Patents

Literature

223results about How to "The same thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

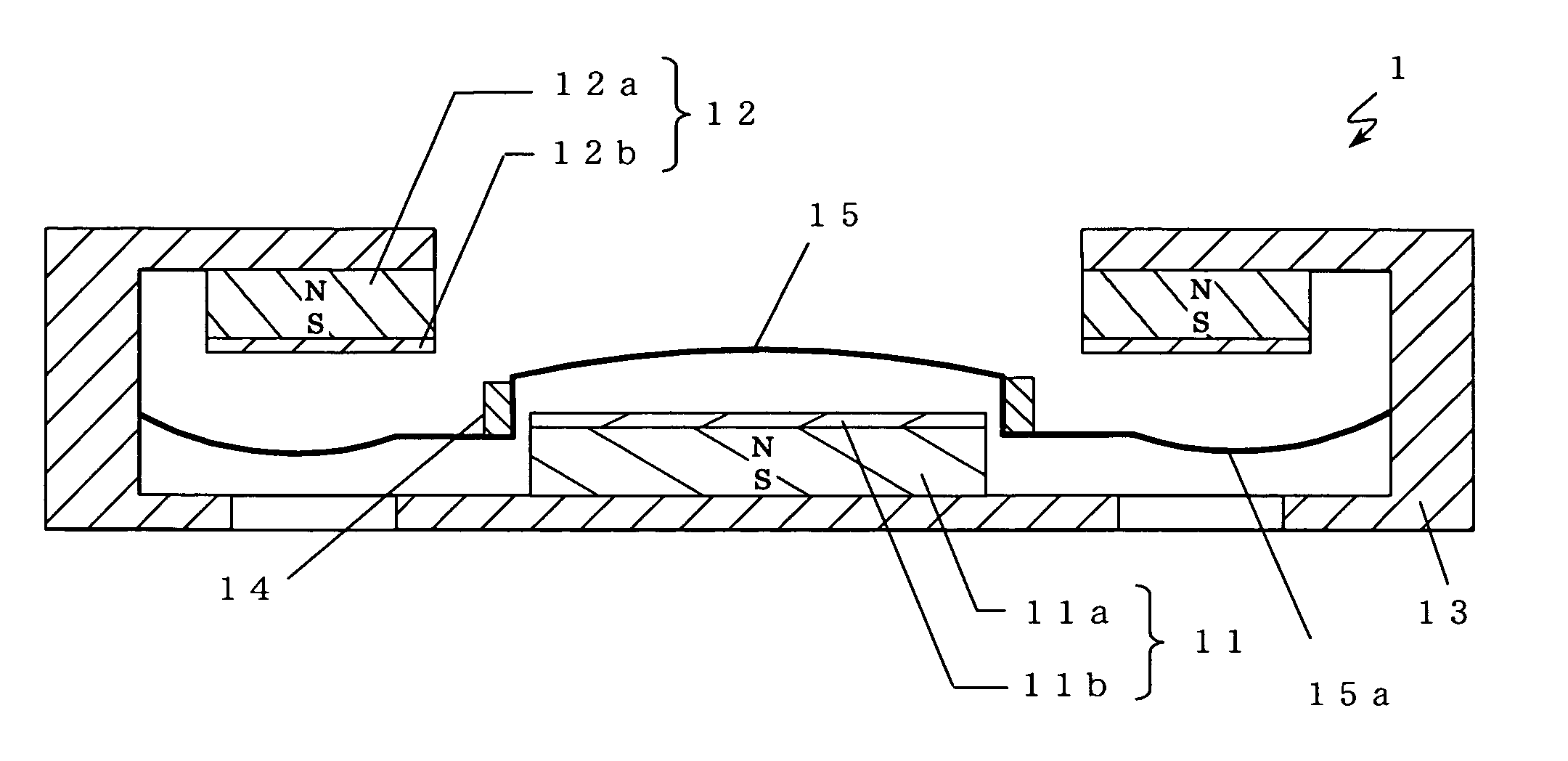

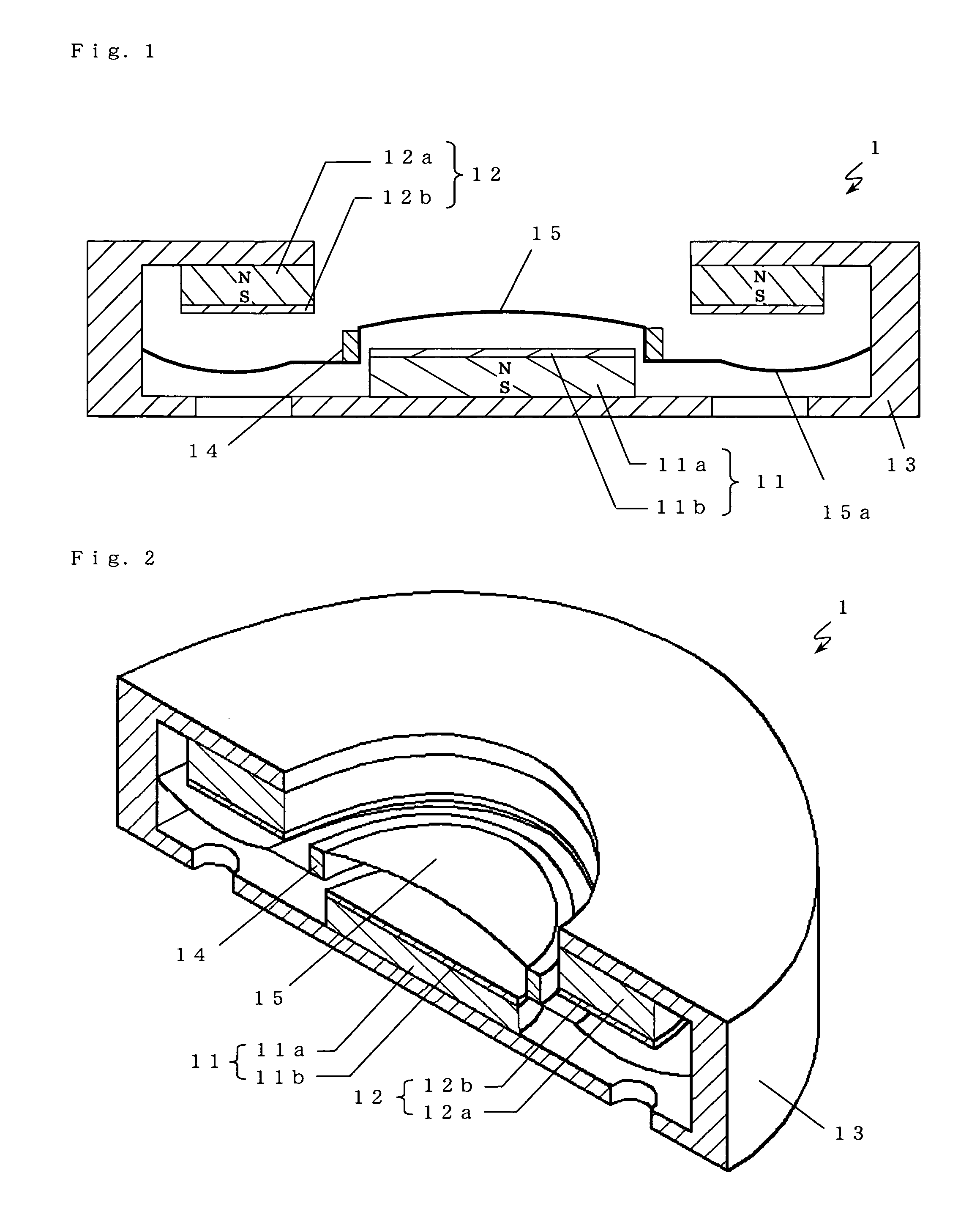

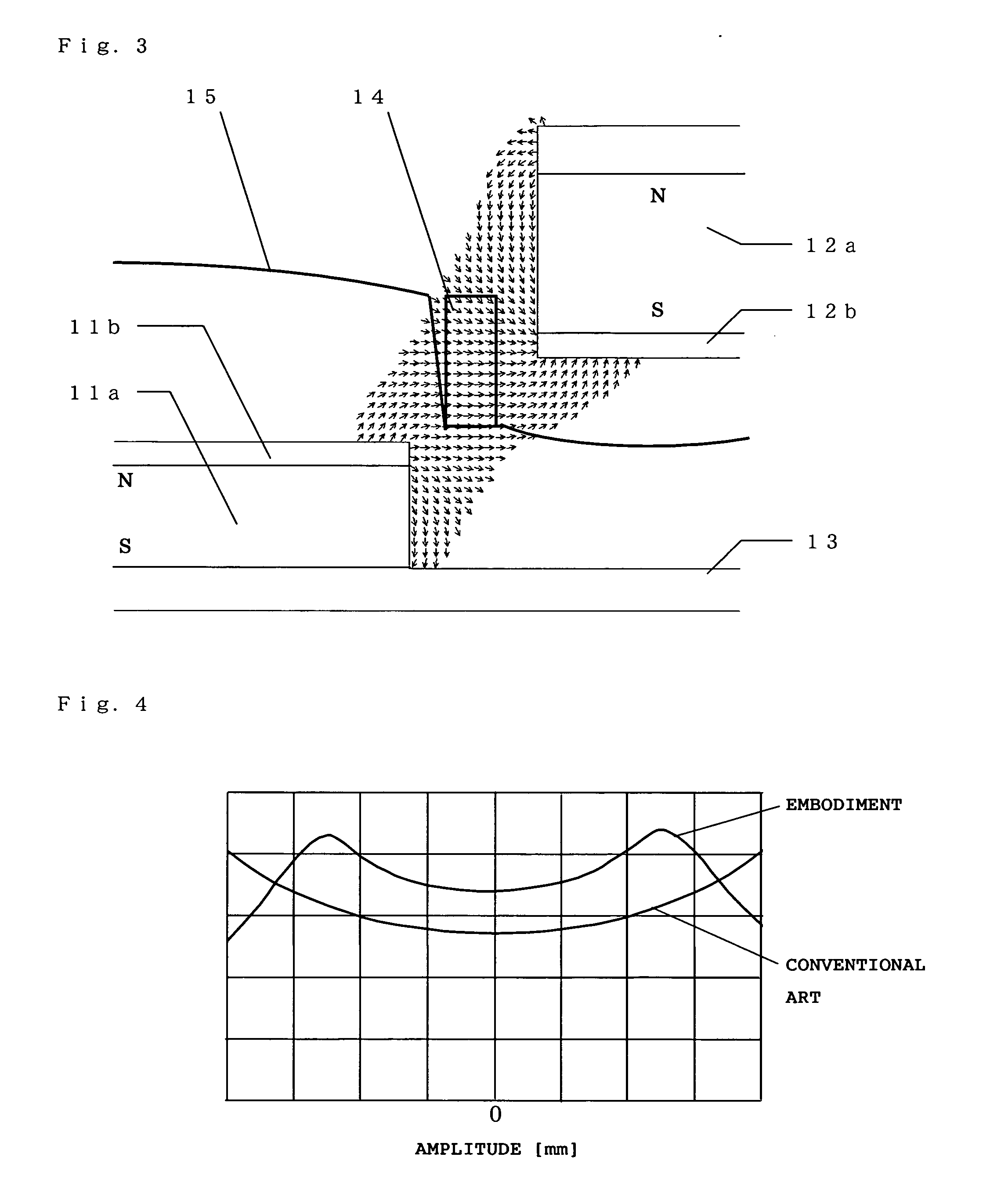

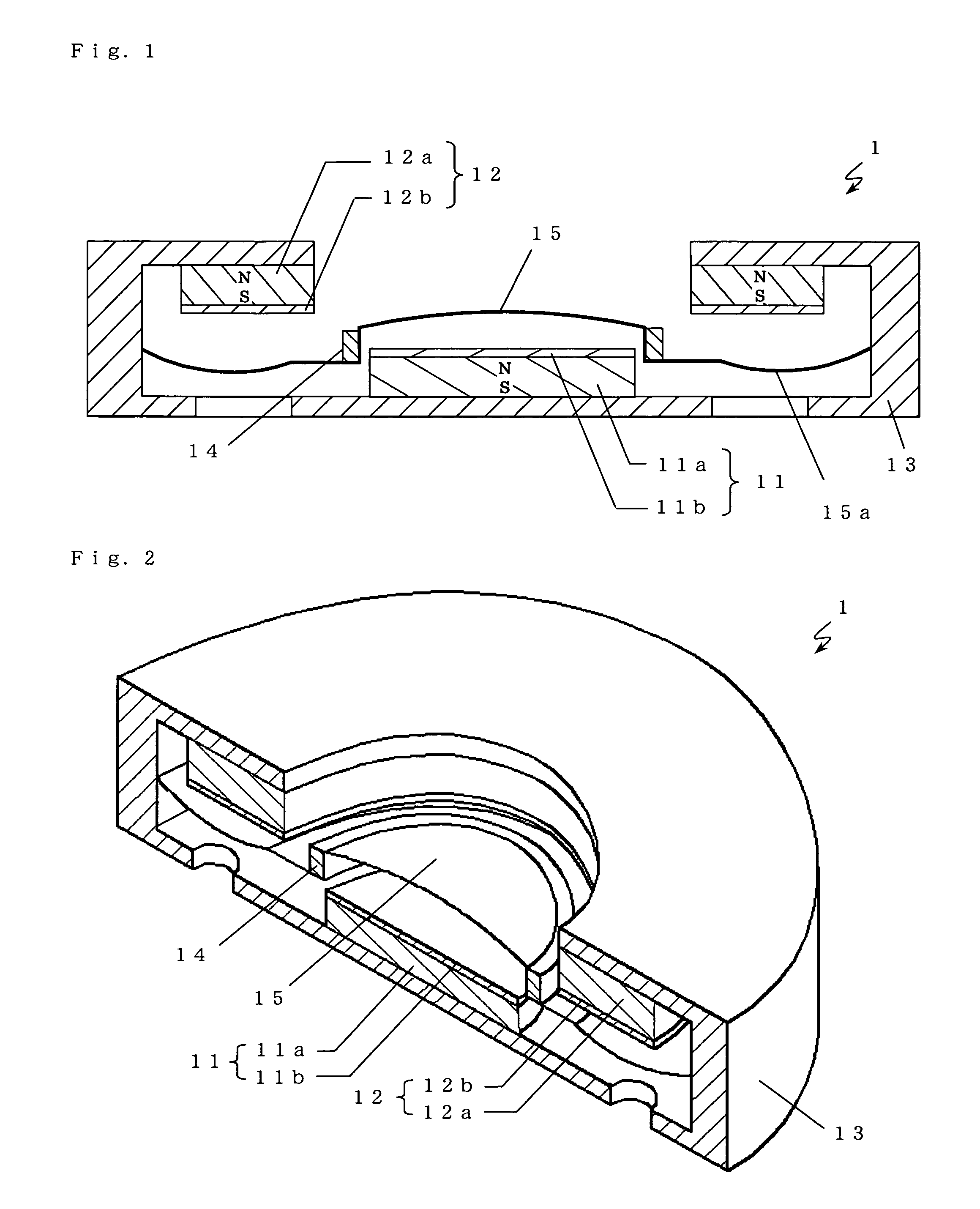

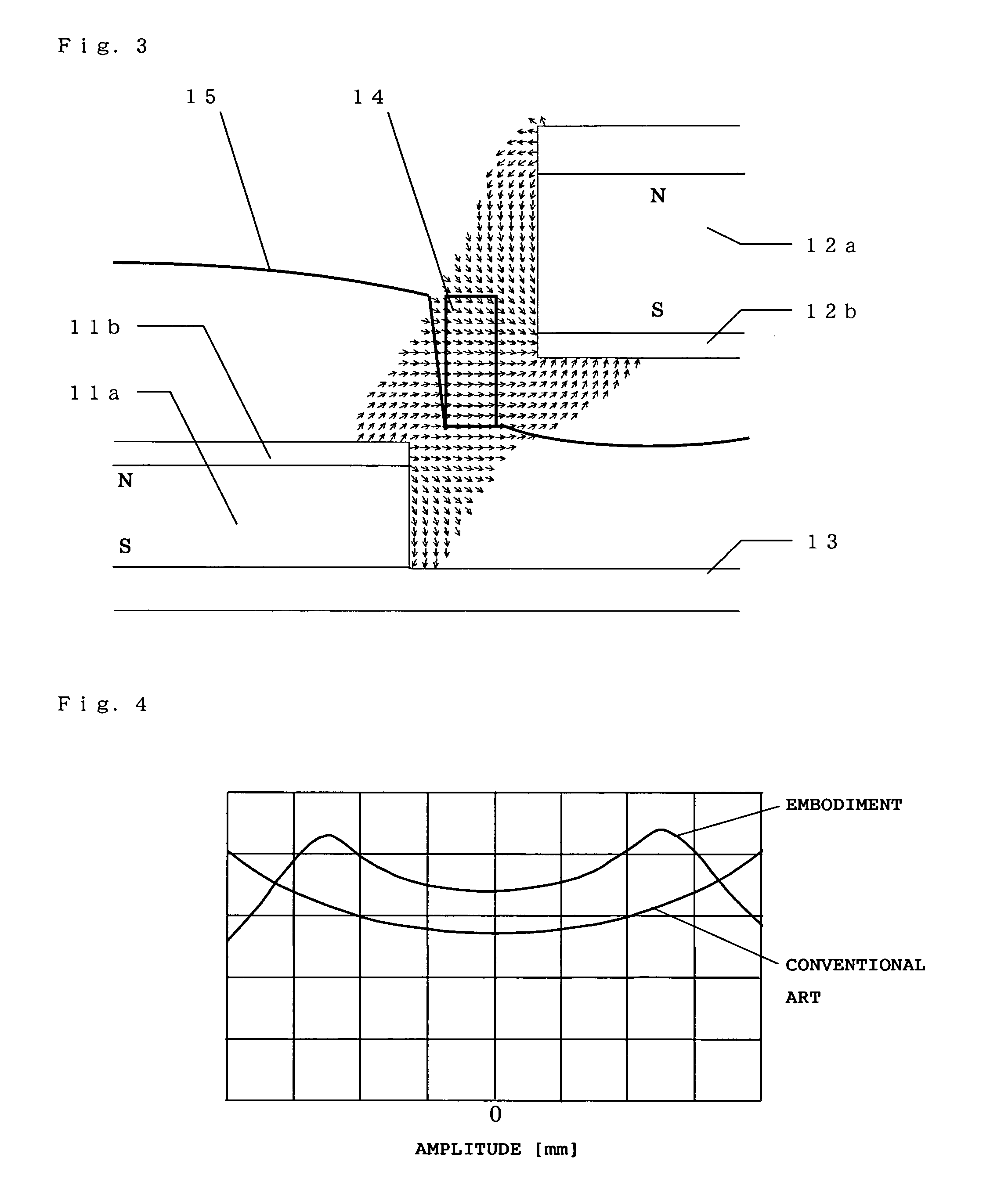

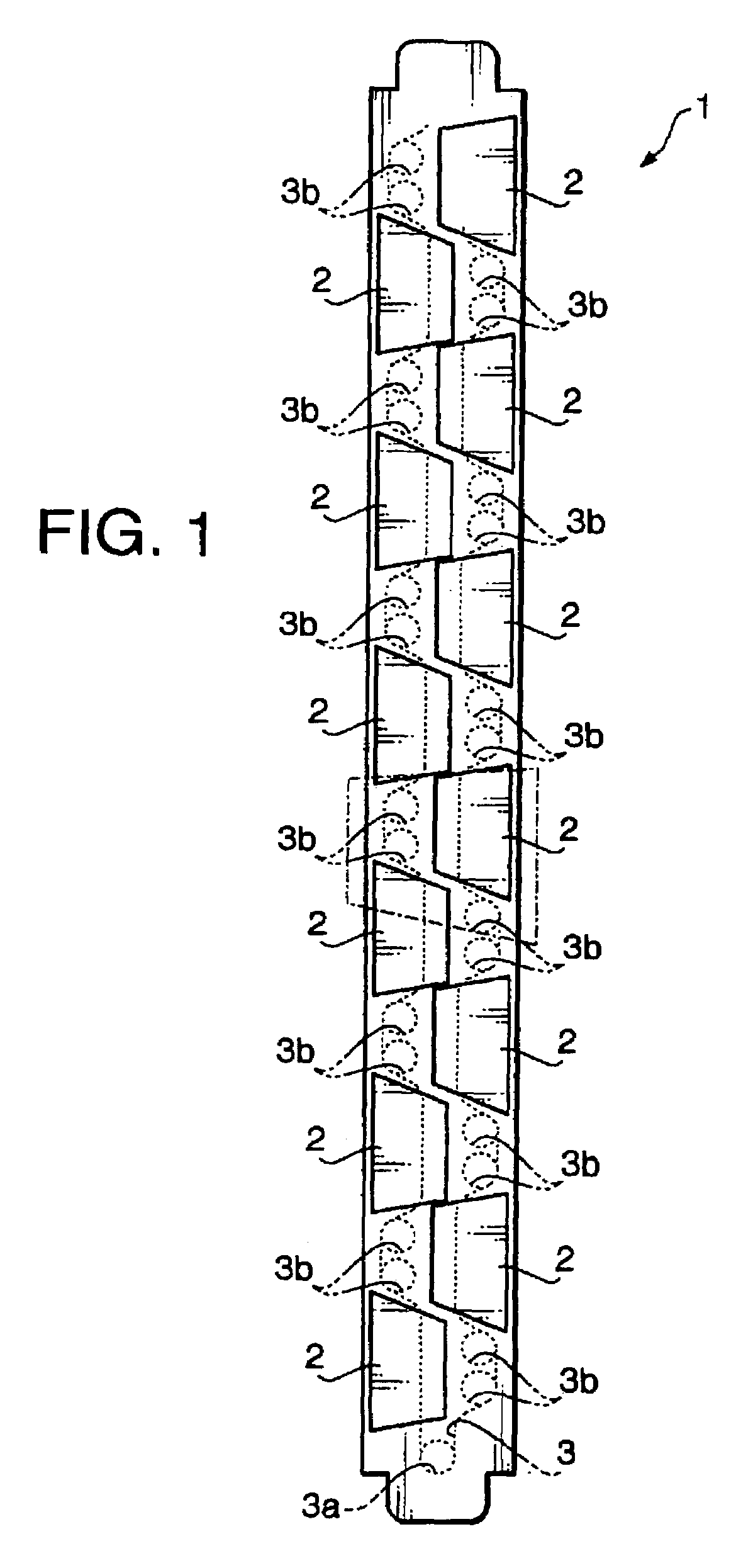

Electrodynamic electroacoustic transducer and electronic device

ActiveUS20070165902A1High magnetic flux densityImprove performanceTransducer detailsTransducerMagnetic poles

An electrodynamic electroacoustic transducer comprises: a first magnetic pole; a second magnetic pole that forms a magnetic gap between itself and the first magnetic pole and is arranged in a space excluding spaces in upper and lower face directions of the first magnetic pole; a yoke; a diaphragm; and a voice coil. The yoke magnetically couples one magnetic pole face of the first magnetic pole with one magnetic pole face of the second magnetic pole so as to support them. The diaphragm is arranged in a space in an upper face direction of the first magnetic pole and in a space in a lower face direction of the second magnetic pole, while its outer periphery is supported by the yoke. The voice coil is arranged in the magnetic gap and adhered to the diaphragm. At least one of the first magnetic pole part and the second magnetic pole part includes a magnet.

