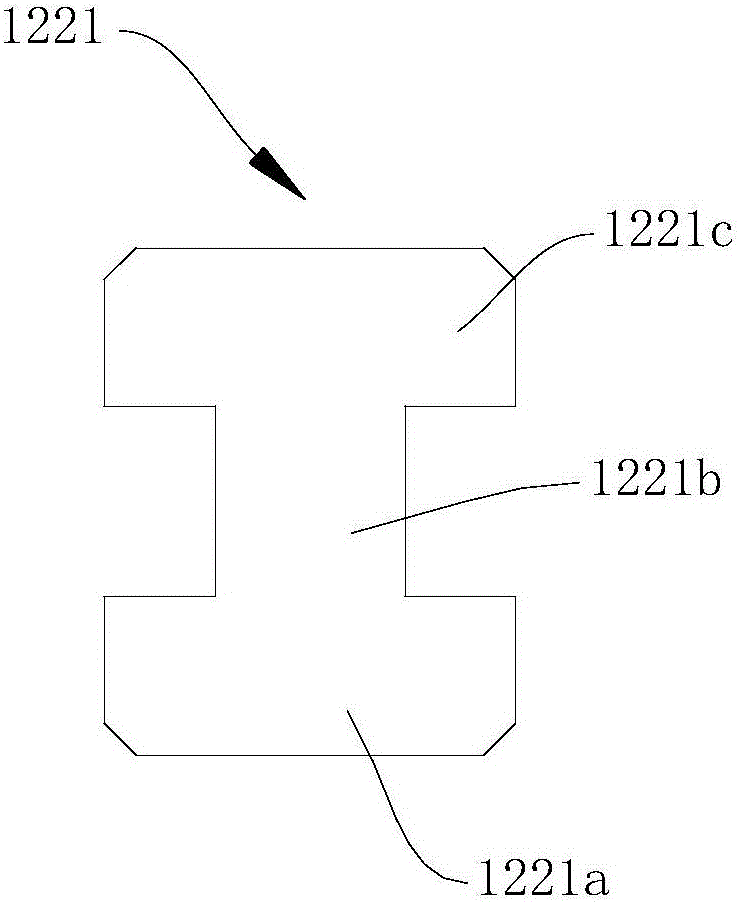

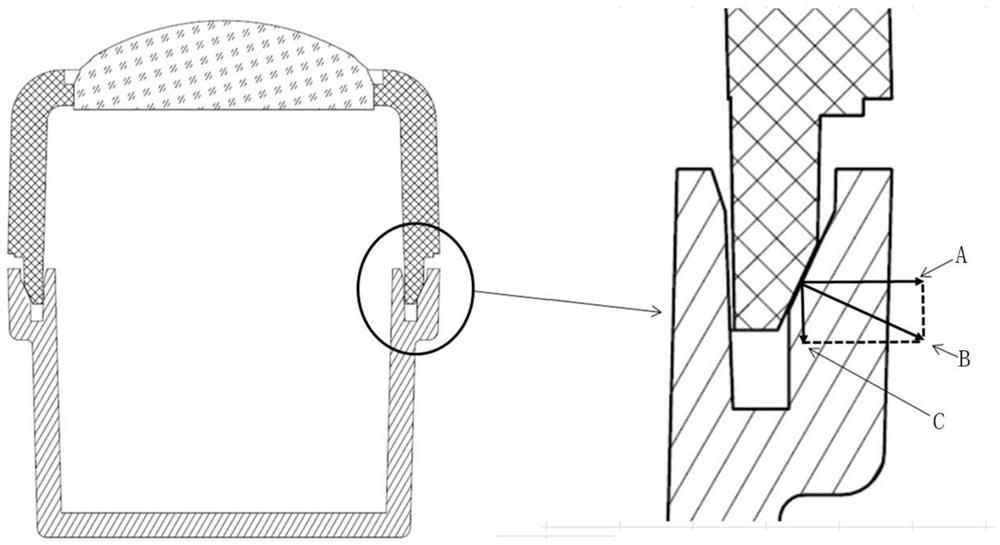

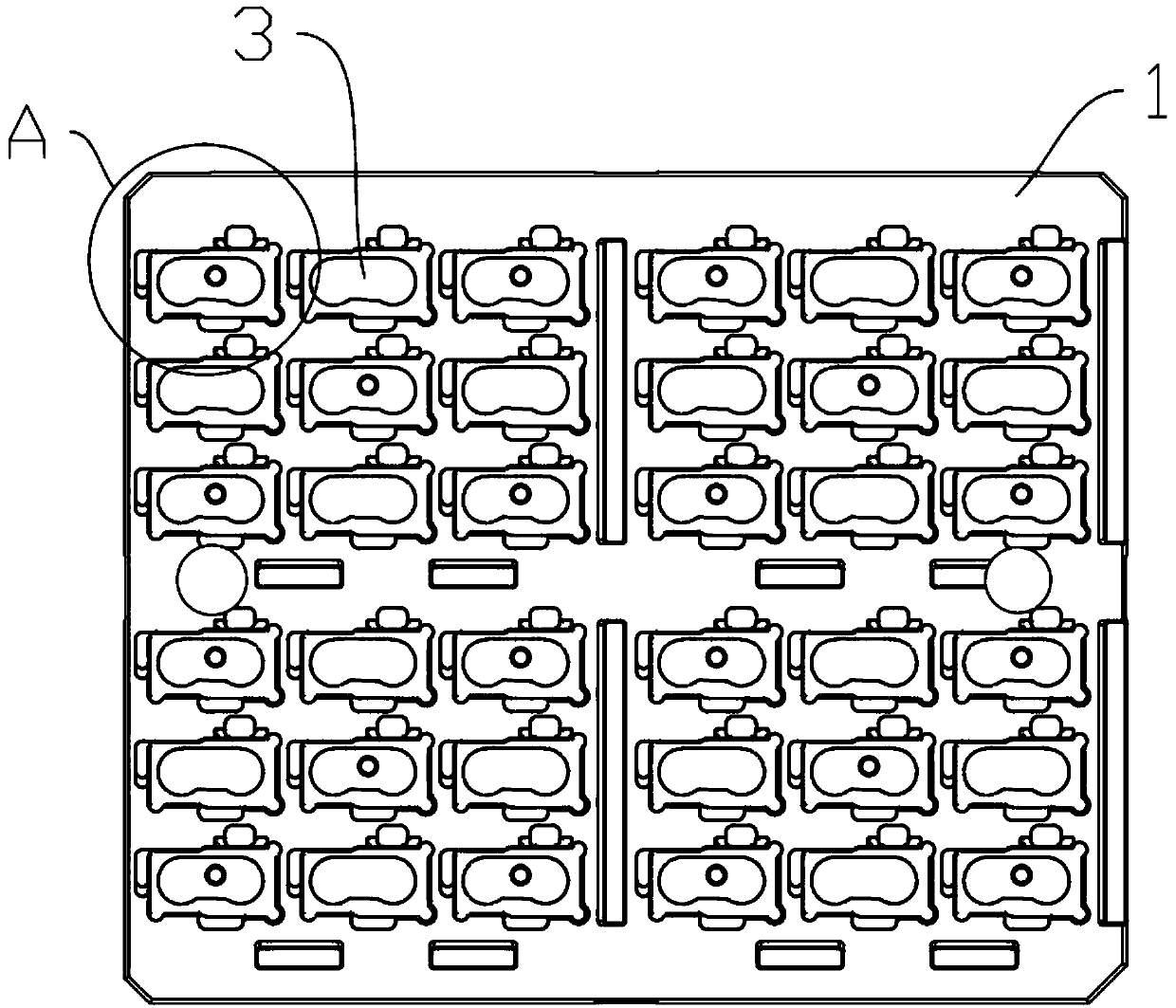

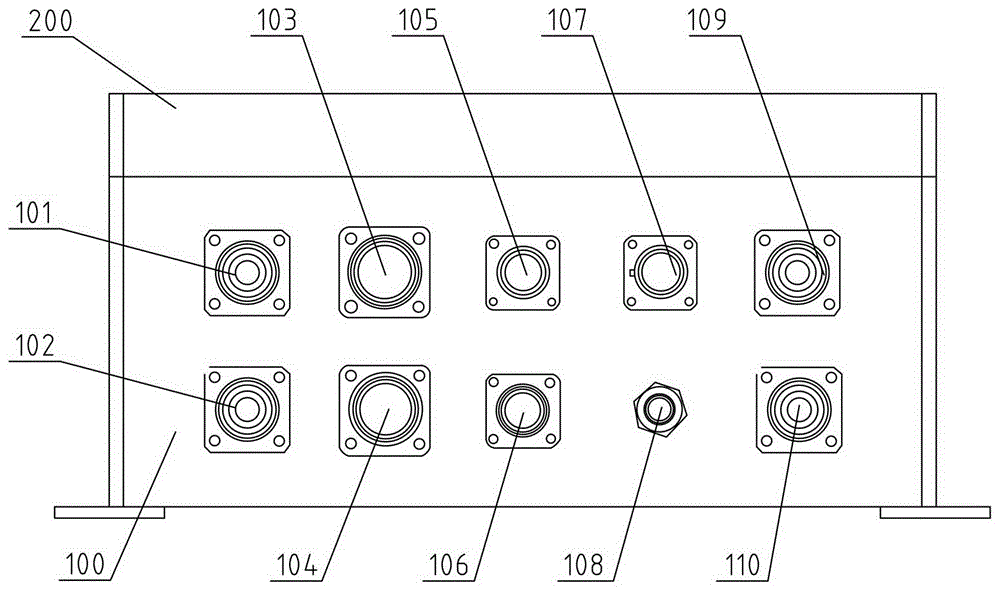

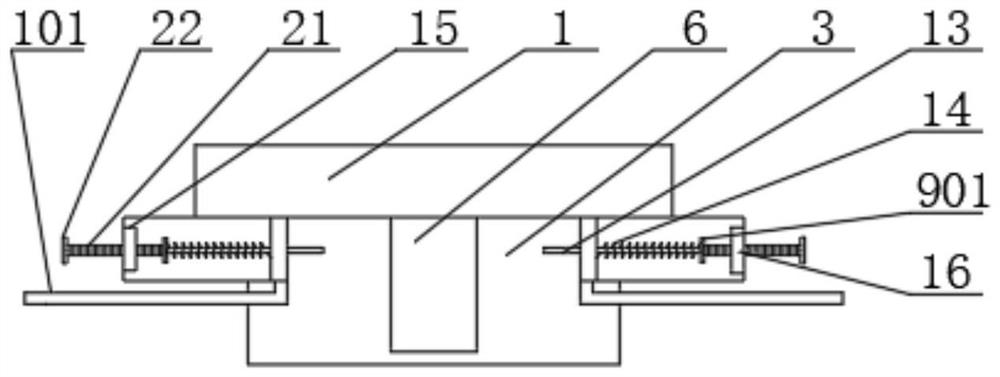

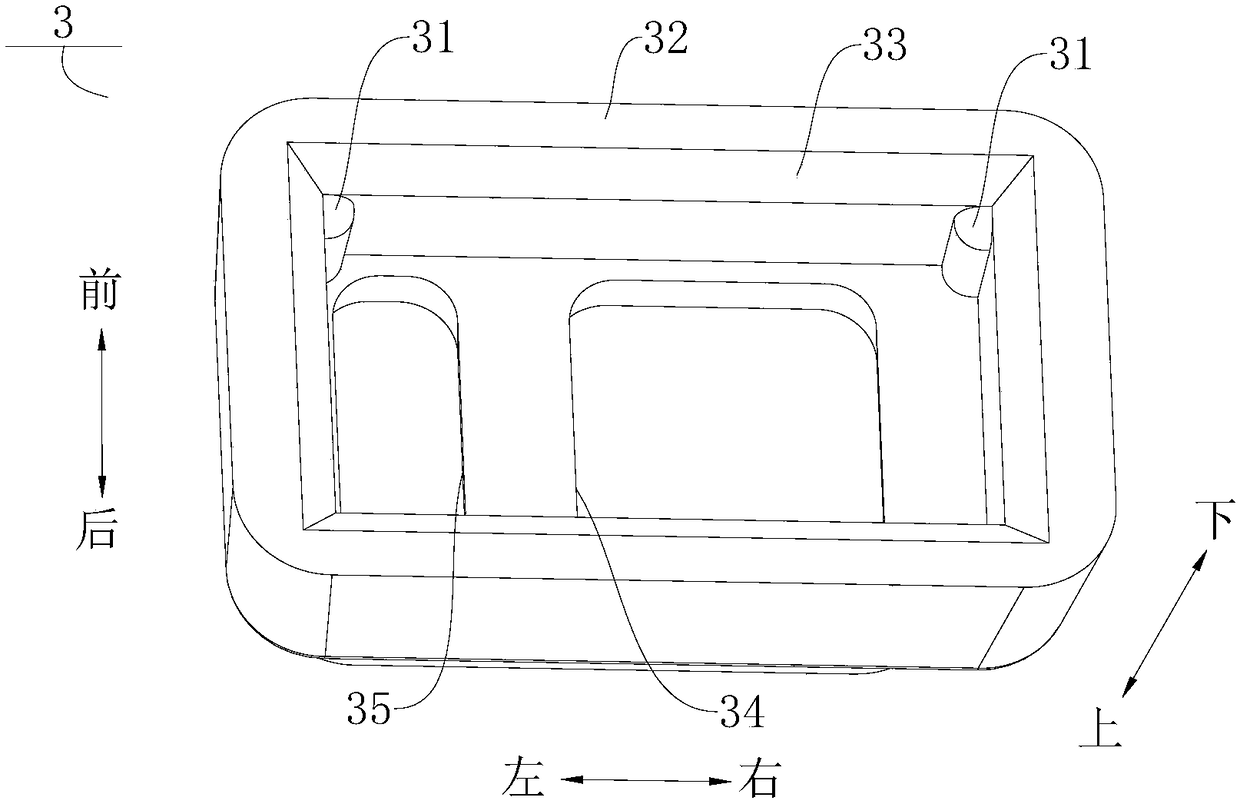

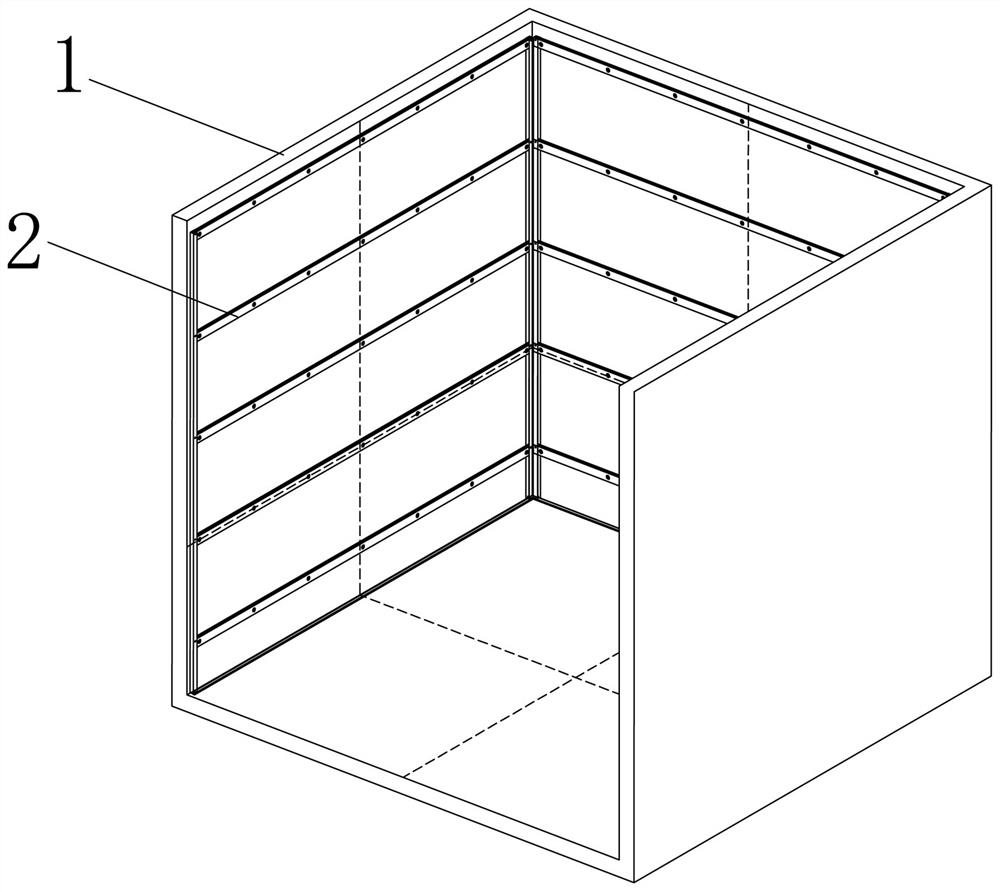

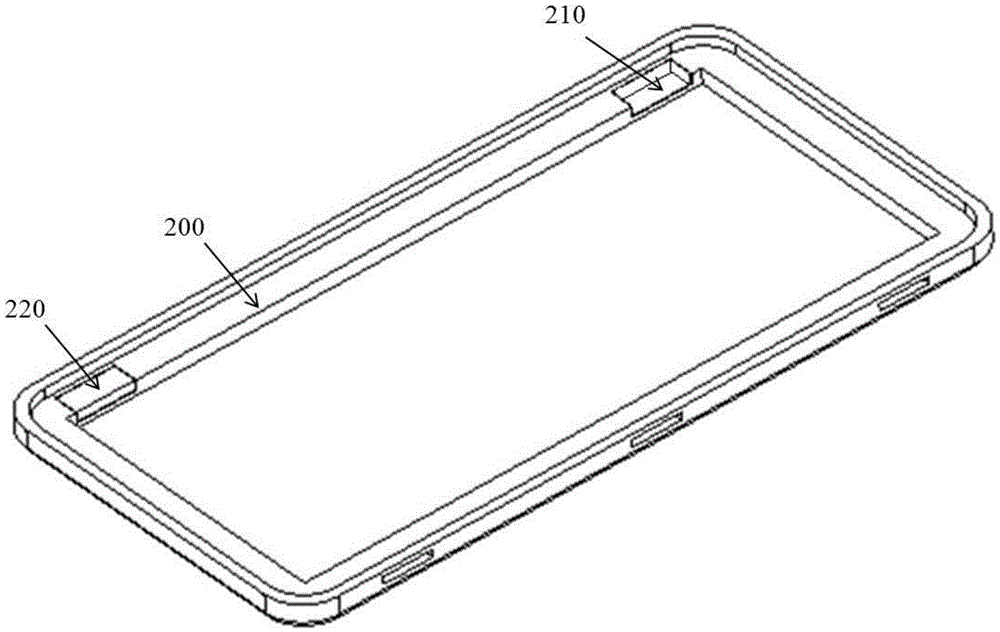

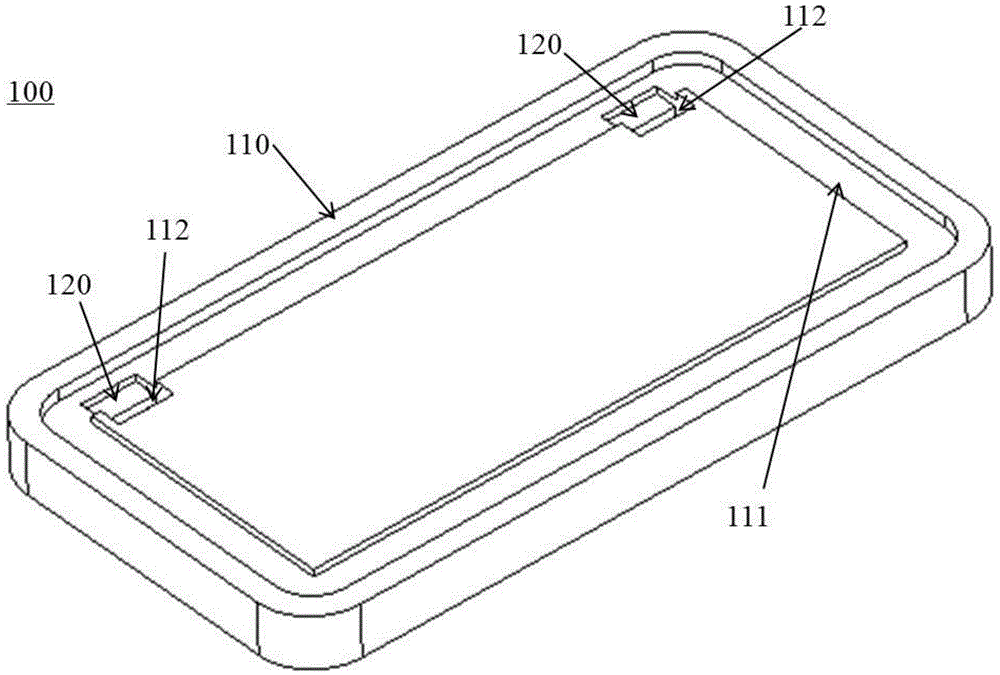

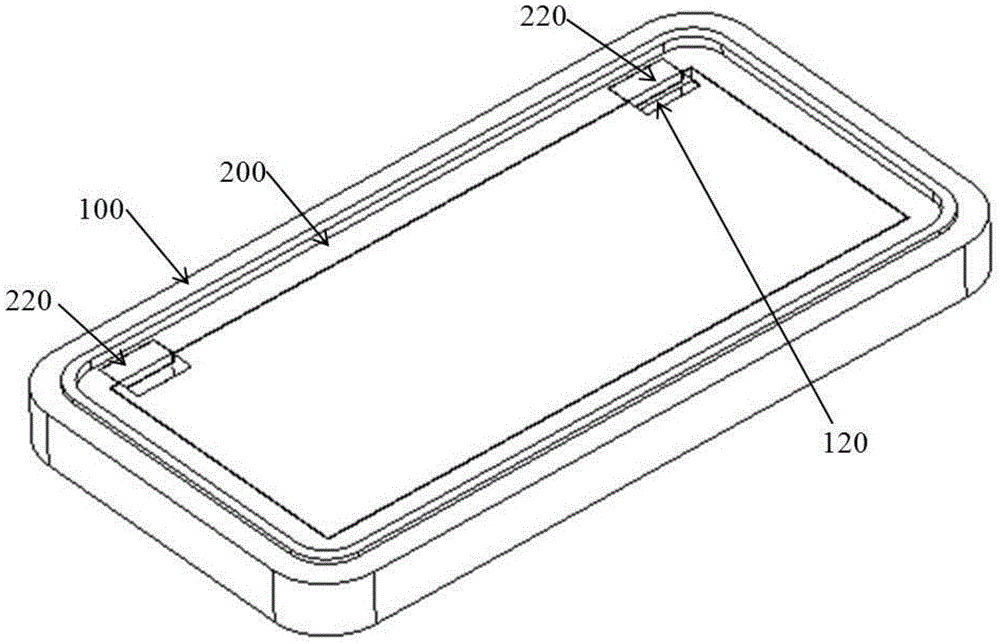

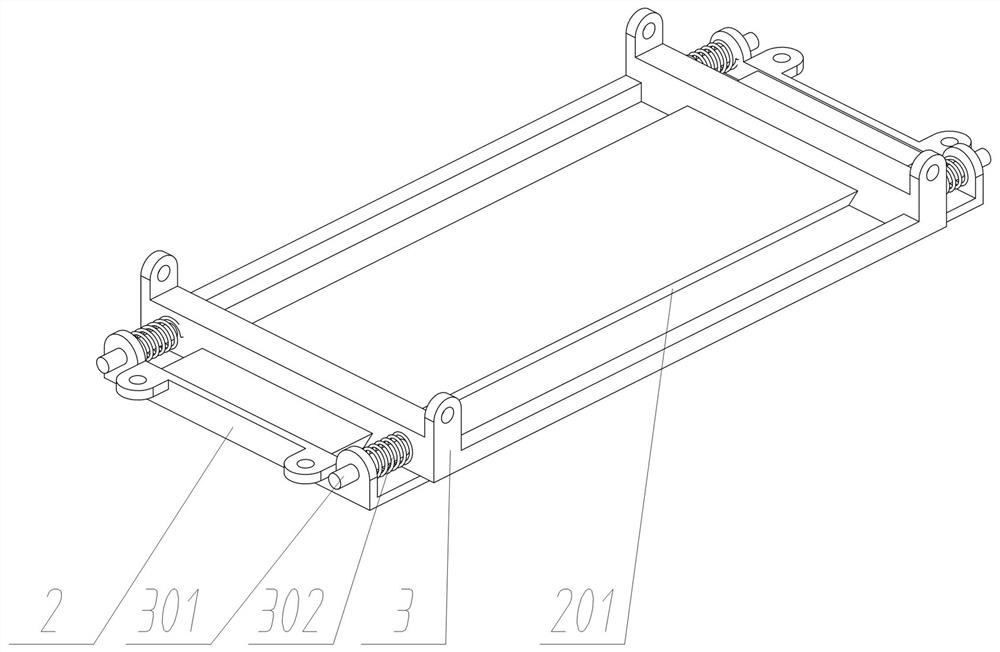

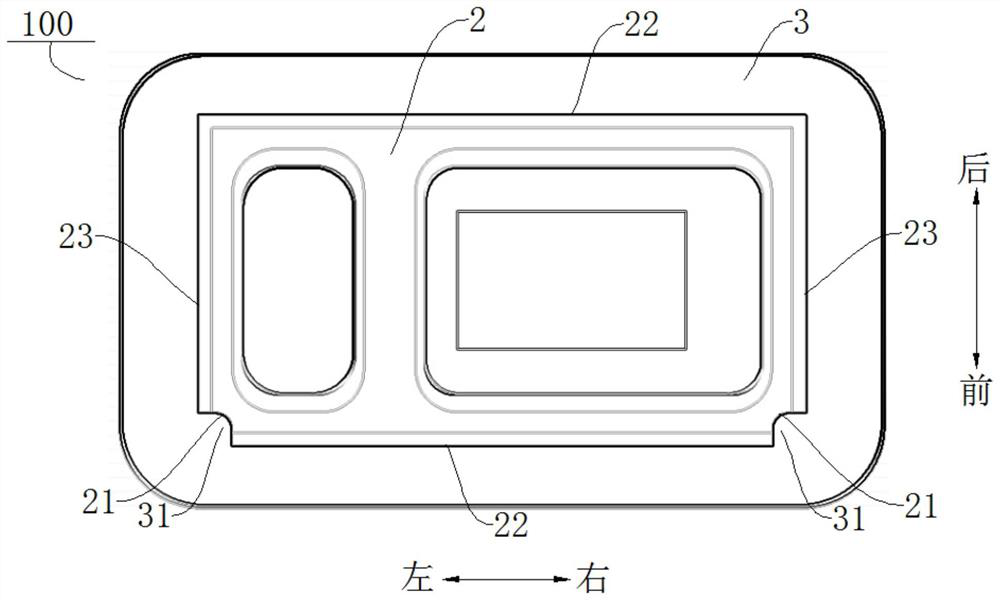

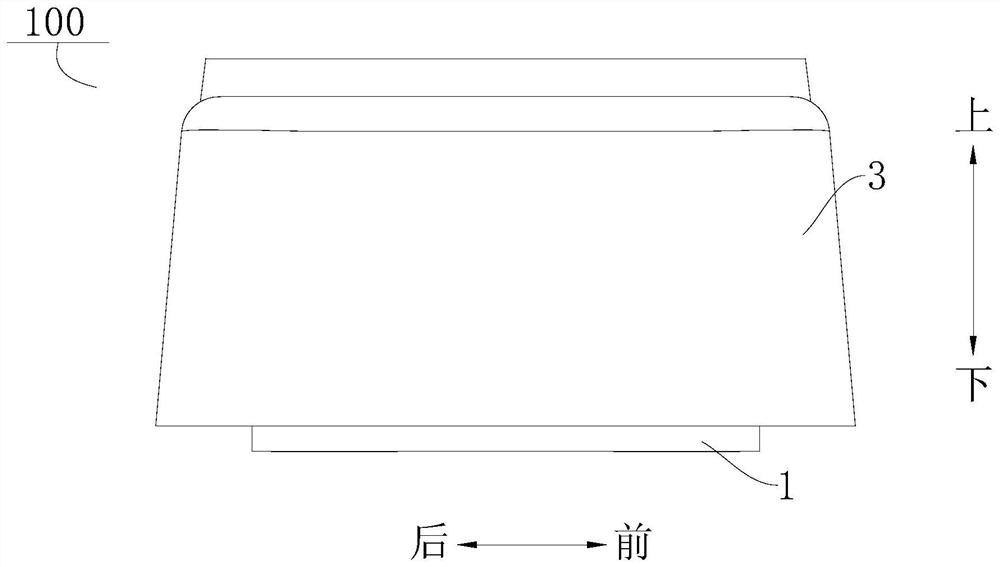

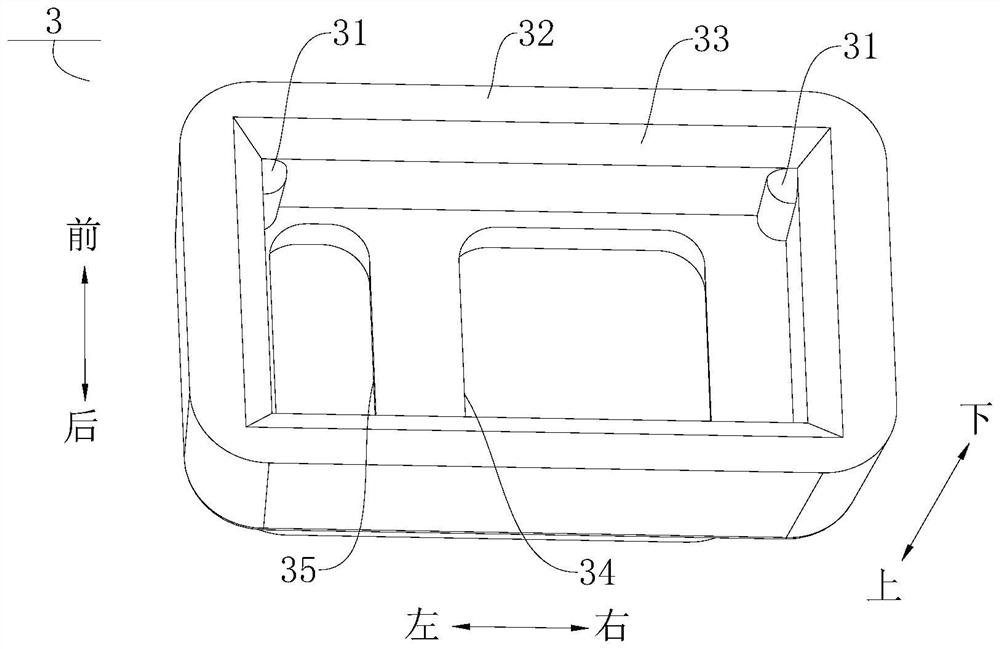

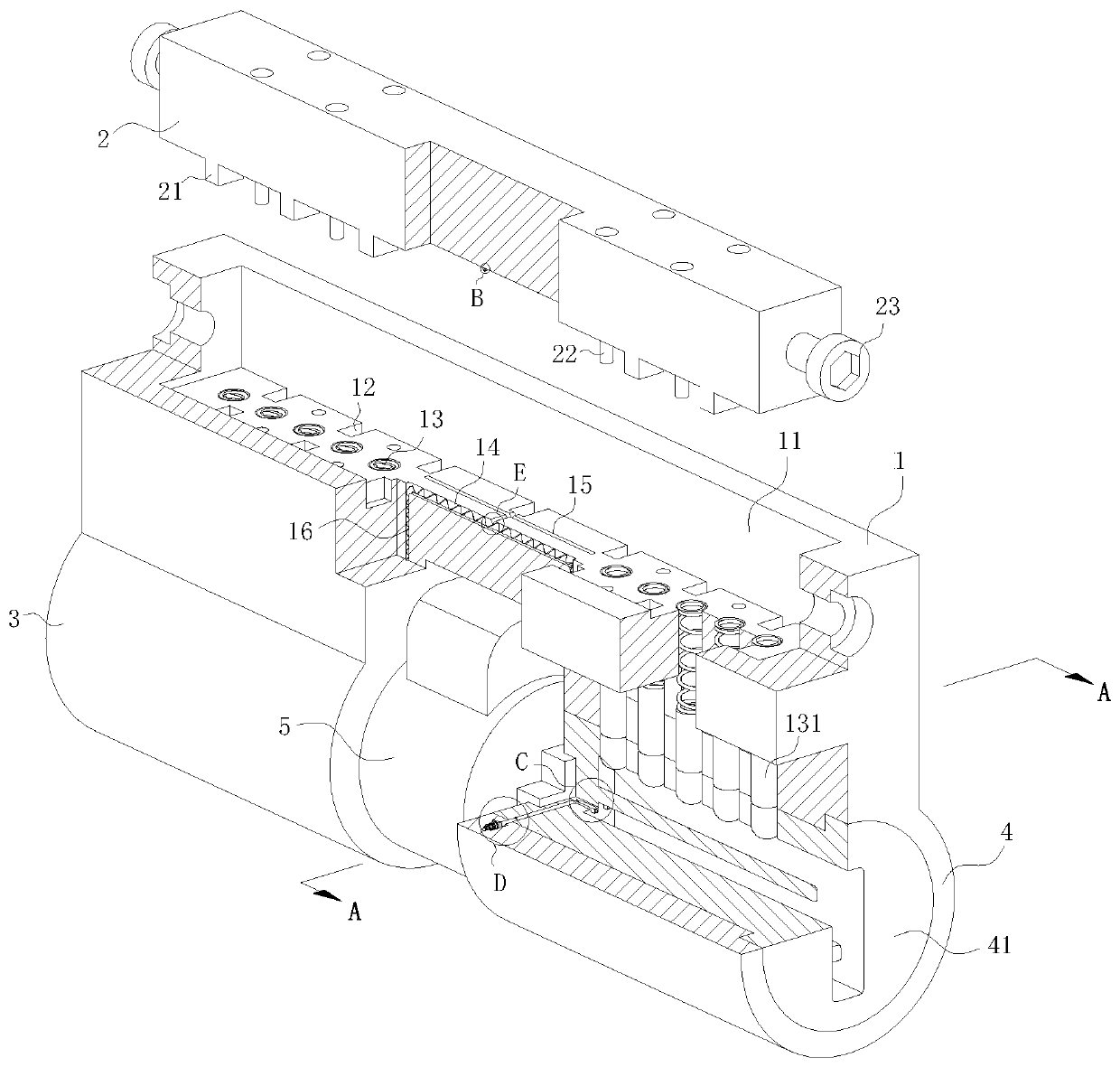

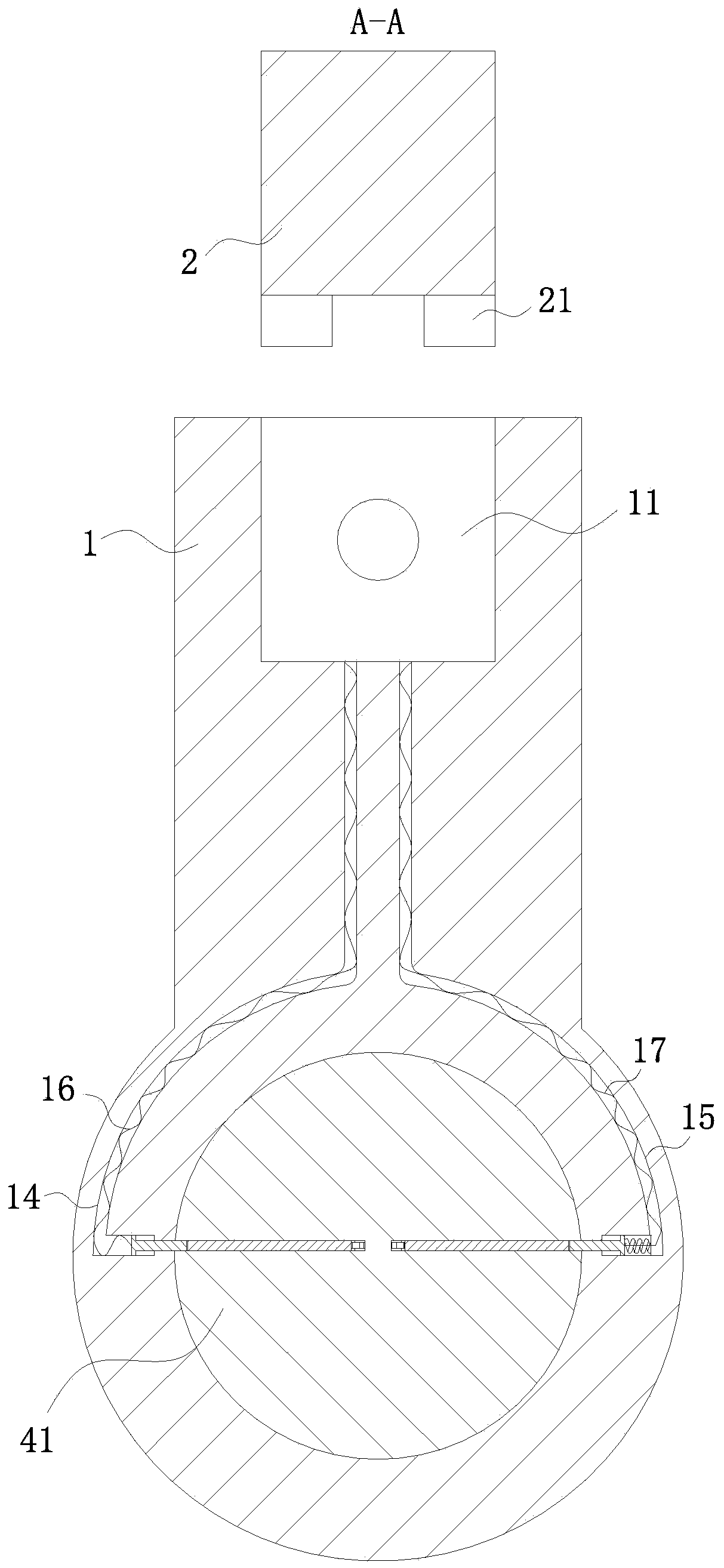

Testing tool for display screen of electronic device

ActiveCN108039141AGood anti-fooling effectStatic indicating devicesEnergy efficient computingElectricityControl switch

The invention discloses a testing tool for a display screen of an electronic device. The testing tool is characterized by comprising a base station, a mainboard, a control circuit and a control switch, wherein a containing part is arranged on the base station; the display screen is applied to being arranged in the containing part; one end of the control circuit is connected with the mainboard; theother end of the control circuit is applied to being connected with the display screen; and the control switch is positioned in the containing part and controls on-off of the control circuit. When the display screen is arranged in the containing part, the display screen triggers the control switch to be turned on, and the control circuit is connected; and when the display screen deviates from thecontaining part, the control switch is turned off, and the control circuit is disconnected. According to the testing tool for the display screen of the electronic device disclosed by the invention, the control switch is arranged in the containing part, so that the display screen can be located in a power-off state in the plugging / unplugging process, and the defect that the display screen is damaged due to generated electrical surge is avoided. Moreover, connection and disconnection of the control circuit can be controlled by placing the display screen in the containing part or not, so that the testing tool can achieve an excellent fool-proofing effect.

