Hinge-lid container with additional spacer panel

A technology for hinged lids and containers, which is applied in the direction of containers, containers, and rigid containers of flexible objects, which can solve problems affecting the appearance, interfering with production and transportation, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

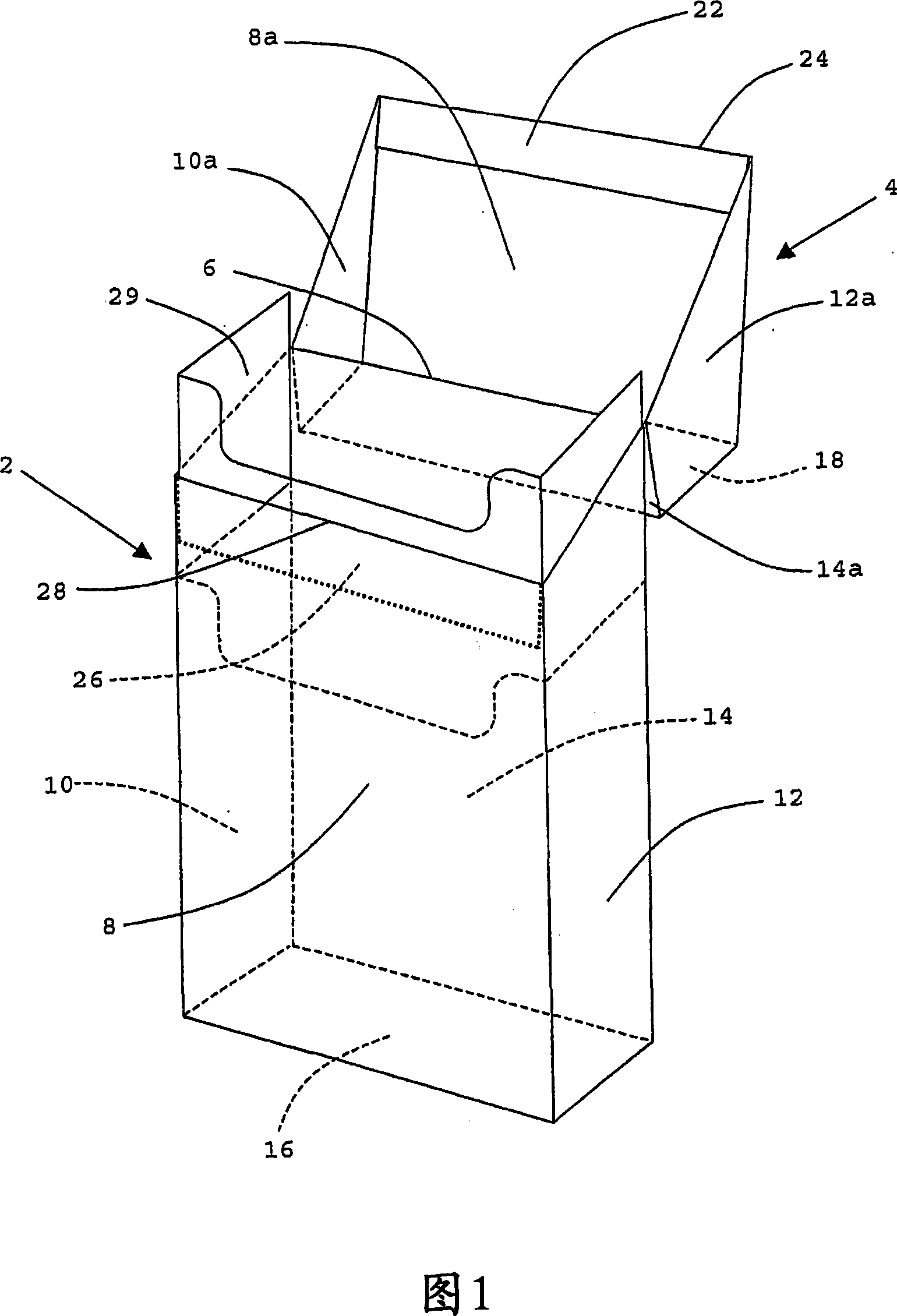

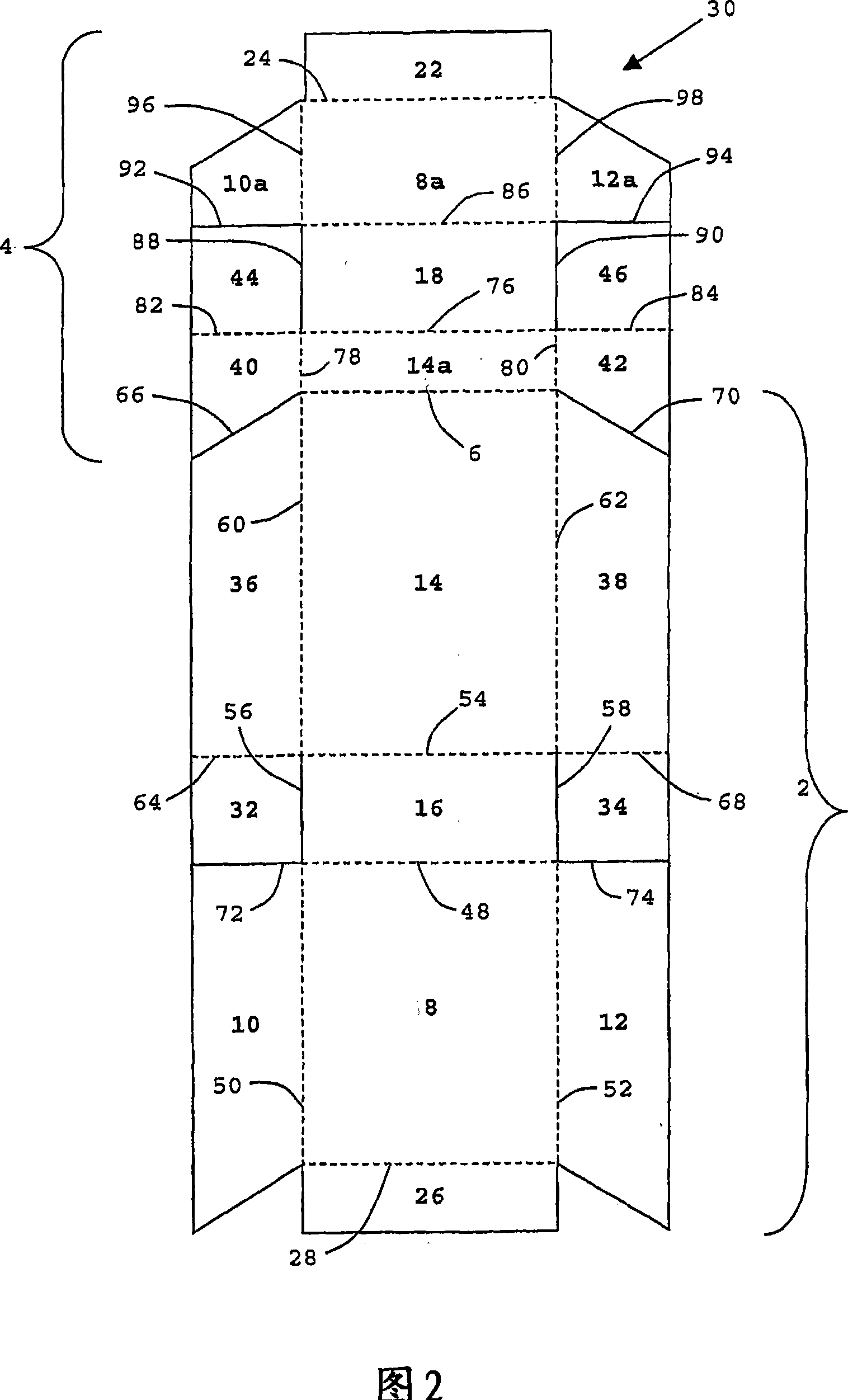

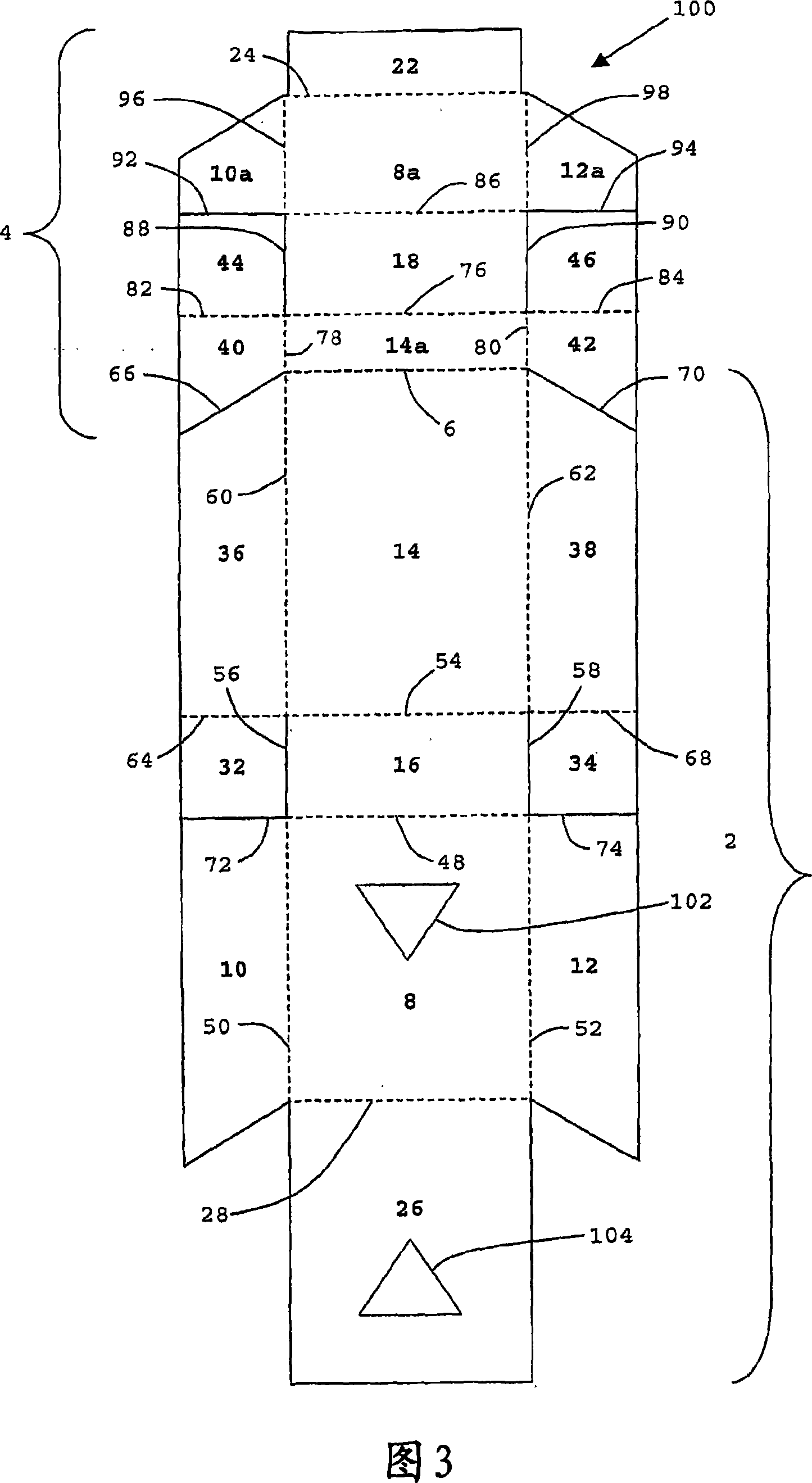

[0029] Most of the structure of the hinged lid container shown in Figure 1 is the same as that of a conventional hinged lid cigarette pack with right-angled vertical edges, including a lower box body 2 and an integral upper box hinged to the lower box body along the hinge line 6 Cover 4. The lower box body 2 and the upper cover body 4 are folded from a single thin-layer cardboard blank.

[0030] The lower box body 2 has a front wall 8 , a left side wall 10 , a right side wall 12 , a rear wall 14 and a bottom wall 16 . Lid 4 also similarly has a front wall 8a, a left side wall 10a, a right side wall 12a and a rear wall 14a, and these walls are along hinge line 6 from box body 2 and cover body 4 as shown in Figure 1 When the open state is rotated to the closed state, they are respectively connected to the walls of the lower box body 2 with similar numbers. The upper cover 4 of the container also includes a top wall 8 .

[0031]The first flap 22 is adjacent to and parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com