Owner:PANASONIC CORP

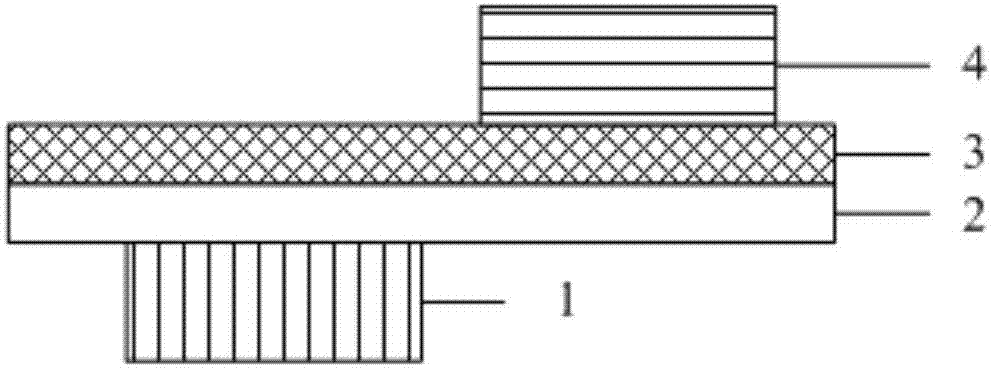

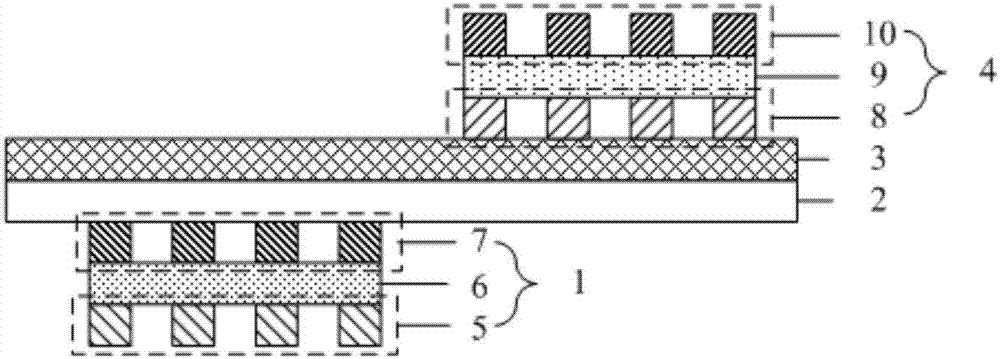

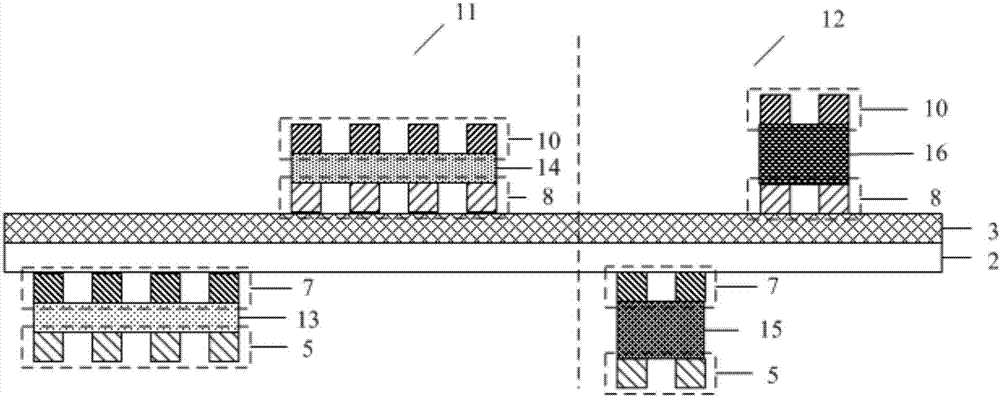

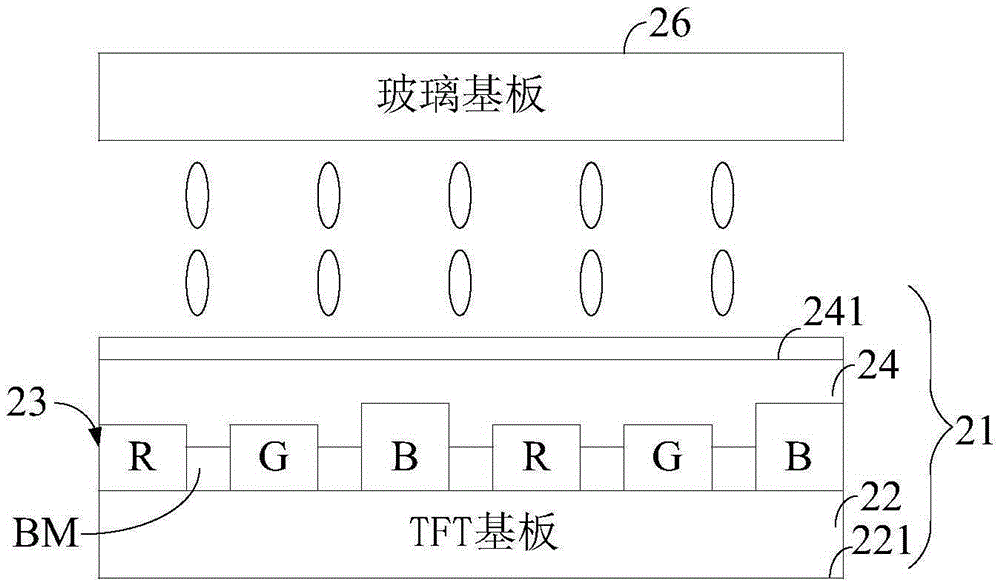

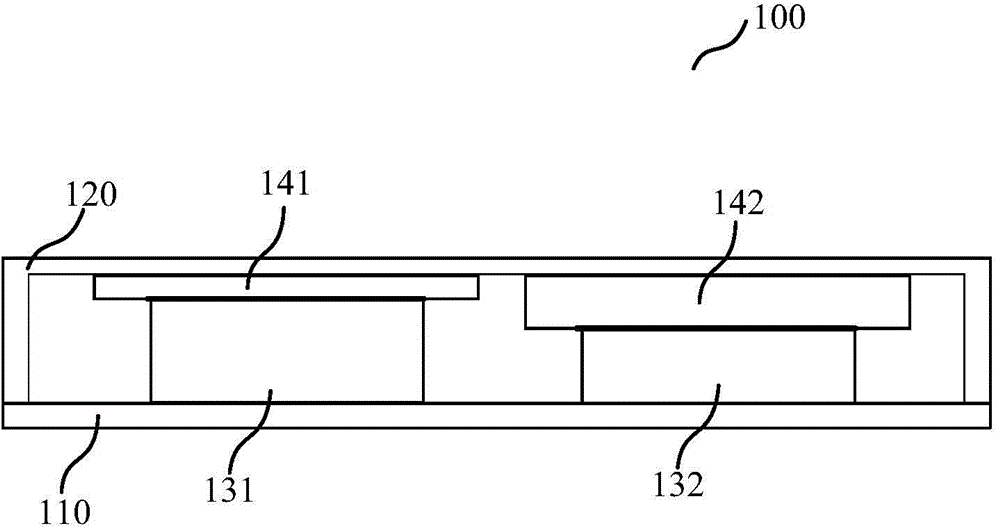

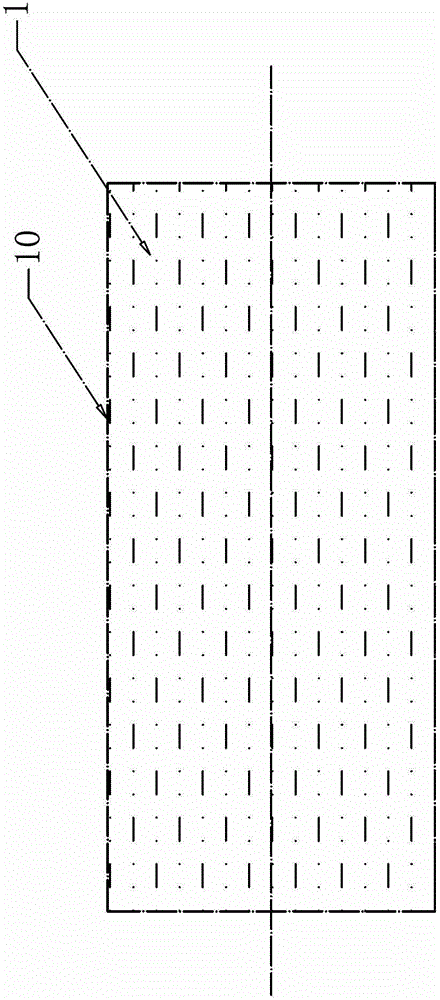

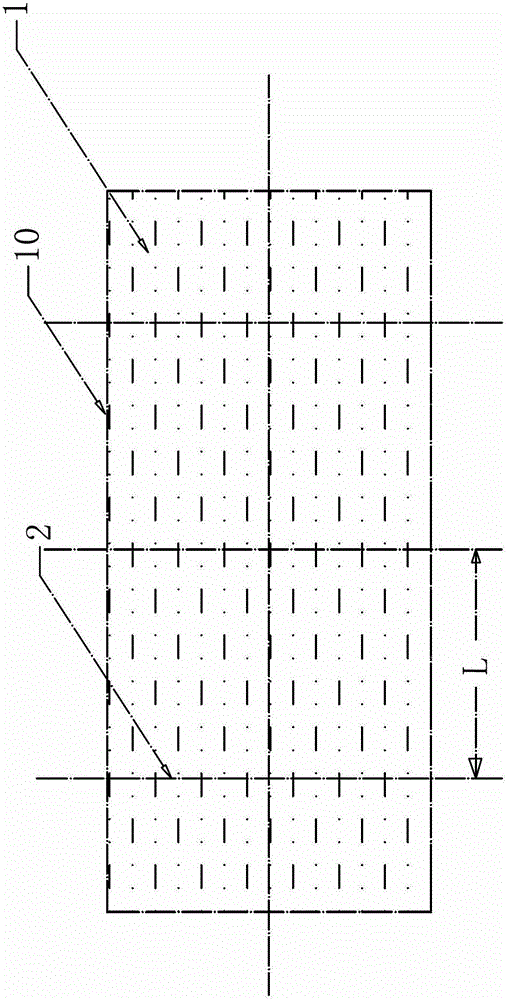

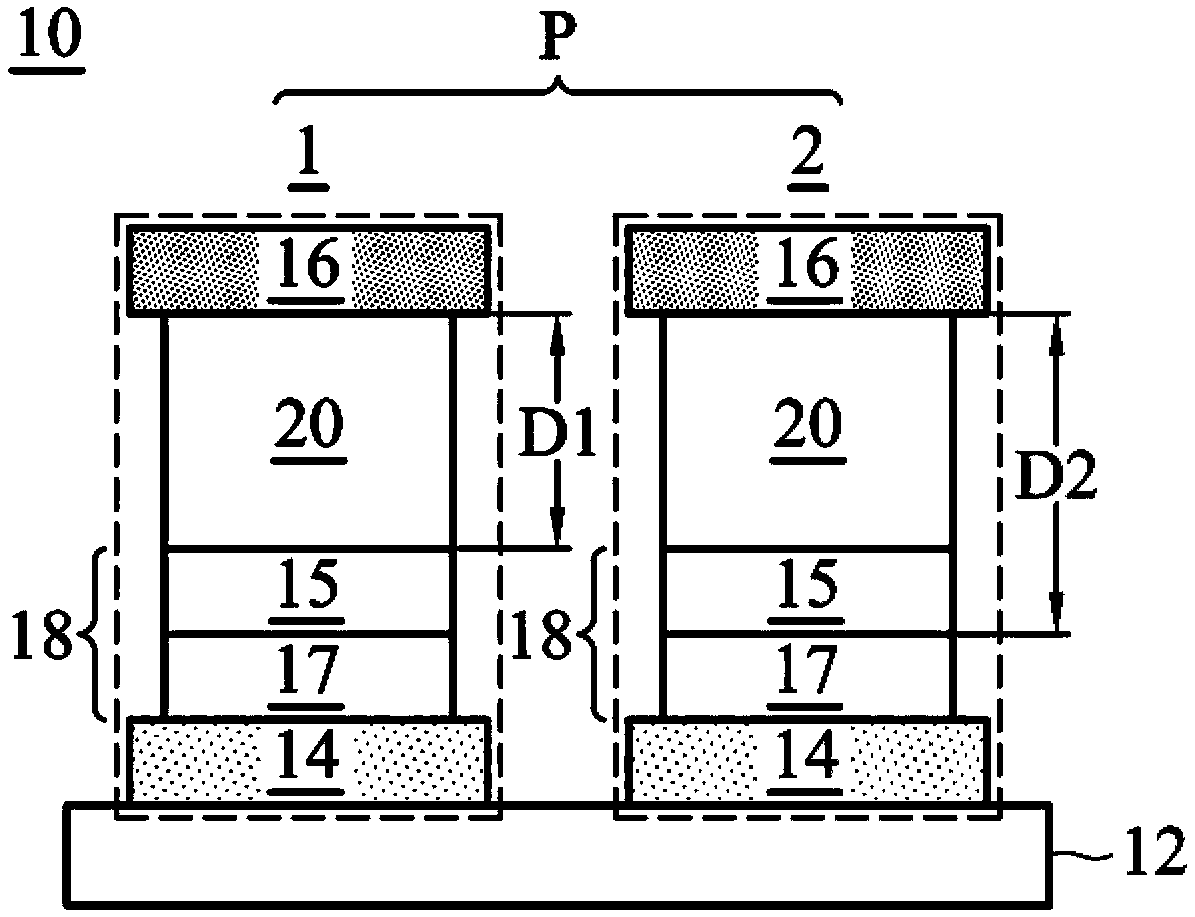

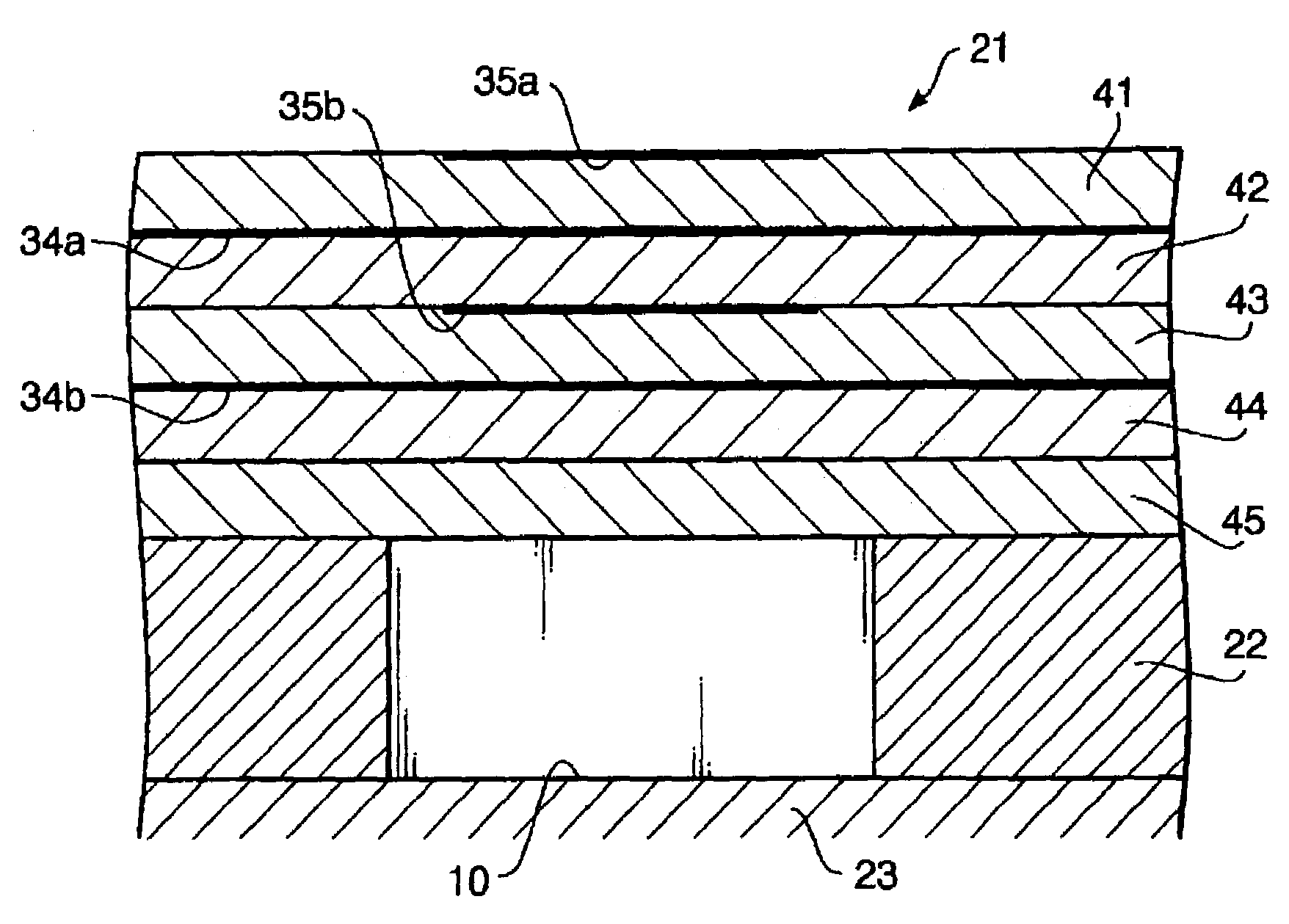

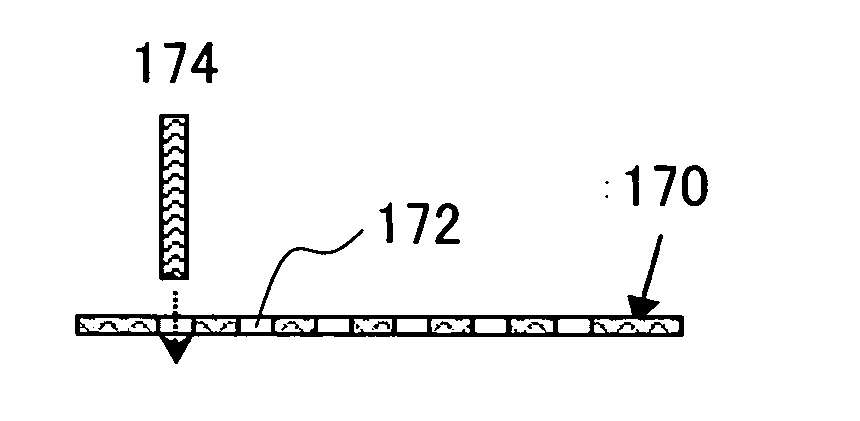

Array substrate, display panel, display device and preparation method for array substrate

ActiveCN106951130AIncrease the use of added valueRaise the natural frequencySolid-state devicesPrint image acquisitionUltrasonic sensorDisplay device

The invention provides an array substrate, a display panel, a display device and a preparation method for the array substrate and is used for integrating a gesture identification and / or fingerprint identification ultrasonic sensor and the array substrate. According to the array substrate, on the basis of realizing a display function, gesture identification and / or fingerprint identification can be realized, so an application additional value of the array substrate is increased. The array substrate provided by the embodiment of the invention comprises an ultrasonic transmitting sensor, a glass substrate on the ultrasonic transmitting sensor, a thin film transistor TFT pixel circuit layer on the glass substrate, and an ultrasonic receiving sensor which is arranged on the TFT pixel circuit layer and is electrically connected with the TFT pixel circuit layer, wherein projections of the ultrasonic transmitting sensor and the ultrasonic receiving sensor vertical to the direction of glass substrate are not overlapped.

Owner:BOE TECH GRP CO LTD

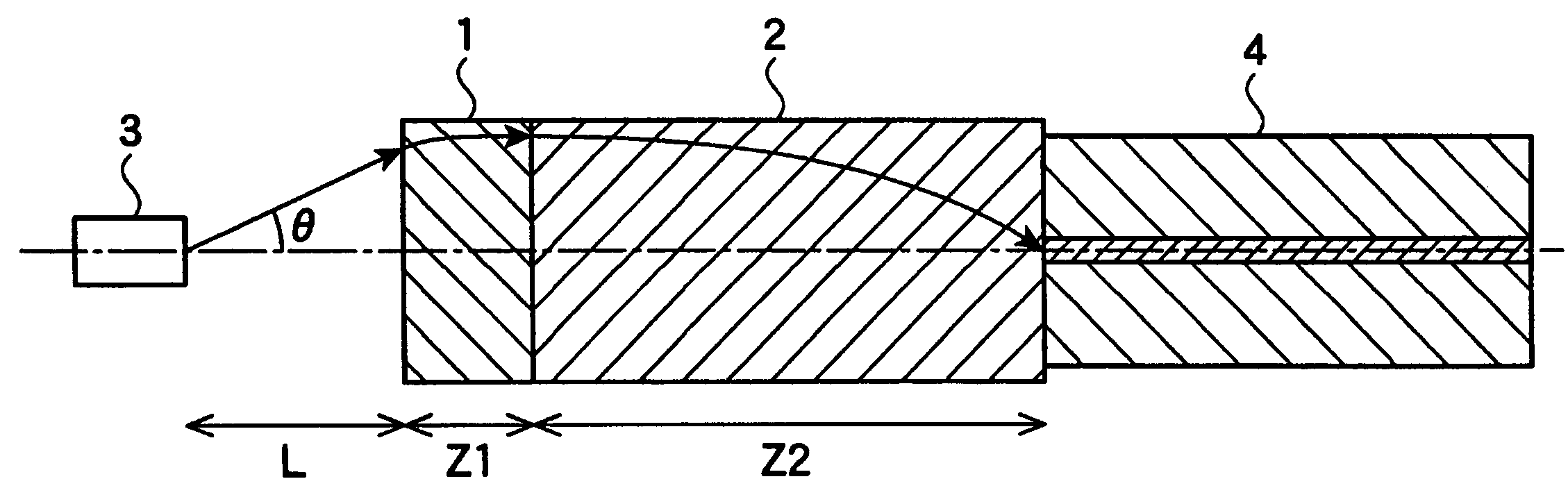

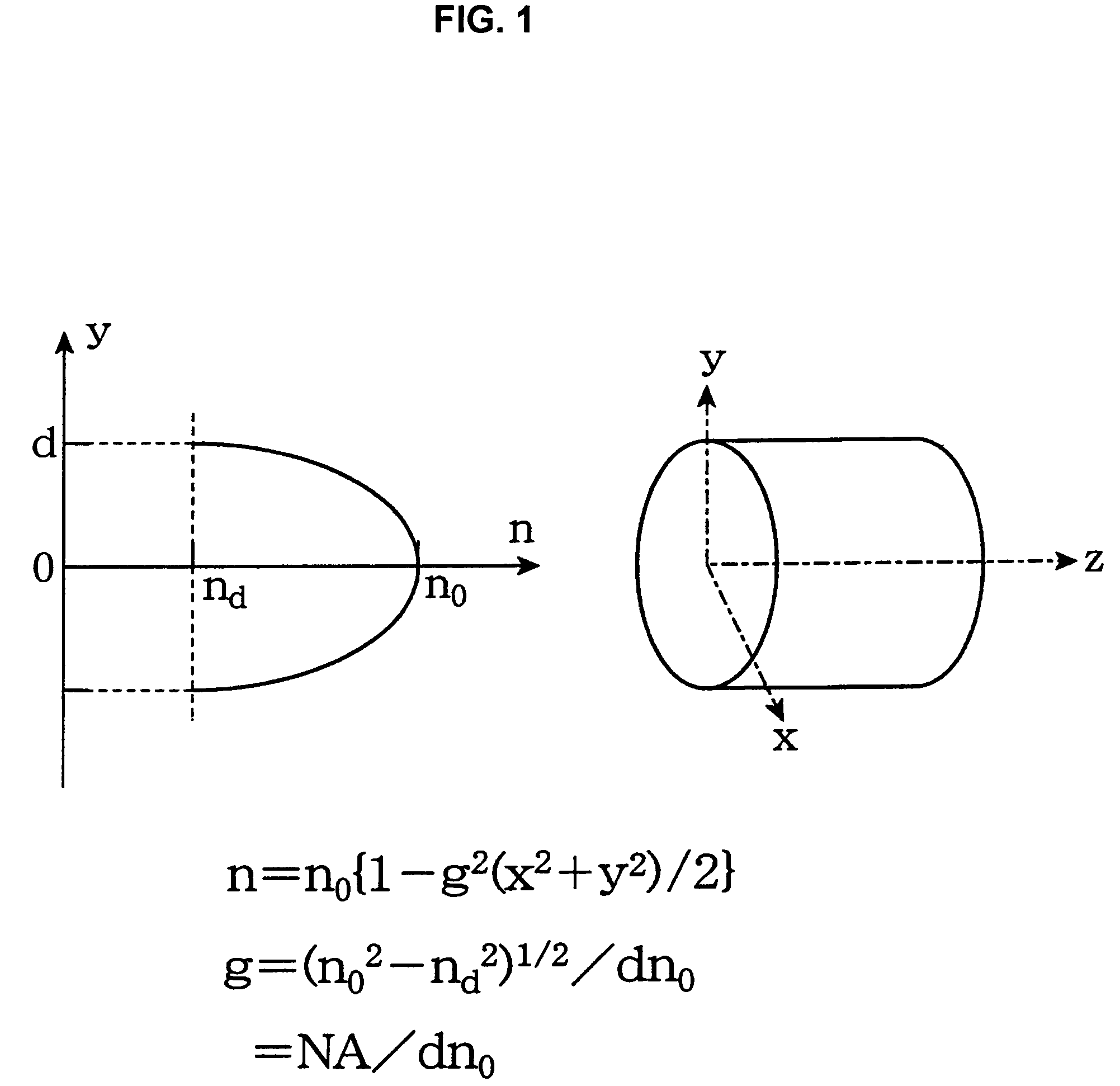

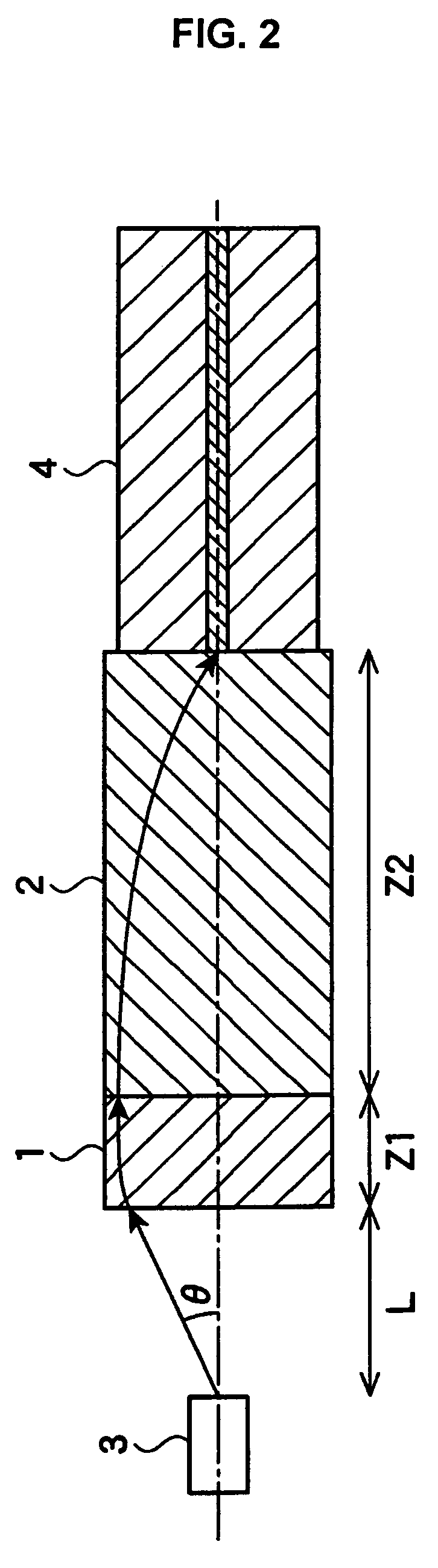

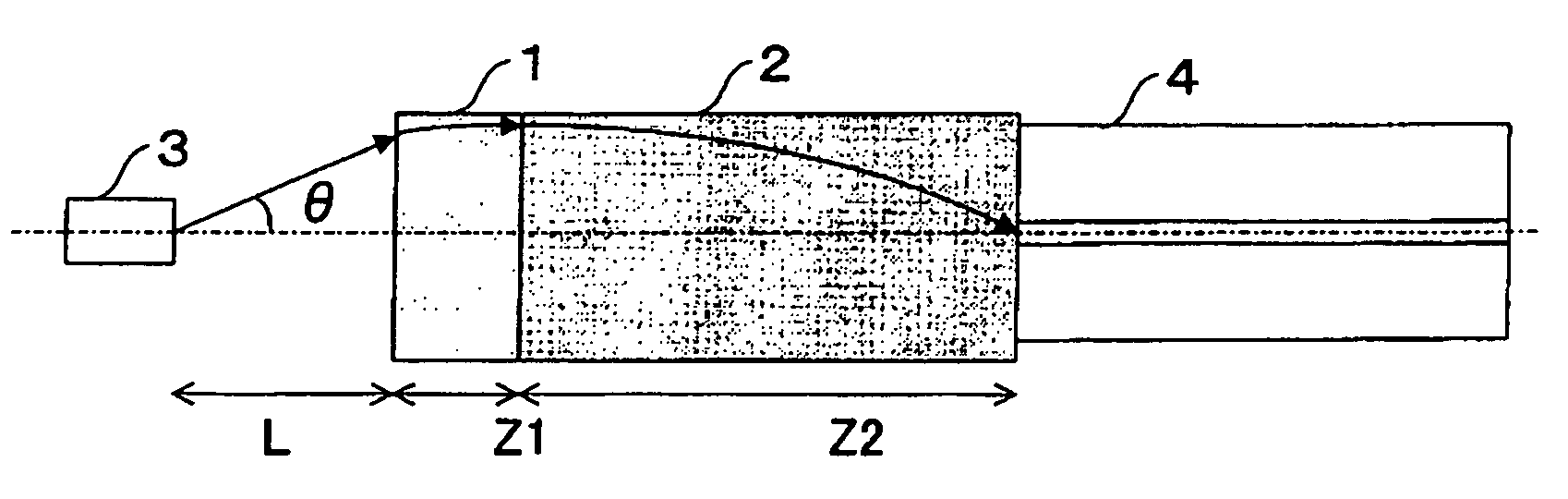

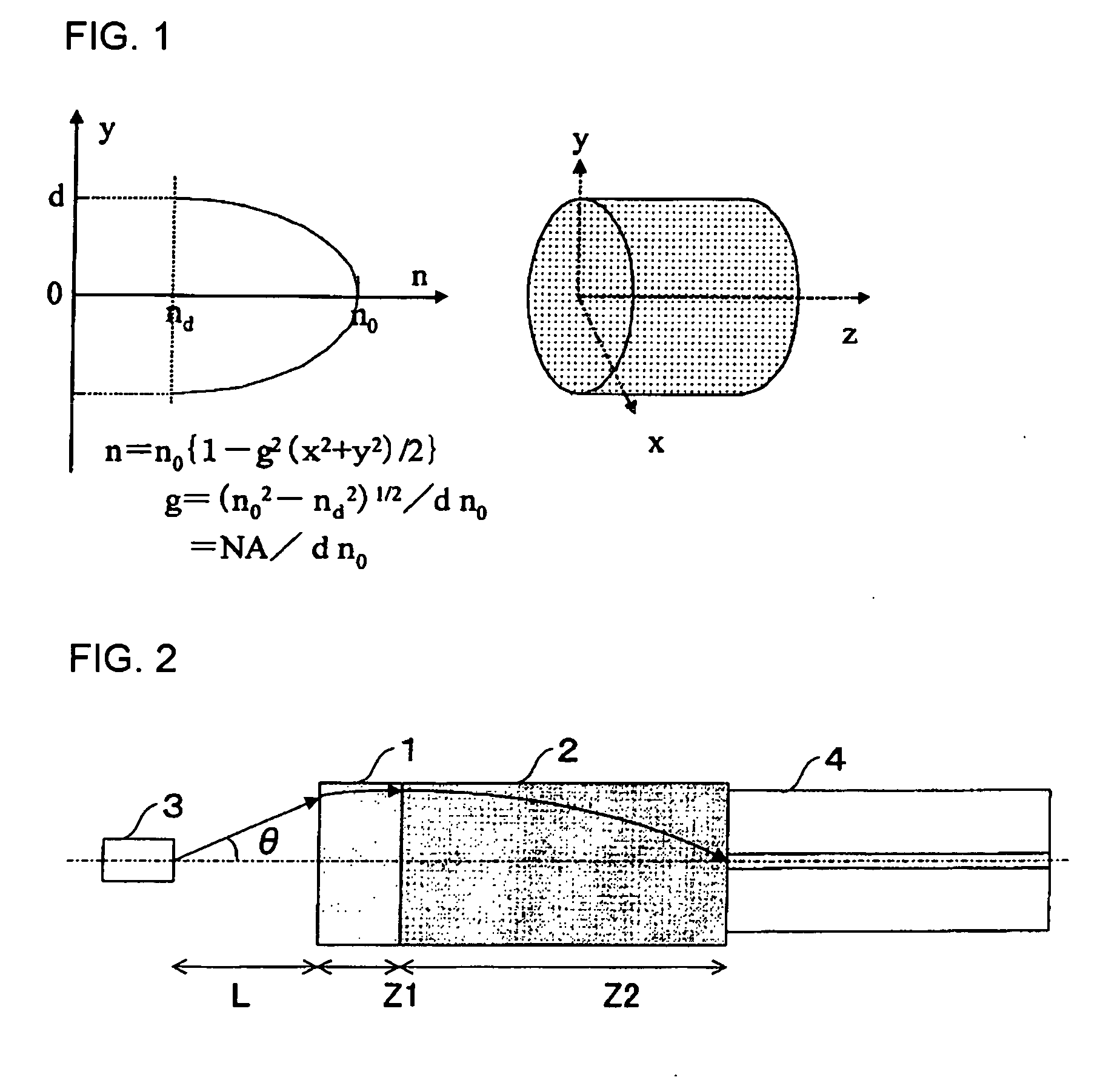

Optical fiber coupling part

ActiveUS7346237B2Send efficientlyLarge numerical apertureCladded optical fibreCoupling light guidesCoupling lossSemiconductor

An optical fiber coupling part capable of reducing coupling loss while maintaining a large operating distance, and having a good module assembling property. AT least one GRIN lens having numerical aperture NA that is larger than numerical aperture NAs of a light-emitting source (such as a semiconductor laser) is fusion-spliced with one end of the optical fiber. All lights emitted from the light-emitting source can enter the GRIN lens, and the loss of the light can thereby be reduced. In addition, a second GRIN lens having numerical aperture NA2 is fusion-spliced with one end of the optical fiber having numerical aperture NAf, and further a first GRIN lens having numerical aperture NA1, which is larger than numerical aperture NA2, is fusion-spliced with the other end of the second GRIN lens. Thereby, the light emitted from the light-emitting source can efficiently enter the optical fiber, and loss of the light can thereby be reduced. In this case, the formula expressed by NAf≦NA2<NAs≦NA1 is desirable.