Owner:SHENZHEN HEYTAP TECHNOLOGY CO LTD

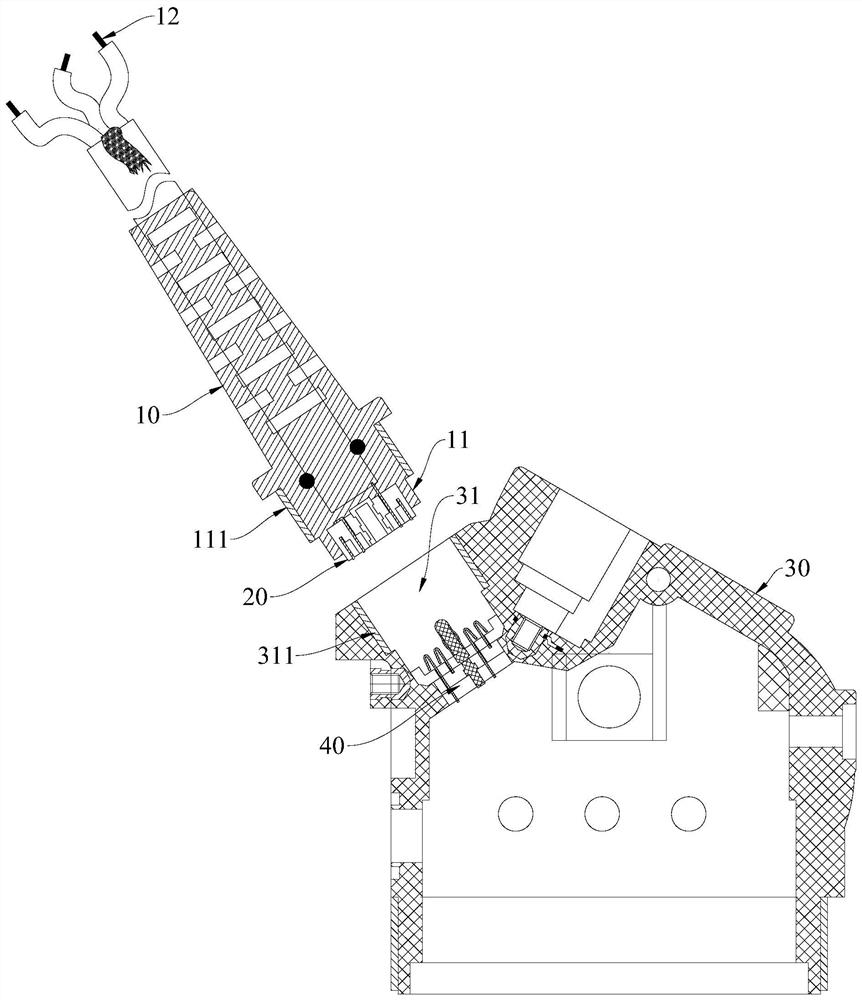

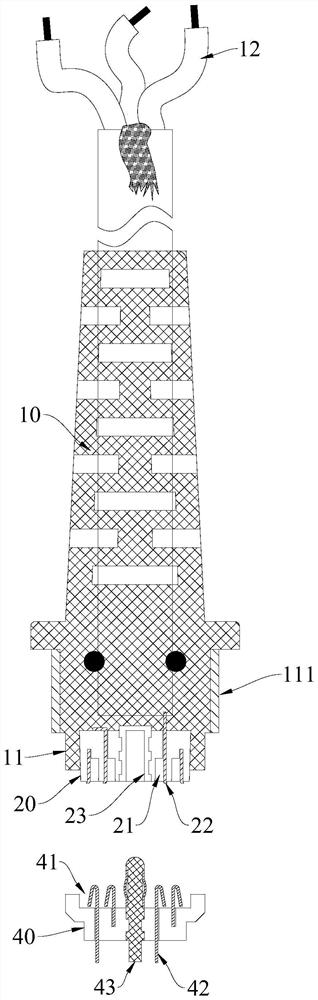

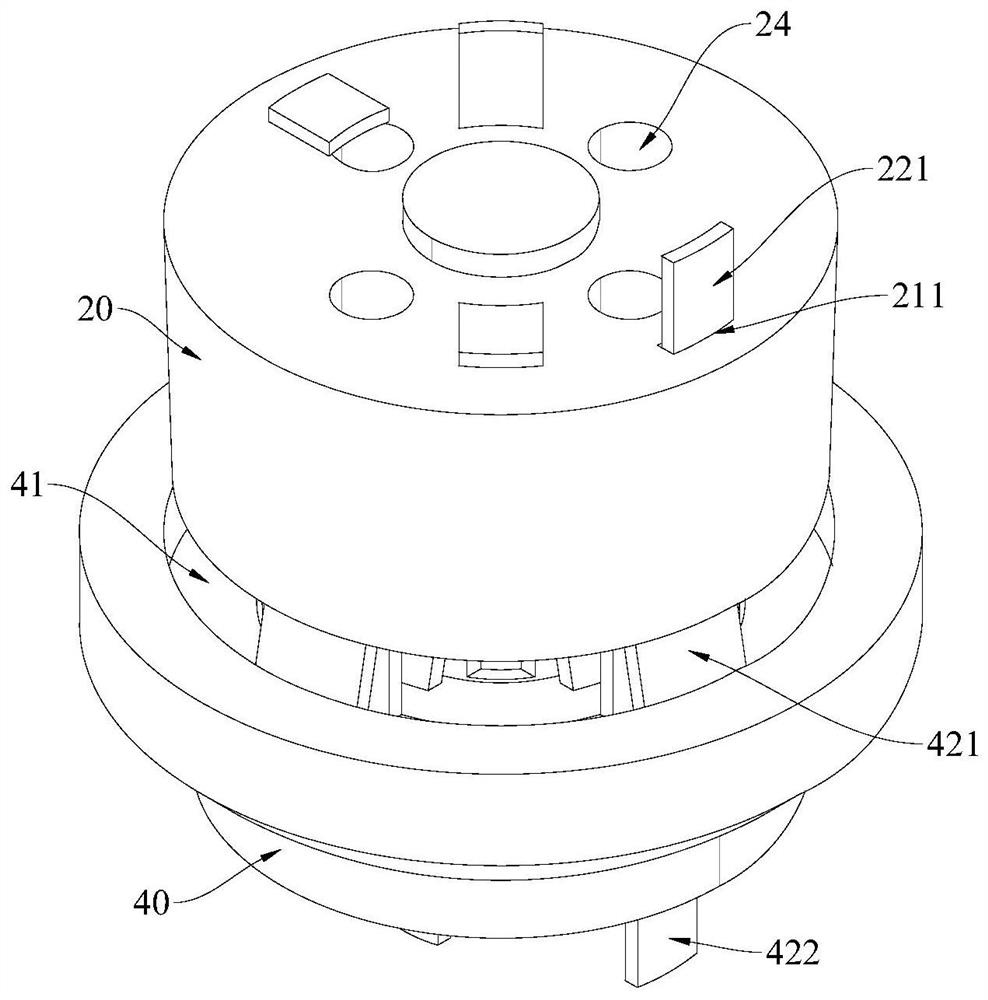

Electronic equipment, charger and charging combination device

InactiveCN105896184AImprove securityPrevent short circuitEngagement/disengagement of coupling partsBatteries circuit arrangementsElectricityMagnetic poles

The invention provides electronic equipment, a charger and a charging combination device. The electronic equipment comprises a shell, a circuit board arranged in the shell, a plurality of electrical contact components arranged on the shell and electrically connected to the circuit board, and magnetic components arranged on the inner side of the shell, wherein the magnetic components comprise a first magnetic piece and a second magnetic piece; and the magnetic pole, facing the shell, of the first magnetic piece is opposite to that, facing the shell, of the second magnetic piece. The charging combination device comprises the electronic equipment and a charger. According to the charging combination device provided by the invention, a pair of magnetic pieces are arranged on the electronic equipment and the charger respectively, so that the positions of charged positive pole and negative pole can be automatically corrected by the electronic equipment and the charger, the charging combination device has a good foolproof effect, and then the safety for equipment charging is improved.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

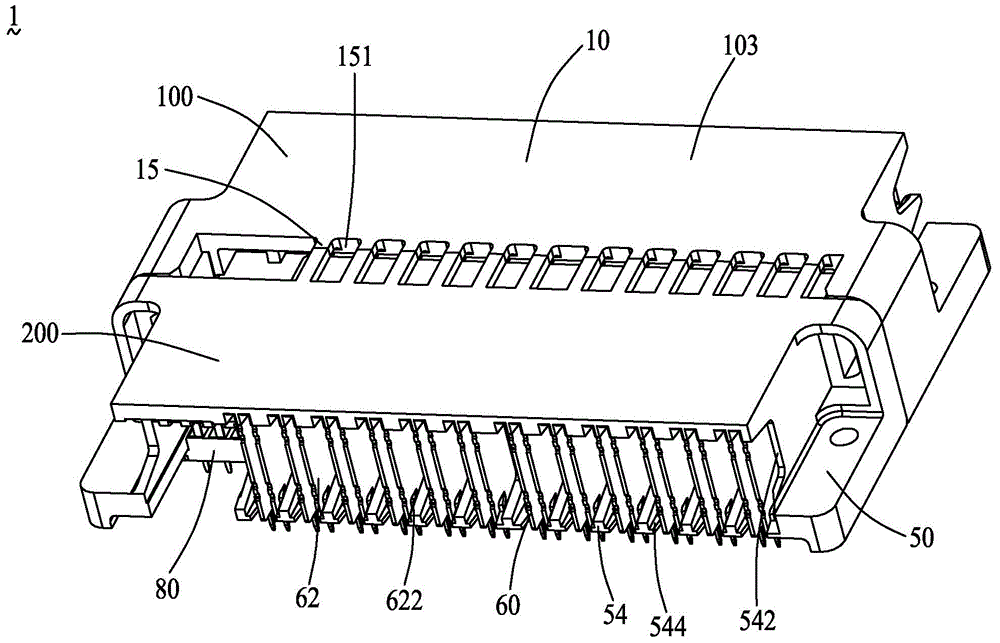

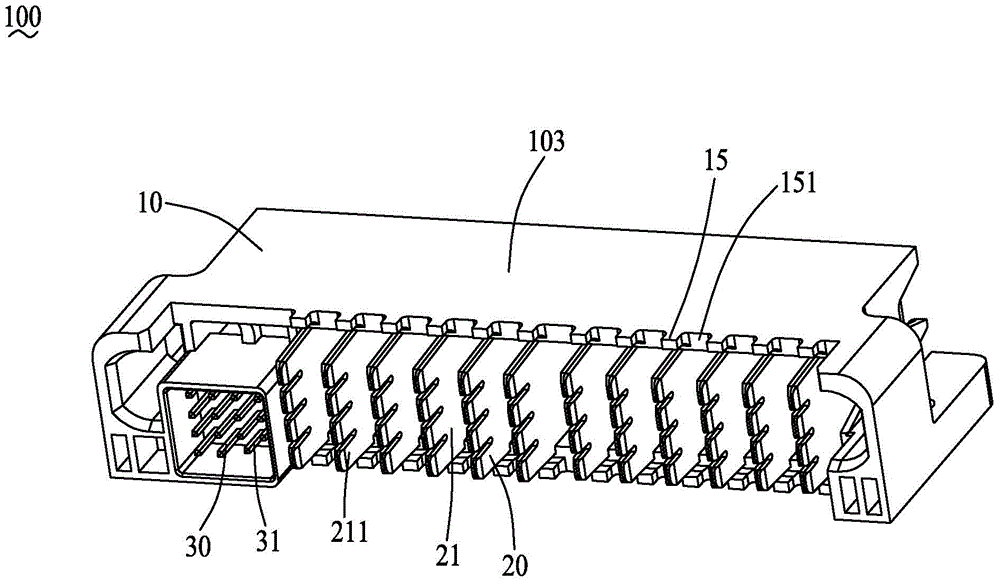

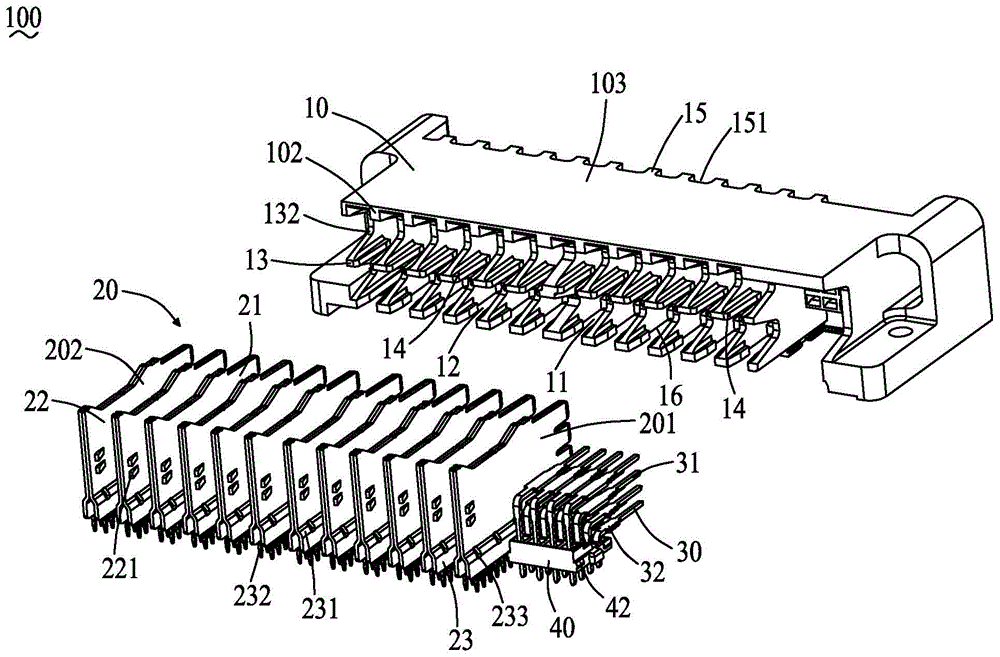

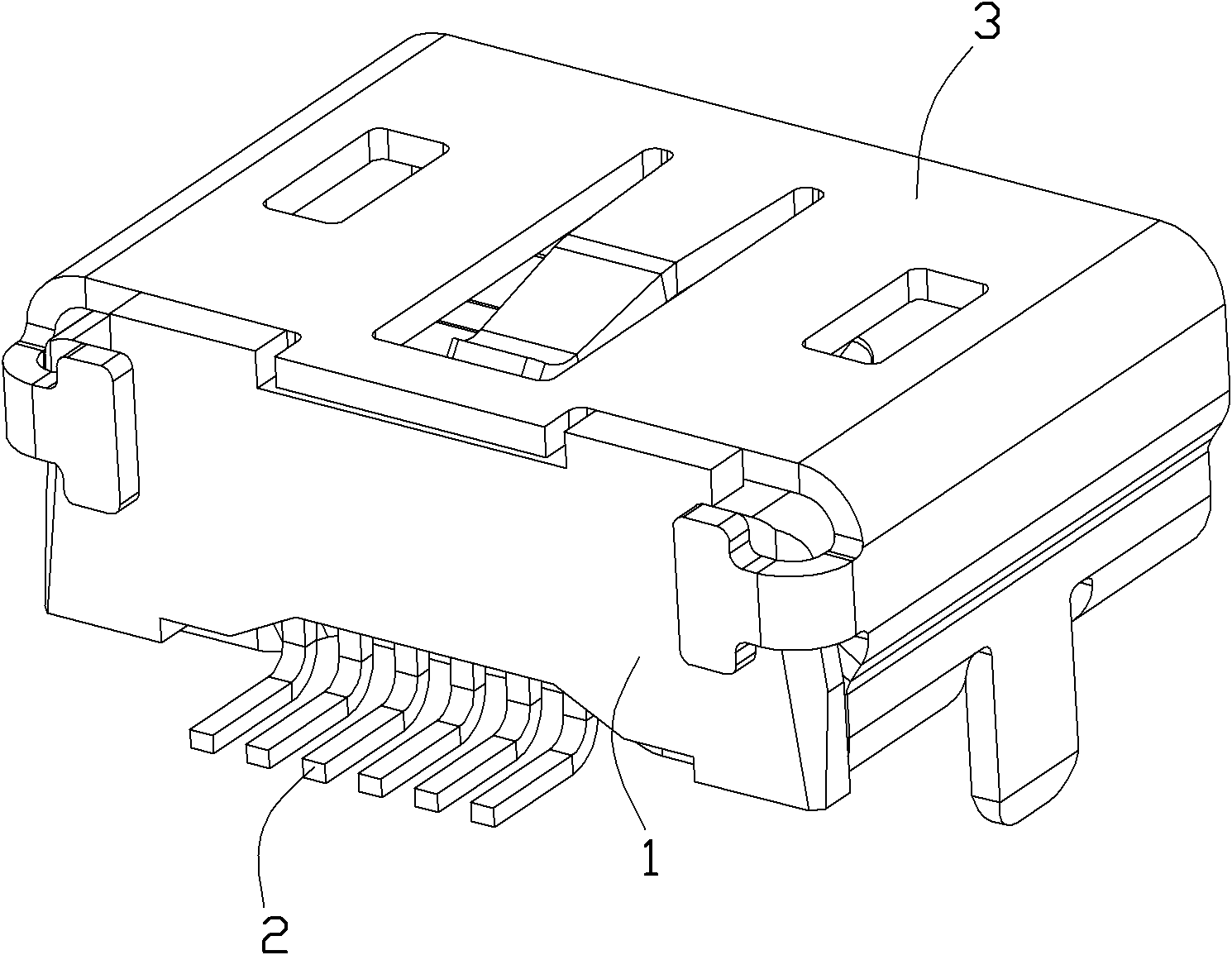

Plug connector and electric connector combination

ActiveCN104810646APrevent mis-insertionGood anti-fooling effectSecuring/insulating coupling contact membersCouplings bases/casesElectrical and Electronics engineering