Owner:TOYO SEIKAN GRP HLDG LTD

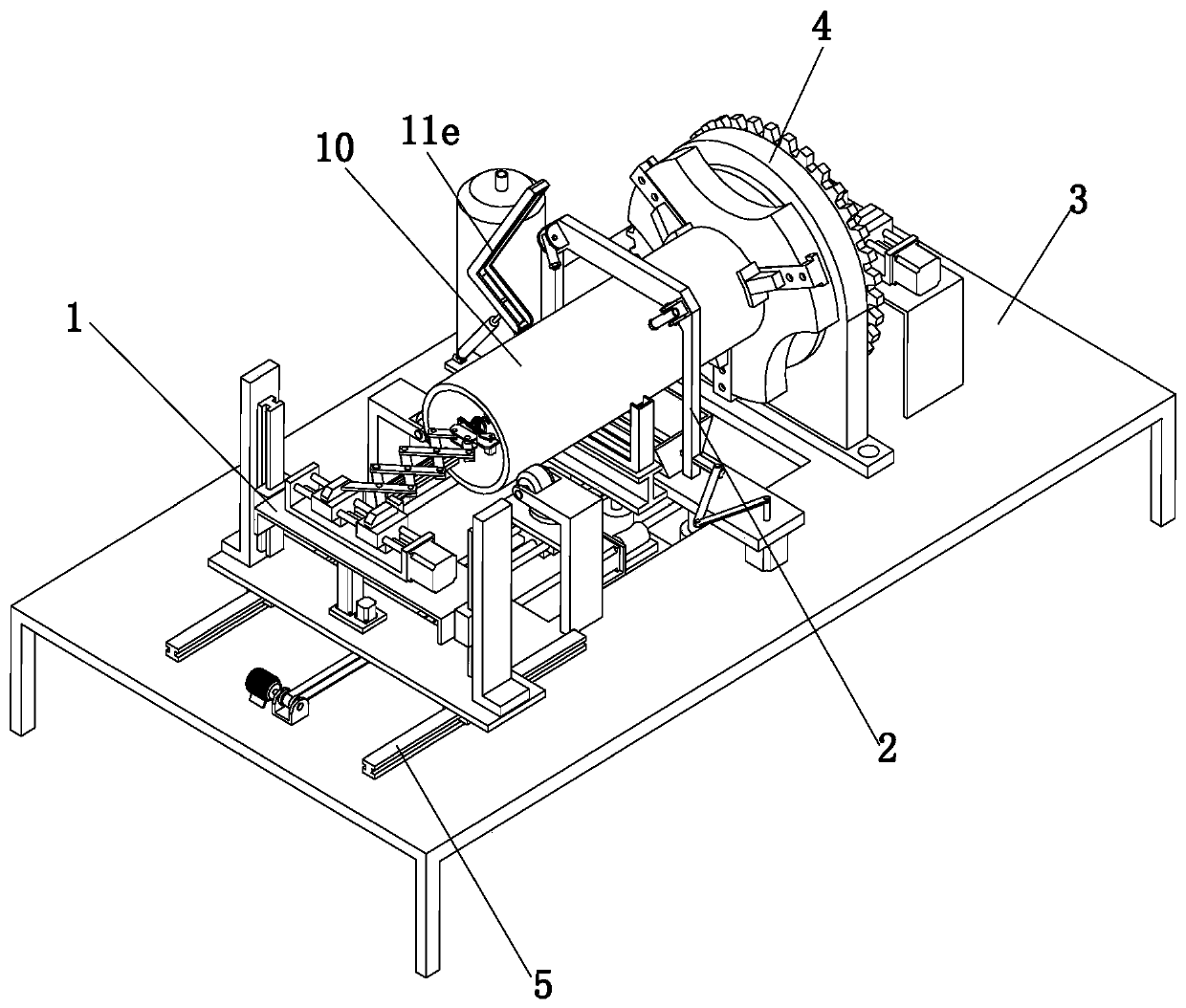

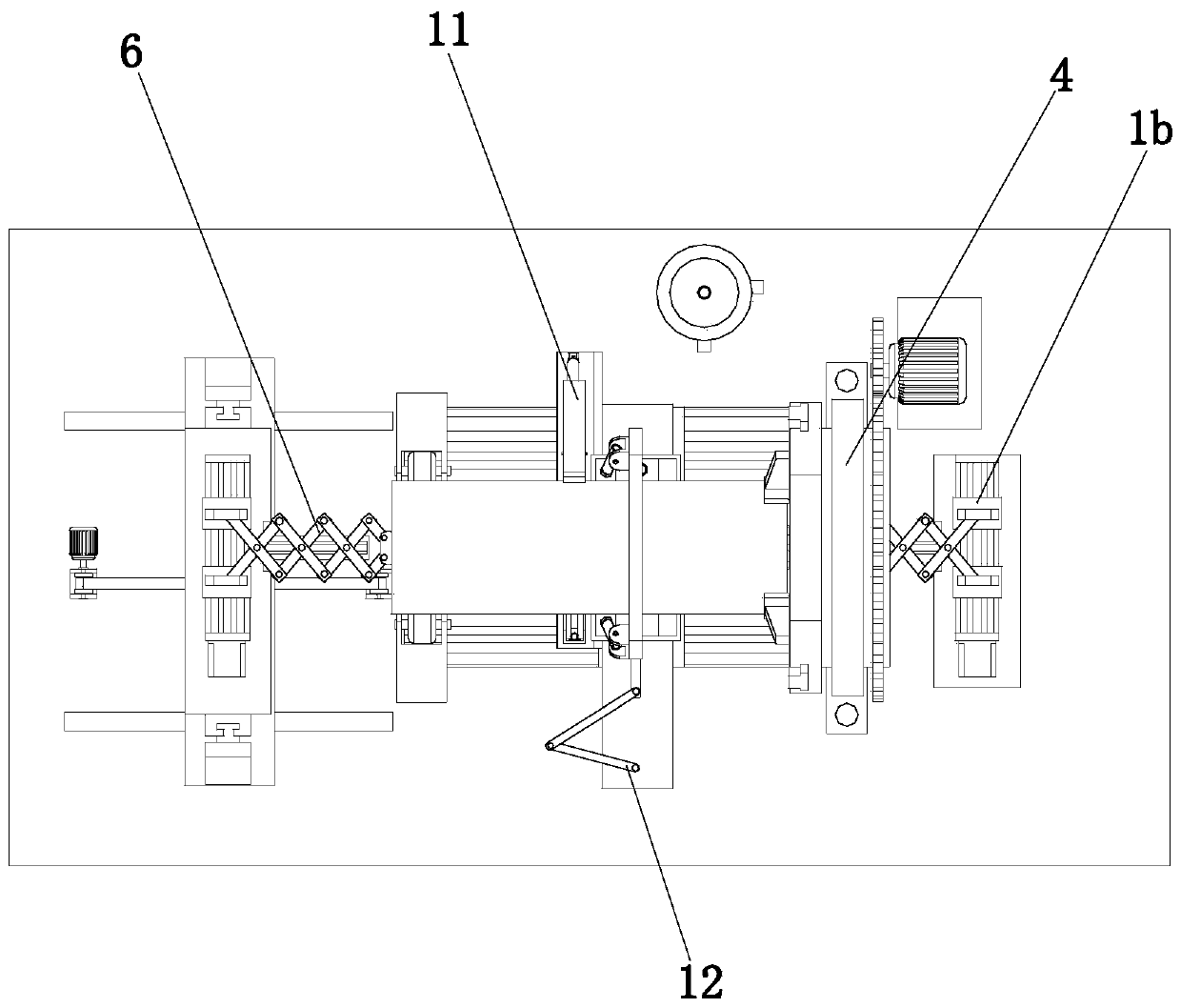

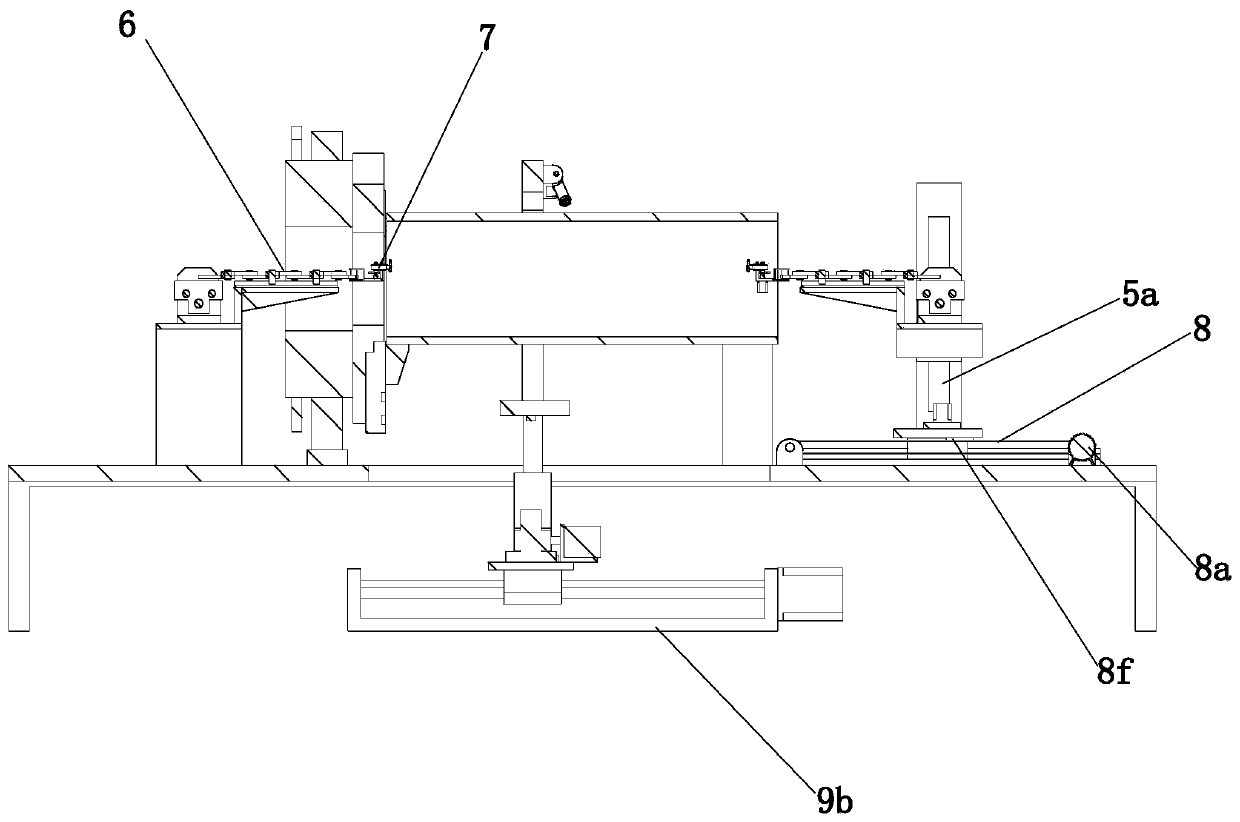

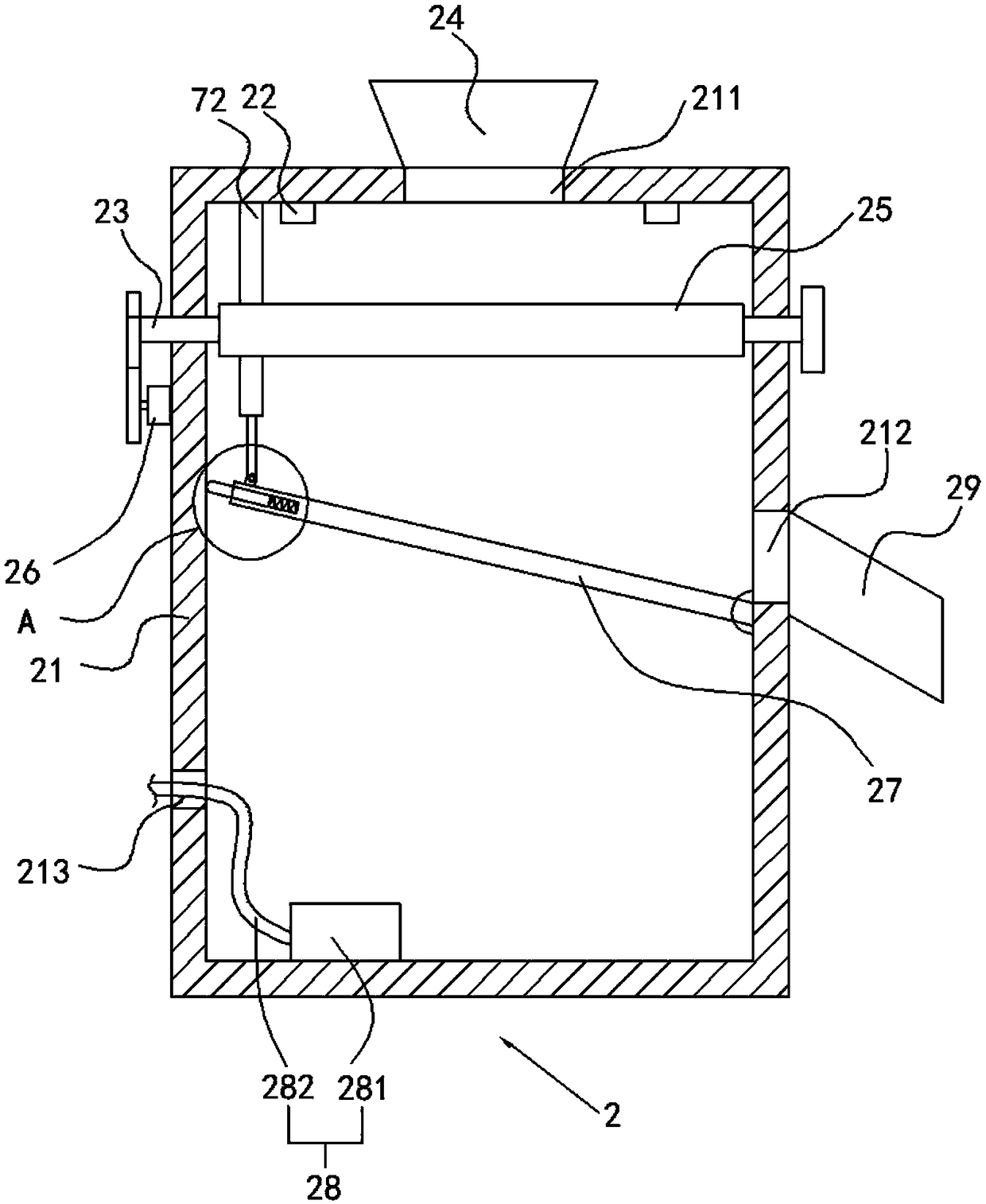

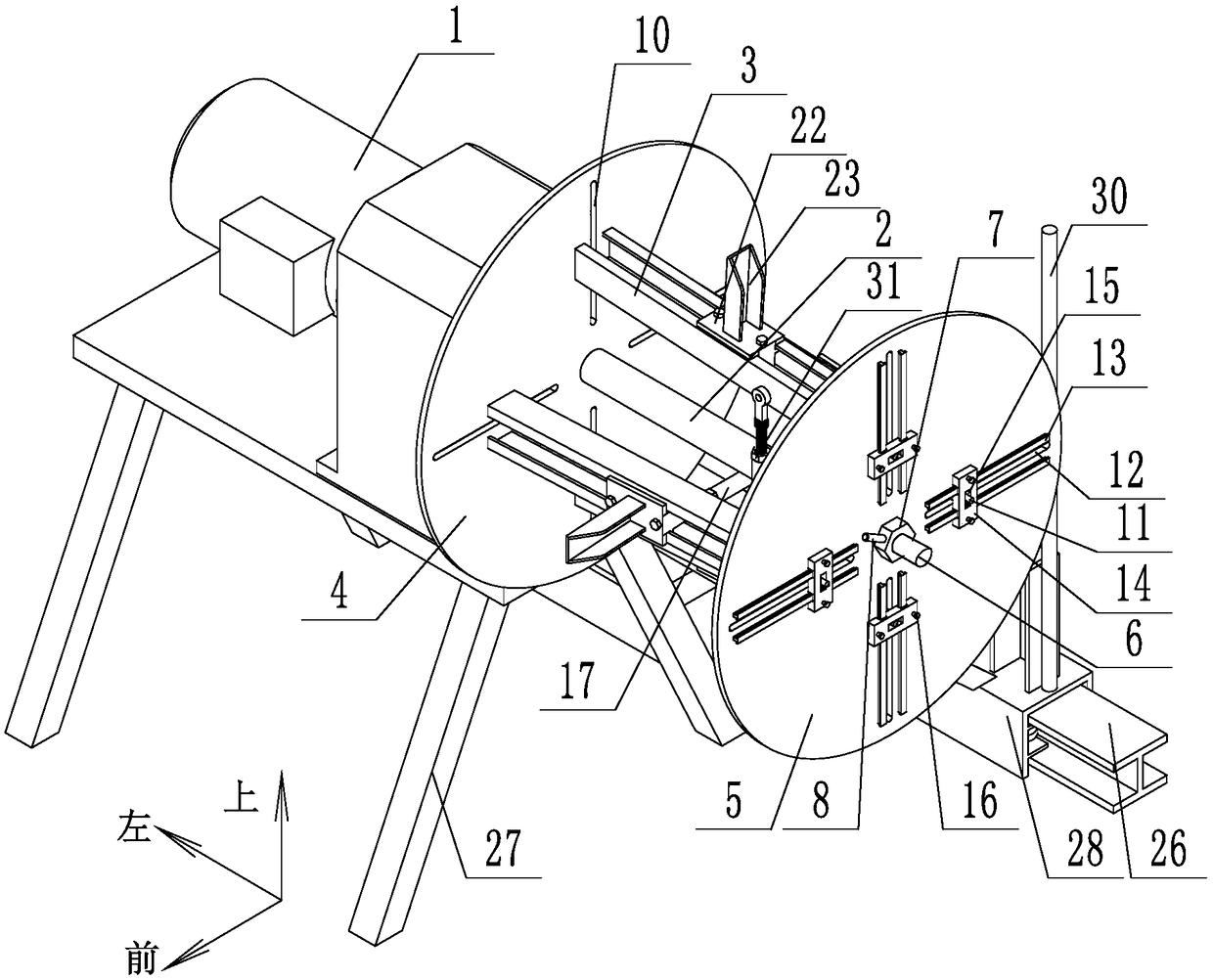

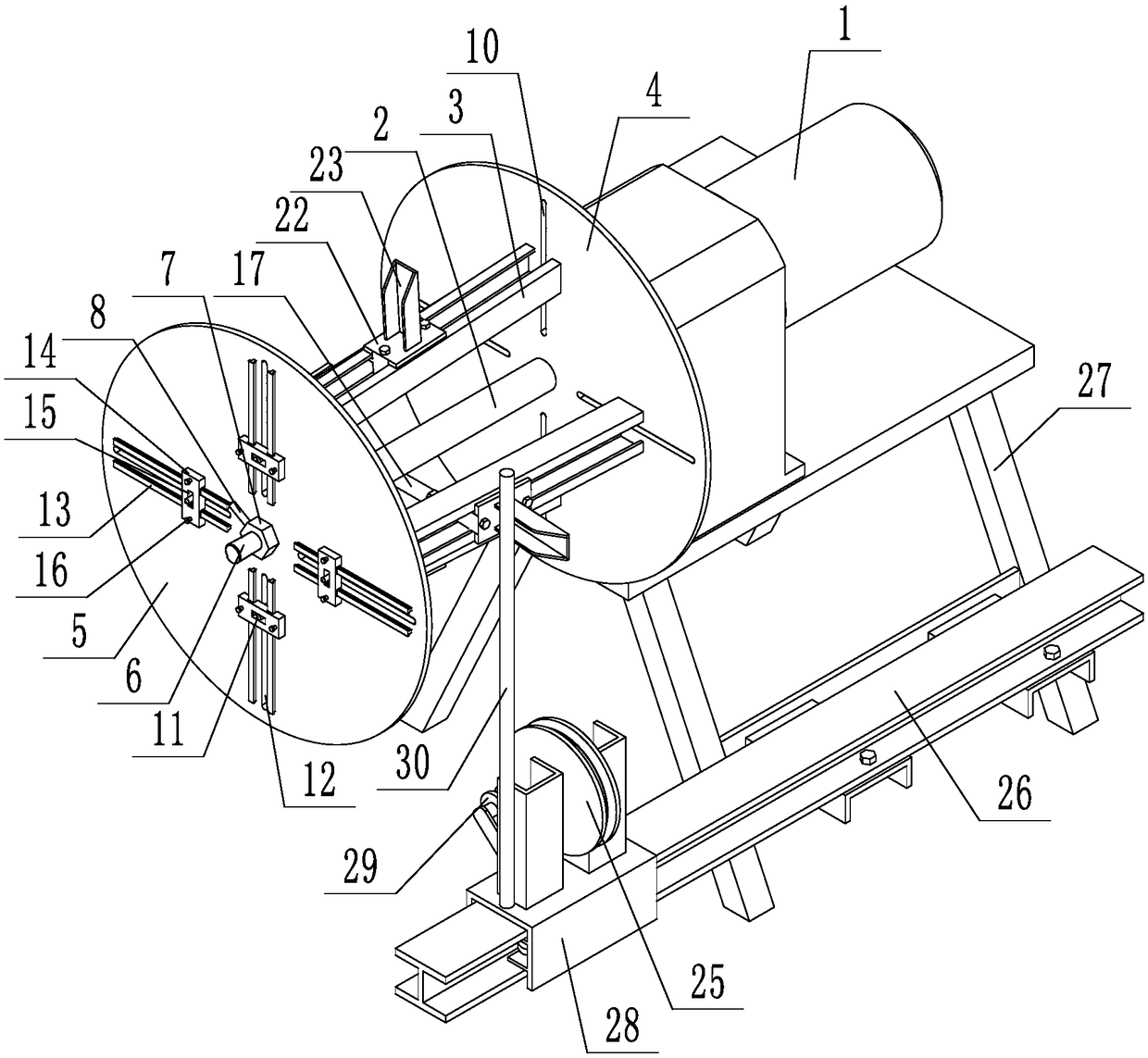

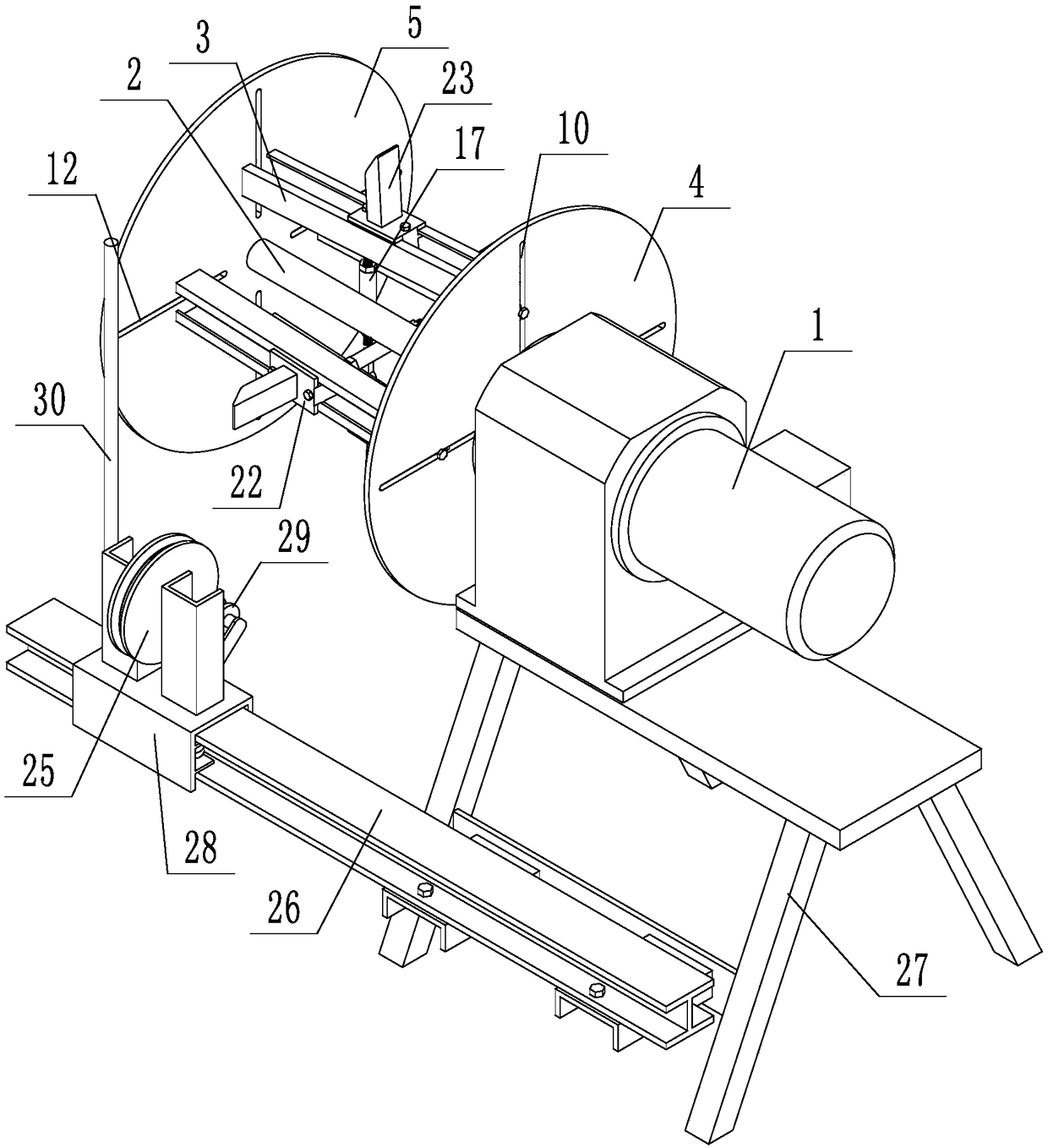

Automatic spraying machine for inner wall and outer wall of steel pipe

ActiveCN109746144AAvoid Unsprayed SituationsSolve the difficulty of spraying the entire inner wall of the steel pipePretreated surfacesCoatingsEngineeringAutomation

The invention discloses an automatic spraying machine for the inner wall and the outer wall of a steel pipe, and belongs to the field of steel pipe spraying equipment. The automatic spraying machine comprises an inner wall spraying mechanism, an outer wall spraying mechanism, an operation table and a rotating mechanism, wherein the inner wall spraying mechanism comprises a first spraying assembly,a second spraying assembly and a material moving assembly; the first spraying assembly and the second spraying assembly comprise an extending and feeding component and a rotating and spraying component; the material moving assembly comprises a lifting component, a material moving plate and a material moving component; and the lifting component is arranged at the top of the material moving plate.According to the automatic spraying machine disclosed by the invention, the inner wall spraying mechanism can extend to the inner part of the steel pipe and automatically perform the operation of uniform spraying on the inner wall of the steel pipe, the situation that the local inner wall of the steel pipe is not sprayed is avoided; and the operation of spraying can be automatically performed on the outer wall of the steel pipe through the outer wall spraying mechanism, so that the automation degree is high, and the situation that a worker manually performs the operation of spraying on the outer wall of the steel pipe is not needed.

Owner:浙江金汇休闲制品有限公司

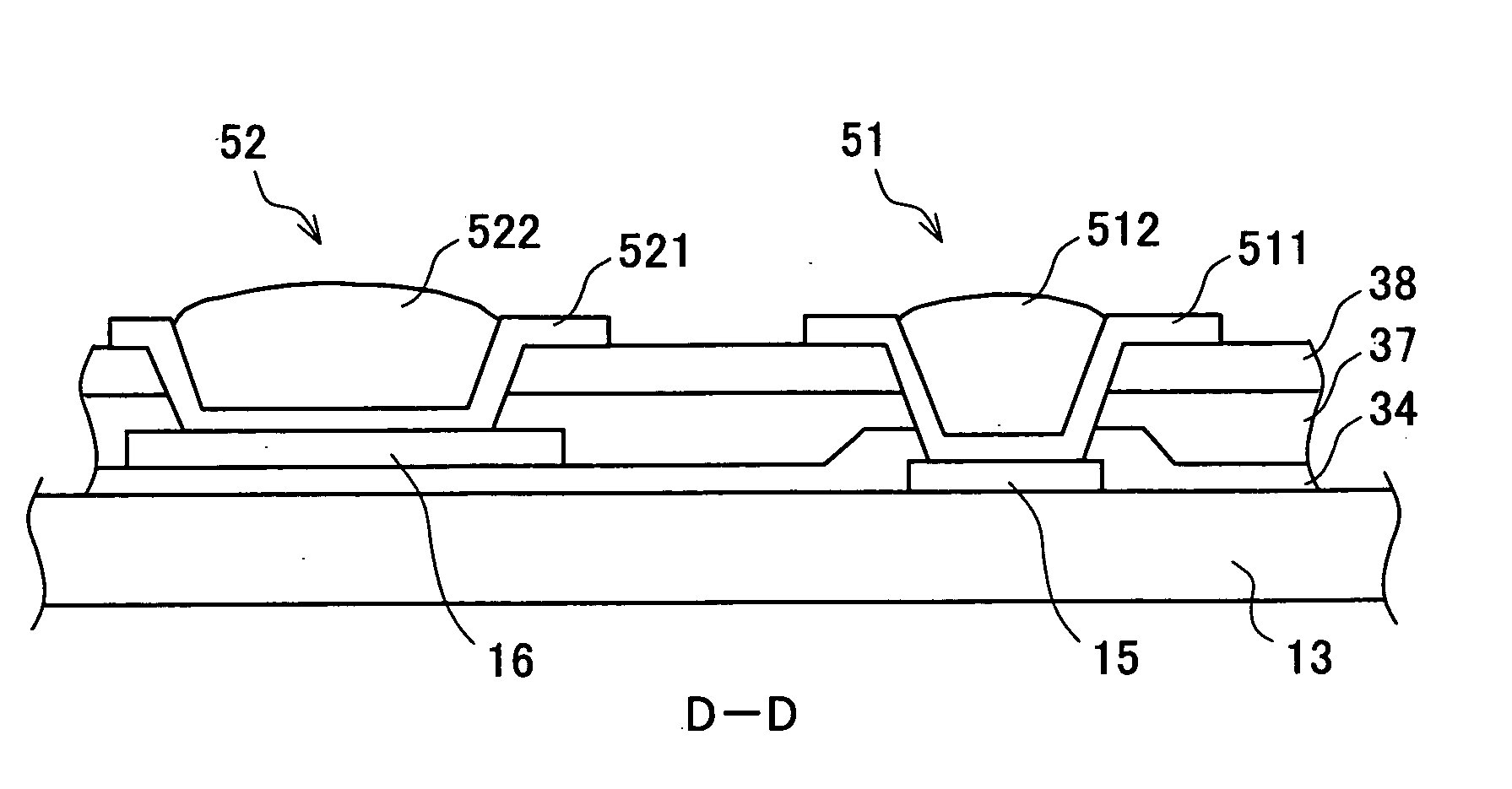

Active matrix substrate and manufacturing method thereof, and electronic device

InactiveUS20050285987A1Reduce resistanceImproves a resistance against a process environmentSolid-state devicesNon-linear opticsCapacitanceActive matrix

An auxiliary line including a guide layer and an auxiliary metallic member is formed with respect to a signal transmitting line or a main auxiliary capacitance line formed on a glass substrate. The guide layer is formed in the same layer where pixel electrodes are formed. The auxiliary metallic member is formed by using a method such as an inkjet method, in which fine particles of metal is ejected or dropped.

Owner:SHARP KK

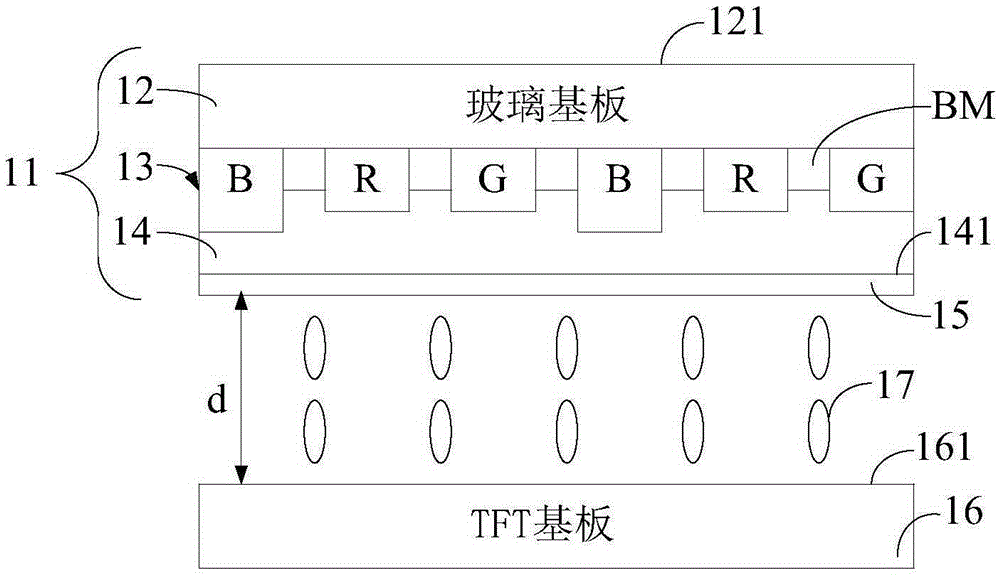

Liquid crystal display device and color film substrate thereof

InactiveCN105259693AAvoid light leakage or color castOptimization adjustmentNon-linear opticsLiquid-crystal displayResistor

The invention discloses a liquid crystal display device and a color film substrate thereof. The color film substrate comprises a first substrate, multiple color resistors arranged on the first substrate and used for presenting multiple colors, and a transparent resin layer arranged on the multiple color resistors, wherein the thickness of blue color resistors in the multiple color resistors is greater than that of the color resistors in other colors, and the surface, away from the multiple color resistors, of the transparent resin layer is parallel to the surface, away from the multiple color resistors, of the first substrate. Through the above mode, the color film substrate can avoid light leakage or color cast and improve adjustment on white balance, and the work complexity is lowered.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