The invention provides a plug connector and an electric connector combination. The plug connector comprises an insulating body and a plurality of male power terminals; a plurality of first terminal accommodating channels and a plurality of second terminal accommodating channels for accommodating the plurality of male power terminals are formed in the insulating body; every male power terminal is composed of a contact unit, a terminal tail unit and a fixing unit connecting the contact unit and the terminal tail unit; the insides of both the first terminal accommodating channels and the second terminal accommodating channels are provided with terminal clamping units; the fixing unit of every male power terminal is matched with the corresponding terminal clamping unit to fix the male power terminal into the corresponding terminal accommodating channel; the terminal clamping units of the first terminal accommodating channels and the terminal clamping units of the second terminal accommodating channels are arranged in a vertically staggered mode in the height direction of the plug connector.

Owner:立全科技(太仓)有限公司

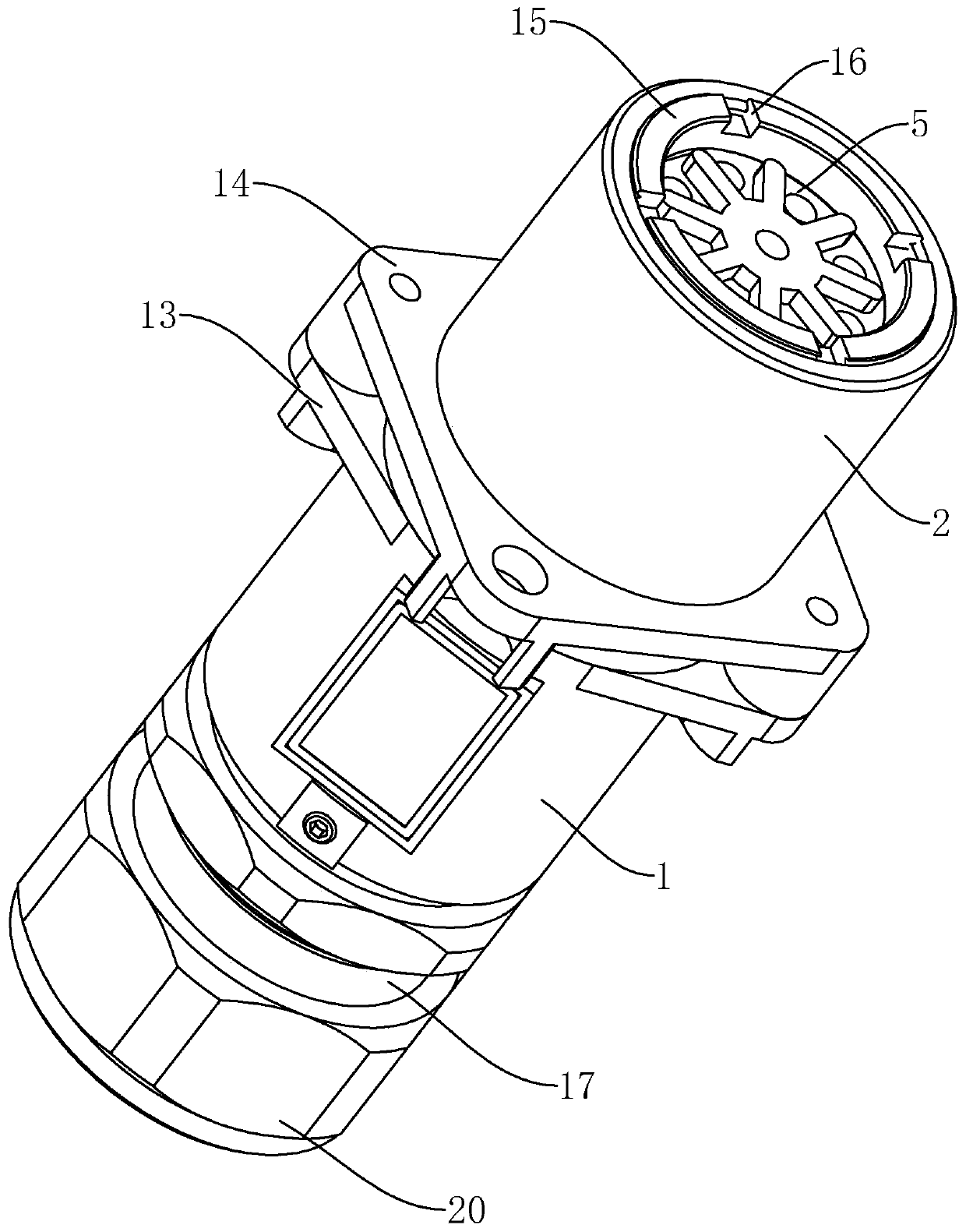

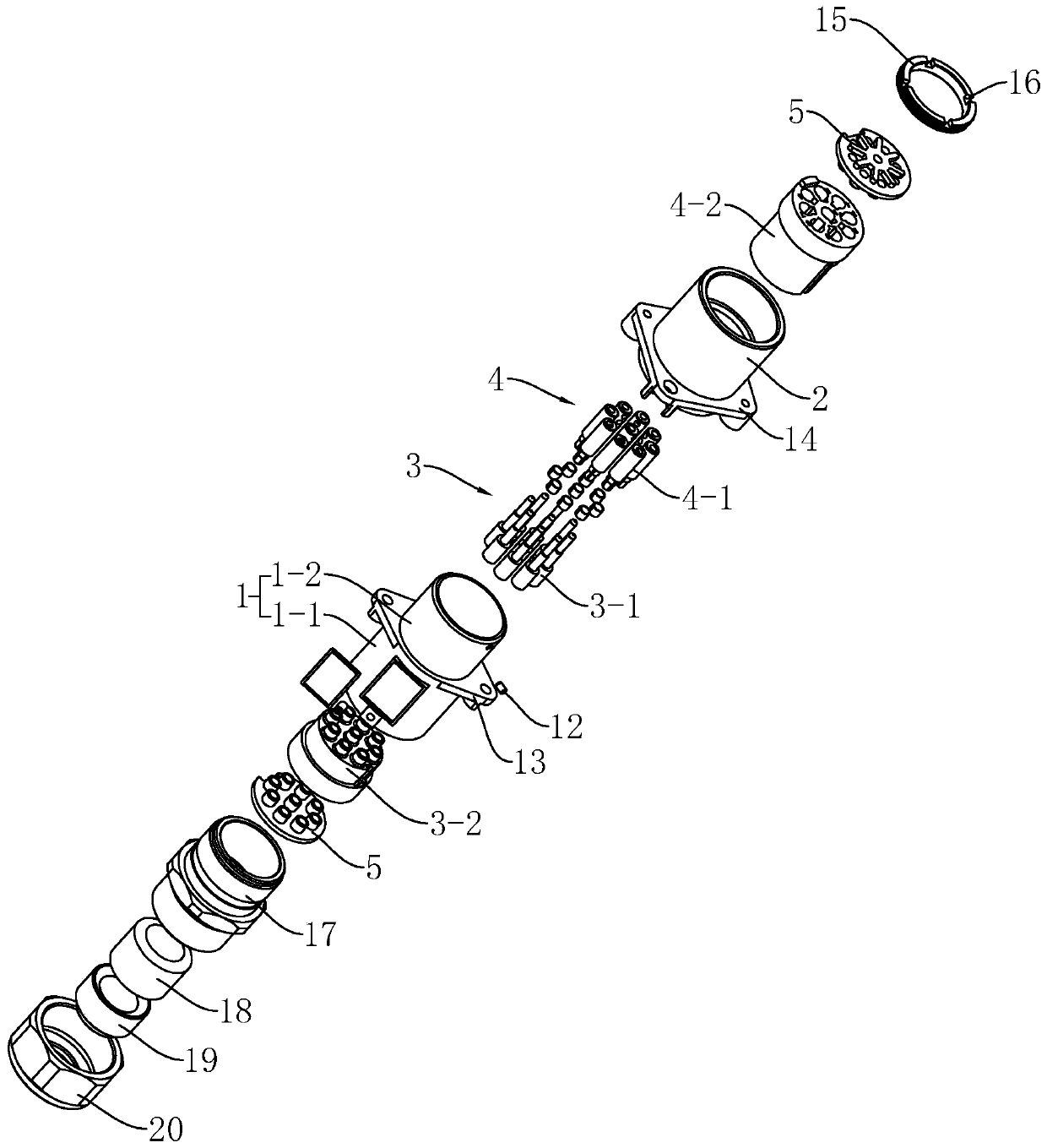

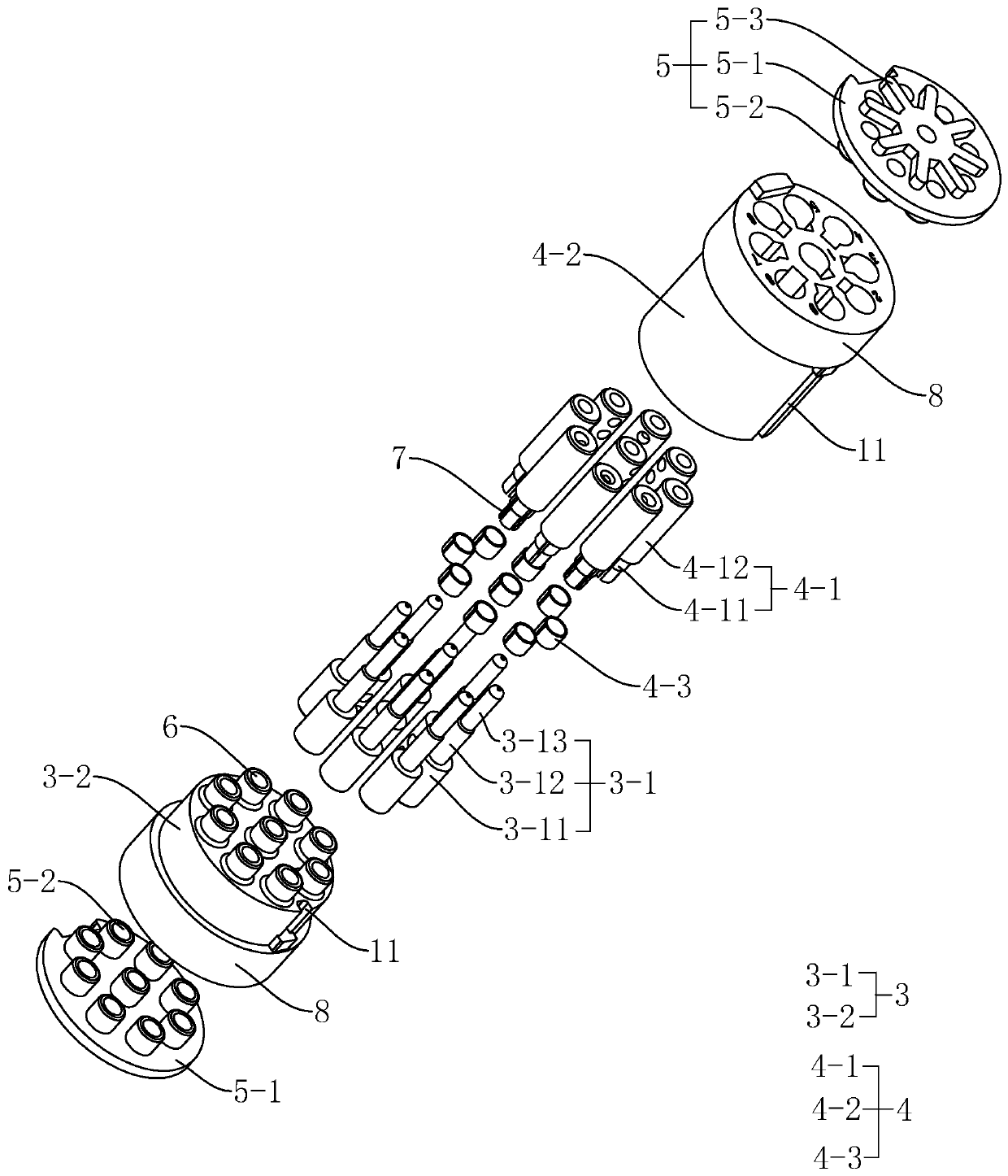

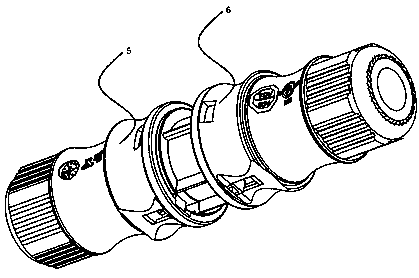

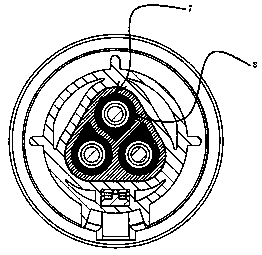

Explosion-proof cable connector

PendingCN110165487AEasy to assembleNot easy to mistakeIncorrect coupling preventionCoupling parts mountingBiomedical engineering

The invention discloses an explosion-proof cable connector, which comprises a first shell, a second shell, a socket assembly and a plug assembly, wherein the first shell and the second shell can be mutually inserted, the socket assembly and the plug assembly can be mutually inserted, and the plug assembly and the socket assembly can be adapted to the first shell or the second shell; the plug assembly includes a plurality of convex pin bodies, a convex pin seat for insertion of the plurality of convex pin bodies and a pin cover capable of abutting the convex pin bodies against the internal partof the convex pin seat; the socket assembly includes a plurality of concave pin bodies capable of forming insertion with the corresponding convex pin bodies, a concave pin seat for insertion of the plurality of concave pin bodies and a pin cover capable of abutting the concave pin bodies against the internal part of the concave pin seat; and the ends for installation of the first shell and the second shell are respectively provided with a first installation groove and a second installation groove, and both the first installation groove and the second installation groove can be used for installing and positioning the plug assembly and the socket assembly. The advantages of the invention lie in that it is more convenient for workers to assembly the connector, mistaken assembly is not easy to occur, and the assembly efficiency is facilitated to be improved.