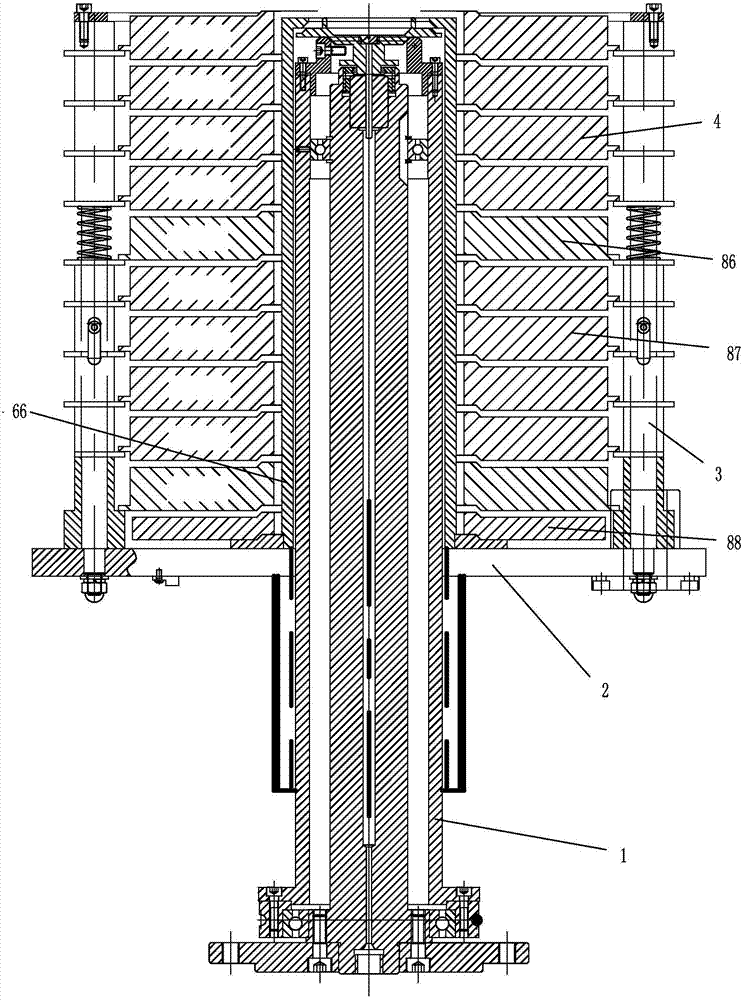

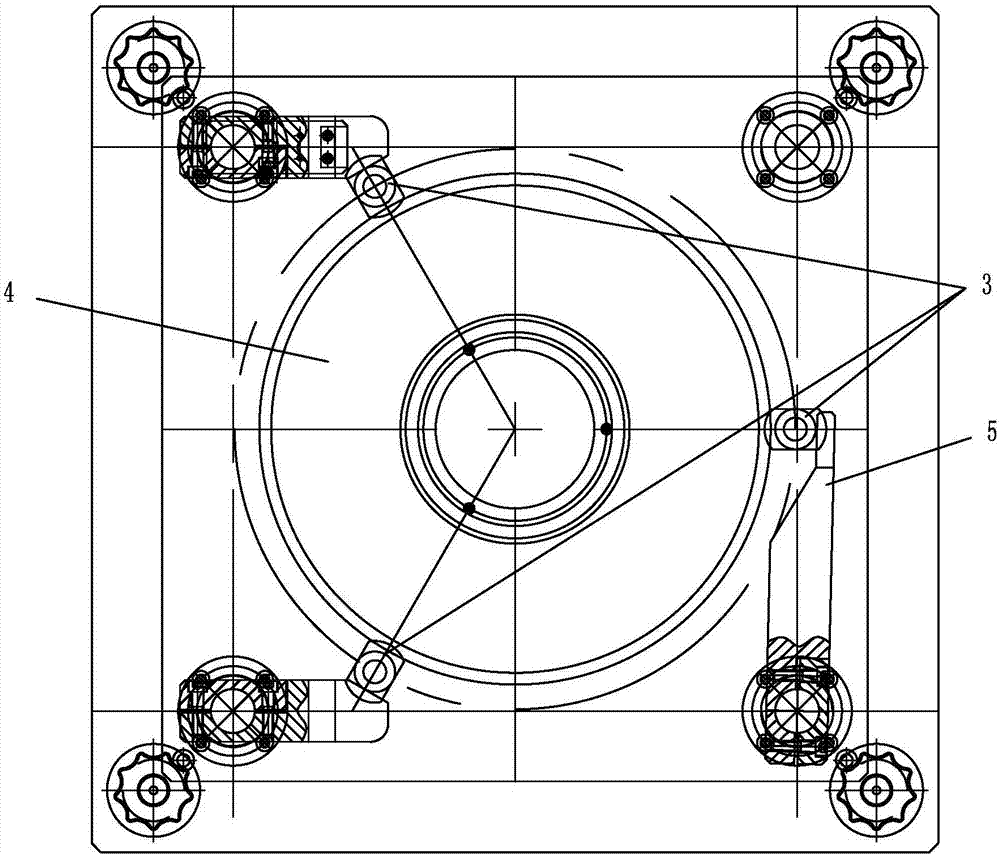

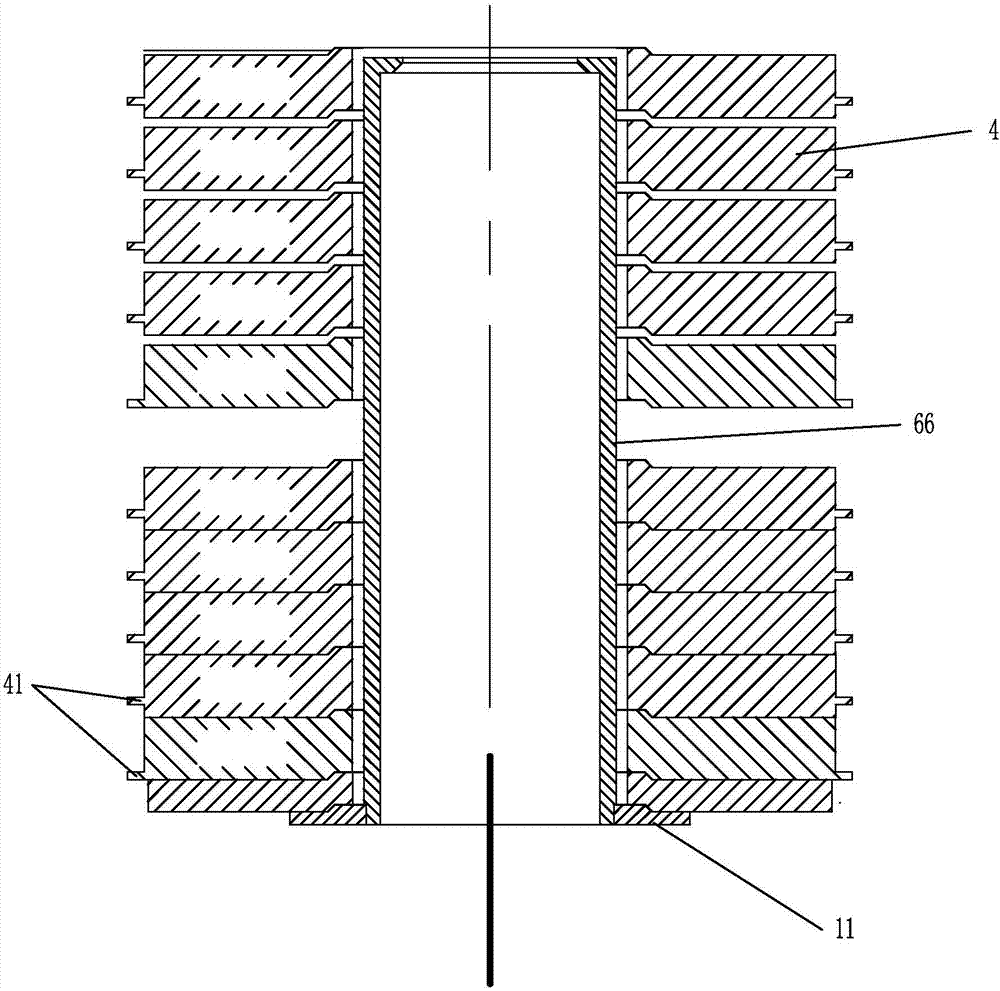

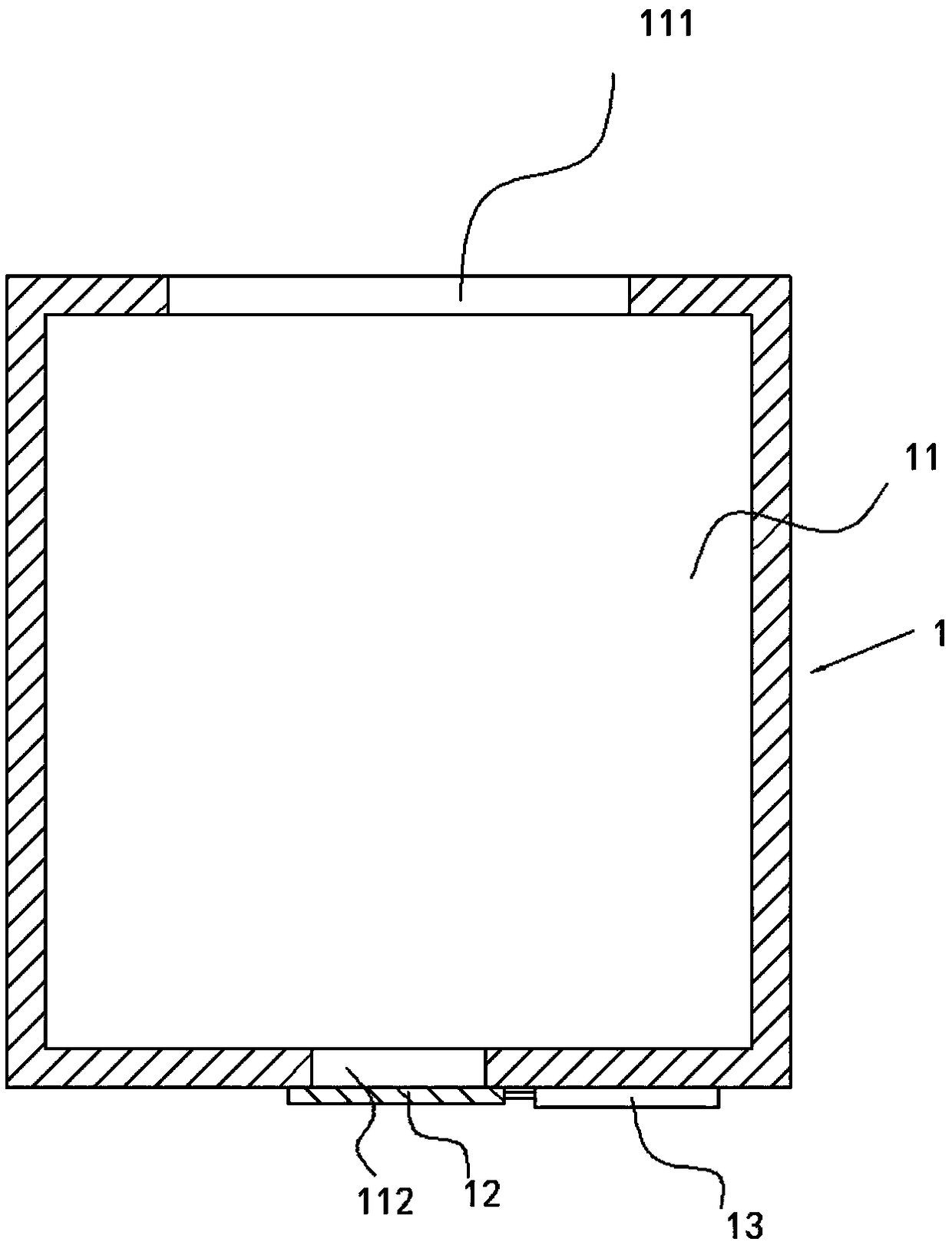

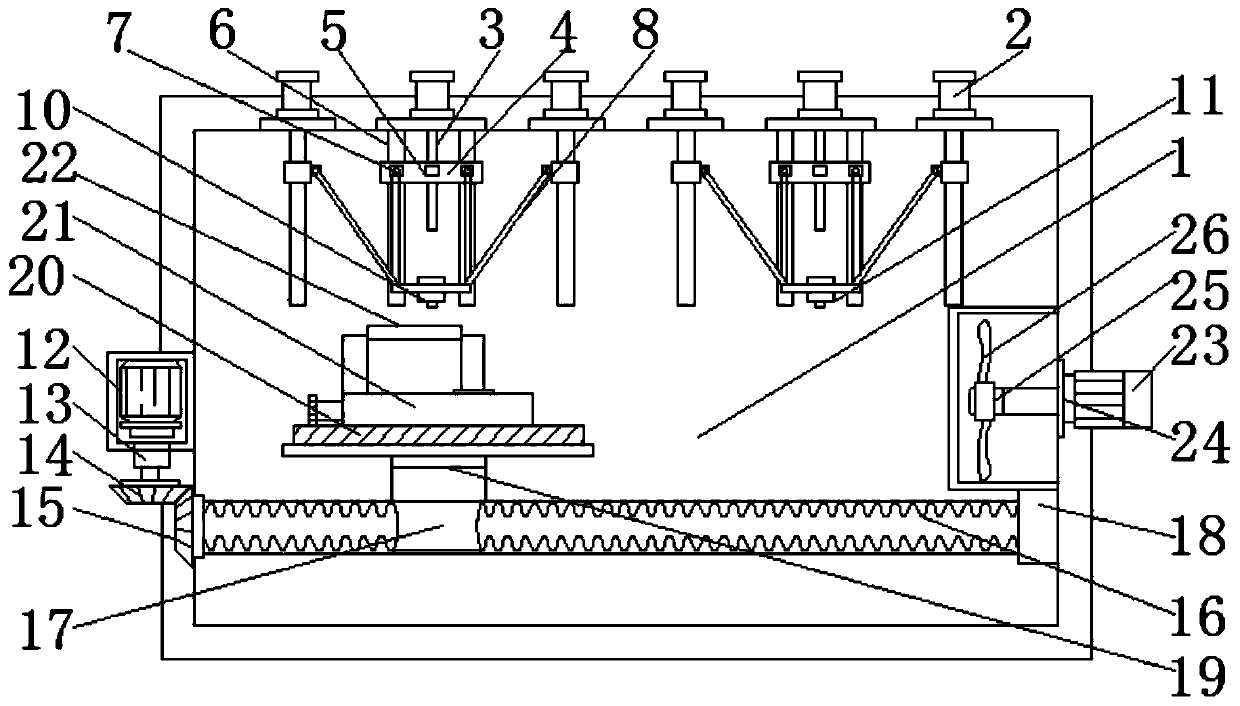

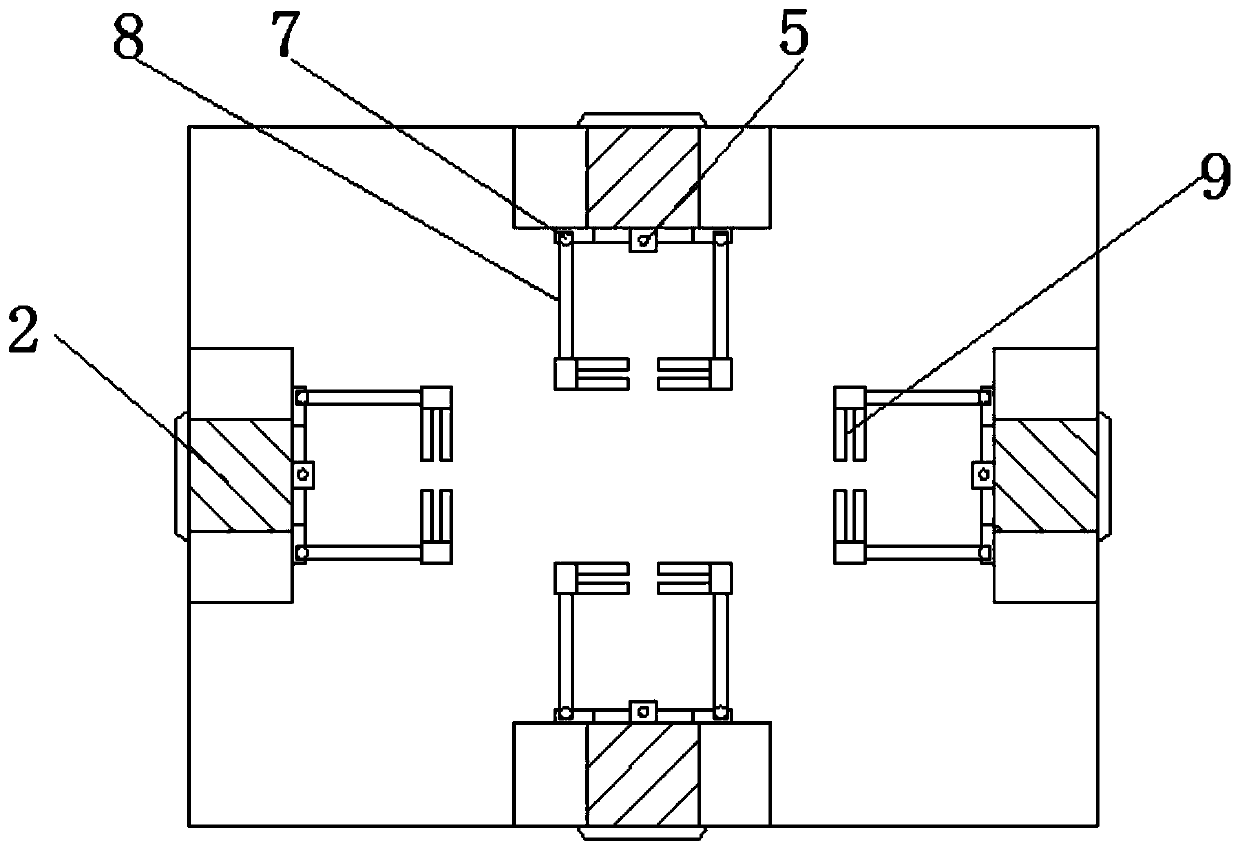

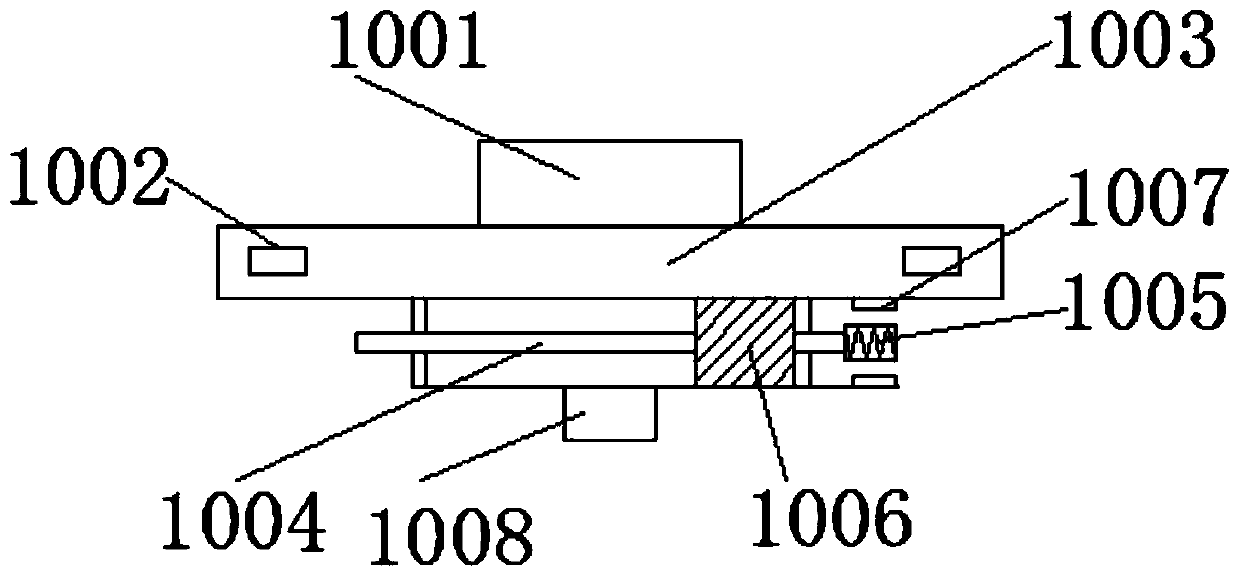

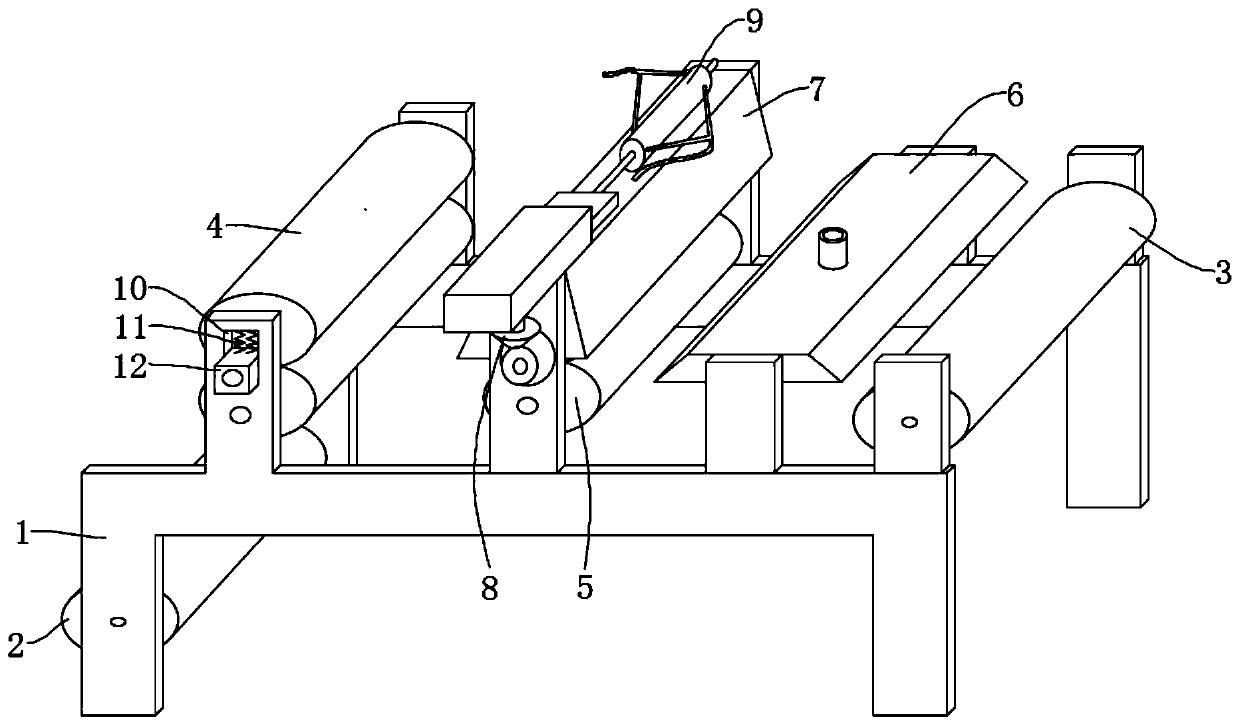

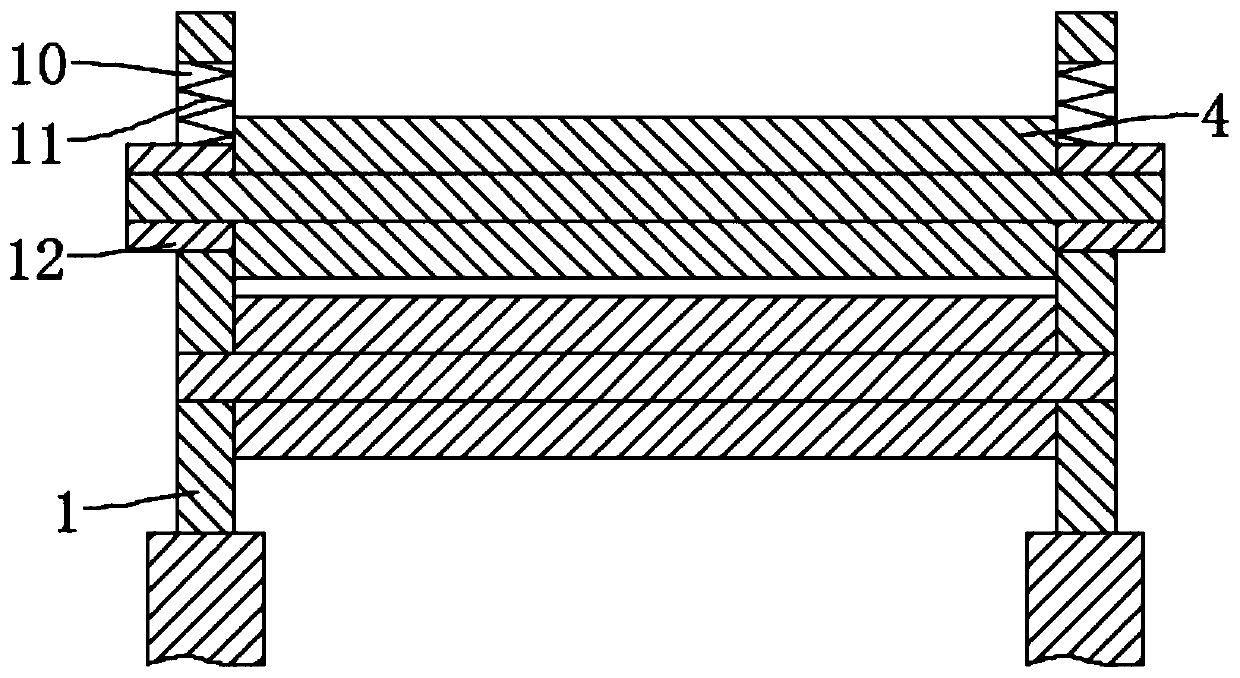

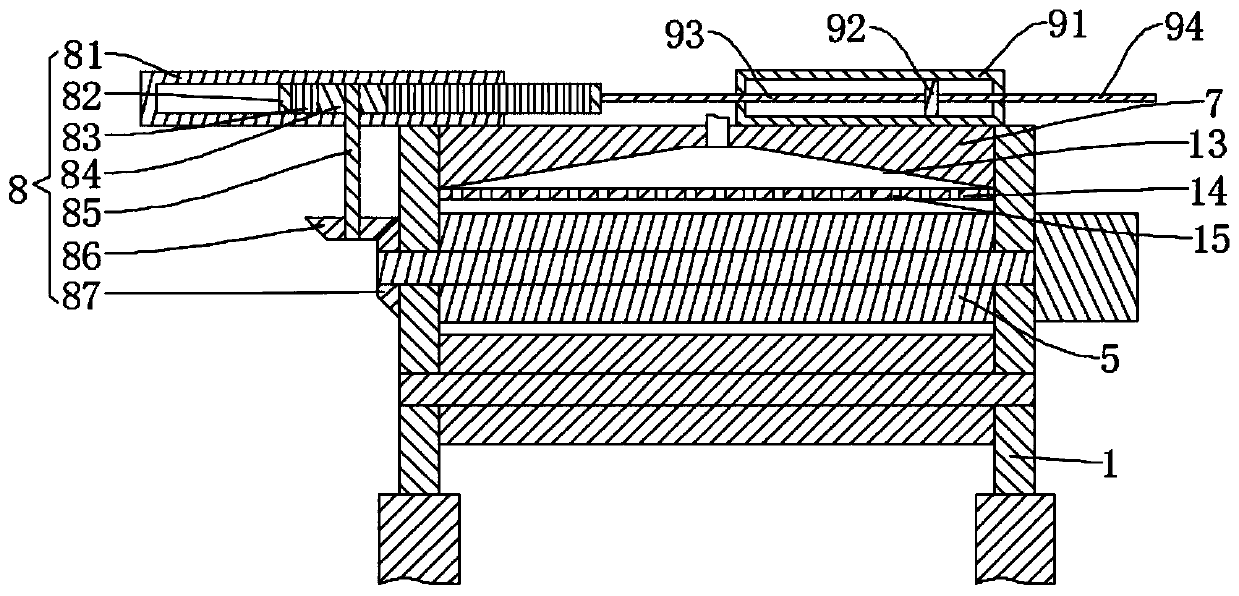

Automatic orderly weight adding mechanism

ActiveCN107238429AReduce the difficulty of processing and manufacturingSame frame sizeWeighing apparatus detailsEngineeringLoading unloading

The invention discloses an automatic orderly weight adding mechanism, comprising a plurality of plate shaped weights 4, a weighing part and a loading-unloading part. The weighing part comprises a weighing plate 11. The loading-unloading part comprises support column components 3. Each support column component 3 comprises a support column 31 whose lower-part rod section is an optical rod section; a sleeving tube 33 sleeving the optical rod section in sequence, and an elastic body 32 topped between the support column and the sleeving tube. The upper-part rod sections of the support columns and the outer part of the sleeving tubes are provided with outwardly protruding support steps 69 arranged in the axial direction and at interval. The lower ends of the optical rod sections of the support columns are fixedly arranged on the lifting platform 2 that is arranged horizontally and driven to lift by a driving mechanism. Each sleeving tube is provided with an external support body 5 used to restrict the sleeving tube from falling to the lowest position. The mechanism of the invention aims to reducing the dimension in the vertical direction, to reducing the fabricating difficulty and to increasing the operation precision of equipment and provides this automatic orderly weight adding mechanism. With such a designed structure, the increase in the number of weights under a specific size can be realized so as to realize the goals of a compact structure and an enlarged measurement scope.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Optical fiber coupling componet

ActiveUS20060045419A1Send efficientlyLarge numerical apertureCladded optical fibreCoupling light guidesCoupling lossNumerical aperture

An optical fiber coupling part capable of reducing coupling loss while maintaining a large operating distance, and having a good module assembling property. AT least one GRIN lens having numerical aperture NA that is larger than numerical aperture NAs of a light-emitting source (such as a semiconductor laser) is fusion-spliced with one end of the optical fiber. All lights emitted from the light-emitting source can enter the GRIN lens, and the loss of the light can thereby be reduced. In addition, a second GRIN lens having numerical aperture NA2 is fusion-spliced with one end of the optical fiber having numerical aperture NAf, and further a first GRIN lens having numerical aperture NA1, which is larger than numerical aperture NA2, is fusion-spliced with the other end of the second GRIN lens. Thereby, the light emitted from the light-emitting source can efficiently enter the optical fiber, and loss of the light can thereby be reduced. In this case, the formula expressed by NAf≦NA2<NAs≦NA1 is desirable.

Owner:TOYO SEIKAN GRP HLDG LTD

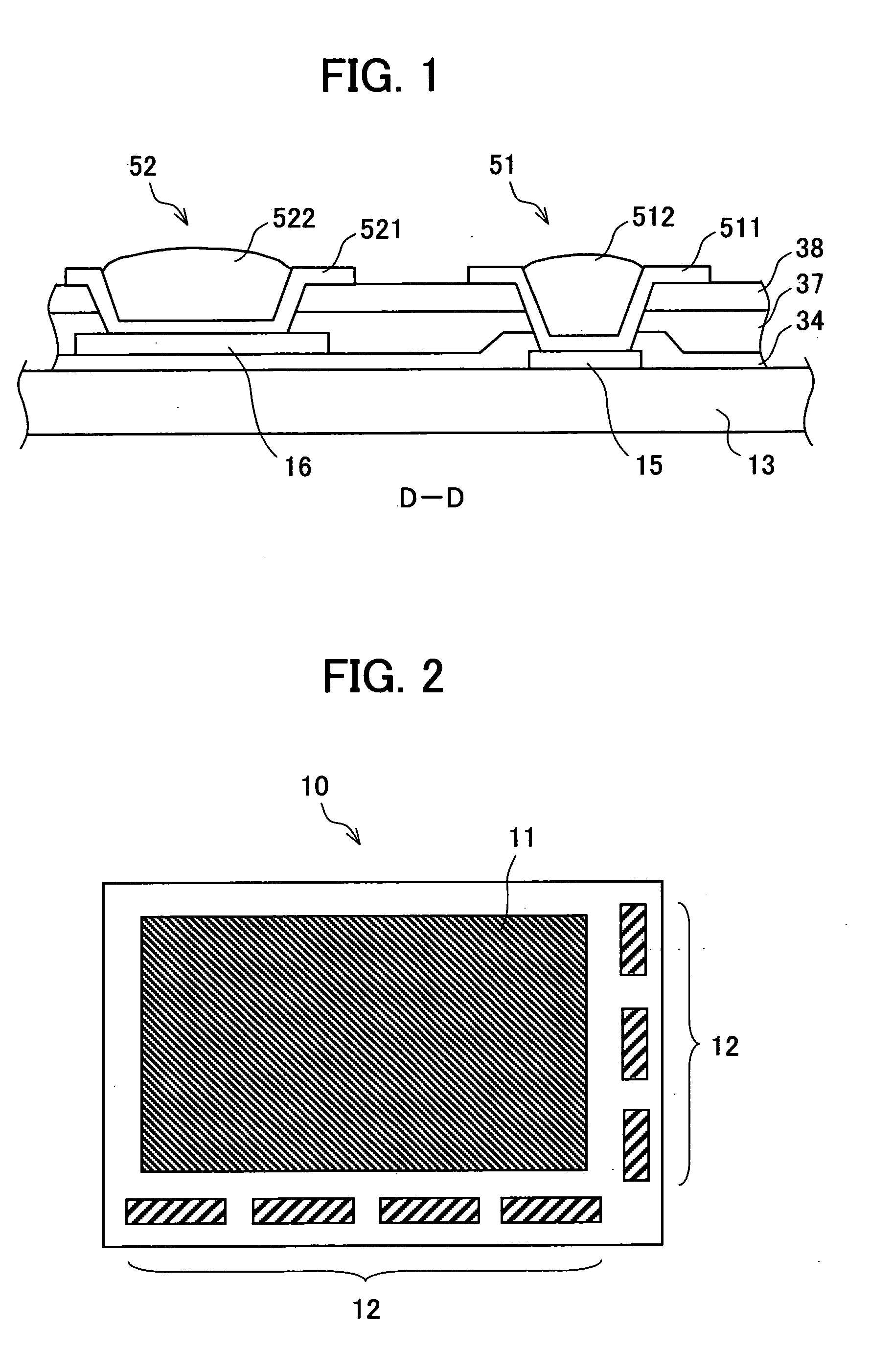

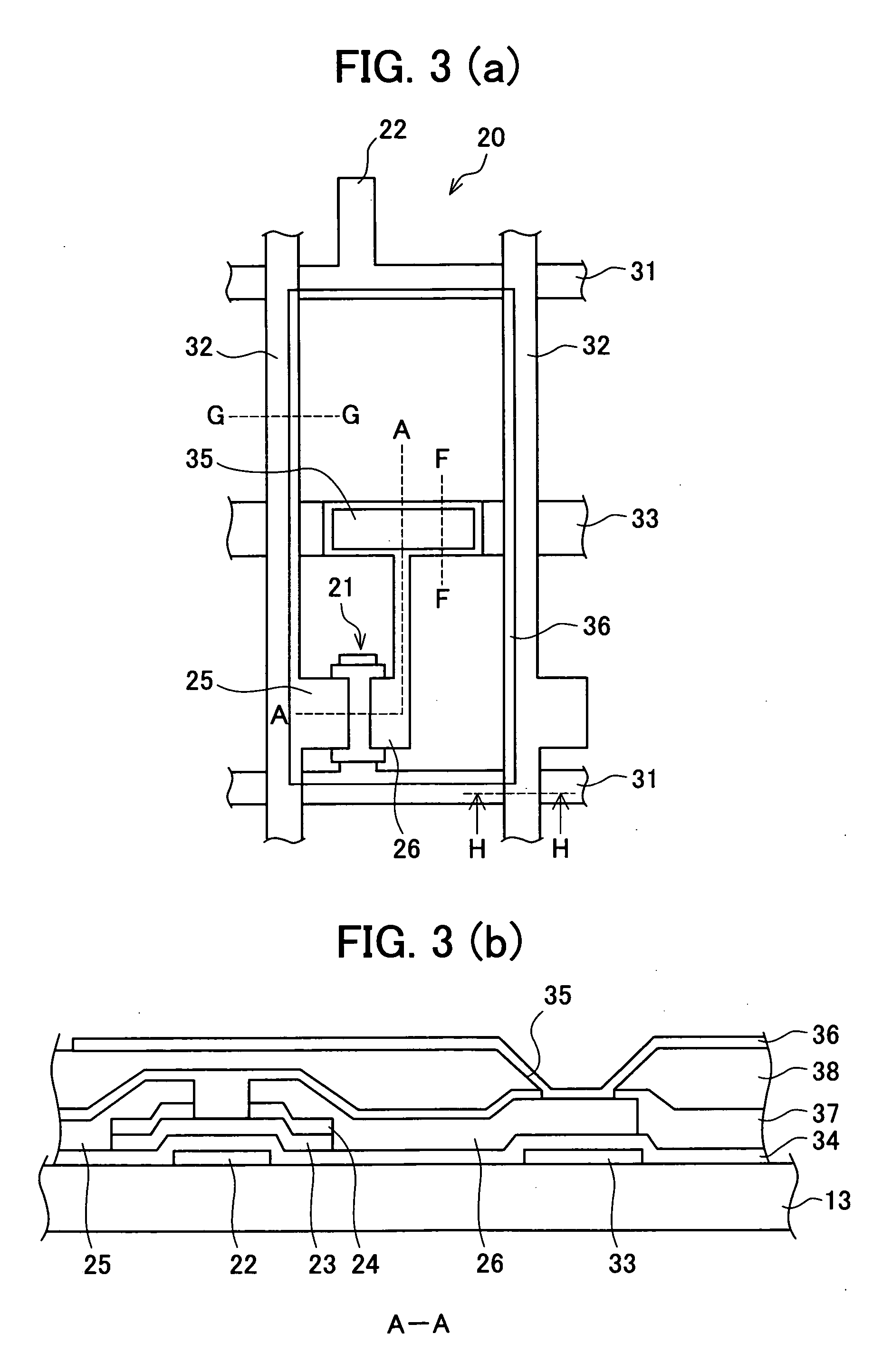

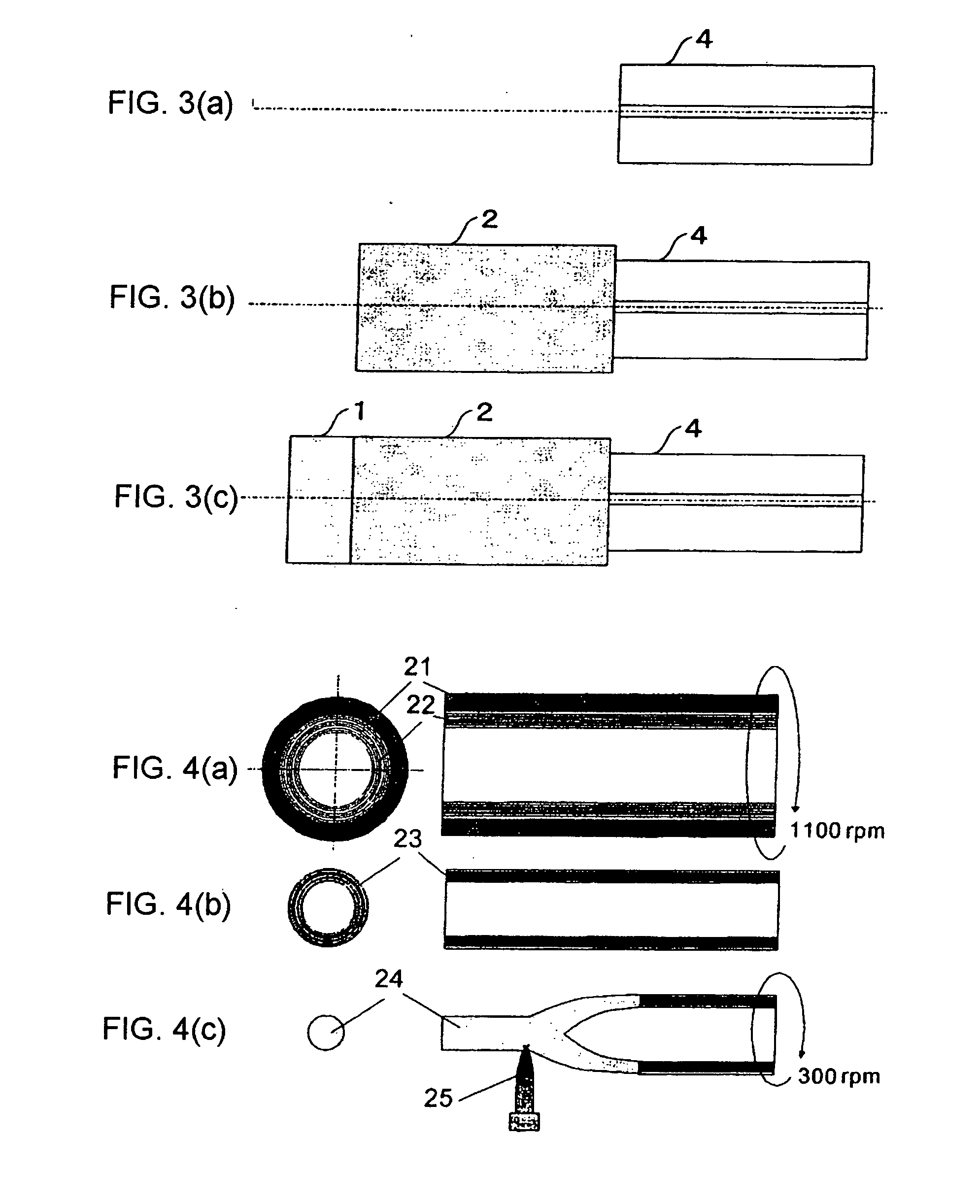

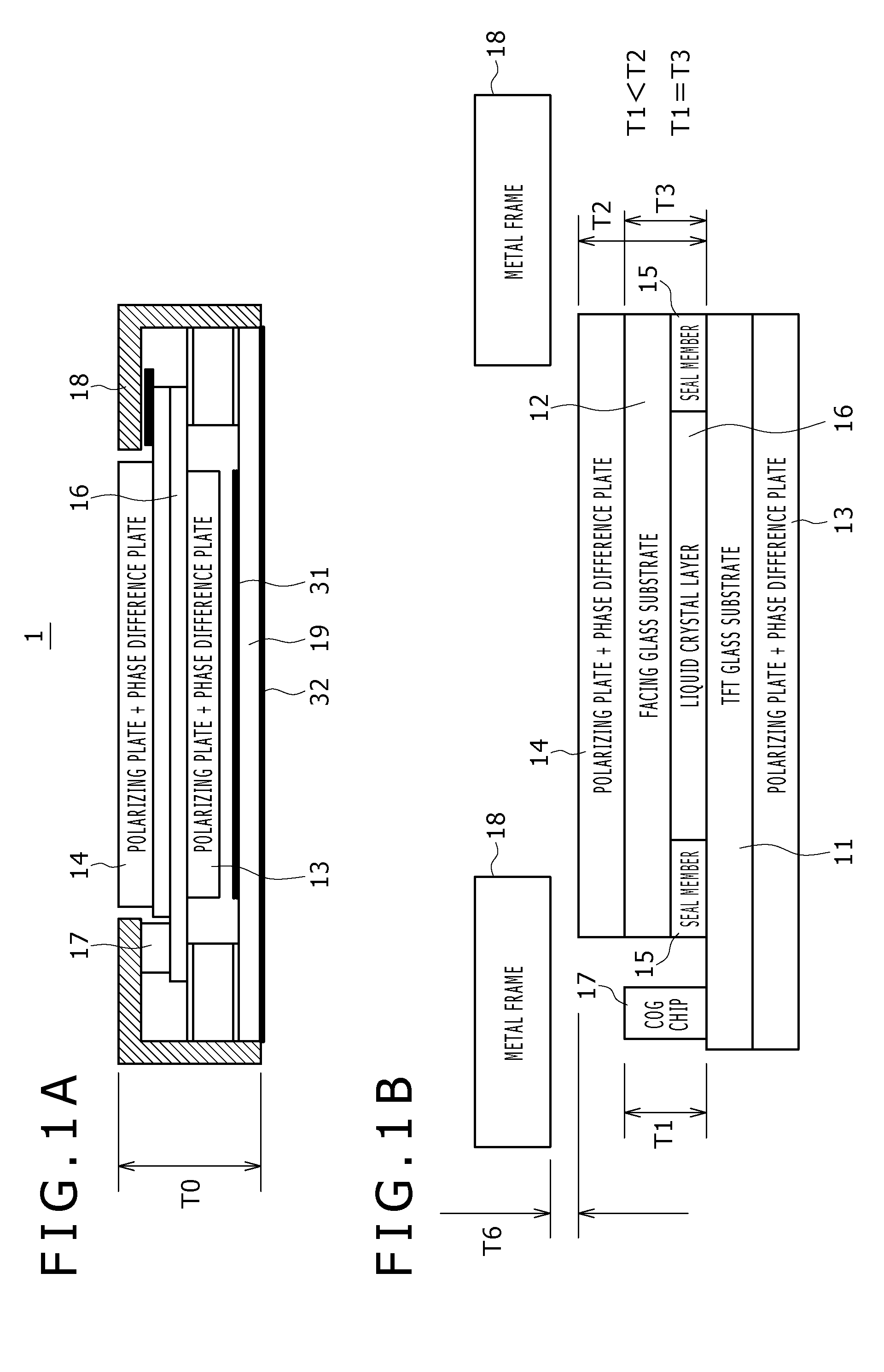

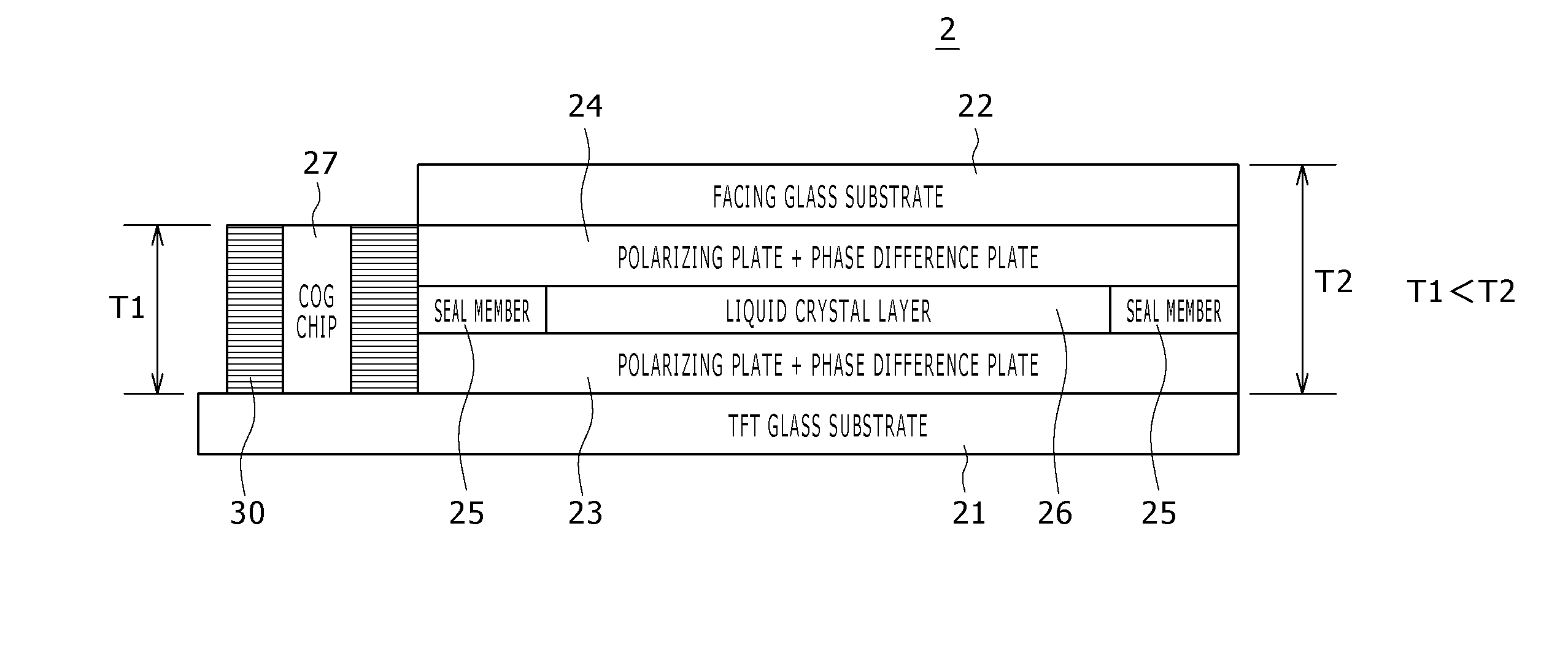

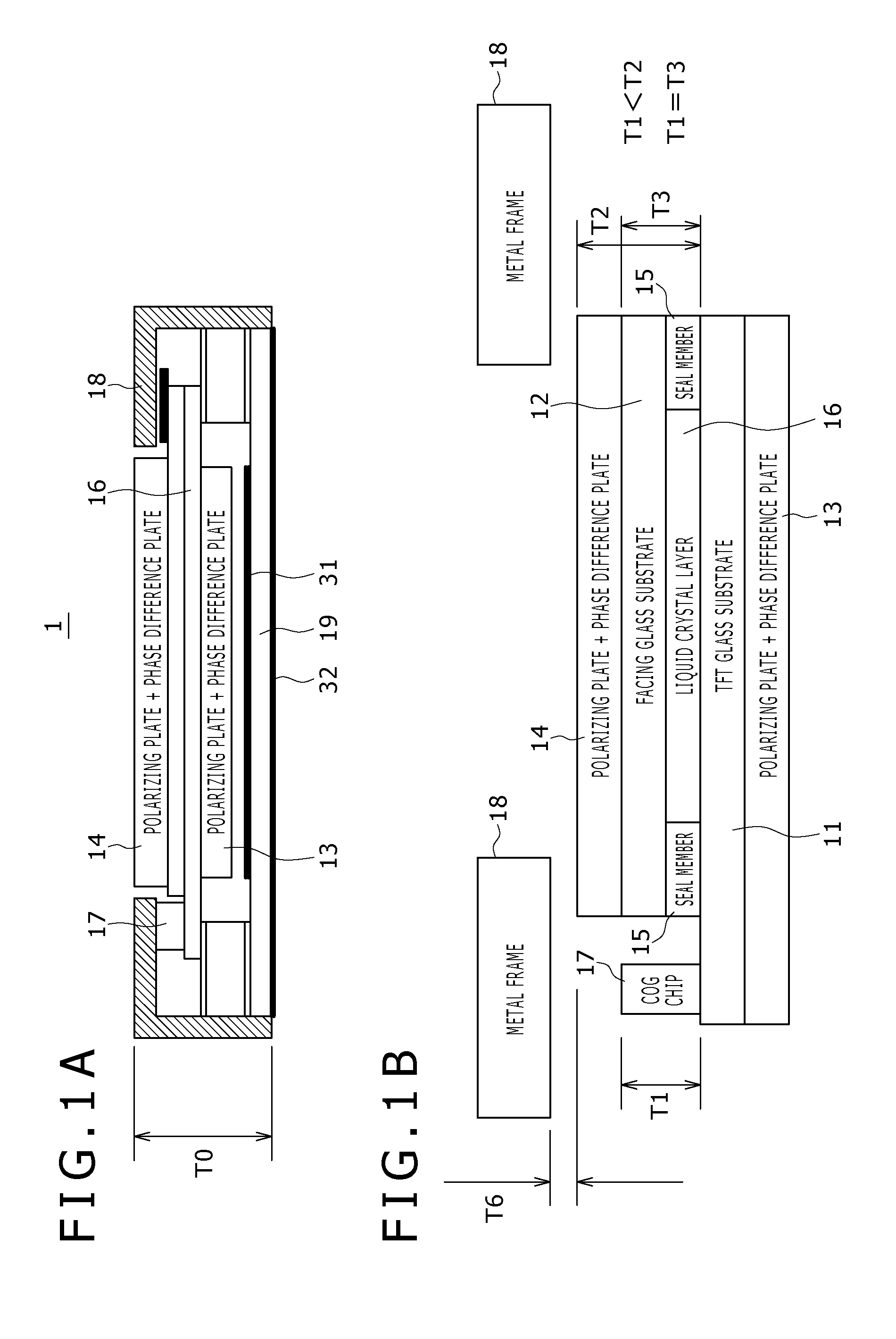

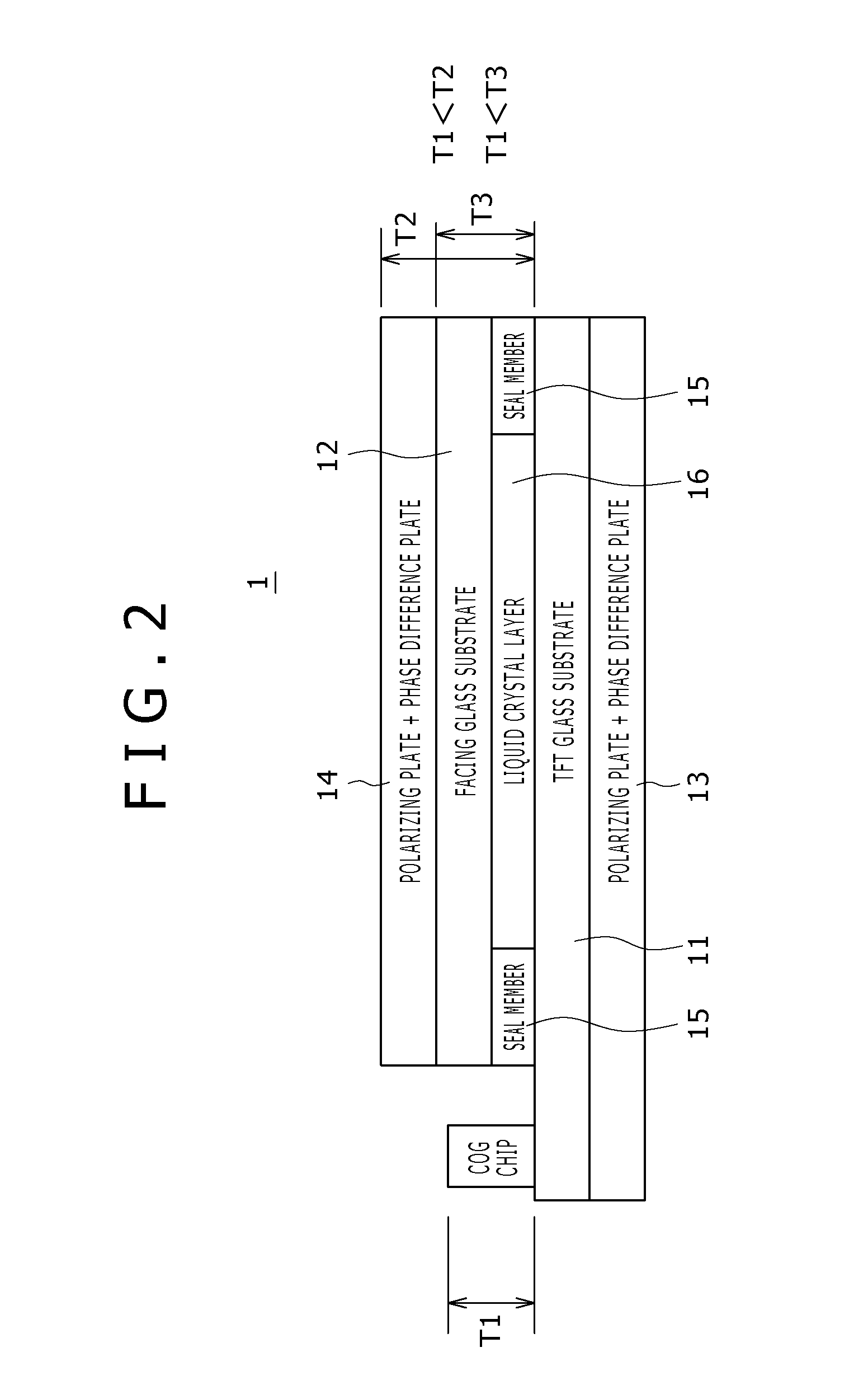

Display device, method of manufacturing display device, and electronic apparatus

ActiveUS20080143949A1Filling spaceThe same thicknessTube/lamp screens manufactureSemiconductor/solid-state device manufacturingControl systemDisplay device

Disclosed herein is a display device including: a first substrate with a pixel switch and drivers mounted thereon; a second substrate disposed in facing relation to the first substrate; a material layer held between the first substrate and the second substrate and having peripheral edges sealed by a seal member, the material layer having an electrooptical effect; and a semiconductor chip mounted as a COG component on the first substrate, the semiconductor chip having a control system configured to control the drivers; wherein the semiconductor chip having a thickness equal to the total thickness of the seal member and the second substrate or larger than the thickness of the seal member and smaller than the total thickness.

Owner:JAPAN DISPLAY WEST

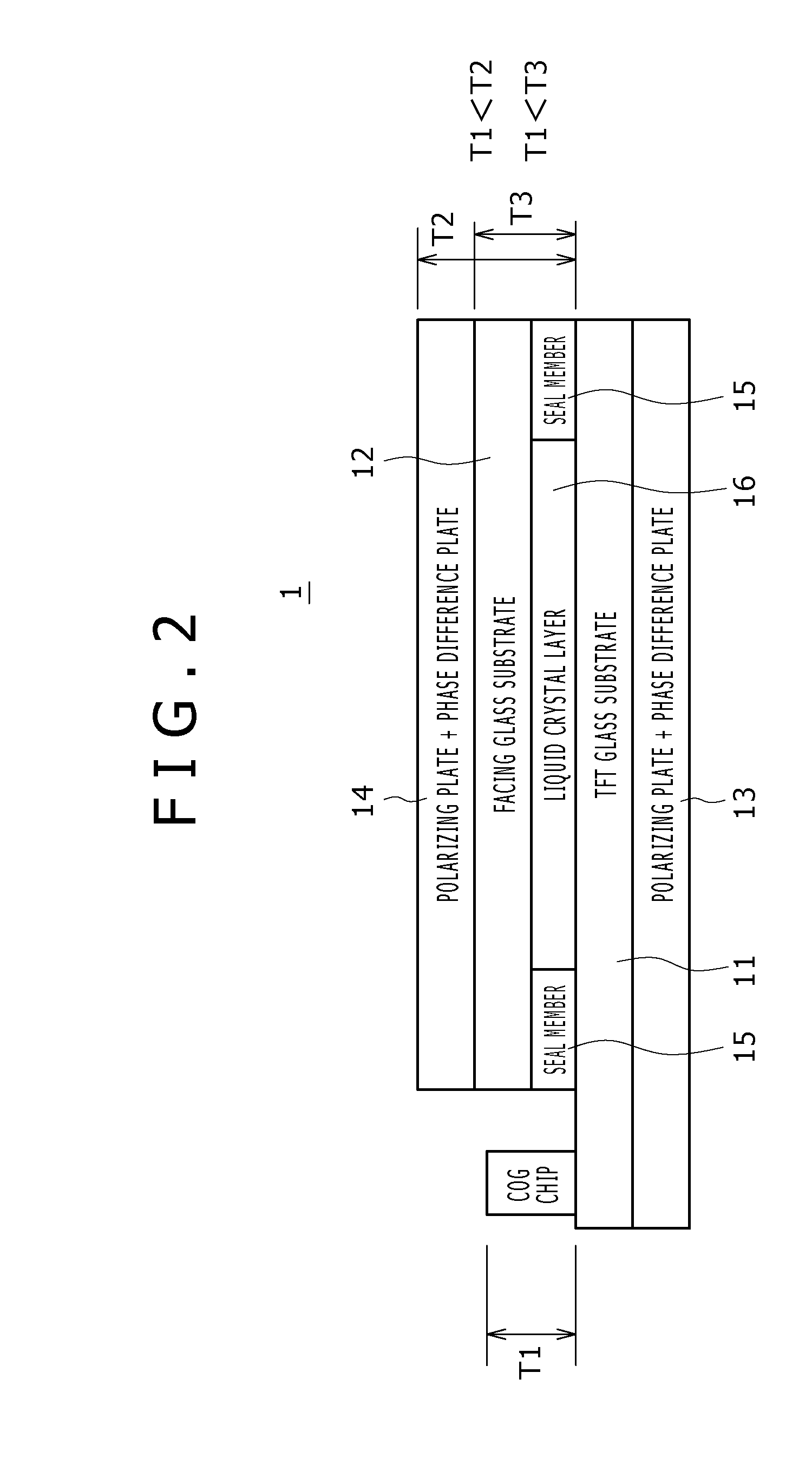

Heat-resistant corrosion-resistant rubber tube

InactiveCN104595593AImprove heat resistanceAccelerated corrosionFlexible pipesHeat resistanceEngineering

The invention discloses a heat-resistant corrosion-resistant rubber tube, and relates to the technical field of manufacturing of the rubber tube. The heat-resistant corrosion-resistant rubber tube comprises a rubber tube body, wherein the rubber tub body comprises an inner rubber layer, a cord fabric layer, a middle rubber layer, a coppered steel wire woven layer and an outer rubber layer which are arranged from inside to outside in sequence; the inner rubber layer is a fluorine rubber layer; the middle rubber layer and the outer rubber layer are both butadiene styrene rubber layers; the inner rubber layer, the cord fabric layer, the middle rubber layer and the coppered steel wire woven layer and the outer rubber layer are connected in a vulcanized manner. Compared with the prior art, the heat-resistant corrosion-resistant rubber tube has the advantages that the heat resistance and the corrosion resistance are greatly improved and the requirement on delivery of high-temperature gas or liquid with certain corrosiveness is met.

Owner:LIUZHOU ERHE AUTO PART

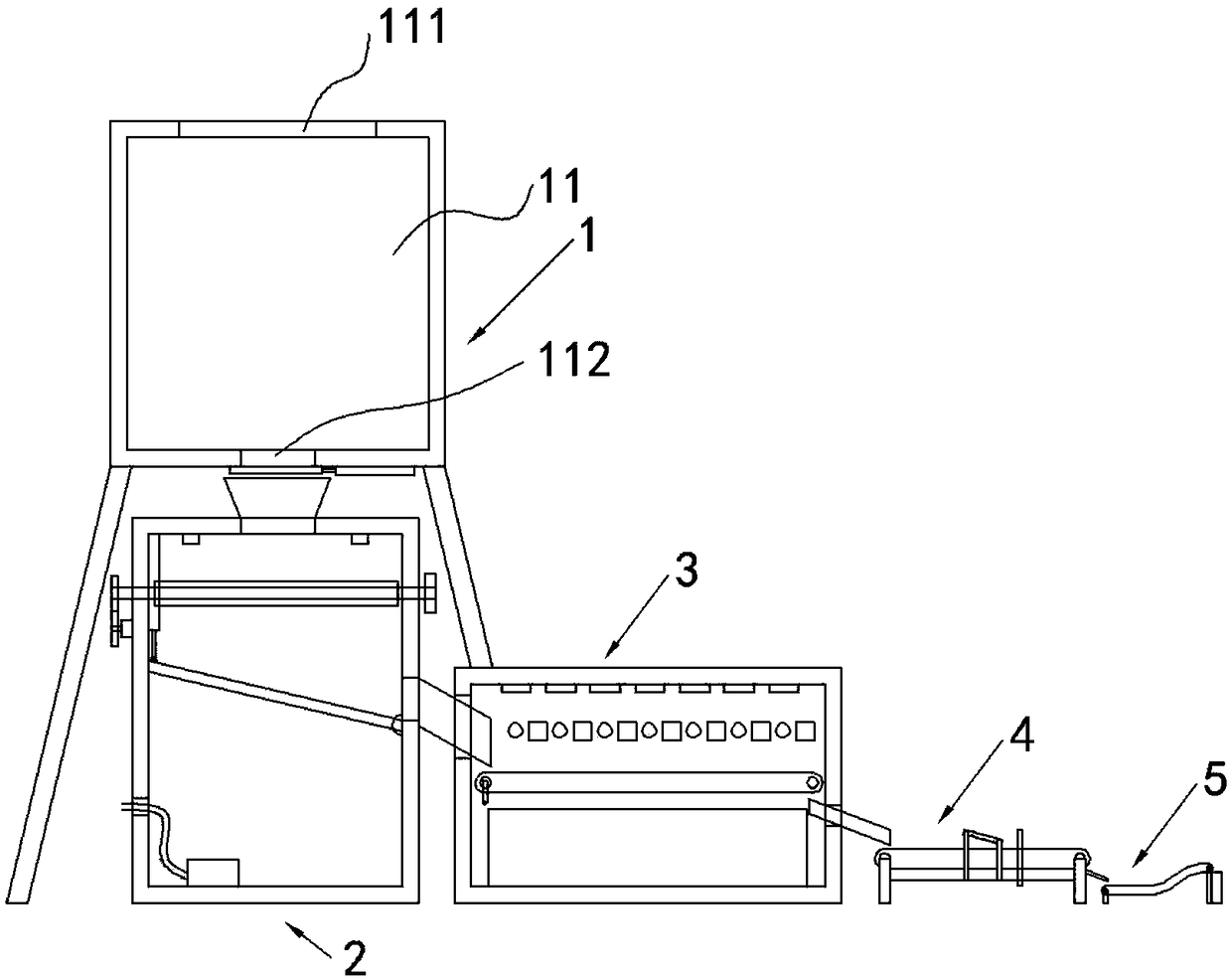

Full-automatic chopped pepper production and processing equipment and production and processing method thereof

PendingCN108450974AThe same thicknessImprove chopping qualityGrain treatmentsFood treatmentElectric heatingEngineering

The invention discloses full-automatic chopped pepper production and processing equipment and a production and processing method thereof and belongs to the technical field of food processing equipment. The full-automatic chopped pepper production and processing equipment comprises a pepper storage mechanism, a pepper cleaning mechanism, a pepper dewatering mechanism, a chopped pepper mechanism anda pepper particle conveying mechanism; the pepper storage mechanism comprises a pepper storage barrel; the pepper cleaning mechanism comprises a cleaning tank, nozzles and a cleaning rotary shaft; the pepper dewatering mechanism comprises a dewatering tank, a first conveyor belt, air blowers, an electric heating sheets, ultraviolet disinfection lamps and a collection pool; the pepper chopping mechanism comprises a second rack, a second conveyor belt and a cutter; the pepper particle conveying mechanism comprises a third conveyor belt and a collection barrel. By adopting the full-automatic chopped pepper production and processing equipment provided by the invention, the thicknesses of pepper layers chopped by the cutter are identical, and the effect of the whole chopping quality is improved; the cleaning tank is internally provided with a filter plate in a hinging and slant manner, and angle rotation of the other end of the filter plate is realized through a second electric push rod, so that the effects that angle rotation changes entrance of a pepper cleaning outlet by peppers on the filter plate are changed to enter a pepper cleaning outlet and the filter water speed is changed;and the first conveyor belt is shaken to increase the pepper drying speed.

Owner:邵阳市万兴农业食品开发有限公司

Heat dissipation device for electronic equipment

ActiveCN105338783AThe same thicknessImprove thermal conductivityCooling/ventilation/heating modificationsHeat conductingElectric equipment

The invention provides a heat dissipation device for electronic equipment. The electronic equipment comprises a circuit board, wherein the circuit board is provided with a plurality of electronic devices, and the plurality of electronic devices generate heat in operation. The heat dissipation device comprises a heat conducting bracket which is fixed on the circuit board and covers the plurality of electronic devices, and the heat conducting bracket performs heat conduction with the electronic devices so as to carry out heat dissipation on the electronic devices. The side surface, which is close to the circuit board, of the heat conducting bracket comprises a first region and a second region, wherein the first region corresponds to positions of the electronic devices whose height is not greater than a first threshold on the circuit board; and the second region corresponds to positions of the electronic devices whose height is greater than the first threshold on the circuit board, and the heat conducting bracket is sunk inwards so as to form a plurality of grooves. The heat dissipation device provided by the invention can enable heat to be transferred to the metal bracket from heat generating elements quickly and more effectively, thereby improving the heat dissipation effect.

Owner:LENOVO (BEIJING) LTD

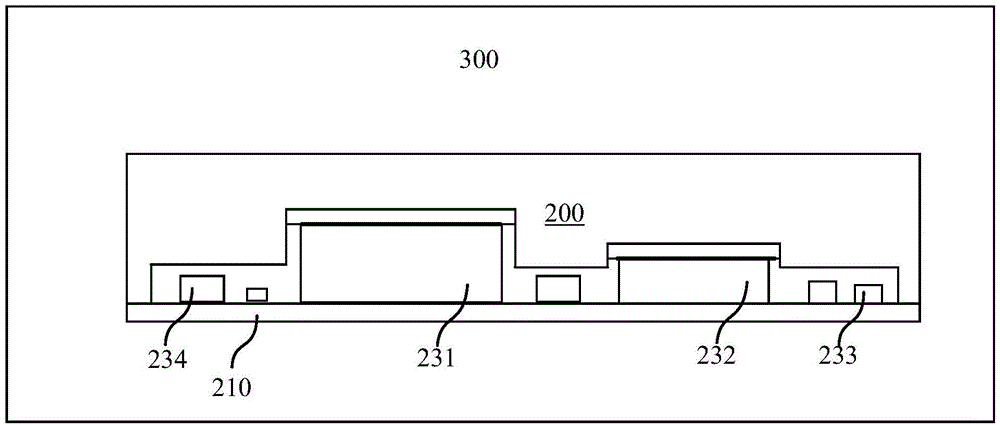

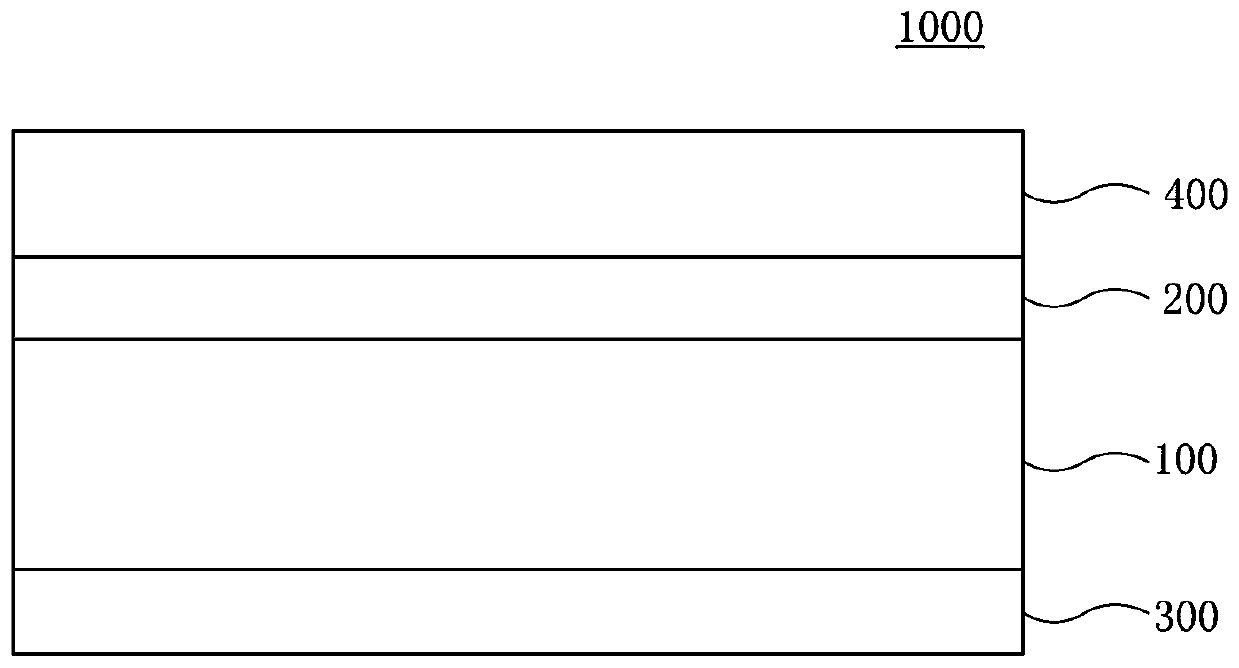

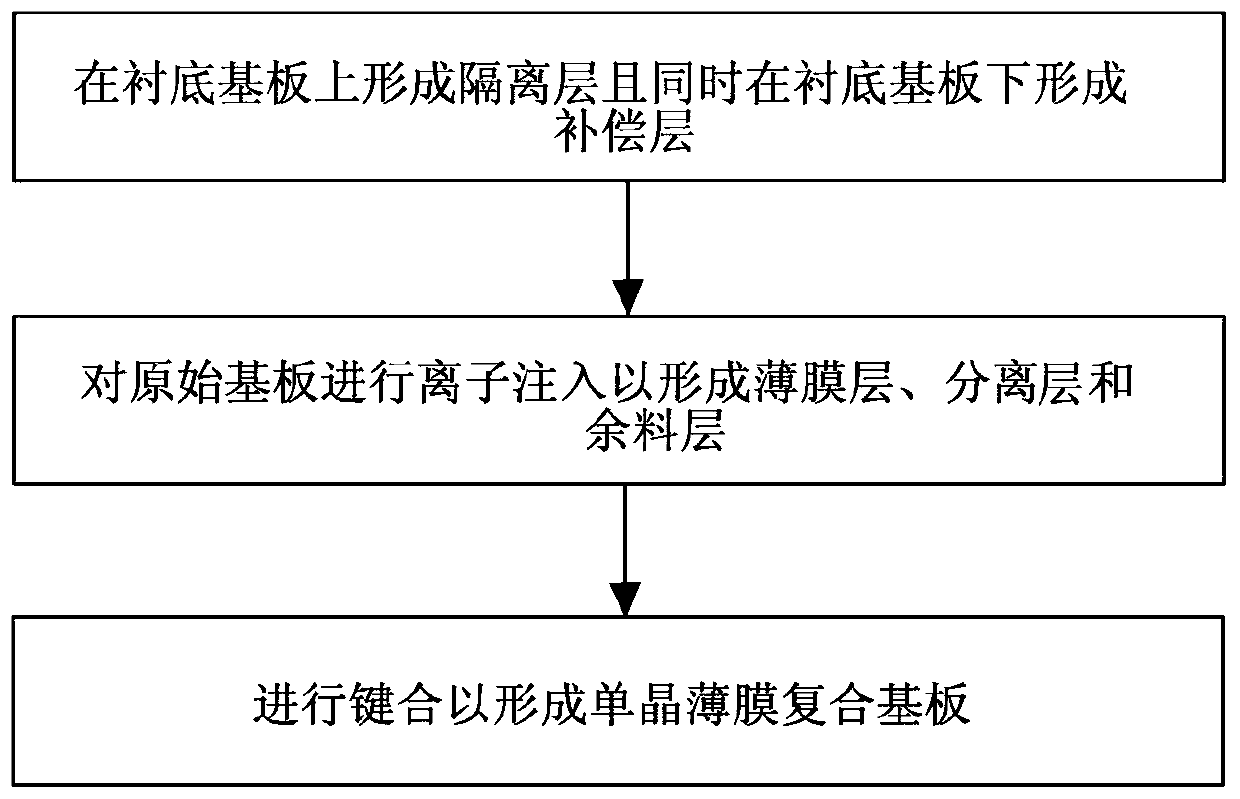

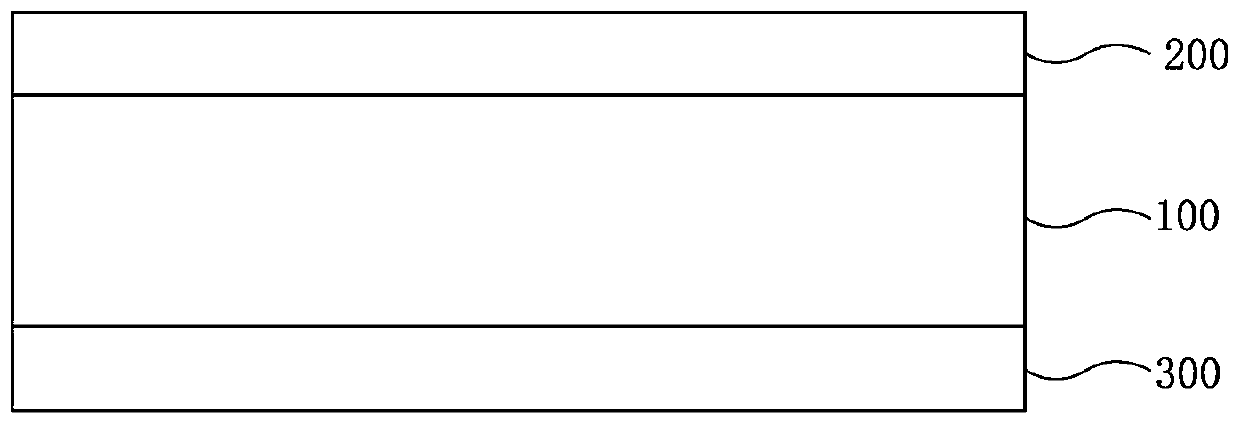

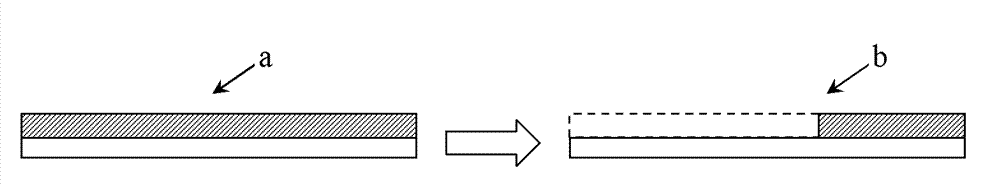

Single crystal thin film composite substrate and manufacturing method thereof

PendingCN110828298AWarpage suppressionThe same thicknessSemiconductor/solid-state device manufacturingPhysical chemistryComposite substrate

The invention discloses a single crystal thin film composite substrate and a manufacturing method thereof. The single crystal thin film composite substrate comprises an underlayer substrate, an isolation layer, a compensation layer and a single crystal thin film functional layer, wherein the isolation layer is located on the underlayer substrate; the compensation layer is located below the underlayer substrate; and the single crystal thin film functional layer is located on the isolation layer, and the isolation layer and the compensation layer are made of the same material. According to the invention, the defect of obvious warpage of the underlayer substrate in the single crystal thin film composite substrate is solved. Meanwhile, the tedious preparation process is avoided, and the process cost is reduced.

Owner:JINAN JINGZHENG ELECTRONICS

Pole lug single body with embedded composite metal structure, row type pole lug, and manufacturing method of pole lug single body

InactiveCN103928651ADoes not affect aestheticsHigh bonding strengthCell component detailsPhysical metallurgyAluminum substrate

The invention relates to a pole lug single body with an embedded composite metal structure, a row type pole lug, and a manufacturing method of the pole lug single body. The pole lug single body is in a strip sheet shape, the whole thickness is 0.05-0.3mm, and the pole lug single body comprises a strip-shaped aluminium substrate and an easily-welded part at one end or the middle position of the aluminium substrate, wherein the easily-welded part is an easily-welded layer rolled and combined with a concave part of the aluminium substrate, the side part and the whole bottom part of the easily-welded layer and the concave part of the aluminum substrate form a physical metallurgy layer, and the thickness of the easily-welded layer is 1-95% of the total thickness of the pole lug single body. The row type pole lug is formed by combining a plurality of the pole lug single bodies through pole lug glue. The manufacturing method comprises: inlaying an easily-welded metal belt in a groove on an aluminium belt surface, and rolling; performing continuous bright annealing and rolling on the rolled composite metal belt; shearing to obtain the pole lug single body; and performing surface de-oiling, passivation and drying processing on the pole lug single body. The pole lug is high in combination strength and small in contact resistance. The method is low in cost and easy to realize.