Owner:浙江旭通智能科技有限公司 +1

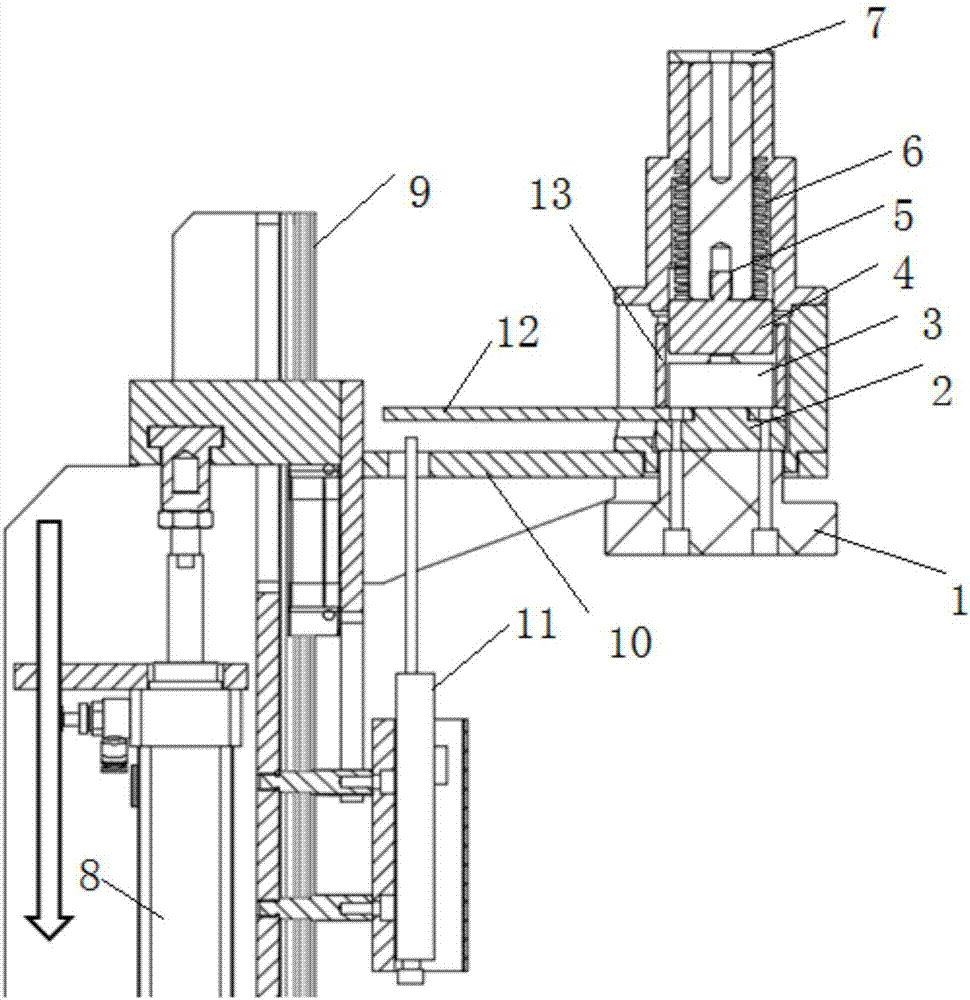

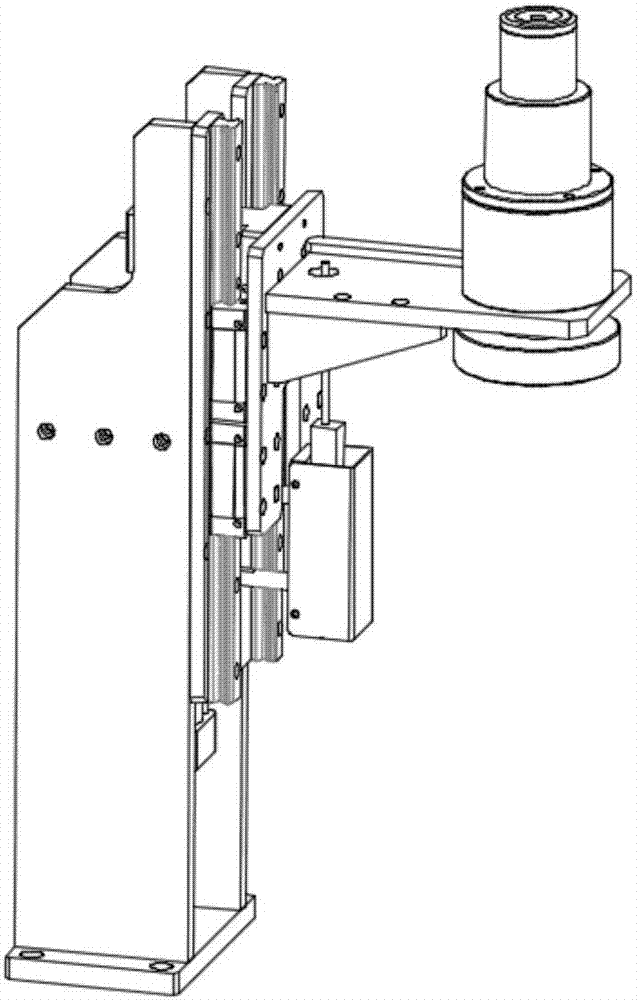

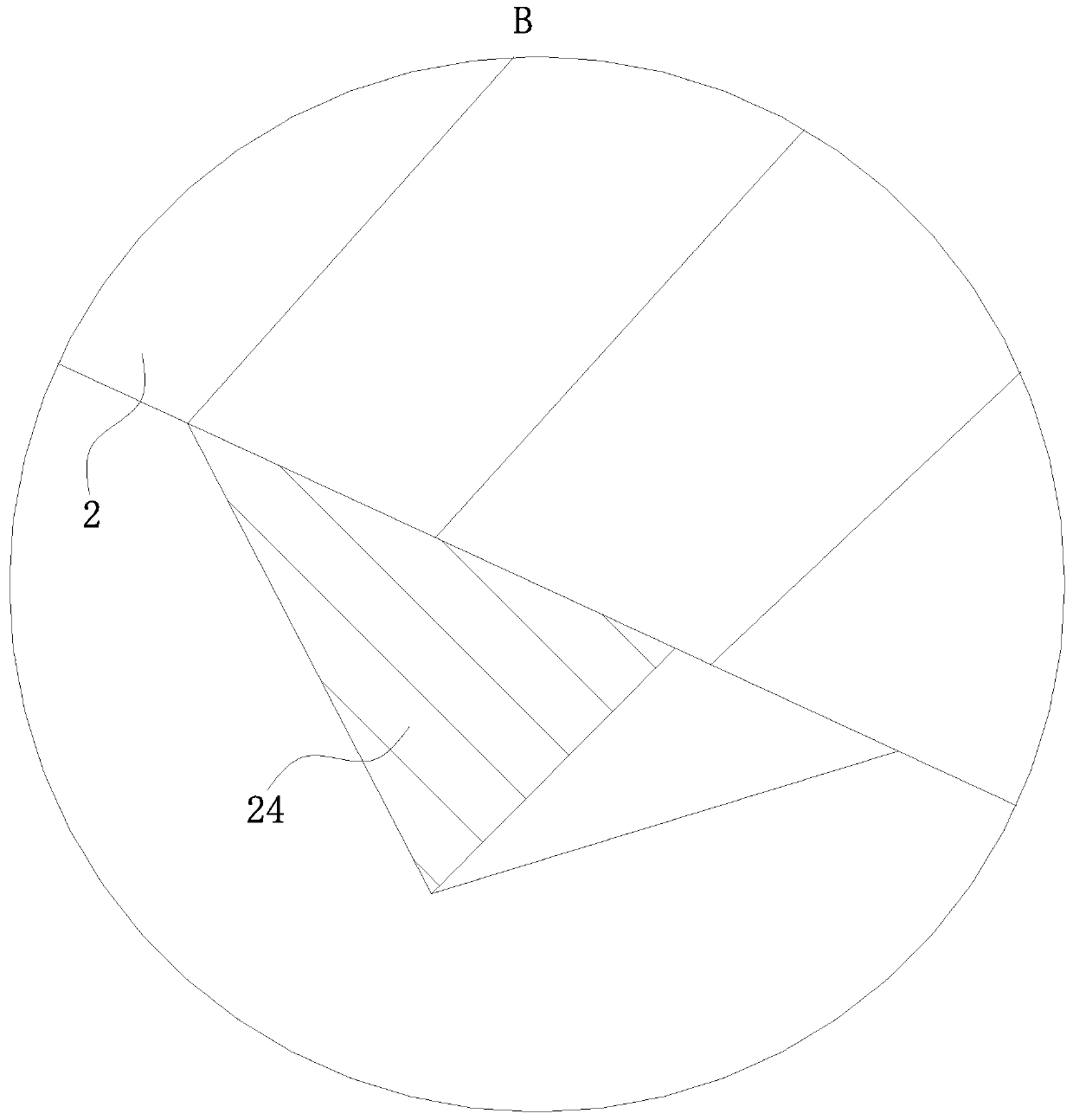

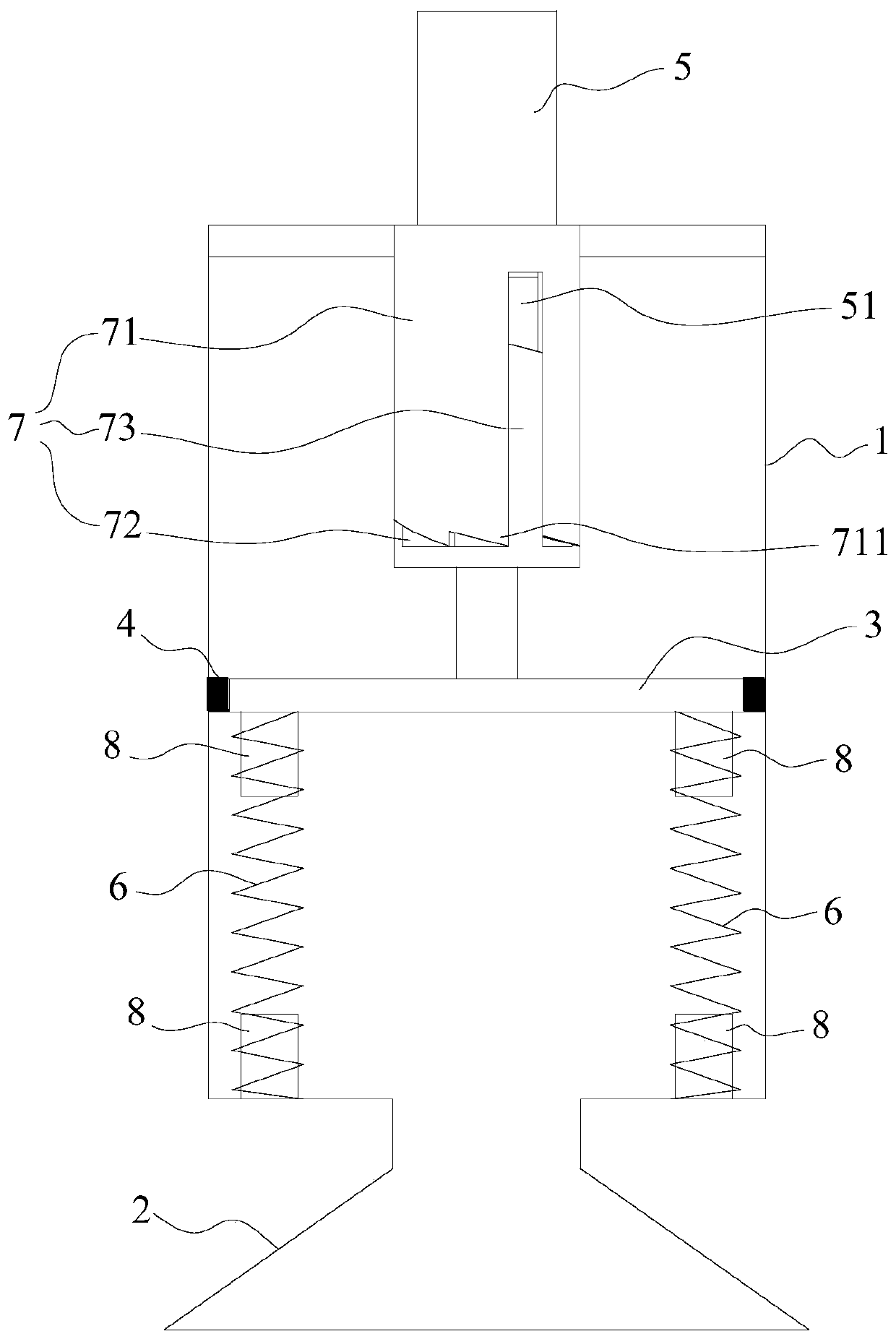

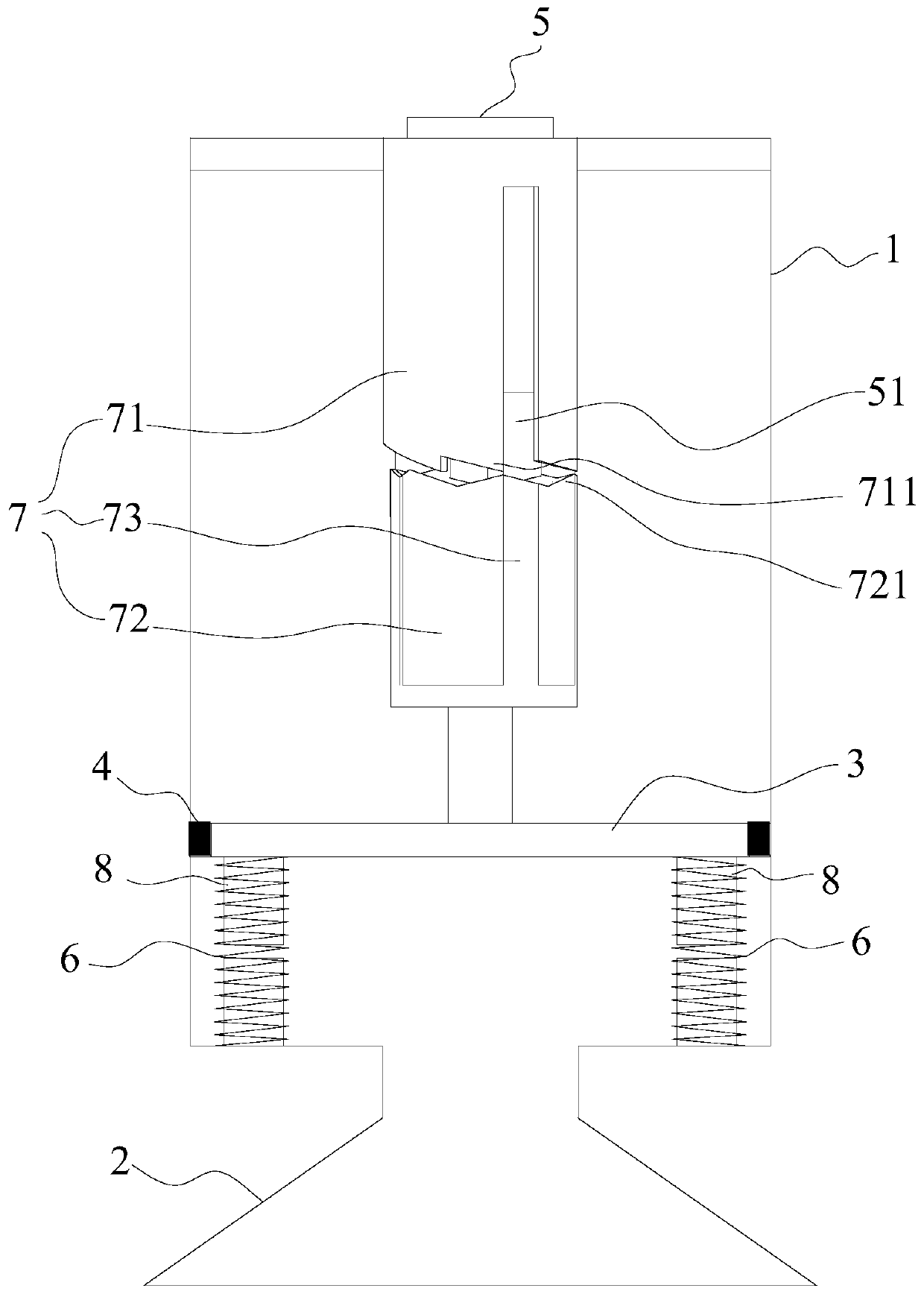

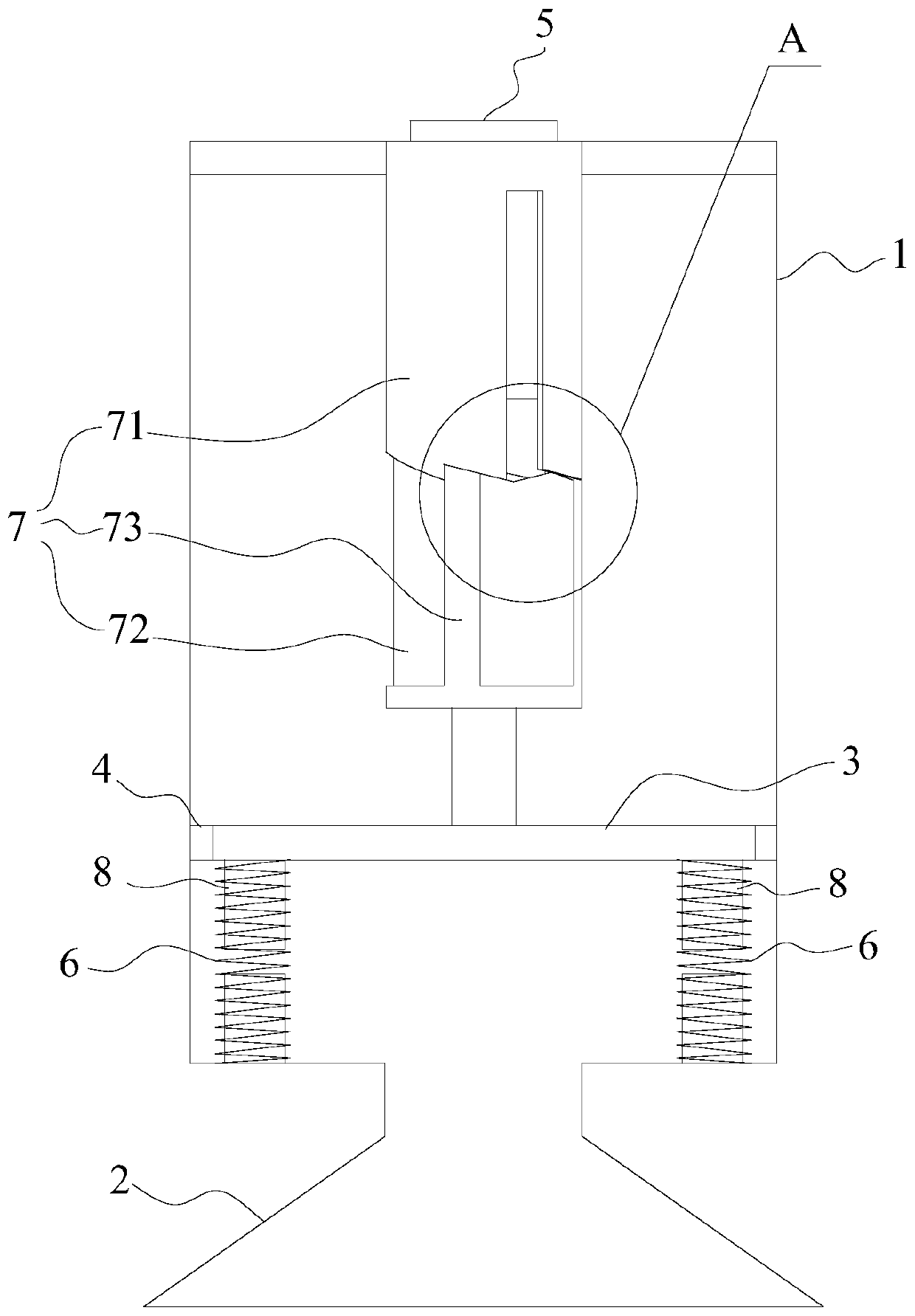

Press fitting device

The invention discloses a press fitting device. The press fitting device comprises a housing, a spring, a pressing plate, a pressure transducer, a pressure head connecting plate, a pressure head, a displacement ruler pressing plate, and a displacement ruler. Under driving of a cylinder, the downward-pressing of the pressure head is realized, and by using the displacement ruler and the pressure transducer, detection of a corresponding relation between a press-in distance and a corresponding pressure value is realized, and a structure of preventing the pressure transducer from being damaged by pressure is provided.

Owner:力茨(江苏)机电装备有限公司

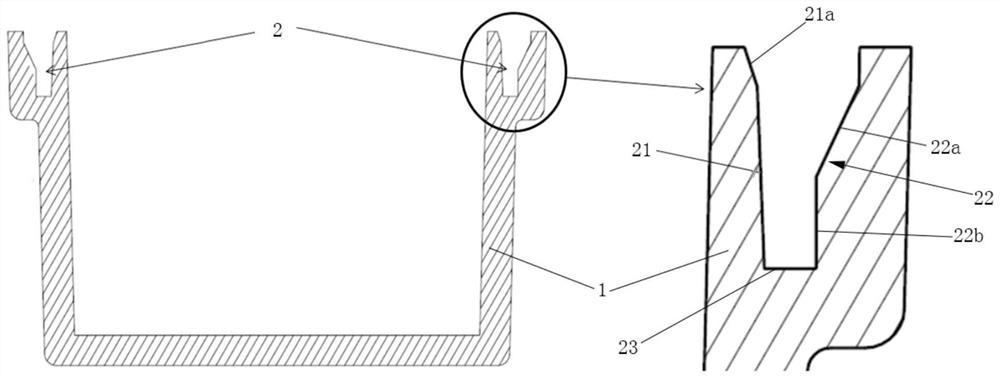

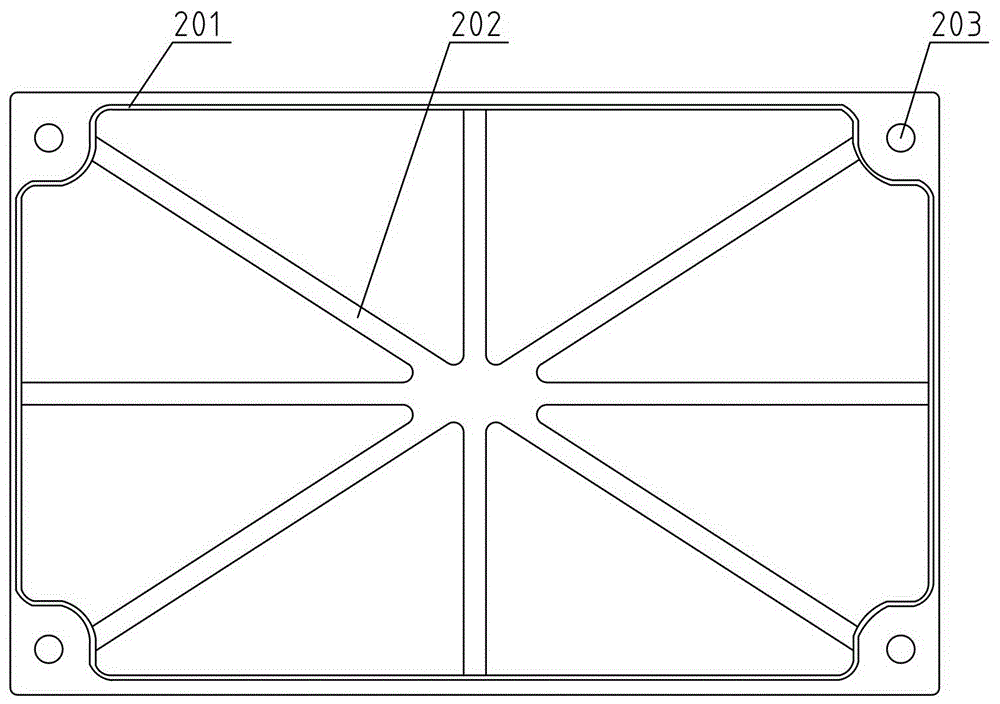

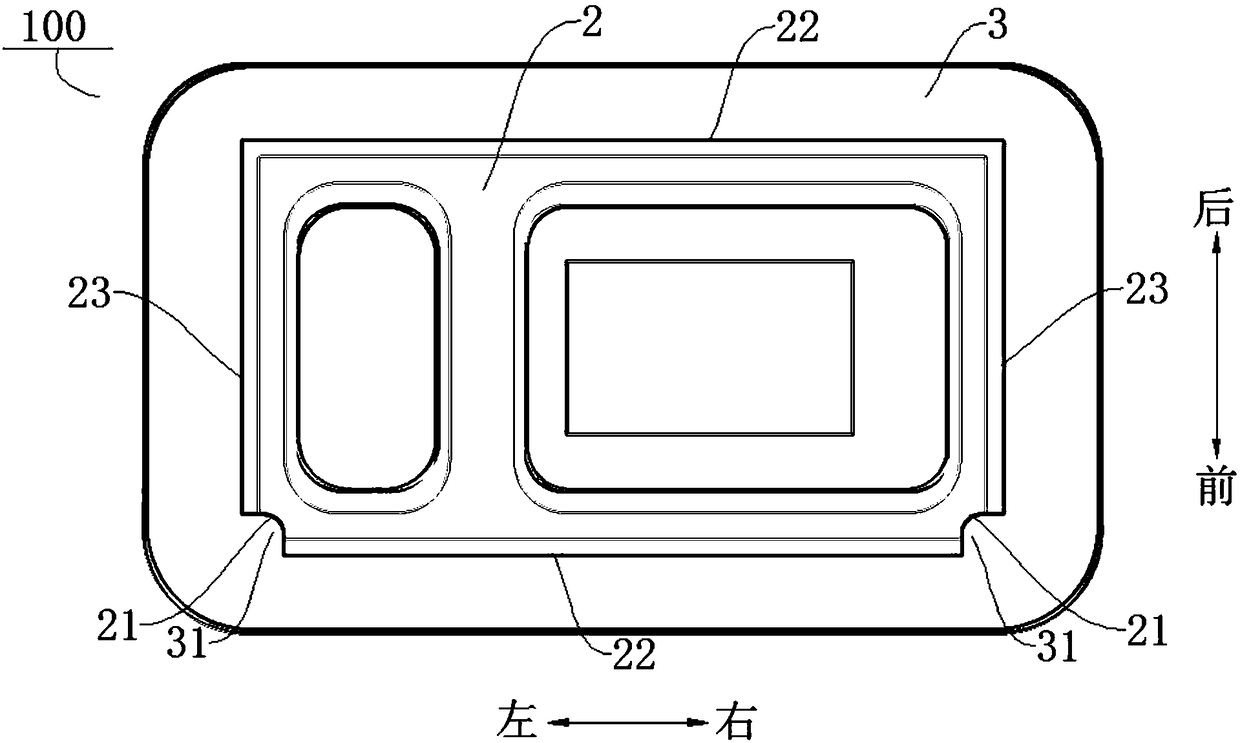

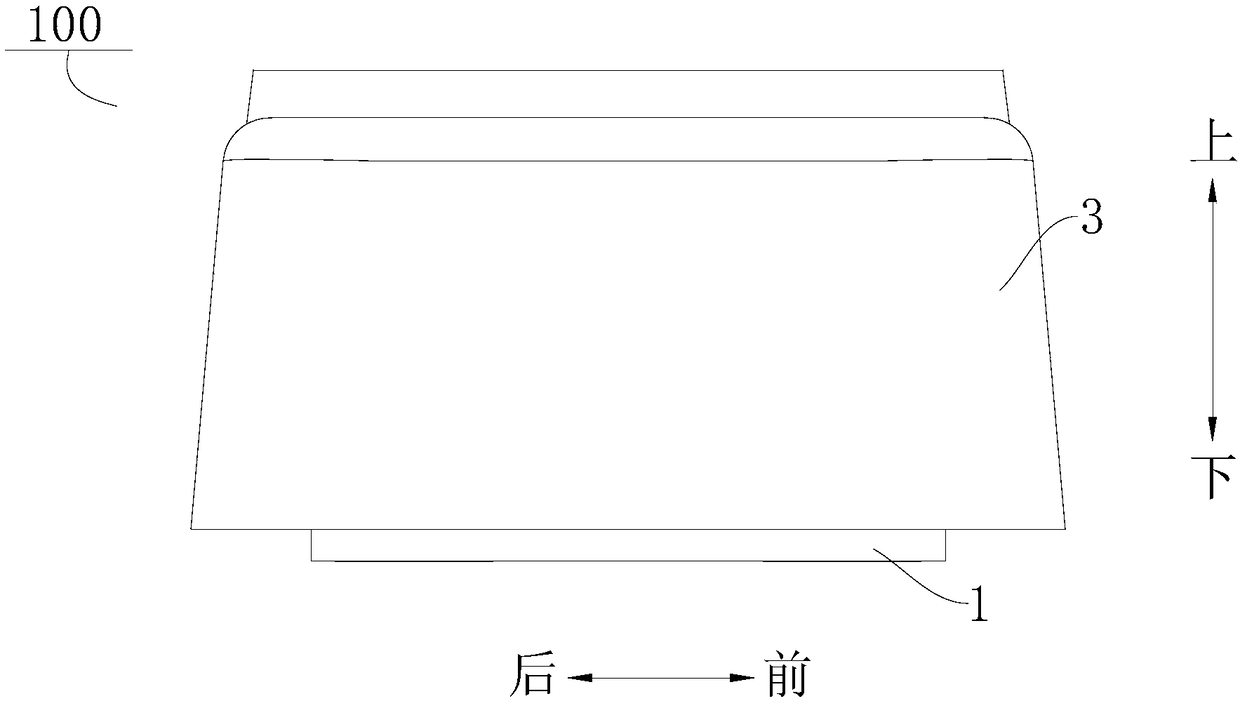

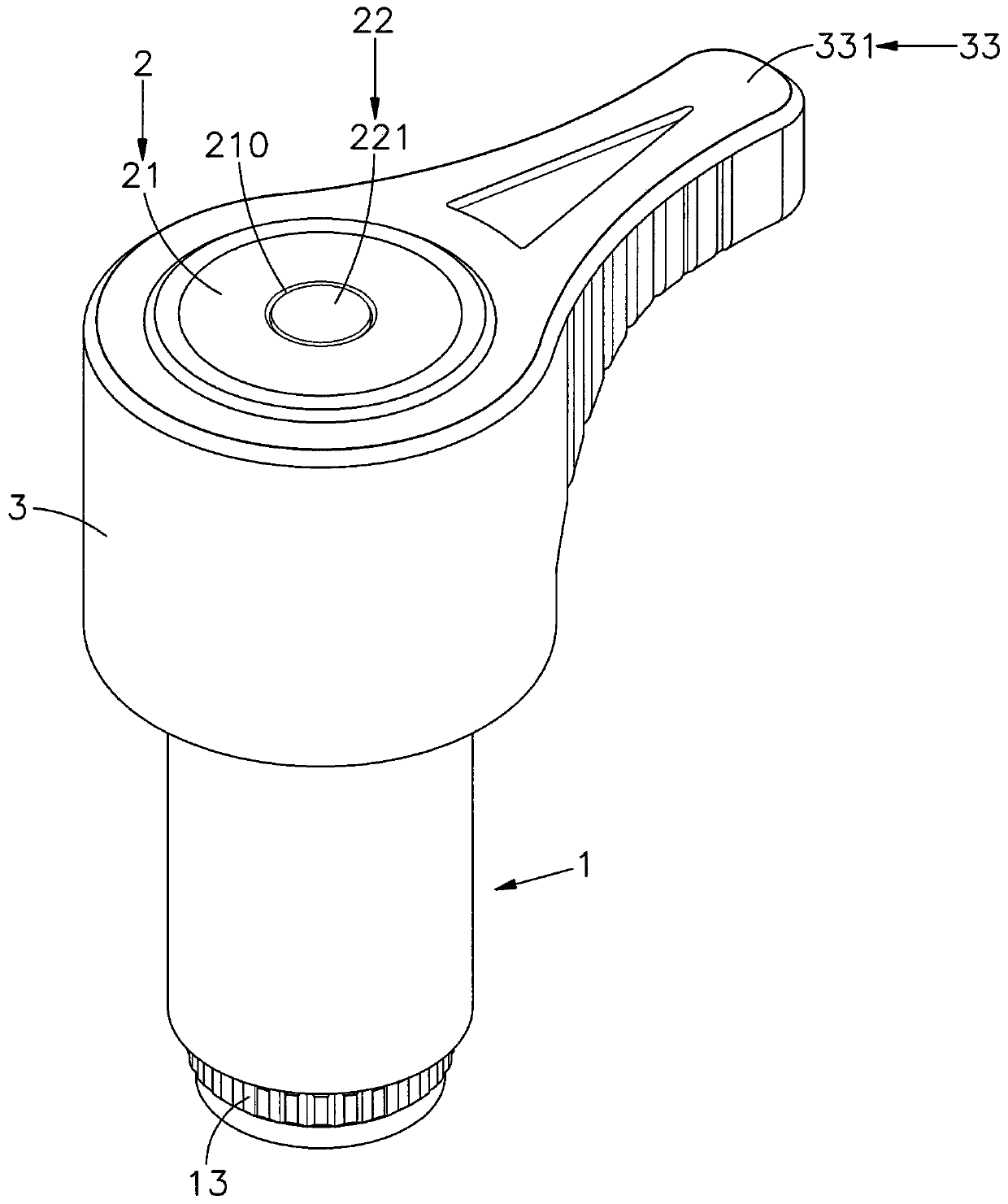

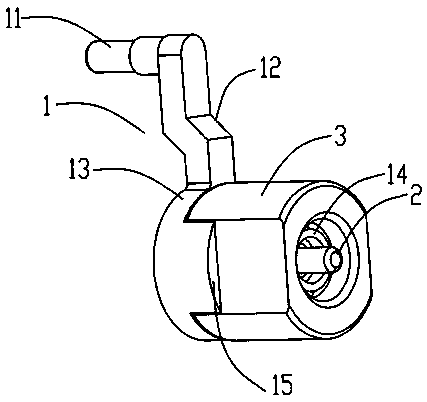

Camera module shell

PendingCN112388221AIncrease flexibilityImprove versatilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCamera module

The invention relates to a camera module shell. The camera module shell comprises a shell body (1), one side of the shell body (1) is open, an annular containing groove (2) is formed in the end face of the open side of the shell body (1), the containing groove (2) is composed of an inner groove wall (21), an outer groove wall (22) and a groove bottom (23), and the inner groove wall (21) obliquelyextends outwards from the opening side of the shell body (1) to the other side. According to the camera module shell, the inner groove wall in the containing groove is inclined, so that an upper shellcannot deviate in the welding process, and the anti-stay function is achieved.