Owner:徐卓辉 +1

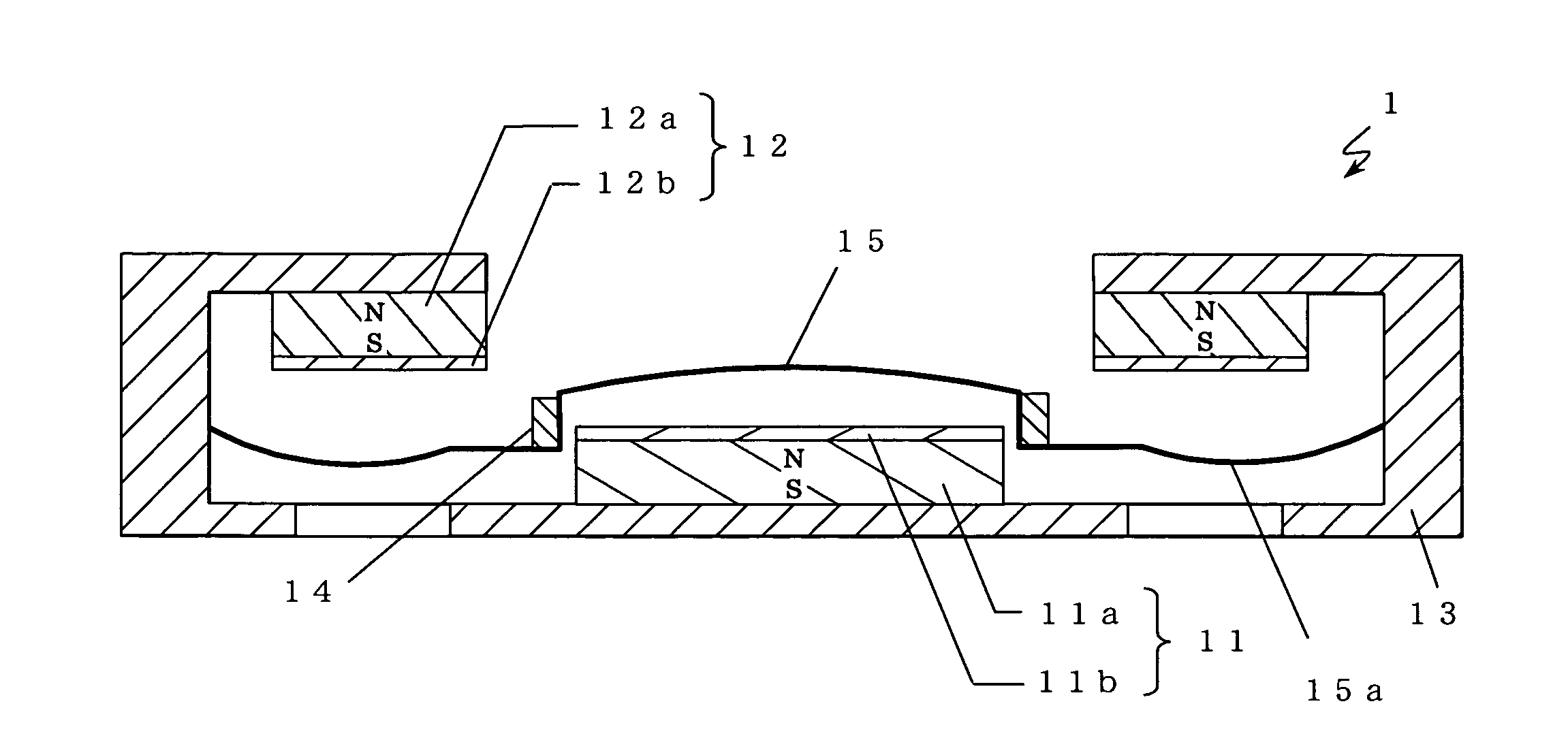

Electrodynamic electroacoustic transducer and electronic device

ActiveUS7885425B2Improve performanceReduce flux densityTransducer detailsDeaf-aid setsTransducerMagnetic poles

An electrodynamic electroacoustic transducer comprises: a first magnetic pole; a second magnetic pole that forms a magnetic gap between itself and the first magnetic pole and is arranged in a space excluding spaces in upper and lower face directions of the first magnetic pole; a yoke; a diaphragm; and a voice coil. The yoke magnetically couples one magnetic pole face of the first magnetic pole with one magnetic pole face of the second magnetic pole so as to support them. The diaphragm is arranged in a space in an upper face direction of the first magnetic pole and in a space in a lower face direction of the second magnetic pole, while its outer periphery is supported by the yoke. The voice coil is arranged in the magnetic gap and adhered to the diaphragm. At least one of the first magnetic pole part and the second magnetic pole part includes a magnet.

Owner:PANASONIC CORP

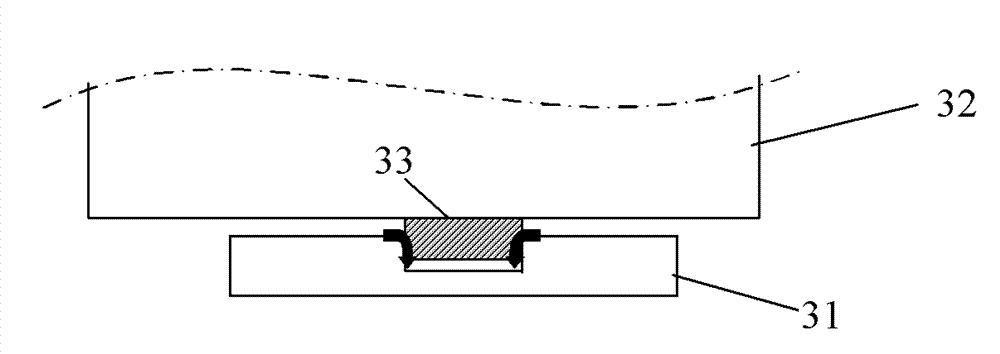

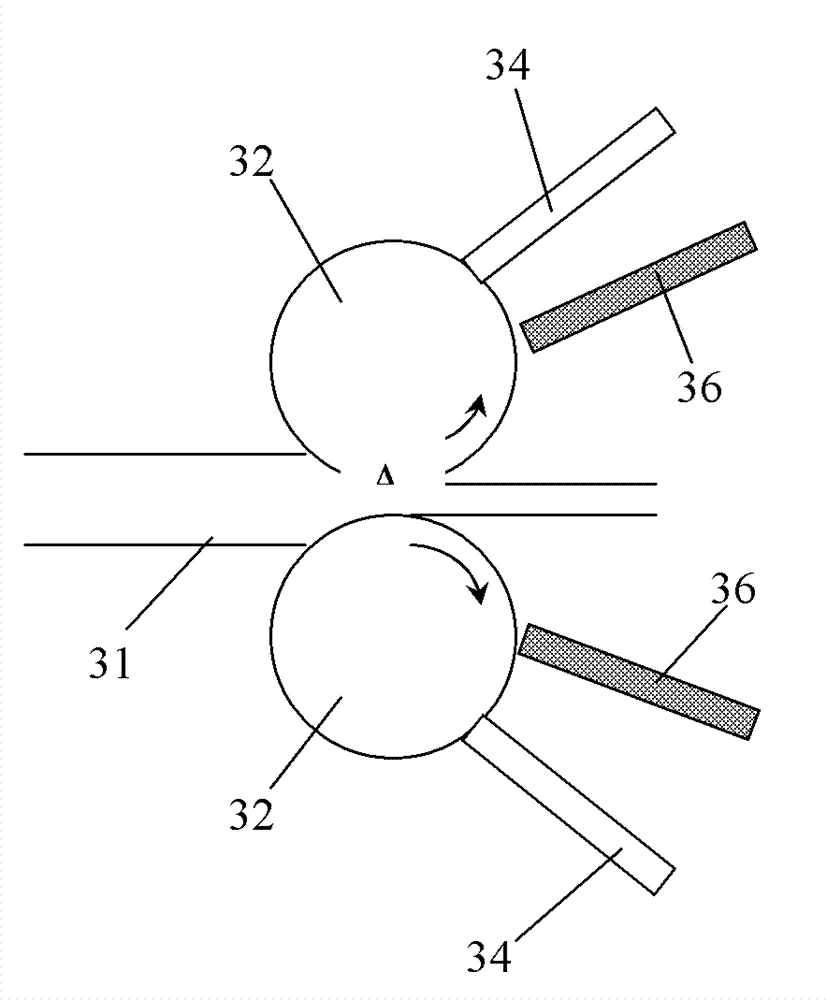

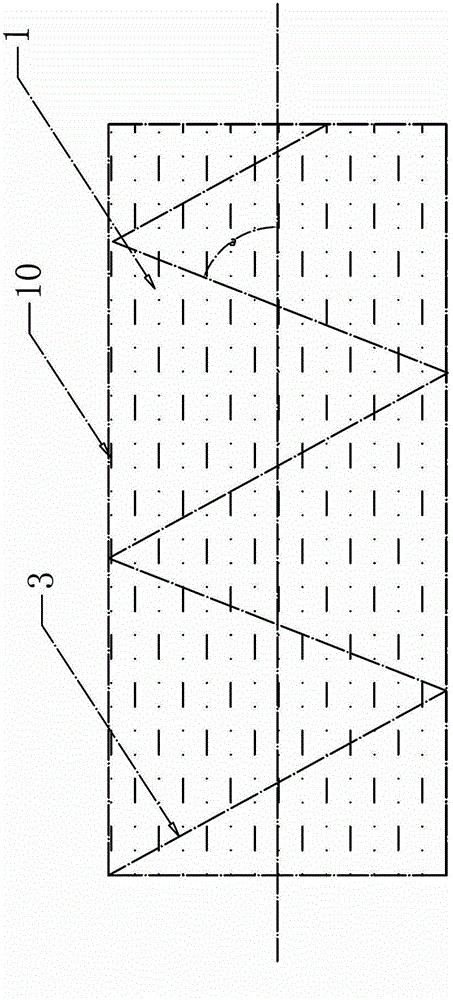

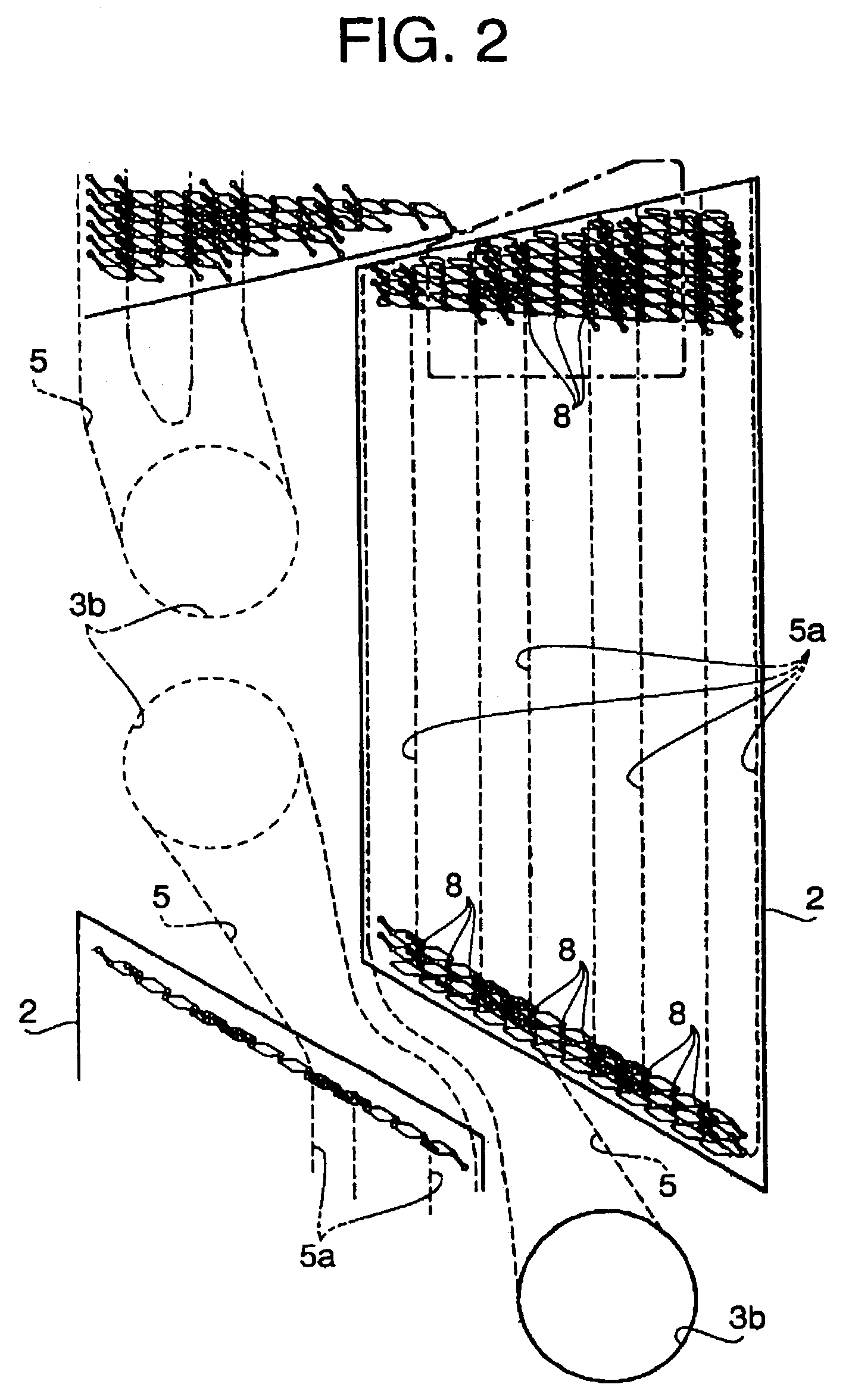

Manufacturing method of whole-piece bamboo-bunch veneer and overlong bamboo-bunch laminated veneer lumber

The invention discloses a manufacturing method of a whole-piece bamboo-bunch veneer and an overlong bamboo-bunch laminated veneer lumber. The method comprises the specific steps that a raw material is selected and pretreated; bamboo wood is conveyed to brooming rolling equipment in a rift grain direction; the conveyed bamboo wood is broomed, beaten and rolled by the equipment, and is subjected to devillicate treatment after a plurality of periods to be manufactured into bunchiness fibers with uniform specifications; bunchiness fiber units that are arranged tightly and orderly in the rift grain direction are discharged; the bunchiness fiber units are sewn or bonded to ensure that the bunchiness fiber units in the same row are connected together; a bamboo-bunch veneer is manufactured; the whole-piece bamboo-bunch veneer is manufactured; a plurality of whole-piece bamboo-bunch veneers are overlaid, assembled, and subjected to cold pressing and heat pressing treatment; and the finished overlong bamboo-bunch laminated veneer lumber is manufactured. The whole-piece bamboo-bunch veneer and the overlong bamboo-bunch laminated veneer lumber manufactured by the method are uniform in density; the raw material can be saved greatly on the premise that national standards are met; bamboo green and tabasheer in the raw bamboo wood can be kept; and bamboo wood consumption and waste of manpower and material resources caused by removing the bamboo green and the tabasheer in the prior art can be avoided.

Owner:INT CENT FOR BAMBOO & RATTAN

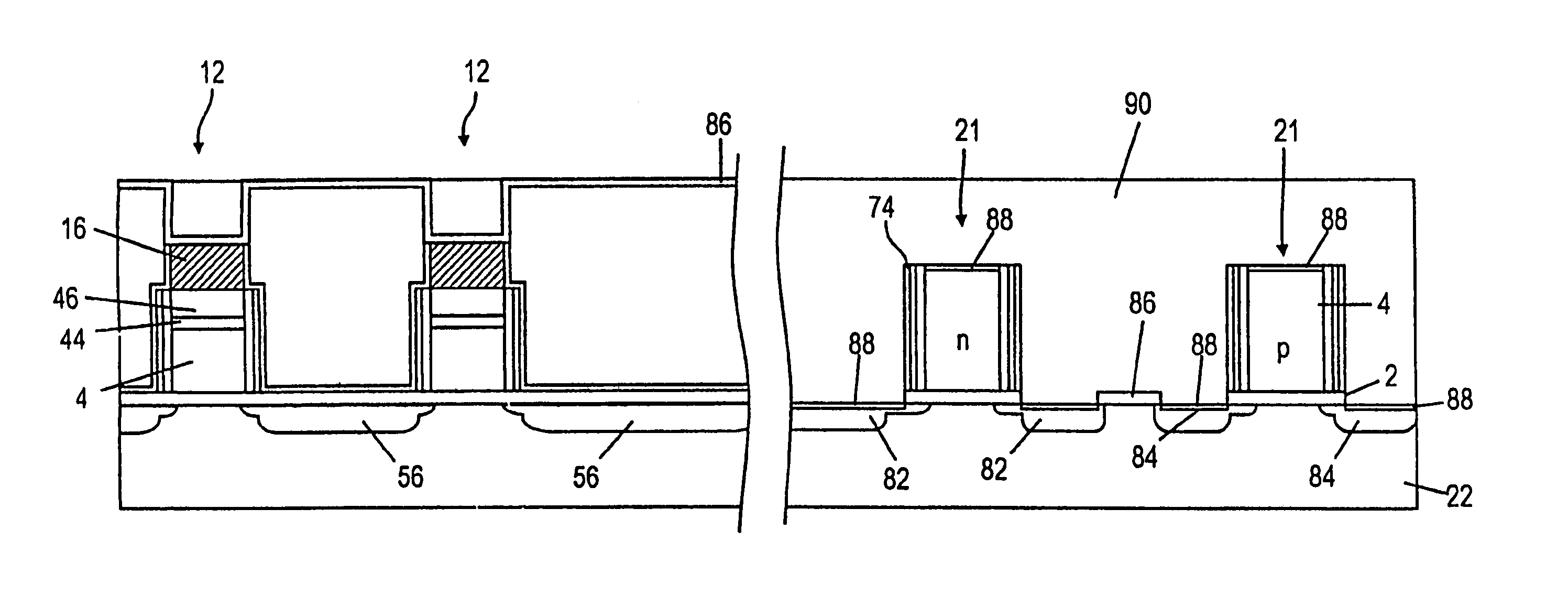

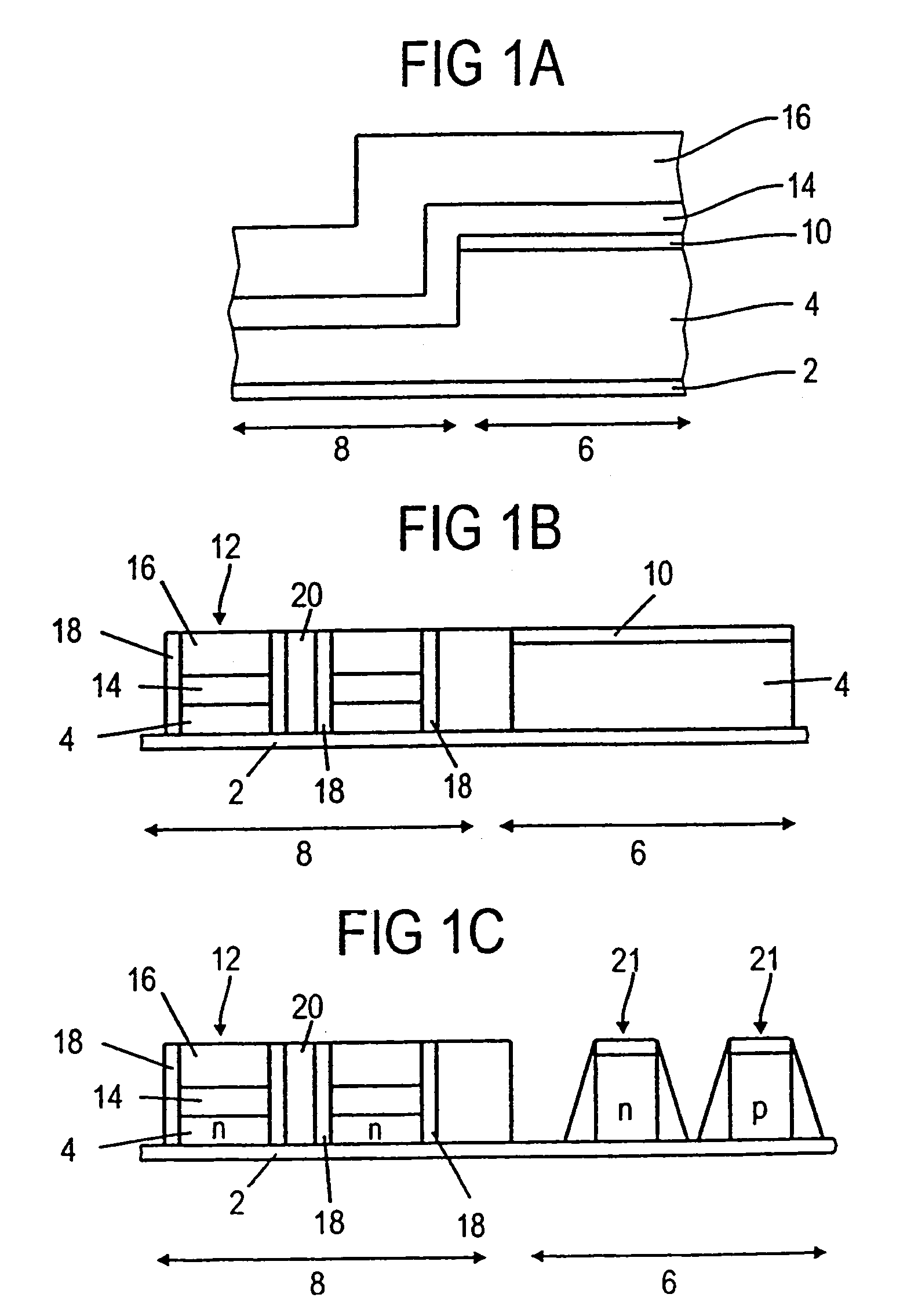

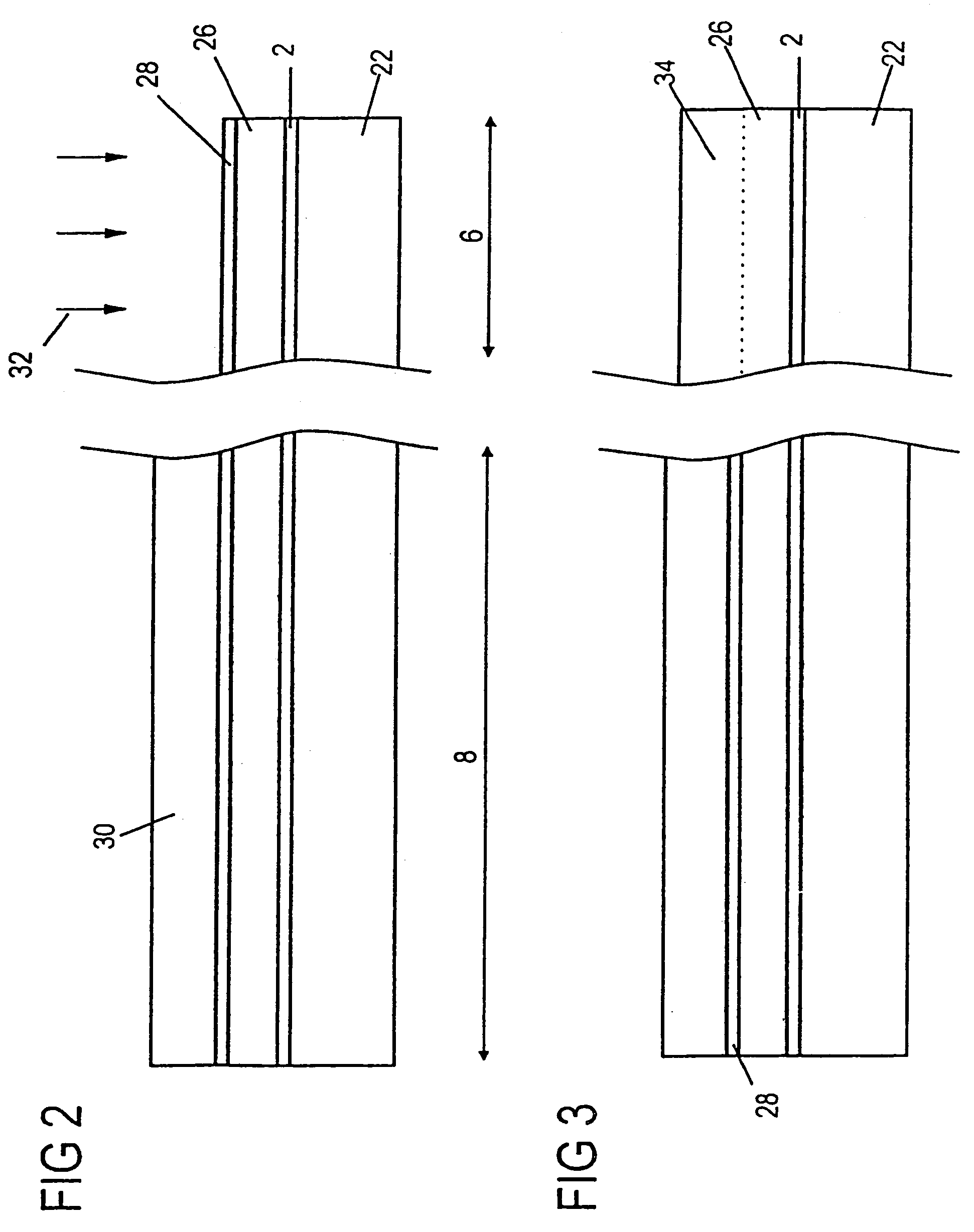

Method for fabricating a semiconductor product with a memory area and a logic area

InactiveUS7217610B2Highly uniform dopingEasy to fillTransistorSolid-state devicesGate dielectricField-effect transistor

A method for the integration of field-effect transistors for memory and logic applications in a semiconductor substrate is disclosed. The gate dielectric and a semiconductor layer are deposited over the whole area both in the logic region and in the memory region. From these layers, the gate electrodes in the memory region are formed, the source and drain regions are implanted and the memory region is covered in a planarizing manner with an insulation material. Afterward, the gate electrodes are formed from the semiconductor layer and the gate dielectric in the logic region.

Owner:POLARIS INNOVATIONS

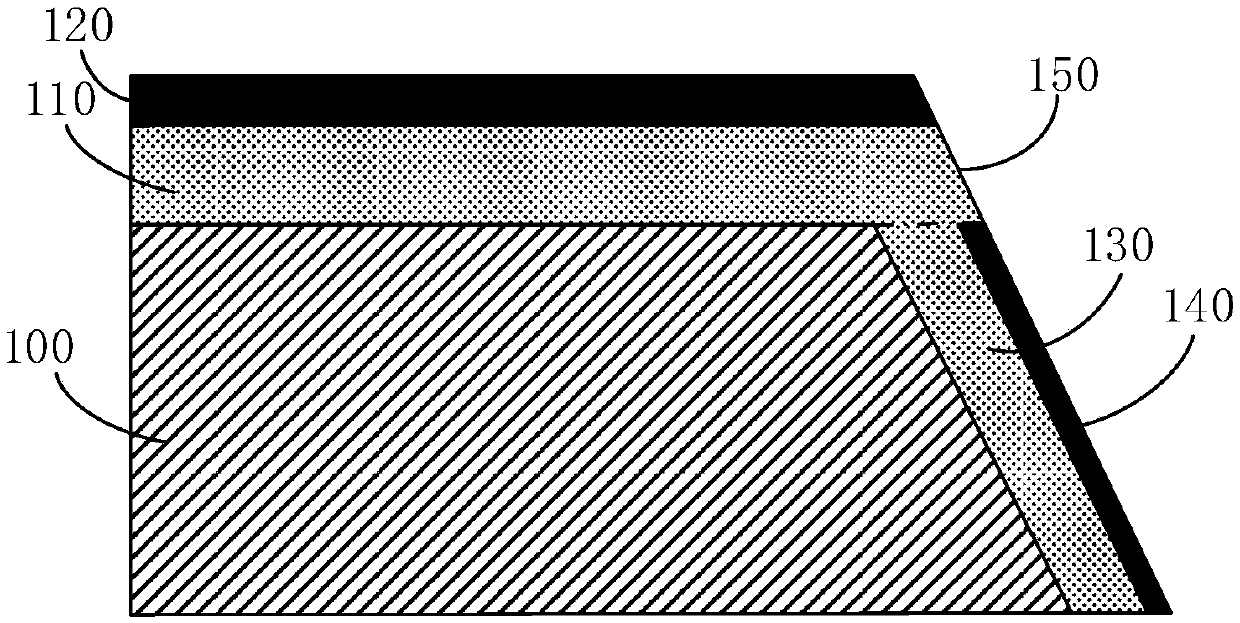

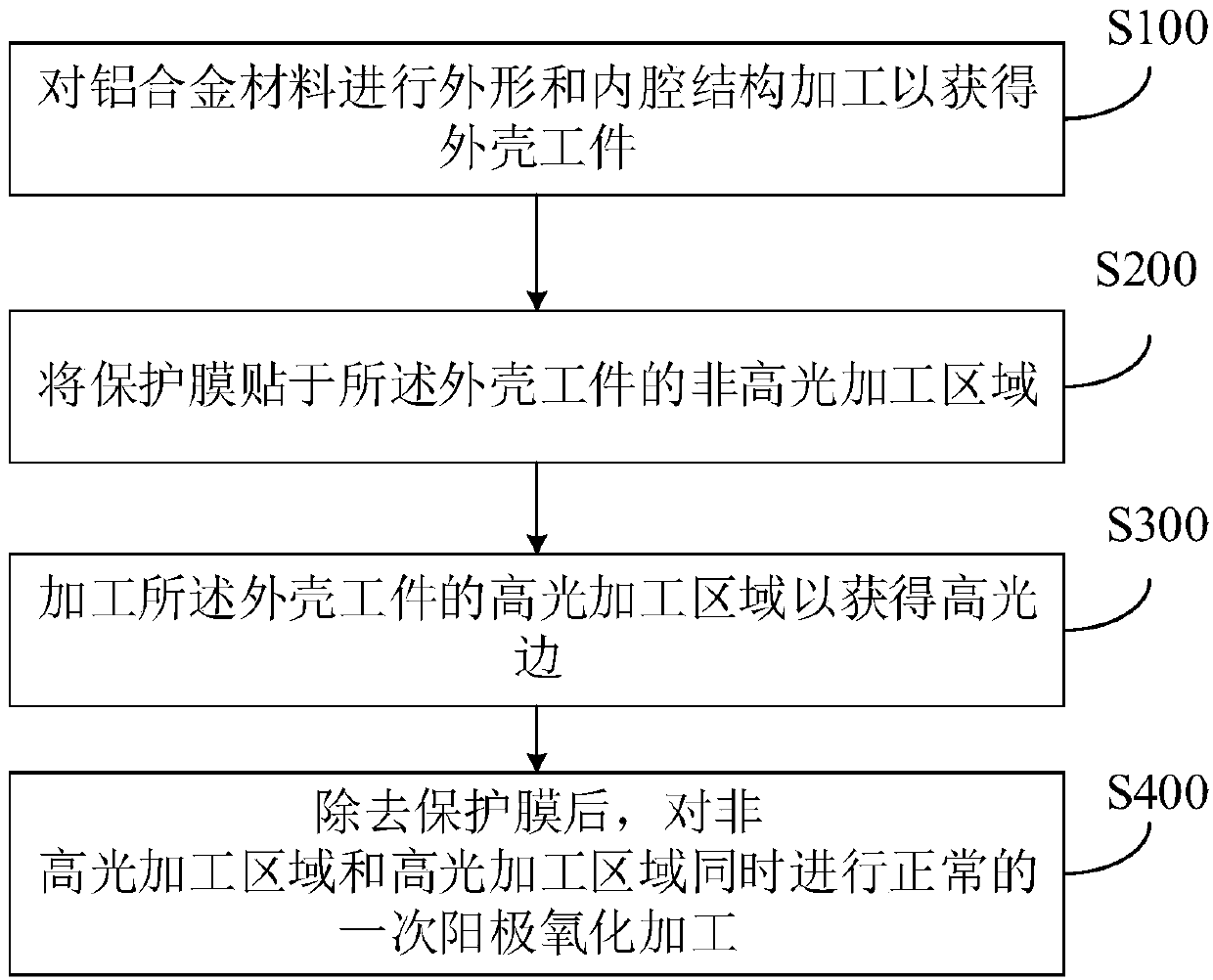

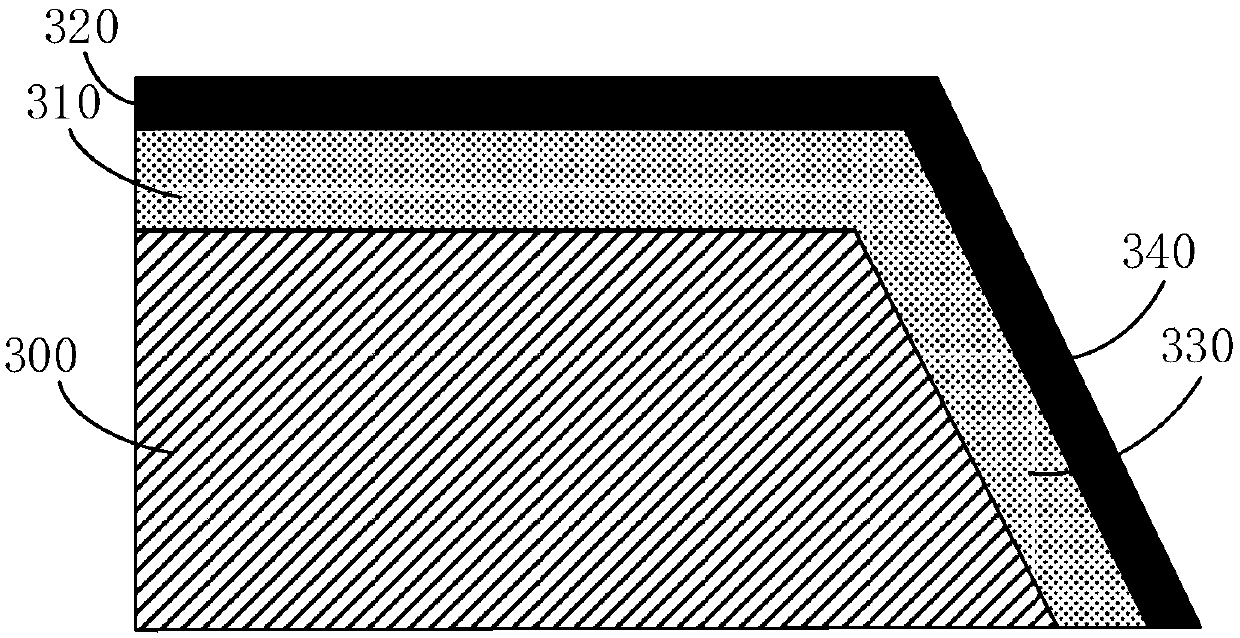

Aluminum alloy shell, machining method thereof and electronic equipment

InactiveCN107740154AGood overall appearanceLow costAnodisationTelephone set constructionsAnodic oxidationWhite line

The invention discloses an aluminum alloy shell, a machining method thereof and electronic equipment. The machining method of the aluminum alloy shell comprises the steps that the shape and an inner cavity structure of an aluminum alloy material are machined, so that a shell workpiece is obtained; protective film is attached to a non-highlight machining area of the shell workpiece; a highlight machining area of the shell workpiece is machined to obtain a highlight side; and after the protective film is removed, the non-highlight machining area and the highlight machining area are subjected tonormal primary anodic oxidation machining at the same time. According to the technology provided by the invention, oxidation film of the highlight side and the oxidation film of the non-highlight areaare the same in thickness, color and film layer property, white line defects existing during ordinary highlight same color anodic oxidation do not exist, and the appearance integrity is very good.