Owner:ZHEJIANG SUNNY SMARTLEAD TECH CO LTD

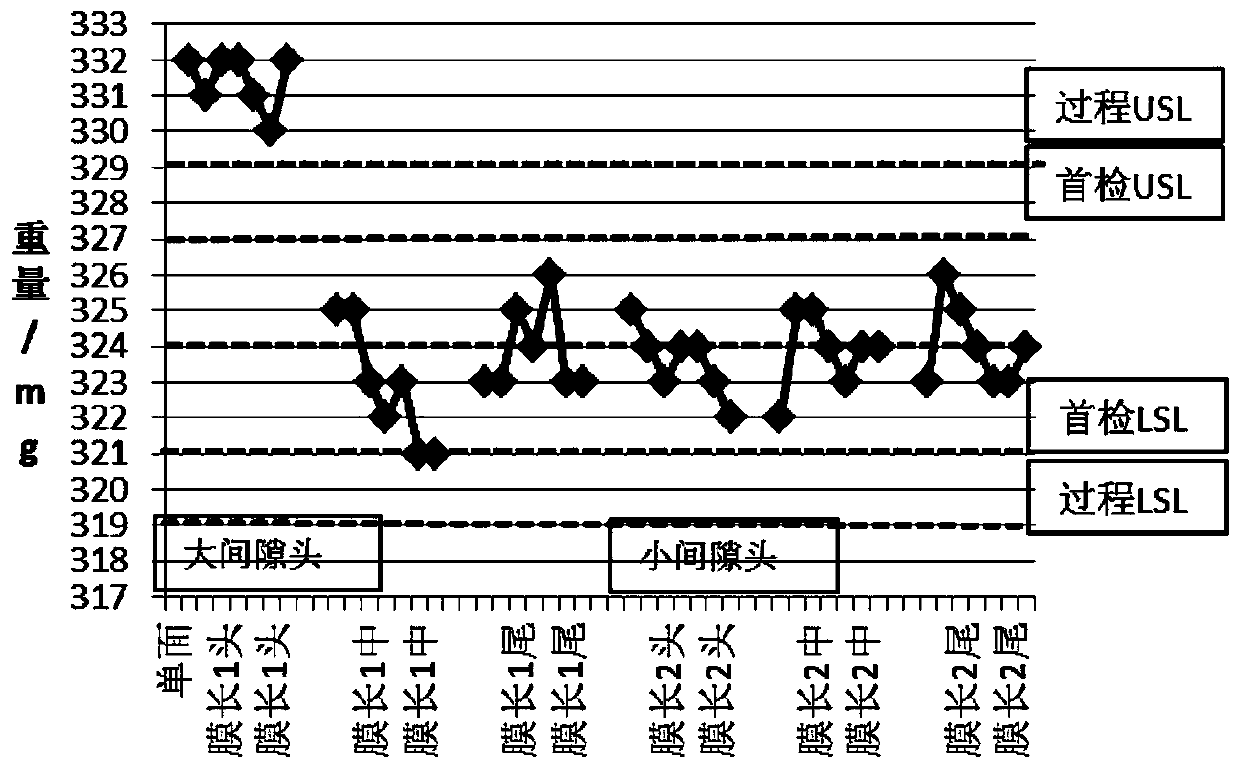

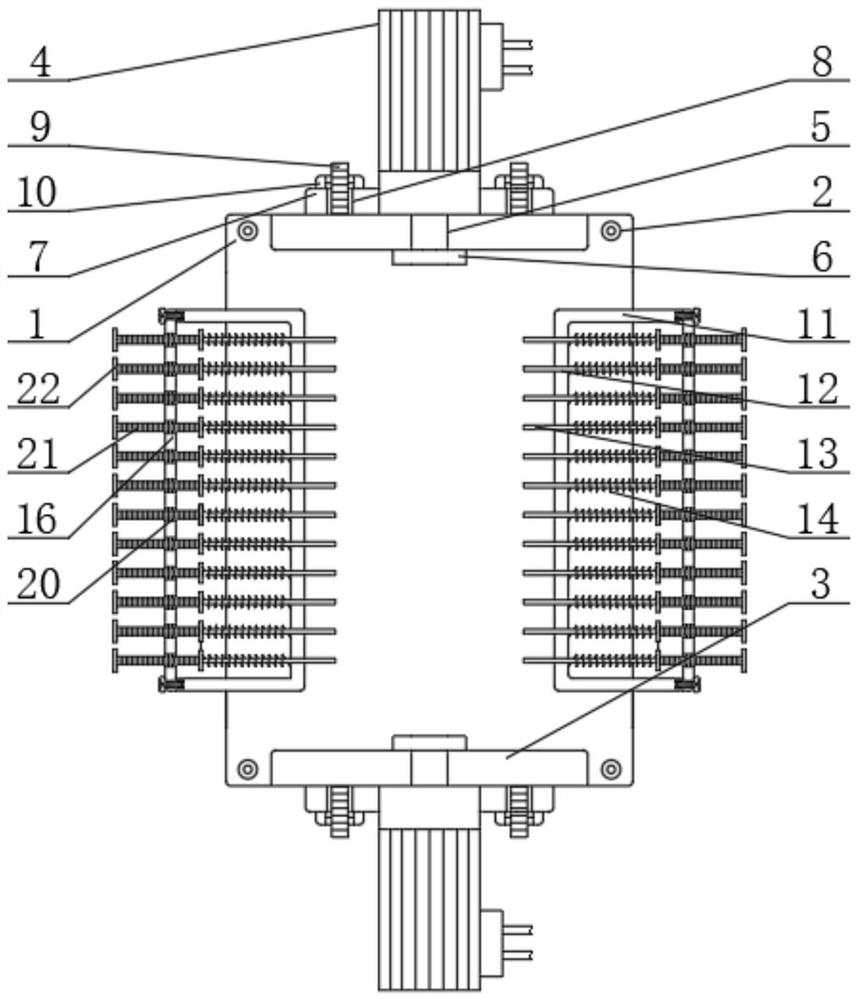

Reflux device for controlling film thickness of multi-gap pole piece and control method thereof

PendingCN110227634ASame densityThe same thicknessLiquid surface applicatorsElectrode collector coatingPole pieceEngineering

The invention belongs to the technical field of batteries, and particularly relates to a reflux device for controlling the film thickness of a multi-gap pole piece. The reflux device comprises a feedpipe, a coating valve, a return valve, a return pipe and a membrane head pipe, the membrane head pipe is in communication with the feeding pipe to form a main trunk line, the coating valve and the return valve are sequentially connected to the main trunk line in series, the return pipe is in communication with the return valve, the return pipe comprises a first pipeline and a second pipeline, andthe first pipeline and the second pipeline are connected in parallel. The reflux device is simple in structure, achieves multi-gap pole piece production, and is simple to operate, stable in work and high in production efficiency. In addition, the invention further provides a control method of the reflux device so as to improve the working stability and efficiency of the reflux device.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

Electric connector

InactiveCN102290655BReduce volumePrecise positioningCouplings bases/casesCoupling protective earth/shielding arrangementsFirst insertionElectrical and Electronics engineering

The invention provides an electric connector which is applicable to inserted connection of two different plug connectors. The electric connector comprises an insulating body, a plurality of conductive terminals fixedly clamped in the insulating body and a shielding shell covering the insulating body, wherein the insulating body is provided with a base part and a clapper extending forwards from the base part; the conductive terminals are provided with contact parts extending onto the clapper; the shielding shell is provided with a top wall and a bottom wall which are oppositely arranged as well as two side walls connected between the top wall and the bottom wall; the two side walls of the shielding shell have step-like outlines so as to form a first insertion hole corresponding to the outer outline of one plug connector and a second insertion hole corresponding to the outer outline of the other plug connector together with the top wall and the bottom wall; and the first insertion hole and the second insertion hole are partially shared.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Anti-interference low-loss drop-shaped waterproof connector for power distribution control equipment

PendingCN110932031ASave spaceGood anti-fooling effectIncorrect coupling preventionCouplings bases/casesDistribution controlEngineering

The invention relates to an anti-interference low-loss drop-shaped waterproof connector for power distribution control equipment, in particular to an electronic component connector structure. The structure comprises a wire male end connector, a wire female end connector and a board male end connector, and is characterized in that the wire male end connector comprises a wire male rubber core, te wire female end connector comprises a wire female rubber core, the board male end connector comprises a board male rubber core, the wire male end rubber core and the wire female end rubber core are provided with fool-proof structures which are matched with each other, the wire female end rubber core comprises a guide shell and an inner jack cylinder, the wire female end rubber core comprises an inner hole and an inner hole shell, the inner hole is drop-shaped, the inner jack cylinder is a drop-shaped cylinder matched with the drop-shaped inner hole, and through the guide shell, the drop-shaped cylinder and the drop shape are completely matched, so that the beneficial effects of the invention are that the drop shape of the rubber core is utilized to be matched with the jack structure, the product space is saved, the fool-proof effect is better, and the appearance of the product is improved.

Owner:苏州鲁益电子科技有限公司

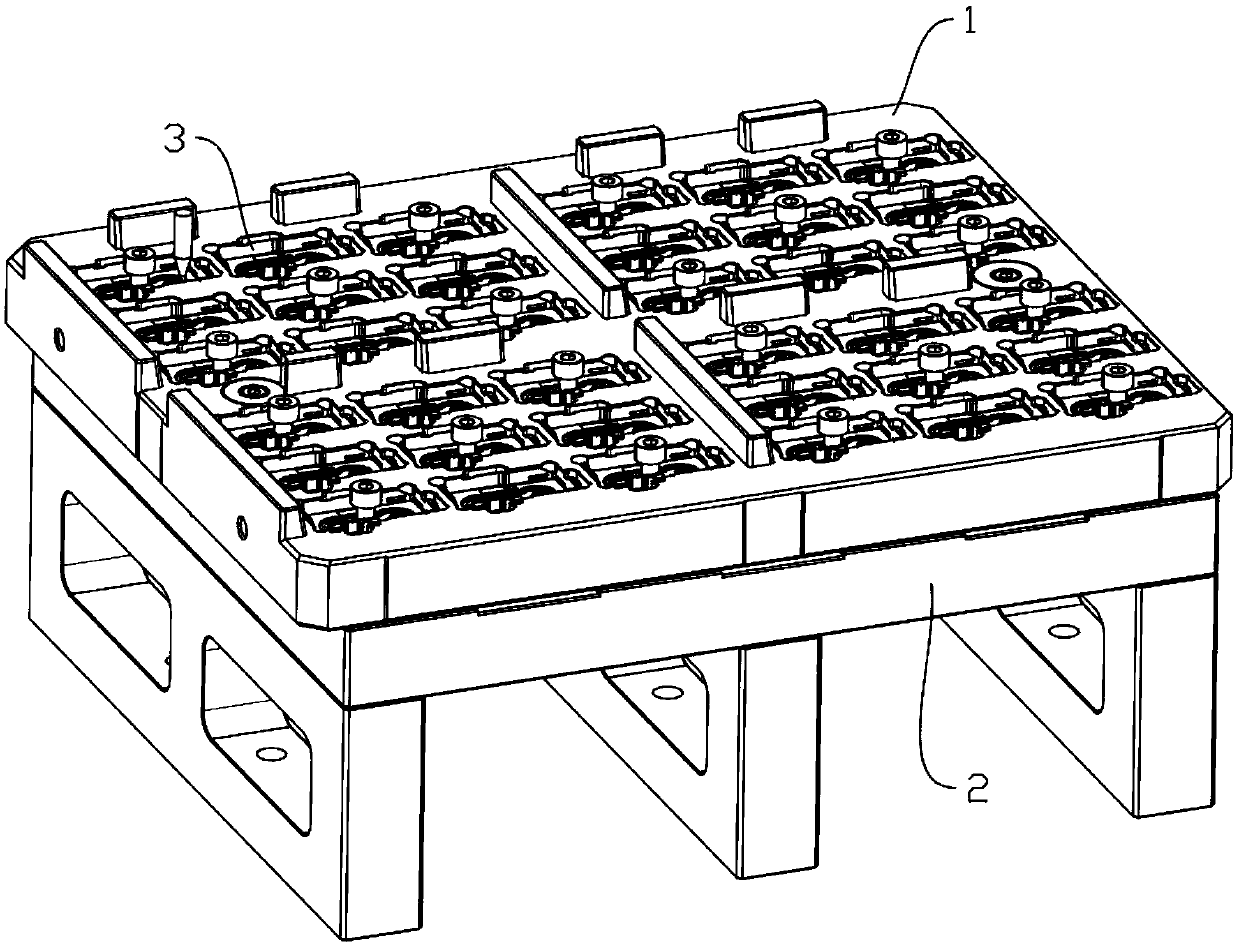

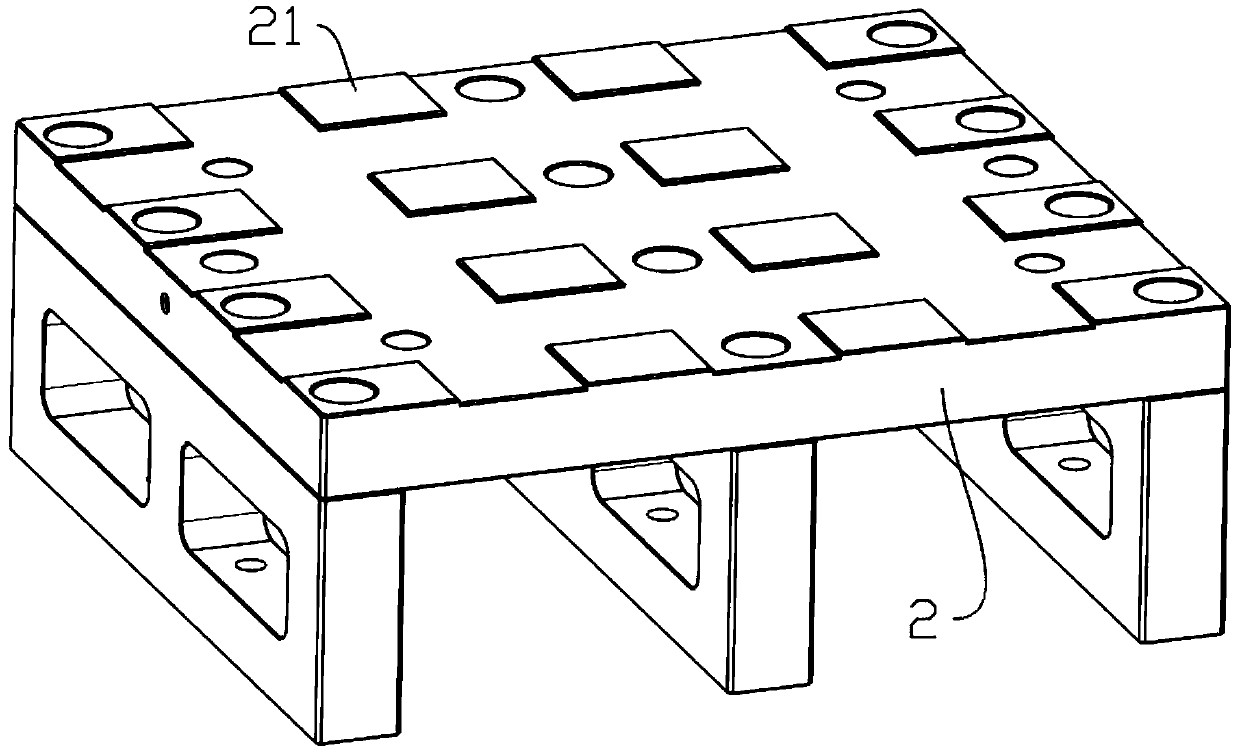

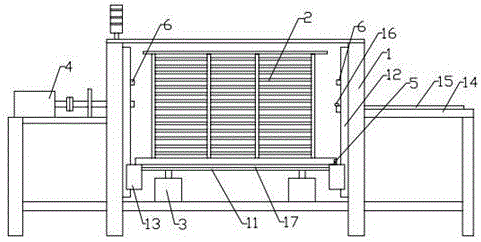

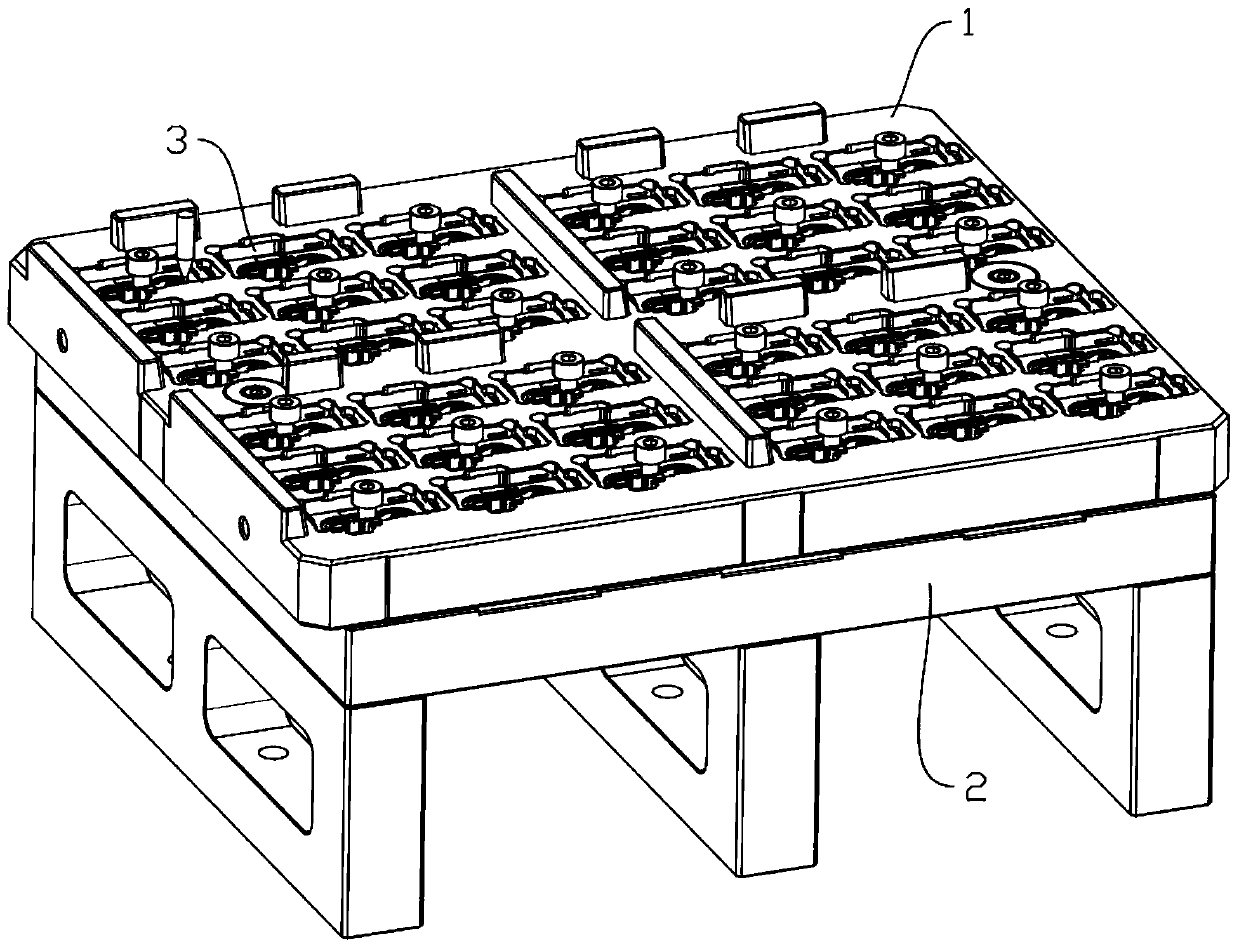

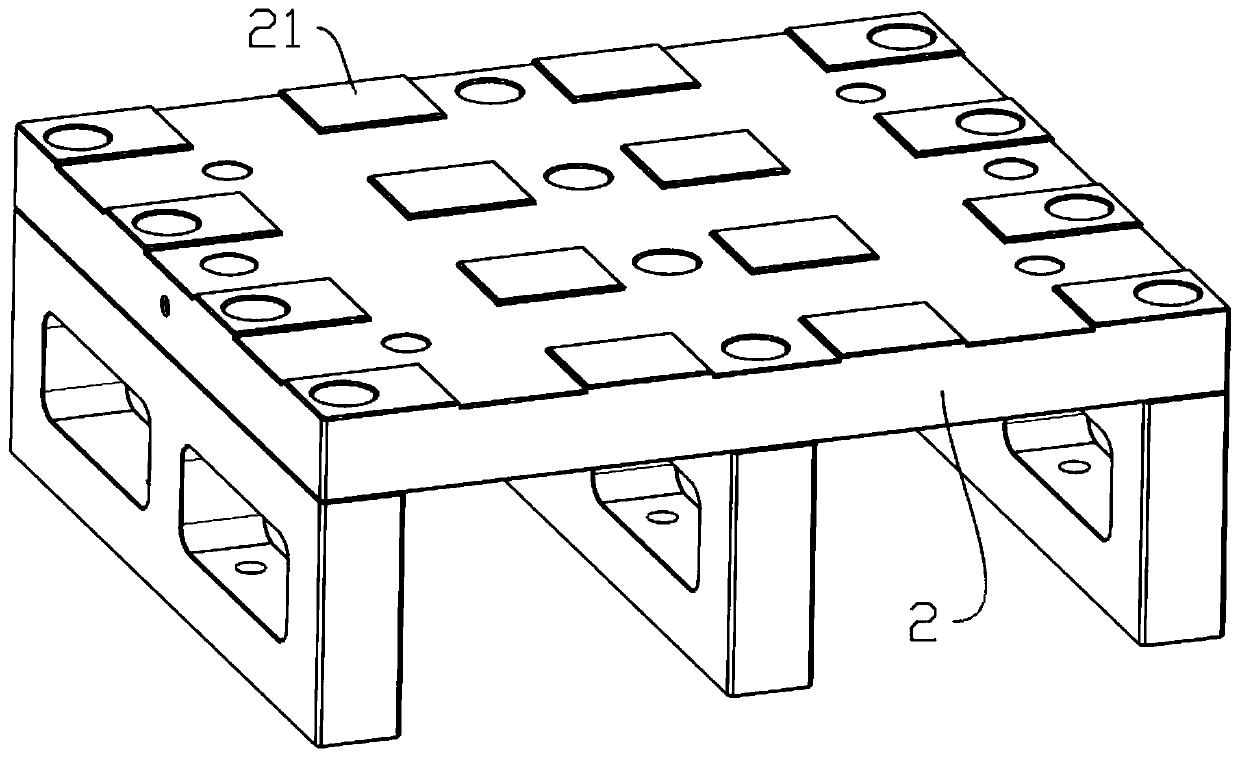

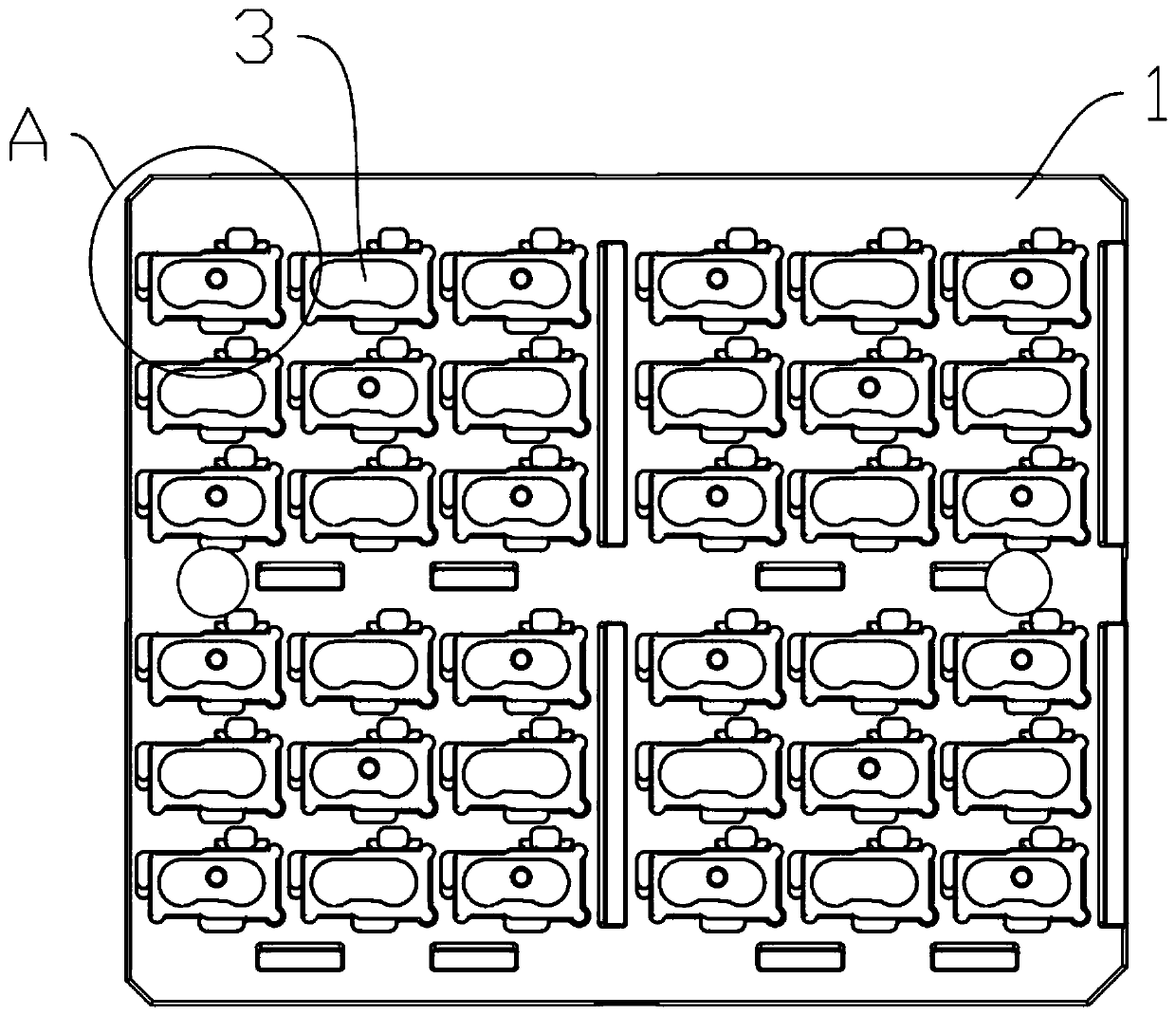

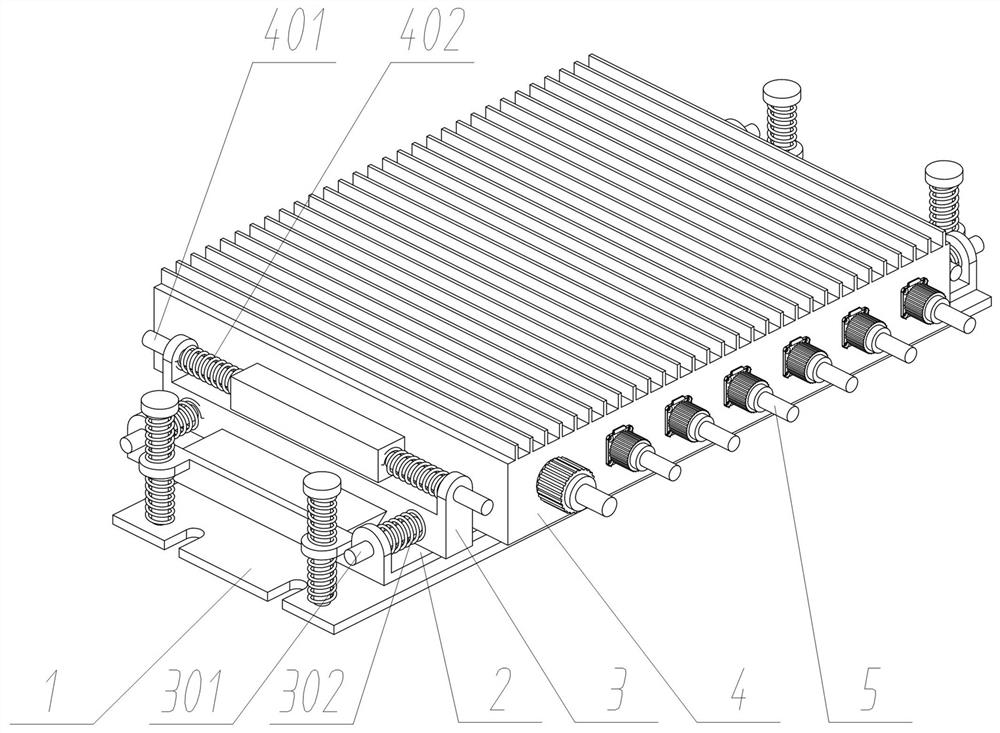

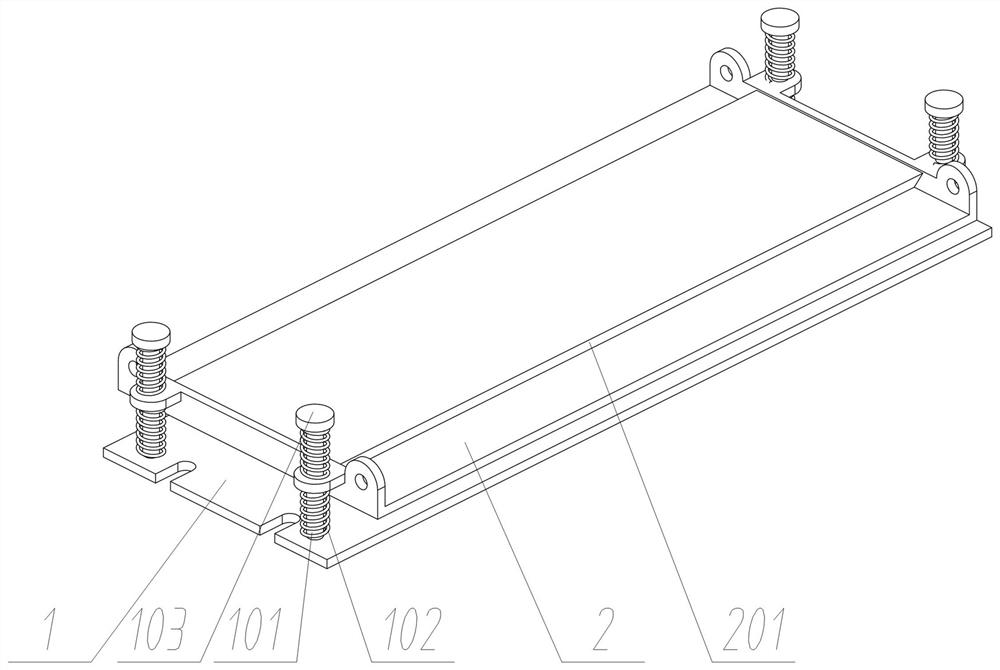

Batch machining workbench suitable for CNC machine tool and detection machining method

ActiveCN109571076AGood anti-fooling effectSave man hoursMeasurement/indication equipmentsPositioning apparatusEngineeringMachine tool

The invention discloses a batch machining workbench suitable for a CNC machine tool. The batch machining workbench comprises a workpiece positioning and placing plate and a machine tool connecting seat. The workpiece positioning and placing plate is fixedly connected with the upper surface of the machine tool connecting seat. A plurality of cavities used for containing workpieces are evenly formedin the upper surface of the workpiece positioning and placing plate at intervals in sequence. A plurality of taking grooves are annularly formed in outer rings of the cavities. Feeding inclined planes are arranged on the inner walls of the cavities. The invention further discloses a detection machining method implemented based on the batch machining workbench suitable for the CNC machine tool. The batch machining workbench is reasonable and ingenious in structural design. Errors caused by the floating of the sizes of the workpieces are reduced as much as possible. The quality of products is improved. The detection machining method is suitable for the detection machining of most workpieces arranged equidistantly. The reject ratio is reduced. Cavities without workpieces are prevented from being detected. The flexibility is good. The working time is shortened. The cost is saved. The cavities with no workpieces are not machined repeatedly. The working efficiency is improved.

Owner:常州新嘉精密科技有限公司

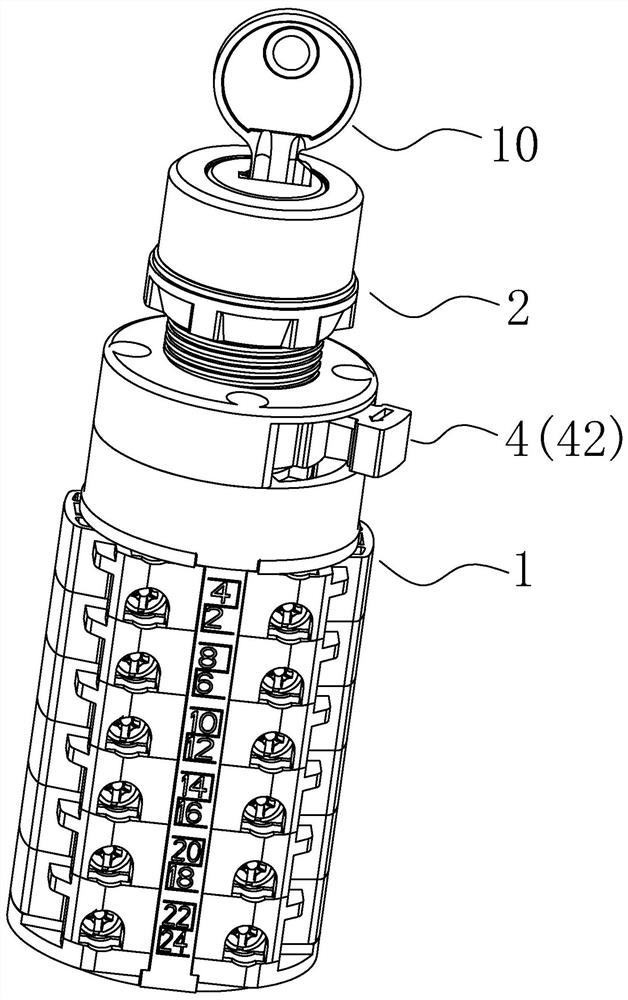

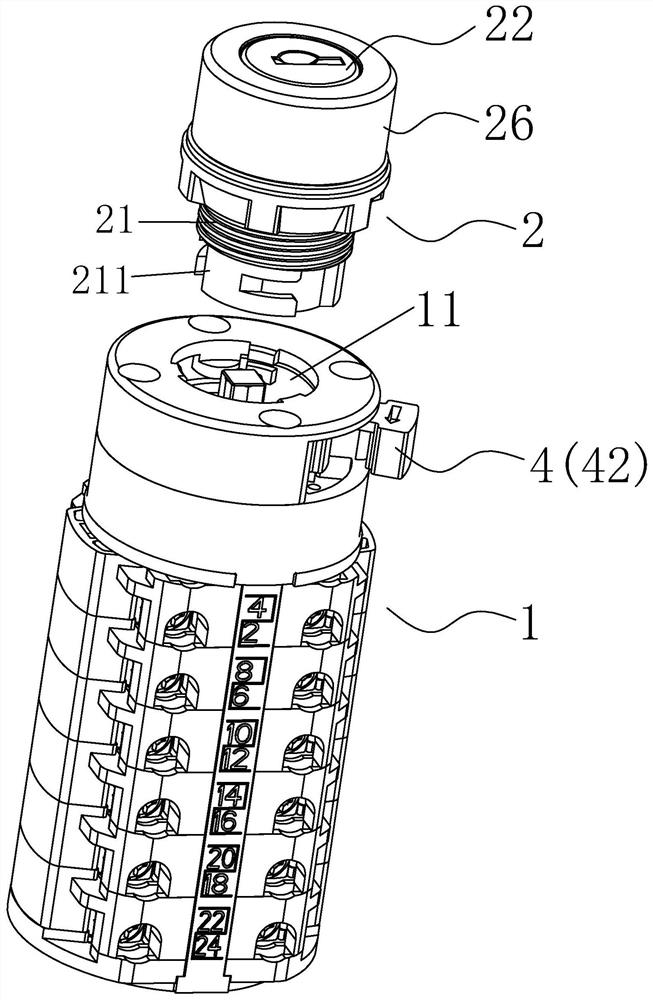

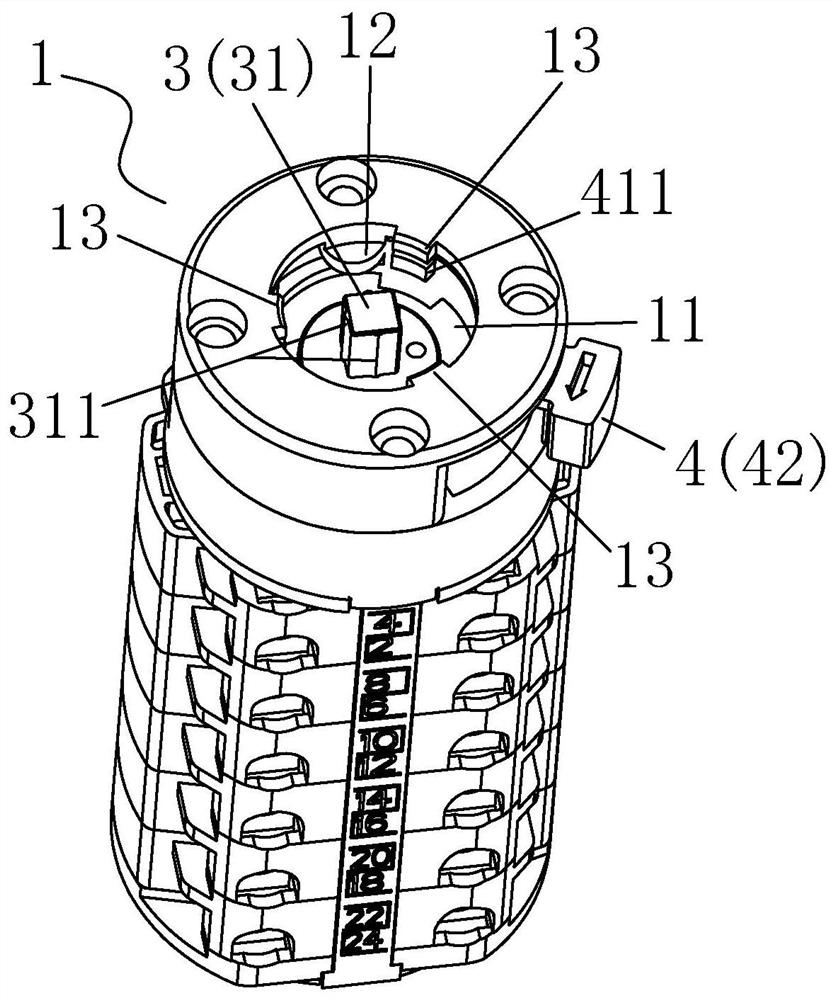

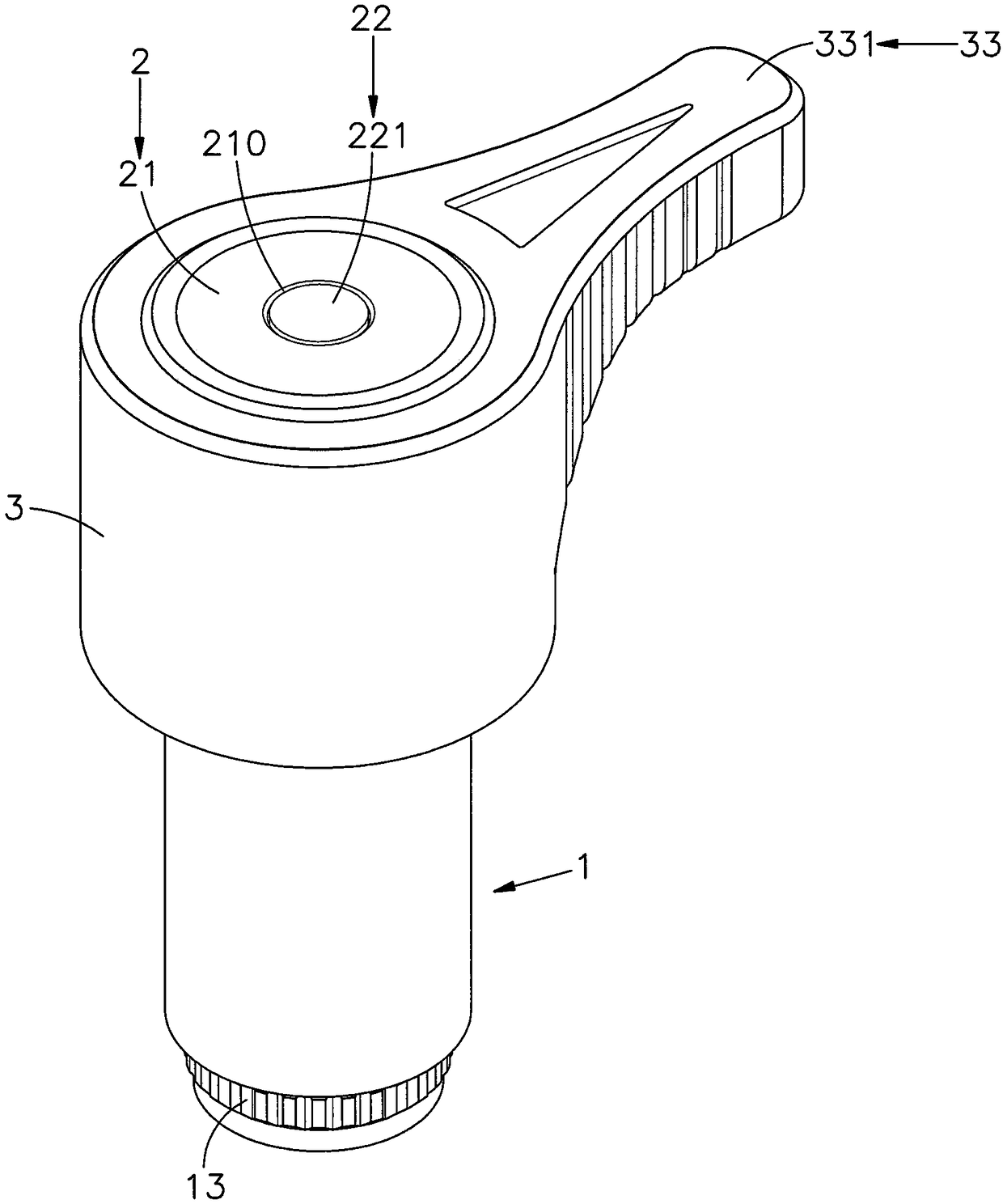

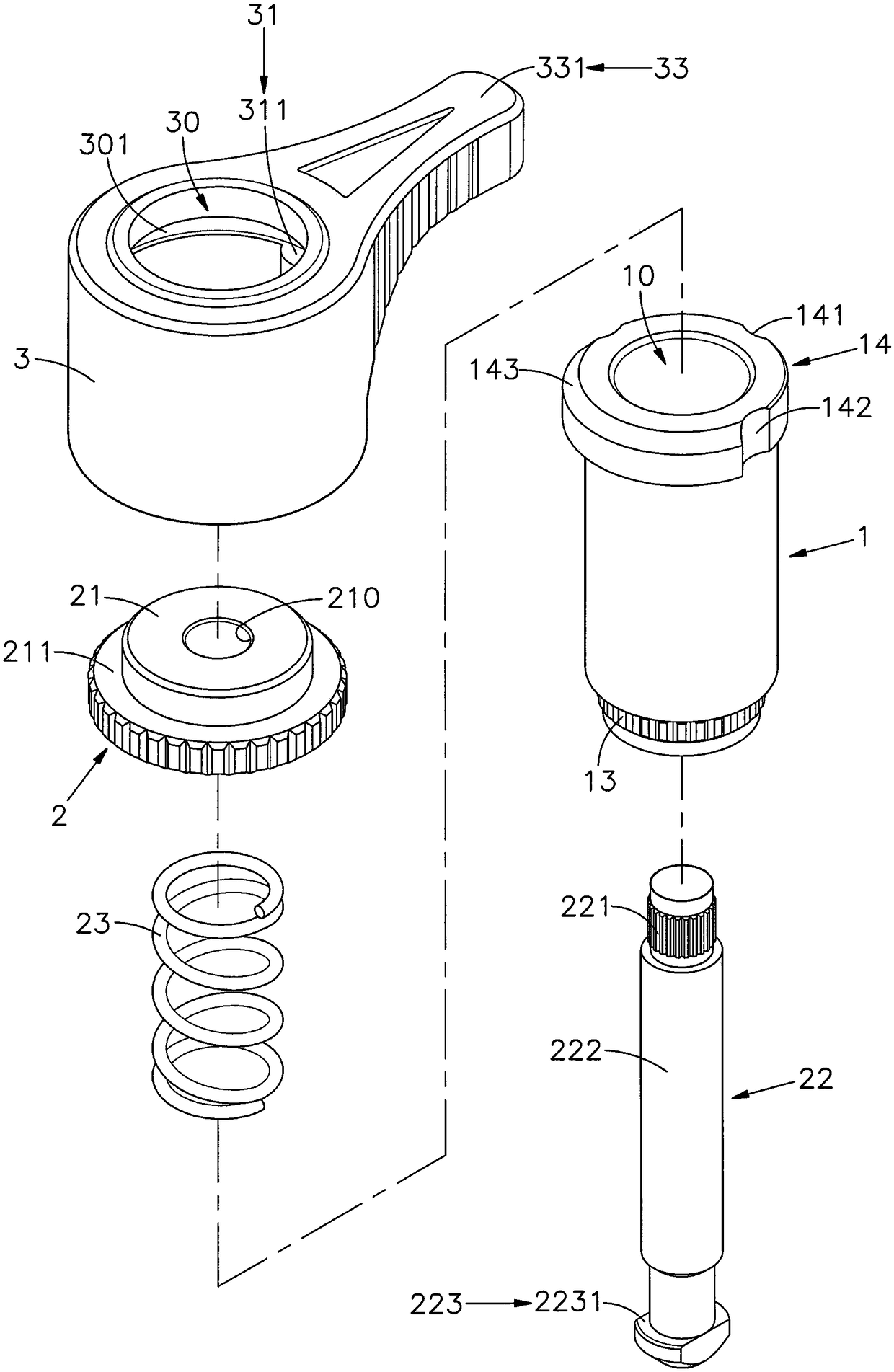

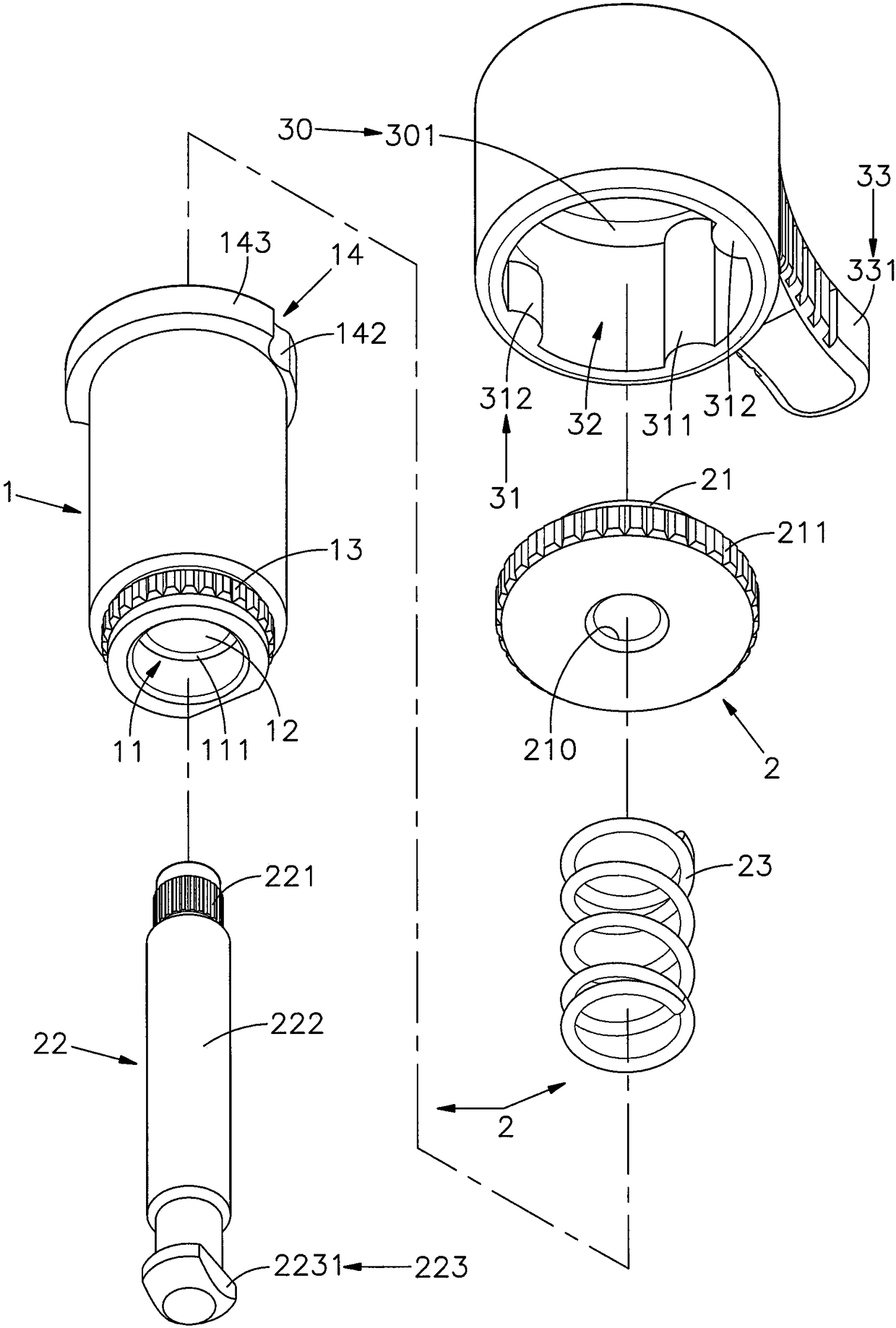

Key type universal change-over switch

PendingCN112786338AImprove the safety of usePrevent random installationElectric switchesTransfer switchStructural engineering

The invention discloses a key type universal change-over switch, which comprises a switch main body and a key knob. The key knob comprises a sleeve, a lock cylinder and a coupler, a fool-proof structure is arranged at the joint of the switch main body and the key knob, and a positioning slot for insertion of an insertion part of the sleeve is formed in the switch main body; the fool-proof structure comprises a center insertion shaft arranged in the positioning insertion groove and a center insertion hole formed in the coupler and used for the center insertion shaft to be inserted, strip-shaped convex edges are formed on the periphery of the center insertion shaft, and strip-shaped grooves are formed in the inner wall of the center insertion hole; a locking buckle assembly is arranged on the switch body, the locking buckle assembly is mainly composed of a locking ring and a locking operation rod connected to the locking ring, a locking protruding block is arranged on the inner wall of the locking ring in a protruding mode, and a locking side groove for the locking protruding block to be embedded in is formed in the outer wall of the inserting part. The switch is reasonable and compact in structure, high in stability, convenient and fast to install, flexible, diversified and comprehensive in design, capable of meeting diversified requirements of customers, low in cost, high in use safety and long in service life.