Owner:QIKU INTERNET TECH SHENZHEN CO LTD

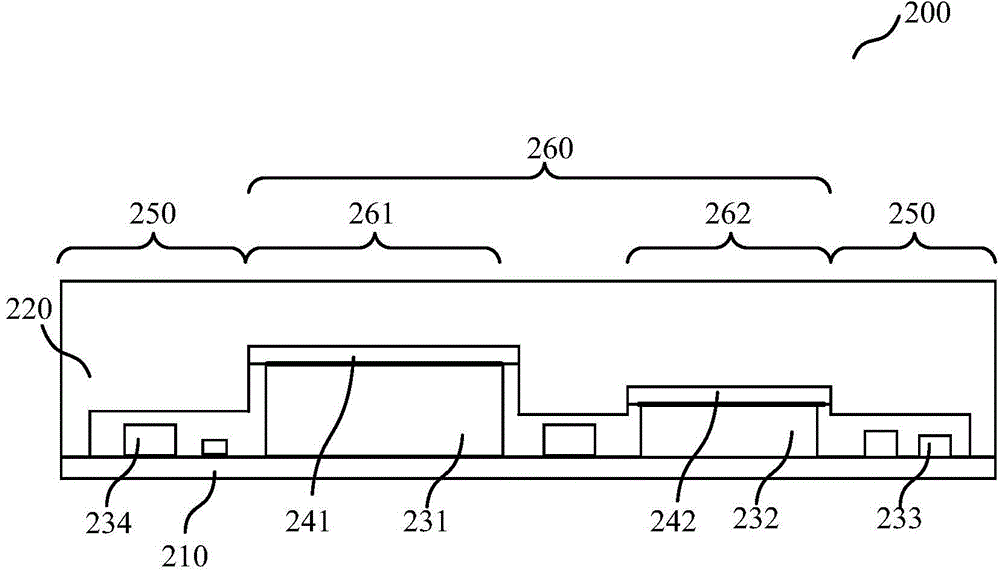

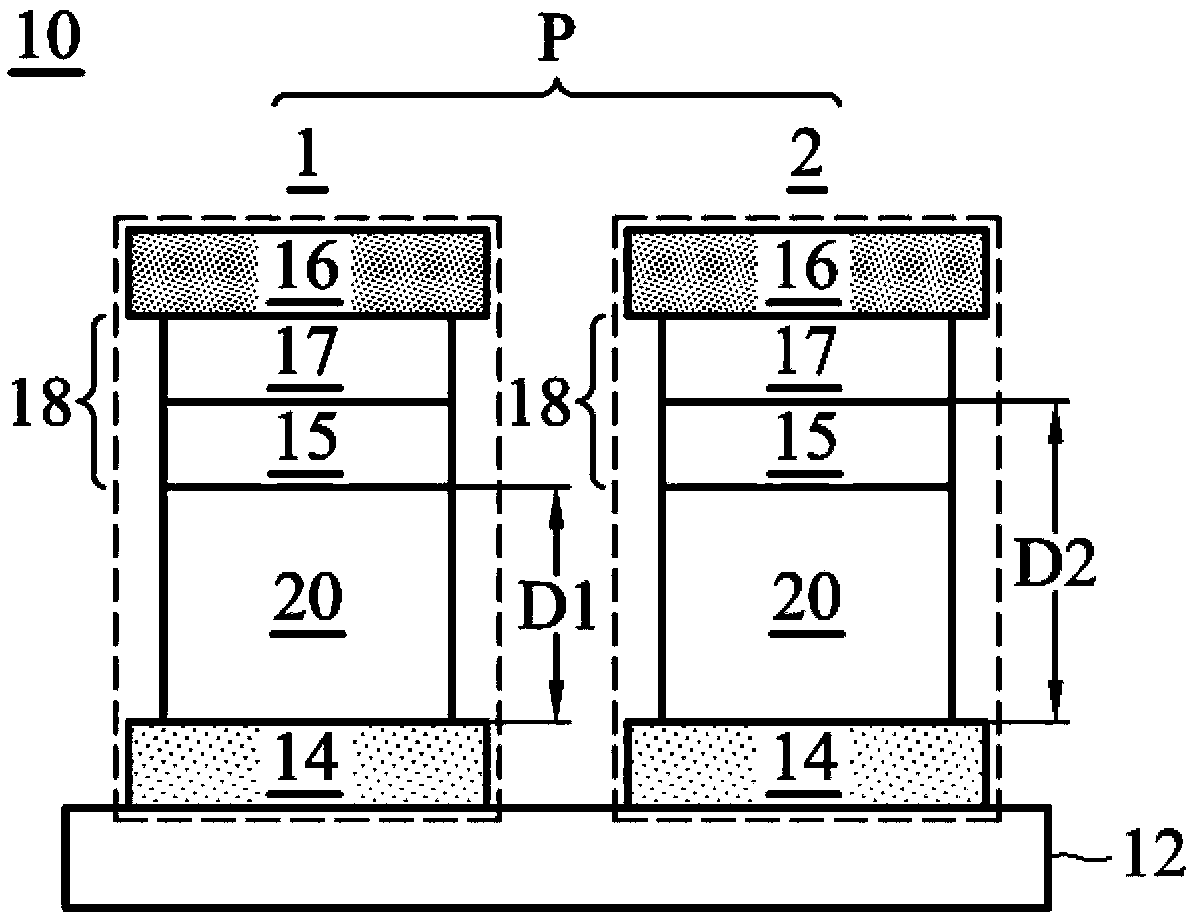

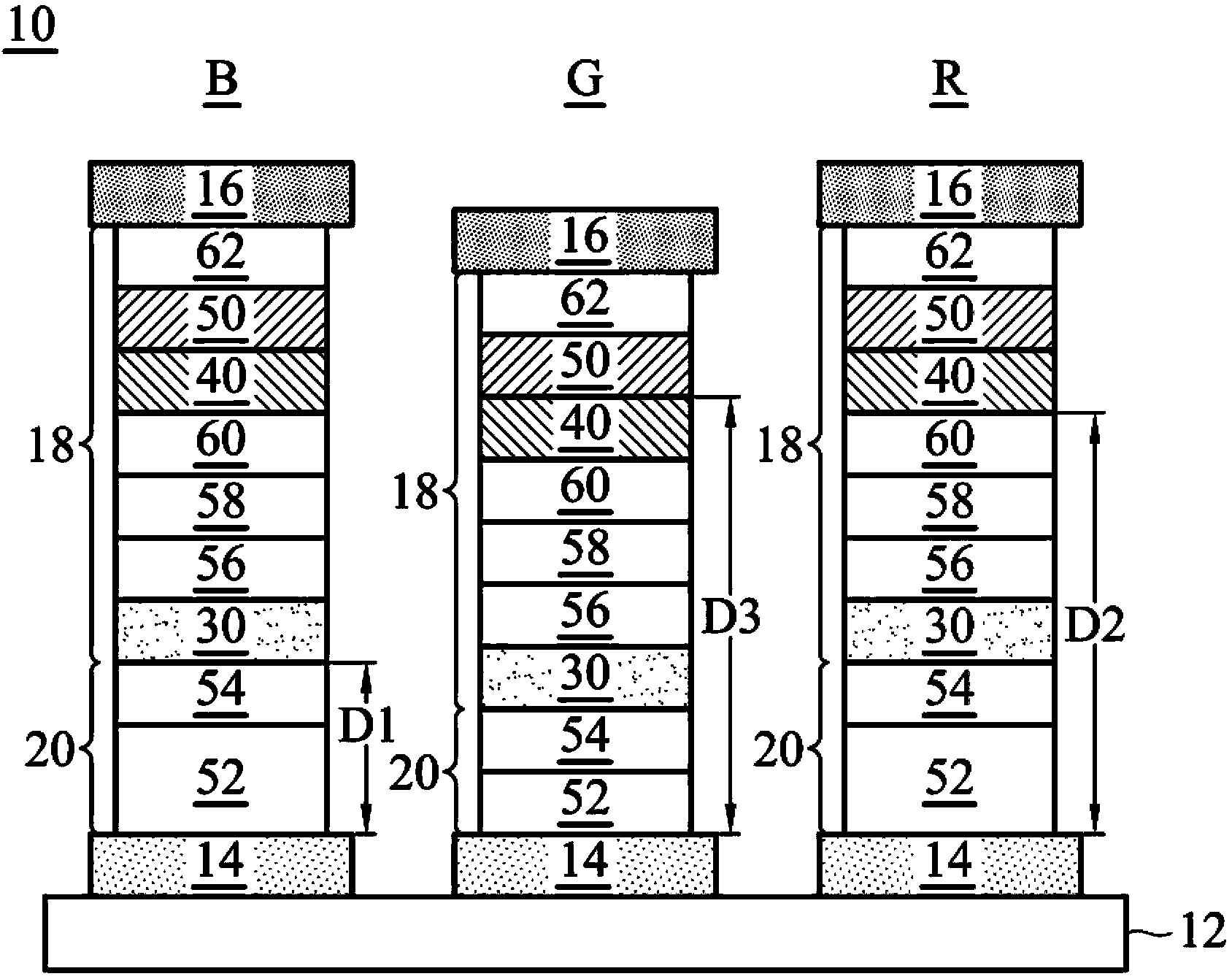

Organic light-emitting device and image display system comprising organic light-emitting device

ActiveCN104218169AThe same thicknessSolid-state devicesSemiconductor/solid-state device manufacturingOptical pathPixel array

The invention discloses an organic light-emitting device and an image display system comprising the organic light-emitting device. The organic light-emitting device comprises a substrate and an organic light-emitting pixel array arranged on the substrate, wherein the organic light-emitting pixel array comprises a plurality of pixels; each pixel comprises a first sub-pixel and a second sub-pixel; each sub-pixel comprises a first electrode, an organic light-emitting unit and a second electrode; an optical path adjusting layer is arranged between the first electrode and the organic light-emitting unit or between the second electrode and the organic light-emitting unit; and the optical path adjusting layer of each first sub-pixel and the optical path adjusting layer of each second sub-pixel are substantially the same in thickness.

Owner:INNOLUX CORP

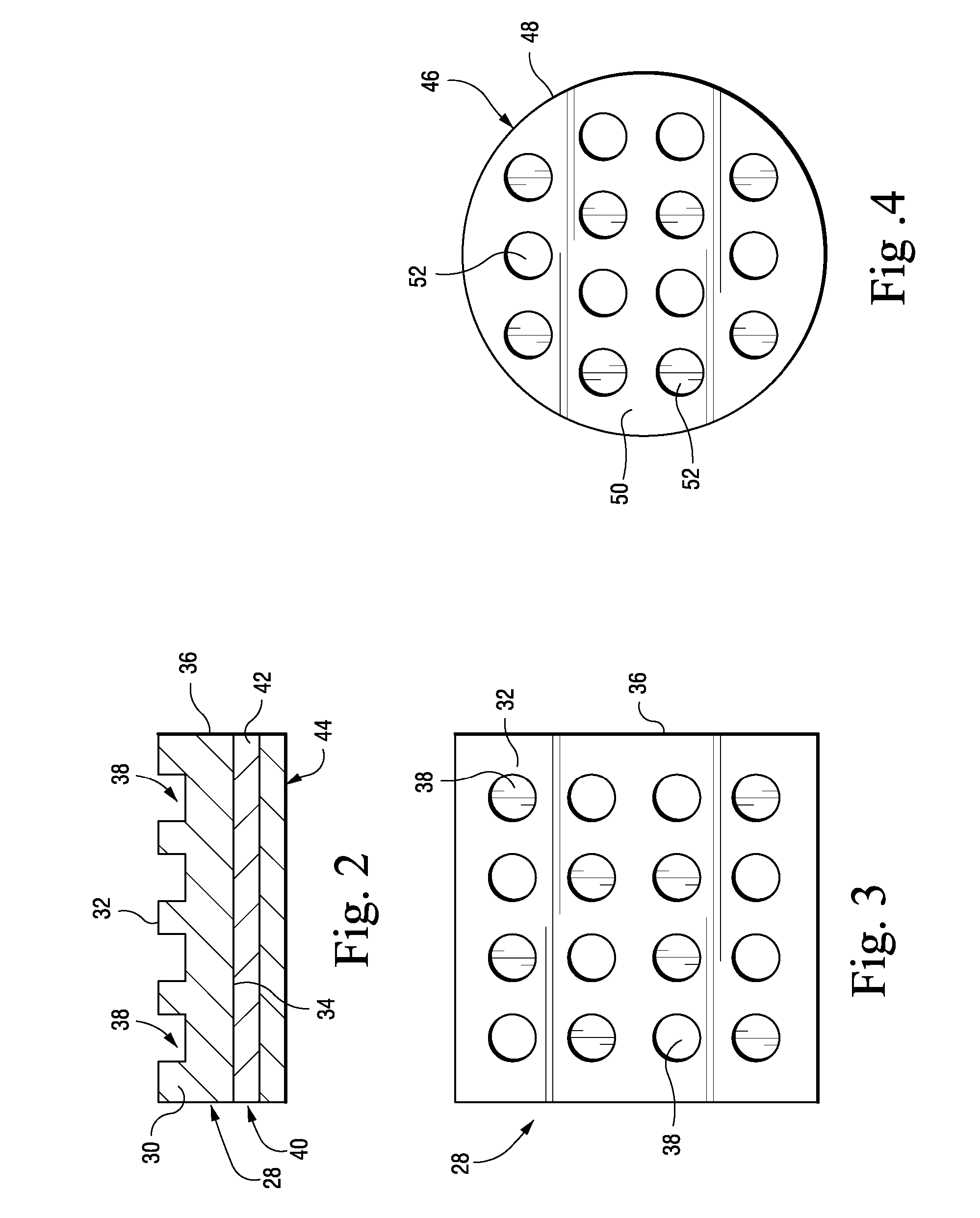

Inkjet head for inkjet printing apparatus having pressure chambers and actuator unit

InactiveUS6986565B2Improve electricity efficiencyIncrease the areaInking apparatusEngineeringActuator

An inkjet head is provided with a plurality of pressure chambers, each of which is configured such that an end thereof is connected to a discharging nozzle and the other end is connected to an ink supplier, and an actuator unit for the plurality of pressure chambers. The actuator unit is formed to be a continuous planar layer including at least one inactive layer arranged on a pressure chamber side and at least one active layer arranged on a side opposite to the pressure chamber side with respect to the inactive layer, the planar layer covering the plurality of pressure chambers. The at least one active layer is sandwiched between a common electrode and a plurality of driving electrodes arranged at positions corresponding to the plurality of pressure chambers. The continuous planar layer includes a plurality of active layers or a plurality of inactive layers.

Owner:BROTHER KOGYO KK

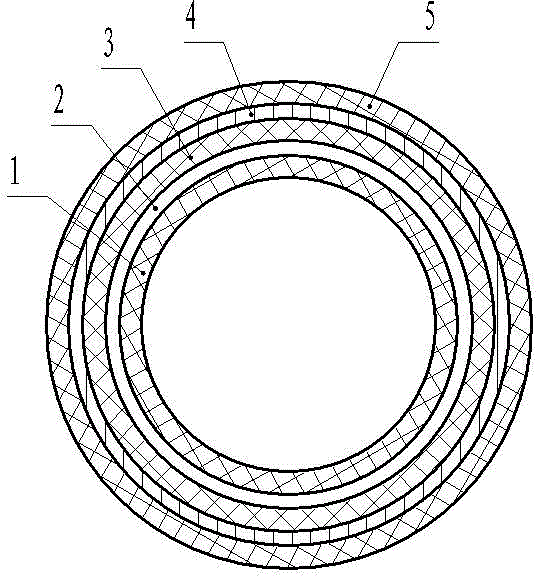

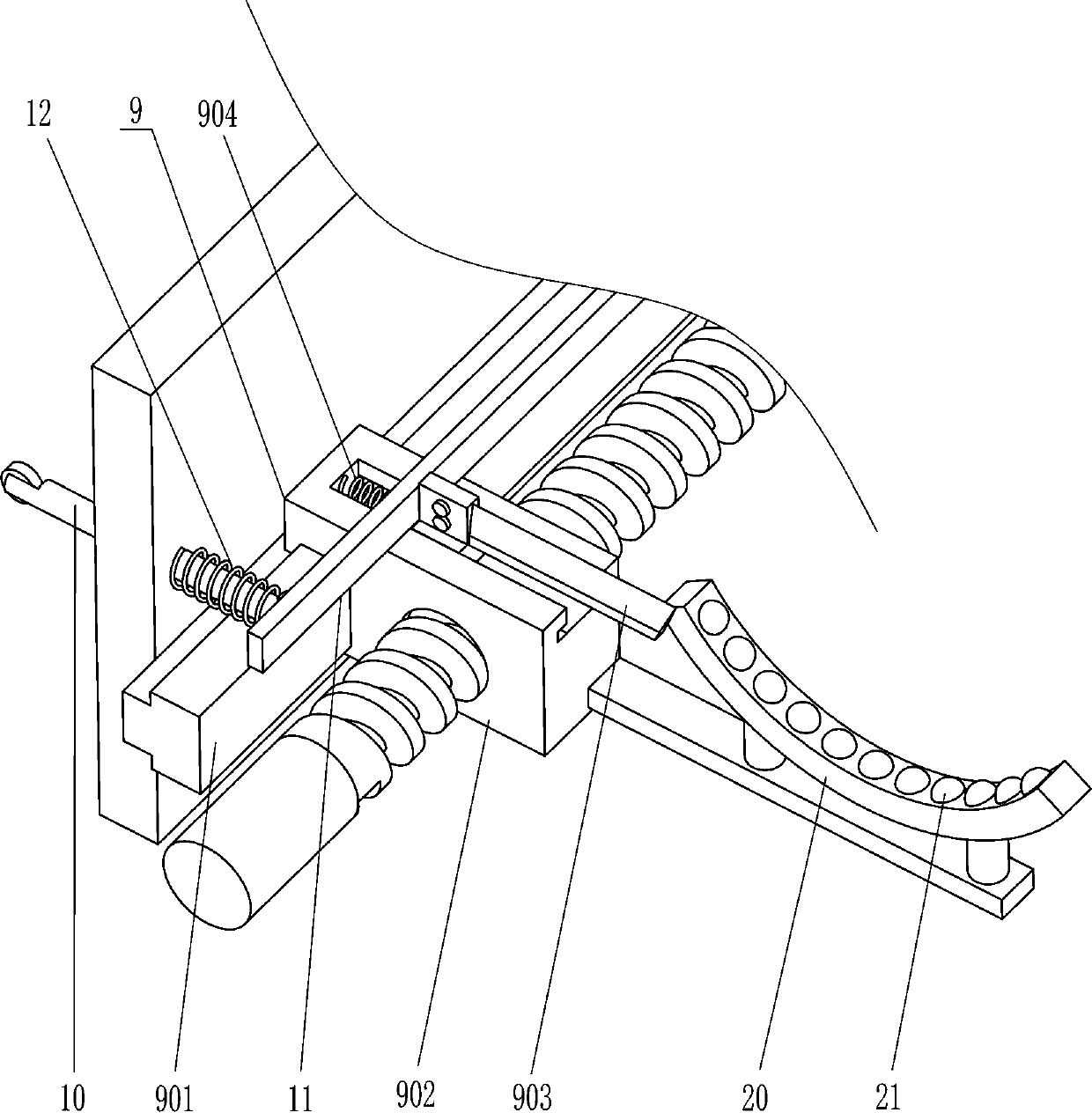

Sealing ring edge cutting equipment

ActiveCN111469177AThe same thicknessAvoid affecting cuttingMetal working apparatusElectric machineryIndustrial engineering

The invention relates to edge cutting equipment, particularly relates to sealing ring edge cutting equipment, and aims to provide the sealing ring edge cutting equipment which can replace people to cut a rubber cylinder into sealing rings so as to enable the thicknesses of the cut sealing rings to be consistent and enable the use cost to be low. The sealing ring edge cutting equipment comprises abottom plate and a supporting frame, wherein a mounting frame is arranged on one side of the bottom plate, and the supporting frame is installed on the side, close to the mounting frame, of the bottomplate. According to the equipment, the rubber cylinder is placed in an annular placing frame and fixed by a fastening bolt, a first motor is started to enable the rubber cylinder to rotate forwards,then an edge cutting assembly is pushed to move forwards to cut part of the rubber cylinder into a sealing ring, a driving assembly is started to enable the edge cutting assembly to move rightwards bythe same distance every time, and then the edge cutting assembly is pushed to cut the rubber cylinder, so that manual cutting is not needed, time and labor are saved, and the thicknesses of the cut sealing rings are the same.

Owner:赵正芽

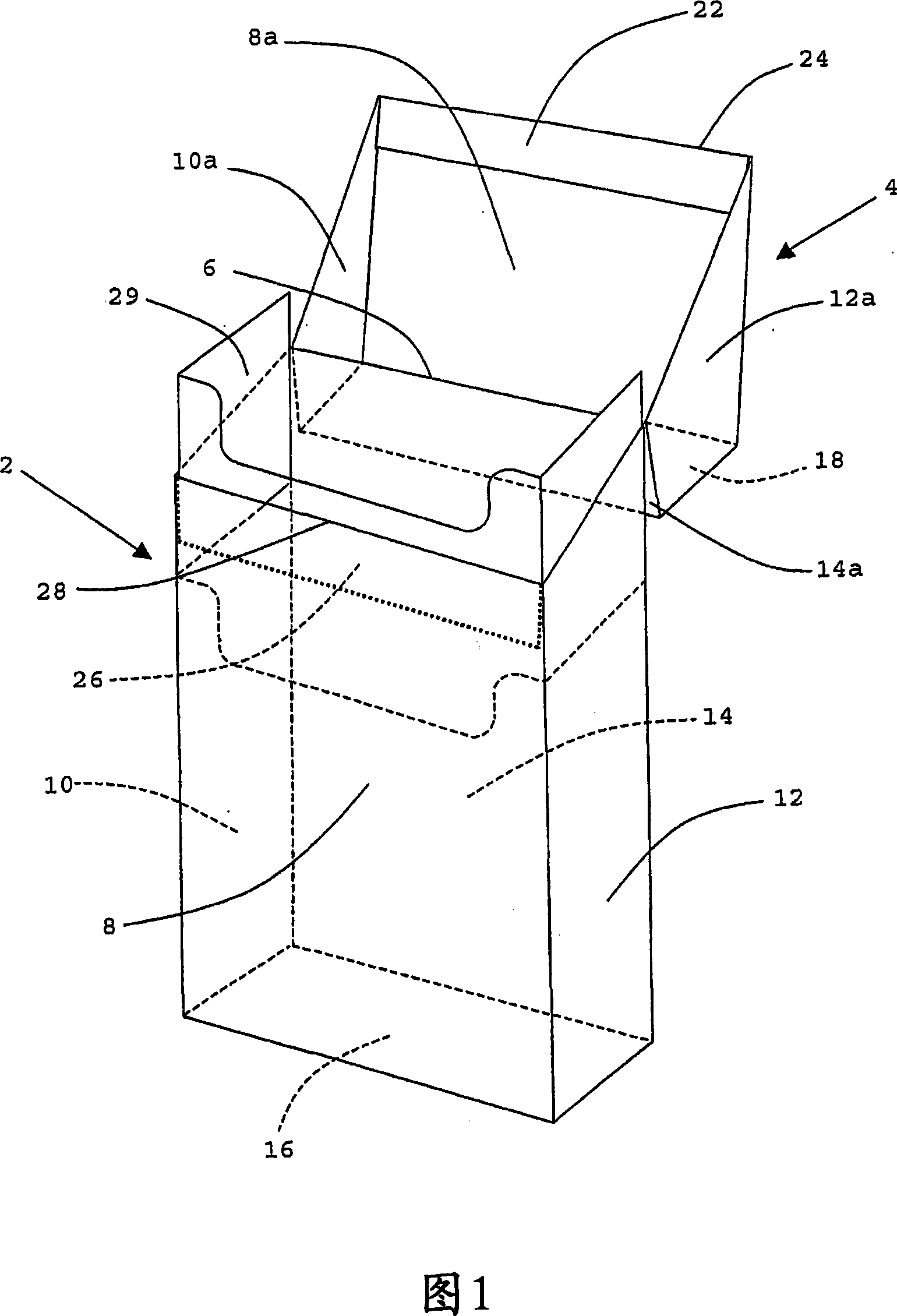

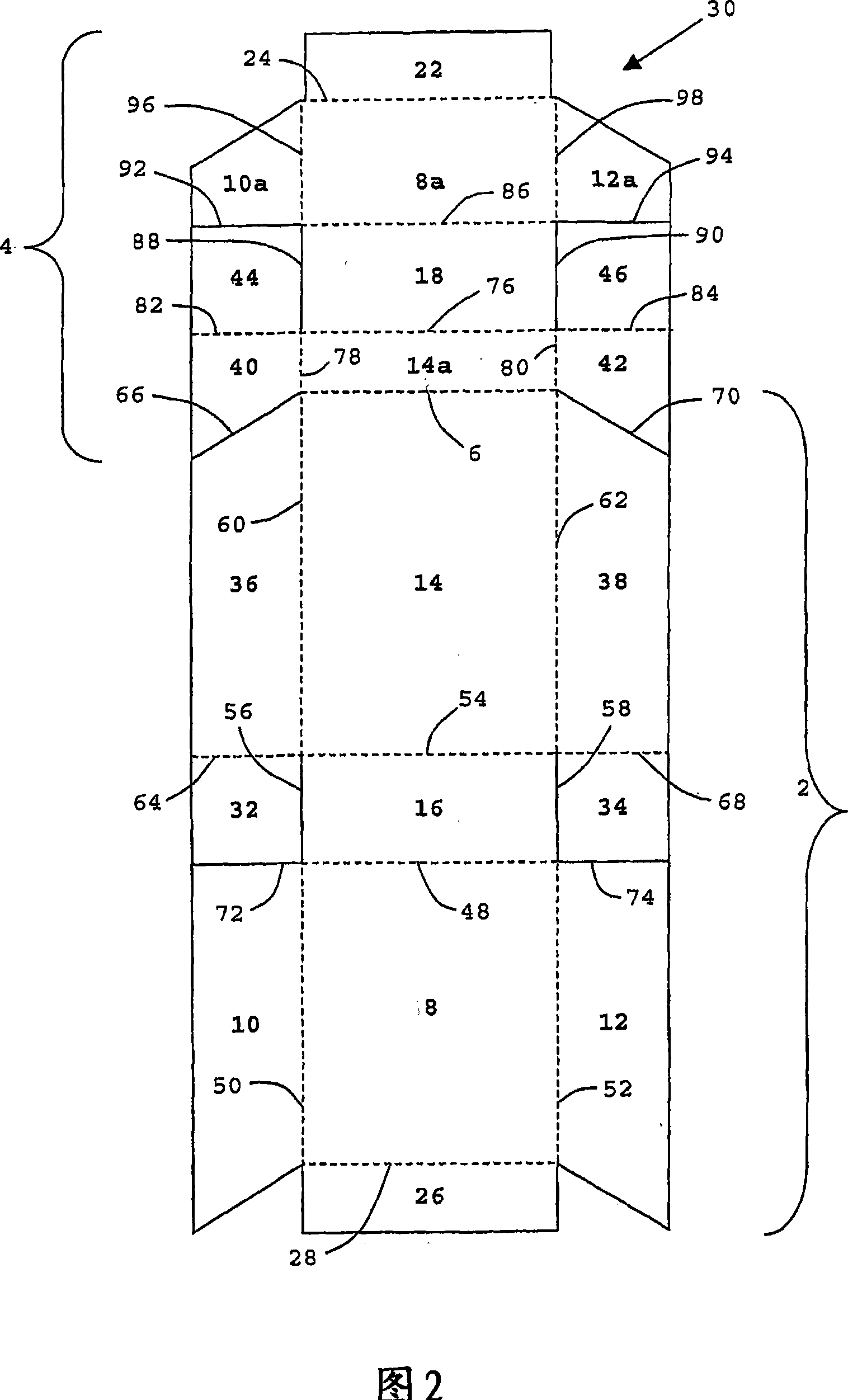

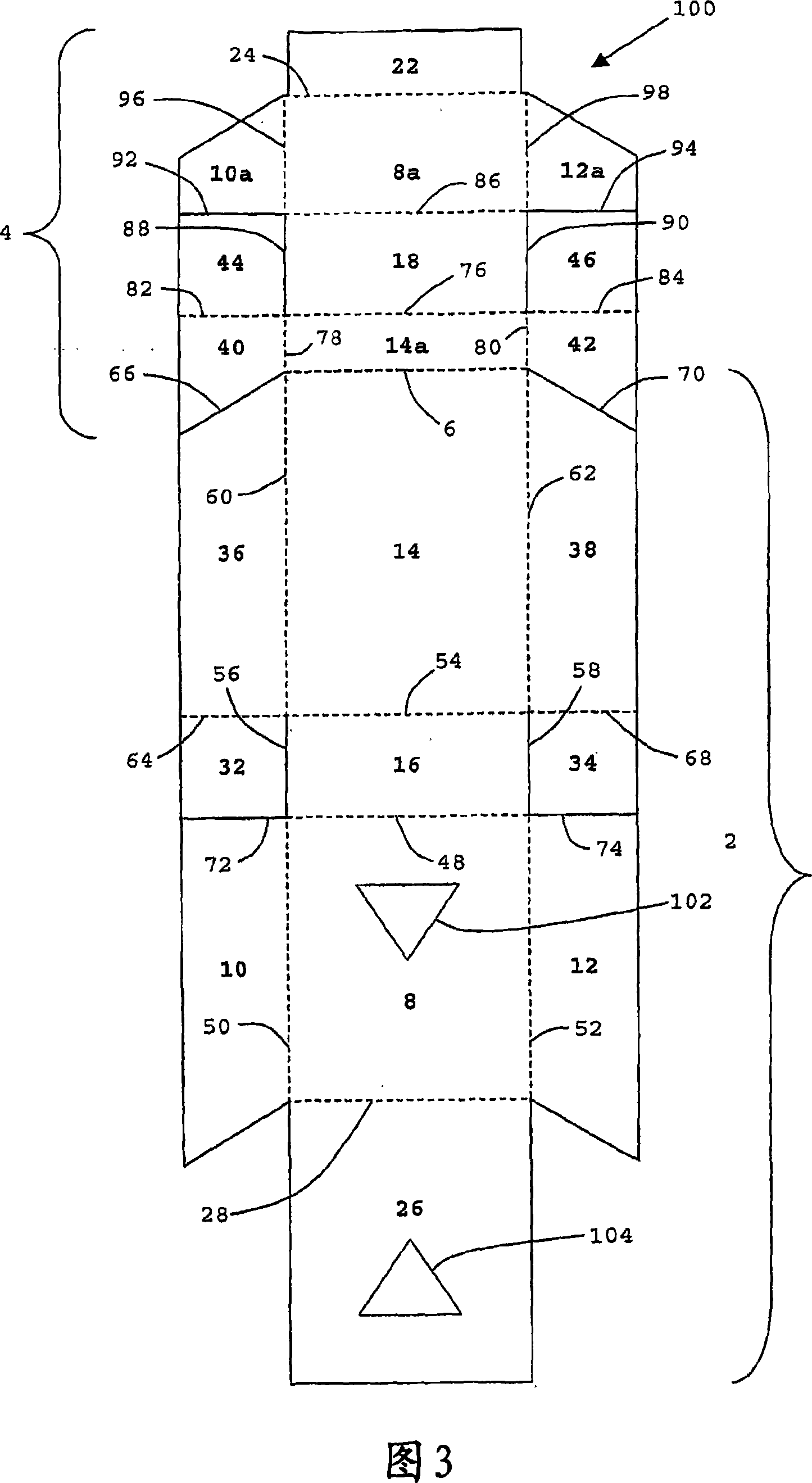

Hinge-lid container with additional spacer panel

InactiveCN101072711AHigh strengthIncreasing the thicknessContainers for flexible articlesPackaging cigaretteCardboardCarton

A hinge-lid container finding particular application as a hinge-lid pack or carton for elongate smoking articles such as cigarettes comprises: a box portion (2); a lid portion (4) hinged to the box portion (2) across a rear wall (14) thereof for pivotal movement between an open position and a closed position; a flap (22) extending across a lower part of the inner surface of a front wall (8a) of the lid portion (4); and a spacer panel (26) extending across at least an upper part of the inner surface of a front wall (8) of the box portion (2). The spacer panel (29), which preferably depends from and is folded about the upper edge (28) of the front wall (8) of the box portion (2), has a free edge that extends across the inner surface of the front wall (8) of the box portion (2) and does not project from the box portion (2) into space covered by the lid portion (4) in the closed position.