Owner:广州本立智控科技股份有限公司

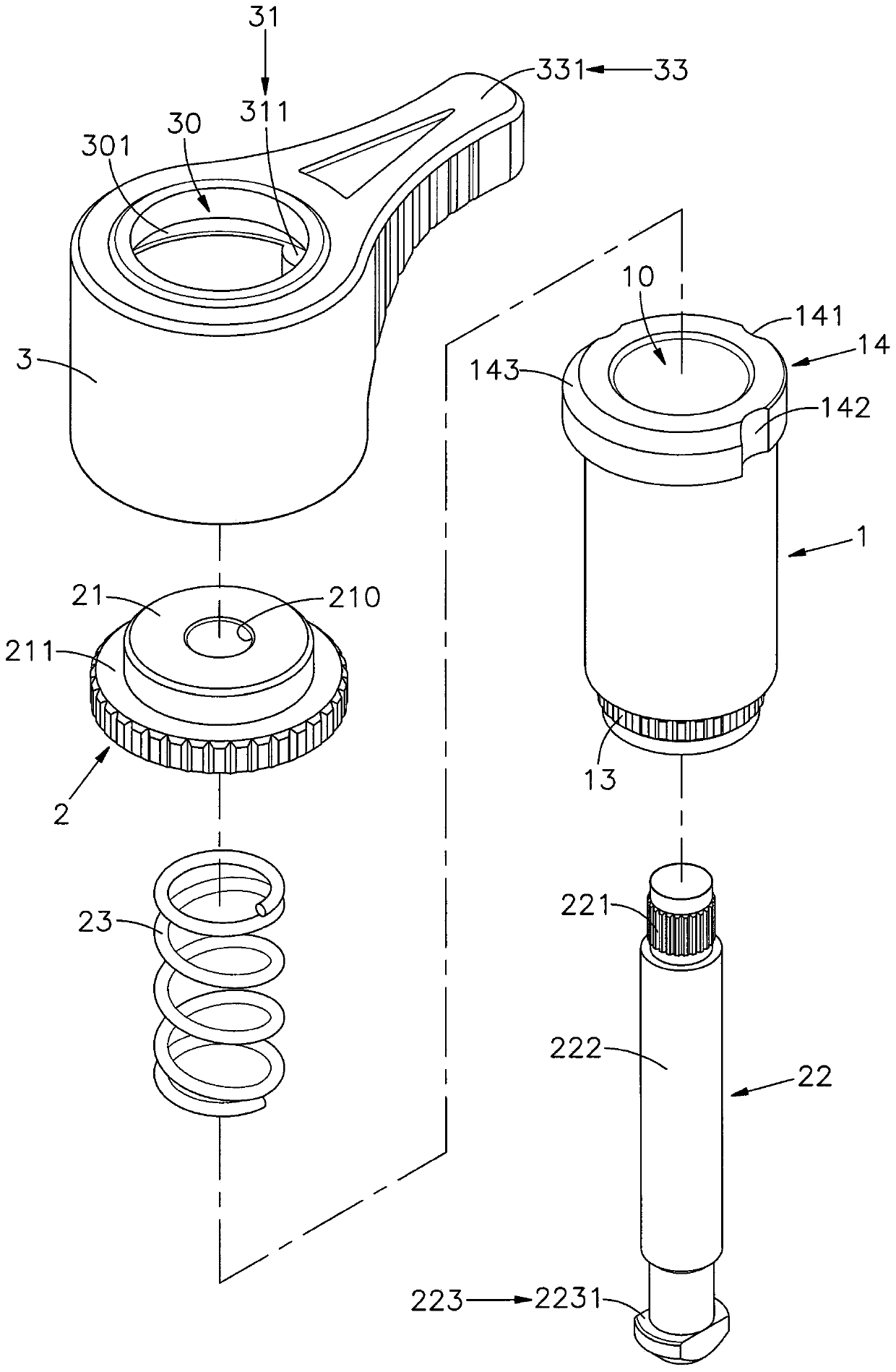

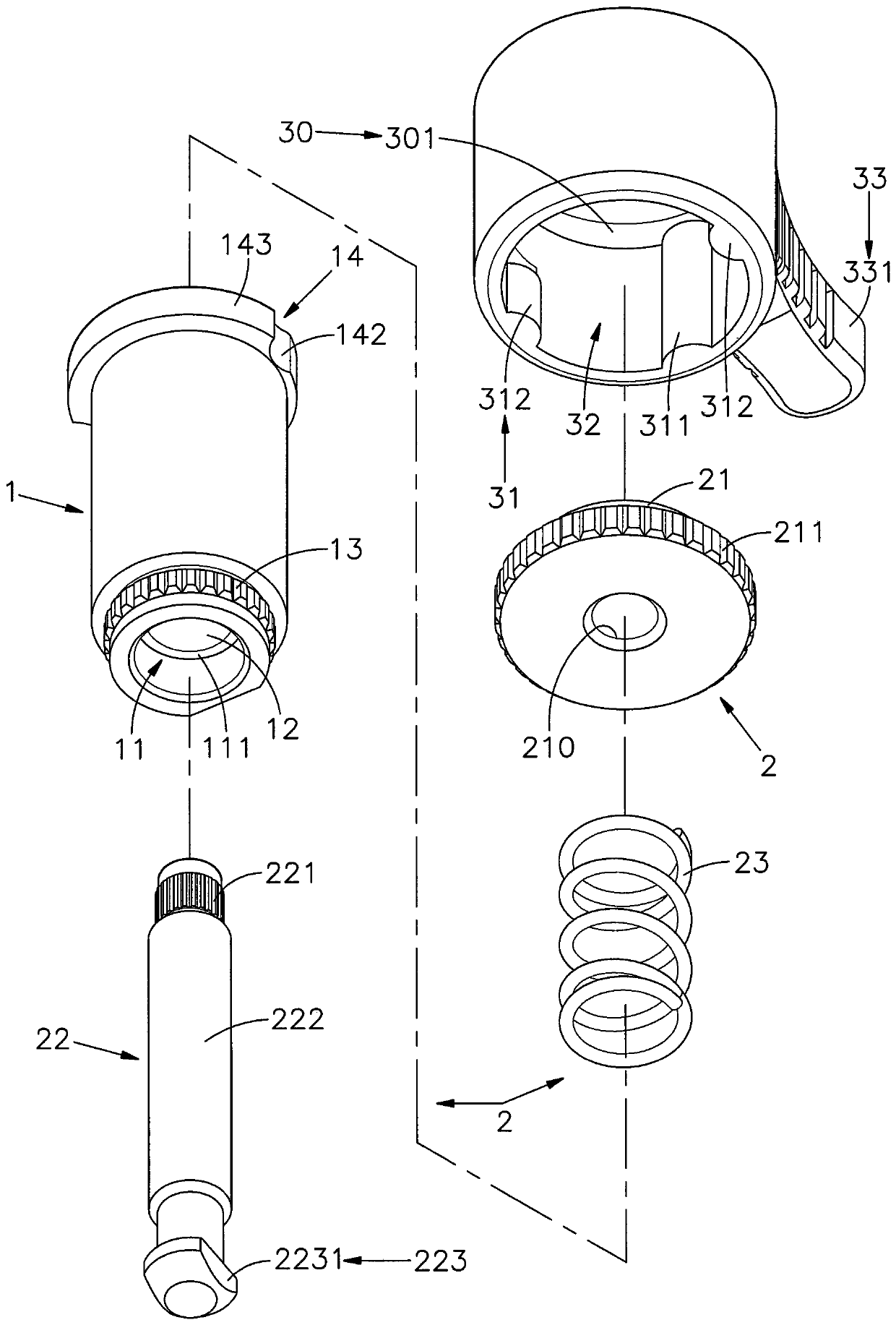

Positioning device

Owner:HANWIT PRECISION IND LTD

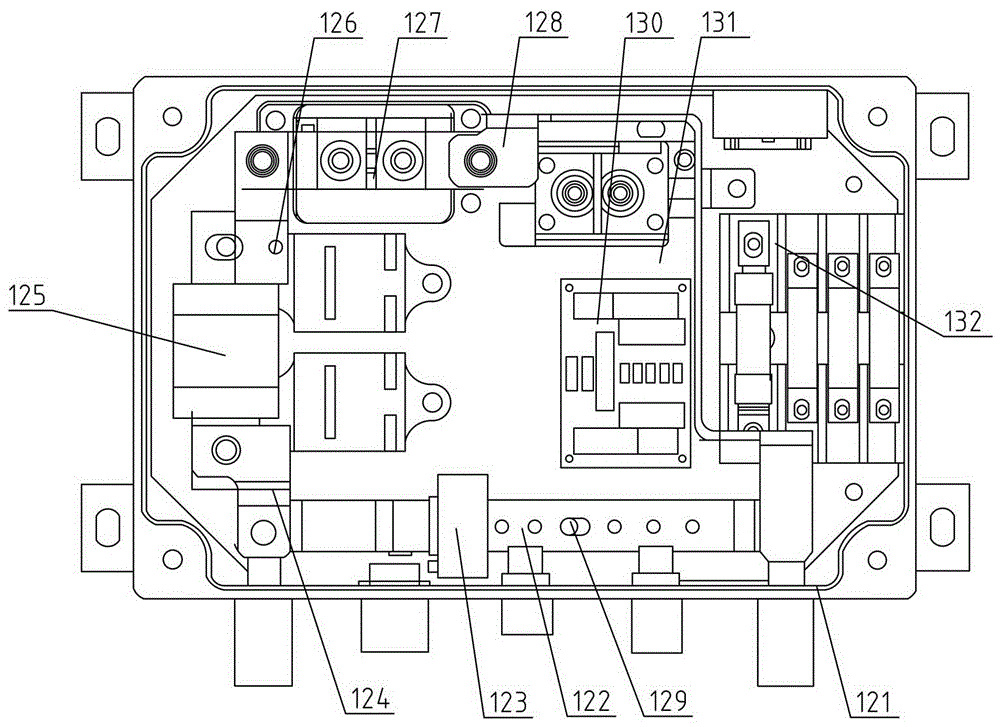

High-voltage distribution cabinet of electric vehicle

InactiveCN106159732AHigh protection levelGood anti-fooling effectBoards/switchyards circuit arrangementsSubstation/switching arrangement casingsSafety coefficientThermistor

The invention discloses a high-voltage distribution cabinet of an electric vehicle. The cabinet comprises a cabinet body and a cabinet cover. A concave cavity is formed in the cabinet body and internally provided with a circuit board, a current detector, a fuse, thermistors, a relay, a copper bar and a wire. A plurality of electrically connected connectors are arranged on the outer wall of the cabinet body, a boss is circumferentially arranged on the end face of an opening of the concave cavity of the cabinet body, the cabinet cover is provided with a groove matched with the boss in a clamped mode, and a rubber ring is disposed in the groove. By means of the connectors, electricity allocated into the high-voltage distribution cabinet is transmitted to various electric appliances, the protection grade of the cabinet body can be improved, and a good fool-proof function can be achieved. The positive temperature thermistor and the negative temperature thermistor can effectively prevent the situation that a circuit is too hot and accordingly resistors and elements are burnt, and the safety coefficient of equipment is improved.

Owner:湖南长高电气有限公司

Automatic board conveyer with mistake-proofing system

PendingCN106276279AEasy and fast loadingSmooth transmissionConveyorsDe-stacking articlesControl systemEngineering

The invention discloses an automatic board conveyer with a mistake-proofing system, which comprises a rack, a board storage frame and a control system, a lifting platform which is located on the bottom of the board storage frame is arranged in the lower end of the rack, slide rails are arranged on the inner sides of the uprights of the rack, sliders which are located on the slide rails are arranged on the four corners of the bottom plane of the lifting platform, lifting cylinders which are connected with the bottom plane of the lifting platform are arranged on the bottom of the rack, a driving mechanism is arranged on the left side of the rack, a conveying platform is arranged on the right side of the rack, a horizontal slide way is arranged on the upper plane of the conveying platform, a stop is arranged on one side, which is located in the rack, of the horizontal slide way, a limit switch which corresponds to the stop is arranged on the bottom end of the board storage frame, opposite light curtains which correspond to each other are arranged on the inner sides of the uprights, and the control system is respectively electrically connected with the limit switch, the opposite light curtains, the lifting cylinders and the driving mechanism. Thus, the automatic board conveyer has the advantages of convenient and quick board loading, stable and smooth conveying and good mistake-proofing effect, and guarantees the safe conveying of products.

Owner:FLEXTRONICS ELECTRONICS TECH SUZHOU

A probing method for batch processing workbench suitable for cnc machine tools

ActiveCN109571076BPrevent detectionGood anti-fooling effectMeasurement/indication equipmentsPositioning apparatusProcess engineeringMachine tool

The invention discloses a batch machining workbench suitable for a CNC machine tool. The batch machining workbench comprises a workpiece positioning and placing plate and a machine tool connecting seat. The workpiece positioning and placing plate is fixedly connected with the upper surface of the machine tool connecting seat. A plurality of cavities used for containing workpieces are evenly formedin the upper surface of the workpiece positioning and placing plate at intervals in sequence. A plurality of taking grooves are annularly formed in outer rings of the cavities. Feeding inclined planes are arranged on the inner walls of the cavities. The invention further discloses a detection machining method implemented based on the batch machining workbench suitable for the CNC machine tool. The batch machining workbench is reasonable and ingenious in structural design. Errors caused by the floating of the sizes of the workpieces are reduced as much as possible. The quality of products is improved. The detection machining method is suitable for the detection machining of most workpieces arranged equidistantly. The reject ratio is reduced. Cavities without workpieces are prevented from being detected. The flexibility is good. The working time is shortened. The cost is saved. The cavities with no workpieces are not machined repeatedly. The working efficiency is improved.

Owner:常州新嘉精密科技有限公司

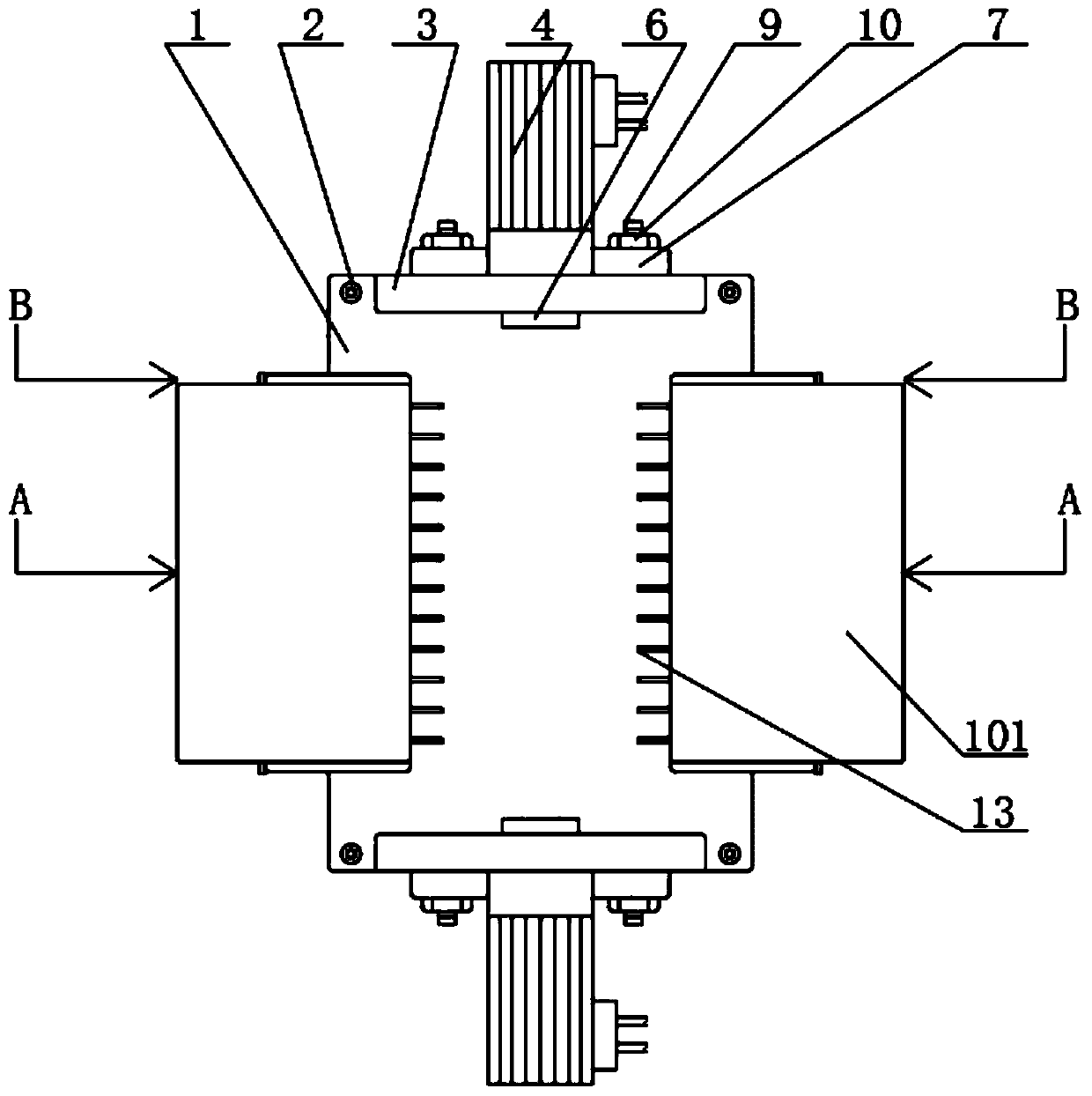

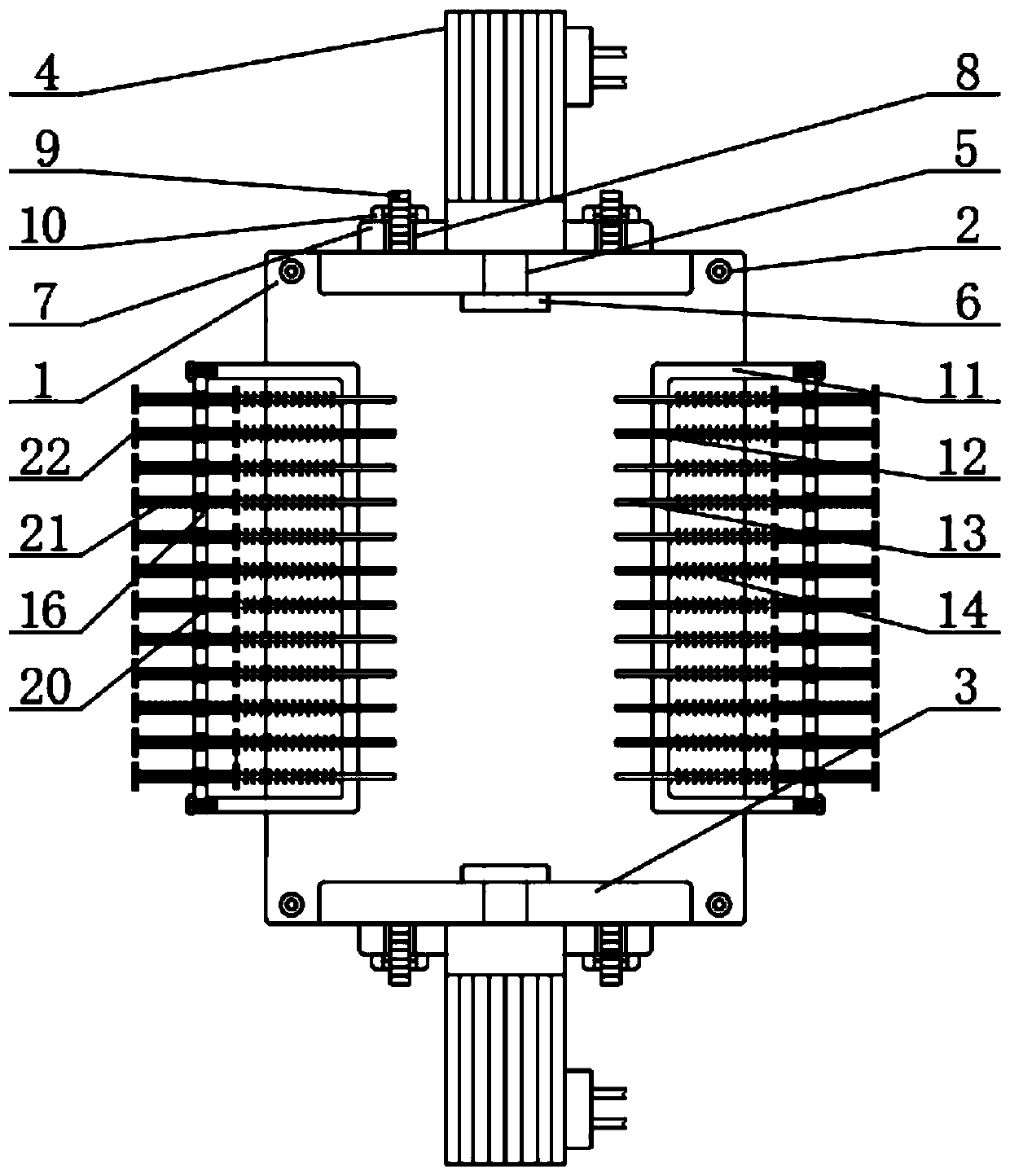

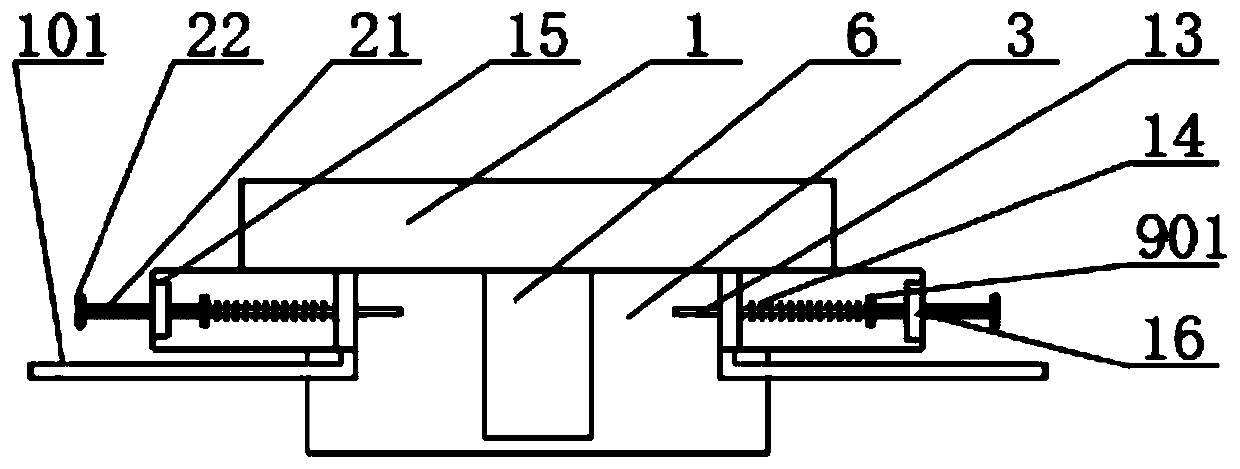

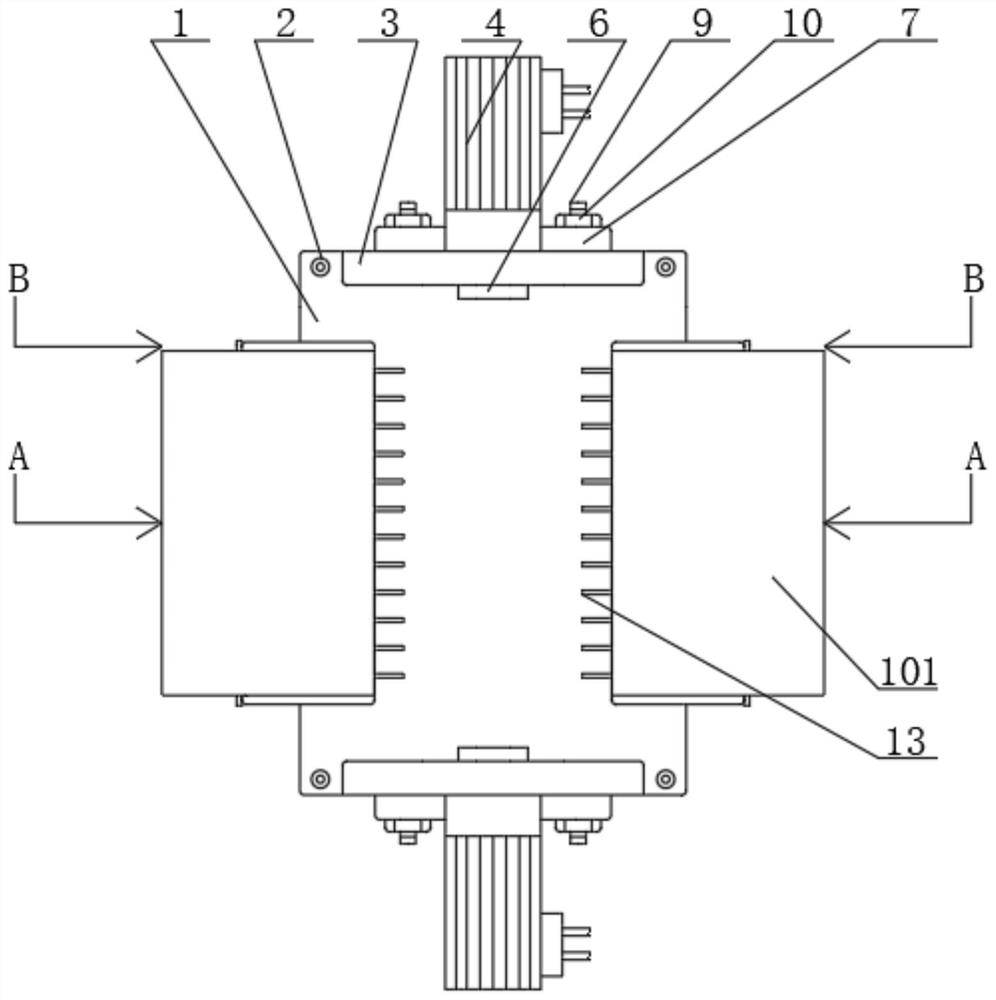

Workpiece processing safety fool-proof device of numerical control machine tool

ActiveCN111360564AGood anti-fooling effectSolve the problem that there is no fool-proof effect for clamping plate-shaped workpiecesPositioning apparatusMetal-working holdersNumerical controlPin distance

The invention discloses a workpiece processing safety fool-proof device of a numerical control machine tool. The workpiece processing safety fool-proof device of the numerical control machine tool comprises a mounting plate and mounting holes arranged on four sides of the mounting plate, wherein support frames are symmetrically arranged on the other two sides of the mounting plate, sliding holes are uniformly formed in one sides of the support frames, limiting pins are inserted into the sliding holes in a penetrating mode, an abutting plate is arranged at one end of each limiting pin, a fixingplate is arranged on the other side of each support frame, screw holes are formed in the fixing plates and correspond to the positions of the sliding holes and are in threaded connection with lead screws, and one end of each lead screw is provided with a rotating plate. By disassembling and assembling the fixing plates, springs can be conveniently replaced. Through the fool-proof limiting of thelimiting pins, a plate-shaped workpiece can only be placed corresponding to the fixed limiting pin distances on the left side and the right side, so that the plate-shaped workpiece can stably contactwith the mounting plate, only one time of adjustment is needed, tool resetting is not needed, safety and high efficiency are achieved, the fool-proof effect is good, and the problem that the fool-proof effect of clamping the plate-shaped workpiece does not exist in the prior art is solved.

Owner:杭州联德精密机械股份有限公司

A safety fool-proof device for workpiece processing of CNC machine tools

ActiveCN111360564BGood anti-fooling effectSolve the problem that there is no fool-proof effect for clamping plate-shaped workpiecesPositioning apparatusMetal-working holdersNumerical controlScrew thread

The invention discloses a safety fool-proof device for workpiece processing of a numerical control machine tool, which comprises a mounting plate and mounting holes arranged on four sides of the mounting plate, support frames are symmetrically installed on the other two sides of the mounting plate, and one side of the support frame is evenly provided with Sliding holes, the limit pins are interspersed in the sliding holes, one end of the limit pins in the support frame is equipped with a pressure plate, the other side of the support frame is equipped with a fixing plate, and the positions of the fixing plates corresponding to each sliding hole are provided with wires. Hole, the screw hole is threadedly connected to the lead screw, and one end of the lead screw is provided with a rotary plate. By disassembling the fixing plate, it is convenient to replace the spring. Through the anti-fooling limit of the limit pin, the plate-shaped workpiece can only be placed corresponding to the fixed limit pin distance on the left and right sides, so that the plate-shaped workpiece can be stably contacted with the mounting plate. Only one adjustment is needed, and there is no need to re-set the tool, which is safer And high efficiency, good anti-fooling effect, solves the problem in the prior art that there is no anti-fooling effect for clamping plate-shaped workpieces.

Owner:杭州联德精密机械股份有限公司

Light sensor component and electronic device with the same

ActiveCN108259647ASmall sizeRealize thinner and lighterTelephone set constructionsLight sensingEngineering

The application discloses a light sensor component and an electronic device with the same. The light sensor comprises a main board, a light-sensing device, and a cover body, wherein the light-sensingdevice is arranged on the main board and connected with the main board; N ridges are formed on the peripheral wall of the light-sensing device; a groove extending along the length direction of the ridges of n adjacent ridges, wherein n is more than 0 and not more than N-1; the cover body is covered on the light-sensing device, the inner peripheral wall of the cover body is cooperated with the peripheral wall of the light-sensing device, and a bulge cooperated with the groove is arranged at n adjacent ridges corresponding to the groove on the inner peripheral wall of the cover body, and the bulge extends along the length direction of the ridge of the cover body. According to the light-sensor component disclosed by the application, an operation of reversely installing the cover when the light-sensing device is assembled can be prevented, and good poka-yoke effect is provided. Furthermore, the connection fixation of the cover body and the light-sensing device can be realized through the cooperation of the groove and the bulge, the size of the light-sensor component can be reduced, and the occupied space in the electronic device is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

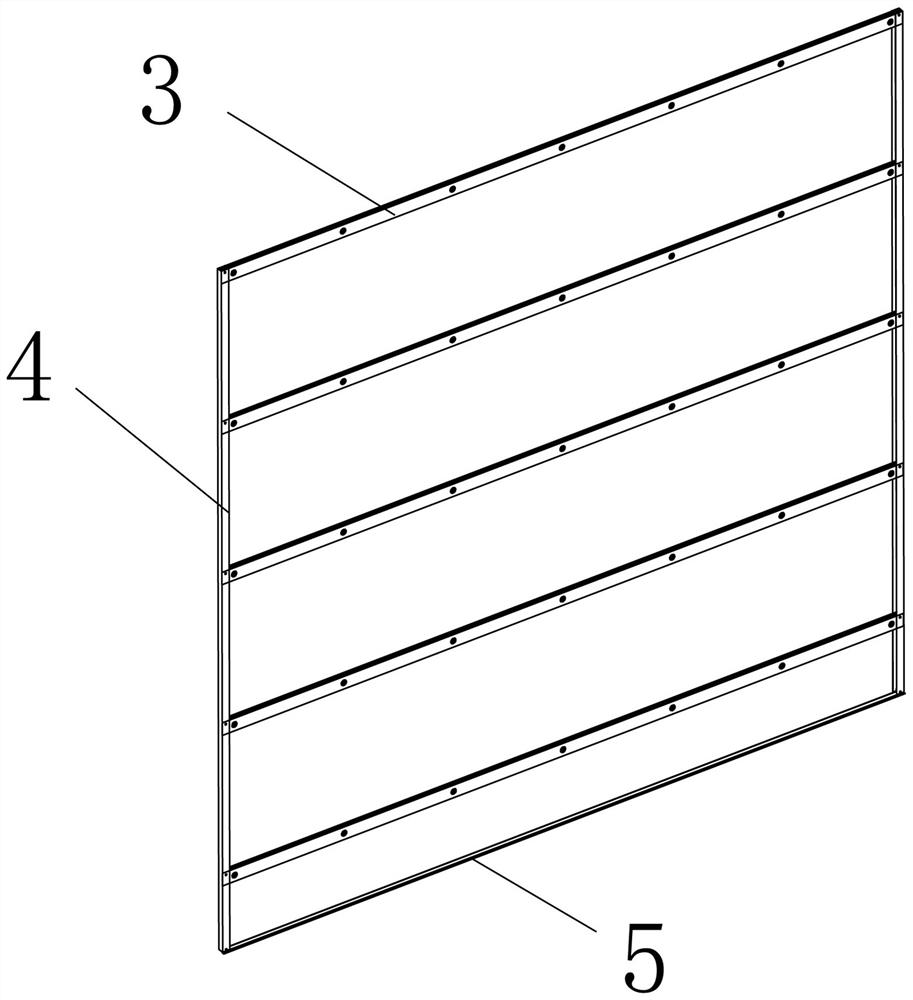

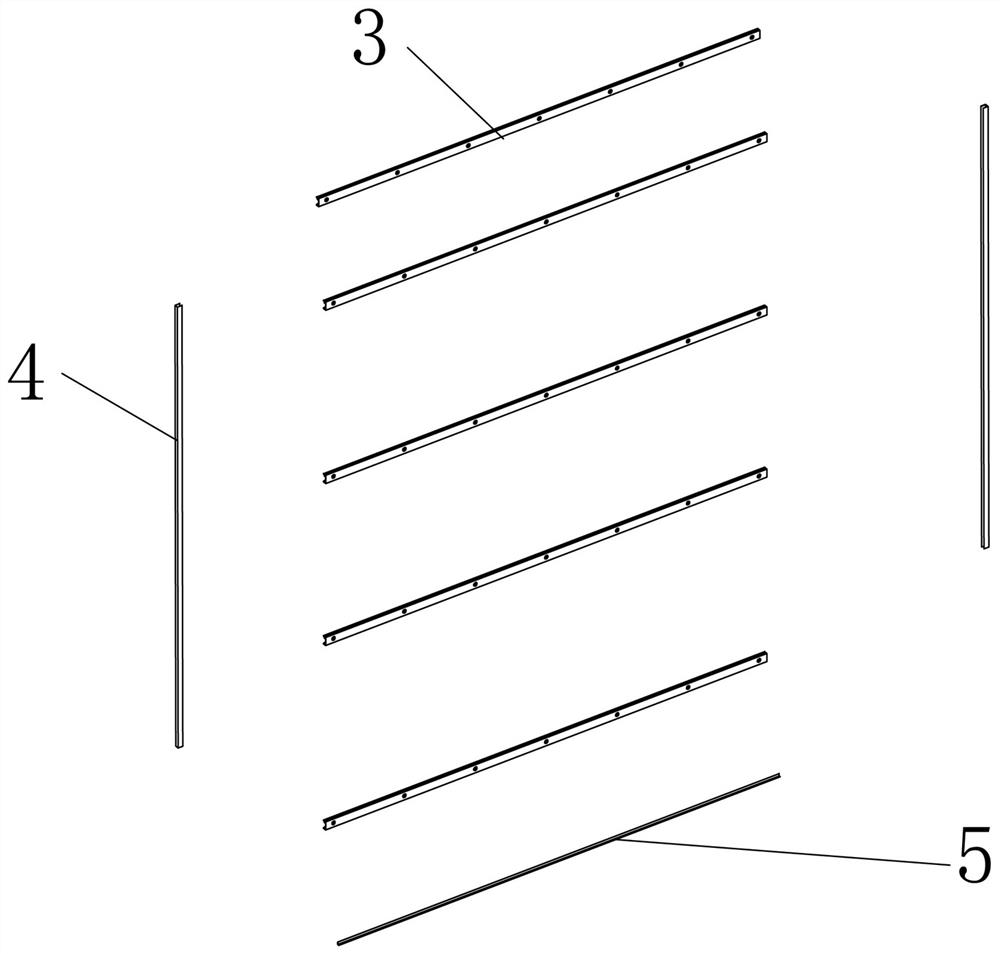

Leveling frame structure and installation method thereof

PendingCN112575990ASimple structureIncrease productivityCovering/liningsEngineeringMechanical engineering

The invention discloses a leveling frame structure and an installation method thereof. The leveling frame structure specifically comprises an original wall surface and further comprises a leveling keel frame used for being laid on the original wall surface, wherein the leveling keel frame comprises horizontally-arranged transverse strips, vertically-arranged U-shaped keels and L-shaped angle steelarranged at the bottom of the original wall surface; the two ends of each transverse strip are embedded into the two corresponding U-shaped keels to form the frame structure; and when the leveling keel frame is vertically laid on the original wall surface, the spacing distances between every two adjacent transverse strips are equal, the two ends of the uppermost transverse strip are fixedly connected with the top ends of the two corresponding U-shaped keels correspondingly, and the bottom ends of the two corresponding U-shaped keels are fixedly connected with the two ends of the angle steel correspondingly. According to the leveling frame structure, the L-shaped angle steel, the U-shaped keels, metal keels, supporting bases and wood-plastic insertion strips can be assembled and produced in batches in a factory, efficiency is high, and the leveling frame structure can be applied to various different occasions.

Owner:ZHEJIANG YASHA DECORATION

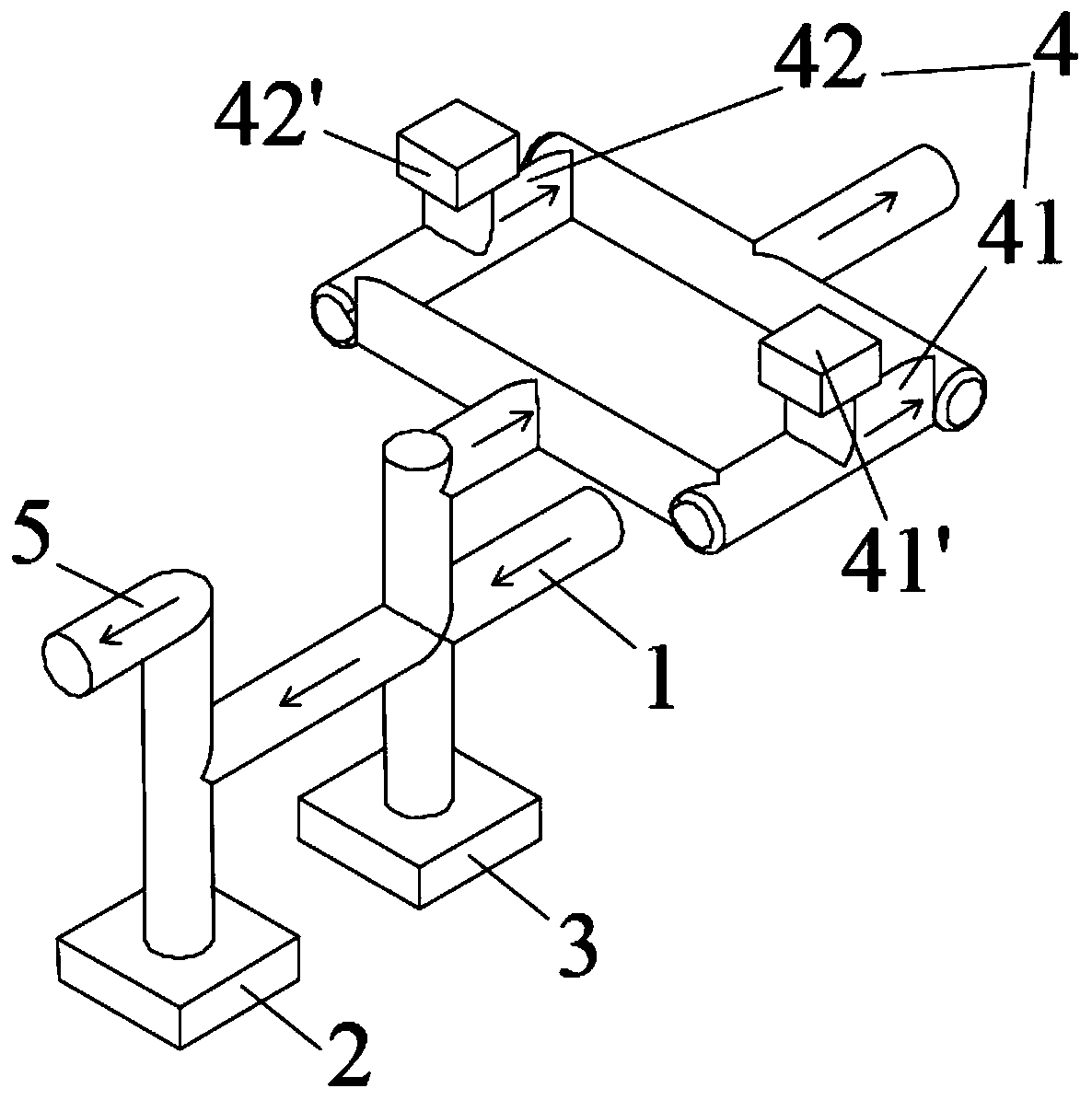

Jig and method adopting jig in mounting of magnets of mobile terminal

The invention discloses a jig and a method adopting the jig in mounting of magnets of a mobile terminal. The mobile terminal comprises a target component, wherein the target component comprises mounting parts used for mounting of the magnets. The jig comprises a main body part and fool-proof magnetic pieces, wherein the main body part is used for positioning the target component; the fool-proof magnetic pieces are arranged on the main body part; when the target component is positioned by the main body part, the fool-proof magnetic pieces are opposite to the mounting parts, and suitable for generating magnetic functions with the magnets, so as to pop the magnets out of the mounting parts when the magnets are mounted reversely. The jig provided by the embodiment of the invention has the advantages that mounting of the magnets can be simplified; the fool-proof effect is high; mistaken assembly of operation staff can be prevented effectively; the process of checking after assembly is eliminated; the production efficiency is high; the product yield is high.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Positioning means

Owner:HANWIT PRECISION IND LTD

Protective mounting shell based on new energy networked automobile control gateway

InactiveCN112406742AReduce impactBuffer slider to buffer the impact force up and downEngagement/disengagement of coupling partsIncorrect coupling preventionNew energyStructural engineering

The invention discloses a protective mounting shell based on a new energy networked automobile control gateway, relates to the technical field of automobile parts, and solves the problems that parts in a gateway are easy to loosen or damage, the gateway is invalid, the working stability of the gateway is influenced, a gateway connecting cable is prone to loosening due to vibration, and the workingstability is affected. The protective mounting shell comprises a fixed mounting base; and an upper and lower buffer seat pair is in sliding connection to the top of thefixed mounting base. Vibrationborne by the gateway can be effectively reduced, all components in the gateway can be better protected, gateway failure caused by vibration is prevented, working stability is guaranteed, connection cables are effectively prevented from loosening through threaded connection, and meanwhile, a good waterproof effect is ensured between the connecting cable and the control gateway main body, and the interface has a good fool-proof effect and is more convenient to install and use.

Owner:孙方义

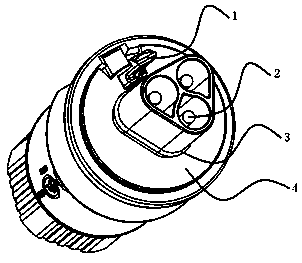

Rotary quick connector for lamp holder of miner lamp

PendingCN113612064AImprove fault toleranceImprove reliabilityEngagement/disengagement of coupling partsSecuring/insulating coupling contact membersElectrical connectionLight head

The invention relates to a rotary quick connector for a lamp holder of a miner lamp, which belongs to the technical field of mining equipment and comprises a female head and a male head which are matched with each other. A plug is arranged on the outer side of the female head, the female head is arranged on a plug connecting end of the plug, the plug connecting end is provided with external threads, an equipment body is arranged on the outer side of the male head, a plug interface is formed in the equipment body, the male head is arranged at the bottom of the plug interface, and internal threads corresponding to the external threads are arranged on the inner wall of the plug interface; an annular groove is formed in the female head, a female head conductive contact piece is arranged in the annular groove, a male head conductive contact piece is arranged on the male head, and a contact piece bending end is arranged on the male head conductive contact piece. The bent end of the contact piece of the male head of the rotary quick connector for the lamp holder of the miner lamp can rotate in the annular groove of the female head, and normal electric connection can still be ensured in the rotating process, so that the fault tolerance during butt joint of the male head and the female head is improved, disassembly and assembly are safer and more reliable, and the beneficial effect is remarkable.

Owner:SHANGHAI SHANYUAN ELECTRONICS SCI & TECH CO LTD

Photosensor component and electronic device having same

ActiveCN108259647BSmall sizeRealize thinner and lighterTelephone set constructionsEngineeringMechanical engineering

The application discloses a light sensor component and an electronic device with the same. The light sensor comprises a main board, a light-sensing device, and a cover body, wherein the light-sensingdevice is arranged on the main board and connected with the main board; N ridges are formed on the peripheral wall of the light-sensing device; a groove extending along the length direction of the ridges of n adjacent ridges, wherein n is more than 0 and not more than N-1; the cover body is covered on the light-sensing device, the inner peripheral wall of the cover body is cooperated with the peripheral wall of the light-sensing device, and a bulge cooperated with the groove is arranged at n adjacent ridges corresponding to the groove on the inner peripheral wall of the cover body, and the bulge extends along the length direction of the ridge of the cover body. According to the light-sensor component disclosed by the application, an operation of reversely installing the cover when the light-sensing device is assembled can be prevented, and good poka-yoke effect is provided. Furthermore, the connection fixation of the cover body and the light-sensing device can be realized through the cooperation of the groove and the bulge, the size of the light-sensor component can be reduced, and the occupied space in the electronic device is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Rotor assembly, solenoid valve, ir-cut switch and iris aperture

ActiveCN106439174BEliminate dispensing processIncreased rotational pull-out forceOperating means/releasing devices for valvesPermanent magnetsPull forceSolenoid valve

The invention discloses a rotor component, an electromagnetic valve, an IR-CUT switcher and an IRIS aperture, and relates to the technical field of electromagnets, IR-CUT switchers and IRIS aperture driving devices. The rotor component comprises a crank, a shaft core and a permanent magnet, wherein the shaft core is fixed on the crank or passes through the crank and is fixedly connected with a device outside the rotor component; a block is arranged on the crank and is coaxial to the shaft core; the permanent magnet has an annular structure; two planes are arranged on the outer side wall of the permanent magnet and are relatively parallel; and when the permanent magnet is arranged on the crank in a sleeving manner, the plane on the side wall of the permanent magnet is in direct contact with the plane on the inner wall of the permanent magnet. According to the rotor component, a dispensing process between the permanent magnet and the crank can be reduced, fool-proofing spacing is carried out for the permanent magnet structurally, the magnetic poles of the permanent magnet are marked, and the rotation pulling force between the crank and the permanent magnet is large. The rotor component has the advantages of high stability, high uniformity, high accuracy, simple process, high efficiency, good operability and excellent automation.

Owner:东莞市维斗科技股份有限公司

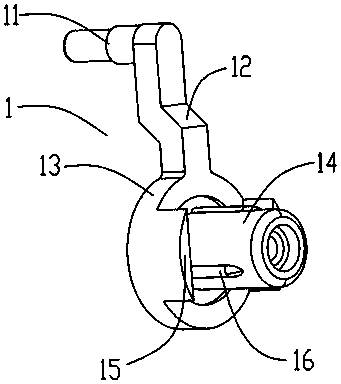

Anti-break mortice door lock head

InactiveCN111550126AHigh strengthPrevent interrupts onCylinder locksEngineeringStructural engineering

Owner:淮南普玖机械设备有限公司

Adsorption device

ActiveCN106865229BEasy to operateNot easy to changeCharge manipulationConveyor partsLower limitEngineering

The invention provides an adsorbing device. The adsorbing device comprises a tube body, an adsorbing disc, a piston, a sealing part, a pressing part, an elastic part and a positioning assembly, wherein an accommodating cavity is arranged inside the tube body; the adsorbing disc is arranged on the end part of the tube body and communicates with the accommodating cavity; the piston is arranged in the accommodating cavity and sequentially moves back and forth among an upper limit position, a middle position and a lower limit position along the tube body; the sealing part is arranged between the piston and the tube body; the pressing part is arranged at one end of the tube body in a penetrating mode, and is used for pushing the piston to move towards the lower limit position under action of pressure; the elastic part is arranged in the accommodating cavity and is used for continuously applying force towards the pressing part to the piston; and the positioning assembly is matched with the elastic part after the piston moves to the lower limit position, and is used for positioning the piston to the middle position or the upper limit position. The adsorbing device disclosed by the invention can be used for improving adsorbing stability and the fool-proof effect.

Owner:BOE TECH GRP CO LTD +1

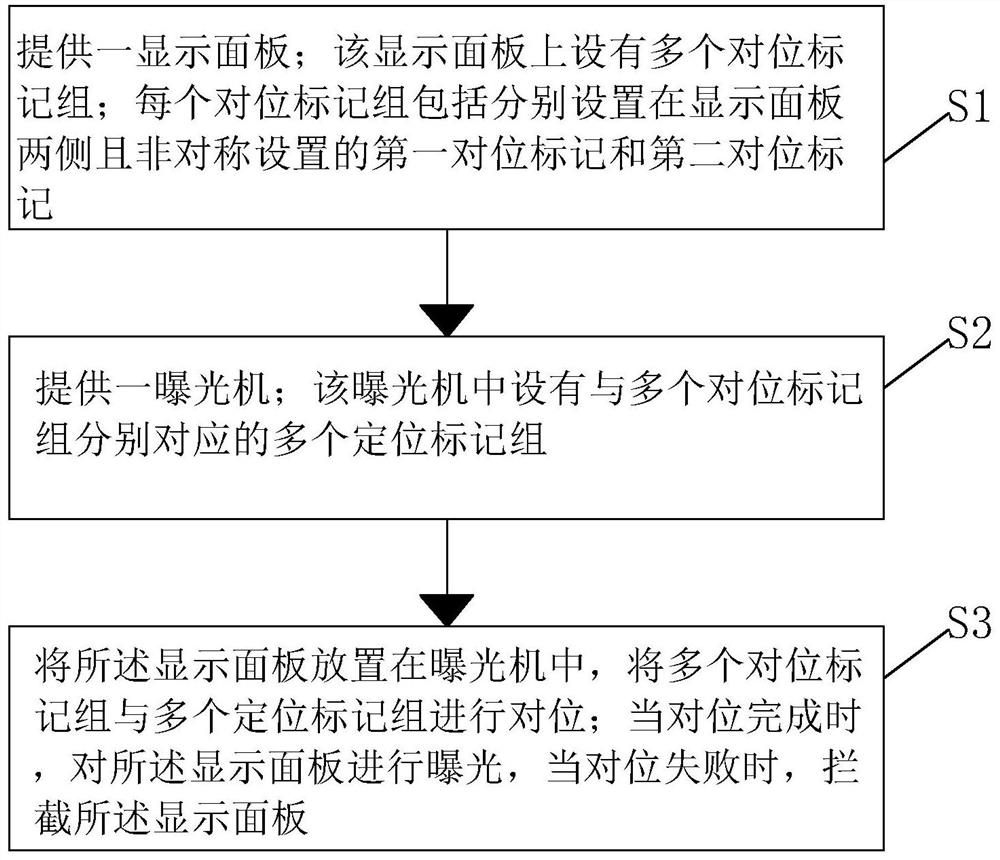

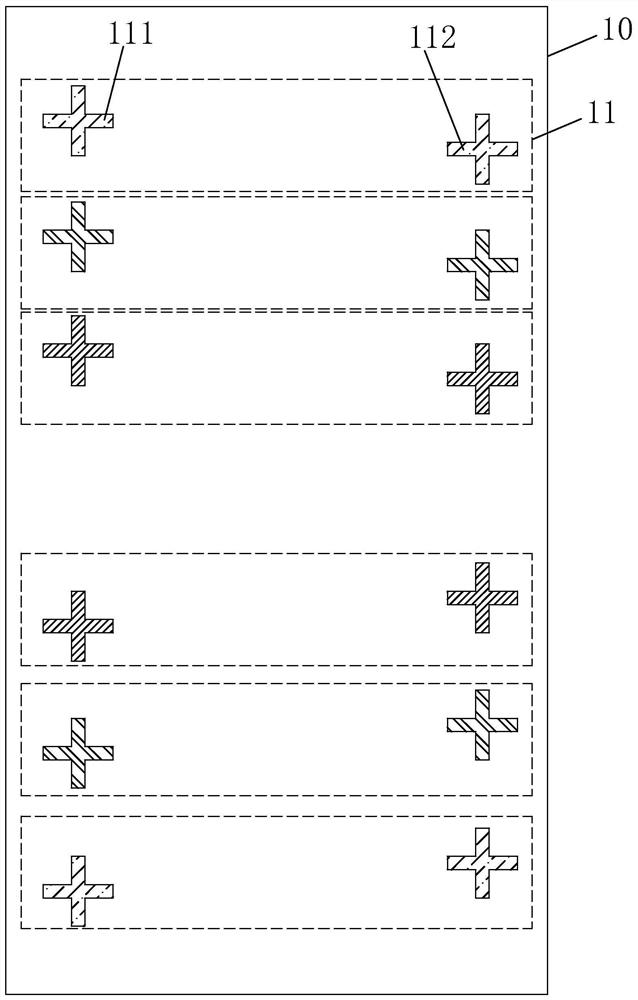

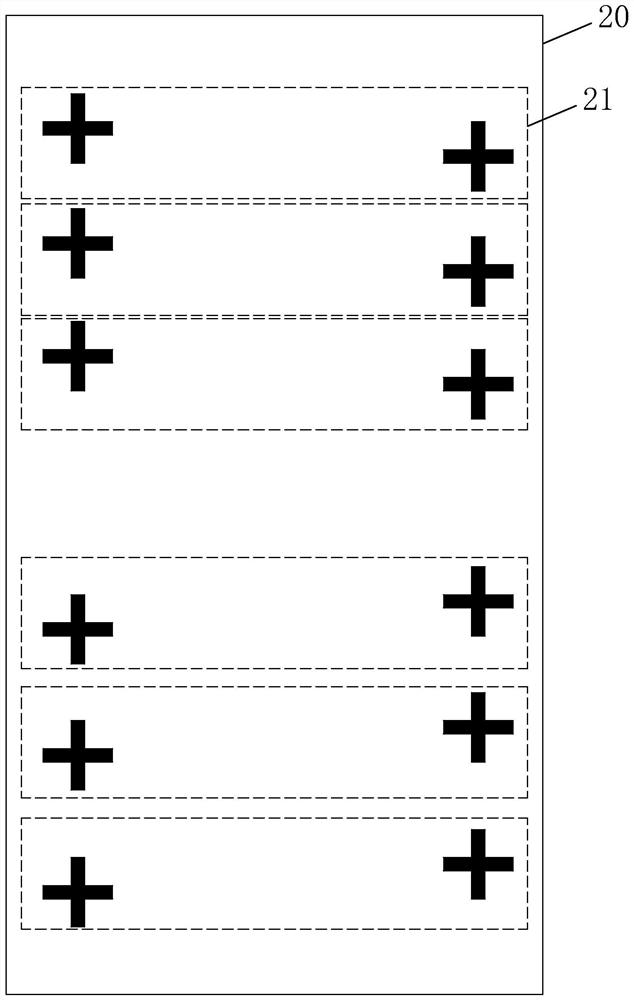

Display panel exposure alignment method and display panel

ActiveCN110568734BAvoid exposurePrevent exposure anomaliesSemiconductor/solid-state device detailsSolid-state devicesComputer graphics (images)Engineering

The invention provides a display panel exposure alignment method and a display panel. In the display panel exposure alignment method, a plurality of alignment mark groups are provided on the display panel; each alignment mark group includes a first alignment mark and a second alignment mark that are respectively arranged on both sides of the display panel and are asymmetrically arranged. mark, a plurality of alignment mark groups corresponding to a plurality of alignment mark groups are provided in the exposure machine; the display panel is placed in the exposure machine, and the plurality of alignment mark groups are aligned with the plurality of alignment mark groups When the alignment is completed, the display panel is exposed, and when the alignment fails, the display panel is intercepted to avoid exposing the turned display panel, which has a good fool-proof effect.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com