Owner:PHILIP MORRIS PROD SA

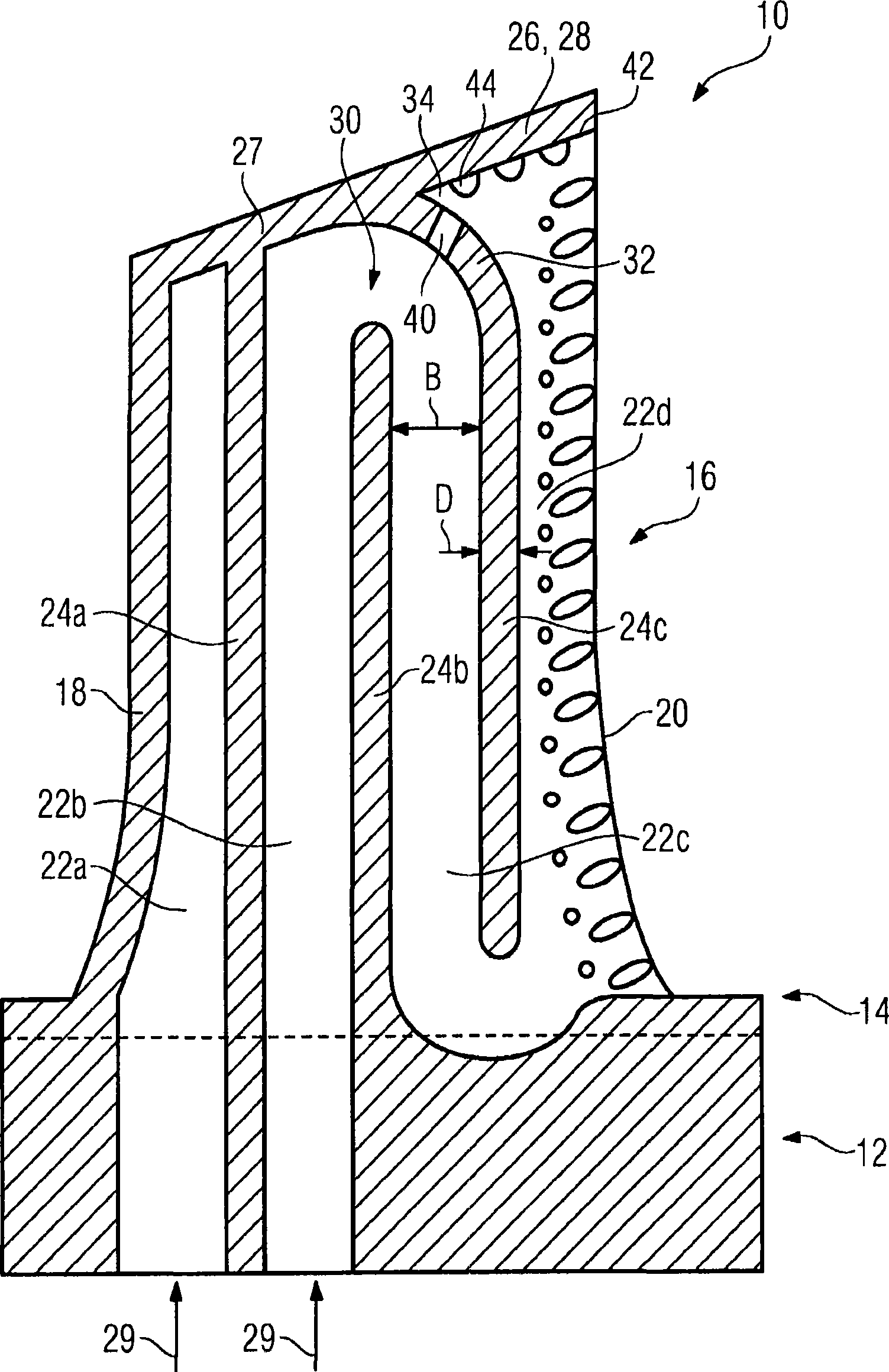

Cooled turbine rotor blade

InactiveCN101512106AAerodynamicEasy to manufactureEngine manufactureEngine fuctionsTurbine bladeFront edge

The invention specifies a turbine rotor blade (10) for a gas turbine which is traversed axially by flow, which turbine rotor blade (10) is equipped with a fastening region (12) and an aerofoil profile (16). Meandering cooling ducts (22b, 22c, 22d) with interposed deflecting regions (30) are provided in the interior of the aerofoil profile (16). In the deflecting regions (30), it is possible to prevent dead water regions, which are generated in the prior art, by virtue of at least one of the fins (24) running so as to curve towards the front edge (18) or towards the rear edge (20) in the region of the aerofoil tip (27). At the same time, an opening (40) is provided in the curvature (32) of the fin (24), through which opening (40) a part of the coolant (29) which flows in the deflecting region (30) can pass over into the adjacent cooling duct (24).

Owner:SIEMENS AG

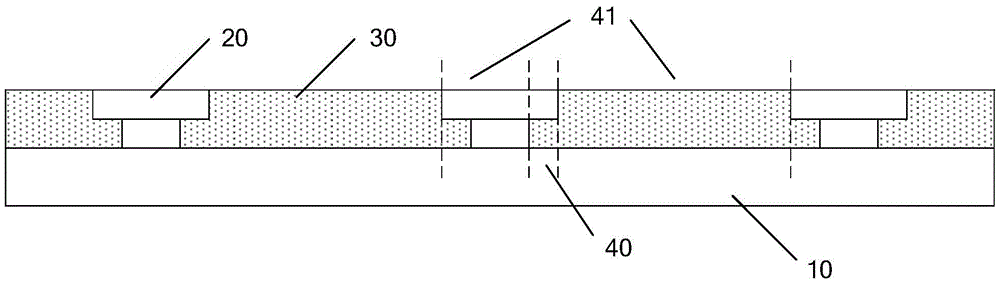

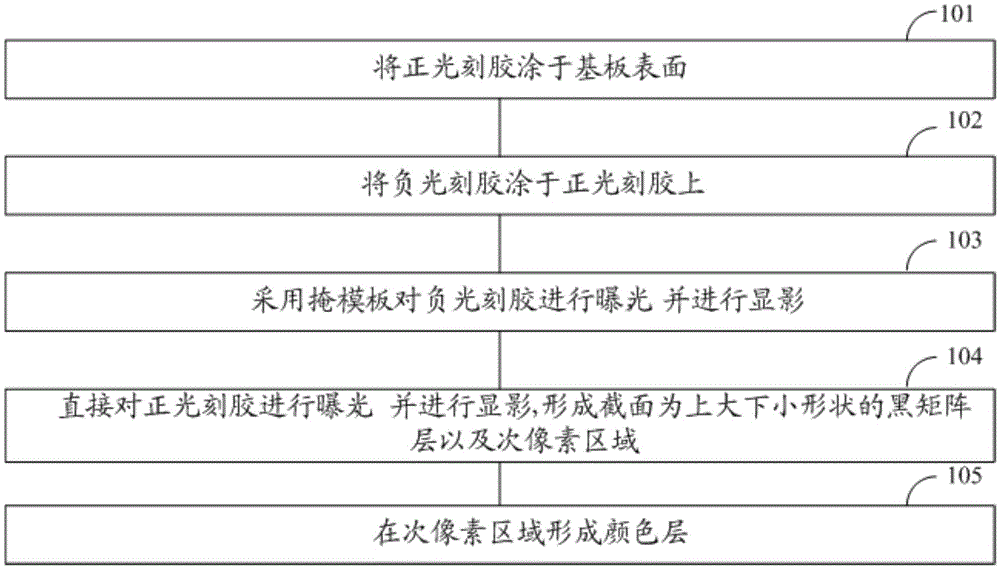

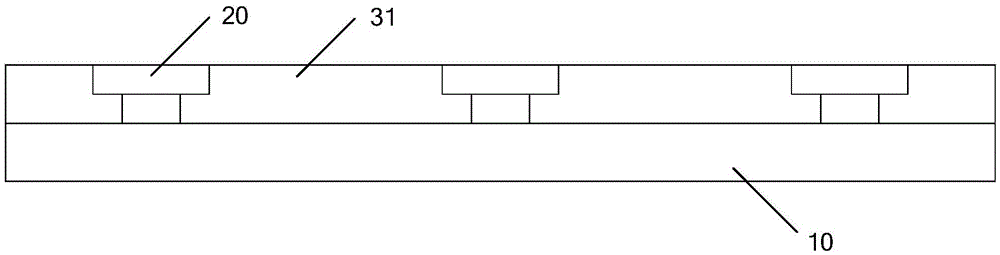

Color filter and manufacturing method thereof

InactiveCN105652512AThe same thicknessOptical filtersPhotomechanical apparatusComputer visionMembrane thickness

The invention provides a color filter and a manufacturing method thereof and relates to the field of a liquid crystal display. The problem of the prior art that the technique is complex because a flat layer is required to be manufactured in the manufacturing process of the color filter is solved. The embodiment of the invention provides the color filter and the manufacturing method thereof. The color filter comprises a black matrix layer and a color filtering layer, wherein the black matrix layer is formed on a substrate; the color filtering layer is formed in a sub-pixel region limited by the black matrix layer; the black matrix layer with the cross section of big-top small-bottom shape and the color filtering layer with the cross section of small-top big-bottom shape have a coincident area; and the membrane thickness in the coincident area is as same as the membrane thickness in the non-coincident area. The black matrix layer and the color filtering layer have the coincident area and the membrane thickness in the coincident area is as same as the membrane thickness in the non-coincident area, so that the manufacturing for the flat layer is not required and the manufacturing technique is simple.

Owner:BOE TECH GRP CO LTD

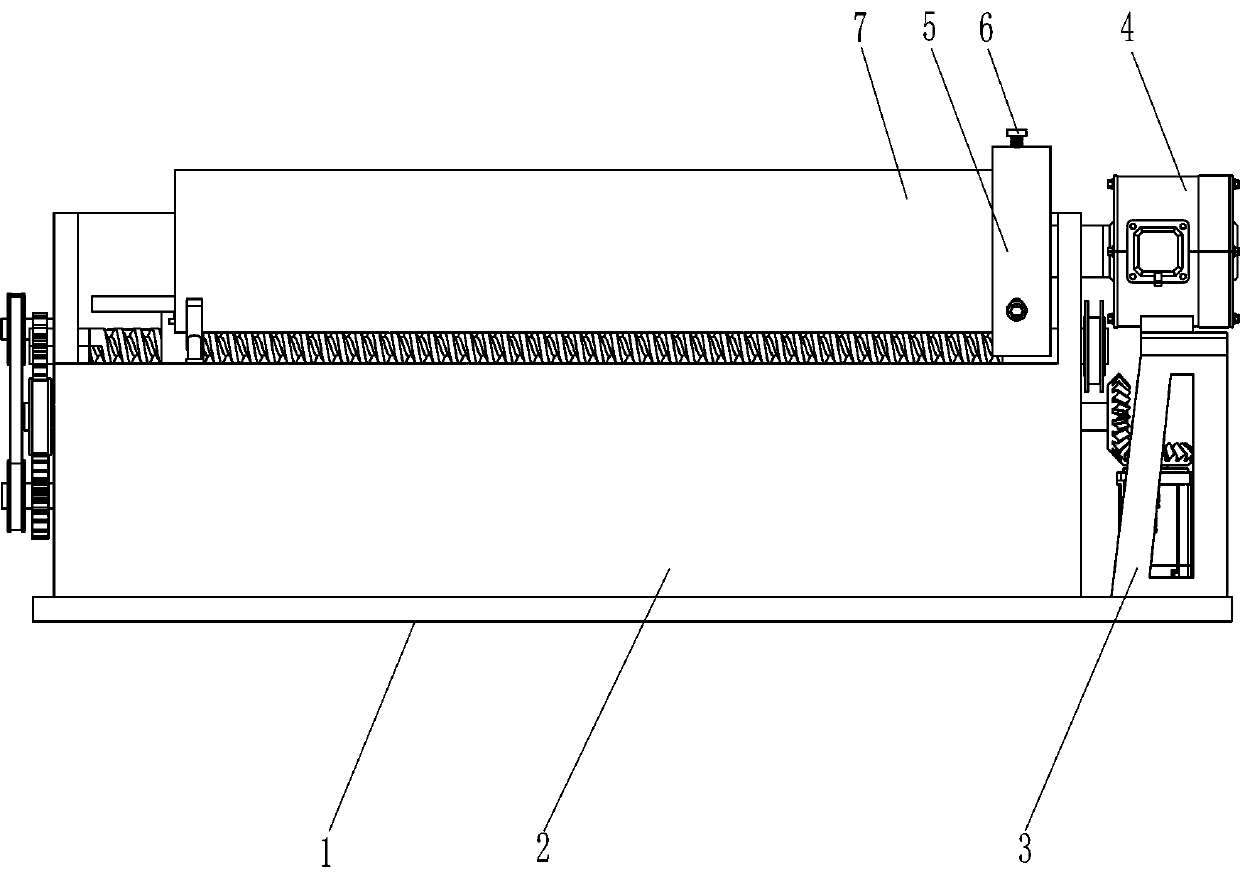

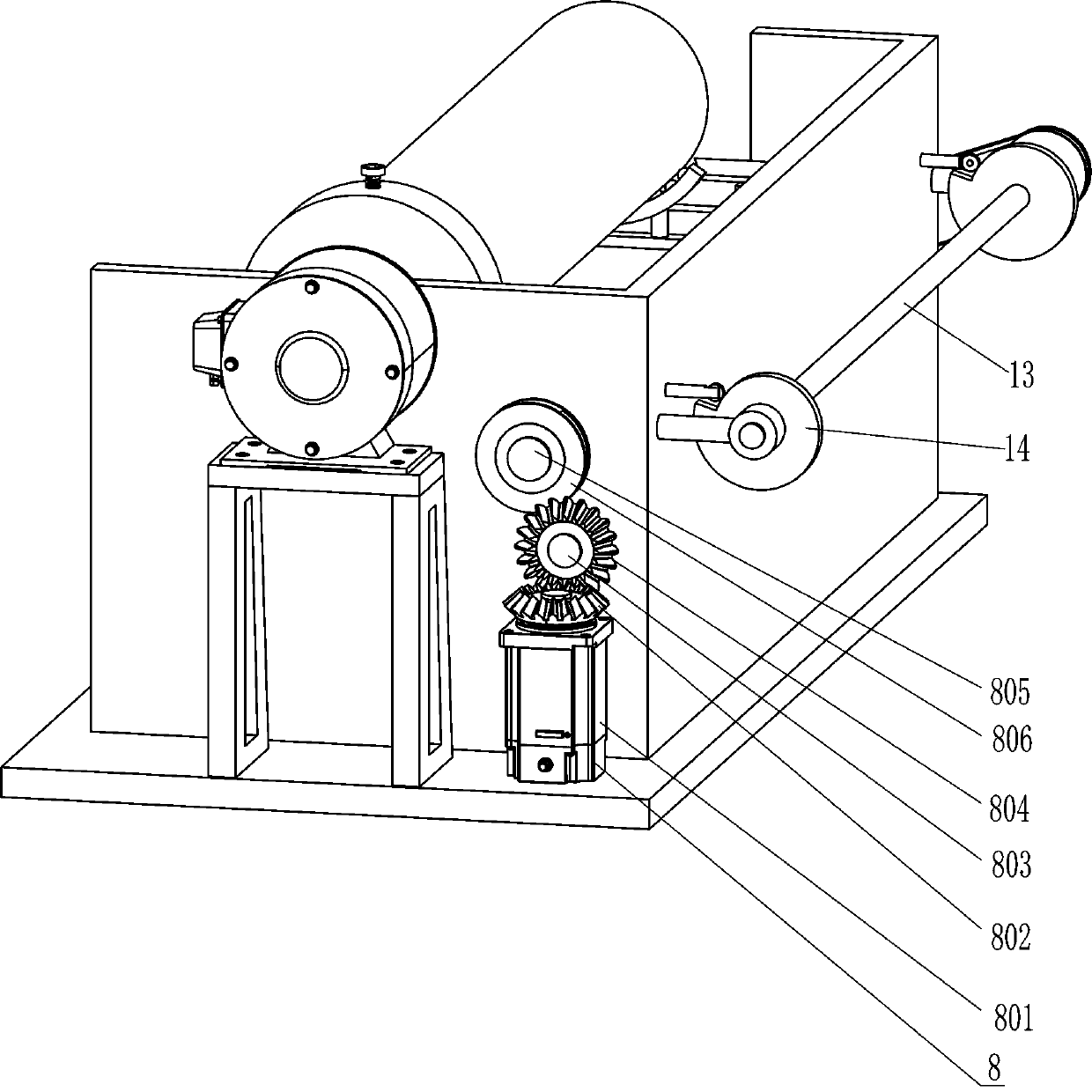

Steel wire rope winding device

ActiveCN109399354AThe winding process is simple and convenientImprove efficiencyFilament handlingEngineeringUltimate tensile strength

The invention discloses a steel wire rope winding device. The steel wire rope winding device comprises a motor, a winding roller and a guiding mechanism, wherein the output end of the motor is connected with the winding roller, and the guiding mechanism is located behind the winding roller; and in the winding process, the winding roller is driven by the motor to rotate, a steel wire rope is woundon the winding roller to realize steel wire rope winding, the winding process is simple and convenient, the efficiency is high, and the labor intensity is reduced.

Owner:SHANDONG BOLT ELEVATOR

Anti-shifting coating device for semiconductor production

ActiveCN110773381AAvoid offsetEasy to adjust the positionPretreated surfacesCoatingsEngineeringFan blade

The invention discloses an anti-shifting coating device for semiconductor production. The anti-shifting coating device for semiconductor production comprises a device main body, a vertical screw rod,a connecting sleeve, a first rotating shaft, a clamping groove, a second coating device, a second rotating shaft, a second gear, a first screw rod, a first bearing, a rotating turntable, a to-be-processed semiconductor and fan blades, wherein a first motor is arranged at the upper end of the device main body. A fixing device is arranged in the anti-shifting coating device for semiconductor production, a second screw rod is rotated by manually rotating a knob on the fixing device, and the second screw rod is in threaded connection with a first clamping block, so that the first clamping block moves on the horizontal plane, a sliding block is driven to move on a sliding rail, and the position of the first clamping block is convenient to adjust. The distance between the first clamping block and a second clamping block is conveniently adjusted by adjusting the position of the first clamping block, so that the to-be-processed semiconductor is clamped, and the to-be-processed semiconductor isprevented from being shifted.

Owner:江苏钰晶半导体科技有限公司

Fabric coating uniform coating device for garment processing

InactiveCN111229535AEasy to tightenUniform coatingLiquid surface applicatorsCoatingsMechanical engineeringCoating

The invention discloses a fabric coating uniform coating device for garment processing. The fabric coating uniform coating device for garment processing comprises a support. A pay-off barrel is mounted at one end of the support, a take-up barrel is mounted at the other end of the support, a pressing roller, a coating roller and a drying box are sequentially mounted on the portion, between the pay-off barrel and the take-up barrel, of the support, a uniform distributing cover is mounted on the portion, on the top of the coating roller, of the support, a linkage mechanism is mounted between oneend of a driving roller of the coating roller and one end of the top of the uniform distributing cover, a feeding mechanism is mounted at the other end of the top of the uniform distributing cover, and the feeding mechanism is connected with the linkage mechanism and an inner cavity of the uniform distributing cover. Fabric is paid off from the pay-off barrel to sequentially penetrate through thepressing roller, the coating roller and the drying box and then wound around the take-up barrel, coating is carried out when the coating roller drives the fabric to move, when the coating roller rotates, the feeding mechanism is driven by the linkage mechanism to continuously convey coating, the conveying amount of the coating and the rotating arc length of the coating roller are in a definite proportion, it is guaranteed that the coating thickness on the fabric is always equal, the coating uniformity is guaranteed, and finally the fabric is dried through the drying box and then taken up on the take-up barrel.

Owner:江西政高技术服务有限公司

Display device, method of manufacturing display device, and electronic apparatus

InactiveUS20120314162A1Filling spaceThe same thicknessTube/lamp screens manufactureSemiconductor/solid-state device manufacturingControl systemDisplay device

A display device including: a first substrate with a pixel switch and drivers mounted thereon; a second substrate disposed in facing relation to the first substrate; a material layer held between the first substrate and the second substrate and having peripheral edges sealed by a seal member, the material layer having an electrooptical effect; and a semiconductor chip mounted as a COG component on the first substrate, the semiconductor chip having a control system configured to control the drivers; wherein the semiconductor chip having a thickness equal to the total thickness of the seal member and the second substrate or larger than the thickness of the seal member and smaller than the total thickness.

Owner:JAPAN DISPLAY WEST

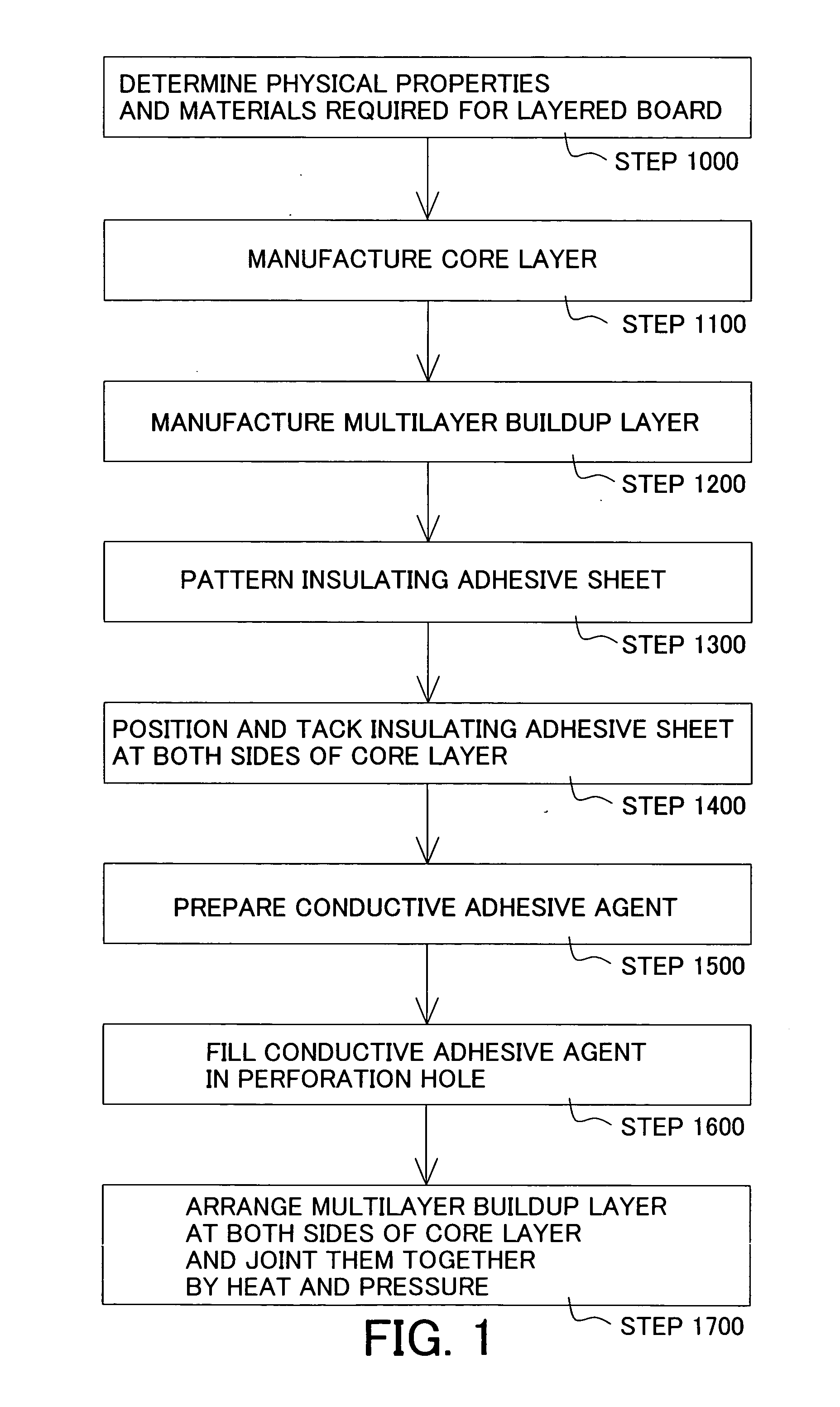

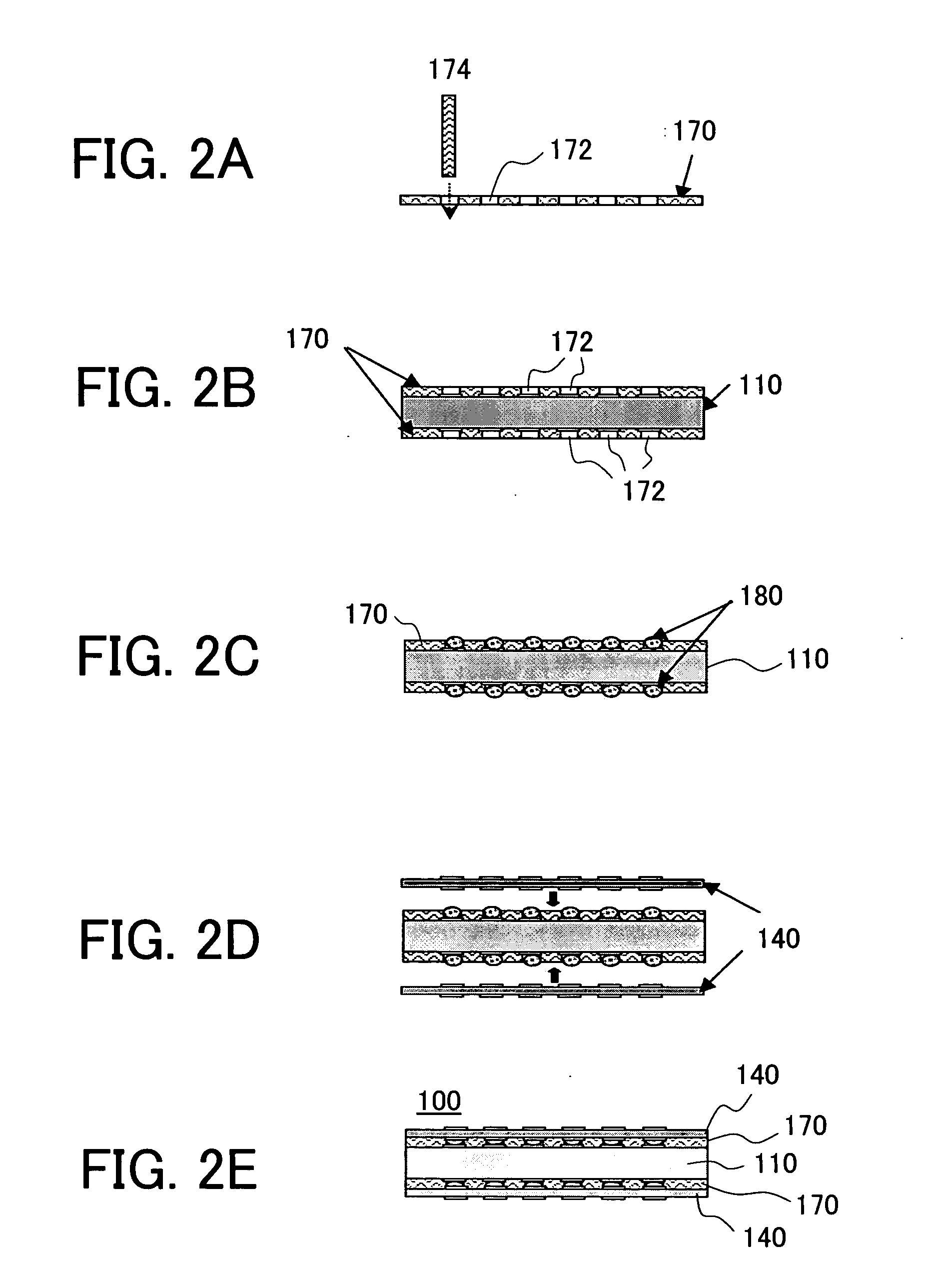

Layered board and manufacturing method of the same, electronic apparatus having the layered board

InactiveUS20050266212A1Increase productionGood reproducibilitySemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringThermal expansion

A manufacturing method of a layered board that includes a core layer that serves as a printed board, and a buildup layer that is electrically connected to said core layer, said buildup layer including an insulation part and a wiring part includes the step of setting a coefficient of thermal expansion, a thickness and a modulus of longitudinal elasticity of each layer so that the layered board has a predetermined value of the coefficient of thermal expansion.

Owner:FUJITSU LTD

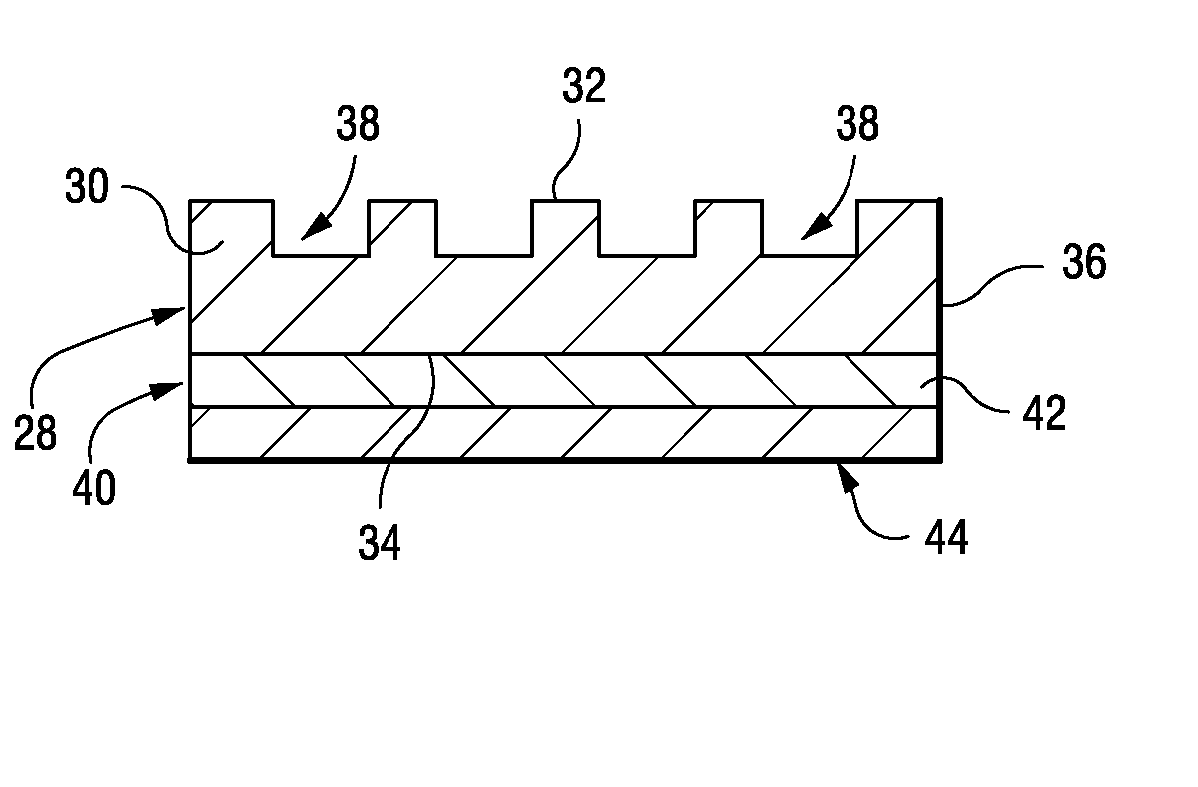

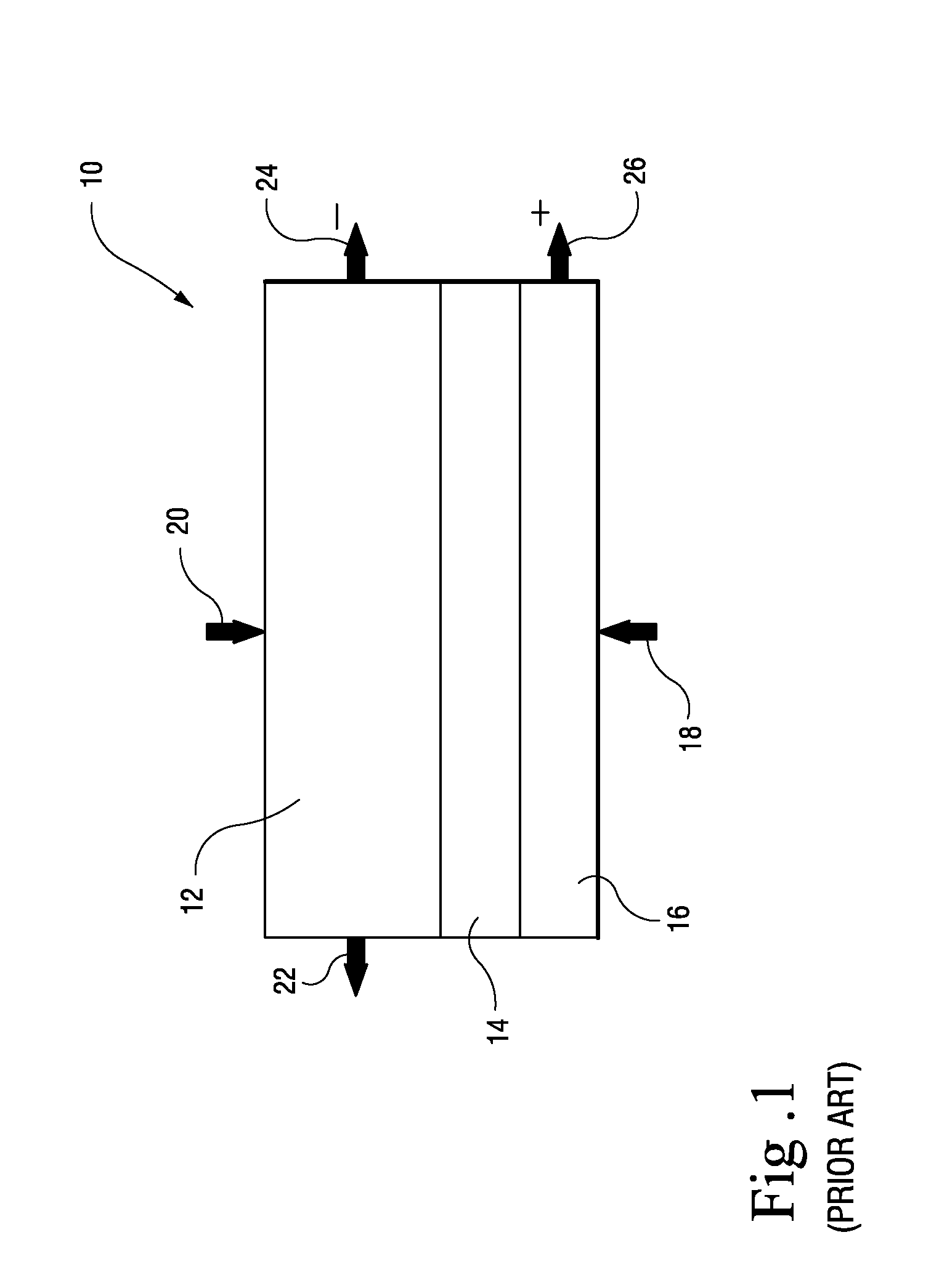

Solid-state fuel cell and related method of manufacture

InactiveUS20050003262A1Added fabricationEasy to operateCell electrodesFinal product manufactureFuel cellsEngineering

An electrode for a solid-state fuel cell includes a tape having opposite sides joined by a peripheral edge, one of the opposite faces having a plurality of surface depressions therein extending partially through the tape.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com